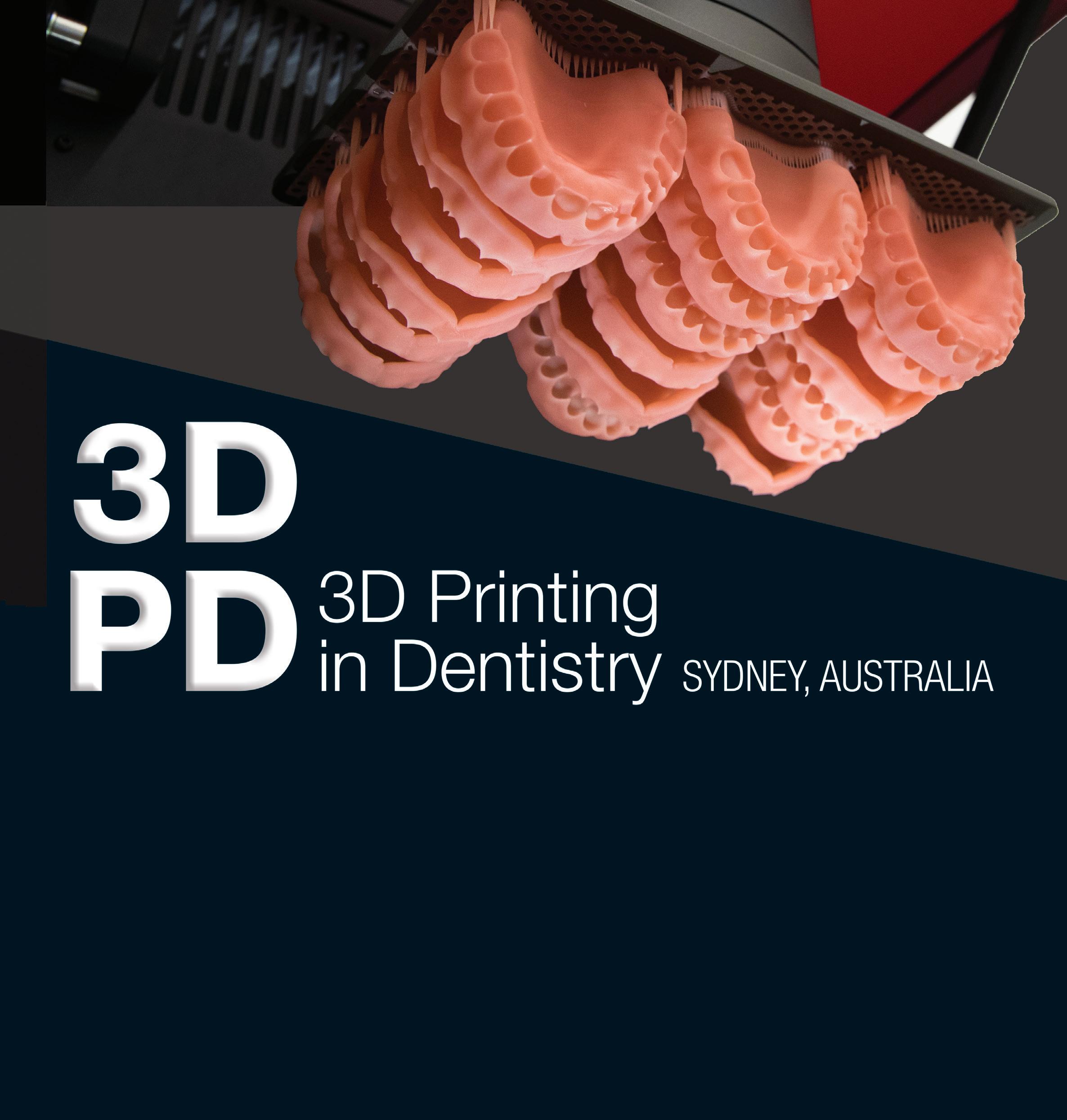

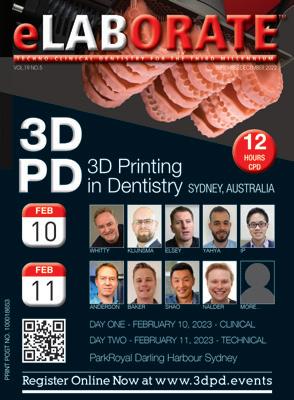

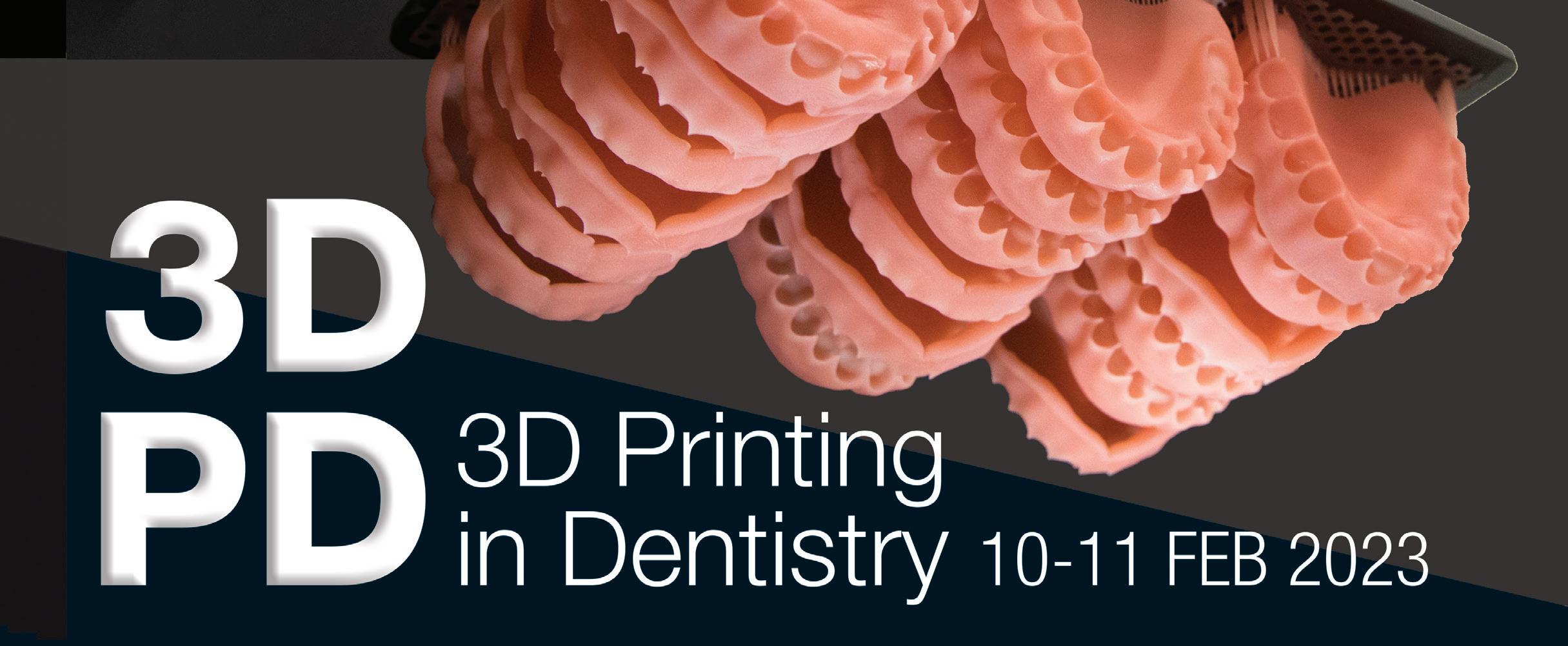

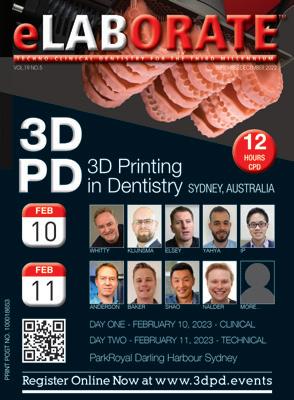

VOL.19 NO.5 SEPTEMBER/DECEMBER 2022 PRINT POST NO. 100018653 Register Online Now at www.3dpd.events FEB 10 FEB 11 12 HOURS CPD WHITTY IP KLIJNSMA ELSEY YAHYA ANDERSON BAKER SHAO NALDER MORE... DAY ONE - FEBRUARY 10, 2023 - CLINICAL DAY TWO - FEBRUARY 11, 2023 - TECHNICAL ParkRoyal Darling Harbour Sydney

Digital Dentistry & Dental Technology SYDNEY 2-3 JUNE 2023 NOVOTEL SYDNEY BRIGHTON BEACH TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL TECHNICIANS AND DENTAL PROSTHETISTS dentevents presents... INDUSTRY SUPPORTERS SPONSORS

Full details of the speakers and presentations online www.dentaltechnology.com.au Organised by Dentevents™ a division of Main Street Publishing Pty Ltd ABN 74 065 490 655 www.dentevents.com • info@dentist.com.au • Tel: (02) 9929 1900 • Fax: (02) 9929 1999 REGISTRATION FEES $880 inc gst EARLY BIRD PRICING $330 before 2 Jan 2022 price increases $110 on the 2nd of every month INCLUSIONS Registration fee includes participation in TWO full days of education (12 CPD hours), all catering and Friday drinks. Multiple lectures and workshops are being run concurrently to allow you to build your own program to suit your specific interests. Price is all inclusive. VENUE DETAILS Novotel Sydney Brighton Beach - The Grand Parade, Brighton-Le-Sands NSW 2216 - Close to Sydney Domestic and International Airports Check the website for details of discounted accommodation rates for the conference • Ample parking available at the hotel PROGRAMME DETAILS FRIDAY 2 JUNE 2023 9.00am - 5.00pm - education 5.00pm - 7.00pm - happy hour SATURDAY 3 JUNE 2023 9.00am - 5.00pm - education 12 HOURS CPD Join us again or for the first time at Digital Dentistry & Dental Technology 2023 for a fun, exciting and fully immersive learning experience with the best of the best in the new age of dentistry. This year’s program will cover Digital Smile Design • Digital orthodontics • Intraoral scanning • Digital implantology • Digital full arch restorations and full mouth rehabilitations • Digital Dentures • 3D Printing • Milling • CBCT • Material and applications • Software and more with MORE Hands-on Sessions • MORE Advanced Sessions • MORE New Products • NEW Masterclasses and more! ONLY $330 FOR 2 DAYS OF EDUCATION (12 HOURS OF CPD) IF YOU REGISTER BEFORE 2 JANUARY 202 3 (SAVE $550)

eLABORATE | CONTENTS 6 BRIEFS 8 SPECTRUM 24 CPD CENTRE 42 NEW PRODUCTS

and Publisher: Joseph Allbeury

Editor: Terence Whitty, Dip. DT (Syd) eLABORATE™ ISSN 1834-9110 is published six times per year by Main Street Publishing Pty Limited ABN 74 065 490 655 | Printed in AUSTRALIA PO Box 586,

NSW 2062 AUSTRALIA Tel: (02) 9929-1900 Fax: (02) 9929-1999 Email: info@dentist.com.au © 2022 All rights reserved. The contents of this magazine are copyright and must not be reproduced without the written permission of the publisher. Permission to reprint may be obtained upon application. Correspondence and manuscripts for publication are welcome. Although all care is taken, the editor and publisher will not accept responsibility for the opinions expressed by contributors to this magazine, or for loss or damage to material submitted for publication facebook.com/elaboratenow twitter.com/eLABORATEnow instagram.com/dentevents On the cover... Join us in early February for a great two day program on 3D Printing in Dentistry, covering both the clinical applications and technical challengesvisit www.3dpd for details CAD/CAM26 ANTERIOR AESTHETIC VENEERS USING A DIGITAL WORKFLOW 32CAD/CAM 3D PRINTING DENTURESPART 2: DESIGNING DENTURES USING CAD SOFTWARE 40THERMOFORMING BASIC PRINCIPLES FOR THERMOFORMING VOLUME 19 | NUMBER 5 SEPTEMBER/DECEMBER 2022

Editor

Technical

Cammeray

By Joseph Allbeury

Everyone’s doing it...

Last school holidays, we joined pretty much every other Australian (or so it seemed) and jumped on a plane to take an overseas trip.

A buddy of mine who runs a travel agency tells me that every month in the latter half of 2022 has set a new financial record, exceeding anything he’d ever seen in his long career - everyone just can’t wait to get on a plane! And that’s despite domestic and international airfares equally being at all time highs.

For us, our destination was Singapore, timed for attending the kick off for the first IDEM meeting post COVID. We visited Singapore, Malaysia and Indonesia on the trip and all COVID protocols are now pretty much gone. It was literally like COVID had never happened - mostly anyway - and that was comforting to see. I think we’ve all looked forward to everything getting back to normal and that new normal looks pretty much the same as the old one.

IDEM Singapore 2022 was also same-same but different. Mostly on account of the move from the Suntec conference centre to the Sands Expo & Convention Centre at the Marina Bay Sands hotel complex. There were lots of exhibitors, lots of conference sessions with great speakers - like our own Dr Chris Ho and Dr Anthony Mak - and lots of Australians visiting the event.

The face-to-face event scene post-COVID has roared back to life this year... particularly in Australia as the 3-year CPD cycle, which essentially spanned the pandemic, comes to an end. And lets face it, the only reason anyone in dentistry wants to hear the word Zoom is when a patient wants whiter teeth!

And things are looking great for 2023 as well. Over 100 people have already registered for Digital Dentistry & Dental Technology 2023, coming up on June 2-3 in Sydney. This will be the fourth edition of this enormously popular event that each year sees around 500 delegates participate in the 2-day multi-stream, multi-session, multi-speaker programme. You can register before January 2 for just $330 at www.dentaltechnology.com.au which is excellent value.

Next year, we also have a brand new 3D Printing for Dentistry (3DPD) event over two days from February 10-11 in Sydney. Day 1 covers the clinical aspects of 3D printing while Day 2 looks at the technical side. You can choose to do either day or both days and if you’re interested in this burgeoning area, you will find value in coming for the entire event. All the speakers and sessions can be found at www.3dpd.events.

Finally, we’re still looking for readers to start contributing videos to Dentevents.TV and each month we’re offering a prize for the video that receives the most votes from viewers! Visit www.dentevents.tv to sign in and begin uploading.

With the holiday season upon us, I hope all our readers, contributors and advertisers have a very Merry Christmas and a Happy New Year. Stay safe and see you in 2023!

Joseph Allbeury, Editor and Publisher

Formlabs

appoints Dental Sales Manager

3 D Printing giant Formlabs has appointed Mr Louis Manera as its Dental Channel Sales Manager for Australia and New Zealand. Mr Manera is well known in the dental industry, having previously held roles as a Dental Equipment Specialist for KaVo and Dürr at Ivoclar and most recently in his founding role as Country Manager (ANZ) for Dürr Dental SE over the last 15 years. “I am very excited to be joining a passionate, technology-driven organisation that has already had successes globally in cutting edge engineering applications including aerospace [NASA], automotive [Audi, BMW and Bosch], aircraft [Boeing] and healthcare (prosthetics).” Formlabs is based in Somerville, Massachusett and was founded in September 2011 by three MIT Media Lab students. The company develops and manufactures 3D printers and related software and consumables for a variety of appli cations. Mr Manera is fully focused on growth within the dental space with Formlabs 3D printing solutions already being prominent in dental and orthodontic clinics as well as many dental laboratories. He can be contacted via email on louis.manera@formlabs.com or call 0412-959-525.

NSW CENTRAL COAST DENTAL LABORATORY FOR SALE

EXPRESSIONS OF INTEREST

W Well established 2-person dental laboratory operating on the NSW Central Coast for over 34 years.

W Well established client list. Situated close to the M1 Tuggerah in large airconditioned premises with ongoing lease.

W Currently servicing the Northern part of the Coast from Bateau Bay to Lake Munmorah.

W Predominantly Acrylic dentures, Repairs, Relines, Mouthguards, bite Splints and some Ortho, etc. Plenty of opportunity for expansion and to offer other services such as Crown and Bridge, Casting etc.

W Extended hand over and mentoring can be offered.

Contact Steve on 02 4355 4747 or 0438 881 818

6 eLABORATE September/December 2022

briefs | NEWS

MO - TC 1 MO - TC 2 MO - TC 3 MO - TC 4 Black MO - SC 1 Yellow MO - SC14 Cherry MO - SC27 MO - TC 1M MO - TC 2M MO - TC 3M MO - TC 4M Dark Blue MO - SC 2 Fluro Orange MO - SC15 Amethyst MO - SC28 Maroon MO - SC 3 Fluro Yellow MO - SC16 Teal MO - SC29 MO - TC 5 MO - TC 6 MO - TC 7 MO - TC 8 Silver MO - SC 4 Fluro Green MO - SC17 Dark Yellow MO - SC30 MO - TC 5M MO - TC 6M MO - TC 7M MO - TC 8M Gold MO - SC 5 Clear MO - SC18 Metallic Mist MO - SC31 Royal Blue MO - SC 6 Fluro Pink MO - SC19 Shrimp MO - SC32 MO - TC 9 MO - TC10 MO - TC11 MO - TC12 Lillac MO - SC 7 Racing Green MO - SC20 Metallic Green MO - SC33 Sky Blue MO - SC 8 Brown MO - SC21 Cornflower MO - SC34 MO - TC 9M MO - TC10M MO - TC11M MO - TC12M Green MO - SC 9 Fluro Red MO - SC22 Leaf Green MO - SC35 MO - TC13 MO - TC14 MO - TC15 MO - TC16 Pink MO - SC10 Apple MO - SC23 Solid Orange MO - SC36 Red MO - SC11 Lavender MO - SC24 MO - TC13M MO - TC14M MO - TC15M MO - TC16M Turquoise MO - SC12 Cerise MO - SC25 White MO - SC13 Sandstone MO - SC26 MO - TC17 MO - TC18 MO - TC19 MO - TC20 *Actual colors may vary MO - TC 17M MO - TC18M MO - TC19M MO - TC20M MO - TC21 MO - TC22 MO - TC23 MO - TC24 MO - TC21M MO - TC22M MO - TC23M MO - TC24M MO - TC25 MO - TC26 MO - TC27 MO - TC28 MO - TC25M MO - TC26M MO - TC27M MO - TC28M Mouthguards Online PO Box 1193 Mandurah 6210, Western Australia ACN 619 344 786 www.mouthguardsonline.com.au www.mouthguardsonline.com.au MOUTHGUARDS ONLINE Retainer cases large | 12 for $14.40 Retainer cases small | 12 for $12.00 Clear 1mm round | 10 pkt for $17.00 Clear 2mm round | 10 pkt for $24.50 Clear 1.5mm square | 10 pkt for $19.50 MOUTHGUARDS ONLINE TEAM COLOURS Quality laminating mouthguard material ORDER ONLINE

Updated CAD software delivers ultimate efficiency for dental technicians

3Shape has released its Dental System 2022, the newest version of its power-packed CAD software for dental laboratories.

The choice of more than 30,000 dental labs around the world, 3Shape Dental System makes your restorative design and manufacturing so much easier with intuitive next-next workflows for a wide range of indications. Its simplified lab-to-dentist communications and open and streamlined digital integrations, make working with your dentists a breeze.

What’s new

n Virtual preparation - gives lab technicians more control over the restorative design workflow by enabling them to virtually recommend tooth prep designs to dentists.

n Web case 3D preview - Dental System creates a URL link to a lab’s restorative design to make it easier for dentists to review treatment proposals. With the URL, dentists can now preview designs from any device - even when not using 3Shape solutions.

n Denture on implants - Dental System preserves space for screw holes in implant supported dentures and STUD (locator) attachments for overdenture designs to make planning restorative designs more predictable.

n New Sculpt features - Dental System’s superior sculpt tools help dental technicians to design digitally the way they always have done conventionally.

n Models for articulator - it is now so much easier for dental technicians to go from digital back to analog because Dental System adds print material, based on the technician’s physical articulator brand, to the digital dental models. So, the model fits when printed.

“3Shape Dental System 2022 is really a team effort between 3Shape developers and dental technicians in the field,” said 3Shape Senior Vice President for Product Strategy, Rune Fisker. “Together, we have optimised Dental System to make their workflows faster and more predictable. We take what dental technicians have always done analog and make it more efficient and cost effective for them to do digitally. And we do it with easy to do and open workflows. The result, we believe, is our most dependable and powerful Dental System yet.”

7Learn more about 3Shape Dental System

Learn more about 8 3Shape Dental System 2022

8 eLABORATE September/December 2022 spectrum | NEWS

All about NEW Get 5-years warranty AND €900 Automate credits with any 3Shape E-Series scanner purchase Terms and conditions:

Promo is only available to customers within Australia

Credits must be manually claimed by creating an 3Shape Automate account, and emailing automate@3shape.com with account email, contract of purchase and promo code

Receipts will be validated by 3Shape resellers before equivalent design credits is added to the customers account

3Shape E Scanner €900 design credits is limited to a one-time use, and limited to 1 credit per lab

3Shape software package €900 design credits is limited to a one-time use, and limited to 1 credit per lab

Customers can redeem up to €1,800 design credits with the purchase of both an 3Shape E Scanner and 3Shape Software package Automate credits have no cash value and are not redeemable for cash

Return and refunds for E-scanners and or software purchases must be made through the reseller

3Shape reserves the right to change terms and conditions at any time 11049 Promo code: Valid through Dec 31, 2022.

•

•

•

•

•

•

•

•

Ivoclar and exocad extend the options for digital dentures in DentalCAD

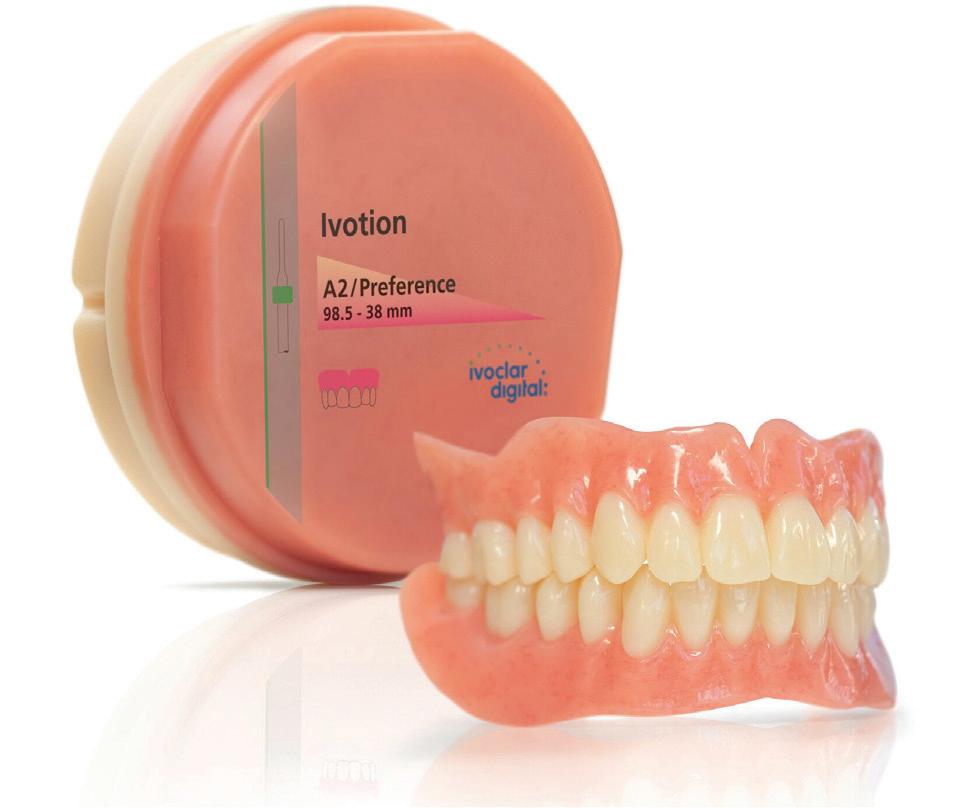

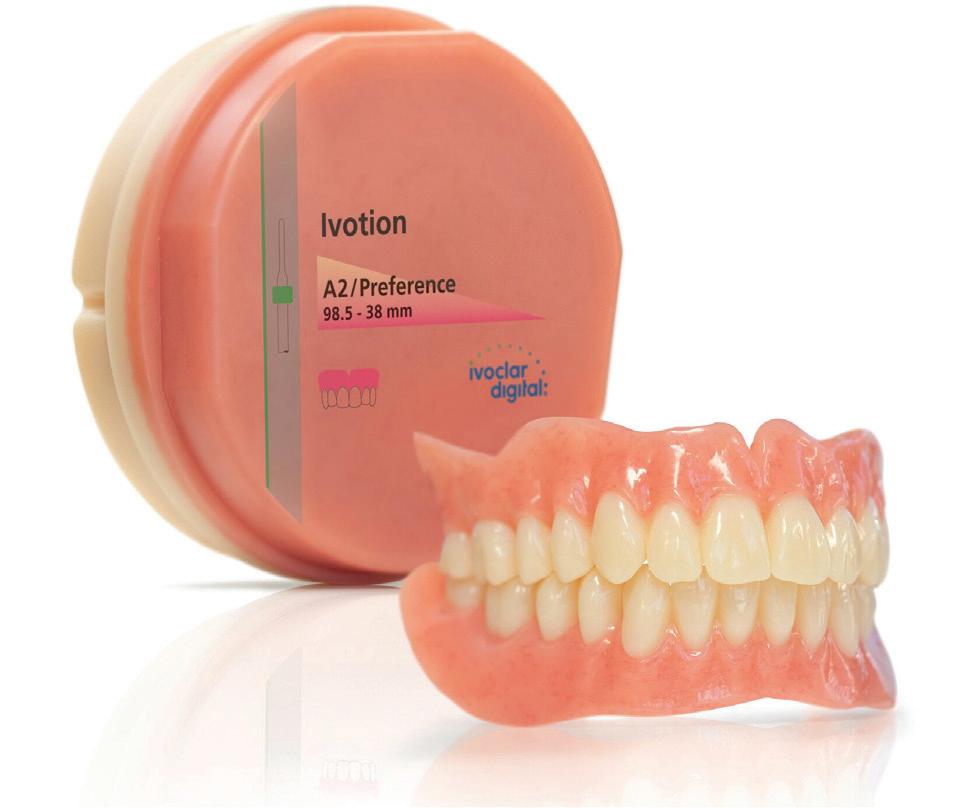

Ivoclar, one of the world’s leading suppliers of integrated solutions for high-quality dental applications with a comprehensive range of products and systems for dentists and dental technicians, revolutionised the fabrication of complete dentures two years ago with the introduction of the Ivotion Denture System. This innovative, multiaward-winning system, pioneered a complete workflow for the digital fabrication of high-quality dentures from a single monolithic disc in just one milling cycle. Only just recently, Ivotion was awarded the Innovation Prize at the “Dental Forum 2022” in Paris as well as the prize for best dental technology product at “KRAKDENT 2022” in Kraków. In October, the company took things a step further and expanded its partnership with exocad, one of the leading providers of dental CAD/ CAM software. The integration of the Ivotion Denture add-on module in the exocad DentalCAD software will provide users with an efficient manufacturing workflow for digital fabrication of superior quality, removeable dentures.

By integrating the Ivotion Denture add-on module in the DentalCAD software solution from exocad, Ivoclar is expanding its successful partnership with exocad in the area of digital dental workflows. As one of the leading manufacturers of dental CAD/CAM software in the dental industry, exocad has a large customer base as well as comprehensive experience in dental software products. Thanks to this collaboration, customers of both companies can now enjoy a seamless and state-of-the-art workflow for rapid digital fabrication of removeable dentures. As part of this cooperation, the Ivotion Denture add-on module will be integrated with the exocad DentalCAD system so that users of the software can design their digital dentures in the environment to which they are accustomed. The optimised workflow enables custom fabrication and a result that is adapted to the needs of the patient.

10 eLABORATE September/December 2022

Ivoclar and exocad: A big-impact partnership

spectrum | NEWS

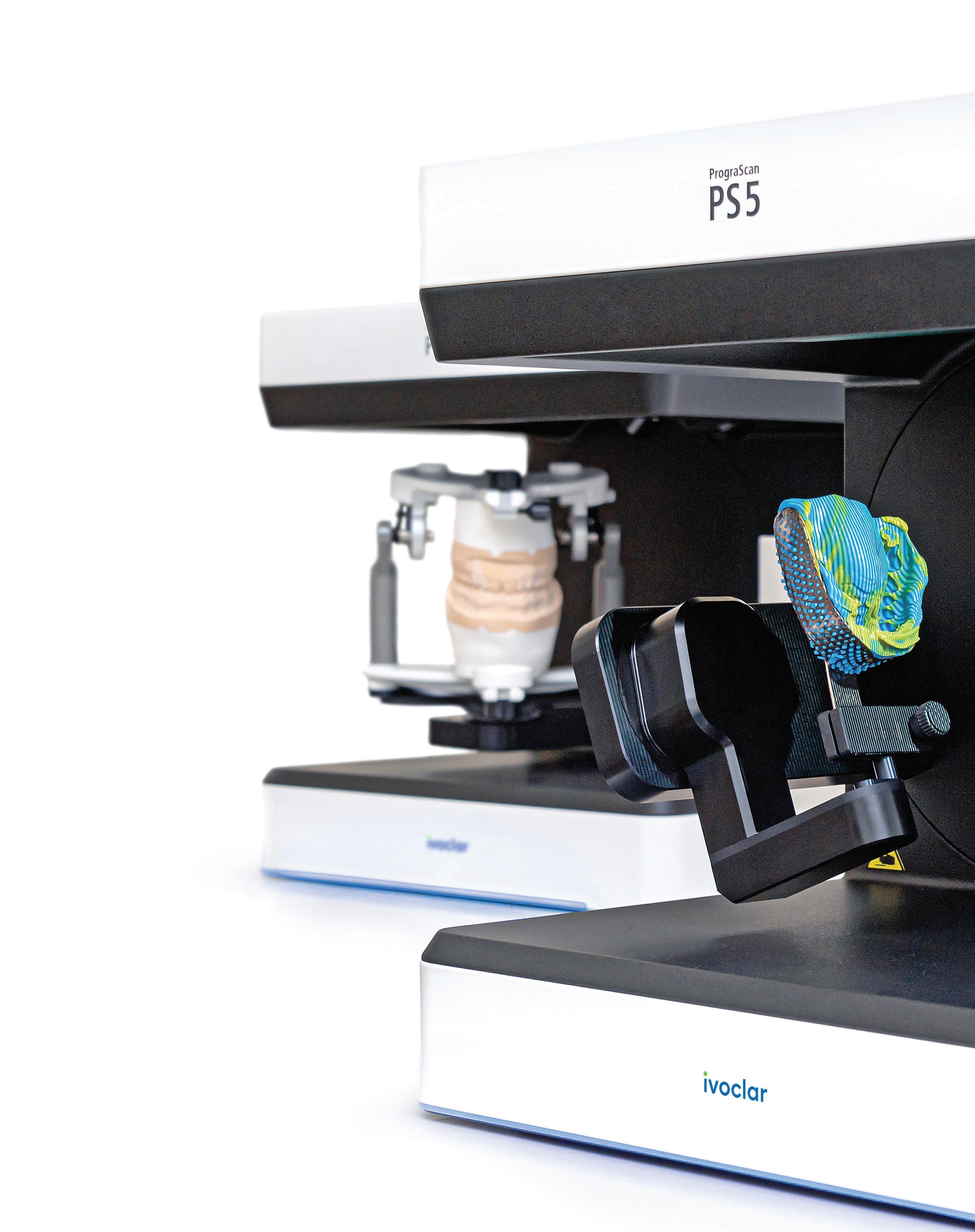

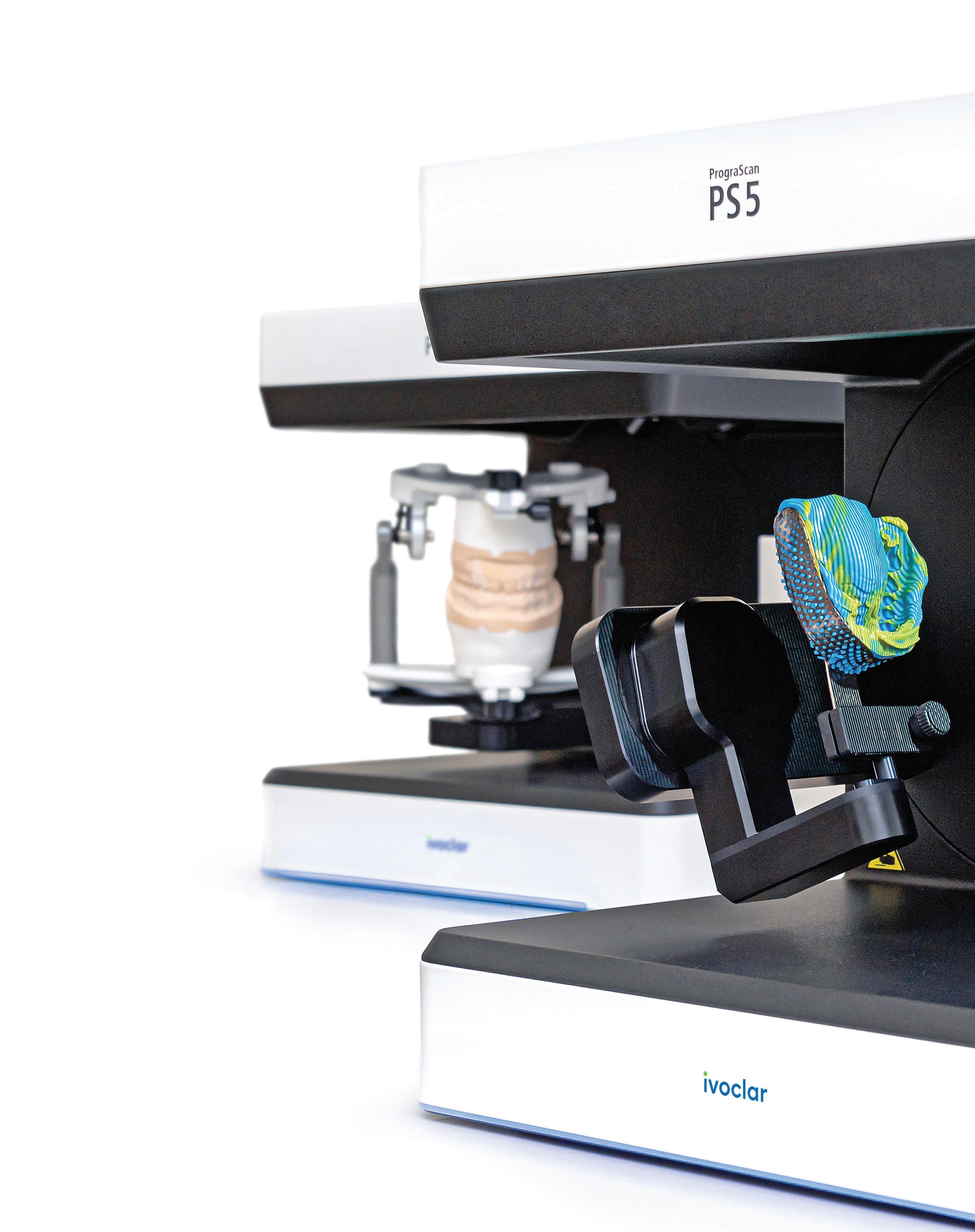

scan and design PrograScan® PS5 PS3 – Precise scans and rapid scanning speed – Extensive application options in seamless workflows for optimal results – Easy handling and intuitive design with exocad DentalCAD Scan here for more information ivoclar.com | AUS 1300 486 252 | NZ 0508 486 252 Making People Smile

Simply

Moreover, the integration also provides users with access to the popular Ivoclar tooth libraries with full-arch setups, morphing tools and setup features. For even better offer customisation, the third gingival shade that was introduced for the first time last year can also be used. The Ivotion Denture add-on module from Ivoclar also contains all the features of the oversize workflow in combination with the proven Ivotion Base, Ivotion Dent and Ivotion Dent Multi discs. To round off the range of applications, the features of the monolithic workflow with Ivotion and Shell Geometry are also on board.

The Ivotion Denture SystemA successful, forward-looking system solution

Thanks to its open structure, exocad DentalCAD can be easily used with existing systems in the Ivoclar range of PrograScan laboratory scanners and PrograMill milling machines and can be seamlessly integrated in the digital Ivotion workflow. The PrograScan PS5 and PS3 laboratory scanners have made a lasting impact on the market with their powerful and reliable scanning. Thanks to the interface, their high precision and speed can now also be used with the exocad DentalCAD software and digital impressions can be integrated directly as colour models. As a flagship product, PrograScan PS5 also allows scanning of conventional impressions and enables reliable, high-resolution results. The sophisticated scanning software of the Ivoclar PrograScan series provides intuitive handling for preparing the fabrication of digital dentures as well as a guided scan workflow.

In combination with the sophisticated design options of the exocad DentalCAD software, users benefit from a logical, integrated workflow that significantly eases the design phase and subsequent fabrication.

Digital dentures are gaining ground around the world and a growing number of dentists, dental technicians and dental laboratory owners are switching their processes to an entirely digital workflow. That is why Ivoclar is increasingly focused on effective digital solutions and was hugely successful in 2020 with a completely new workflow for high-quality digital dentures. Thanks to the Ivotion Denture System, the company already set new standards two years ago in the fabrication of complete dentures and since launching, has impressed customers worldwide with its very own system solution. The state-of-the-art system is part of the Digital Denture Workflow and allows dentists and dental technicians to benefit from efficient digital fabrication of dentures at revolutionary speeds. In addition to user-friendly handling, the rapid results, in particular, have won over users as well as a large number of patients. It is now already possible for users to intuitively design digital dentures with the 3Shape Dental system software. In the next stage of development, exocad users should now also be able to make the most of efficient design using Ivotion.

The key element of the Ivotion Denture System is the innovative Ivotion disc. It is used in monolithic fabrication of complete dentures and combines proven tooth and denture base materials in a single disc. As a result, digital dentures can be fabricated from just a single unit. Eliminating the usual cementation step in this way results in a significantly longer lifetime and considerably faster fabrication.

With their outstanding precision, the PrograMill series of milling machines enable the perfect fit. Alongside integration in the sophisticated Digital Denture Workflow, aesthetic, fractureresistant results have never been easier to achieve. The PrograMill milling machines have impressed for years with their power and dynamic functionality, setting new standards in digital fabrication of restorations. The 5-axis high-performance milling machine PrograMill PM7 supports a wide range of materials and applications in both wet and dry mode and thanks to its high-performance spindle, delivers first-class surface quality in an incredibly short time. The seamless connection with the digital workflow, in combination with intuitive operation, enables smooth handling as part of the daily routine. With the introduction of the Ivotion Denture System, Ivoclar achieved a milestone in removeable dentures. Now, with the Ivotion Denture add-on module, it has cleverly expanded this successful product.

As a result, exocad users can also access the entire range as well as all the benefits it provides. The partnership with exocad represents another logical step for Ivoclar in the continuous expansion of the Ivotion Denture System, optimising it to suit customer needss, and so providing even more users with access to the digital workflow for denture fabrication.

About the Ivoclar Group

The Ivoclar Group, headquartered in Schaan, Liechtenstein, is one of the world’s leading manufacturers of integrated solutions for high-quality dental applications. The company’s success is based on a comprehensive portfolio of products, systems and services, strong research and development capabilities and a clear commitment to training and further education. The group, which sells its products to around 130 countries, has 47 subsidiaries and branch offices and employs roughly 3,500 people worldwide.

More information on the digital workflow and digital solutions from Ivoclar is available at: https://www.ivoclar.com or in Australia, call 1300-486-252 or email orders.au@ivoclar.com. In New Zealand, call 0508-486-252 or orders.nz@ivoclar.com.

12 eLABORATE September/December 2022 spectrum | NEWS

Fast, efficient, predictable - The comprehensive approach of the Ivotion workflow

ivoclar.com | 1300 486 252 Making People Smile

Programat® G2 series – Fast and high-quality firing results due to infrared technology – New user interface for easy and intuitive operation – IoT function for free monthly equipment usage reports and customer-specific recommendations Learn more https://bit.ly/3MaNbQ7

Modern, intuitive, smart

Zirkonzahn: From the Alps to worldwide

In the heart of the Italian Alps, with the fundamental values of discipline, innovation, trust and responsibility, the family-run Zirkonzahn company provides innovative solutions for the dental sector. Under the motto “Everything under one roof”, all Zirkonzahn’s processable materials, hardware and software are conceived and developed in-house, in order to guarantee constant control over the production process and therefore comply with the company’s high-quality standards. In their homeland, South Tyrol, Italy, Zirkonzahn has their headquarters, main education centres, a dental laboratory and operates five production sites, all located within a few kilometres from the head office. Purchasing raw materials only from specially selected suppliers, the company develops new visions, dental materials, tools and technologies providing dentists and dental technicians with dedicated, simplified instruments for a smooth and reliable workflow, from implant planning procedures to the final restoration.

Zirkonzahn’s workflow can be carried out 100% digitally and depending on the dental laboratory’s working procedures, analogue steps can also be included. Furthermore, the wide range of CAD/CAM equipment and materials are perfectly integrated with each other, ensuring better communication within the techno-clinical team from patient data registration to restoration delivery. Based on the accurate record of a patient’s data, Zirkonzahn’s workflow is also perfectly combined with patient diagnostic technologies such as PlaneSystem® (MDT Udo Plaster) and

Face Hunter 3D facial scanner: a transfer method which recognises the patient as a person, allowing a simple acquisition 1:1 of patient-specific information into the virtual world without loss of information.

From scanning to sintering: Everything for your workflow

In order to meet the patient’s growing demand for fast and aesthetic solutions without compromising on quality, some of the latest technological solutions recently launched in the market greatly simplify the production process. With the new Detection Eye intraoral scanner, the patient’s jaw can be easily digitised in less than 60 seconds, making the impression-taking more comfortable and patient-friendly. The scanner has been designed to be lightweight, compact and ergonomic and the scanning areas do not need to be pretreated with powder, which simplifies the acquisition process. Once the data have been captured, they can be easily and quickly loaded into the Zirkonzahn.Software for the model design. The created model can then be milled in one of the five milling units of the new M2 comfort line or 3D printed using the P4000 Printer. Fully automatic, flexible and vibration free, the M2 milling unit comfort line exemplifies precision and flexibility. With the M2 Wet Heavy Metal, the M2 Teleskoper, the M2 Dual Wet Heavy Metal, the M2 Dual Teleskoper and the M2 Dual Double Teleskoper, the comfort line comprises five milling machines with fully automatic 5+1 axis simultaneous milling technology. The highlight is the

extra-large Teleskoper Orbit (ø 125 mm): in combination with special interchangeable holders, it allows the processing of all common soft and hard material blanks of ø 95 mm, ø 98 mm, ø 106 mm or even ø 125 mm. With the Teleskoper Orbit, blanks can be removed and reinserted back into the orbit at the same position with high precision in the micron range.

No limitations! With the extra-large Teleskoper Orbit it is now possible to mill material blanks with ø 95 mm, 98 mm, 106 mm or even 125 mm, as well as glass-ceramic and Raw-Abutments® blanks. Discs can be removed and reinserted back into the orbit at the same position with high precision in the micron range - this is particularly useful for the two-stage fabrication of immediate restorations in case of implant-supported prostheses (Double Milling technique).

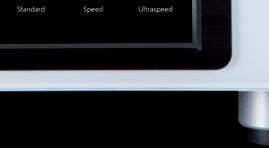

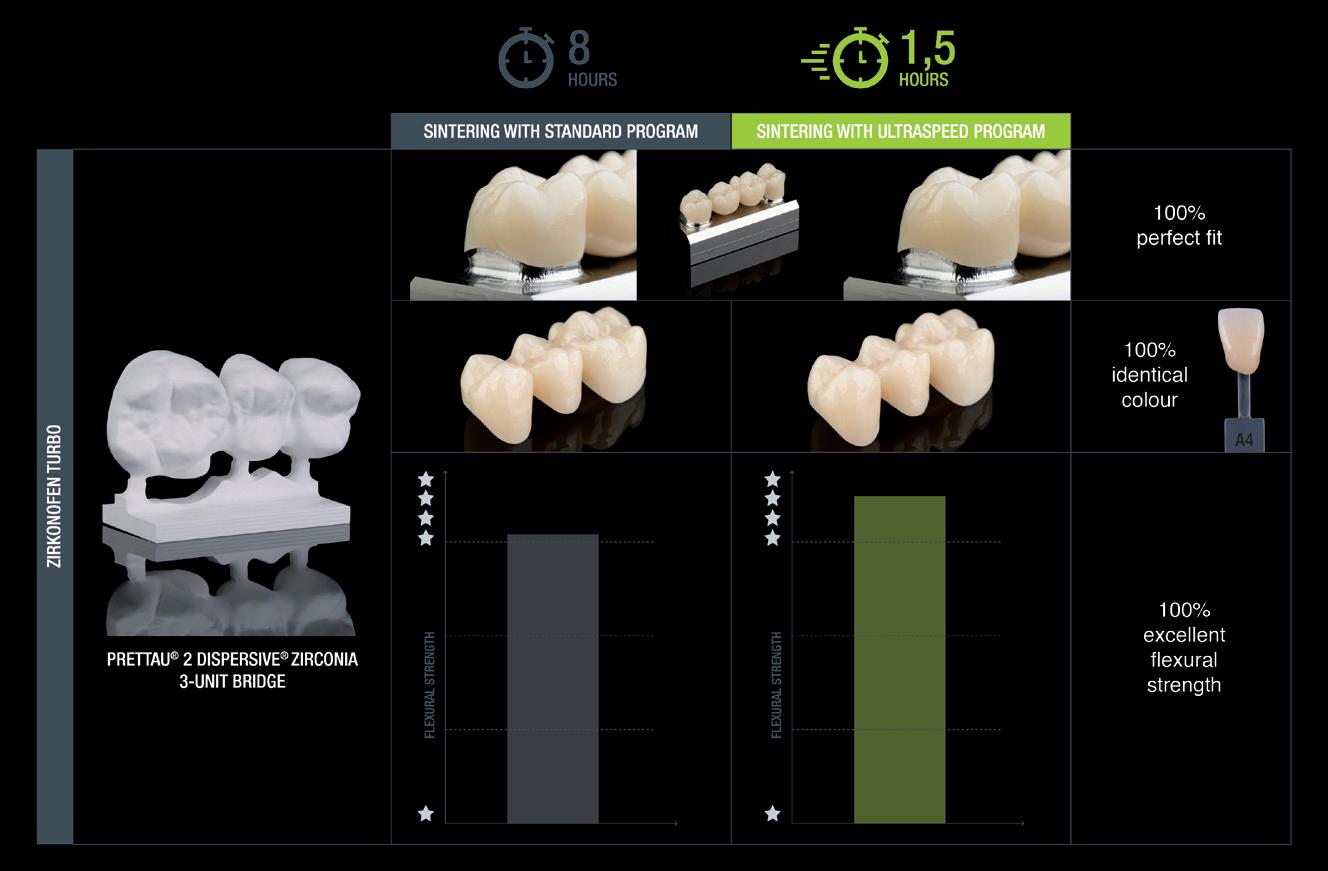

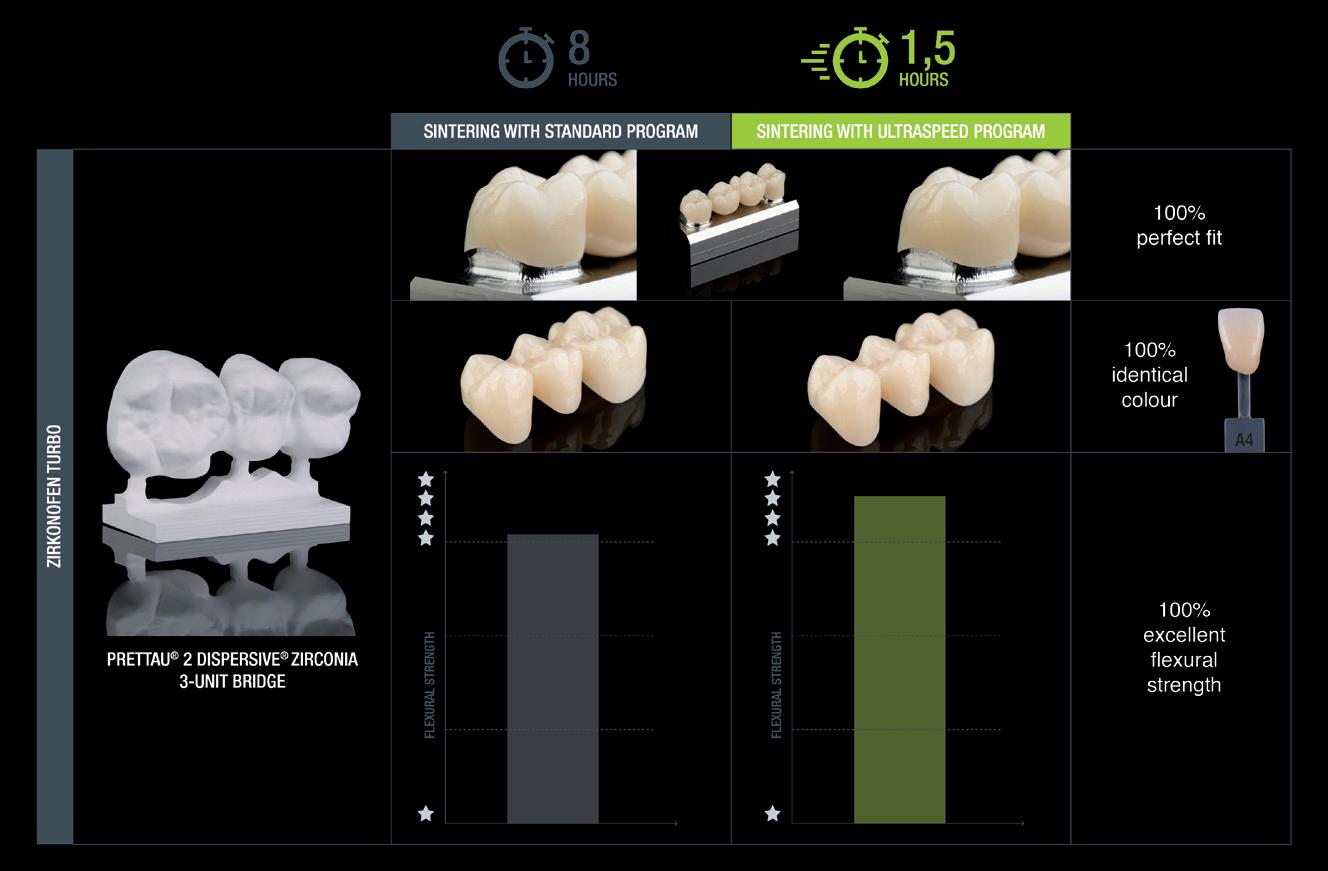

In addition, the pre-set Ultraspeed programs of the Zirkonofen Turbo, perfectly adapt to each kind of Zirkonzahn zirconia, allow to sinter small zirconia structures in about 90 minutes only, with no variation of flexural strength, colour and fit values. This cuts processing time by 81% and reduces electric consumption by 73%.

on page 18 88

14 eLABORATE September/December 2022

spectrum | NEWS

Continued

The M2 milling unit comfort line includes 5 machines, provided with one or two milling chambers, the Teleskoper Orbit ø 125 mm and a tool magazine with up to 84 tool slots (depending on the model).

NEWS Zirkonzahn Worldwide – T +39 0474 066 680 – info@zirkonzahn.com – www.zirkonzahn.com ZIRKONOFEN

With pre-set programs for sintering small zirconia structures in about 1 hour and 30 minutes M2 MILLING UNIT COMFORT LINE Machines with one or two milling chambers and the extra-large Teleskoper Orbit Ø 125 mm Ø 95 Ø 98 Ø 106 Ø 125 100 % FROM THE DOLOMITES EVERYTHING FOR YOUR WORKFLOW In the heart of the Italian Alps, with the fundamental values of discipline, innovation, trust and responsibility, we produce everything on our own. Purchasing raw materials only from specially selected suppliers, we develop new visions, dental materials, tools and technologies all under one roof. We provide dentists and dental technicians with technical support as well as educational trainings, to help them stand out in terms of quality and excellence. ZIRKONZAHN SHADE GUIDES With monolithic Prettau® zirconia sample teeth INTRAORAL SCANNER AND 3D PRINTER For a smooth digital workflow MORE INFORMATION PRETTAU® 3 DISPERSIVE® Zirconia typologies with natural colour gradient or with Gradual-Triplex-Technology Prettau® 3 Dispersive® IMPLANT PROSTHETICS TGA approved components for more than 140 implant systems and with up to 30-year warranty

TURBO

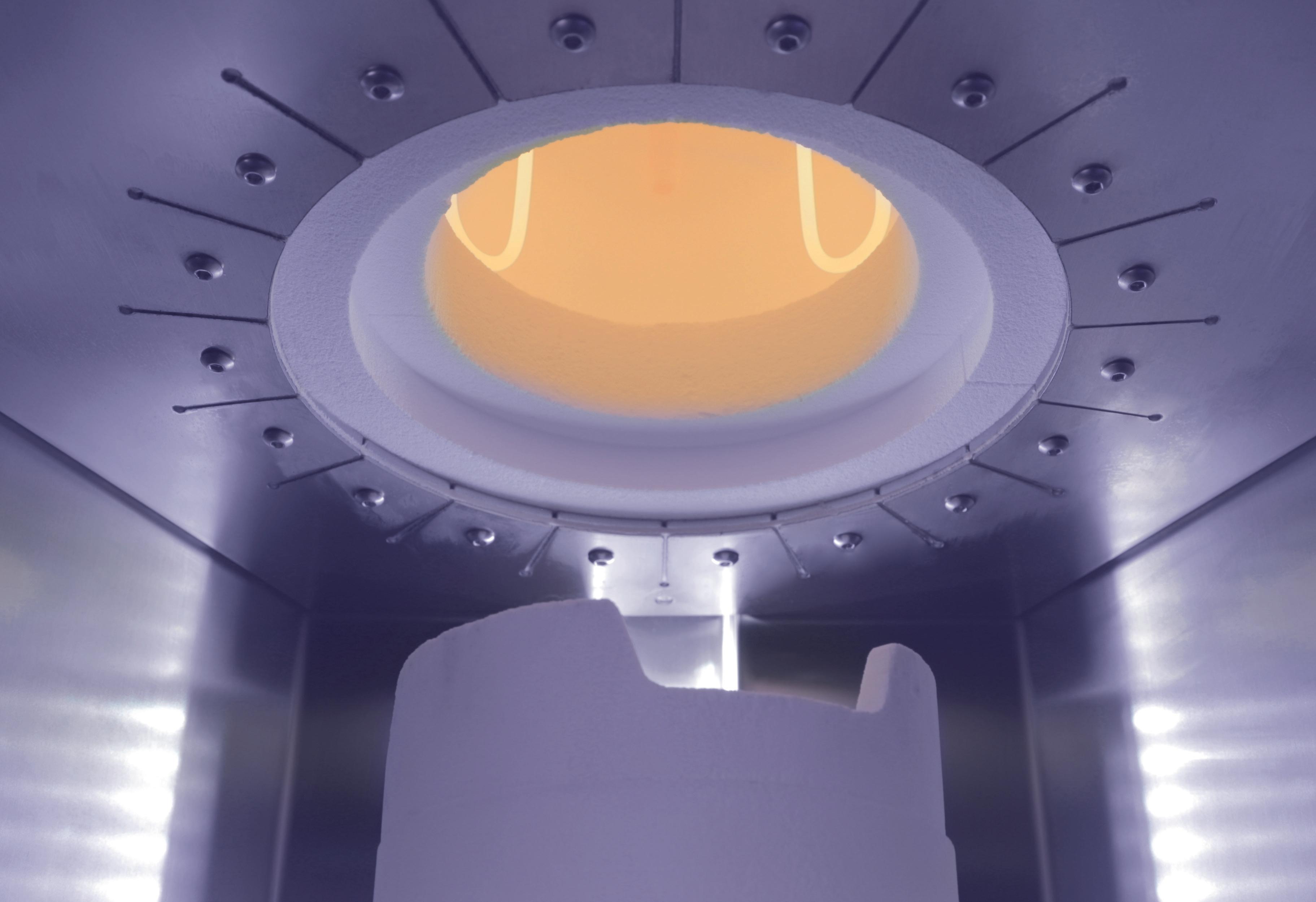

Zirkonofen Turbo: Speed beyond any expectations

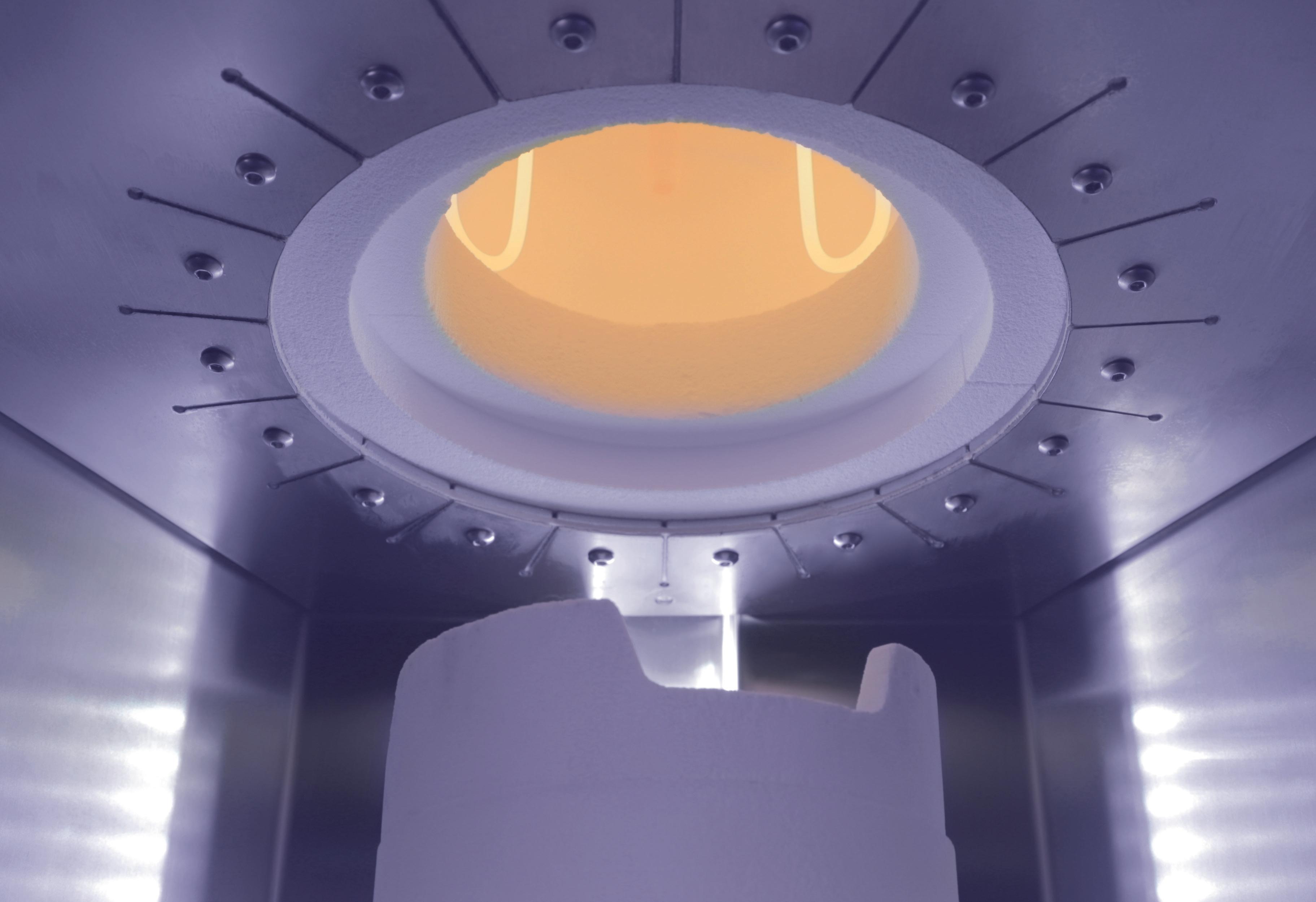

Using the new Zirkonofen Turbo and its pre-set fast sintering programs perfectly adapted to each kind of Zirkonzahn zirconia, it is now possible to sinter smaller zirconia structures in about 90 minutes. This cuts processing time by 81% and reduces electrical consumption by 73% (Figure 1). As a result, zirconia restorations can be realised and finalised in 2 hours and 10 minutes only.

The round shape of the sintering chamber ensures optimum heat distribution and a uniform sintering of all zirconia

elements. With a volume of 0.9 L, the sintering chamber can contain up to 3 sintering trays stacked on top of each other, which permit sintering of up to 120 zirconia elements in one sintering process. If bridges are sintered with a sintering stabiliser, the ceramic plate must be used, which offers space for up to 3 full-arch bridges.

The software, developed in-house, has been re-designed especially for this new furnace. Via the Internet connection, the user can download and install the updates directly in the furnace in order to always work with the latest functions and sintering programs. With Zirkonofen Turbo,

In the Zirkonofen Turbo, zirconia restorations can be sintered by means of special accessories to prevent discolouration and pressure marks on the zirconia structures.

the user can also create individual sintering programs in addition to the already existing ones and perform independent temperature calibrations. In case of power failures, unsatisfactory sintering results are nearly impossible thanks to the Baking Recovery function. Indeed, after a power failure, the software checks whether the sintering program can be regularly completed without compromising the result or whether the sintering process must be suspended, informing the user.

16 eLABORATE September/December 2022 spectrum | NEWS

- 81 % TIME - 73 % ELECTRIC CONSUMPTION 120 ZIRCONIA ELEMENTS 1 . 5 HOURS ONLY WATCH THE VIDEO NEW! ZIRKONOFEN TURBO SPEED BEYOND ANY EXPECTATIONS - Round sintering chamber with room for up to 120 zirconia elements or 3 full-arch bridges - Ultra speed sintering in 1.5 hours only – zirconia structures can be milled, sintered and veneered in 2 hours and 10 minutes only! - Independent temperature calibration - Optimised cooling through the fully automatic sintering platform - Baking Recovery function in case of power failure - Large number of pre-set programs perfectly adapted to each Zirkonzahn’s zirconia - Download of updates via LAN or WiFi - Creation of individual sintering programs with the new software - High resolution 7” colour touch screen and status display via LED lighting Zirkonzahn Worldwide – T +39 0474 066 680 – info@zirkonzahn.com – www.zirkonzahn.com

88 Continued from page 14

Prettau® zirconia is namely the material of choice for functional and aesthetical solutions - from single crowns to monolithic full arches. The Prettau line includes different zirconia typologies. The materials are available as discs (ø 95 or 98 with step) as well as mini blanks to mill single crowns. In the last years, the company’s range of zirconia typologies has recently embarked even more on the path of monolithic design with the new Dispersive® versions. In this case, ceramic layering and manual colouring are not necessary anymore, since materials are provided with a very smooth, natural colour transition already during the manufacturing process. However, for an even more patient-specific result,

structures can be further characterised with colouring liquids or alternatively, a minimal cutback can be applied for subsequent application of a slight layer of Fresco Ceramics. Developed for both gingival and vestibular regions, these new ceramic pastes do not require staining anymore. Prettau 3 Dispersive is the latest material developed by the company, characterised by a triple gradient of colour, translucency values and flexural strength (GradualTriplex-Technology).

Using three sintering trays stacked on top of each other or the ceramic plate, it is now possible to sinter up to 120 zirconia elements or three full-arch bridges with sintering stabiliser in just one sintering process. For a deformation-free framework, the base of the trays should be covered with special sintering granules. In order to prevent discolouration or contamination of the zirconia bridges, it is recommended to cover them with a ceramic protection cover, which guarantees - in combination with the ceramic plate - optimal heat distribution thanks to its curved shape.

Faster than ever before!

With the Ultraspeed programs perfectly adapted to all typologies of Zirkonzahn zirconia, it is now possible to sinter small zirconia structures in approximately 90 minutes only, with no variation of flexural strength, colour or fit values.

inspired by the VITA classic range, comprised of 16 dentine colours (A1-D4) and 3 bleach shades.

With the new Zirkonzahn Shade Guides, the patient’s tooth colour can be precisely determined on the basis of monolithic sample teeth made of zirconia. In this way, it is possible to determine the most suitable Prettau zirconia material in a safe and quick manner: if the shade guide and the material of the zirconia prosthesis are identical, it is ensured that the colour of the zirconia restoration corresponds 1:1 with the natural tooth colour of the patient. The colour spectrum is

Optimal material and colour selection: monolithic sample teeth available in the shape of upper incisor, upper incisor with minimal cutback for further characterisation, lower incisor and premolar.

All innovative Zirkonzahn’s devices, materials and software have been conceived in order to create accurate restorations in a smooth and time-efficient manner. This ensures a more achievable function and aesthetic design of restorations and enables the techno-clinical team to provide their patients with a comprehensive consultation based on 100% individual and predictable outcomes, resulting in a greater engagement of the patient, who can have an accurate preview of their final restoration.

18 eLABORATE September/December 2022

Prettau® zirconia manufactured with pride

Monolithic Prettau zirconia shade guidesidentical to the final restoration

September/December 2022 eLABORATE 19 Working hand and hand towards innovative prosthetics. Kulzer’s Denture Solution Journey For all of your PALA® denture needs and solutions. Contact your trusted Kulzer Partner TODAY! Durodent dental / Alphabond dental / City Dental / Oraltec NZ Giving a hand to oral health info.australia@kulzer-dental.com Kulzer.com/australia © 2022 Kulzer GmbH 2326-10-22 KULZER Pala Ad 120x170 Ad 1.indd 1 12/10/2022 8:30 am

40th IDS: 100-year success story set to continue with 1600+ exhibitors so far

IDS 2023 is not only celebrating its 40th edition, as the leading trade fair; the International Dental Show has also now been shaping the future of the global dental industry for 100 years. And the success story continues in 2023: So far, over 1600 exhibitors from 60 countries, including 14 group stands from 12 countries, have registered for the world’s largest trade fair for the dental industry, dental medicine and dental technology, which is being staged from 14 to 18 March 2023. And the online platform IDSconnect will allow all of the industry players to network, physically and digitally.

In addition to the largest participation from Germany, the strongest international exhibitor participants currently come from Italy, the Republic of Korea, France, Switzerland, Spain, Turkey and the USA. Beyond this, group stands from Argentina, Brazil, Bulgaria, China, Israel, Italy, Japan, Hong Kong, Korea, Singapore, Turkey and the USA are represented in Cologne. IDS 2023 will be staged in Halls 1 [new], 2, 3, 4, 5, 10 and 11 of the Cologne fair grounds in Germany on exhibition space spanning around 180,000 m2

IDSconnect

In addition to the physical exhibition, the digital platform IDSconnect, provides information on products and system solutions as well as enabling the streaming of webinars, press conferences, events and one-to-one interaction with industry decision-makers. This means consistent international reach combined with a successful in-person trade fair experience. Trade visitors of IDS can go live any time or call up content precisely when they have the time.

Furthermore, IDSconnect provides a range of digital offers that enrich the trade fair visit: from learning sessions, to online seminars, through to corporate and product presentations.

IDSconnect is very easy and intuitive for everyone to use - even without previous digital experience - bringing the world’s largest dental show directly to your screen for an authentic trade fair experience. All functions are presented as video tutorials on the IDS website - from the navigation through to networking at https://www.english.ids-cologne.de/ trade-fair/idsconnect/

IDS Ticket Shop is available from mid-December

All tickets for IDS 2023 can be booked exclusively online.

Free use of public transport in the Cologne region and the entire Ruhr region is included with your IDS ticket. That means that trade fair participants who travel from the metropolitan areas of Düsseldorf, Duisburg, Essen, Gelsenkirchen, Mülheim and Dortmund, who have booked accommodations there or who fly to Düsseldorf, can travel to the trade fair in Cologne with an Interregio train and other local public transport options free of charge.

About IDS

DS (International Dental Show) takes place in Cologne every two years and is organised by the GFDI Gesellschaft zur Förderung der Dental-Industrie mbH, the commercial enterprise of the Association of German Dental Manufacturers (VDDI) and is staged by Koelnmesse GmbH, Cologne. For more information, visit www.ids-cologne.de

I

20 eLABORATE September/December 2022 spectrum | NEWS

SINCE 1923 ids-cologne.de SHAPING THE DENTAL FUTURE 14 March 2023: Trade Dealer Day 40 th International Dental Show 14. – 18.03.2023 COLOGNE inclusive IDSconnect Robert Laing · Messe Reps. Pty. Ltd. · Tel. +61 427353536 robert@messereps.com

Intraoral scanning for Digital Dentures

Workflows for fabricating Full and Partial dentures digitally SYDNEY | FEBRUARY 25, 2023

Presented by Sam Dias, Dental Prosthetist

This event is both a lecture documenting why you should choose digital dentures today as the optimal solution for your dental practice or denture clinic together with a LIVE systematic run-through of the process for fabricating both full and partial digital dentures. You will be able to follow Sam Dias as he explains the step-by-step process he uses in his four clinics across Sydney every day.

A demonstration of accurate intraoral scanning and prosthetic design ensures that the outcome won’t be compromised while saving time and money for you and your patient.

The session will conclude with a Q&A session discussing options leading to self-design or aided design as well as the finishing and polishing process. This course will cover the following...

1. Impression vs Scanning

A discussion and slide presentation comparing intraoral scanning and traditional impressions including a live scan of dentures will be shown. The scanning process will be shown step-by-step and the many different impression techniques currently used will be reviewed and details of how these can be carried on to the digital world shown.

2. Adding mesh and articulator adjustment

Combining multiple scans and adjusting the setup of the virtual articulator will be shown.

3. Wizard and model analysis

Wizards and model analysis tools will be explained.

4. Digital denture teeth selection

How to select the correct digital denture teeth library will be discussed as well as the use of the measure tool plus patient notes and extra scans. Denture teeth library options and applications will be discussed.

5. Digital denture teeth setups

Digital denture teeth setup tips and tricks for faster and more effortless setups will be detailed.

6. Denture base design

Key principles to bear in mind when designing your denture bases plus a guide to troubleshooting.

7. 3D printing

3D printing techniques plus a guide to material selection and achieving better outcomes.

8.

Carded denture teeth

Step-by-step bonding technique with tips and tricks.

9.

Staining technique

Techniques for staining and filling in the gaps.

10. Finishing and polishing

Tips to achieve a great final outcome.

Discussion + Q&A Session

dentevents presents...

Register Online Now at www.ios.events

6 HOURS CPD

Register Online Now at www.ios.events REGISTRATION FEES Registration $660 inc gst Earlybird $550 inc gst Before 25 jan 2023 DATE AND TIME SYDNEY Saturday, 25 February 2023 Starts 9.00am | Ends 5.00pm | Rego opens 8.30am ParkRoyal Darling Harbour Sydney Intraoral Scanning for Digital Dentures is presented by Dentevents, a division of Main Street Publishing Pty Ltd ABN 74 065 490 655 • www.dentevents.com • info@dentist.com.au Tel: (02) 9929 1900 • Fax: (02) 9929 1999 • Intraoral Scanning for Digital Dentures™ and Dentevents™ are trademarks of Main Street Publishing P/L © 2022 Main Street Publishing Pty Ltd

Answer the questions online at www.dentalcommunity.com.au To retrieve your FREE Dental Community Login, Call (02) 9929 1900 or email joseph@dentist.com.au

READ ME FOR CPD

Figure

Initial situation. Figure 2. Close-up of initial situation.

Treatment plan

8) This was the only analog process in an otherwise digital workflow.

clinical appointment

First

READ THE ARTICLES AND ANSWER THE QUESTIONS ONLINE

3D printing dentures - Part 2: Designing dentures using

By Terry Whitty

CAD software

I

cad CAM READ ME FOR CPD 32 eLABORATE September/October 2022 cad CAM

Question 1. A digital wax up was performed in minutes due to...

a. Uploading a DICOM 3 image.

b. Sending a broken model to the lab. c. Uploading an intraoral scan and loading this into CAD software. d. The antagonist not being involved.

Question 2. The diastema was quite large so the patient decided on...

a. Two crowns on the central incisors. b. Two veneers closing the diastema. c. RCT. d. Two single central veneers not closing the diastema.

Question 3. When the teeth were prepared a...

a. Surgical guide was used. b. Tooth reduction guide was used. c. Bone reduction guide was used. d. Wax knife was used.

Question 4. If a tooth reduction guide is not used you may risk...

a. Under prepping teeth. b. Over prepping teeth. c. Not having a good aesthetic outcome. d. All of the above.

Question 5. The digital workflow...

a. Is not accurate. b. Reduces clinical stress and anxiety. c. Can eliminate remakes. d. B and C

Question 6. One way or another you will need to digitise...

a. A wire bite rim strengthener. b. The upper and lower arches in the correct bite relationship. c. Nothing. d. Only the upper model.

Question 7. Manufacturers will try and limit the amount of carded tooth libraries...

a. Available for printing or milling in house. b. For using directly in 3D printed bases. c. In shade D3. d. Available in tapered moulds.

Question 8. 3Shape and exocad are fairly similar in workflow because...

a. Both are made by the same company. b. You import models, create landmarks, set teeth and create bases using a wizard interface. c. Both let you set the teeth before importing models. d. There is no other way to do it.

Question 9. Some companies will only let you use their library teeth to make...

a. A special tray. b. Registration rims. c. A monoblock try-in file ready for printing. d. Upper dentures only.

Question 10. Use spray scan on registration rims because...

a. It will scan too well without spray. b. It helps with the texture of the scan. c. It preserves the wax. d. Wax is naturally reflective and it dulls this reflection and allows the wax to be scanned.

INSTRUCTIONS:

eLABORATE™ is now offering subscribers the ability to gain 1 Hour CPD credit from reading articles in this edition of the magazine and answering the questions above. To participate, log in to the Dental Community website at www.dentalcommunity.com.au and click on the CPD Questionnaires link; select the eLABORATE Sep/Oct 2022 questionnaire and then click START. A score greater than 80% is required to PASS and receive CPD. If you do not have a free login, call (02) 9929-1900.

ONLINE CPD CENTRE 26

2022

70-year-old patient presented with a diastema and failed composite restorations that had been used to correct excessive tooth wear and incisal chipping on teeth 11 and 21. A retracted intraoral scan of the patient’s preoperative condition was taken and sent to the laboratory and uploaded into CAD software for a diagnostic wax-up of the proposed final case outcome (Figures 3-4). Within minutes, the technician proposed two solutions for the patient to view onscreen. One solution proposed lengthening the teeth slightly and fabricating veneers that would close the diastema. The second solution proposed keeping the diastema and repairing the two anterior centrals with highly aesthetic veneers (Figure 5). After viewing the virtual proposals, the patient expressed that she was less concerned by the aesthetics of her diastema. She declined the proposed design for tooth lengthening and diastema closure and approved the proposed design for two single central veneers.

eLABORATE September/October

A

Aclinical appointment was scheduled one week after the initial presentation for tooth preparation and provisionalisation. Before the first scheduled clinical appointment, the laboratory used CAD/CAM technology to design the temporaries and the final restorations in exact accordance with the patient-approved 3D virtual diagnostic wax-up of the final case outcome. A 3D-printed model of the approved smile design (Figures 6-7) was used to produce an analog silicone putty reduction matrix chairside (Figure

The teeth were prepared using the reduction guide to ensure that tooth reduction replicated the digital treatment plan (Figures 9-10). The prepared teeth were then scanned using an intraoral scanner (Figure 11) and the scans were uploaded to the lab for final design of the provisionals and final restorations (Figure 12). 1.

Anterior aesthetic veneers using a digital workflow

By Dr Jonathan Ferencz, NYC Prosthodontics

n the first part of this series, we looked at various printers and what to look for when selecting a printer for printing dentures. In this part, we will look at the software packages available to design the dentures and get them ready to print. will say right up front that I’m not covering the clinical side of digital dentures as this will be covered in other articles. Rest assured there are many methods available and also some in development to assist you in this so for now, let’s assume that our records are being done in the traditional way. That is impressions, models and registration rims to collect the relevant data from the patient, being the VD, OVD, occlusal plane, midline, canine line, high smile line, etc.One way or another, you have to firstly digitise the anatomy and the records of the patient. This can be done in a number of ways but I will describe a method using a bench top scanner. A lot of people get confused about how a set of models are digitised into the correct bite relationship so this will surely enlighten. Firstly, take the models and the registration rims and inspect for intimate fit, as this is really important as it will affect the outcome just as it would making dentures in the traditional way. Next, on the land area of each model, make a series of markings (Figure 2). I generally use a carbide bur and create 8-10 marks on each model. This will become very important later when the scanning software calculates the reference bite scan to each model.

Straumann Pty Ltd/Straumann New Zealand Limited 93 Cook Street, Port Melbourne VIC 3207, Australia

AU Toll Free 1800 660 330 | NZ Toll Free 0800 408 370

Straumann Pty Ltd/Straumann New Zealand Limited 93 Cook Street, Port Melbourne VIC 3207, Australia

Email customerservice.au@straumann.com www.straumann.com.au www.straumann.co.nz

AU Toll Free 1800 660 330 | NZ Toll Free 0800 408 370

Email customerservice.au@straumann.com www.straumann.com.au www.straumann.co.nz

©Institut Straumann AG, 2021. All rights reserved. Straumann® and/or other trademarks and logos from Straumann® mentioned herein are the trademarks or registered trademarks of Straumann Holding AG and/or its affiliates.

©Institut Straumann AG, 2021. All rights reserved. Straumann® and/or other trademarks and logos from Straumann®

your cards right. Contact your Straumann Group Solutions Specialist to claim your free trial

Play

Compatible with Neoss® & MegaGen Implant Systems Medentika® MPS Multi Platform System NE & MG SERIES

Anterior aesthetic veneers using a digital workflow

By Dr Jonathan Ferencz, NYC Prosthodontics

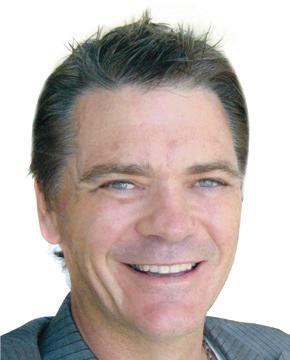

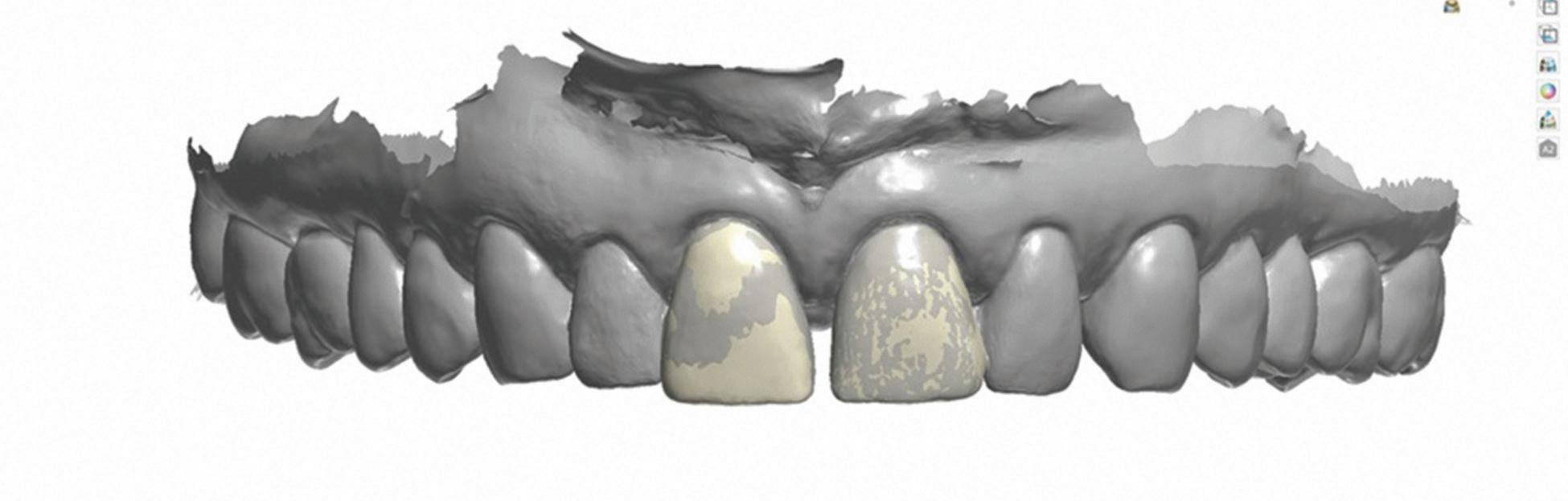

A70-year-old patient presented with a diastema and failed composite restorations that had been used to correct excessive tooth wear and incisal chipping on teeth 11 and 21.

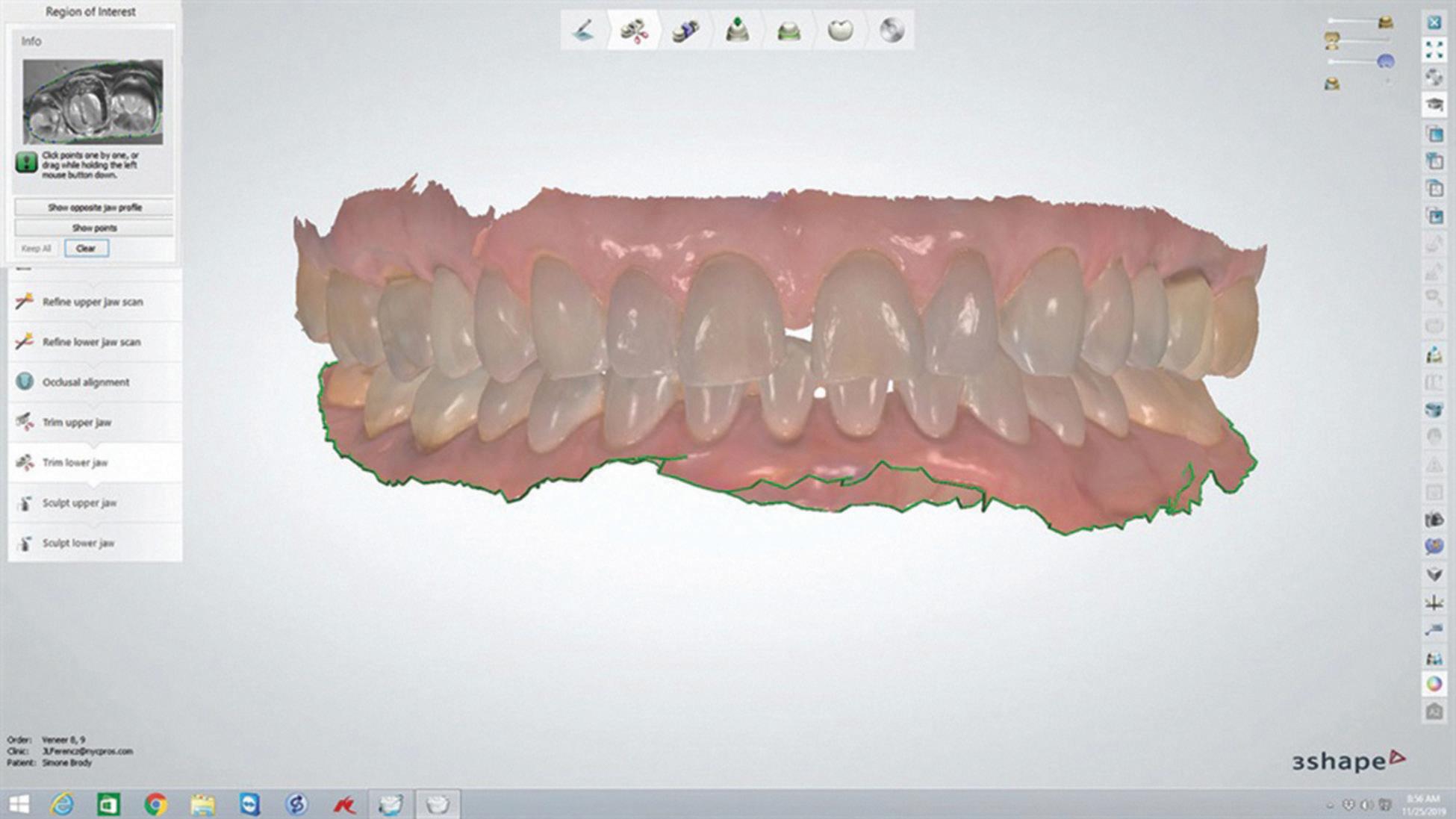

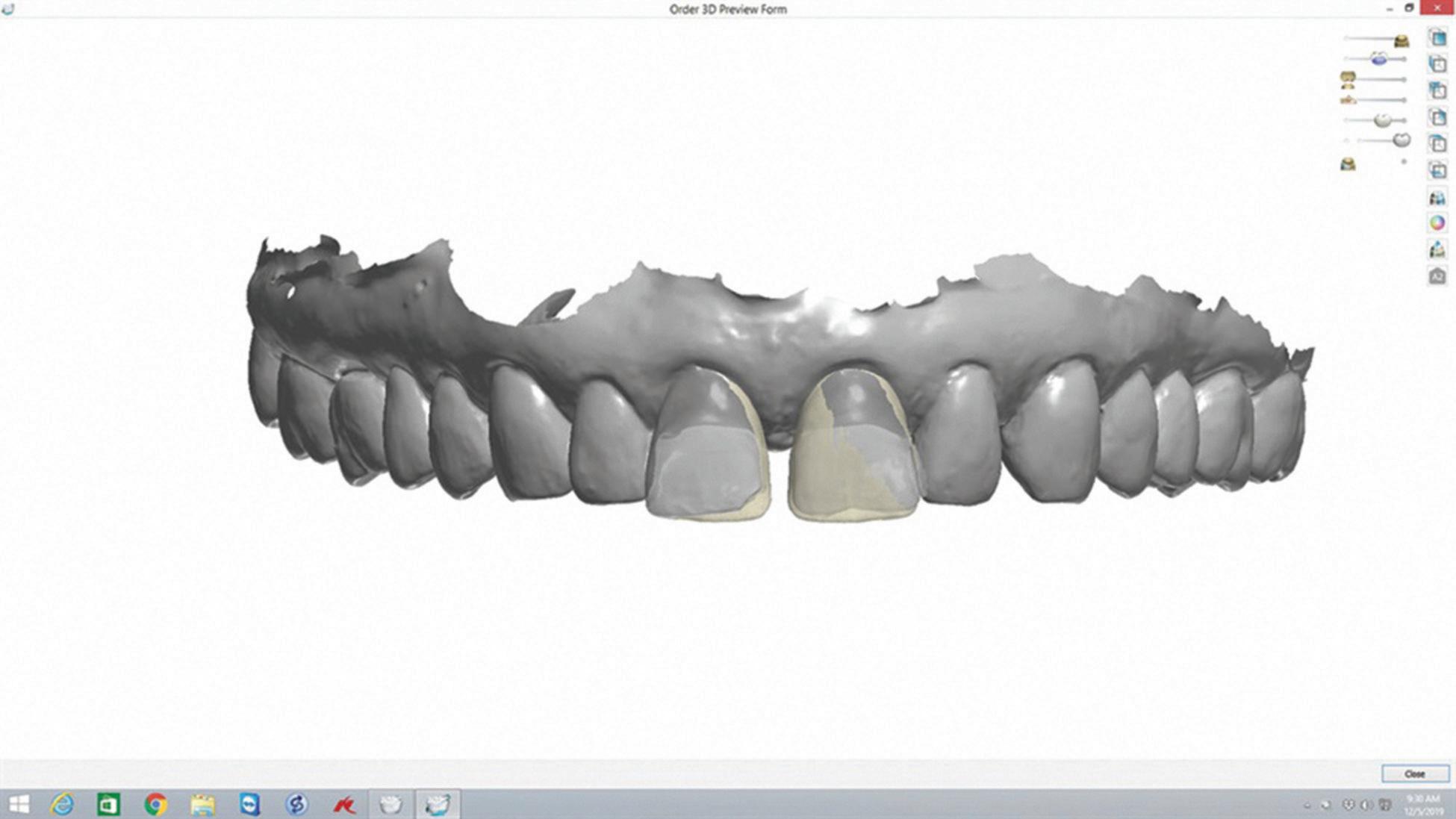

A retracted intraoral scan of the patient’s preoperative condition was taken and sent to the laboratory and uploaded into CAD software for a diagnostic wax-up of the proposed final case outcome (Figures 3-4).

Within minutes, the technician proposed two solutions for the patient to view onscreen.

One solution proposed lengthening the teeth slightly and fabricating veneers that would close the diastema. The second solution proposed keeping the diastema and repairing the two anterior centrals with highly aesthetic veneers (Figure 5).

After viewing the virtual proposals, the patient expressed that she was less concerned by the aesthetics of her diastema. She declined the proposed design for tooth lengthening and diastema closure and approved the proposed design for two single central veneers.

A

Treatment plan

clinical appointment was scheduled one week after the initial presentation for tooth preparation and provisionalisation.

Before the first scheduled clinical appointment, the laboratory used CAD/CAM technology to design the temporaries and the final restorations in exact accordance with the patient-approved 3D virtual diagnostic wax-up of the final case outcome.

A 3D-printed model of the approved smile design (Figures 6-7) was used to produce an analog silicone putty reduction matrix chairside (Figure 8) This was the only analog process in an otherwise digital workflow.

First clinical appointment

he teeth were prepared using the reduction guide to ensure that tooth reduction replicated the digital treatment plan (Figures 9-10). The prepared teeth were then scanned using an intraoral scanner (Figure 11) and the scans were uploaded to the lab for final design of the provisionals and final restorations (Figure 12).

T

26 eLABORATE September/December 2022

Figure 1. Initial situation.

Figure 2. Close-up of initial situation.

cad | CAM READ

ME FOR CPD

While the patient waited, the laboratory milled the tooth-coloured temporaries from polymethyl methacrylate (PMMA) on an Ivoclar PrograMill PM7 mill. The PMMA veneers were delivered and tried in for patient approval. Once the patient approved the aesthetics and fit chairside, we recommended the provisionals be worn for at least a couple of days to test the fit and function before we move on to milling the final definitive veneers. When the patient called approving the fit and function, we confidently moved forward with milling the final restorations using the same digital file used to fabricate the temporaries (Figure 13). In this case, the final veneers were milled from IPS e.max CAD on our PrograMill One mill by Ivoclar, which is well suited for producing thin margins and thin 0.5mm monolithic veneers. The final veneers are monolithic with no cutback, thus retaining the material’s 500MPa strength.

At the second clinical appointment, the provisionals were removed, the preparations cleaned and the final veneers seated using Variolink Esthetic dualcure composite luting cement (Figures 14-15). Patient satisfaction was high as no adjustments were needed and the final restorations precisely duplicated the proposed and approved provisionals.

Comments

Digital technologies have significantly streamlined the workflow and eliminated the guesswork from the timeintensive analog processes with intraoral scanning technology and CAD smile design software. However, for veneer cases, the one missing link in today’s digital workflow is the creation and delivery of a reduction guide that exactly duplicates the digital plan.

In an analog environment, the reduction guide fabrication would typically start with a traditional impression. The impression would then be sent to the laboratory with instructions for design and fabrication of a diagnostic wax-up for patient approval of the final treatment outcome.

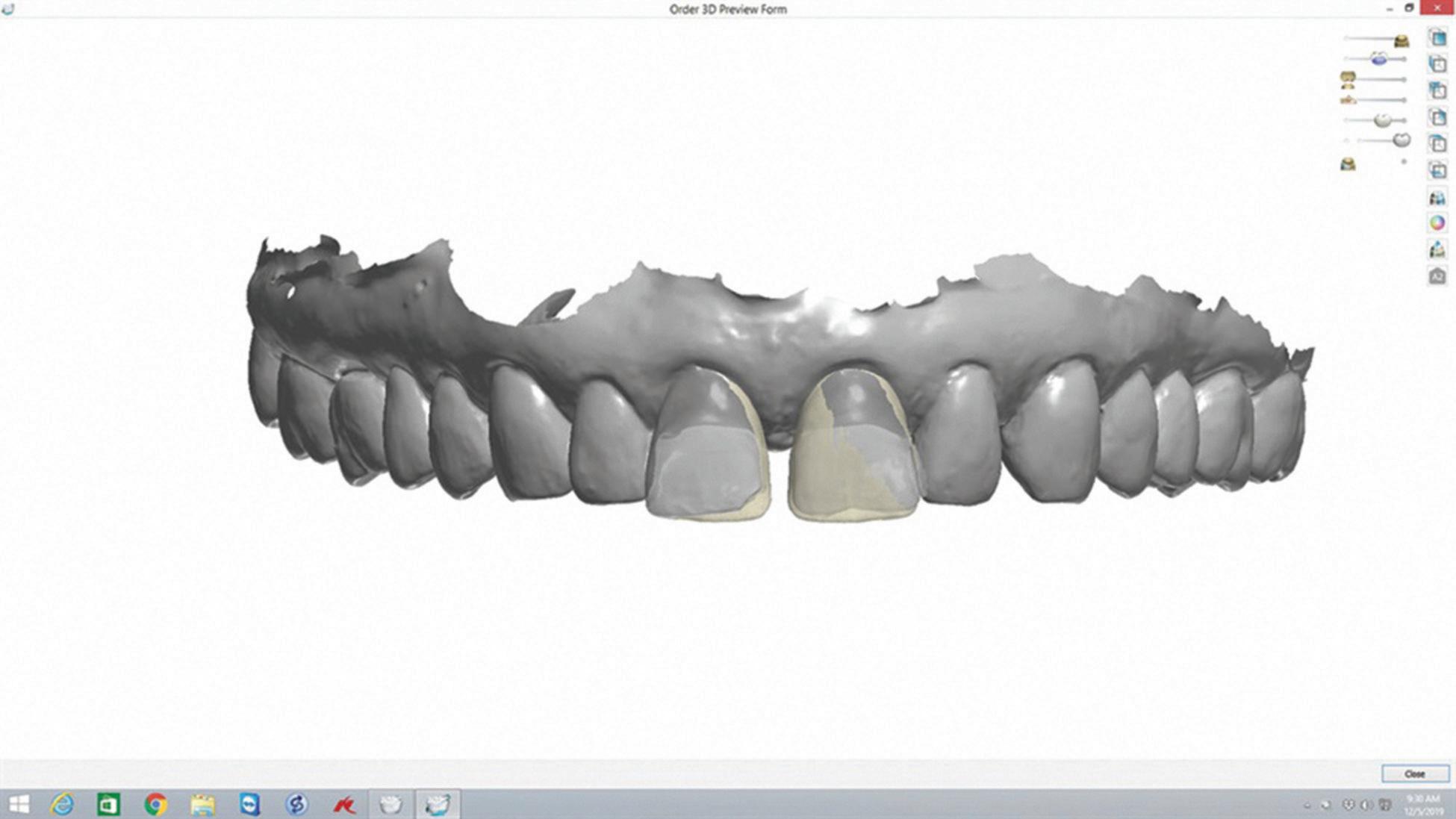

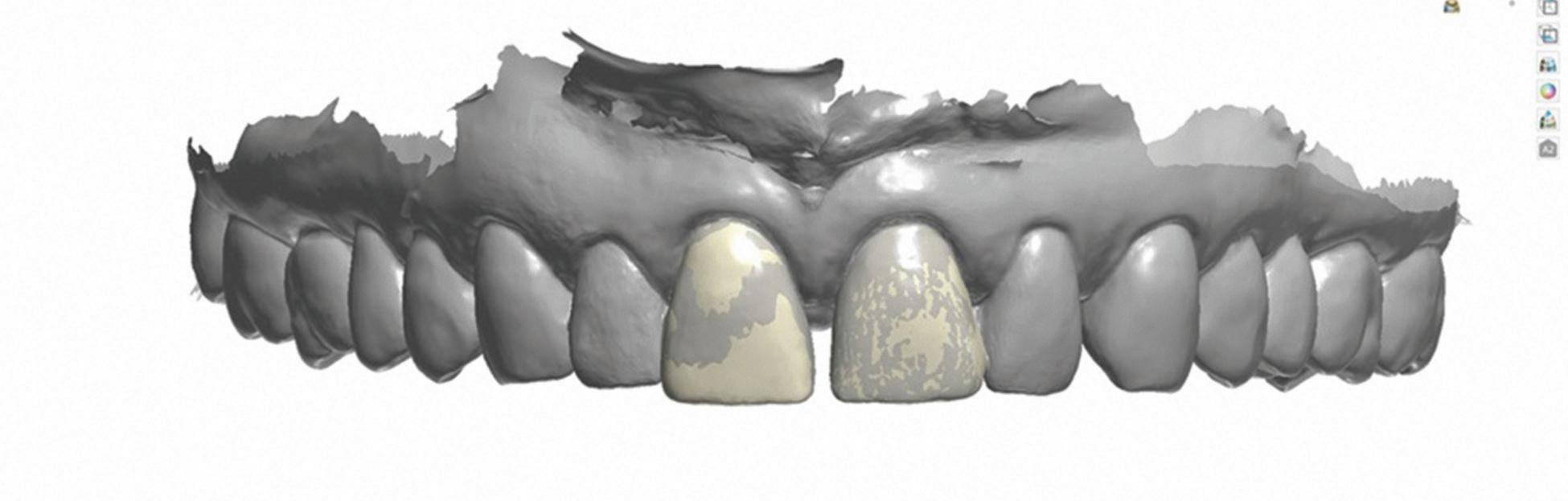

Figure 3. TRIOS intraoral scan displayed in 3Shape Dental System CAD software.

Figure 4. Diagnostic wax-up.

Figure 5. The patient approved the second solution proposed, keeping the diastema and repairing the two anterior centrals with highly aesthetic veneers.

September/December 2022 eLABORATE 27

cad | CAM

If the patient approves the wax-up of the final design, the laboratory creates a putty impression of the wax-up for the dentist to use as a reduction guide during the tooth preparation appointment. Should the patient demand changes to the wax-up smile design, the dentist would communicate those requests to the laboratory and a new diagnostic wax-up and reduction guide would be created, with associated increased costs, patient visits and chair time.

The risks of working in the aesthetic zone without a reduction guide are either under- or overprepping the natural teeth. If the teeth are underprepared, the final veneers will be overcontoured to hide underlying stump shades. If the teeth are overprepared and enamel removed, the veneers’ bond strength may be significantly compromised. In either case, the provisionals and final restorations may not accurately match the digital diagnostic wax-up and the dentist risks patient rejection of the final restorations, resulting in a remake.

One solution would be a virtual 3D-printed reduction guide that is delivered with the 3D-printed diagnostic wax-up model. Alternatively, another solution would be to design the intraoral scanner software with the ability to compare the preparation to the virtual diagnostic wax-up and identify areas that are underprepared.

In the future, I am confident that CAD software will address the need for a digitally driven 3D reduction guide.

Figure 8. Analog silicone putty reduction matrix.

Conclusion

Digital technologies eliminate the guesswork and inherent inaccuracies of analog processes and improve clinical workflows and efficiencies.

For example, intraoral scanners eliminate the need for physical impressions and the inaccuracies inherent in the handling and processing of impression material. The digital impression scan is uploaded to the dental laboratory and in conjunction with CAD software, is used to create a virtual digital diagnostic wax-up of the proposed case outcome.

28 eLABORATE September/December 2022

cad | CAM

Figures 6-7. A 3D-printed model of the smile design approved by the patient.

Figures 9-10. Teeth prepared using the reduction guide to ensure that tooth reduction replicated the digital treatment plan.

Changing

Changing

Elegant new design

Elegant new design

New and improved high-performance spindle

New and improved high-performance spindle

Sealed chamber to keep milling waste isolated

Sealed chamber to keep milling waste isolated

Built in webcam for real-time mill monitoring

Built in webcam for real-time mill monitoring

DGSHAPE CLOUD performance visualisation software

DGSHAPE CLOUD performance visualisation software

Optional tablet integration

Optional tablet integration

The NEW DWX-53DC 5-Axis Dental Milling Machine

the World of Dental Labs www.rolanddg.com.au/dwx53dc sales@rolanddg.com | 1800 500 119

5-Axis Dental Milling Machine

the World of Dental Labs

www.rolanddg.com.au/dwx53dc sales@rolanddg.com | 1800 500 119

In terms of the workflow, from approval of the virtual treatment design and milled provisionals to delivery and seating of the final veneers, the precision of CAD/ CAM technologies ensures exact duplication from start to finish. This level of predictability reduces clinical stress and anxiety, eliminates remakes and increases practice profitability.

About the author

Dr Jonathan Ferencz graduated from Rensselaer Polytechnic Institute with a degree in biology in 1967 and the New York University College of Dentistry in 1971. He subsequently opened a private practice in midtown Manhattan and enrolled in the part-time postgraduate program in prosthodontics. In 1984, he established the first honors programs in prosthodontics for fourth-year students at NYU. In 1990, Ferencz became clinical professor of postgraduate prosthodontics and was certified by the American Board of Prosthodontics in 1998. In addition to numerous fellowships, memberships and published materials, Ferencz is a clinical professor of prosthodontics at the NYU College of Dentistry, University of Pennsylvania and the Columbia University School of Dental Medicine. He also is a consultant for Henry Schein, 3Shape and Ivoclar Vivadent, focused on dental materials and emerging technologies used in CAD/CAM and other digital dental applications.

Figure 11. Intraoral scan of prepared teeth.

Figure 12. Design of provisional restorations.

Figure 13. Design of final restorations.

Figures 14-15. Final veneers after seating. Patient satisfaction was high as no adjustments were needed.

30 eLABORATE September/December 2022 cad | CAM

3Shape TRIOS intraoral scanner 3Shape Dental System Ivoclar PrograMill PM7

Solutions featured

Register Online Now at www.3dpd.events REGISTRATION FEES One Day $660 inc gst Two Days $990 inc gst sAVE $110 BEforE 10 JAn 2023 DATE AND TIME SYDNEY 10-11 February 2023 Starts 8.30am | Ends 5.00pm | Rego opens 8.00am ParkRoyal Darling Harbour Sydney 3D Printing in Dentistry is presented by Dentevents, a division of Main Street Publishing Pty Ltd ABN 74 065 490 655 • www.dentevents.com • info@dentist.com.au Tel: (02) 9929 1900 • Fax: (02) 9929 1999 • 3D Printing in Dentistry™ and Dentevents™ are trademarks of Main Street Publishing P/L © 2022 Main Street Publishing Pty Ltd WHITTY IP KLIJNSMA ANDERSON ELSEY BAKER YAHYA SHAO NALDER DAY ONE - FEB 10 - CLINICAL n Understanding 3D Printing applications, equipment, materials and workflows for dentistry n Case study: 3D Printing in General Dental Practice n Applications of 3D Printing in Cosmetic Dentistry n Case study: Optimising your practice to produce aligners in-house n One Visit Aligners - Print Fast Aligner Models In Office n Printing Class IIa appliances in-house n Partial and Full Digital Denture workflows DAY TWO - FEB 11 - TECHNICAL n Latest advances in 3D printer materials n Additive vs Subtractive manufacturing - which is best and when n 3D Printing Advanced Masterclass n The Top Ten 3D Printing Tips n Using and Maintaining a 3D printer - Real world Tips and Tricks n Integrating 3D Printing into your computer network n Digital manufacture of full and partial dentures n FORUM: The future of Dental 3D Printing Join Australia’s leading experts on dental 3D printing at this two day event exploring the applications of 3D printing in both the clinic and the laboratory. Visit the website for information and additional speakers. THIS EVENT IS DESIGNED FOR DENTISTS, SPECIALISTS, DENTAL PROSTHETISTS & DENTAL TECHNICIANS

3D printing dentures - Part 2: Designing dentures using CAD software

By Terry Whitty

By Terry Whitty

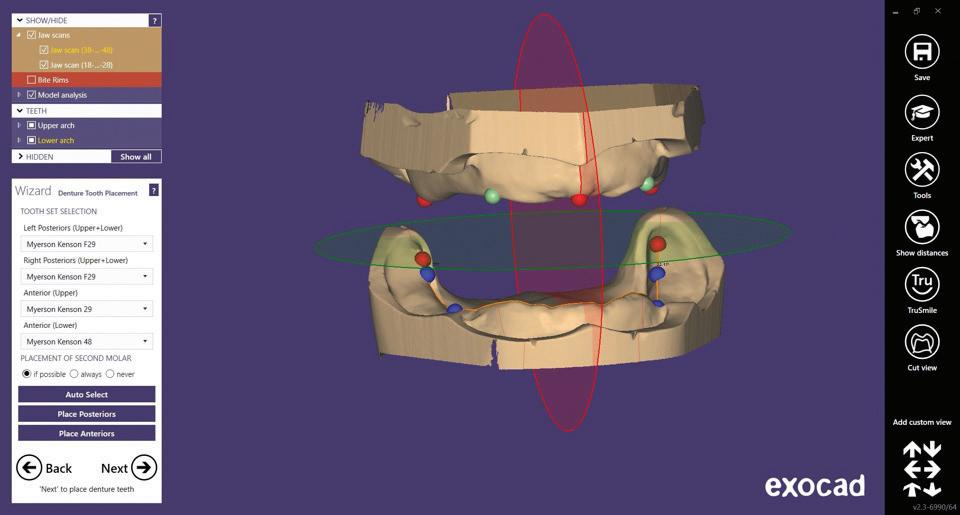

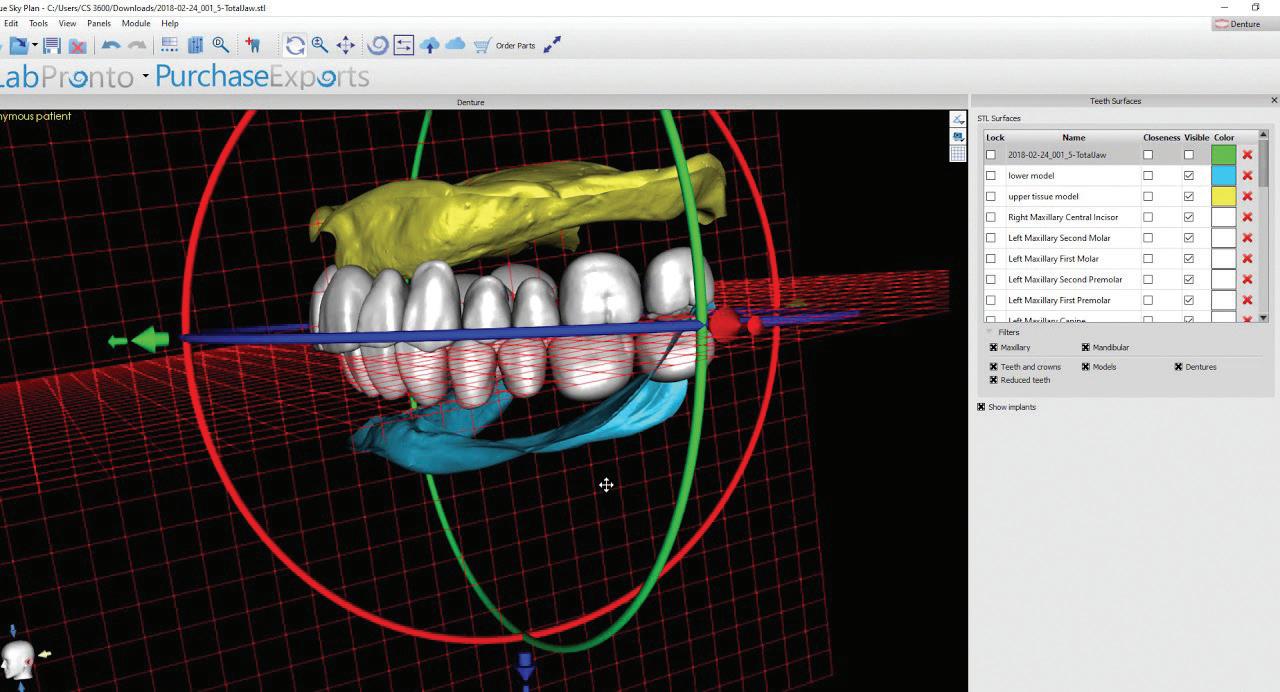

In the first part of this series, we looked at various printers and what to look for when selecting a printer for printing dentures. In this part, we will look at the software packages available to design the dentures and get them ready to print.

I will say right up front that I’m not covering the clinical side of digital dentures as this will be covered in other articles.

Rest assured there are many methods available and also some in development to assist you in this so for now, let’s assume that our records are being done in the traditional way. That is impressions, models and registration rims to collect the relevant data from the patient, being the VD, OVD, occlusal plane, midline, canine line, high smile line, etc.

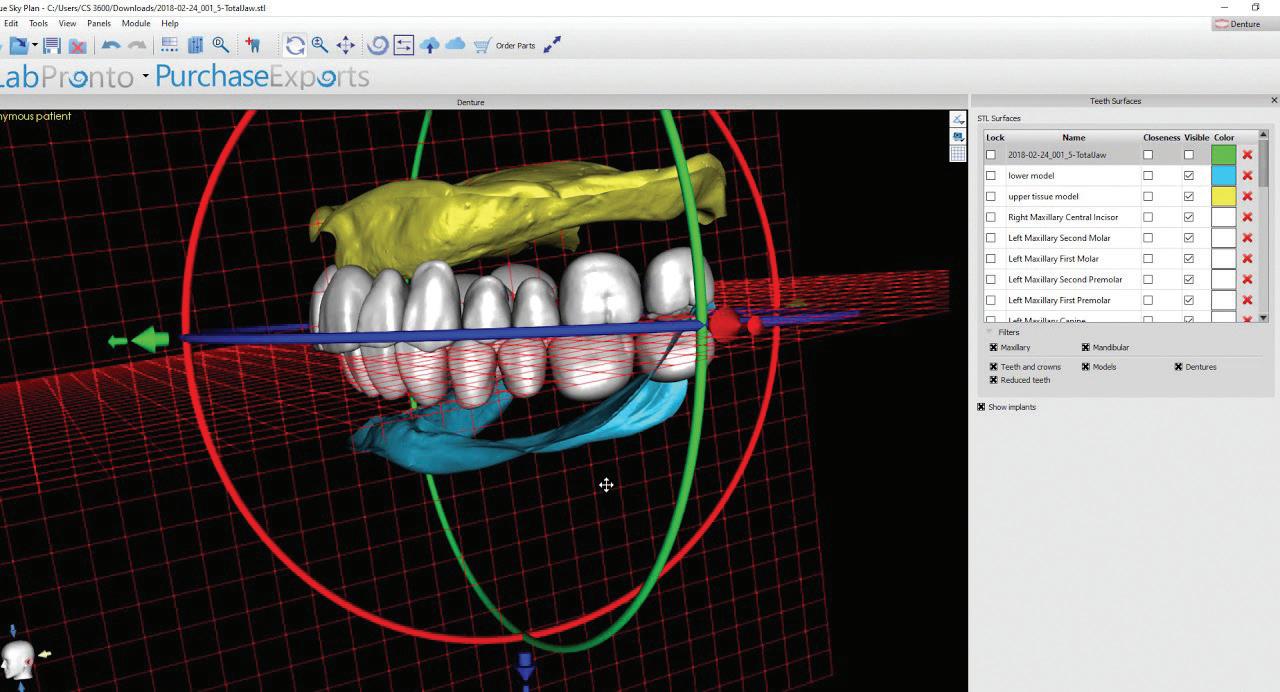

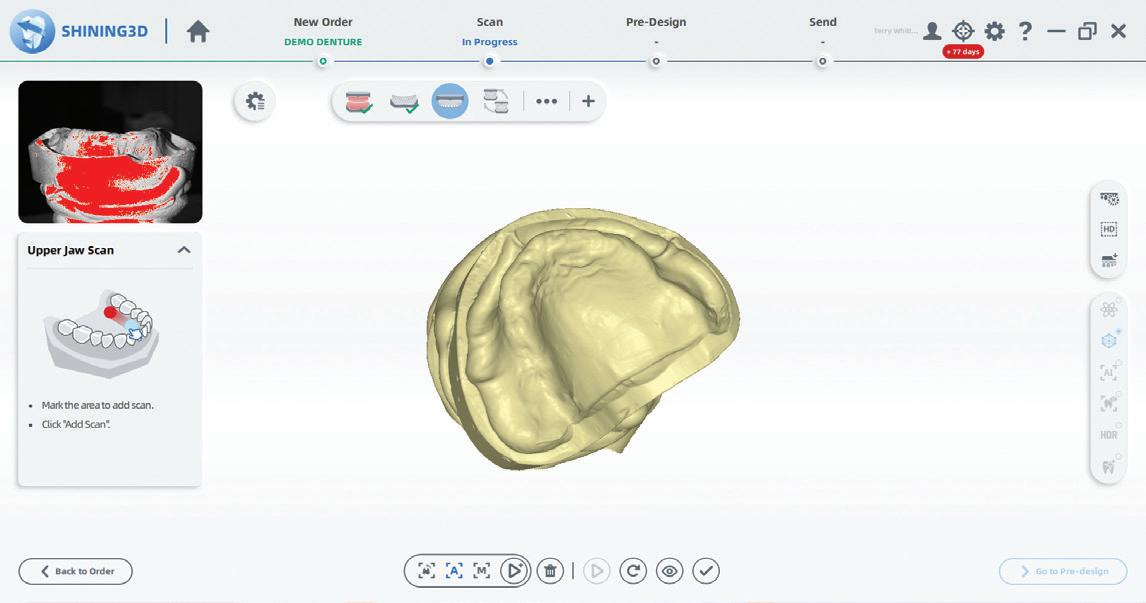

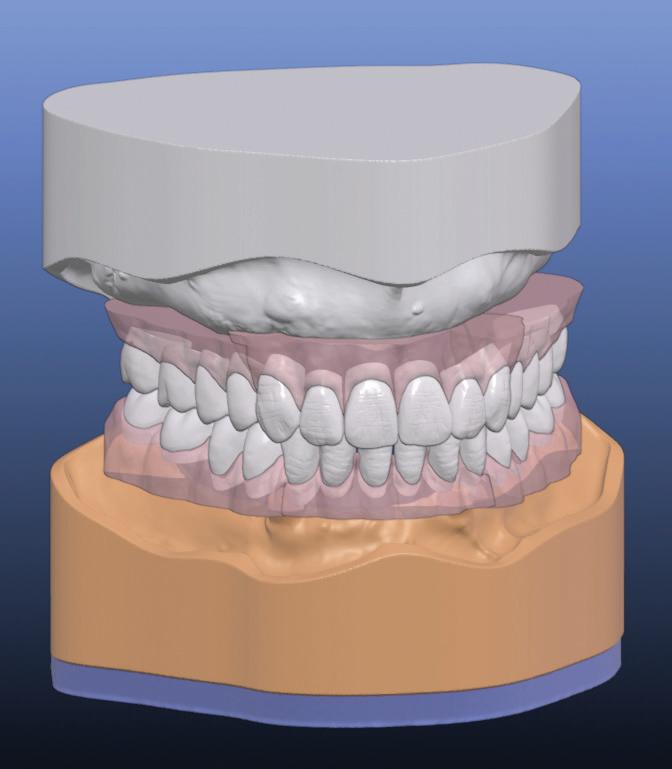

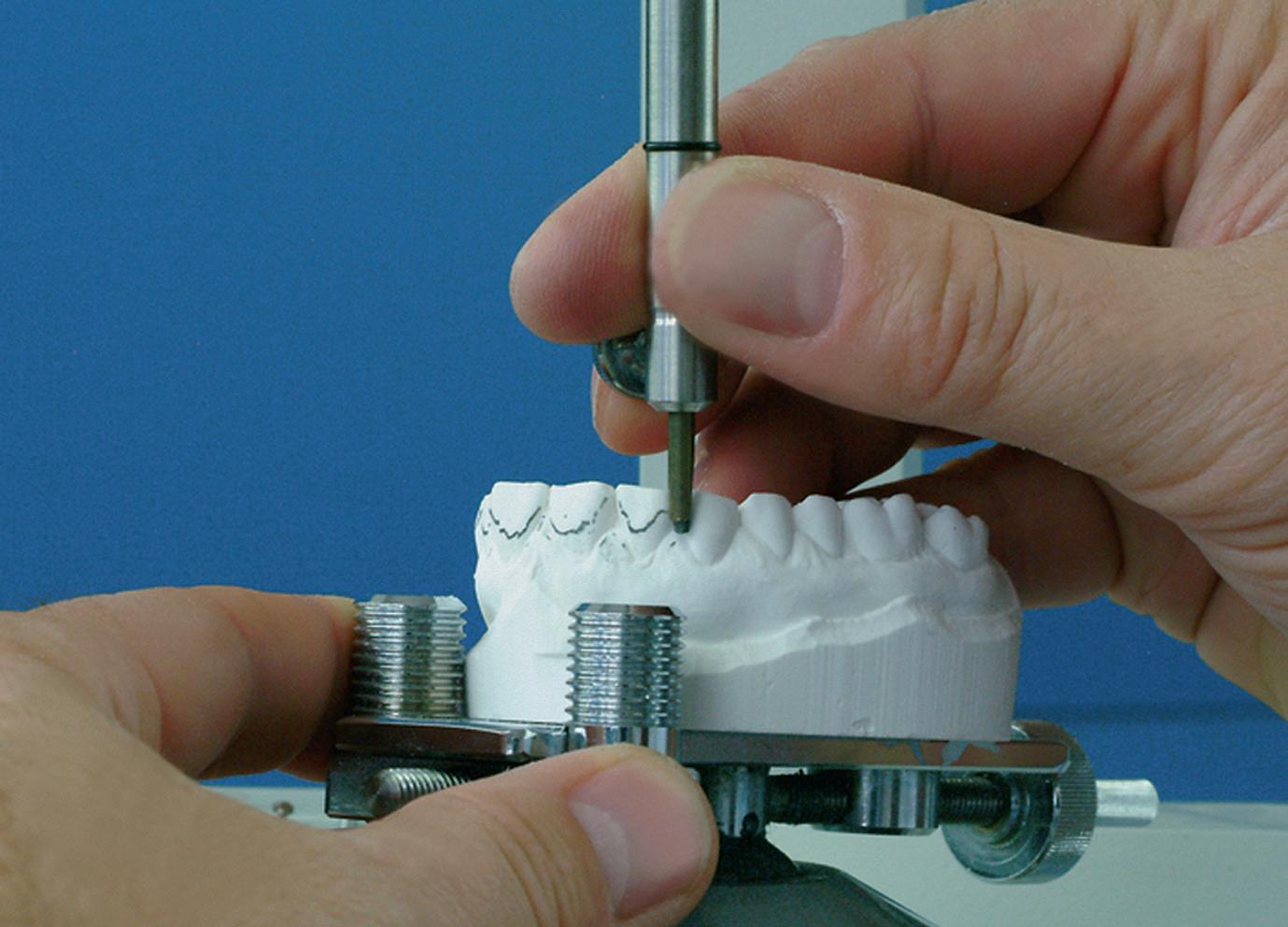

One way or another, you have to firstly digitise the anatomy and the records of the patient. This can be done in a number of ways but I will describe a method using a bench top scanner. A lot of people get confused about how a set of models are digitised into the correct bite relationship so this will surely enlighten.

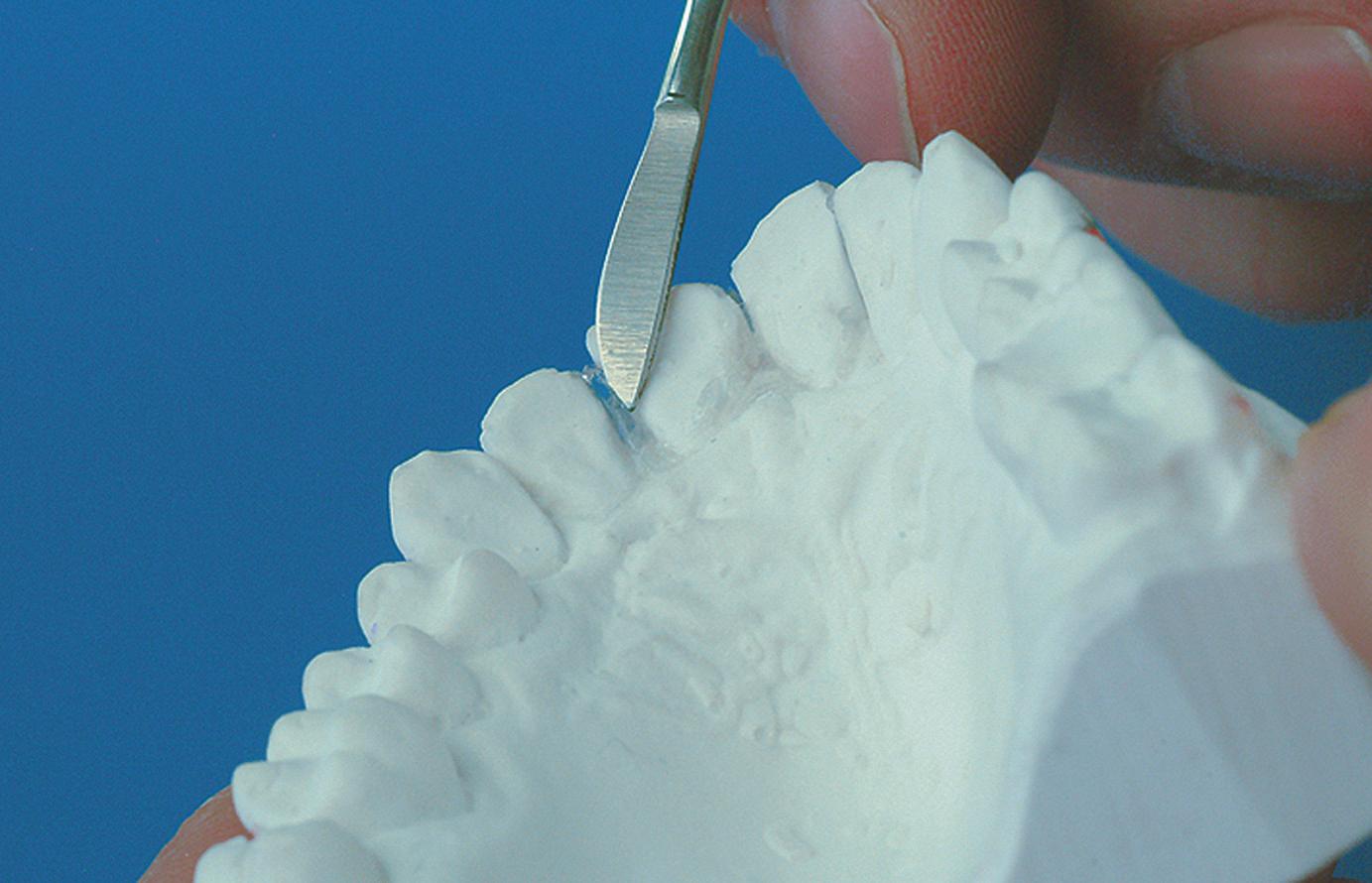

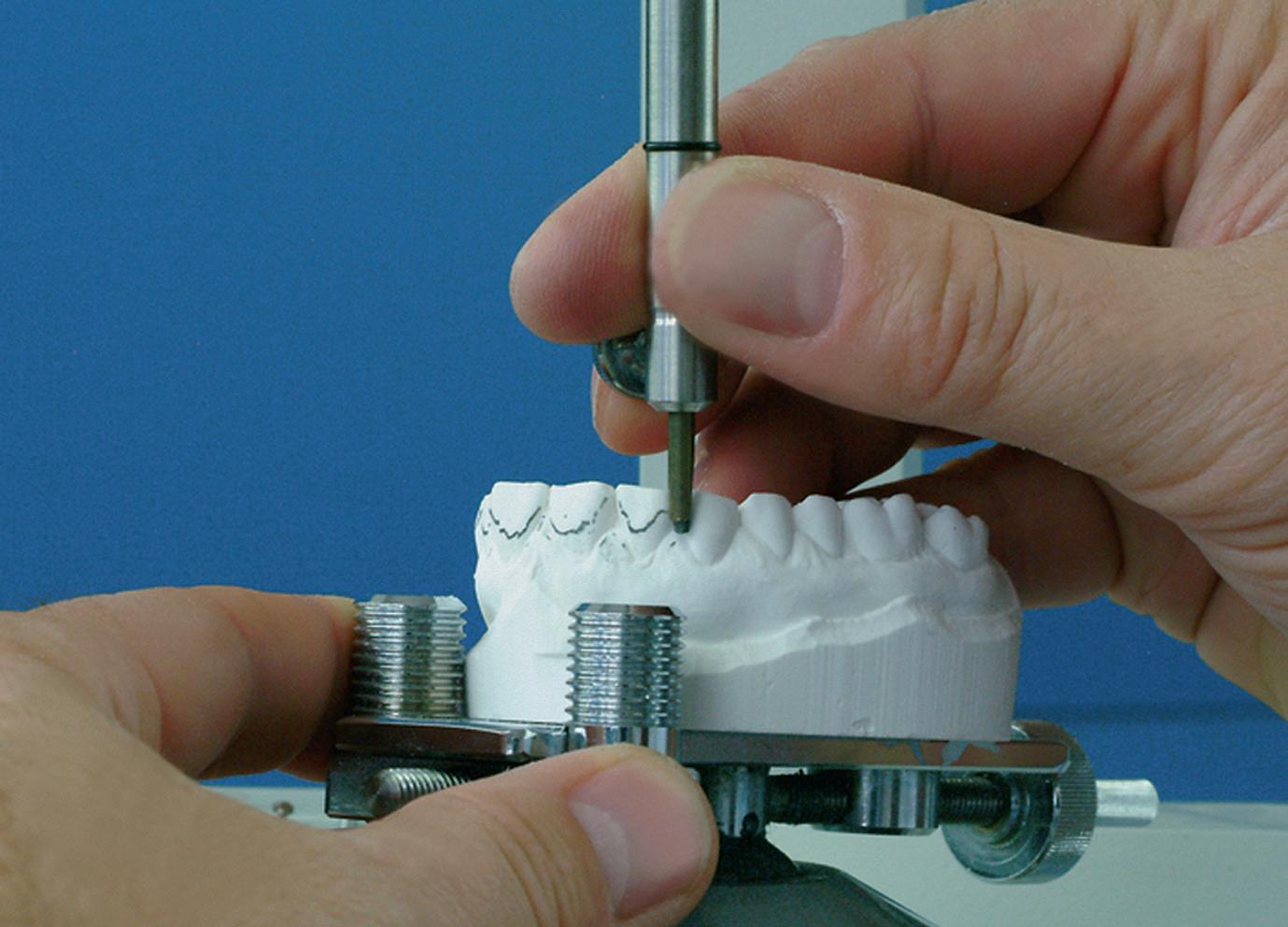

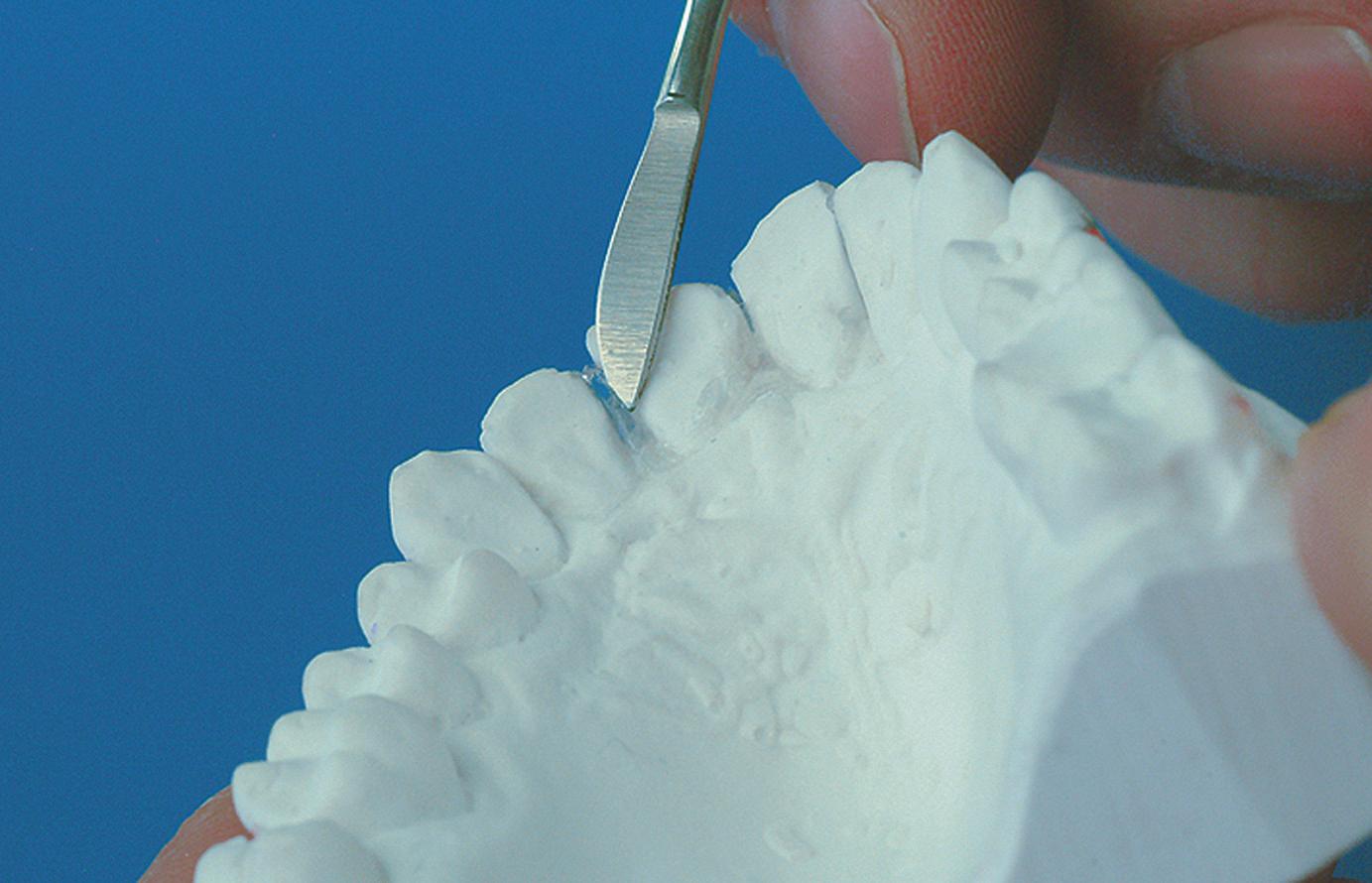

Firstly, take the models and the registration rims and inspect for intimate fit, as this is really important as it will affect the outcome just as it would making dentures in the traditional way. Next, on the land area of each model, make a series of markings (Figure 2). I generally use a carbide bur and create 8-10 marks on each model. This will become very important later when the scanning software calculates the reference bite scan to each model.

32 eLABORATE September/December 2022 cad | CAM

READ ME FOR CPD

Next, take the two models and the registration rims and place them together. I highly recommend spraying the wax rims with a scanning spray as wax tends to be reflective and may not scan well naturally. There is a new product on the market called xSCAN that does a great job as it evaporates in a short time and does not need washing off - highly innovative!

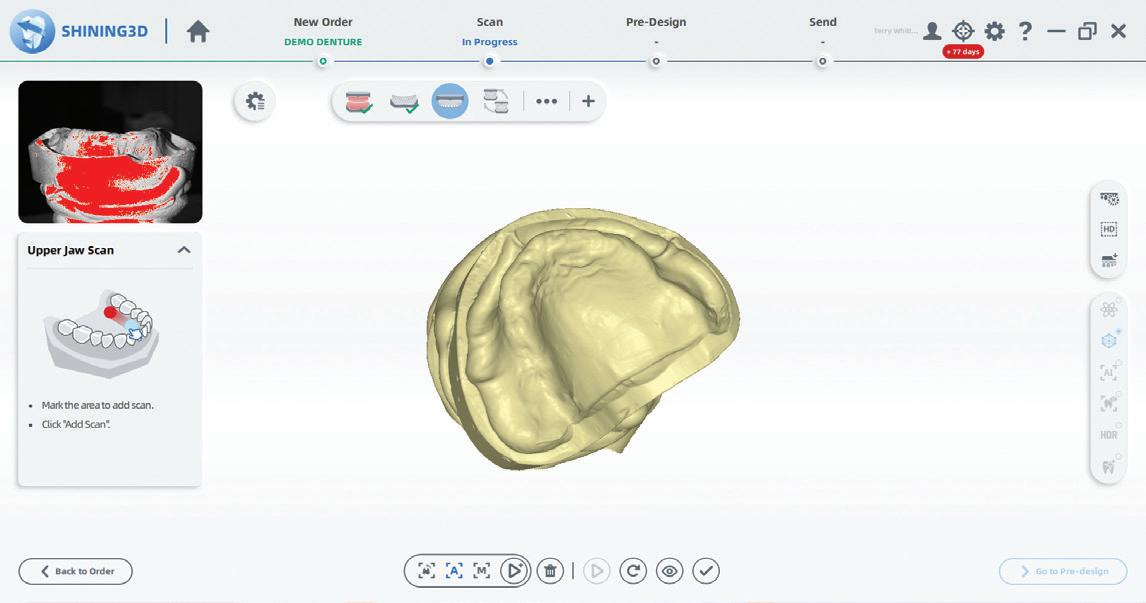

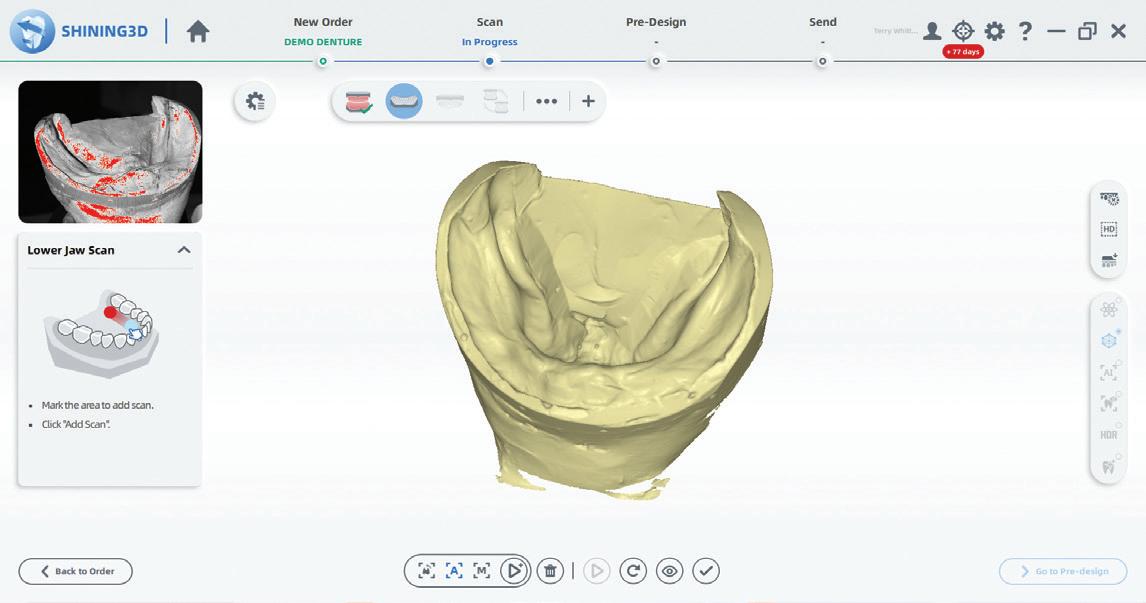

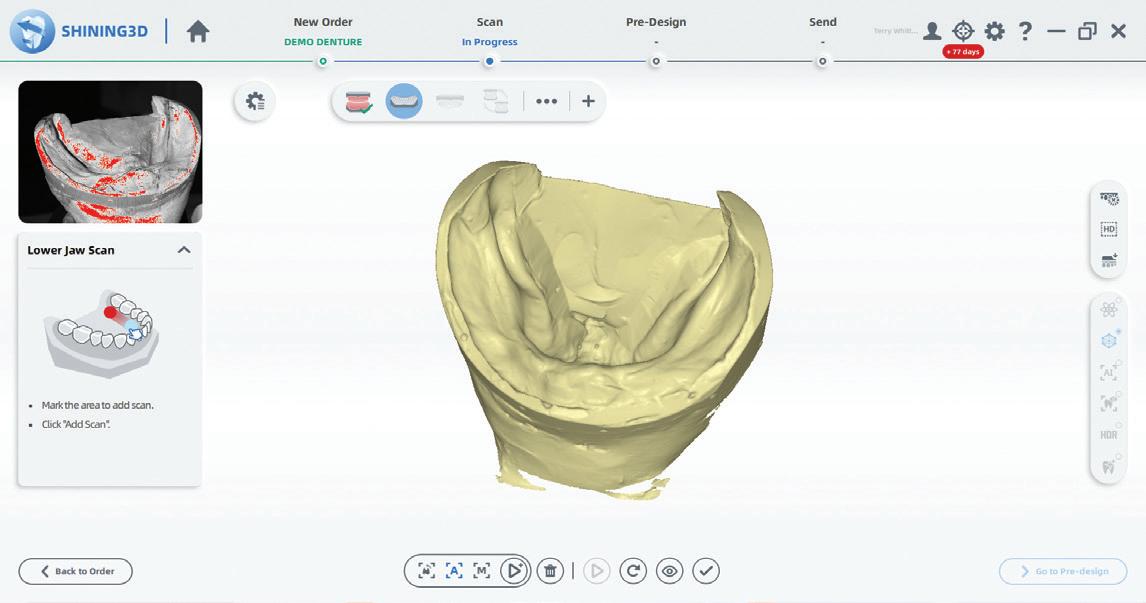

Of course, the sequence of scanning the component parts may vary from scanner to scanner, but the process is essentially the same for all scanners. I will describe the scanning process for the Shining 3D DSEX PRO Lab scanner here.

After setting up the prescription for scanning (Figure 4), you will be prompted to place the two models with rims in place onto the scanner and create a bite

Figure 2. It’s wise to add small marks to the art portion of the model as this will help register the model digitally.

Figure 3. Spray rims with scanning spary; Here I’m using xScan, a new brand that disappears after a few hours so it does not need washing off. xSCAN is from www.x-dentaldepot.com.

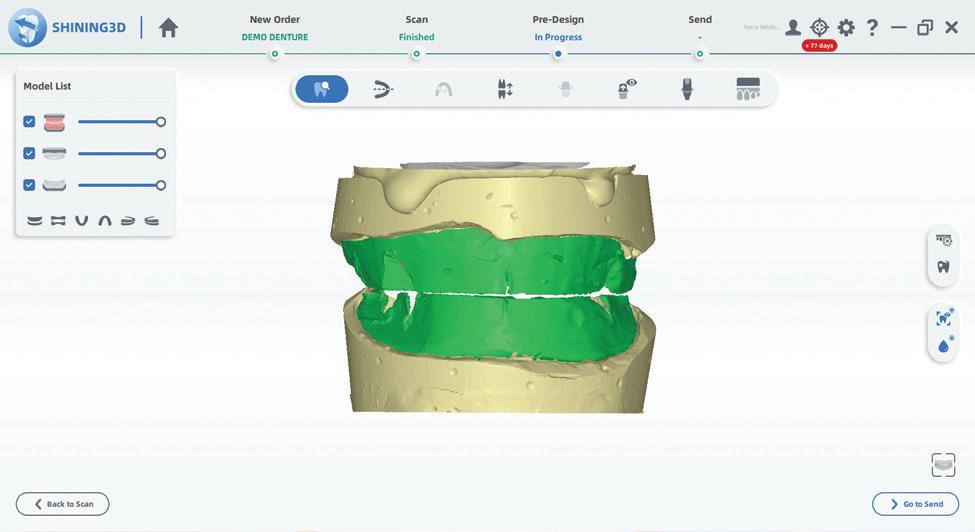

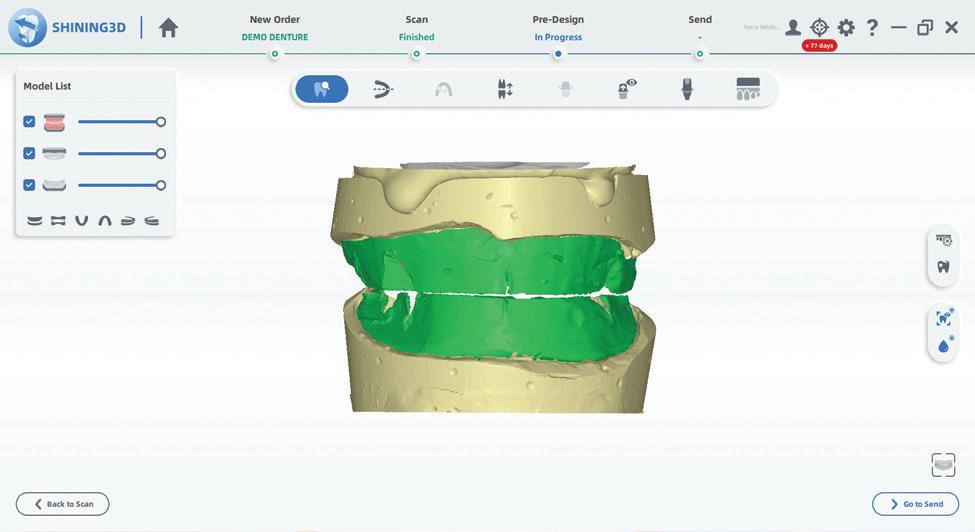

You can then trim the unnecessary data from the composite bite scan, leaving you with Upper Model; Lower Model; and a virtual Registration Rim ready to load into your CAD software of choice.

CAD software choices

scan. Next, scan the upper model, then the lower. All modern scanning software uses a wizard interface that will guide you through this process so in fact, it is quite straightforward.

After these three scans are taken, the software will accurately align the upper and lower model scans to the composite bite scan. The markings made on the land area are crucial here as it will guide the software to locate the upper and lower models to the correct orientation.

In case the auto alignment fails, which is rare, do not despair as manual alignment is always available where you will place corresponding virtual points on the composite bite scan and the respective model. It will align perfectly as long as all the steps are followed correctly.

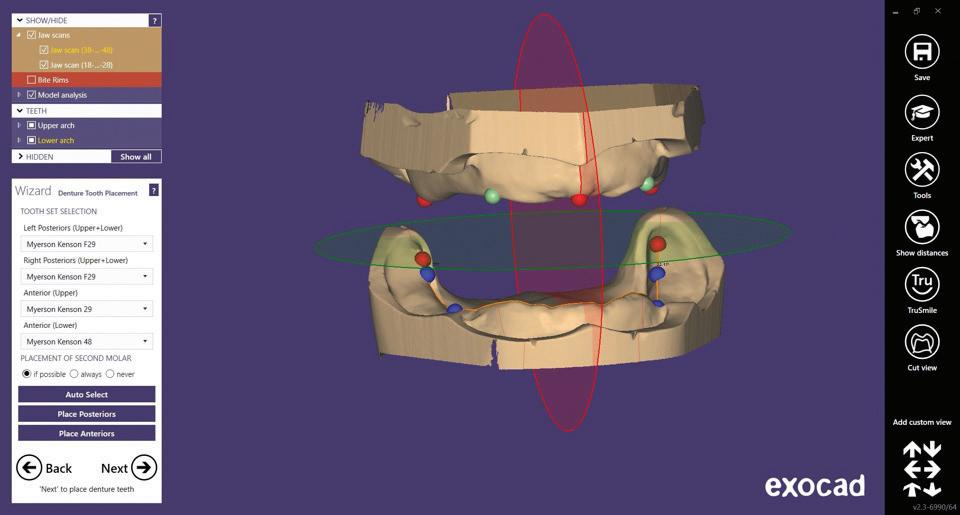

There are only a handful of Denture Design CAD software available and all have their pros and cons, however they all do essentially the same thing. The one you choose may depend on your scanning hardware or the software you already own as it may be available as an add on. Denture Design CAD software includes:

• 3Shape Denture Designer

• exocad Full Denture Module

• Blender for Dental

• Dentca Design

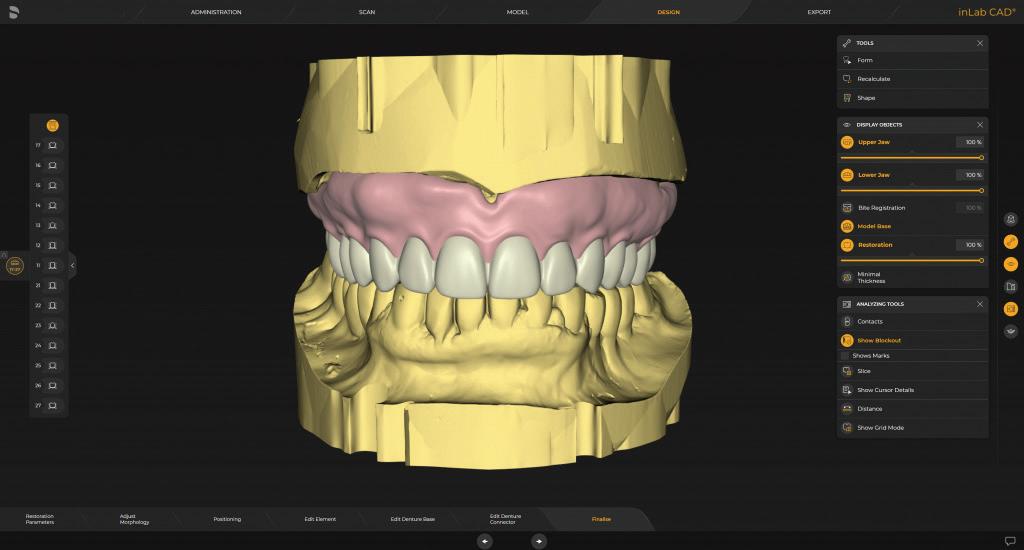

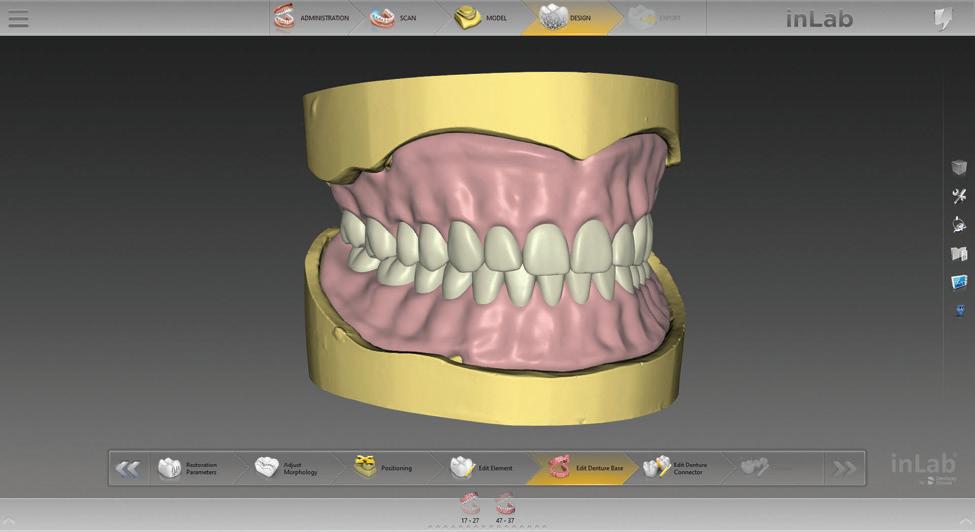

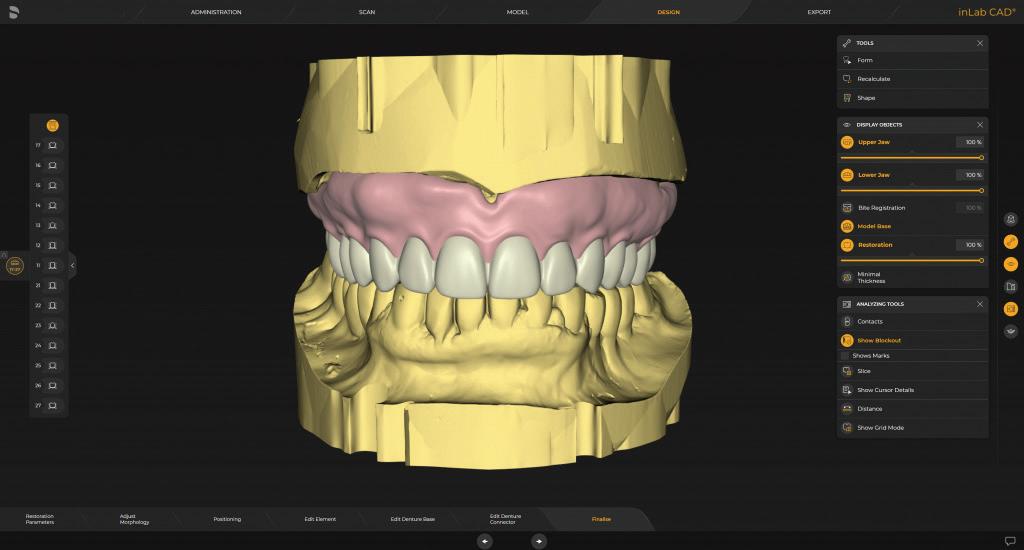

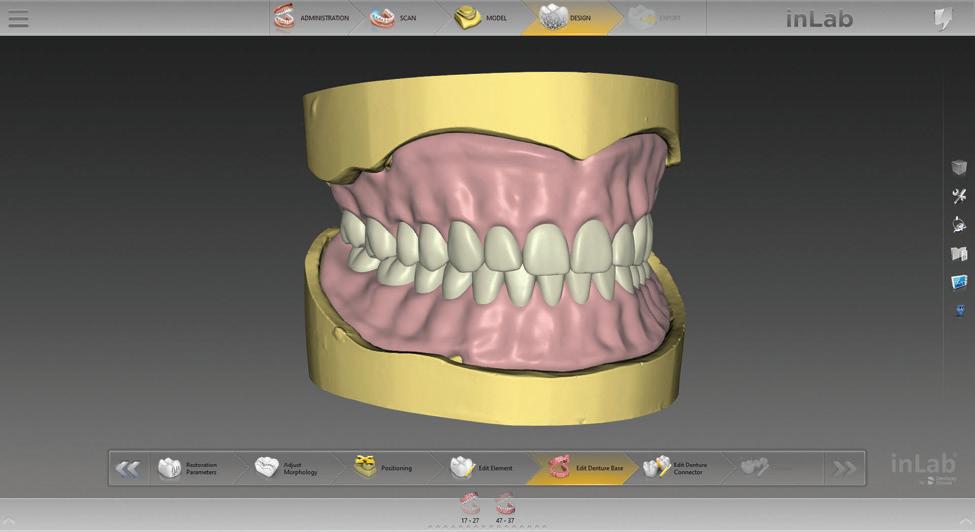

• Sirona INLAB Software 20.0

• Hypsocad

• Blue Sky Plan

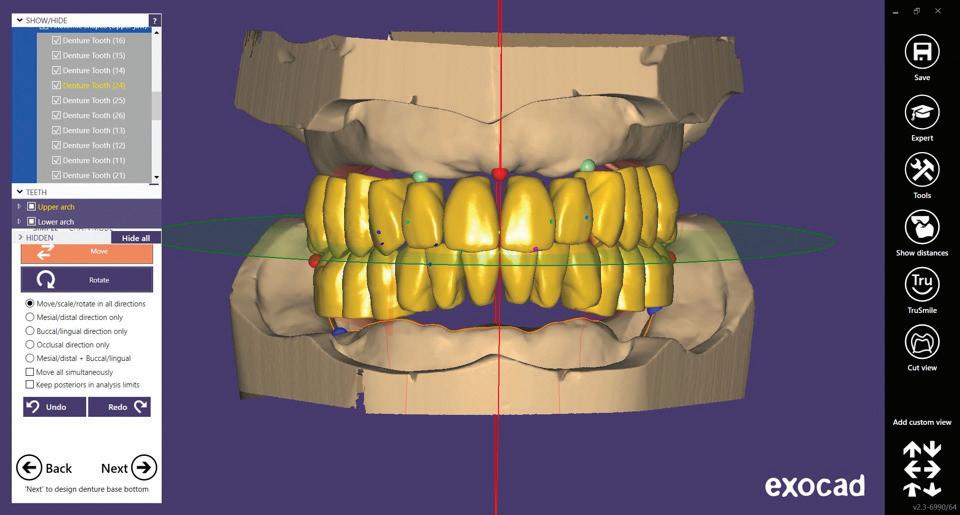

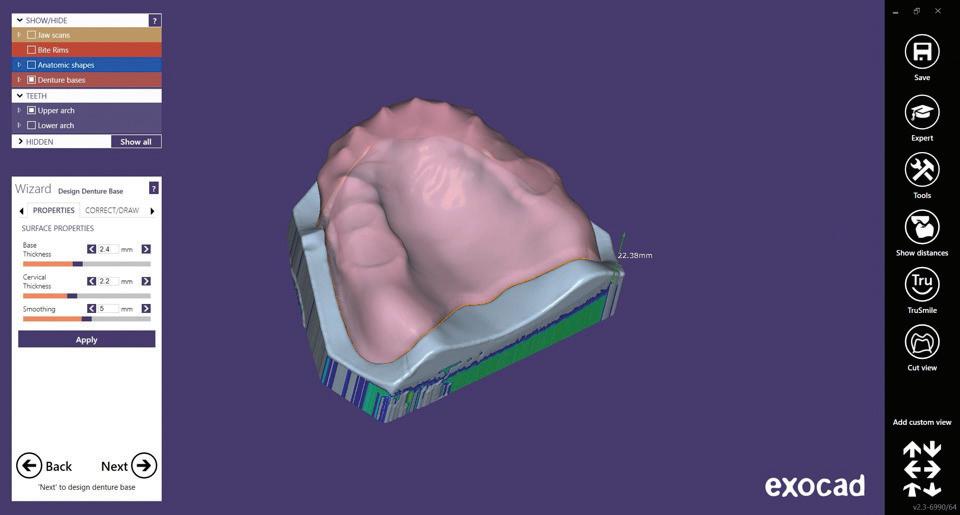

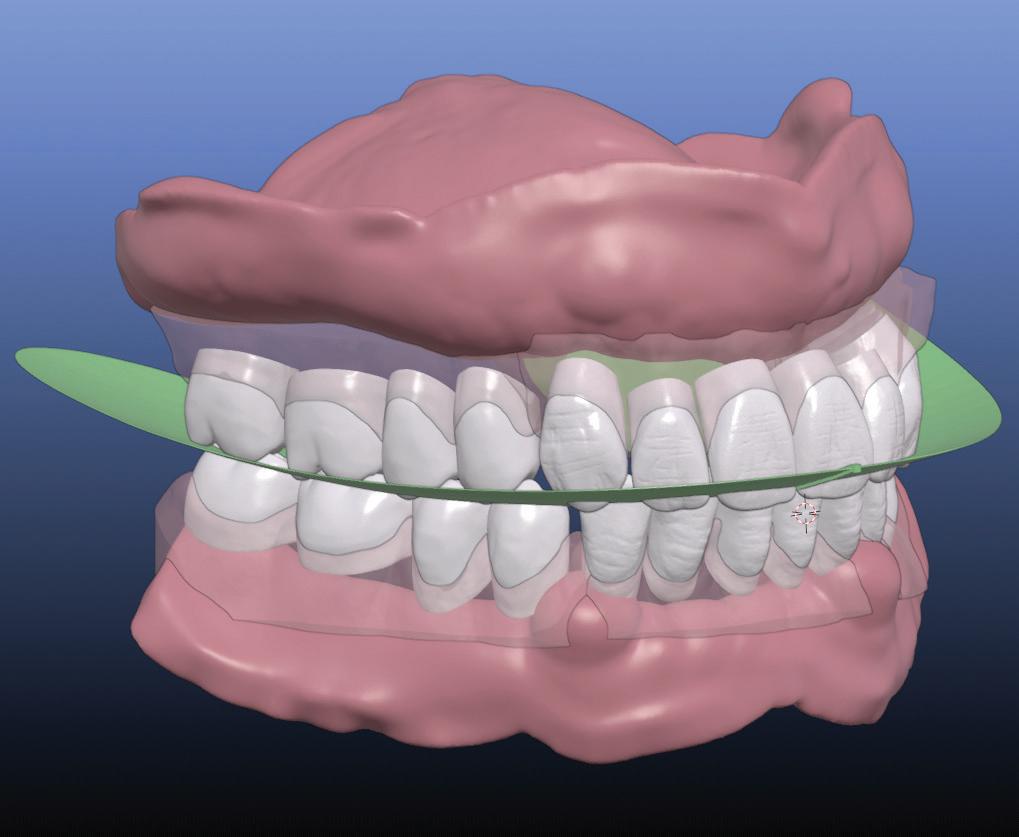

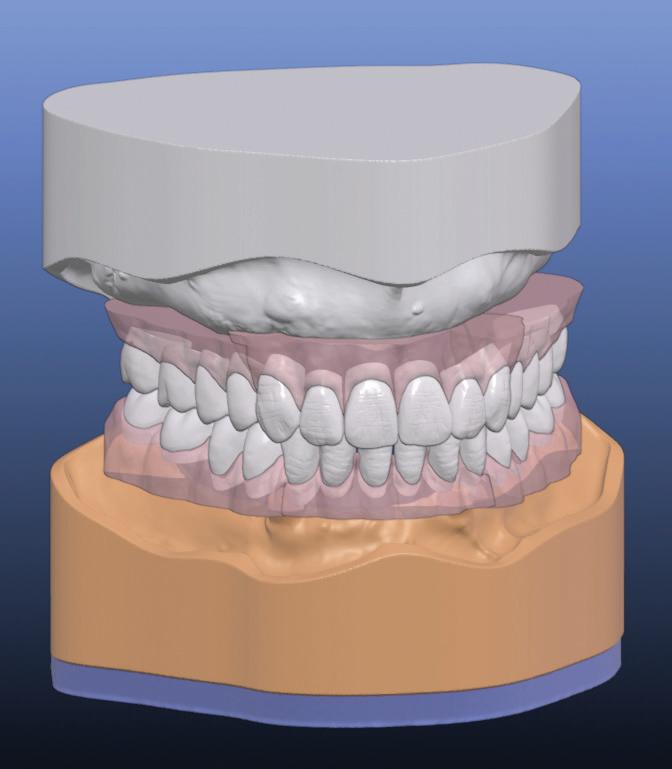

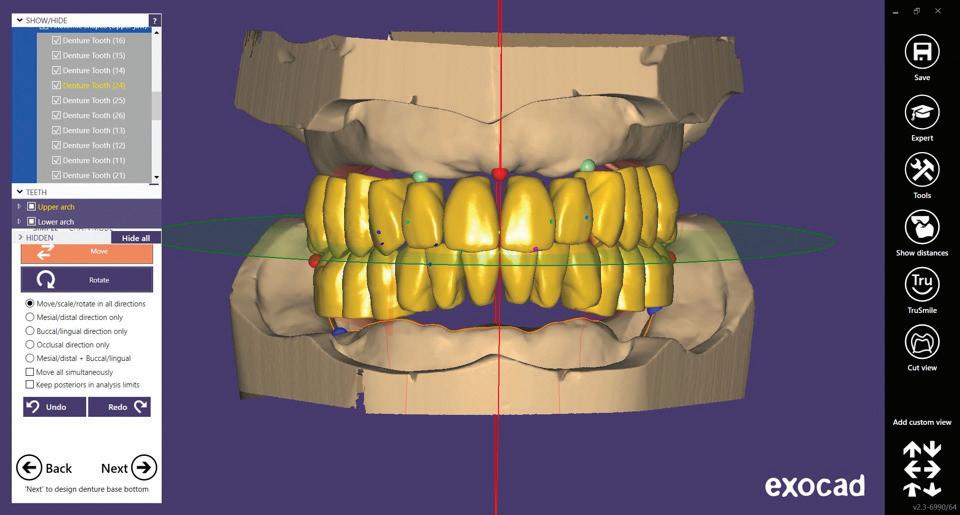

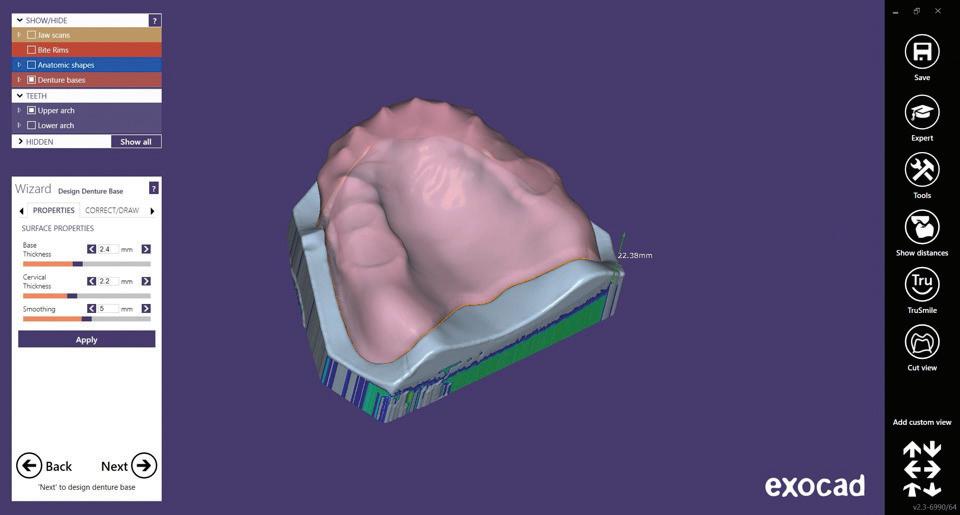

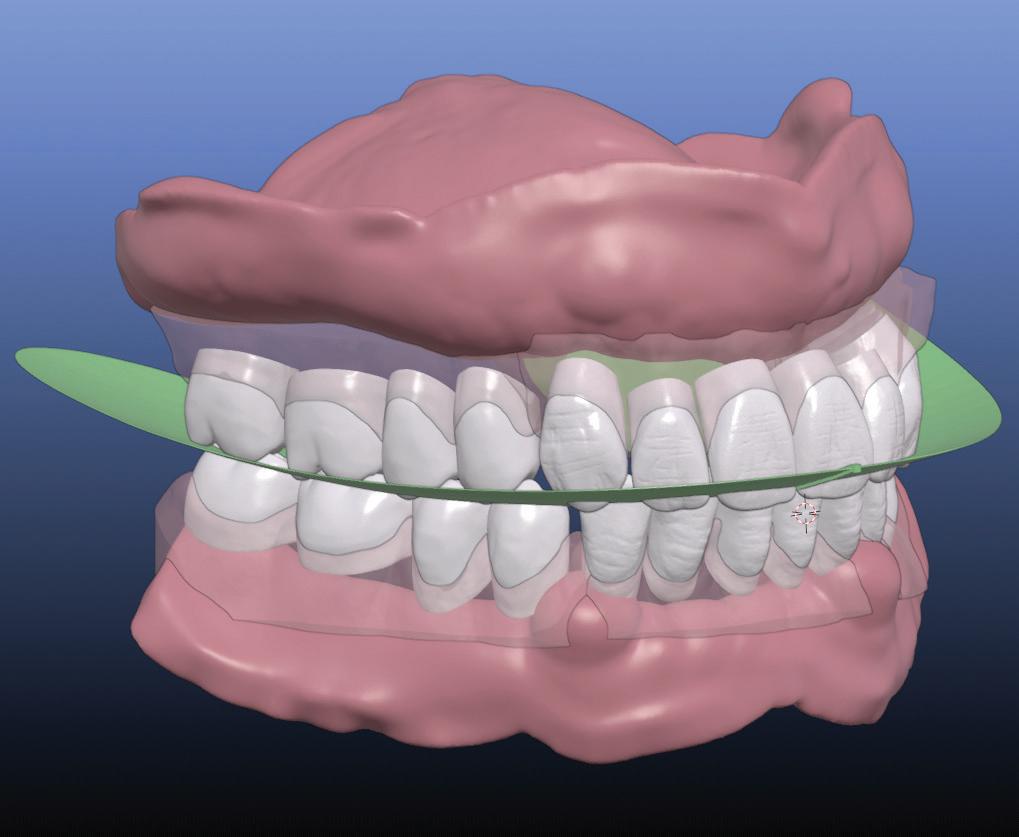

Out of all of these, 3Shape and exocad would arguably be the most popular and comprehensive software packages for designing dentures. Interestingly, they both work relatively similarly and you can see a basic pictorial run through in this article (Figures 11-23).

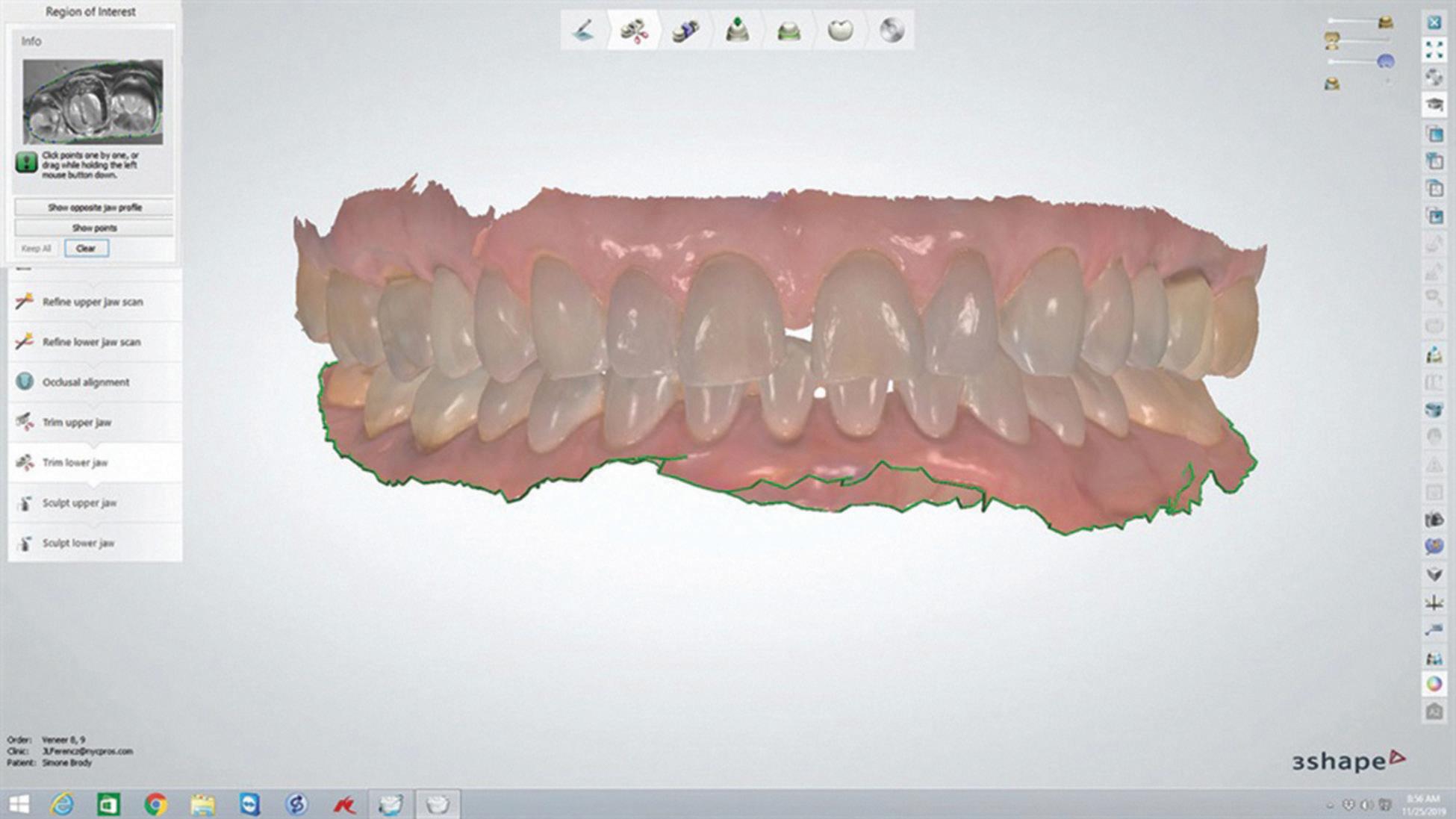

Briefly, for these two software programs you will establish the occlusal plane, mark certain landmarks on the scans such s midline, incisive papilla retromolar pad, etc.

September/December 2022 eLABORATE 33

cad | CAM

Figure 1. Registration rims on traditional articulator.

Figure 4 Setting up to scan models and rims in Shining software. Note the Scan Bite Rim button.

Figure 8. Lower scan.

Figure 10. Upper scan.

The software will then proceed to choose a set of teeth that are set by the landmarks. The teeth can then be manipulated in various ways depending on the library you choose. After setting your teeth, a baseplate if formed and can be saved joined to the teeth and exported as one file - great for a try in - or you can also save as individual files for printing or milling if desired.

Sirona inLAB may be a good choice for those of you who already have inLAB software and there is a new version that boasts ease-of-use and some innovative features. The design software has some interesting concepts that make it quite easy to use such as the biogeneric functions where the occlusion is optimised based on samples of many different teeth. This is only useful if you are to print or mill the teeth so forget carded teeth here. It may not be the most flexible solution but worth a look.

The team at Blender for Dental are always doing a great job and their new denture module is very interesting. If you’re a newbie at computers, it may seem a little daunting at first but they have great training and support so by all means have a peek at this too. It now includes the whole Ruthinium Mould library.

Dentaca Design is basic online denture design software that I urge everyone to also have a look at as it has an interesting approach to making digital dentures. It’s limited to certain teeth libraries but if these are what you use, its very well worth playing with.

Hypsocad is a pay by the month software suite that includes a denture design module. You need to have the “all in” software option rather than the lite version to be able to use the denture module but they do offer a 15 day free trial so I suggest you go check this out too.

34 eLABORATE September/December 2022

cad | CAM

Figure 5. Set up models and rims on scanner.

Figure 7. Lower model on scanner.

Figure 9. Upper model on scanner.

Figure 6. Bite rim scan.

Figure

Figure

Figure

Figure

Blue Sky plan is pay as you go software. It’s rudimentary but you can make dentures from it. If nothing else, download it and have a look at the plethora of tutorial videos on YouTube that will help you get your head around it. Interesting and free to play with.

About tooth libraries

This is where things start to get a bit tricky. Most companies that sell teeth on a card want to keep doing so; it’s a natural business decision to keep on selling what you’re selling. They don’t want to “give away” their libraries so people can just mill or print them and fair enough.

36 eLABORATE September/December 2022

cad | CAM

11. Alignment of models. Note the marks on the art portion of the models line up perfectly.

12. Scanned models with virtual registration rims.

13. Rims removed and relationship of upper and lower scanned models is maintained ready to transfer to CAD software of choice.

Figure 14. 3Shape software models and virtual rims imported.

17. Upper and lower denture design with bases.

Figure 15. Various landmaks on virtual models.

Figure 16. Tooth library placement (you can adjust as needed).

September/December 2022 eLABORATE 37

Figure 18. exocad with models and virtual rims imported. Figure 19. Landmarks placed after model analysis.

Figure 20. Teeth from library placed. Figure 21. Creating virtual base.

Figure 24. Inlab Software full upper denture.

Figure 25. Inlab software full upper and lower dentures.

Figure 22. Upper denture.

cad | CAM

Figure 23. Upper denture base ready to print - just export the file.

SCAN FOR VIDEO

Hence why there are only limited libraries available for digital dentures that allow you to “make your own teeth”. However, there are clever ways companies can offer their libraries but protect them from being manufactured in-house and still be used in a digital denture. Honestly, who wants to mill or print a set of individual teeth for a full denture? Nobody really as the manufacturer will generally do a

better job of making quality teeth. Often a manufacturer will offer the library to be only available in the mono block or try in stage then when you manufacture the final denture, you use their teeth. Sometimes if you try and save them for in-house manufacturing, you will be stumped as they intentionally will have artefacts added to them so you can’t produce them inhouse. You will have to check with the

Figure 28. Dentures designed with Blender for Dental.

manufacturer of your favourite teeth if they are available for your chosen software and how they are available to use.

Summary

s you can see, there are many choices for designing digital dentures in software. It can be a little overwhelming at first to get your head around it and there are multiple methods available to achieve the end product. It’s important to know these methods as you will come across scenarios where making a digital denture may be a challenge. It is not as plug-and-play as a lot of people may tell you because like anything new, there is a learning curve and the sooner you start the better prepared you will be for the future. The good news is that those with sound underpinning knowledge of denture fabrication will find it much easier.

A

In Part 3, we will have a look at printing dentures and the materials currently available and what’s coming next.

About the author

Terence Whitty is a well-known dental technology key opinion leader and lectures nationally and internationally on a variety of dental technology and material science subjects. He is the founder and owner of Fabdent, a busy dental laboratory in Sydney specialising in high tech manufacturing. Using the latest advances in intra- and extra-oral scanning, CAD/ CAM, milling, grinding and 3D printing, most specialties are covered including ortho, fixed and removable prosthetics, computerised implant planning and guidance, TMD, sleep appliances and paediatrics.

38 eLABORATE September/December 2022

cad | CAM

Figures 26-27. Blender for Dental denture designing.

Figure 29. Dentca Design online denture design.

Figure 30. Blue Sky Plan.

1300 878 336 Contact us today and we will show you how to integrate 3D Printing into your Laboratory fabdent.com.au PRINT MODELS IN 5 MINUTES UNBEELIEVABLE 1300 878 336 Contact us today and we will show you how to integrate 3D Printing into your Laboratory fabdent.com.au PRINT MODELS IN 5 MINUTES UNBEELIEVABLE Scan the QR code to see six models printed in 5 minutes on the amazing NBEE 3D Printer from UNIZ

Basic principles for thermoforming

By Peter Herring, Adv Dip Dent Tech, ACCDP

Figure 1. Fill narrow gaps between the teeth with Erkogum (transparent 110 844 / lilac 110 847).

Figure 2. Remove positive plaster bubbles.

Figure 3. Fill negative plaster bubbles and repair small defects with blocking out wax (transparent 725 080 / lilac 725 055).

Poured stone models should be of a hard gypsum (class 3). Particularly for pressure forming a hard and bubble free model is optimum.

When thermoforming the stone model can contain residual moisture but must not be wet. Excess moisture will inhibit air flow as well as causing possibly causing water damage to the forming equipment.

Figure 4. If the splint covers the gingival margin, relieve it with Erkoskin (625 050).

For a good adaptation, the gypsum model must be permeable to air. Some especially hard and dense artificial stones - particularly those used in the orthodontic field - do not always ensure this. As when using plastic models or treated models that are impermeable to air, this leads to incomplete adaptation because in some cases, air cannot escape completely between the model and the foil.

3D-printed models should be placed centrally on the model plate for adaptation (on pressure and vacuum forming units). 3D printed models that are to be thermoformed on the metal plate must have perfectly flat and complete bases in order to avoid model flexure and perforations in the foil. Thermoforming on granules can be a better option.

40 eLABORATE September/December 2022

|

thermoforming

TECHNIQUES

The removal of hard thermoformed materials very often leads to breakage of models. The use of super hard gypsum does not solve this problem; it is better to thermoform on a duplicated model.

Model preparation. Areas of the model which obstruct the thermoforming process have to be removed. Remove sharp plaster edges which may perforate the hot material.

Materials

Be familiar with the properties of the material you are thermoforming. The adaptation of thermoforming materials always means a stretching and hence a thinning of the original material thickness.

A rough guide is 1 cm model height corresponds to 20-25 % loss of thickness. It is useful to embed the models for thermoforming as far into the high grade steel granules so that only the area that has to be thermoformed plus 3-5 mm is visible. The granules allow for a fast adaptation of the thermoforming materials and is a very simple way to adjust the model height and inclination.

About the author

Peter Herring is a dental technician, prosthetist and a regular contributor to eLABORATE. He is the Australasian and Indonesian distributor for Erkodent products and spends his time between offices in Perth and Bali. He also operates a busy Australian lab dedicated to thermoformed appliances. He can be contacted at pjh@erkodent.com.au or for general enquires, call Freecall 1800-242-634.

September/December 2022 eLABORATE 41 telephone toll free

242 634 - email

online shop

www.erkodent.com.au www.erkodent.co.nz 24 hour online ordering Technical support, service and training Downloads, instructions & new products thermoforming | TECHNIQUES

1800

info@erkodent.com.au

www.erkodent.com.au

Figure 5. When there are large undercuts, mark the prosthetic equator and limit the extension of the appliance border.

Information contained in this section is provided by the manufacturers or distributors. eLABORATE does not assume responsibility for the accuracy of the data.

3D print permanent restorations

KeyMill™ Denture Base Disc

BEGO VarseoCrown Plus 3D is a ceramic filled hybrid resin for 3D printing. The chemical and mechanical properties of the versatile material make it ideal for a single crown, inlays, onlays, veneers and veneers on metal frameworks. Resin sedimentation is minimised for easy handling and no mixing or shaking is necessary with regular use. BEGO VarseoCrown Plus 3D comes in 7 VITA classical shades - A1, A2, A3, B1, B3, C2 and D3 - and fulfills all the requirements for a Class

II medical device for in-mouth use. Thanks to the full integration into the digital workflow and the low material costs, its a fast supply option with an excellent price-performance ratio. It is suitable for BEGO Varseo printers and validated on many 3D printers from well-known manufacturers, such as the ASIGA MAX UV.

Available: Alphabond Dental Tel: (02) 9417-6660 info@alphabond.com.au www. alphabond.com.au

Bredent – crea.lign® veneering resin

KeyMill™ high-impact denture milling discs featuring industry-leading Diamond D® denture acrylic are able to be perfectly and accurately milled for denture base applications, without any melting of the material during production. The final product is extremely strong, vibrant and aesthetic with minimal finishing or polishing required. The high impact material is less brittle

Synca - Fiber Force®

and more fracture resistant than PMMA denture discs and are compatible with 4-axis and 5-axis milling machines. The 95mm diameter discs are available in thicknesses of 25mm or 30mm in Original or Light Reddish Pink shades.

Available: Alphabond Dental Tel: (02) 9417-6660 info@alphabond.com.au www. alphabond.com.au

crea.lign veneering composites (from the Visio.lign system) are setting new standards in the dental industry for permanent veneering of metal, ceramic and polymer substructures. Available as a gel and a paste, the flowability of crea.lign improves masking and gap-free transitions to the veneer. The Benefits of crea.lign include natural opalescence; outstanding effect of depth thanks to specific refractive indices; Translucency (more options

than in ceramics); Design and layer structure according to natural teeth; Red-white aesthetics in 1 system: Matched crea. lign materials for individualising teeth and gingiva; Classic range of shades; Higher impact strength than ceramic (protects the antagonist by reducing the occlusal force) and more.

Available: Alphabond Dental Tel: (02) 9417-6660 info@alphabond.com.au www. alphabond.com.au

Available in a range of options, Fiber Force is the ideal product to reinforce any appliance. Pink Fiber Force Mesh is used primarily to fabricate reinforcement frameworks for newly constructed dentures, but can also be used for repairing dentures. Each package contains 2 sheets of material 53 mm x 80 mm, which is enough to fabricate at least 2.5 frameworks on average with full palatal coverage. Pink Fiber

Force Braided Rope is excellent as a denture repair material as well as to reinforce provisional and final fixed bridges or to reinforce orthotic appliances. Braid is available in 1mm or 2mm. Each pack consists of two strips 15cm long - total 30cm of material.

Pink Fiber Force LC Resin Syringe is used in the framework fabrication process to create tissue stops. lt can also be used to tack the framework to the model when using an injection process and as a repair acrylic to replace cold cure acrylic.