Standard Machine designs and manufactures high quality gearboxes for all mining applications. From design concept to manufacture, whatever your critical equipment needs are we have the engineering experience and know how to get your equipment up and running.

The Timken Power Systems team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide. The company designs, makes and markets mechanical components, including bearings, gears and related mechanical power transmission products and services.

protective coating and

needs.

can work on your site or in our

large shops (53,000 sq ft),30 acres of yard

and cranes and forklifts on site.

• Spray Polyurethane Foam Insulation

• Fire Proof Coatings

• Stainless Steel Pickling and Passivation

• NACE Certified Inspectors on Staff

• Industrial Standard Quality Program

Message from the editor, Shayna Wiwierski – 6

Message from the Minister of Energy and Resources, the Honourable Jim Reiter – 8

From where I sit:

It’s summer and that means reading time… – 10

Meet the Olszewski’s: A story of family, community, and lasting legacy – 14

Mosaic’s Belle Plaine potash solution mine – 18

Switching the substation that’s powering Jansen – 20

Unlocking value in the Gabon Potash Basin – 22

Top 10 potash countries by production (updated 2024) – 26

Building policies to boost the potash sector and its workers – 30

The hidden dangers of asbestos in potash mining – 32

Canpotex gifts $120,000 through its Food for Kids initiative to Hope’s Home for the Inclusive meal program at Saskatoon’s new medically inclusive child care centre – 34

Increasing fertilizer demand creates opportunity for profit – 35

Invest in leadership development to retain and attract talent – 38

Supplying an education for a brighter future – 40

From

the

the

the

and the

in no way guarantees nor

and is

or

DEl communications inc. and potashworks.com are extremely grateful to our advertisers for their support in this publication. click here to download the media kit.

by

for

of

or

its

Welcome to Issue 2, 2024 of The Potash Producer e-newsletter. In this issue, we delve into stories that highlight innovation, leadership, and market dynamics shaping our industry today.

Firstly, we showcase Mosaic’s Belle Plaine site, a beacon of safety and excellence in potash production. Mosaic has long been synonymous with industry leadership, and their commitment to safety at Belle Plaine sets a standard for all. By implementing rigorous safety protocols and fostering a culture of continuous improvement, Mosaic not only ensures the well-being of its workforce but also enhances operational efficiency. Their efforts serve as a testament to what can be achieved through dedication and steadfast adherence to best practices.

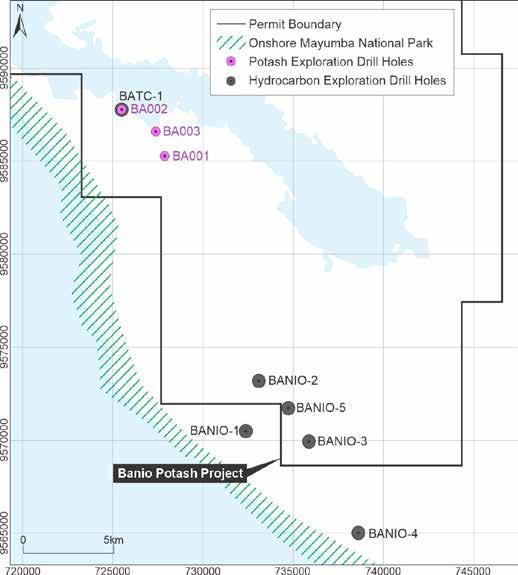

Next, we turn our attention to Millennial Potash Corp. and their ambitious Banio Potash Project in Gabon. Millennial Potash Corp. has rapidly emerged as a key player in the potash market, drawing attention with their innovative approach and strategic investments. The Banio Project not only promises substantial production capacity but also underscores the potential of untapped resources in emerging markets. As global demand for potash continues to rise, initiatives like the Banio Project are crucial in meeting future agricultural needs sustainably.

Additionally, we feature a comprehensive report from the Investing News Network highlighting the Top 10 potash countries by production. This insightful analysis provides a detailed overview of the top producing countries, highlighting their contributions to global supply chains. From established leaders to emerging markets, understanding the dynamics of global potash production is essential for navigating the complexities of our industry.

As we navigate through these compelling narratives, it’s evident that the potash industry is at a pivotal juncture. Rapid technological advancements, coupled with evolving market demands, necessitate continuous adaptation and innovation. Whether it’s enhancing operational efficiencies, exploring new frontiers, or redefining industry benchmarks, each story in this issue underscores the resilience and dynamism of the potash sector.

I encourage you to delve into these stories, reflect on the insights shared, and consider how they resonate with

your own operations and strategies. In a rapidly changing world, staying informed and proactive is key to sustaining growth and seizing new opportunities.

We encourage you to explore the content in this issue, engage in the conversation, and share your thoughts with us.

With that, we would like to thank our contributors for this issue:

• Minister of Energy and Resources, the Honourable Jim Reiter

• Steve Halabura

• BHP

• Canpotex

• CDM Systems

• Investing News Network

• The Mosaic Corp.

• Nutrien

• RESPEC

• The Saskatchewan Chamber of Commerce

• Supply Chain Canada

• Sutton Benefits & Pension

• WorkSafe Saskatchewan

• Millennial Potash Corp.

We invite all interested companies to share their news and editorial ideas with us. If you would like to contribute a story for future issues of The Potash Producer e-newsletter, please contact myself at shayna@delcommunications.com.

Finally, we also welcome you to help spread the message about our publication. In addition to The Potash Producer e-newsletter, we publish a handful of other mining-related e-newsletters. You can find out more and subscribe at www.delcommunications.ca/mining/.

Thank you for your continued support and engagement. Together, we propel the potash industry forward, shaping a future defined by innovation, sustainability, and excellence.

Shayna Wiwierski shayna@delcommunications.com

l

GMR Electric Motors started from small beginnings and, over the last 45 years, has grown into one of North America’s leading electric motor repair facilities. Our customers are coast to coast in Mining, Oil+Gas, Power, Marine and Agriculture. We work with our customers to find solutions with long-term partnerships in mind; we are here for the long haul. With our current facilities in Saskatoon and Estevan, we are proud to be part of the diversified and vibrant supply chain in Western Canada. Our customers, suppliers and, most importantly, our employees have gotten us where we are today; we are excited and looking forward to another 45 years of growth.

am pleased to contribute to another issue of The Potash Producer e-newsletter to give an update on the Saskatchewan potash sector.

Potash producers are continuing to deliver for our province, as BHP continues with the development of the Jansen potash mine southeast of Saskatoon.

Following BHP’s additional commitment of $6.4 billion for Stage 2, municipalities, regional development interests, First Nations communities, the Government of Saskatchewan, and BHP established the Sylvite Four-Six (S4-6) Regional Development Partnership. While the name pays homage to the two treaty areas where BHP is operating, four and six, and to the natural state of the potash mineral, the partnership has been formed to help guide regional development priorities.

Approximately 34,000 people live within the 100-kilometre radius around the Jansen site. The partnership group anticipates this number could grow by 20 per cent as a result of the Jansen mine coming online. This includes the BHP operational workforce, their families, and the supporting services needed. Other growing industries in the region may attract more families to the area.

To help support these coming changes, local municipal and Indigenous leaders, BHP, and the Government of Saskatchewan have co-created the S4-6 Regional Community Action Plan. I am confident that with this effective collaboration, the region will be well-served to support a growing population. Services to support housing, labour, infrastructure, childcare, training and education, emergency services, and economic development will be in place for years to come.

The BHP investment is one part of the larger picture of longterm commitments and community support that industry partners like Mosaic, Nutrien, and K+S Potash Canada have made in Saskatchewan. Over the past two decades, the potash industry here has committed over $35 billion in capital investments in expansions and new mines, and significant philanthropic contributions.

In 2023, 6,300 potash workers and their families called Saskatchewan home, with thousands more employed in the mining supply and services sector. The Jansen project is creating 5,500 construction jobs throughout the two phases of construction, and it will create 900 permanent full-time jobs in operations.

This industry continues to be a reliable pillar of the provincial economy. In 2023, Saskatchewan’s potash producers reached a new record for volume of sales — 14.5 million tonnes K2O. The value of sales last year was also strong, reaching $10.9 billion, one of the best years on record.

These numbers mean Saskatchewan’s potash producers continue to provide consistent and reliable delivery of sustainably produced Saskatchewan fertilizer to the world, playing a significant role in addressing the global food security challenges being faced today.

As the worldwide population grows and brings greater demand for better-quality food, it is clear Saskatchewan will continue to deliver and meet that demand in the years ahead.

Thank you. l

by steve halabura, P.geo., halabura Potash Consulting Ltd.

What’s better than shutting down Zoom, grabbing a case of your favourite brew and a couple packs of Cheezies, and heading off to the lake with a good book or two? The only question is what to read?

Well, let me recommend a good one!

To separate politics from potash in Saskatchewan would be like separating conjoined twins connected at the head, heart, abdomen, hip, and leg; it’s impossible!

For this reason, it’s hard to write a Saskatchewan potash history that does not interweave throughout its narrative a strong political flavour. It’s not that the potash story has been politicized; rather, it is that politics is fundamental from its birth.

I’ve noticed that there has been some increased attention focused upon resource royalty and taxation issues, although not as much as I would have expected, given that this is an election year in Saskatchewan. One event that created a ripple was the publication of a book by former NDP cabinet min-

ister Eric Cline. The book, entitled Squandered – Canada’s Potash Legacy, was released in March 2024.

Cline practiced law in his hometown of Saskatoon prior to serving 16 years in the Saskatchewan legislature where he held several senior cabinet positions, including the portfolios of health, finance, and industry and resources. After his retirement from public service, he worked for 12 years as a corporate executive in the mining sector before setting up an arbitration practice and working as a fused glass artist. Given this background, Cline is highly qualified to sift through not only the opacity but also the complexity of Saskatchewan potash production, sales, taxation, and policy, and it would be an error to dismiss his work as being simply a matter of partisan politics.

On a recent business trip, I had the opportunity to spend some undisturbed time with the book. It is an easy weekend read, largely due to Cline’s simple

and straightforward writing style. He is a clear and concise communicator, and demonstrates, time and again, his ability to render complex technical and financial issues into explanations easily understood by the layperson.

Cline’s basic thesis is that while industry profits rose exponentially, the public’s share of those profits remained stagnant, at about one-quarter to onethird. What would be fairer would be a structure that if the industry share rose exponentially, so to would the public share, which is the theory of economic rent.

The theory of economic rent for the extraction of resources is that companies should make a reasonable rate of

return on investment and the balance goes to the resource owners (p.95). The justification for this approach is the unique position Saskatchewan enjoys with respect to potash. “To say that Saskatchewan is the Saudi Arabia of potash is no exaggeration; in fact, it is an understatement” (p.6). Given this natural wealth provides the government with a strong negotiating tool – it can be more assertive, as “you cannot pick up and move the mine”.

In the introductory chapters, Cline presents a continuation of Saskatchewan’s potash history, somewhat overlapping John Burton’s book, Potash –

An Inside Account of Saskatchewan’s Pink Gold, but bringing to light more detail

• Regional evaporite basin analysis

• Early-stage exploration program design and management

• Mineral Resource assessment (NI43-101 and JORC standards)

• Class 5 Concept and PEA study management

• Solution mining design and planning

• Economic modelling

on BHP Billiton’s failed 2010 bid for PotashCorp, and also closely examining the subsequent merger of PotashCorp with its competitor Agrium Inc. to form Nutrien in 2018. He brings the history forward to Russia’s invasion of Ukraine in 2022 and explores somewhat BHP Billiton’s decision to build the Jansen mine.

The heart of Cline’s analysis is Chapter Eight, “The Profits of Potash”, and the attached Appendix A “Value of Potash Sales and Payments to Public Treasury, 1962 – 2022” and Appendix B “Potash Production Volume and Average Price, 1997 – 2022”. Cline spent considerable time researching the public filings and annual reports of the major producers, including Nutrien, Agrium, the now-defunct PotashCorp, and Mosaic, to prepare tables that present year-byyear data such as potash sales, gross profit, realized price, etc. From a public policy perspective, he presents database analyses of industry and public shares of profits, using the province’s own royalty and tax structure. It is worth buying the book, if only for this data, and I thank Cline for this most useful summary.

However, the book is more than a technical and financial treatise; Cline is also an impassioned Saskatchewan patriot and spokesperson. Chapter Nine presents Cline’s solution to the discrepancy between “producer profits and the people’s share” by offering several solutions and ends the book by making an impassioned case for the impact this “shortfall” makes upon the lives of Saskatchewan’s citizens. It is in these two chapters that Cline demonstrates his deep Saskatchewan identity and a compassion for people that no doubt was the root of his public service career.

As often happens, books such as these immediately create an alienation in the popular media, as those to the left argue for elimination of an injustice and those on the right state that it is business that elevates the people by means of employment and the purchase of services. Nevertheless, this does not negate one of Cline’s recurring themes in the book: the potash sector is a huge moneymaker. His demonstration of this fact makes the book of singular importance.

In closing this review, I offer two observations derived from Cline’s work: his analysis expresses volumes using two units – “K2O” and “KCl”. As followers of my column know, the measure used by the province is K2O, the standard dating back to the inception of the industry in the late 1940s. Industry uses the other measure, as this reflects product tonnes. Cline is scrupulous in his analysis not to directly compare volumes using one standard against volumes expressed in the other, although at first, I did question whether his stated “discrepancy” between the provincial and industry volumes may have originated from such a confusion. For those of you who intend to buy the book, if for nothing else other than its statistical data, keep this in mind.

accurate, as when the settler colonists arrived, in all cases they saw there already were people here, these being the original owners – Saskatchewan’s Indigenous peoples. Perhaps if there is a question to be asked it is this: “What should the direct benefit be to Saskatchewan’s Indigenous people with-

in whose traditional territories potash development occurs?” However, this is material for another book.

‘Nuff

Eric Cline, 2024, “Squandered - Canada’s Potash Legacy”, published by University of Regina Press, 170 pp. l

The second observation is one derived not only from his work, but also derived from the authors that he quotes. There is the presupposition that the original owners of the resource are the same owners we see today, i.e., the “settler colonists” who came and populated Saskatchewan at the turn of the 20th century onward. This is not CAB® Products are proudly made in the USA by persons with disabilities at the Cambria County Association for the Blind and Handicapped. www.cabproducts.com

keith o lszewski was born and raised in allan. h e worked at, and has now recently retired from n utrien after a successful 46 years, nearly half of a century.

In the heart of Saskatchewan lies the small town of Allan, known for its potash deposits and strong community spirit, and is home to one of Nutrien’s potash mines

For the Olszewski family, Allan is the definition of home. It’s a place where generations of this family were born, raised, work, and are planning to stay.

Nutrien’s Allan mine is more than just a place of employment for the family. It’s been a place to build community, friendships, and successful careers.

The story begins with Keith Olszews-

ki, who was born and raised in Allan. Keith’s father was the town administrator for 40 years. Keith met his wife in Allan, who he has been married to for 39 years, and together they have two sons, Braden and Brent. Keith worked at, and has now recently retired from Nutrien after a successful 46 years, nearly half of a century.

Keith began his career at the Allan mine on January 9, 1978. He started underground as a mine operator and performed roles as a service crew operator and back-up operator for the first 20

years of his career. In 1998, he started his mechanical millwright apprenticeship and became a journeyman mechanical millwright soon after. He came to surface in 2001 and remained in this area as a millwright for the last 26 years of his employment.

Now Keith’s sons Braden and Brent have a legacy to uphold.

Braden, Keith’s oldest son, moved away from Allan briefly to play junior hockey after he graduated high school, but moved back in 2007 and has now been at the mine for 17 years. He now lives

on an acreage about 30-kilometres east of the mine site with his family. Braden played senior hockey in Allan for Keith is the third person on the right-hand side.

13 years with the mine supporting the team in supplying jerseys and other essential items.

Now hiring at all Potash sites across Saskatchewan:

- Industrial and Heavy Duty Mechanics

- Engineers and Technologists

- Mill and Mine Operators

- Electricians and other Trades

“Nutrien has provided me with a lot of opportunities to grow my career. I started underground as a back-up operator then moved to surface a year later in mill operations. I was then promoted to staff as a control room supervisor in 2013 then to mill operation planner, then to my current role as mill operations general foreman,” says Braden. “My role has moved around a lot over the years as opportunities arose with the expansion. I supported the large expansion and was on the rollout team when we transitioned from 3270 to Oracle, as well as several other change management initiatives that took place at site.”

Nutrien’s priority on safety also gave Keith and Braden the opportunity to share the experience of being members of Allan’s emergency and mine rescue teams throughout their careers. Keith was a member of the mine rescue team for numerous years and won two provincial competitions. Braden has been a part of the emergency response team since he came to surface in different capacities and his team won Nutrien’s an-

nual Firefighter’s Rodeo in 2018.

Brent, Keith’s youngest son, has also stayed near the town of Allan, living on an acreage about 40-kilometres west of the mine. He started at the mill in 2010 and moved underground in 2011 where he operated the borer and shaft until 2023. Now his career is growing, and he is currently an apprentice millwright and worked on the same crew as his dad, Keith, until his recent retirement.

Keith and Brent have had two vastly different experiences due to techno logical advancement at the mine. Keith had to complete tasks with a hands-on approach and without computers, com pared to Brent who was one of the first operators to run the tele-remote borer underground and the first operator to run it from surface.

Keith, Braden, and Brent have worked alongside each other for the last 17 years and have valued getting to see each oth er every day. Their shared experiences made their bond stronger and allowed them to easily blend work-related tasks

with family matters, making the workplace feel like an extension of home.

“It was great working with my sons, and it made me proud to watch them progress in their areas of work,” says Keith. “Now that I am retired, my advice to my sons is you’ve got to have a little fun to keep things rolling.”

The legacy of the Allan potash mine is interwoven with the legacy of the Olszewski family—a testament to hard work, community, and the importance of family. It’s a story that resonates not just in Allan but throughout Saskatchewan, showing how Nutrien can leave a lasting impact on its people and the community. l

Written by the mosaic Company

Mosaic’s Belle Plaine facility continues to achieve impressive safety results, embedding a strong safety culture among its employees and contractors. In 2023, the Belle Plaine site celebrated zero recorded injuries for the third time in seven years. This achievement highlights the site’s dedication to following industry-standard safety procedures and protocols. The Belle Plaine team also consistently enhances safety measures, challenges norms, and reduces risk.

Belle Plaine’s commitment to safety has garnered national recognition. The site received the John T. Ryan National Safety Trophy for Select Mines from the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) for its impressive safety performance in 2023. Belle Plaine employees worked over 1.1 million hours in 2023 with a reportable injury rate of zero. Belle Plaine shares this award with Calibre Mining Corporation’s Valentine Mine in Newfoundland and Labrador and North

American Construction Group’s Aurora Mine Site in Alberta, which also had reportable injury rates of zero.

This annual award is presented to mining operations/companies with a low to no reportable injury frequency rate. The award committee looks at a combination of lost time injuries and modified work injuries based on accepted Workers Compensation Board (WCB) claims. Belle Plaine has received the John T. Ryan award in 2017, 2022, and 2024.

“It is an honour to receive the John T. Ryan National Safety Trophy for the third time at Belle Plaine, but what matters most is the record behind the award and what that means,” said Lawrence Berthelet, vice-president of operations – Potash. “Our top priority is to ensure every person at a Mosaic facility returns home safely every day. The recognition highlights the level of engagement the Belle Plaine team has and the safety culture they’ve built.”

Belle plaine’s Emergency response team competing at the s askatchewan mining association’s annual Emergency response/mine rescue skills competition in June 2024.

2023 also marked the site’s fifth-best potash production year since opening in 1964. Belle Plaine produces three-million tonnes of potash annually.

Mosaic’s Belle Plaine site continues its quest to remain one of the safest mines in Canada. One aspect of preparedness comes with emergency response training.

In June, Mosaic’s Belle Plaine team placed first in the First Aid – Surface and the Surface Field Problem events at the 54th Annual Emergency Response/Mine Rescue Skills Competition, organized by the Saskatchewan Mining Association (SMA). The skills competition tests Saskatchewan mining sites on various safety challenges, such as extinguishing fires, rescuing personnel, and managing medical emergencies. This friendly challenge between Saskatchewan mining teams adds an element of competition for all the sites to try and ensure their emergency response teams are trained and ready for any emergency event at their facilities.

“It’s a tradition for Mosaic’s Emergency Response Team (ERT) to participate in the SMA’s Mine Rescue competition,” Lawrence said. “These events simulate real emergencies that could occur. While we hope these scenarios never occur, our teams need to practice. Mosaic is proud of all our ERT members and their work year-round to keep us safe.” l

From left to right: l awrence Berthelet, vice-president, operations – potash; r yan t homas, general manager – Belle plaine; matthew swedburg, senior manager, maintenance and engineering – Belle plaine; Brad sigurdson, vice-president - environment, safety and regulatory affairs receiving the Saskatchewan Mining Association’s 2024 National trophy in Vancouver in may 2024.

Parkland is not just your standard steel fabrication shop.

In our fabrication facilities we complete projects of all aspects from a small repair on a trailer to surge bins and cyclones. Our custom fabrication shop is 10,000 sq.ft. with overhead cranes and five acres of yard space, so no matter how big or how small your project is we are able will handle it with ease.

Parkland Manufacturing – We Build relationships through our fabricated solutions.

Construction at the Jansen potash project in Saskatchewan, Canada is nearing the halfway point, and a reliable source of energy is needed to power the mine’s essential infrastructure in readiness for production.

The amount of power required to operate a potash mine may not be immediately obvious, but electricity is essential for processing, material transportation, ventilation systems, lighting, and other auxiliary services.

“Until now, the Jansen site’s electricity requirements have been supported by a temporary feed from SaskPower, which is the primary power utility in our province,” explains Sabri Hamida, area manager for port and non-process infrastructure. “As we move closer to a number of key construction milestones, including hoist commissioning, we’ve reached the point where onsite supply of high-voltage power is critical for the development of the mine – both on the surface and underground.”

On a mild winter’s day during Febru-

Specializing in structural steel, miscellaneous metal & custom fabrication with carbon steel, stainless steel and aluminum. www.imwelding.com | info@imwelding.com | 306-955-4546

• Mine shaft rope steel

• Conveyor belt reclaim skids

• Pump skids

• Potash hoppers

• Underground conveyor drive frames

• Potash brine piping tower

• Pipe bridges

• Surge bin support beams

• Mosaic stadium rails

• Belt conveyor pulley frames

• Underground work platform

• Belt conveyor skirting

ary, Jansen’s very own 230 kilovolt (kV) substation came to life with a brief zap. It was the culmination of years of planning and months of dedicated support from SaskPower and within Team Jansen.

A major advancement for the Jansen site, the 230kV substation is similar to a city’s power grid which urban residential homes connect to for a reliable supply of power.

Safely delivering one of the world’s largest and most sustainable potash mines requires careful planning, including of the site’s anticipated energy consumption requirements now and in the decades to come once operations commence.

“The 230kV substation is really the heart of the project because without it, we wouldn’t be able to run Jansen at full capacity,” said Arlene Baquiran, deputy commissioning manager. “It feeds everything downstream from it, and not only for Jansen Stage 1, but future stages as well. The 230kV is the first point where electricity we’ve secured enters the site boundaries.”

As is standard for any land disturbance, BHP’s environment team performed a habitat review to ensure no wildlife was displaced.

With the 230kV substation now successfully commissioned, Team Jansen’s focus has moved to energizing the 34.5kV substation – the final piece of the puzzle that’s powering Jansen. l

PCL.com

Edmonton: 780-733-6201

Regina: 306-347-4200

Early Contractor Involvement

Sustaining Capex Projects

Large Complex Projects

Maintenance & Turnaround

We mobilize rapidly to adhere to aggressive fasttrack schedules meeting occupancy, turnover and all crucial milestones.

Backed by one hundred years of experience, lean methods, advanced technology and in-house experts for the best price.

Delivered in operational mission critical spaces with zero tolerance for disruption.

Saskatoon: 306-931-3322

Sudbury: 705-995-2225

Smaller scale projects delivered by lean, specialized services teams.

For over 40 years, the largest mining companies in the world have put their confidence in Richwood’s innovative material handling solutions.

When it comes to solving problems with dust and material containment, Richwood achieves success with engineered passive dust containment systems. Application-specific solutions optimize efficiency through sealed and protected load zones without the need for vacuums, filters or other additional equipment. The reduced wear and tear on equipment and controlled dust and spillage create a safer and more productive work environment. Worry free load zones are designed and built by Richwood every day.

What would it mean for your productivity if dust and spillage issues were eliminated? Contact Richwood today for a review of your application.

Millennial Potash Corp. (TSX-V: MLP) is making waves in the global potash market. With an experienced management team renowned for creating substantial shareholder value, Millennial Potash is set to make significant contributions to global agriculture through its Banio Potash Project in Gabon. This project has the potential to meet the increasing global demand for potash fertilizers, which are essential for enhancing food security worldwide.

The leadership of Millennial Potash is a strong indicator of the company’s potential. The board and management collectively own 30 per cent of the company’s shares, ensuring their interests are aligned with those of other shareholders. The team includes industry veterans such as Farhad Abasov, Graham Harris, Paul Matysek, Peter Maclean, and Jason Wilkinson. Their track record is impressive: they developed and sold Millennial Lithium to Lithium Americas for CDN $491 million, Allana Potash to Israel Chemicals for CDN $170 million, Potash One to Kali + Salz for CDN $434 million, and Energy Metals to Uranium One for CDN $1.8 billion. These successes highlight their ability to identify, develop, and monetize high-potential resource projects.

The Banio Potash Project, located on Gabon’s coast, has several strategic advantages. Its proximity to shipping ports and established infrastructure facilitates efficient logistics and market access to key regions such as Brazil, the U.S., and Asia. Extensive potash mineraliza-

tion has been identified on the property, with drillholes demonstrating seam thicknesses of up to 80 metres. The simple geology and mineralogy of the deposit makes it amenable to low-cost and environmentally responsible solution mining. Furthermore, the Gabonese government fully supports the project, reflecting the country’s commitment to attracting foreign investment and fostering infrastructure development.

Millennial Potash has made significant progress with the Banio Potash Project. The maiden mineral resource estimate identified significant indicated and inferred mineral resources exceeding 1.7 billion tonnes with over 289 million tonnes of contained potassium chloride (KCl). This estimate covers only five per cent of the 1,200-square-kilometre project area, hinting at substantial future resource expansion possibilities. The Preliminary Economic Assessment (PEA), completed in April 2024, returned an after-tax NPV(10) of USD $1.07 billion and an after-tax IRR of 32.6 per cent, positioning the Banio project as one of the

most potentially economically viable potash deposits globally, and a highly attractive investment proposition. The project also boasts extremely competitive operating costs of USD $61 per tonne of granular muriate of potash (gMOP), ensuring cost-effective

operations and sustainable profitability.

Millennial Potash is committed to moving the Banio Potash Project towards production. Leveraging its strategic location, robust resource base, and favourable market dynamics, the company aims to expand the project resources and initiate a Definitive Feasibility Study later in 2024. The Banio Potash Project’s coastal location in Gabon offers significant logistical advantages. Its proximity to major shipping ports enables efficient transportation to key markets in Brazil, the U.S., and Asia. This logistical advantage, combined with Gabon’s supportive government stance, creates a conducive environment for project development.

The Banio project’s operating costs are highly competitive at USD $61 per tonne of granular muriate of potash (gMOP) and an attractive CAPEX estimate of USD $ 480 million for an 800,000 tonne per year gMOP operation. This low-cost structure is pivotal in ensuring possible sustainable profitability and may position Millennial Potash as a cost leader in the potash industry. The Gabonese government’s endorsement of the Banio project underscores the country’s commitment to fostering foreign investment and infrastructure development. This support is crucial in facilitating project advancement and ensuring a favourable operational environment.

Millennial Potash is dedicated to sustainable development. The company’s operations align with global best practices in environmental stewardship, social responsibility, and corporate governance. By prioritizing sustainability, Millennial Potash aims to contribute positively to Gabon’s socio-economic landscape and the global agricultural sector.

Millennial Potash Corp. is on a transformative journey to unlock the full potential of the Banio Potash Project. With a clear roadmap for value creation and a proven history of success, the company is well-positioned to become a leading supplier of potash fertilizers.

millennial potash is committed to moving the Banio potash project towards production.

This will not only contribute to global agricultural sustainability and food security for many, but also drive significant shareholder value. Investors are invited to join Millennial Potash on this exciting journey. As the company advances towards production, the Banio

Potash Project promises to play a critical role in meeting the growing global demand for potash fertilizers, ensuring food security, and fostering sustainable agricultural practices worldwide. l

Canada leads the top potash countries by production, but what are the other major producers? This list outlines the Top 10.

by melissa Pistilli, investing news network

Robust demand for potash pushed prices to a 13-year high in 2021, and that trend continued in the first half of 2022 as price levels rose on supply chain concerns sparked by Russia’s invasion of Ukraine.

In mid-May 2022, the World Bank said global fertilizer prices were up 30 per cent for the year so far, adding that those price-positive conditions were expected to continue through the year and beyond. In fact, bullish sentiment had major market participants such as BHP (NYSE:BHP,ASX:BHP,LSE:BHP) investing billions into new potash production.

All of this was welcome news for potash investors — many potash-mining operations have closed in recent years, and some are waiting on the sidelines for better days and improvements in potash prices.

However, rising prices for the fertilizer ultimately led to demand destruction in the second half of 2022.

“World potash supply was affected by economic sanctions on Belarus and Russia and resulted in higher prices and lower consumption,” explains a recent report from the US Geological Survey. “World potash consumption in 2022 for fertilizers was estimated to have decreased to between 35 to 39 million tons from 40.6 million tons in 2021.”

The organization sees world potash capacity rising to 66 million metric tons (MT) in 2025 from 64 million MT in 2021. Most of the increase will come from new muriate of potash (MOP) mines and project expansions in Belarus, Canada, and Russia — the big three MOP producers. Past 2025, new MOP mines are expected to come online in Brazil, Canada, Ethiopia, Morocco, Spain, and the U.S. As for sulfate of potash, new mines are planned in Australia and Eritrea.

The US Geological Survey estimates that global annual potash production reached 40 million MT in 2022. So, what were the top potash countries by production that year? Read through the list below to find out.

Mine production: 16 million MT

Leading the list of the top potash countries by production is Canada. The nation is the world’s largest potash producer, with potash production growing by 180,000 MT in 2022 over 2021 production levels.

Nutrien (TSX:NTR,NYSE:NTR), the world’s largest potash company, is based in the Canadian prairie province of Saskatchewan. It was born from a 2018 merger between two major crop nutrient companies, Potash Corporation of Saskatchewan and Agrium. The deal

created “a global agricultural giant” now valued at more than US$38 billion.

Mine production: 6 million MT

China’s potash production remained flat in 2022, with no growth over 2021 output. However, the country still jumped to the second spot on the list of top potash-producing countries as output fell in Russia and Belarus.

Potash is extremely vital for China — the country is the largest consumer of the fertilizer, accounting for approximately 20 per cent of world potash consumption. China’s domestic demand for the material is higher than its homegrown potash supply, making the country reliant on potash imports, especially when it comes to MOP.

Mine production: 5 million MT

In 2022, Russia posted five-million MT in potash production, plummeting 45 per cent from 9.1 million MT the year prior. Uralkali is Russia’s premier potash company and one of the world’s leading potash producers, accounting for roughly 20 per cent of global supply pre-war. The company has five mines and seven ore treatment and processing mills.

In response to Russia’s invasion of Ukraine, the EU placed import quotas on potash from Russia, while U.S. sanctions on specific companies limited potash imports.

“Russia responded by suspending fertilizer exports to countries that it deemed unfriendly. Russia continued exports to China, India, and some countries in Africa and South America, but its exports were about 30 per cent lower in 2022 compared with those in 2021,” the U.S. Geological Survey notes.

By late 2022, both the EU and U.S. had eased their restrictions on Russian fertilizer imports in reaction to growing concerns about global food insecurity. However, Russia had set quotas on fertilizer exports until May 2023 in an effort to protect domestic supply levels,

and in September introduced a seven per cent duty for fertilizer products.

Mine production: 3 million MT

Potash production in Belarus fell by nearly 61 per cent from 2021 levels to total three-million MT in 2022. Prior to Russia’s invasion of Ukraine, output from the Eastern European country had been on an upward trajectory since 2016. Belaruskali is the country’s largest industry operator, with six mines and four processing factories.

Belarus’ support of Russia’s war with Ukraine has placed its potash industry in the same predicament as that of its comrade.

“In January 2022, the Government

of Lithuania, citing national security concerns, cancelled the rail transport contract that allowed the state-run producer in Belarus to ship potash from the port of Klaipeda on the Baltic Sea, its only marine export facility,” the US Geological Survey states. “This followed the enactment of economic sanctions on Belarus in 2021 by the European Union and the United States, which banned the import of potash.”

Mine production: 2.8 million MT

Although Germany produced three-million MT of potash in 2019, production has fallen slightly since then and came in at around 2.8 million MT of the material in both 2021 and 2022. K+S (ETR:SDF) is one of Germany’s leading

potash miners and has a number of projects, operating six mines in three districts in the country.

Mine production: 2.5 million MT

Annual potash production in Israel has remained in the two-million to 2.5 million MT range since 2017. The country is sixth in terms of global potash output, and also hosts the world’s sixth-largest potash-producing company, Israel Chemicals (NYSE:ICL,TLV:ICL). Aside from potash, the company produces roughly a third of the world’s bromine, which is often extracted from the same salt water and brine deposits that produce potash.

The outbreak of war between Israel and Hamas in October 2023 has created some concerns over potash supply disruptions. However, because demand was lower than it was when the Russia-Ukraine war broke out, market watchers are not expecting a similar price shock to hit the potash market.

Mine production: 1.7 million MT

Potash production in Jordan decreased marginally from 2021 to 2022. Arab Potash Company, located in Jordan, is the seventh largest producer of potash by volume and the sole producer of potash in the Arab region. It has helped make Jordan a key potash supplier for India and Asia. Both Israel and Jordan recover potash from the Dead Sea.

Mine production: 850,000 MT

Chile recorded production of 1.2 million MT of potash in 2018, the same as the prior two years; however, production dropped below one-million MT in 2019 and has slipped further since then to reach 858,000 MT in 2021. However, Chilean potash production stabilized last year, coming in at just 8,000 MT less than its output the previous year.

One of the largest producers of potash in the country is SQM (NYSE:SQM),

which is also a leading producer of lithium. South America in general is a large consumer of potash.

Mine production: 600,000 MT

The Southeast Asian nation of Laos was the ninth-largest potash-producing country in 2022, bumping the U.S. from the position. The country put out 600,000 MT of potash last year, a relatively big leap from the previous year’s output of 260,000 MT of potash. Laos has potash reserves of 75 million MT.

Asia-Potash International Investment (SZSE:000893), one of the largest potassium fertilizer producers in Asia, is at the helm of the country’s potash industry. In December 2022, the company announced it would be implementing Huawei’s Smart Mining Solution at its Laos operations.

Mine production: 450,000 MT

In 2022, Spain’s potash output grew by 85,000 MT from its 2021 level, allowing the country to hold onto its spot as the 10th largest potash-producing nation. This figure is still down significantly from 2016, when the country produced 670,000 MT of potash. Spain has potash reserves of 68 million MT.

Highfield Resources (ASX:HFR) and its subsidiary Geoalcali have a few potash projects in the country, including the Muga, Izaga, and Sierra del Perdón projects. In March 2023, Geoalcali received its construction license for Muga; it finished acquiring the necessary lands for the mine in July of that year.

Securities Disclosure: Melissa Pistilli, hold no direct investment interest in any company mentioned in this article. l

In today’s rapidly evolving global economy, the significance of government policy cannot be overstated. As Saskatchewan residents approach the upcoming provincial election, it is crucial we call upon our political leaders to act on the material opportunities facing the province through strategic efforts.

The Saskatchewan Chamber of Commerce believes good ideas cross political party lines and are supported by a broad swath of the public. Recently, the Saskatchewan Chamber of Commerce released its policy guide for the 2024 Provincial Election. Fueling Momentum 2024 lays out a plan to enhance the business environment for all industries, including potash development, while

also securing future prosperity for its workforce.

“This is a pivotal time for the province. We are positioned to become a critically important partner in addressing global food insecurity and energy transition. Over the coming four years, the Saskatchewan government needs to continue to capitalize on the province’s vast potential to fuel growth and new investment,” explained Prabha Ramaswamy, CEO of the Saskatchewan Chamber of Commerce.

Fueling Momentum 2024 is built on five strategic pillars designed to propel Saskatchewan’s economy forward. While not a comprehensive list, here’s how some elements of these pillars will benefit the potash sector:

cOmPetitive taxes and affORdaBle living

Reducing the provincial sales tax from six per cent to five per cent will lower the overall cost of living and business operations. This reduction means more disposable income for workers and reduced operational costs for potash companies, fostering a more robust economy.

leveRaging OuR stRengths: fOOd, fuel, feRtilizeR, and cRitical mineRals

Ensuring stable regulatory and royalty regimes will provide the certainty needed for long-term investments in the potash sector. By focusing on the growth of the Food, Fuel, Fertilizer, and Crit-

ical Mineral sectors, such as through diversifying markets, the Chamber’s platform ensures that Saskatchewan remains at the forefront of these supply chains, stabilizing operations and employment.

Enhancing the local vendor supply chain while supporting the development of our Saskatchewan businesses through the implementation of a small business incentive based on local employees will open new opportunities and build resiliency in our community.

Supporting energy-efficient technologies and alternative energy sources not only helps reduce the environmental impact but also positions Saskatchewan as a leader in green mining practices. This shift can attract environmentally conscious investors and customers, further bolstering the industry’s growth.

Investing in infrastructure, education, and community development is crucial for the long-term success of the potash sector. Fueling Momentum 2024 emphasizes these investments, which can enhance the quality of life for workers

Fueling m omentum 2024 lays out a plan to enhance the business environment for all industries, including potash development, while also securing future prosperity for its workforce.

and their families while providing the necessary skills and infrastructure to support industry growth.

In total, the chamber recommends 26 policy actions for the next Government of Saskatchewan to ensure the success of our most critical industries. The Fueling Momentum 2024 platform is not just a list of wants; it is a roadmap to a more

prosperous and sustainable future for Saskatchewan’s potash industry.

By advocating for these policies, you can help ensure a stable and thriving environment for your industry. Whether you’re talking to the candidates in your riding or sharing all or parts of this platform with your contacts, we believe better engagement makes better policy and a better province.

Potash mining is a cornerstone of Saskatchewan’s economy, playing a crucial role in boosting the province’s economic stability and job creation. As a key global supplier of potash, this sector not only supports the world’s agricultural needs by providing essential nutrients for crop growth, but also demonstrates a strong commitment to safeguarding its workforce. Amidst these contributions, however, the industry faces challenges, notably the hidden danger of asbestos exposure. Asbestos, a group of naturally occurring fibrous minerals, is notorious for its carcinogenic properties and is a well-documented cause of occupational diseases, including mesothelioma and lung cancer.

Asbestos is the generic term for six fibrous mineral silicates: chrysotile, crocidolite, amosite, tremolite asbestos, anthophylite asbestos, and actinolite asbestos (atsdr.cdc.gov/asbestos). In the context of potash mining, asbestos can be present as a contaminant in the ore body itself or in the ancillary materials like brake linings, thermal insulation, or fire-resistant construction materials used in mining equipment and facilities.

Even minimal inhalation of asbestos fibers can lead to severe, life-threatening diseases decades after initial exposure, making them difficult to detect early. Mesothelioma, an aggressive cancer affecting the lining of the lungs, is almost exclusively caused by asbestos exposure and often does not manifest until many years after the initial inhalation of asbestos fibers. Sim-

ilarly, asbestos can cause lung cancer and asbestosis, a type of pulmonary fibrosis that severely impacts respiratory function.

Asbestos-related lung diseases continue to be a leading cause of work-related fatalities in Saskatchewan. Since asbestos has been largely banned in Canada, there may be a temptation to disregard asbestos as no longer a threat. However, asbestos-containing materials may be present in common building products built before 1990, as well as contaminating the materials being mined. The Saskatchewan Workers’ Compensation Board has noted a rise in injuries and illnesses related to asbestos in soft-rock mining. From 2014 to 2023, there were 512 asbestos claims in this industry alone (WCB, 2024).

Across all Saskatchewan workplaces in 2023, the occupational health and safety division of the Ministry of Labour Relations

and Workplace Safety received 542 high-risk asbestos notifications and completed 217 asbestos-related worksite visits, issuing 81 contraventions (WorkSafe Saskatchewan, 2023). The top five contraventions issued on asbestos-related worksite visits were:

health of those who labour at the heart of this vital industry and ensure that the legacy of potash mining is not marred by preventable diseases.

The dangers of asbestos in potash mining are profound and pose a significant health risk to workers. It is imperative that the industry, health authorities, and regulators collaborate, not only to raise general awareness about the dangers of asbestos, but to mandate specific training for workers who may come in contact with asbestos to address these risks proactively. Only through such concerted efforts can we hope to safeguard the

To take a more proactive approach to asbestos safety, WorkSafe Saskatchewan, a partnership between the WCB and the Ministry of Labour Relations and Workplace Safety, developed a training standard for occupational health and safety for asbestos workers. This standard establishes minimum criteria for training, to strengthen workplace safety culture, and to reduce the number of asbestos-related incidents, illnesses, and fatalities. Providers who meet or exceed the minimum requirements for the standard can become WorkSafe-approved training providers. Approved training providers gain benefits to help them manage training programs and customer experience more easily, including training documents and free access to the WCB’s learning management system.

Learn more about the dangers of asbestos and the asbestos worker training standards at worksafesask.ca/asbestos. l

Asbestos exposure is the number one cause of work-related deaths in Saskatchewan.

Asbestos was commonly used in homes built before 1990. More than 3,000 building materials and other products contain asbestos, such as vinyl floor tiles, window putty and duct coverings. When tiny asbestos fibres are airborne, they can get into the lungs and cause severe damage over many years.

If you think there is a risk of asbestos, test for it to protect yourself and your co-workers.

initiative, has partnered with Hope’s Home by gifting $120,000 to support the Canpotex Inclusive Meal Program at Hope’s Home’s new medically inclusive child care centre in Saskatoon. Hope’s Home is the only medically inclusive child care centre in Canada, providing care where kids with complex medical and typical needs can learn, grow, and thrive.

This generous gift will provide all children at Hope’s Home’s new medically inclusive child care centre with access to nutritious, wholesome meals that meet each child’s dietary needs and sensitivities. Many children with complex medical needs require unique, specialized ingredients and preparation to meet their nutrition needs. With the support of the Canpotex Food for Kids initiative, nutritionists can accommodate these unique needs so that no child feels left out when sitting around the table.

“This incredible partnership with Canpotex through its Food for Kids initiative will make a significant impact on the health of medical and typical kids at the new Saskatoon location, opening later this year,” said Jacqueline Tisher, founder and CEO of Hope’s Home. “With this support, we are also able to

purchase adaptive kitchen equipment in Saskatoon, which gives kids independence to feed themselves. We are grateful to have community partners like Canpotex, allowing us to bring medically inclusive child care to Saskatoon families.”

Hope’s Home’s new Saskatoon location will feature two separate centres caring for 144 kids ages six weeks to six years old. Spaces will be held for kids with complex medical needs making this centre an extension of pediatric healthcare. On-site nurses, early childhood educators, developmental workers, and physical development consultants will provide Saskatoon families with a safe and inclusive environment where children receive the care they need.

“At Canpotex, we are deeply committed to global food security and understand the vital role that nutrition plays in fostering healthy communities,” said Gordon McKenzie, president and CEO of Canpotex. “By supporting the Canpotex Inclusive Meal Program through our Canpotex Food for Kids initiative, we are putting our belief into action, ensuring that children of all backgrounds have access to nutritious meals at Hope’s Home. This initiative aligns with our core purpose of exporting potash to

improve agricultural productivity overseas, helping us make a direct impact on the lives of those in our community and reaffirming our dedication to helping nourish the world.”

To learn more and to support the There’s No Place Like Hope capital campaign, visit hopeshome.org.

The first medically inclusive child care centre in Canada. Hope’s Home is a charitable organization providing inclusive care where kids with complex medical and typical needs learn, grow, and thrive. Hope’s Home provides families with a safe and inclusive environment for their children to play and be kids regardless of their medical needs. For more information, visit hopeshome.org.

Canpotex is one of the world’s largest suppliers of potash overseas. On behalf of its shareholders, Mosaic and Nutrien, Canpotex markets and delivers Saskatchewan potash, a valuable fertilizer nutrient, to customers. Canpotex’s potash helps the world’s farmers grow more food. For more information, visit www.canpotex.com. l

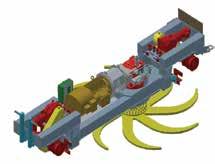

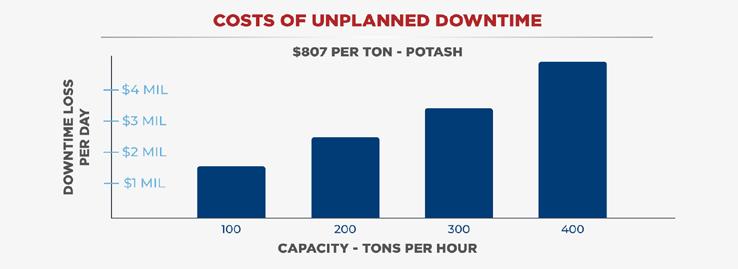

to take advantage of the escalated price and demand on products like potash, fertilizer operations must produce higher volumes at a faster pace.

by andrew Parker, President, CDm systems, inc.

The global fertilizer industry is seeing unprecedented growth and record-setting prices.

And with the global population expected to reach nearly 9.7 billion by 2050, the need for better crop yields will continue to push the demand for fertilizer.

Additionally, growers are facing the diminishing availability of suitable farmland, and arable soil can lose its natural nutrients over time. Those growers will need more fertilizer –which will cause demand and prices to stay sky high.

The upside is significant profits for fertilizer facilities that are able to consistently meet high demand as the global market continues to grow.

Fertilizer Market Figures:

Annual Market Value = $182.2 billion (2021), expected to be $254.87 billion by 2030

Compound Annual Growth Rate (CAGR) = 3.89 per cent from 2021-2030

To take advantage of the escalated price and demand on products like potash, urea and monoammonium/diammonium phosphates, fertilizer operations must produce higher volumes at a faster pace. That’s much more difficult with equipment that’s prone to failure.

Older machinery cannot efficiently handle rigorous schedules that ramp up production levels – especially for 24/7/365 operations. Thus, fertilizer facilities are seeking ways to eliminate the threat of costly downtime from failed equipment.

That’s why dependable conveyors are so critical for fertilizer operations.

The more reliably they function, the more material – whether dry, caustic, or wet – can be transferred from one part of the facility to another. This improved efficiency helps crank up production – and sends profitability soaring.

Certain planned downtime is expected. Whether it’s preventative maintenance, hardware updates or anything else that requires your attention, facilities can plan for those types of minimal production interruptions. But unplanned outages can be costly.

Even catastrophic.

As of December 2022, potash has an average per-ton cost of $807. At this price, a small-to-midsize operation could easily lose more than $100,000 per hour and potentially millions in lost profits per day if equipment failures occur. Millions. Therefore, it is crucial conveyors are designed specifically for fertilizer and the problems that come with the corrosive nature of material like potash.

The right conveyor design should include components built to handle increased fertilizer volume; optimal operation and design parameters; thorough material and environmental data analysis; and built to handle the stress of increased capacity.

The design-to-task efficiency of the individual components is what leads to dependable conveying. Poorly designed or illequipped systems will cost you more in the long term because of the increased frequencies of maintenance and downtime. To keep production strong, operations must successfully manage this threat.

ReliaBle cOnveyORs cOntRiBute diRectly tO exPansiOn and PROfitaBility

Facility and maintenance managers understand the need for a conveyor built for fertilizer. With prices high, successfully boosting production capacity helps a business to expand. But how do you get there?

One-size-fits-all conveyor systems may seem like a budget-friendly answer for expanding capacity. But often, such systems are not purpose-built for the application – whether that’s the level of capacity, the characteristics of fertilizer, or the intricacies of a site’s layout. This inevitably leads to equipment failures. Given the symbiotic relationship between unplanned breakdowns and profit loss, a present-day investment in the right conveyor is key to “big picture” profitability and growth.

This is where the conveyor manufacturer is an important partner.

It is essential to thoroughly understand the properties of an operation to spec out the right equipment for the job. Custom-engineered conveying systems with flexible chain formulas and durable construction mean your operation is set-up for the long haul.

This gives managers peace of mind. That’s because they have a conveyor built to eliminate downtime and keep production – and profits – flowing.

• Global agricultural markets are increasingly dependent on fertilizers

• Fertilizer demand continues to rise, creating major profit opportunities

facility and maintenance managers understand the need for a conveyor built for fertilizer.

• High fertilizer output required to meet demand will put stress on handling equipment

• Customized conveyors built for fertilizer are key to meet increased production goals

Andrew Parker is president for CDM Systems, Inc. He has more than 20 years of experience in the bulk material handling industry. He oversees operations including conveyor design and development.

https://www.gminsights.com/industry-analysis/ fertilizer-market

https://www.globenewswire.com/en/newsrelease/2022/10/12/2533096/0/en/Global-Fertilizer-MarketSize-to-grow-USD-254-87-Billion-by-2030-CAGR-of-3-89Spherical-Insights-Consulting.html

https://www.ibisworld.com/industry-statistics/market-size/ fertilizer-manufacturing-united-states/ https://www.un.org/en/global-issues/population

https://www.yahoo.com/now/ global-fertilizer-market-size-grow-140000366.html

https://mineralseducationcoalition.org/elements/potassium/

https://www.dtnpf.com/agriculture/web/ag/crops/ article/2022/12/21/potash-leads-retail-fertilizer-lower l

By Andrea Hansen, President, Sutton Benefits & Pension

Workforce dynamics are changing, especially in skilled trades. Workers seek environments with less stress, better work-life integration, and more specialization opportunities. The country faces record retirement numbers, and motivation amongst young employees seems to be polarized — very high or very low.

One of the most challenging employment issues is simply finding workers who show up, are reliable, and take accountability. Some companies that depend on highly skilled and experienced workers are forgoing traditional skills and experience for less skilled candidates who are reliable.

The results are problematic. Less capable employees require more training, supervision, and time to get fully op -

Poorly designed transfer chutes reduce productivity along your conveyor system — often increasing the chances of costly downtime.

erational. Without allocating time for a formal mentorship program, this reliance on your senior workers can create frustration because they are expected to train new hires while doing more work and take on the stress of managing another worker.

An approach where rewards and opportunities are earned through dedication and commitment can enhance personal responsibility and employee

The transfer chute is a critical piece of equipment in mining, quarrying, and other material handling operations. Considering all factors up-front will result in a transfer chute design that aids, rather than restricts, production.

West River Conveyors pays careful attention to the properties of the material being conveyed — with an expert understanding of how it moves through the transfer chute. From the design stage forward, we can find a solution that fits your needs.

Contact us for more information on Transfer Chutes and our many other products and services.

engagement. Employers may be able to tailor benefits and rewards to different employee segments, recognizing and rewarding high achievers while offering support and motivation to others.

Increasing the value of benefits, pension, and health and wellness programs based on years of service provides additional compensation to loyal, highly skilled employees. It shows that you care about their overall health and financial wellbeing.

Effective leadership is a cornerstone in fostering personal responsibility and engagement. The adage, “employees don’t leave jobs; they leave people”, underscores the significance of investing in a leadership development program that enhances technical and interpersonal skills, thereby improving employee satisfaction and retention.

Implementing mentorship initiatives that pair experienced employees with newcomers to facilitate knowledge transfer and personal development helps young or inexperienced individuals develop the skills and responsibility necessary to work autonomously.

Preventive assistance platforms (preAPs) are an emerging category in workplace wellbeing that provides access to training in resilience, behavioural health, and psychological safety to help the workforce manage stress and mental wellbeing proactively. These resource programs are proactive: rather than helping an employee cope with the effects of a problem, they try to prevent the problem.

tract and retain talent while also generating cost savings through reduced disability time, fewer WCB claims, lower health premiums, increased productivity, and better performance. By investing in these programs, you’re prioritizing your employees’ well-being and ensuring your organization’s long-term success.

With so many changes happening in the workforce, a proactive approach can help your organization create engaged leaders. Reward core competencies that emphasize critical thinking, problem-solving, and responsibility and weave those throughout your recruitment and retention processes. l

Implementing workplace wellness programs not only improves employee satisfaction and engagement but also enhances your company’s reputation. This, in turn, boosts your ability to at-

For Dana Hough, getting his SMT was the first step toward where he is today as an inventory controller at n utrien, a position he has held for the last six years.

Dana Hough has almost literally worked his way up to where he is today at one of Canada’s largest agricultural and resource firms.

Having started with Nutrien at its Allan potash operation southeast of Saskatoon working underground in the mine, he eventually moved above ground to work in shipping and receiving, where he learned many aspects of the supply chain and warehousing. Yet, after a few years, he recognized the need for more education to advance his career in supply chain management.

“So, I started to take night classes to work toward my diploma in the field,” says Hough about the Supply Chain Management Training (SMT) program.

Offered by Supply Chain Canada Institutes, the SMT program offers early-stage to mid-level practitioners working in warehousing, logistics, procurement, and shipping and receiving the necessary skills to advance their careers in this important facet of operations for many different sectors of the economy, mining and agriculture included. Learners completing the training earn a diploma in supply chain management, which often leads them in the future to take a more advanced training from Supply Chain Canada and earn a Supply Chain Management Professional designation (SCMP).

Available online, both programs offer learners the flexibility to work through course materials while continuing to work in their current supply chain-related occupations.

For Hough, getting his SMT was the first step toward where he is today as an inventory controller at Nutrien, a position he has held for the last six years.

The SMT program covers many aspects of supply chain management, providing comprehensive knowledge of all aspects of the field. Courses cover, for example, procurement, logistics, and transportation and operations management. As well, the

SMT course provides soft skills training so individuals graduate as better communicators, are able to foster better workplace relationships, and become more adept negotiators on procurement and other contracts.

“The SMT program is an excellent foot-in-the-door for individuals early in their roles in supply chain seeking to advance their careers,” says DonnaLyn Thorsteinson, chief executive officer of the Saskatchewan Institute for Supply Chain Canada.

Many SMT diploma graduates often then pursue a SCMP designation from the institute as they progress into management roles.

It’s a path Hough followed while taking night classes at the University of Saskatchewan’s Edwards School of Business to gain many of the prerequisites to enrol in the SCMP program, which requires a business-related post-secondary degree or diploma, or five years of supply chain work experience.

Individuals taking the course receive in-depth education on global, public sector, and major capital project supply chain management. As well, they participate in facilitated workshops providing hands-on knowledge in leadership, negotiation, and contract law.

“The SCMP designation is Canada’s leading designation for supply chain professionals,” Thorsteinson says.

Hough can certainly attest to that.

“Without a doubt, what I learned through these programs helped me excel at Nutrien, applying acquired skills and concepts daily as a supply chain management professional,” says Hough.

Other individuals working in supply chain positions in the province can look forward to a similar trajectory upon receiving their SMT diploma and SCMP designation, Thorsteinson says.

Dana h ough receives his scmp designation from board president, harley camsell at the scmp graduate celebration in august 2023.

“While Hough’s story may differ from yours, there are numerous paths to successfully complete our programs, and we look forward to working with you to explore your options,” says Thorsteinson.

To learn more about the Supply Chain Management Professional (SCMP) and Supply Chain Management Training (SMT) programs, visit supplychaincanada.com, email info.sk@supplychaincanada.com, or call 306-653-8899. l

Rotex screeners offer potash producers the total solution for their dry separation requirements, including screeners for raw ore preparation, standard, coarse and granular product sizing, glazing and post treatment, and reclaim/load-out. With over 1,000 installations worldwide, Rotex has the experience and proven record to understand your specific requirements. When it comes to potash, talk to the experts.

Pumps are at the heart of fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. As an expert in solutions for corrosive and abrasive liquids, or those with high gas content, Sulzer offers a complete range of pumps, agitators, mixers and compressors for the fertilizer industry. Our innovative products are suitable for the production of potash, phosphate and NPK compound fertilizers as well as acids and industrial chemicals.

Sulzer’s global presence provides local support and expertise through a network of manufacturing facilities and service centers. Our solutions combine energy efficiency, low lifecycle costs, reduced environmental footprints and excellent reliability.

Contact us today to learn more.

Sulzer Pumps (Canada) Inc. Phone (514) 836-3796, salah.attie@sulzer.com

www.sulzer.com

Rby Jakub hladysz

ESPEC has a strong reputation for helping clients increase profitability through its world-class Rock Mechanics Laboratory. Whether a mine is in development or operations, taking and testing core samples reveals how the rock performs and where more ore could be extracted. RESPEC’s materials laboratory in Rapid City, South Dakota, has operated since the 1970s and pioneered rock mechanics technologies. Companies are hard-pressed to find a laboratory that outperforms RESPEC.

At the heart of RESPEC’s success is its specialized approach to handling and testing not just any samples but specifically salt and potash samples. From the moment of collection, every sample goes through meticulous handling to prevent any compromise in its integrity. This is particularly important for potash samples, where errors at early stages like drilling can

lead to significant analytical errors, impacting a project’s economic feasibility. RESPEC employs specific strategies, such as using oil-based mud or diesel during drilling to prevent the washout of potash and preserve its complex mineral composition.

Once in the laboratory, samples are carefully processed to maintain their original condition as much as possible. Techniques include immediate washing with appropriate fluids to minimize dissolution, minimal atmospheric exposure, and long-term storage methods like shrink wrapping and cellophane to maintain integrity. Special attention is given to hydrophilic minerals like carnallite, ensuring that they do not dissolve during handling. Also, the pre-consolidation of potash samples before creep and dilation strength testing brings the samples closer to their in-situ state.

RESPEC’s laboratory is equipped with state-of-the-art facilities for preparing and analyzing these samples. The laboratory

features 16 creep machines for testing large-diameter cores, a constant mean stress testing machine for determining potash’s dilation strength, and specialized equipment and techniques for managing samples with large crystal sizes or those from challenging formations. Dissolution testing is another service RESPEC’s laboratory provides, being an important variable in solution mine design.

Analytical capabilities extend to advanced tests such as gamma logging, which employs a spectral gamma logger for detecting uranium, thorium, and potassium, giving insights into ore grade and potassium concentration. X-ray diffraction (XRD) is used for mineralogical analysis, effectively revealing the presence of sylvite and other minerals at low concentrations through the pulverization of samples and assessment using an X-ray diffractometer.

RESPEC goes beyond standard laboratory practices by developing and modifying equipment to meet specific client needs, including the design of the direct shear testing machine and the constant mean stress test. These tests not only evaluate the technical aspects of rock and potash but also translate findings into actionable insights for enhancing mine designs, ensuring that our clients receive the most relevant and accurate data for their specific projects.

The Rock Mechanics program’s expertise extends to on-site work, where geologists implement rigorous core handling procedures for materials such as potash, salt, and non-salt. From logging recovered cores to preparing them for transport while minimizing environmental exposure, RESPEC’s attention to detail ensures the highest standard of sample integrity. This approach increases the reliability of subsequent tests and builds confidence in the results.

RESPEC’s Rock Mechanics Laboratory provides a thorough and specialized approach to managing, preparing, and analyzing samples for potash mining companies. We focus on maintaining the integrity of each sample from the moment of collection through our advanced testing, which delivers accurate and dependable data crucial for successful mining operations. Our laboratory is dedicated to expanding the possibilities in mineral analysis, ensuring our clients receive the data they need for informed decision-making and advancing their projects. l