MINING your business E-NEWSLETTER | A NORTH OF 60 COMPANION PubLICATION Issue 1 2024 Gold Terra continues its drilling program targeting the gold-bearing Campbell Shear below the former Con Mine B2Gold partners with the Redfish Arts Society to spark career opportunities for Nunavut youth Positive measures for mining in Budget 2024 and a potential blow to mineral exploration miningnorthof60.com

Message from the editor, Shayna Wiwierski – 3

Gold Terra continues its drilling program targeting the gold-bearing Campbell Shear below the former Con Mine – 4

Going for the gold: Sixty North Gold Mining Ltd. – 8

Sparking career opportunities for Nunavut youth: B2Gold – 10

Positive measures for mining in Budget 2024 and a potential blow to mineral exploration – 12

Building a hydrogen hub on the prairies – 14

Technical guidance from mining industry advisory committee – 16

Whistleblowing’s significance in preserving ethical standards in mining – 17

An engineered approach to solving dust containment problems at conveyor transfers – 20

PDAC 2024 Convention welcomes the world to the premier mineral exploration and mining event in Toronto – 21

Over 130 northern engineers and geoscientists convened in Yellowknife on Building a Resilient North – 22

Managing Editor shayna WiWiErski shayna@delcommunications.com

Advertising Manager Dayna ouLion

Sales Representatives brEnt astropE | brian gEroW miC patErson

Contributing Writers Erin matthEWs shannon WaLkEr

2024 DEL Communications Inc.

All rights reserved. Contents may not be reproduced by any means, in whole or in part, without the prior written permission of the publisher.

While every effort has been made to ensure the accuracy of the information contained in and the reliability of the source, the publisher in no way guarantees nor warrants the information and is not responsible for errors, omissions or statements made by advertisers. Opinions and recommendations made by contributors or advertisers are not necessarily those of the publisher, its directors, officers or employees.

DEL Communications Inc. and miningnorthof60.com are extremely grateful to our advertisers for their support in this publication. Click here to download the media kit.

2

Bulkley Valley Wholesale ................................................... 11 Gold Terra Resource Corp..................................................... 7 GroundTruth exploration.................................................... 13 Major Drilling 20 NapeG.................................................................................... 23 Northbest Distributors Ltd. ............................................... 12 Osisko Metals/Refined Substance ................................... 21 pinepoint Mining Limited 9

DEL

inC. www.delcommunications.com

IN THIS ISSUE

CommuniCations

President & CEO DaviD Langstaff

©

MINING your business

message from the editor ShAyNA WIWIeRSkI

Welcome to another edition of Mining Your Business e-newsletter, where we delve into the latest developments and endeavours shaping Canada’s northern territories’ mineral landscape. As we navigate through the intricate veins of the mining industry, our spotlight remains firmly fixed on the remarkable initiatives and projects that define the region’s economic and social fabric.

In this edition, we are thrilled to showcase a fusion of innovation, community empowerment, and geological exploration that epitomizes the essence of responsible mining. B2Gold, a global leader in sustainable resource extraction, has embarked on a transformative journey in partnership with the Redfish Arts Society to foster the talents of youth in Cambridge Bay, Nunavut. Through a pioneering welding arts program, B2Gold is not only nurturing local talent but also forging pathways to meaningful employment within Nunavut’s burgeoning mineral development sector. This collaboration exemplifies B2Gold’s unwavering commitment to catalyzing socio-economic progress, echoing their recent expansion into Nunavut through the acquisition of Sabina Gold & Silver and the Back River Gold District in April 2023.

Meanwhile, Gold Terra’s relentless pursuit of gold-bearing treasures beneath the Former Con Mine continues to captivate the industry’s attention. With an ambitious drilling program targeting the Campbell Shear, Gold Terra exemplifies the resilience and determination required to unlock the untapped potential of Northern Canada’s geological riches. Their unwavering dedication to exploration underscores the region’s status as a gold-rich haven, ripe with opportunities for discovery and growth.

Amidst these ventures, Sixty North Gold stands poised on the cusp of a remarkable resurgence as it endeavours to breathe new life into the historic Mon Mine. Situated amidst a backdrop of rich mineralization, the Mon Mine represents a tantalizing prospect for investors and explorers alike. Sixty North Gold’s meticulous efforts to revive this dormant treasure trove highlight the timeless allure of Archean gold deposits, reminiscent of the nearby Discovery Mine. With a focus on high-grade, low-sulfide ores and extensive metasomatic alteration, the Mon Mine project exemplifies the enduring legacy of Northern Canada’s mining heritage.

As we navigate the complexities of the mining industry, it is

imperative to recognize the symbiotic relationship between economic prosperity and community well-being. The stories featured in this edition underscore the pivotal role of responsible mining practices in fostering sustainable development and empowering local communities. Through collaboration, innovation, and a steadfast commitment to environmental stewardship, the mining industry continues to chart a course towards a brighter, more inclusive future for Northern Canada.

I hope you enjoy Issue 1, 2024 of Mining Your Business e-newsletter and we hope you will help us spread the message about this exciting publication to your colleagues and friends. Also, if you haven’t signed up already, we invite you to share this and to sign up for our newsletter at miningnorthof60.com/ mining-your-business/.

We also wish to thank all the companies who have contributed a story for Issue 1, 2024 of Mining Your Business. Special thanks go out to the following contributors:

• B2Gold

• Gold Terra

• Sixty North Gold

• The Saskatchewan Research Council (SRC)

• Whistleblower Security Inc.

• Workplace Safety North

We invite all interested companies to share their news and editorial ideas with us. If you would like to contribute a story for future issues of Mining Your Business e-newsletter, please contact myself at shayna@delcommunications.com.

We also invite you to reach the 2024 issue of North of 60 magazine, which was released in early 2024. You can read all the previous issues, plus past issues of this e-newsletter, via our official site, miningnorthof60.com.

In closing, we extend our heartfelt gratitude to all our readers, contributors, and partners who continue to enrich the pages of Mining Your Business with their invaluable insights and perspectives. Together, let us embark on this journey of exploration, discovery, and responsible resource management, as we strive to unlock the boundless potential of Canada’s northern territories.

Enjoy!

Shayna Wiwierski shayna@delcommunications.com

3

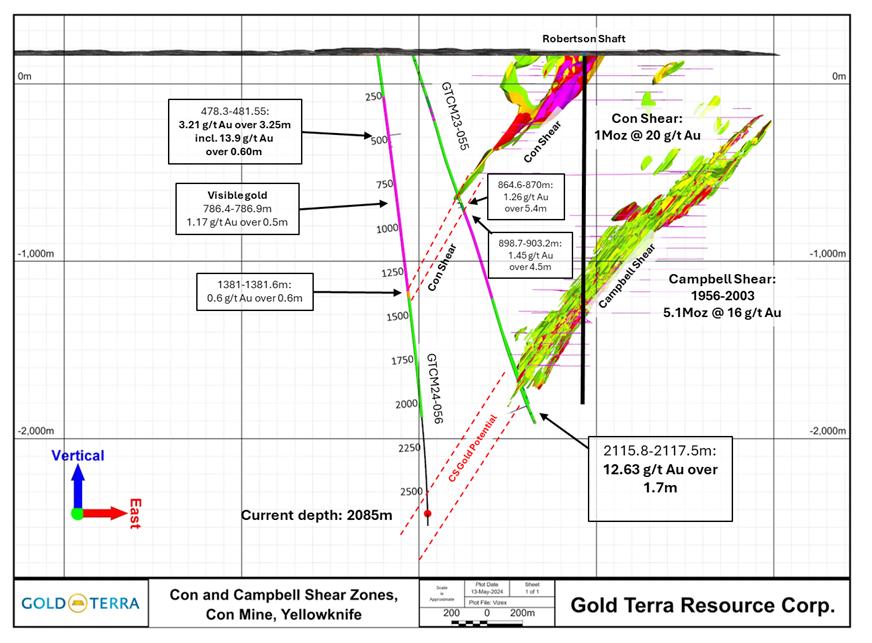

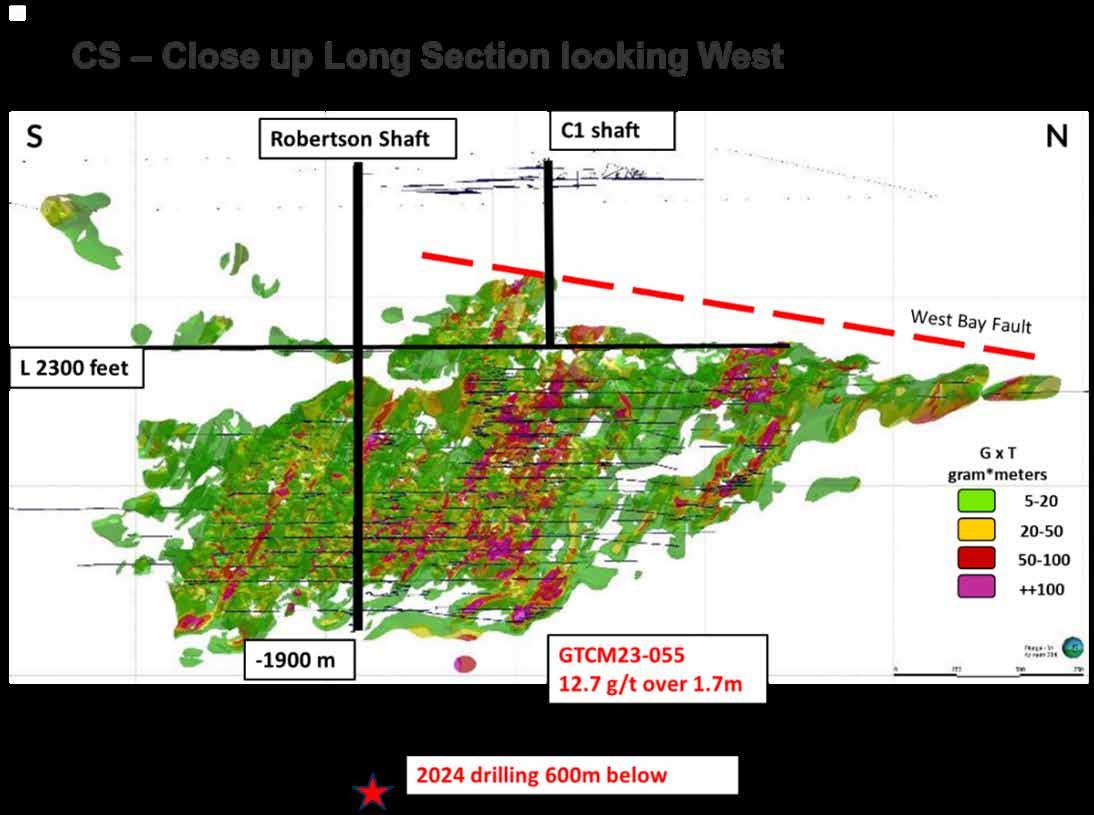

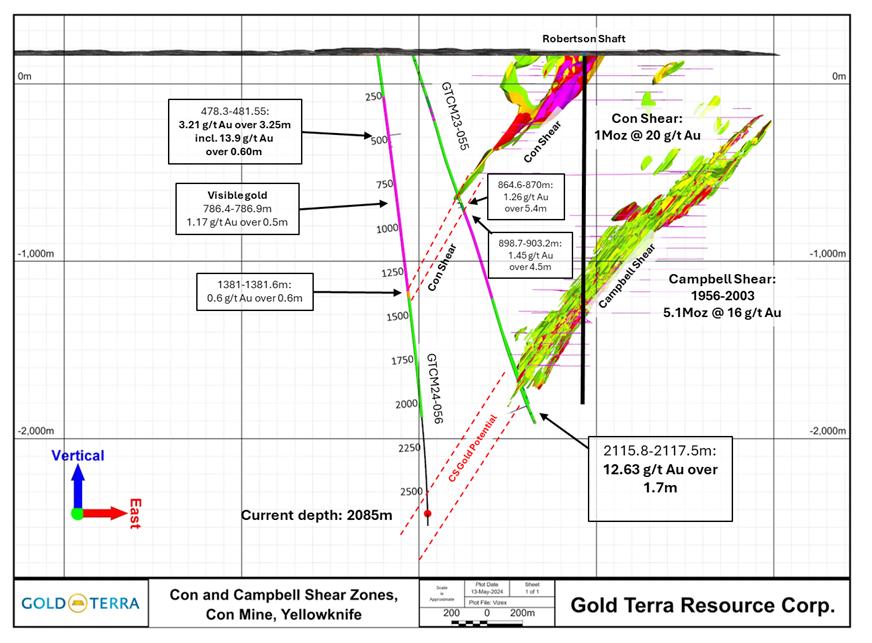

Gold Terra continues its drilling program targeting the gold-bearing Campbell Shear below the former Con Mine (1938-2003 and produced 6 Moz @ 16-20 g/t Au)

The Yellowknife Gold Belt in the Northwest Territories is one of Canada’s richest historic mining camps, creating wealth for the community over a span of 65 years from the production of 14 million ounces at grades between 16 to 22 grams/tonne mainly from one deposit and two mines, the Giant and Con Mines. The potential for a multiple gold deposit discovery is highlighted by Gold Terra’s drilling results in the under-explored Campbell Shear and subsidiary Con Shear zones. This potential to discover another high-grade deposit is what has attracted Gold Terra to explore in the Yellowknife gold belt.

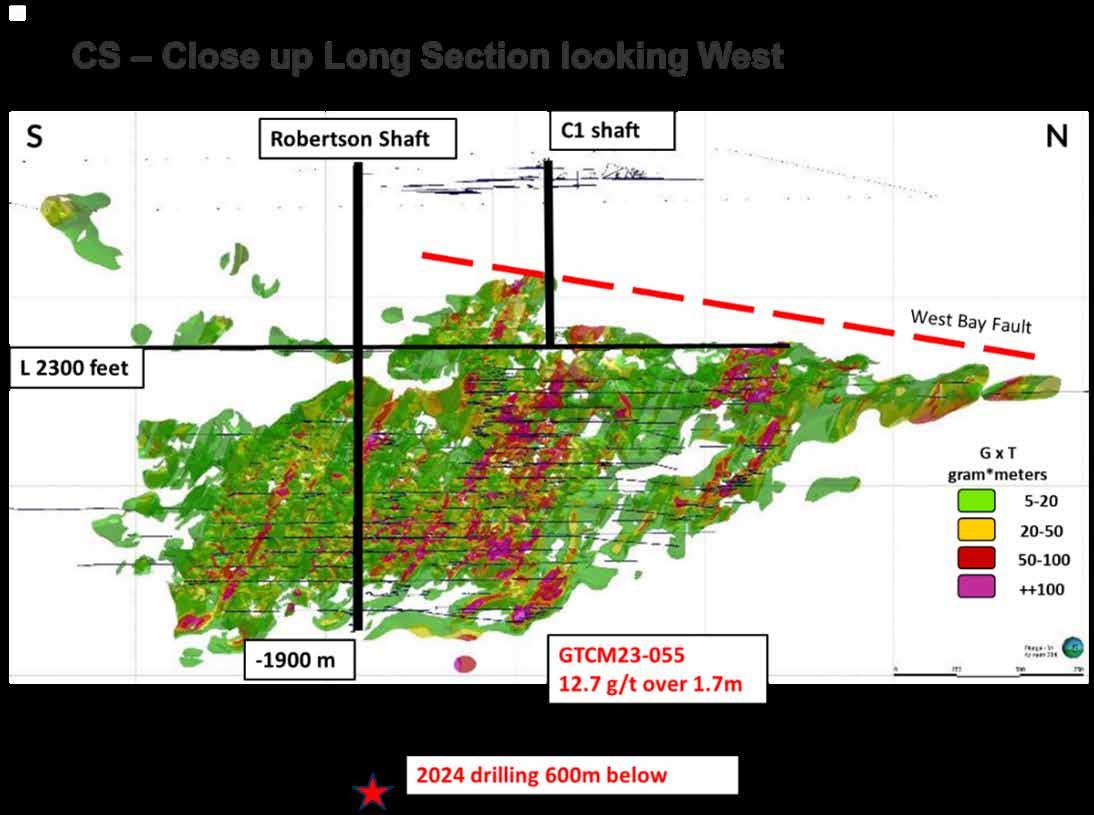

Gold Terra’s current drilling program aims to confirm the

company’s proposition that the gold-rich Campbell Shear continues even further than what was mined at the former Con Mine (6.1 million ounces of gold with an average gold grade of 16-20g/t between 1938-2003).

Gold Terra is continuing with a second deep drill hole targeting high-grade gold mineralization after the success with their first drill hole in 2023, which intersected the high-grade gold-bearing Campbell Shear (CS) at a downhole depth of approximately 2,100 metres, or 200 metres below the former Con Mine underground workings. In February, the company started a second deep drill hole, GTCM24-056, to assess

4

Aerial view of Yellowknife, the Con Mine and projection of the Campbell Shear.

2024.

the potential some 600 metres below the historic Con Mine workings.

Gold Terra is another step closer to confirming the extension of gold mineralization past the current underground workings with their successful drill results. Not only was the CS structure intersected below the historic Con Mine, drilling has also identified new gold mineralization in the hanging granite wall of the Con Shear, a secondary shear structure with a past production of one Moz at 20 g/t gold. Gold mineralization ranging up to 13.90 g/t Au over 0.60 metres was discovered in the hanging wall granite host of the Con Shear at multiple downhole depths (478.30 to 546 metres and at 748 metres). The Con Shear was intersected further down the hole at a depth of

1,366 to 1,405 metres from surface. The Con Shear intersection and the gold-bearing quartz veining in the granite higher up in the hole illustrate the untested endowment of gold in this hanging wall area.

The Con Shear Deposit is located approximately one-kilometre west in the hanging wall of the main Campbell Shear target on the Con Mine Option Property. The company signed an option agreement to purchase 100 per cent of the Con Mine Option Property from Newmont in November 2021.

One major advantage of the company’s current drilling program is that the cost of the deep drilling is comparably low for northern regions. The drilling is close to the city of Yellowknife so that remote drill setup is not needed. In

The Con shear Deposit is located approximately one-kilometre west in the hanging wall of the main Campbell shear target on the Con Mine Option property.

5

Section showing Campbell Shear target in May

addition, the deep holes will serve as a master hole for several more wedge holes that can branch out from the master hole and can test other adjacent targets without incurring extremely high drilling costs.

A second major advantage of the project is the existing infrastructure with the Robertson shaft extending down to 1,900 metres. The deep drilling program has opened a onekilometre strike length of the CS with potential for more ounces at depth and south of the Robertson shaft. Readily available infrastructure available at the former mine includes multiple

existing underground access openings, including the original C-1 shaft opening, and the deep Robertson shaft with a 2,000 tpd (ton per day) capacity for future underground exploration and mining, and surface infrastructure including a large 10,000-square-foot warehouse and dry; surface vehicles; and a C$20 million water treatment plant recently built in 2015. These assets will provide cost savings for future exploration and potential development requiring underground access.

Over the last several years, the company has outlined and discovered approximately 1.8 million combined ounces. Gold

The drilling is close to the city of Yellowknife so that remote drill setup is not needed. In addition, the deep holes will serve as a master hole for several more wedge holes that can branch out from the master hole and can test other adjacent targets without incurring

extremely high drilling costs.

6

Readily available underground infrastructure on the Con Mine Option Property.

Terra’s strategy in 2024 is to find more gold on its district-sized land position along the prolific Campbell Shear structure. That strategy includes additional drilling south of the Con Mine to expand their initial near-surface 2022 Mineral Resource estimate of 109,000 gold ounces in the Indicated category and 432,000 gold ounces in the Inferred category; the current drilling target under the current Con Mine workings on the Con Mine Option Property; and, continued assessment of additional targets in the northern belt of their large land holdings, which has a 2021 mineral resource estimate of 1.2 Moz in the Inferred category on four deposits north of Yellowknife.

With a continued large drilling program and positive drill results, Gold Terra is on track to re-establish Yellowknife as one of the premier gold mining districts in Canada. Gold Terra offers a rare opportunity to invest in a world-class high-grade discovery on the doorstep of Canada’s most prolific past gold production.

For more information and company news, please go to our website at www.goldterracorp.com. 7

Multi-million ounce potential in Yellowknife Gold Belt.

Drilling to delineate gold underway with objective to expand current mineral resource estimate on Con Mine Option Property.

7 GOLD TERRA

TSX-V: YGT; FRANKFURT: TXO; OTC QX: YGTFF www.goldterracorp.com

RESOURCE CORP.

Drilling picture in October 2021.

Going for the gold

Sixty North Gold Mining Ltd. is not a typical junior exploration company. Sixty North Gold is going back to the tried-andtrue company building process of mining and processing rock to get gold. And we’re doing it in a very scientific way.

Sixty North Gold acquired a high-grade past-producing gold mine that shut down in the 1990’s. This is significant in that the 1990’s was a time of declining gold prices, challenging at the best of times, but in the late 1990’s the price of gold declined below US$300 per ounce. Very few mines were making money during this period and companies and projects spun off at this time warrant a closer look.

The Mon Gold Mine is located in the Yellowknife Greenstone Belt and have Archean belt of rocks like those found in Red Lake, Timmins, and Val D’Or. The belt has produced over 14 million ounces of gold, largely from three mines at grades exceeding 15 gpt. This is good hunting ground and production in this gold camp inevitably starts on surface and goes deep. The Giant Mine (eight-million ounces of gold) extracted ores to 900 metres below surface, the Discovery Mine (one-million ounces of gold) extracted ores to 1,200 metres below surface, and the Con Mine

(six-million ounces of gold) extracted ores to 1,900 metres below surface.

The company has been working on restarting its wholly-owned Mon Mine where mineralization on surface was extracted to a mere 15 metres below surface. There was development of stopes below the past-producing stopes where 15,000 tonnes of ore was extracted at grades less than 30 gpt. Work shows this to be a “Stratabound non-Stratiform” Archean gold deposit, similar to the Discovery Mine located 45 kilometres to the north of the Mon property. These are high-grade and low-sulphide, with intense and extensive metasomatic alteration.

All mining equipment and supplies are owned and have been delivered to the property, and the shops are installed and operations are ready to commence. A temporary tent camp will be installed in June. A 200-metre-long, three-by-fourmetre ramp is within 60 metres of target where historic drill holes, including 61.38 gpt gold over 1.2 metres in 87-11, 47.49 gpt gold over 3.0 metres in 89-7, 25.31 gpt gold over 1.7 metres in 89-14, and more recently, 15.29 gpt gold over 1.6 metres in NDM-3, have been encountered. Stopes to be developed in this material are expected

to produce material similar in nature to that from the stopes above.

Sixty North Gold recently completed a financing to restart operations with the plan to extract and assess some of the gold-bearing quartz vein in the summer of 2024.

The company is run by an experienced team of miners and financers with many decades of experience. Dr. D.R. Webb, Ph.D., P.Geol., P.Eng, president, CEO, and a director, is committed to this project and leads the team. Webb controls over 48 per cent of the shares in the company on a partially diluted basis. He completed both his M.Sc. and his Ph.D. on projects in Yellowknife and has been involved in mine development in North America, Africa, Asia, and Europe over the past 40 years.

Tom MacNeil, CPA is chairman and John Campbell, CPA is CFO. An independent accountant, geologist, engineer, and former mill equipment manufacturer round out the management team while the operation team includes three individuals with a cumulative experience of over 100 years of underground mine development and operation. 7

8

Helicopter landing south of the A zone in 2017. Seen here is typical topography.

Aerial view of the Mon site in 2021.

9 MINING Review e-newsletter B.C. SUBSCRIBE FOR FREE NOW CLICK HERE There's more to mine at Pine Point, one of Canada's premier past producing zinc assets. We're reviving a nor thern legacy to meet rising demand for critical minerals like zinc.

B2Gold has joined forces with the Redfish Arts Society to deliver a well-loved local welding arts program to youth in Cambridge Bay, Nunavut – creating career and employment opportunities in Nunavut’s growing mineral development sector and beyond.

“We are delighted to partner with B2Gold to offer even more opportunities for youth in our communities,” says Attima Hadlari, chair of the Redfish Arts Society Inc. “This partnership will elevate the training we offer to a new level and expose Inuit youth to amazing career opportunities and further training.

GrowinG local employment throuGh partnerships

The partnership is part of B2Gold’s commitment to serve as a catalyst for socio-economic improvement wherever it works in the world, which – as of April 2023 and the Sabina Gold & Silver and

Sparking career opportunities for Nunavut youth

B2Gold partners with the Redfish Arts Society

Back River Gold District acquisition –includes Nunavut.

“We are proud to work with the team at the Redfish Arts Society to create opportunities for Kitikmeot Inuit,” says Clive Johnson, B2Gold president and CEO. “With the development of our Back River Project, B2Gold is committed to being a partner with Kitikmeot Communities and looks forward to providing opportunities to grow the project’s Inuit workforce through innovative partnerships, such as this one.”

supportinG a hub for inuit culture in nunavut

The established program runs out of the Red Fish Arts Studio, a community hub that is also home to a welding studio. Formerly a processing plant, and renovated with the support of CanNor, the Government of Nunavut and the Municipality of Cambridge Bay, the studio

offers space for local and aspiring artists to grow and develop their skills. The studio also promotes Inuit culture and is used as a base by several community groups.

As students advance through the curriculum, they will receive industry placements at B2Gold’s Back River Project, gaining on-the-job experience in the mineral development sector. The goal is to replicate past successes, where all students secured industry employment as a result of mentorship and training provided.

“We thank B2Gold for lending its support to this program and opening new doors for our youth,” says Attima.

For more information on Redfish Arts Society, go to: www.redfishartsociety.com

Instagram: redfisharts

TikTok: redfishartstudio 7

10

The established program runs out of the Red Fish Arts Studio, a community hub that is also home to a welding studio.

has joined forces with the Redfish Arts Society to deliver a well-loved local welding arts program to youth in Cambridge Bay,

As students advance through the curriculum, they will receive industry placements at B2Gold’s Back River Project, gaining on-the-job experience in the mineral development sector.

11 P.O. Box 667 | Smithers BC | V0J 2N0 | Canada T: 250-847-3313 | F: 250-847-3906 1-800-579-3313 | www.bulkleyvalleywholesale.com Fresh Produce • Frozen Foods • Bulk Foods • Meats • Dairy • Tobacco • Confectionery Your CAMP FILL Specialists

B2Gold

Nunavut.

Positive measures for mining in Budget 2024 and a potential blow to mineral exploration

By the Mining Association of Canada (MAC)

On April 16, 2024, through its federal budget, the government announced a mix of measures that will impact Canada’s mining and mineral exploration sector.

Budget 2024 builds upon earlier commitments in Budget 2023, as well as in the 2023 Fall Economic Statement and the Canadian Critical Minerals Strategy. Specifically, the budget includes:

• Extending the Clean Technology Manufacturing Investment

We have been in business since 1999, and our staff complement has over 25 years experience in the foodservice industry.

Northbest Distributors Ltd. is a full-line foodservice industry distributor. We are proud to distribute well-known brands like Maple Leaf Meats, Lilydale Poultry, Cargill Meats, Canada Bread, Dairyland/Saputo, and McCain Foods. Our company stocks a large selection of these items in our Yellowknife warehouse.

Our online product catalogue will show you the full range of quality products that we carry. We are a representative of The Grocery People, a full-line retail and foodservice supplier located in Edmonton, allowing us to offer an extensive line of brand name grocery products.

If you are interested in our products and services, please feel free to contact us by telephone, fax, or email. Set up a new account online or call us today.

Tax Credit (CTM-ITC) to include the cost of investments in eligible property used primarily (50 per cent or more of the production value) to produce qualifying critical minerals, and to make certain other adjustments to provide greater clarity to businesses involved in polymetallic extraction and processing. This responds directly and positively to a MAC concern with an original proposal of 90 per cent that would have severely limited the applicability, and therefore value, of the CTM-ITC to spur new mining and mineral processing investment.

• Setting a target of five years or less to complete federal Impact Assessment and permitting processes, and two years or less for permitting of non-federally designated projects. In addition, the government is setting a three-year target for nuclear project reviews and commits to working with the Canadian Nuclear Safety Commission and Impact Assessment Agency of Canada to consider how the process can be better streamlined and duplications reduced between the two agencies.

• $5 billion in loan guarantees to unlock access to capital for Indigenous communities, creating economic opportunities and supporting their economic development priorities.

• Creating more work-integrated learning opportunities for post-secondary students, by providing $207.6 million to Employment and Social Development Canada for the Student Work Placement Program.

The government announced in late March that it would extend the Mineral Exploration Tax Credit (METC) through to March 31, 2025, which this budget confirms. In addition, the budget allows individual taxpayers to claim 80 per cent of the Charitable Donations Tax Credit (instead of 50 per cent as originally proposed in 2023). However, the budget’s increase

12

347 Old Airport Rd., Yellowknife, NT X1A 3T4 (867) 873-2364 F: (867) 873-6516 E: northbest@theedge.ca A 100% NORTHERN-OWNED COMPANY

to the inclusion rate for corporations and trusts to two-thirds and for individuals to two-thirds will significantly reduce the value of the METC to many individuals. Unless the government increases the adjusted cost base of all flow-through shares from zero per cent to higher levels, we believe this budget will be very damaging to financing of mineral exploration in Canada at a time when new investment in critical minerals exploration is most needed. The Mining Association of Canada (MAC) hopes to work with Finance Canada to avoid what we hope are unintended consequences of these proposed changes.

“[The April 16] budget has pros and cons,” explained Pierre Gratton, MAC’s president & CEO. “The proposed new threshold for the CTM-ITC is welcome, but the changes to capital gains may undermine the METC and harm mineral exploration financing. We applaud the government’s ambitions with respect to project timelines, but the real success will come down to implementation; we look forward to working with the government to make sure that mines in Canada can be approved

and brought online in timelines that are more responsive to the urgent need for Canadian minerals and metals.”

The mining industry is a major sector of Canada’s economy, contributing $125 billion to the national GDP and is responsible for 22 per cent of Canada’s total domestic exports. Canada’s mining sector employs 665,000 people directly and indirectly across the country. The industry is proportionally the largest private sector employer of Indigenous peoples in Canada and a major customer of Indigenous-owned businesses.

about mac

The Mining Association of Canada is the national organization for the Canadian mining industry. Its members account for most of Canada’s production of base and precious metals, uranium, diamonds, metallurgical coal, mined oil sands, and industrial minerals and are actively engaged in mineral exploration, mining, smelting, refining, and semi-fabrication. Please visit www.mining.ca. 7

13

1 H Hydrogen 1.008 3 Li Lithium 6.94 4 Be Beryllium 9.0121831 5 B Boron 10.81 6 C Carbon 12.011 7 N Nitrogen 14.007 8 O Oxygen 15.999 9 F Fluorine 18.998403163 11Na Sodium 22.9897692812MgMagnesium 24.305 13 Al Aluminium 26.9815385 14 Si 28.085Silicon 15 P Phosphorus 30.973761998 16 S Sulfur 32.06 17 19 K Potassium 39.0983 20Ca Calcium 40.078 21 Sc Scandium 44.955908 22 Ti Titanium 47.867 23 V Vanadium 50.9415 24Cr Chromium 51.9961 25Mn Manganese 54.938044 26Fe Iron 55.845 27Co Cobalt 58.933194 28Ni Nickel 58.6934 29Cu Copper 63.546 30Zn Zinc 65.38 31Ga Gallium 69.723 32Ge Germanium 72.630 33As Arsenic 74.921595 34Se Selenium 78.971 37Rb Rubidium 85.4678 38 Sr Strontium 87.62 39 Y Yttrium 88.90584 40 Zr Zirconium 91.224 41Nb92.90637Niobium 42Mo Molybdenum 95.95 43Tc Technetium 98 44Ru Ruthenium 101.07 45Rh102.90550Rhodium 46Pd Palladium 106.42 47Ag Silver 107.8682 48Cd Cadmium 112.414 49 In114.818Indium 50Sn Tin 118.710 51Sb Antimony 121.760 52Te 56 57 72Hf 178.49 73Ta180.94788Tantalum 74 W Tungsten 183.84 75Re Rhenium 186.207 76Os Osmium 190.23 77 Ir 192.217Iridium 78 Pt Platinum 195.084 79Au Gold 196.966569 80Hg Mercury 200.592 81 Tl Thallium 204.38 82Pb Lead 207.2 83 Bi 208.98040Bismuth 106 107Bh 108Hs Hassium 269 109Mt Meitnerium 278 110Ds Darmstadtium 281 111RgRoentgenium 281 112Cn Copernicium 285 113Uut Ununtrium 286 114Fl Flerovium 289 115Uup Ununpentiu 289 66Dy 67Ho164.93033 68 Er167.259Erbium 69 Lithium 6.94 Li 3 Drones to Drills TM www.groundtruth.ca | info@groundtruth.ca Specialized in grassroots precious and critical metals exploration. 2023-09-27_GTE_Advertisement_Lithium.indd 1 2023-09-28 1:20:09 PM

Building a hydrogen hub on the prairies

By Erin Matthews and the Saskatchewan Research Council (SRC)

Hydrogen is a colourless, odourless gas that produces little to no emissions during its use.

Saskatchewan is poised to be a leader in Canada’s energy transition.

The province’s established oil and gas industry is crucial for diversifying the energy sector and providing solutions that work for the economy and the environment. With over 30 years of industry knowledge and expertise, the Saskatchewan Research Council (SRC) is supporting the province as it turns its attention towards hydrogen.

“There are a lot of great things about hydrogen, and we are excited about hydrogen as part of the energy transition,” says Petro Nakutnyy, director of operations for SRC.

Hydrogen is a colourless, odourless gas that produces little to no emissions during its use. When used as a fuel, hydrogen combines with oxygen and gives off water or vapour as its by-product— making it an ideal candidate for a variety of energy needs.

Hydrogen can be combusted and used similarly to natural gas, diesel, or gasoline, for example in heating and transportation applications. Hydrogen can also be used in a fuel cell to produce electricity. Fuel cell applications are more efficient, but the ability to use hydrogen in internal combustion engines makes it a versatile transition fuel for heavy-duty transportation.

Since hydrogen doesn’t exist freely on Earth, it must be created and can be produced through several processes. In Canada and in Saskatchewan, hydrogen is currently produced from natural gas, but it can also be made from electrolysis or water splitting, which produces hydrogen from water. Its versatility in both production and end-use applications makes it an attractive fuel alternative.

“The multiple production pathways for hydrogen make it a more versatile option for energy transition,” says Nakutnyy. “In some regions of the world where gas supplies are prevalent, hydrogen can be produced from natural gas and combined with carbon capture which allows us to reduce our greenhouse gas emissions significantly right away.”

In other regions with a different energy mix a larger portion of hydrogen is expected to be produced by electrolysis.

hydroGen in the spotliGht

International interest in hydrogen has grown over the last couple of years. Canada has developed its own ambitious hydrogen strategy that recognizes the potential of hydrogen for environmental stewardship and economic growth within the energy sector.

Net-zero goals will require a multitude of different solutions and hydrogen alone will not provide all our energy needs. However, as the world moves towards net zero, there are many industries that will be challenging to transition to electricity.

Hydrogen offers a solution for heavy-duty transportation services, agricultural practices (e.g., fertilizer), steel production, and other difficult-to-abate sectors with complex energy needs.

src has over 30 years of experience in alternative fuel research

After decades of developing technologies that use hydrogen, SRC has the knowledge and expertise to assist Saskatchewan with its energy expansion.

“I think the best contribution we made was the microprocessor that could adapt gasoline and diesel vehicles to hydrogen,” says Mike Sulatisky, a research advisor with SRC’s Process Development team.

Sulatisky began work on alternative fuel research at SRC in 1984, looking first at natural gas before exploring hydrogen-based technology.

In 2004, SRC produced the first Dual-FuelTM diesel-hydrogen vehicle. This was followed by the first hydrogen-gasoline vehicle in 2005. At its height, the project featured a fleet of hydrogen hybrid vehicles. In 2010, a hydrogen fuelling station was established to support these vehicles.

“We advanced the development of a new fuelling system, which allowed us to blend gaseous hydrogen into vehicles along with normal gasoline, and subsequently trademarked dual-fuel technology,” says Anton Farber, project lead and supervisor at SRC. “The control system development and vehicle conversion were completed in-house at SRC.”

14

These vehicle technologies reduced emissions anywhere from 40 to 60 per cent during routine driving conditions. The vehicles could idle on 100 per cent hydrogen, releasing only water vapour from the exhaust, which further reduced overall emissions.

SRC also developed leakage detection technology that used acoustics and ultrasonics to detect weaknesses within a highpressure container before a leak could occur. Since hydrogen must be kept under very high pressure, this technology provided a valuable safety application.

The hydrogen vehicle project at SRC was a bit ahead of its time and the challenges in producing and storing hydrogen economically at scale were difficult to overcome. However, in recent years, the cost of producing, storing, and working with hydrogen has come down and is expected to further decrease over the next decade.

“Today, hydrogen use can be economic on its own merits, in addition to the environmental benefits of converting some applications to hydrogen,” says Nakutnyy.

Hydrogen continues to pose some challenges for producers and users. To store a sufficient amount of energy in hydrogen, the gas needs to be kept under high pressure, which requires specially designed containers. Liquefying hydrogen is one solution, but the liquefaction process is not easy. It requires a lot of energy, and the liquid hydrogen needs to be kept at -250 Celsius.

SRC is also looking at complementary technologies like microsmall modular reactors to support generation and scenarios that involve using ammonia which offers a potential solution as a hydrogen carrier. Another option that could be explored is storage in metal hydride alloys that use rare earth elements like the lanthanum that will be refined in SRC’s Rare Earth Processing Facility.

The creation of hydrogen hubs could help mitigate some of these challenges. The unique geological landscape and the expertise of the province’s established energy industry make Saskatchewan an attractive location for this kind of hydrogen network.

buildinG a hydroGen hub

Over the last two years, SRC worked closely with experts from the Transition Accelerator and the University of Regina, with support from the Ministry of Energy and Resources and industry partners—including Federated Co-operatives Limited and Whitecap Resources—to assess the feasibility of a hydrogen hub and synergies with carbon capture, utilization and storage (CCUS) infrastructure in the Regina-Moose Jaw industrial corridor.

A hydrogen/CCUS hub could help Saskatchewan establish an entire commercial-scale hydrogen supply and demand chain.

Collaboration is key to the success of a potential hydrogen hub.

“Having stakeholders working together throughout the entire value chain to build demand and ensure that it’s met with local production, is important,” says Dave Anthony, research scientist, Process Development.

Saskatchewan’s oil and gas and mining industries both play a significant role in establishing a hydrogen hub. Their expertise and existing infrastructure are invaluable in growing a new hydrogen economy in the province.

Large underground cavities that are used to contain natural gas are located across the province. They may be opportunities to leverage local geological formations, including salt caverns for hydrogen storage as well.

the future of hydroGen in saskatchewan

Hydrogen can address many of Saskatchewan’s needs while using its established infrastructure. Currently, most of the province’s energy comes from natural gas.

“We can use the industries that we have and retool some of it to produce hydrogen, therefore reducing emissions and creating an environment that would then allow further growth of hydrogen use,” says Nakutnyy.

This strategy would provide a transition period where the people, skills, and infrastructure in Saskatchewan can be used to continue supplying clean and inexpensive energy while maintaining economic growth and employment opportunities. Establishing hydrogen transportation, storage, and use infrastructure will enable the transition to renewable sources of hydrogen production.

Saskatchewan’s renewable energy sources, like solar and wind, fluctuate and can’t always provide a consistent amount of energy. This means that there are periods of time when electricity generation capacity exceeds the demand (off-peak hours). Using this surplus energy to generate and store hydrogen could supplement renewable sources during generation lows.

SRC has worked on helping communities that rely on diesel generators gain access to more reliable and clean technologies with its hybrid energy containers. These containers use diesel power to charge a battery that then provides consistent electricity. Hydrogen, in combination with wind and solar energy generation, could be used to replace diesel and provide clean and reliable energy for these communities in the future.

“This is a global phenomenon,” says Anthony. “The whole world is now talking about the possibilities of hydrogen in the energy transition. And while there are challenges that would have to be addressed to establish a hydrogen hub in the region, Saskatchewan has unique qualities in favour of commercial-scale hydrogen hub development.” 7

15

Technical guidance from mining industry advisory committee

To help raise awareness, Workplace Safety North (WSN), in collaboration with its mining advisory committee, has introduced a new hazard alert and information sheet.

“The goal of these new tools is to talk about the potential dangers linked to cyanide use in mining,” says Judit Nelson, WSN industrial hygiene specialist. “The plan is to teach workers, communities, and industry about the risks of cyanide and how to lower the chances of being exposed to it.”

Gettin G to know cyanide in minin G

Cyanide is a chemical widely used in the mining industry for processes like gold and silver extraction. It can pose significant risks to both the environment and human health.

The hazard alert and information sheet provide a comprehensive overview of potential health effects and safety measures to protect workers.

sources of cyanide exposure

During the extraction process, cyanide is added to create alkaline water, aiding in the extraction of precious metals. The high concentrations of cyanide in solutions can pose risks to human health and the environment. Also, when pure cyanide is exposed to air, it breaks down into compounds like nitrate, leading to environmental and health problems.

d etailed G uidance on safety measures

“The information sheet goes into more detail about using cyanide in mining,” says Nelson. “It’s a guide on how to deal with this chemical safely.”

Cyanide is a quick-acting and possibly deadly chemical that can be a crystal, liquid, or colourless gas. Exposure to cyanide through skin, eyes, and breath can cause symptoms such as agitation, confusion, weakness, headache, nausea, vomiting, respiratory changes, seizures, and coma.

Small amounts can lead to dizziness, rapid breathing, and weakness, while large amounts may cause convulsions, unconsciousness, respiratory failure, and, ultimately, death.

The short-term and long-term effects can include skin and eye irritation, breathing problems, and harm to important organs.

“To minimize the hazards associated with cyanide exposure, a thorough risk assessment and safety measures are crucial,” says Nelson. “Controlling spillage during transfer and system failures within mine sites is essential. Personal protective equipment, including respirators, chemical-resistant gloves, suits, and eye protection must be used to ensure worker safety.

Nelson says that diagnosing cyanide exposure involves blood and urine tests, although results may only indicate recent exposure. Immediate treatment is recommended if exposure is suspected, as every minute counts. The treatment varies based on the route of exposure – eye contact, skin contact, inhalation, or ingestion – and involves specific actions to minimize harm.

i mpact and what comes next

The new hazard alert and information sheet are an important step to help make mining safer. By presenting technical information in accessible language, the goal is to effectively communicate with diverse audiences, including workers, communities, and industry.

“The next steps involve keeping up education and awareness so everyone connected to mining knows about cyanide risks and can take the right prevention steps,” says Nelson.

The WSN Workplace Environmental Technical Advisory Committee, made up of members from the mining industry, as well as technical advisors, provided guidance for these resources, along with WSN staff Philip Dirige, senior specialist ground control, and Judit Nelson, industrial hygiene specialist. 7

16

When it comes time to speak up about a workplace issue, feeling safe and secure in the act of speaking up is paramount.

Whistleblowing’s significance in preserving ethical standards in mining

By Shannon Walker

At its core, ethical mining rests on the assumption that mining companies will implement and abide by clear policies to guarantee the safety and wellbeing of all workers. Provincial, territorial, and national laws and regulations create a complex framework for mines in Canada to operate under. Maintaining compliance and a high standard of ethical behaviour requires being alerted to any wrongdoing or compliance concerns at every site before they can

manifest into larger safety issues. ethical standards in mininG

Through the Safe, Healthy, and Respectful Workplaces Protocol, the Mining Association of Canada works to bridge territorial gaps in regulations and raise the standard for ethical mines across the country. Commitments and Accountability; Safety and Health Management Systems; Psychological Safety and Respectful Behaviour;

Training, Behaviour, and Culture; Monitoring and Reporting; and Physical Safety and Health Performance are highlighted as core pillars with a set standard of conditions for mining companies to adhere to.

Even with comprehensive regulations in place, wrongdoing can still easily fly under the radar, especially when multiple employees are involved or covering for each other, or if the issue is condoned or conducted by

17

Having an anonymous outlet, such as a whistleblower hotline, is the answer for many companies that need an alternative feedback mechanism to regular internal HR checks.

supervisors or upper management. In these situations, it can be extremely intimidating for any one employee to step forward and speak up about the issue at hand, even if they know it is wrong. When these issues go unreported or are swept under the rug due to insufficient protections of reporters, ethical issues can plague mining sites, leading to unsafe conditions and hostile work environments.

h ow do whistleblower hotlines help?

As suggested, when it comes time to speak up about a workplace issue, feeling safe and secure in the act of speaking up is paramount. Not every employee will feel comfortable bringing concerns to their manager, especially if that person is implicated in the incident they are reporting. Alternatively,

these employees may be encouraged to go to HR; however, this can also be uncomfortable, hard to access, and insecure for employees, causing them to avoid reporting altogether.

Having an anonymous outlet, such as a whistleblower hotline, is the answer for many companies that need an alternative feedback mechanism to regular internal HR checks.

When thinking about making an incident report or effectively “blowing the whistle” on a workplace issue, many people picture a hotline. These phone systems are one of the more traditional reporting systems and are reliable methods for quickly bringing issues forward. However, with more emphasis put on digital platforms in every industry, having an omnichannel system that also utilizes email and web intake

forms can make your system more accessible for all employees at all times. Where possible, secure platforms that maintain anonymity for the reporter are vital elements of whistleblower reporting systems. Having a protocol in place that ensures the right people are notified of an incident report and that it is escalated according to severity will also be crucial for maintaining employee confidence in the system.

b est practices for hotline implementation

When implementing a new process at a mining site or even across multiple sites, top-down training will be essential to ensure everyone is comfortable and aware of how to use the reporting system. Within training, management and supervisors should aim to achieve the following:

18

Having an anonymous outlet, such as a whistleblower hotline, is the answer for many companies that need an alternative feedback mechanism to regular internal HR checks.

• Every employee knows how to use the tool effectively.

• Employees feel comfortable using the tool without fear of retaliation.

• Any privacy concerns around employee anonymity and data collection are addressed.

• Have a system in place to audit employee reports and collect data around usage rates, response times, and common concerns brought forward.

During training, companies should focus on promoting a speak-up culture, which encourages employees to bring forward concerns, either anonymously or to supervisors, no matter how big or small. Promoting a speak-up culture happens over time, and often requires supervisors to lead by example. One preventative measure you can put

in place to ensure people are further encouraged to speak up is an antiretaliation policy. This policy will effectively outline that no employee can be reprimanded, ostracized, or retaliated against for speaking up against wrongdoing that they witness. In a perfect world, every reporting employee can stay anonymous. However, should anything happen that reveals the identity of an employee, they should not fear their employment or status in the workplace.

Working toward ethical mines nationwide is an ongoing effort. Implementing mechanisms to facilitate on-site and off-site reporting that employees feel safe utilizing is paramount for addressing concerns efficiently. Remember, the importance of comprehensive training when enforcing the use of whistleblower

The strength of a mining company’s ethical practice hinges on its ability to listen to and act upon the concerns of its workforce.

hotlines. Ultimately, the strength of a mining company’s ethical practice hinges on its ability to listen to and act upon the concerns of its workforce, making whistleblowing not just a mechanism for reporting but a foundational element for ethical governance and sustainable success in the mining sector.

Shannon Walker is the founder of WhistleBlower Security Inc. (WBS) and executive VP of Strategy at Case IQ. WBS provides ethics, compliance, and loss prevention hotlines, along with IntegrityCounts, a proprietary case management platform for organizations globally. Walker frequently speaks around the world on whistleblowing, ethics, corporate culture, and diversity. 7

19

An engineered approach to solving dust containment problems at conveyor transfers

Safety and health hazards make containing dust and fines non-negotiable in today’s mining environment. Additional problems associated with dust include environmental risks, increased housekeeping, and damage to equipment, as well as loss of product.

Identifying root causes is the first step to successfully solving the problem of airborne dust. Any time conveyed product is in motion it has the potential to generate dust. Dust and fines can be assumed if the product is moving, if there is an area of material free fall, and at any conveyor transfer areas. Our focus will be on dust that is specifically created at transfer areas where the conveyor is receiving material.

Engineered Passive Dust Containment is a system design that allows airborne dust to “settle” into the main stream of product without auxiliary equipment

dust particles. The Passive System does not require traditional methods of dust suppression such as water or chemical sprays or vacuum dust collection.

A Passive Containment System keeps material on the belt throughout the length of the conveyor transfer. It employs a series of chambers that are designed to reduce air velocity and allow dust particles to settle back down to the belt before exiting the transfer area.

The Passive Dust Containment System uses guidelines from CEMA (Conveyor Equipment Manufacturer’s Association) to determine the recommended time and distance for material settling at the load zone. This helps determine the general length of the skirtboard beyond the impact zone.

This engineered system is built on three essentials:

for consistent support. The impactresistant cradle-shaped Impact Saddle with seal bar is recommended along with the use of Cushion Arc impact idlers placed before and after the Impact Saddle bed. According to CEMA standard 575, Impact Saddles are directly interchangeable with impact idlers and have the benefit of providing full trough support. The full support surface eliminates pinch points or gaps to provide the best foundation for sealing characteristics. Correct belt support and elevation are fundamental to a successful material containment system.

2. Next, a multi-layered approach that contains bulk material with internal wear liners and external skirting media is used to seal dust. Additional components include skirtboards or skirt clamps in a variety of configurations and rubber. Ceramic or rubber/ceramic matrix Canoe Liners can be recommended based on the needs of the application.

3. And lastly, once a solid base is in place and bulk materials and fines are contained, additional dust control components, such as entry and exit dust curtains, dust-settling chambers, and end pieces are added to effectively create a total system design.

When fitted with an Engineered Passive Dust Containment System, busy transfer areas can be well equipped to handle the demands of efficiency, productivity, and safety that are required.

Reliable, worry-free transfer areas are engineered every day at Richwood. To learn more about dust and material containment solutions, visit www.richwood.com. 7

20

majorcanada@majordrilling.com 1-204-885-7532

our team to ensure your next project is safe, successful,

Contact

and on time.

PDAC 2024 Convention welcomes the world to the premier mineral exploration and mining event in Toronto

The Prospectors & Developers Association of Canada (PDAC) was thrilled to welcome 26,926 participants to Toronto for the best business, investment, and networking opportunities in the mineral exploration and mining industry. With more than 1,100 exhibitors, including governments, companies, and leading experts from around the world, PDAC 2024 was one of the largest events in the association’s history.

“PDAC 2024 carried forward the convention’s 92-year legacy, serving as the premier venue for unveiling new trends, technological innovations, and industry discussions,” said Ray Goldie, PDAC president. “Once again, PDAC was proud to showcase a rich array of programming including capital markets, Indigenous relations, student and early career development, and sustainability.”

Keynote speakers included Jakob Stausholm, CEO, Rio Tinto; Michael Stanley, Mining Lead, The World Bank; Denise Johnson, group president, Resource Industries Caterpillar Inc.; and Wojtek Wodzicki, the Lundin Group Vicuña exploration team.

The convention provided a venue for dialogue between industry and government. PDAC’s leadership seized the opportunity to underscore the important role public policy has in supporting the competitiveness of Canada’s mineral sector.

“Canada is poised to lead the green transition as the supplier of choice for responsibly sourced critical minerals,” said Goldie. “It is imperative we bolster our critical mineral wealth, and we cannot ignore the foundations of our mineral industry. PDAC’s closing call to our federal government is that it must renew the Mineral Exploration Tax Credit that is set to expire this month.”

Thank you to everyone who participated in PDAC 2024,

including our volunteers, speakers, sponsors, and participants. We look forward to welcoming you back March 2-5, 2025 for PDAC 2025.

Visit www.pdac.ca/convention for more information. 7

21

Lead

Over 130 northern engineers and geoscientists convened in yellowknife on Building a Resilient North

The Northwest Territories and Nunavut Association of Professional Engineers and Geoscientists (NAPEG) hosted its annual Professional Development Symposium from May 16-17, 2024 at the Explorer Hotel in Yellowknife with Honourable Caroline Wawzonek, Deputy Premier, Minister of Finance, Minister of Infrastructure and Minister Responsible for the Northwest Territories Power Corporation as the keynote speaker.

This year’s theme, Building a Resilient North: People, Projects and Professions brought industry leaders and researchers from across Canada together with over

130 northern professionals to share the latest in what it takes to build a resilient North.

“NAPEG is responsible for the regulation and support of the professional practice of engineering and geoscience in the Northwest Territories in the public interest. Establishing and maintaining the standards of knowledge, skill, and care expected of our professionals is an important part of that responsibility. The annual Professional Development Symposium is our premiere learning event to achieve that,” says Paul Guy, P.Eng., president of NAPEG.

The two-day in-person and virtual

symposium covered emergent topics including examining pipe breaks in Iqaluit’s water supply, a status update on the 30 By 30 initiative by Engineers Canada – an initiative which aims to increase representation of women in the field – and discussions on how to recruit and retain talent in the North in both the private and public sector.

These topics tailored to enrich and develop engineers and geoscientists in the North resonated with Wawzonek’s keynote address, which focused on innovative approaches to climate change mitigation and adaptation, youth engagement in STEM, and the new

22

Practice of Engineering, Geoscience and Applied Science Technology Act.

“The expertise, dedication, and innovation of the territory’s professional engineers and geoscientists are key in meeting the pressing needs of the North and solving complex challenges,” says Wawzonek. “From designing critical infrastructure to developing sustainable energy solutions, this work is woven into the daily lives of all residents.”

In addition to the symposium, the NAPEG Education Foundation hosted its annual Awards Banquet on the evening of May 16 to recognize professionals and firms in the North for outstanding achievements in the field. The following awards were presented:

Professional Award of Merit in Engineering – Rankin Inlet Runway Rehab, Dillon Consulting

Professional Award of Merit in Geoscience – Aurora Geoscience Award for Environmental Excellence –Steve Kokelj, PhD

Science Teacher Award – Nikita Morozov, Chris Silzer, and Jennifer Genge

Young Achiever Award – Rebecca Saari, P.Eng.

Distinguished Life Membership – Peter

Bengts, P.Eng., FEC, FHC (Hon.) and Hendrik Falck, P.Geo., FGC

Past President Award – Melanie Williams, P.Eng.

The Northwest Territories and Nunavut Association of Professional Engineers and Geoscientists (NAPEG) is responsible for the licensing of professional engineers and professional

geoscientists in the Northwest Territories and Nunavut, the regulation of the practices of professional engineering and professional geoscience, the establishment and maintenance of standards of knowledge, skill, care, and professional ethics among its registrants, in order that the interests of the public may be served and protected. 7

If you are a Geoscientist or Engineer working North of 60°, don’t forget to register as a Professional.

If you are already registered with a Canadian Professional Association, it is easy to transfer in and add a northern registration to your qualifications.

To apply or learn more, call us today 867 920 4055 or email napeg@napeg.nt.ca

23 Bowling Green Building | 201, 4817 - 49th Street Yellowknife, NT X1A 3S7 | T 867.920.4055 WWW.NAPEG.NT.CA DO

DO YOU… WRITE 43-101 REPORTS? CALCULATE ORE RESERVES? WORK ON NEW STOPE

PIT DESIGN?

YOU WORK NORTH OF 60° ?

OR

1/3_NAPEG_ NORTH 60_MINING_2024.indd 1 2024-04-18 1:54 PM

Twice annually e-newsletter Learn more Coast to Coast Distribution DIGITAL