RMIT UNIVERSITY RESEARCHERS MAKE HYDROGEN STRAIGHT FROM SEAWATER

INTERNATIONAL MINING AND RESOURCES CONFERENCE (IMARC) 2022

MINERAL RESOURCES FIRST TO SECURE ELECTRIC MEVCO UTES

FINNISS LITHIUM MINE OFFICIAL OPENING

RMIT UNIVERSITY RESEARCHERS MAKE HYDROGEN STRAIGHT FROM SEAWATER

INTERNATIONAL MINING AND RESOURCES CONFERENCE (IMARC) 2022

MINERAL RESOURCES FIRST TO SECURE ELECTRIC MEVCO UTES

FINNISS LITHIUM MINE OFFICIAL OPENING

Updates on recent developments in the energy production, manufacturing, science, and finance industries drew our attention this quarter. We start with Beach Energy who recently announced the first two wells of its offshore Otway Basin campaign - Geographe 4 and 5 - were connected to the Otway Gas Plant and are now delivering gas into the East Coast market following the completion of the commissioning phase. The new wells effectively double the Otway Gas Plant production capacity which now has the well capacity to deliver 180 TJ/d.

Beach Energy Acting CEO, Morné Engelbrecht said the connection of the Geographe wells is an important step towards delivering on Beach’s growth targets at a time when the East Coast Gas market is potentially facing shortfalls as early as 2023. “Achieving first gas from these Geographe wells is an important milestone for Beach as it represents the first gas from our first ever offshore drilling campaign,” Mr Engelbrecht said. “This represents one of the first key building blocks towards our production growth target of 28MMboe in FY24.

Austin Engineering Limited has been selected by the Western Australian (WA) Government for a grant of up to $5 million to boost its advanced manufacturing program at its Perth-based operations in Kewdale. The grant funding has been allocated under the Government’s Investment Attraction Fund (IAF), which was announced in March 2022. The grant will support greater automation and production efficiency in Austin’s manufacturing facilities in Perth as part of the continued rollout of Austin’s global advanced manufacturing plan.

The Company launched the program in 2021 under the Austin 2.0 strategy to transform the business through increased efficiency and capability across its major mining equipment production facilities. The program has involved upgrades to its manufacturing equipment and processes in Perth using the latest technology and innovation to streamline and increase production and improve quality.

Climate change, clean energy and sustainability, building low emissions technologies and developing ethical artificial intelligence are some of the challenges being tackled by CSIRO, Australia’s national science agency, and the United States National Science Foundation (NSF) under a multi-million-dollar partnership. The recently established partnership between the two leading science organisations is aiming to accelerate joint research and initiatives in areas of mutual priority between Australia and the United States.

CSIRO Chief Executive Larry Marshall said the two leading science organisations have already enabled a number of opportunities across the two countries in only a year, launching this month an AUD$100 million Global Centers initiative, partnering in the areas of responsible and ethical Artificial Intelligence (AI) and developing sustainable materials for global challenges. “As national science agencies, CSIRO and the NSF are working together to build international bridges for national benefit, strengthening our science and innovation to improve lives around the world,” Dr Marshall said.

China’s gold reserves continued to rise January 2023. China imported 157t of gold in December 2022, a m-o-m rebound of 18t. With COVID-related border controls softening, international flights saw a notable bounce compared to previous months, making importing activities more convenient. Meanwhile, the still-elevated local gold price premium, albeit sliding from previous peaks, might be another contributor. This brings the annual total to 1,343t, a 64% y-o-y rise and the highest since 2018. 2022 has been a tale of two halves. On- and- off lockdowns in major cities during the first half suppressed local gold demand and imports. As COVID-controlling measures eased and the local gold price premium rose to a multi-year high, imports during the second half jumped.

Best regards

Len Fretwell

Len Fretwell Publisher/Managing Editor

EDITOR’S LETTER

INTERNATIONAL MINING AND RESOURCES CONFERENCE (IMARC) 2022

FINNISS LITHIUM MINE OFFICIAL OPENING

AI GROUP CUSTOM DESIGNED VISUAL AI SOLUTIONS

VOCUS TO ACQUIRE CHALLENGE NETWORKS

KEY ISSUES FACING THE ROBOTICS INDUSTRY IN AUSTRALIA

RMIT UNIVERSITY RESEARCHERS MAKE HYDROGEN STRAIGHT FROM SEAWATER

RESOURCES FIRST TO SECURE ELECTRIC MEVCO UTES

DIGGING & DRILLING

AUSTRALASIA

NEWS INQUIRIES

ADVERTISING INQUIRIES

EDITOR WRITERS

GUEST WRITERS

SPECIAL FEATURES

GRAPHIC DESIGNER

PUBLISHING INFORMATION

VISIT US AT FOLLOW US ON TWITTER

COVER

PO BOX 7566, CLOISTERS SQUARE WA 6850 TEL: +61 1300 284 637

INFO@DIGGINGDRILLING.COM

EDITOR@DIGGINGDRILLING.COM

LEN.FRETWELL@DIGGINGDRILLING.COM • MOBILE: 0417 001 080

LEN FRETWELL

DR NASIR MAHMOOD, MR SURAJ LOOMBA AND DR MUHAMMAD WAQAS

KHAN - RMIT UNIVERSITY AND MS REBECCA KNOL - SACOME CEO

EMMANUEL SOLOMON

ZARA MATHWIN

DIGGING AND DRILLING IS A TRADING NAME OF LF FAMILY TRUST

ABN: 97 893 623 301

WWW.DIGGINGDRILLING.COM

@DiggandDrill

IRON VALLEY ROAD TRAIN LOADING - MINERAL RESOURCES

IMAGE SOURCE: MINERAL RESOURCES

These high strength batteries are manufactured with tough internal components and materials to provide long lasting, superior power for commercial vehicles.

Each year IMARC continues to grow and gain momentum and the 2022 event was certainly no exception. The 2022 event held in Sydney saw 8,094 registrants, a 22% increase from 2019 and included delegates from 109 countries with 46 of them represented at a government or ministerial level. There were nearly 8,000 meetings requested through IMARC Connect with 82.8% of attendees reporting to generate business as a result of attending.

Throughout the three-day conference, 502 speakers took part in 339 technical talks, panel discussions, interviews, and strategic keynote presentations across six concurrent conferences that covered the entire mining value chain. Digital technology and mining innovation were amongst some of the most popular sessions looking at everything from data, minerals processing, safety, and automation.

Closely followed by discussions on the energy transition including renewables, critical and future facing minerals, hydrogen and technologies for decarbonisation including electrification. The underlying theme of collaborating on trends in mining, investment and technology towards a sustainable future resonated strongly with attendees and industry. Especially emphasised by presentations from solution providers and services linking how their offerings could help with the short and long-term decarbonisation and sustainability goals of organisations across the mining value chain.

Whilst all attendees benefited from the free to attend presentation series highlighting trade and investment opportunities from around Australia, Latin America, Canada, Saudi Arabia, Africa, and Indonesia, to name a few. In addition to topical presentations relating to ESG, sustainable mining principles,

social performance, mine closure and rehabilitation, creating a workforce of the future and diversity and inclusion.

Building resilience and transparency, progressing ESG and the energy transition, sustainable and collaborative solutions in digital technology and mining innovation, were just a few of the key themes highlighted. With an increase in insightful panel discussions and interviews this year, along with the return of the popular and engaging pitch battles, and the inclusion of the new Talk it Forward Dialogue Tables, IMARC was able to present ideas that will take the industry forward in various unique formats.

It is a pivotal time for the mining and resources industry as we look at significant global change and the push towards net zero. As one of the leading platforms for industry, IMARC continues to grow and adapt to our industries changing needs, IMARC is built in collaboration with Founding Partners, the Victorian Government, Austmine, AusIMM and Mines and Money.

There were many partners, speakers, sponsors, exhibitors, government delegations and visitors from all over Australia and from around the world who participated in the 9th annual International Mining and Resources Conference (IMARC) and the NSW Government hosted the event in Sydney for the very first time.

There were too many sponsors to list here but Industry Collaboration Partner, METS Ignited, and Plenary Partner, BHP have been part of IMARC since inception and have been strong contributors to the amazing growth you see reflected across the event. The Lead Sponsors were Capgemini, IBM, Sandvik, Ma’aden, Schneider Electric, the Victorian Government and Worley.

Anita Richards, Chief Operations Officer at BEACON said: “On behalf of the whole team, I would like to take this opportunity to thank you, our supporters, as we meet the challenges presented to us and continue to excel and do exceptional work.”

IMARC continues to bring together the whole mining and resources value chain across its conference and exhibition, something quite unique to us in Australia.

With a tranche of meetings and deals taking place between international and local ministers, ambassadors and industry heavyweights, IMARC again proved itself as the only place in Australia for the mining industry to get deals done.

The Honorary Madeline King, Australia’s Minister for Resources and Minister for Northern Australia met with a number of her international contemporaries after her presentation at IMARC. E Bandar bin Ibrahim AlKhorayef, Minister, Ministry of Industry and Mineral Resources, Kingdom of Saudi Arabia also met with a number of dignitaries and local company heads and completed a signing with the ASX in fine style.

“We are enjoying speaking to so many of you post IMARC and hearing about your IMARC experience, how many of you engaged and proactively shared ideas, listened to others to help us shape the future of the minerals sector. You are truly our greatest asset today and tomorrow, and we could not accomplish what we do without your support and leadership. We look forward to seeing you back in Sydney in 2023.”

With 46 international mining ministers, High Commissioner’s and ambassadorial support from Africa, Europe, North America, South America and Asia, IMARC has firmly cemented itself as Australia’s gateway to the world’s mining and energy deal makers.

IMARC will be back in Sydney from 31 October - 2 November 2023 celebrating 10 years of IMARC!

Enaex, a subsidiary of Chilean business group Sigdo Koppers, acquires 100% of MTi Group’s shares, a global leader in blasting consumables for mining. The deal, completed today after a negotiation process in August 2022, was valued at A$125 million, equivalent to US$85 million.

Enaex CEO, Juan Andrés Errázuriz, highlighted that “the acquisition of MTi Group is consistent with our strategic plan to continue strengthening our international presence in the main mining regions, in order to continue providing an excellent service to our customers“.

The company has a commercial presence in Australia, South Africa, the United States, and Latin America, maintaining an essential portfolio of clients, among which the following stand out: BHP, Anglo American, Newmont, Glencore, Rio Tinto, Barrick and Vale among others.

The company has four production sites in Australia, China, The USA, and South Africa.

This acquisition follows the recent incorporation as a shareholder of O-Pitblast, a Portuguese subsidiary of Finland’s Forcit Group. O-Pitblast provides leading technology for the global mining markets.

It offers a wide range of software to optimize excavation, drilling and blasting, enabling efficient control and management of mining activities.

In January 2023, global LNG imports fell by 1.4% (0.51 Mt) y-o-y to 36.71 Mt (Figure 63), which is the first y-o-y decline since February 2021. Similarly, global LNG imports declined by 3.4% (1.29 Mt) m-o-m.

The weaker y-o-y global imports was driven by lower LNG imports across all regions except Europe (Figure 64). Asia and Latin America and the Caribbean (LAC) accounted for the bulk decline in imports.

Source: GECF Secretariat based on data from ICIS LNG Edge

New research by the Electric Vehicle Council has revealed Australia is on track to soon pass the milestone of 100,000 electric vehicles, with more than 83,000 EVs estimated to be on our roads now.

The new research, contained in the Australian Electric Vehicle Industry Recap 2022, also finds that of the 83,000, 79 per cent are battery electric vehicles (BEVs) versus 21 per cent plug-in hybrids (PHEVs).

Only 44,000 EVs were in circulation at the beginning of 2022. The new report also notes that the number of EVs purchased increased by 86 per cent in the last year, with 3.8 per of all new cars purchased being electric.

The new report also notes the number of public chargers has increased from 3,413 in 2021 to 4,943 in 2022. Fast chargers are up from 231 to 365.

TotalEnergies and Corio Generation, two of the world’s leading developers of offshore wind and renewable energies, have announced the creation of a joint venture to develop the “Formosa 3” wind farms off the coast of Taiwan.

As part of this agreement, Corio will retain a majority stake of 50% (plus 10 shares) in the project as lead developer.

The announcement comes as the Taiwan Energy Bureau confirmed in late December 2022 that Formosa 3 ‹s Haiding 2 wind farm had been awarded 600MW of grid capacity after the first phase of Taiwan›s third round of auctions. Composed of three wind farms located off Changhua County -Haiding 1, 2 and 3-, in Changhua County in western Taiwan, the Formosa 3 project received the green light from environmental authorities in 2018, for a authorized capacity of approximately 2 GW.

The development of this wind project will contribute to Taiwan’s energy transition ambition and represents a multi-billion dollar investment from project partners and financiers until construction is complete.

Future investments will be made in proportion to the partners’ participation in the project.

Custom Cars Motor Trimmers is a Family owned and operated trimming company offering superior auto and boat upholstery finishes, seating modifications and installations since 1984.

Custom Cars Motor Trimmers design, build and install specific custom modifications in their own engineering shop with comprehensive welding facilities. From start to finish Custom Cars can help, so much so we are also recognised as a qualified repairer by the Department of Transport.

Drawing on 40 years plus industry experience and knowledge, director Brian and his talented team have extensive skills, establishing them as the ‘go-to-team’ by the major automotive and transport industry leaders, including DoTWA and MTA WA, major truck dealers such as Major Motors, Daimler Trucks, WA Hino, TL Engineering and Osborne Motorbodies.

DOT/ADR Authorised Installer

Authorised Repairer

NO 1 STRATOS DEALER

Lic No. MRB967

3 Fairford Street, Bassendean WA 6054

For consultations or a quote contact: Brian or Michael on 08 9279 3066

E: michael@customcars.net.au

W: www.customcars.net.au

Reduce your diesel generator run time while eliminating expensive AC underground cable runs. Bolt together concrete base lockdown system to give cyclone rating, no need for expenssive earthworks on site.

• Gate houses

• Accommodation units

• Site offices

• Lighting towers

• Power tools and equipment

• Split system air conditioning

Unique Hire can assist with the hybrid power systems, as well as containerized reverse osmosis systems and hydration units, all compatible with our power systems.

• Australian Made 40-foot container with switchboard and powerpoints

• 3Phase Victron Quattro 30kVA Inverter Charger

• Pylontech Lithium Battery Bank customisable to suit your application (minimum 60kWh storage)

• 6 x 250/100 Victron SmartSolar MPPT (allows for plug and play of additional solar panel arrays)

• Victron Cerbo GX System Monitor with Online Access

• 11.7kW Solar Array – 30x 390W JA Mono Solar Panels.

• Incredible Unique Automatic Foldaway Solar Panel design

• Fully wired and programmed so that you can plug and play

• Auto start backup diesel generator

Our Portable Power Stations can be dropped onto site,wired into your switchboard & are ready to provide immediate power!

Call Unique Hire & Sales

+61 499 020 152

sales@uniquehirewa.com.au

Life

When you purchase an Off grid hybrid solar power module you won’t be left in the dark. We are proud to provide specialised lifetime support with every system.

Know how your system is performing with our advanced monitoring tools & allow your generator to autmatically start too.

Core Lithium has announced the official opening of the Finniss Lithium Mine, the Northern Territory’s first lithium mine in production and Australia’s only lithium mine outside of Western Australia.

Core Lithium owns 100% of the Finniss Lithium Project, located just south of Darwin Port in the Northern Territory. Finniss hosts JORC 2012 compliant Mineral Resources of 15 million tonnes (Mt) at 1.3% lithium oxide (Li20).

The flagship Finniss Project lies within one of the most prospective areas for lithium in the NT - the Bynoe Pegmatite Field - and covers over 500km2 of granted tenements.

The Finniss Project has substantial infrastructure advantages; being close to grid power, gas and rail and only 88km trucking distance by sealed road to Darwin Port – Australia’s nearest port to Asia.

In mid-2021, Core completed a Definitive Feasibility Study (DFS) on Finniss, the details of which can be found in the ‘Definitive Feasibility Study’ section below.

Subject to continued favourable market conditions for lithium, financing and a final investment decision, Core expects to commence construction at Finniss before the end of 2021, with first production anticipated before the end of 2022.

In early 2020, the Northern Territory Government formally approved Core’s Mine Management Plan for the Finniss Project, the final regulatory hurdle required for the commencement of site activities.

This was closely followed by the receipt of an offer from the NT Government of a 25-year mineral lease for the BP33 Deposit, in addition to the receipt of a mineral lease for Grants which was awarded to Core in 2019.

In addition, the Northern Territory Environmental Protection Authority has confirmed that Core’s notification of alteration to extend the operation of the Grants open pit mine and proposed 1mtpa dense media separation (DMS) process plant at Finniss to seven years would not be subject to a public environment report or environmental impact statement, further clearing the way for construction and subject operation at Finniss to commence.

In March 2021, Core met a major milestone when the Federal Government awarded Major Project Status (MPS) for the Finniss Project. This is considered the Commonwealth’s recognition of the strategic significance of a project to Australia, and provides Core with extra support from the Major Projects Facilitation

Agency including a single-entry point for Australian Government approvals, project support and coordination with state and territory approvals.

Core has also partnered with global environmental and sustainability consultants ERM Group to provide a carbon footprint evaluation, life cycle analysis and sustainability assessment for the Finniss Project.

A greenhouse gas assessment of the initial seven-year mine life of Finniss identified that the Project aligns well when compared on an emission intensity level (total emissions per tonne of product produced) to published emission intensities for other spodumene concentrate production facilities in Western Australia.

In mid-2021, Core released a DFS for the Finniss Project, marking a major milestone in its goal to become Australia’s next major lithium producer by the end of 2022.

The study highlighted an average production of 173ktpa of high-quality lithium concentrate at a C1 opex of US$364 per tonne, and at a low start-up capital cost of A$89 million thanks to the incorporation of a simple DMS processing plant in the Project’s design.

This will enable the Company to produce high-quality, coarse concentrate using simple gravity DMS processing.

Based on the development of the Ore Reserves within the Grants and BP33 deposits, standard open pit mining operations and the construction of the simple 1Mtpa DMS process plant, Finniss will have capacity to produce up to 197ktpa of lithium concentrate with robust margins.

With a modest pre-production capex of $89 million, strong cash flows and a quick capital payback period of two years, the Finniss Project is on track to become one of the lowest capital intensity lithium projects in Australia.

This will ensure Core is well placed for a first-mover advantage in the Bynoe Pegmatite Field, while laying a solid foundation for the building of a long-term lithium production hub.

Core has established offtake arrangements with various parties and is also in the process of finalising further agreements with other highly interested parties.

China’s Sichuan Yahua Industrial Group (Yahua) has committed to 75,000tpa of product from Finniss over an initial four-year period, with extension options attached.

It is worth noting that in early 2021, Yahua signed a deal to supply battery-grade lithium hydroxide to US EV manufacturer Tesla over the next five years. It is expected that the Finniss Project will be a key source of the raw material for Yahua to meet that commitment.

Core also holds a non-binding Memorandum of Understanding (MOU) with Geneva-based Transamine Trading for the supply of 50,000tpa of spodumene concentrate from Finniss over a five-year period.

A longer-term objective of Core Lithium is to assess and explore the potential of adding downstream processing opportunities in the Northern Territory to accommodate the Finniss Project.

Core is considering the downstream value potential given the Project’s synergies with the adjacent Middle-Arm industrial infrastructure near Darwin, as well as the alignment with Australia’s Modern Manufacturing strategy, and the rapid expansion of global lithium-ion battery (LIB) supply chains to meet the demands of the ever-increasing EV and renewable energy markets.

Combining state-of-the-art Artifical Intelligence and Deep Machine Learning Algorithms, our AIVI video-based real time monitoring technology can be customised to alert and report in real time a specific set of processes & threats, minimising plant and staff down-time and increasing safety and productivity.

Custom AI Alert Algorithms include:

UNCOVERED LAND DETECTION

Uncovered bare soil on site can be identified through a video algorithm.

RESTRICTED AREA BREACH

Sensitive areas can be monitored in real-time. Intrusive work behaviour tagged with individual worker ID detected and reported.

CROWD DETECTION

Monitors and recognises the number of people in an allocated production area and reports any overrun situations.

PPE DETECTION

Used to identify whether workers in the construction area are wearing protective clothing such as hard hats & reflective vests.

HUMAN BEHAVIOR ANALYTICS

Recognise hazardous situations by detecting specific human postures: raised arms, man down detector, crouching, and social distancing.

CHECK-IN OF VEHICLES

Recognises vehicles in specified areas and reports license plates when applicable including,real-time driver identity.

UNCOVERED DIRT VEHICLES

Vehicles can be indentified by license plate and body colour and other registered information.

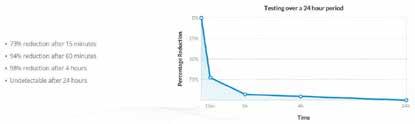

Works 2400 X’S faster than other Hepa Filters

Proactive 24/7 air purification solutions for making in-door settings safer against the coronavirus and other harmful surface and air contaminants.

Puradigm has tested successfully on the actual SARS-CoV-2 virus, including original, BETA and DELTA variants.

Unlike other systems, Puradigm’s “active” technology means pathogens are not required to pass through its system to actively and safely purify both air and surfaces in any room. Instead, Puradigm replicates nature’s natural process indoors by creating charged particles that seek out and attack pathogens in the air and on exposed surfaces.

Work thousands of times faster than an average filtering device

Gets to the source of contamination

Treats the air in between people, rapidly purifying each and every breath at its source

Proven to reduce the risk of COVID-19 transmissions

Cleans surfaces

Effective in the reduction of mould and other pathogens

Standard Filters

Time taken to target most pathogens in a room = 4000 seconds (over 1 hour)

seconds

Puradigm has been proven to inactivate a staggering 99% of surface infectious COVID-19 particles in just 4 hours. After 24 hours of operation, it has also been found to eliminate the virus by 100%.

Successfully tested 3 times against the actual SARS-CoV-2 virus (including the original, Beta and Delta variants), Puradigm is the most validated purifier on the market.

Works within seconds - 2400 times faster on airborne pathogens than standard HEPA filters. This allows Puradigm to provide a superior level of air and surface purification to any indoor space.

Puradigm’s air and surface purification systems are considered to be the most technologically advanced on the market.

Vocus to acquire private LTE/5G provider Challenge Networks, extending ‘Land, Sea, and Space’ network strategy.

Vocus has announced its long-time partner Challenge Networks – a market leader in designing and deploying private mobile networks – will become part of Vocus. Vocus has signed a contract to acquire Challenge Networks, which builds on Vocus’ strategy to provide secure, high-capacity connectivity to Australian enterprise and government customers – wherever they are – through its national fibre, satellite, and now wireless network infrastructure.

The addition of wireless network capability complements Vocus’ $1 billion investment strategy, which includes capacity upgrades to the company’s existing network and the deployment of substantial new fibre infrastructure – including the Horizon and Highclere projects in the north-west of Australia. It also follows the company’s launch of Vocus Satellite – Starlink in December, after Vocus signed an agreement with Starlink to offer low earth orbit satellite (LEO) services to enterprise and government customers across Australia.

As a leading provider of private LTE/5G networks, Challenge Networks designs, deploys, and operates private 4G and 5G networks for customers that require secure, reliable, highcapacity wireless coverage to support operational technology (OT) use cases on their sites.

These custom-built mobile networks can be deployed on sites such as mines, hospitals, universities, floating platforms at sea, vessels, ports, manufacturing and logistics sites, or any other special-purpose site that requires highly reliable and secure wireless connectivity.

“Challenge Networks’ expertise in deploying private LTE is a perfect match for Vocus’ extensive experience supporting Australia’s government, defence, utilities, and resources sector customers with our fibre network and low earth orbit (LEO) satellite capability – both of which provide coverage in areas others don’t,” said Vocus Chief Executive – Enterprise & Government, Andrew Wildblood.

“Through this acquisition, Vocus will be able to provide fibre or LEO satellite connectivity to the perimeter of a site, and then through a private LTE network provide campus-wide wireless connectivity for applications such as autonomous vehicles, IoT sensors, building management systems, voice calls, push-totalk devices, smartphones, tablets, and computers anywhere on the site.”

Challenge Networks co-founder Simon Lardner will join the Vocus business, along with Challenge Networks staff, and said the team was excited for the next chapter of the business’ growth. Wireless industry veteran and Challenge Networks co-founder Jack Smyth will retire from the business.

“Private LTE and 5G puts the control, coverage, reliability and performance characteristics of mobile networks in the hands of companies that really need dedicated, missioncritical communication, without having to compete for network resources with public users,” Mr Lardner said.

“We design, build and operate networks that are well dimensioned for a site to give optimal coverage and performance – even in remote locations such as the Pilbara, or off-shore platforms at sea,” he said.

Private mobile networks are a rapidly growing area of the telecommunications sector, with a forecast compound annual growth rate of 18.6% globally and a market opportunity of $A14.88B by 2029.

Vocus’ acquisition of Challenge Networks will enable it to build more private LTE and 5G networks for customers and then provide them with a fully managed service on a service-billed basis rather than customers’ having to fund the infrastructure build.

The acquisition will give Vocus a significant inventory of mobile spectrum, with a geographic focus in the resource-rich regions of Western Australia, Queensland, South Australia, and the Northern Territory.

This will enable Vocus to deploy private mobile networks to companies with operational technology requirements in these regions without regulatory delays and with superior mobile service levels and bandwidth utilisation. Private mobile networks provide many of the technology advantages of public mobile networks, without the potential downsides.

Public mobile networks can become unreliable in peak hour, have blackspots in regional areas, and can become congested if towers have inadequate backhaul connectivity. Wi-Fi may suit some non-critical environments, but the cost of retrofitting inbuilding cabling for access points can be high and the system still may not cope with many hundreds or thousands of devices connecting at once.

Private mobile networks, in comparison, are engineered to provide perfect coverage for their target site, have superior security and performance, are dimensioned according to a known number of devices connected at the location and can prioritise traffic based on defined criteria.

The technology is ideal for industry sectors such as mining, oil and gas, public safety, defence, utilities and renewable energy. As part of its wider network and product offering, Vocus will now integrate full turnkey private mobile network capability including site survey, spectrum planning, network design, RF engineering, vendor selection, procurement, delivery, acceptance testing and ongoing service operation and network assurance.

“Vocus is looking forward to extending our proven and consistent design methodology, providing engineering excellence and highly customised solutions into the mobile domain,” said Andrew Wildblood.

6. 4G/5G enabled controller/sensor (one of hundreds) The advantage of private 4G/5G in a mine site is that unlike Wi-Fi, it can cover very large distances: 5-10km from a tower, and connect many hundreds of devices. Devices include potentially hundreds of different monitors, sensors and related IoT devices to be seamlessly connected across the mine site.

Wi-Fi struggles with distance and large numbers of devices, so hundreds of Wi-Fi access points would need to be set up to cover the same area as a private 4G/4G network.

7. Mining

As we eagerly await the release of the Department of Industry, Science and Resources Discussion Paper on the National Robotics Strategy, it’s time to reflect on the feedback we’ve received from representatives across the robotics ecosystem.

One of the key issues identified across the board was difficulty in accessing capital in Australia, a reason many companies decide to start-up offshore where we lose the direct benefits of the talent and technologies they produce.

Robotics Australia Group formed to support the development of a sustainable robotics industry here in Australia. We have developed a 7 point action plan outlining some of the key areas which can help us achieve this outcome:

To establish Australia as a global leader in the uptake and supply of trustworthy robotics products and services by 2030.

• Substantially increase and grow Australian-based high growth robotics companies by addressing funding gaps and supporting export development

• Incentivise collaboration to encourage large companies and government agencies to partner, invest and nurture Australian robotics companies as they scale and develop fit-for-purpose solutions

Talent

• Grow robotics talent base in line with Government targets, by increasing university and TAFE graduates, diversifying pathways into robotics, supporting work placements and expanding community literacy of robotics.

• Collaborate with others to address workforce challenges (skills, talent, attraction and retention)

• Develop clusters to form the building blocks of a sustainable robotics industry by supporting collaboration, knowledge transfer and entrepreneurial culture

• Build better linkages with Australia’s strong research base and help bridge the commercialisation gap

• Ensure ethical robotics solutions meet public expectations, improve Australia’s well-being and are consistent with our democratic values

• Our 7 point action plan will form the core of our submission to the federal government once the Discussion Paper on the National Robotics Strategy is released.

We encourage everyone in the local robotics ecosystem, from the companies building robots to those researching and developing new robotic technologies, robotics educators and enthusiasts, and the companies looking to adopt robots and robotics-related technologies to submit a response.

We will also open up a survey so that you can contribute to the Robotics Australia Group response if you prefer and we will endeavour to represent your view (time and space permitting).

Stay tuned for the release of the Discussion Paper so our sovereign robotics industry can take advantage of the great opportunity to influence policy in this area and contribute to Australia’s first ever National Robotics Strategy.

The Kwinana project is one of five biofuel refineries bp has planned globally and is scheduled to be the first to come online.

It is part of bp’s commitment to transform the former refinery into a renewable energy hub.

The Renewable Fuels Project has reached the front-end engineering design phase milestone which is the step before making a final investment.

The Kwinana project will repurpose refining units and infrastructure at bp’s Kwinana site to produce renewable diesel and sustainable aviation fuel.

The biorefinery is planned to produce sustainable aviation fuel and biodiesel from bio feedstocks by 2026.

It will complement the site’s existing import terminal operations and integrate with bp’s plans for green hydrogen production, which are currently being assessed in a feasibility study.

The McGowan Government has provided $300,000 to bp to support the H2Kwinana feasibility study.

Premier Mark McGowan said: “I welcome this latest milestone as bp begins the transformation of its Kwinana infrastructure into a renewables hub.

“This transformational project, which is one of five in the world, is a testament to the fact that WA continues to be an ideal location to invest and do business.

“Initiatives like this bring significant benefits to our State, boost our strong economy and ensure we have a long line of local jobs and work for local businesses into the future.”

State Development, Jobs and Trade Minister Roger Cook said: “There has been a long association between bp and Kwinana over many years.

“It is very encouraging that we are seeing the rebirth of the facility as a renewable energy hub.

“Not only will this create jobs, but it will create jobs for the future as WA plays a leading role in the global shift to renewable energy.”

The Kwinana Renewables Project is located in the Kwinana Industrial Area which has supported tens of thousands of jobs and billions of dollars in investment.

Hon Roger Cook BA GradDipBus MBA MLA WA Deputy Premier; Minister for State Development, Jobs and Trade; Hydrogen Industry; Tourism; Science Hon Mark McGowan BA LLB MLA WA Premier; Treasurer; Minister for Public Sector Management Federal-State Relations

The new method from RMIT University researchers splits the seawater directly into hydrogen and oxygen – skipping the need for desalination and its associated cost, energy consumption and carbon emissions.

Hydrogen has long been touted as a clean future fuel and a potential solution to critical energy challenges, especially for industries that are harder to decarbonise like manufacturing, aviation and shipping.

Almost all the world’s hydrogen currently comes from fossil fuels and its production is responsible for around 830 million tonnes

of carbon dioxide a year*, equivalent to the annual emissions of the United Kingdom and Indonesia combined.

But emissions-free ‘green’ hydrogen, made by splitting water, is so expensive that it is largely commercially unviable and accounts for just 1% of total hydrogen production globally.

Left to right: Mr Suraj Loomba, Dr Nasir Mahmood and Dr Muhammad Waqas Khan.Lead researcher Dr Nasir Mahmood, a Vice-Chancellor’s Senior Research Fellow at RMIT, said green hydrogen production processes were both costly and relied on fresh or desalinated water.

“We know hydrogen has immense potential as a clean energy source, particularly for the many industries that can’t easily switch over to be powered by renewables,” Mahmood said.

“But to be truly sustainable, the hydrogen we use must be 100% carbon-free across the entire production life cycle and must not cut into the world’s precious freshwater reserves.

“Our method to produce hydrogen straight from seawater is simple, scaleable and far more cost-effective than any green hydrogen approach currently in the market.

“With further development, we hope this could advance the establishment of a thriving green hydrogen industry in Australia.”

A provisional patent application has been filed for the new method, detailed in a lab-scale study published in Wiley journal, Small.

To make green hydrogen, an electrolyser is used to send an electric current through water to split it into its component elements of hydrogen and oxygen.

These electrolysers currently use expensive catalysts and consume a lot of energy and water – it can take about nine litres to make one kilogram of hydrogen. They also have a toxic output: not carbon dioxide, but chlorine.

“The biggest hurdle with using seawater is the chlorine, which can be produced as a by-product. If we were to meet the world’s hydrogen needs without solving this issue first, we’d produce 240 million tons per year of chlorine each year – which is three to four times what the world needs in chlorine. There’s no point replacing hydrogen made by fossil fuels with hydrogen production that could be damaging our environment in a different way,” Mahmood said.

“Our process not only omits carbon dioxide, but also has no chlorine production.”

The new approach devised by a team in the multidisciplinary Materials for Clean Energy and Environment (MC2E) research group at RMIT uses a special type of catalyst developed to work specifically with seawater.

The study, with PhD candidate Suraj Loomba, focused on producing highly efficient, stable catalysts that can be manufactured cost-effectively.

“These new catalysts take very little energy to run and could be used at room temperature,” Mahmood said.

“While other experimental catalysts have been developed for seawater splitting, they are complex and hard to scale.

“Our approach focused on changing the internal chemistry of the catalysts through a simple method, which makes them relatively easy to produce at large-scale so they can be readily synthesised at industrial scales,” Loomba said.

Mahmood said the technology had promise to significantly bring down the cost of electrolysers - enough to meet the Australian Government’s goal for green hydrogen production of $2/kilogram, to make it competitive with fossil fuel-sourced hydrogen.

The researchers at RMIT are working with industry partners to develop aspects of this technology.

The next stage in the research is the development of a prototype electrolyser that combines a series of catalysts to produce large quantities of hydrogen.

‘Nitrogen-doped Porous Nickel Molybdenum Phosphide Sheets for Efficient Seawater Splitting’, co-authored by Suraj Loomba, Muhammad Waqas Khan, Muhammad Haris, Seyed Mahdi Mousavi, Nasir Mahmood, et al., is published in Small (DOI: 10.1002/smll.202207310).

*Source: https://www.iea.org/fuels-and-technologies/hydrogen Images: RMIT University

The investment is a demonstration of MinRes’ commitment to decarbonise its mining operations in Western Australia, which includes two of the world’s largest hard-rock lithium mines.

MinRes is cutting emissions at its mining operations through a variety of technologies, including plans to transition road trains at its Onslow Iron project from diesel to electric.

At the Wonmunna iron ore project in the Pilbara, a 2.1 megawatt solar array and battery system is being installed that will provide 30 percent of the site’s energy requirements.

MinRes is also supporting the world’s transition to a clean, renewable future by producing high-quality spodumene concentrate and battery grade lithium hydroxide from the worldclass Mt Marion and Wodgina mines, in the Goldfields and Pilbara regions respectively.

MinRes placed the order with mining industry vehicle supplier and global systems integrator MEVCO, which recently announced a partnership with SEA Electric to electrify Toyota HiLux and LandCruiser utes.

From its factory in Melbourne, SEA Electric is converting the vehicles from diesel-powered engines to all-electric using its SEA-Drive power-system. The HiLux utes purchased by MinRes will be fitted with an 88kWh battery that provides a range of up to 380km and can be charged up to 80 per cent in less than one hour.

The electric ute at the Mineral Resources Park charging station at Lathlain

MinRes Chief Executive Officer, Mining Services Mike Grey said: “MinRes has a plan to transition to a low-carbon future and cutting our reliance on diesel is central to achieving this goal. Our MEVCO electric utes are just one of the many ways we’re driving towards net zero and an exciting step in our decarbonization journey.

The mine site-ready electric vehicles produce no noise, fumes, heat or vibrations. A demonstration model arrived in Perth in February and MinRes is expected to take delivery of the first batch of electric utes in April.

MinRes, which is committed to net zero emissions by 2050, will use the electric utes at its various mine operations across Western Australia, including at the Koolyanobbing iron ore mine in the Yilgarn.

The addition of the electric utes comes two years after MinRes took delivery of the first all-electric light truck to roll off the SEA Electric production line.

“Battery technologies are key to a clean energy future and MinRes is playing a significant role in achieving this global goal. As the world races towards decarbonisation, we are part of the journey because it’s not just good business but the right thing to do.”

MEVCO Chief Executive Officer Matt Cahir added: “While many companies talk about decarbonisation, MinRes is actually doing it. Partnering with one of the leading innovators in the mining industry is testimony to the MEVCO HiLux ute.

“MinRes is a company that is at the forefront of innovation and understands how that culture attracts and keeps the best mining talent in the industry. We are excited to be part of MinRes’ decarbonisation journey.”

MinRes CEO Mining Services, Mike Grey, at the wheel of the electric Ute

MinRes CEO Mining Services, Mike Grey, at the wheel of the electric Ute

The decision by the Minister for Energy and Mining, Tom Koutsantonis MP to decline an application by Terramin Australia Ltd to develop the historic Bird in Hand underground gold mine in Woodside sends a red flag to mineral developers and those seeking to invest in South Australia.

The Minister’s decision appears to be based on the grounds of tourism and amenity, both of which were addressed through an extensive 7-year and $16 million approval process, which the Department for Energy and Mining has advised “satisfies their relevant statutory obligations.”

The Minister is sending a very clear message to investorseven if you have a world class deposit and invest millions to diligently meet the approval requirements, there is absolutely no assurance that you will receive a green light from this Government.

SACOME CEO, Rebecca Knol said: “It’s frustrating that despite jumping through multiple hoops and addressing the social, environmental, and regulatory requirements, the Minister has chosen to ignore the advice of his own department and has opted to reject the project on populist political grounds.”

“This decision represents a missed opportunity for the State at a time when critical minerals are in high demand and this was a ‘golden’ opportunity to send a clear signal that we are ‘open for business’.”

“The grade of the ore found in the Bird in Hand Mine is 13gm/ tonne which puts the deposit in the Top 2 gold mines in Australia and the Top 10 gold mines in the world.”

“It is unusual to have such high grades of ore in a small footprint deposit so close to a ready workforce. Since coming to Government, the Minister has continually asked the sector as to what the biggest roadblock is for projects coming online. The answer is obvious.”

SACOME CEO, Rebecca Knol

Delta Marine is a family run business with years of experience Skippering from 20 to 80ft Vessels. Our Extensive Boating Services include:

Skippering

Maintenance

Delta Marine Western Australia @deltamarinewa

WE ARE A PROUDLY WEST AUSTRALIAN OWNED & OPERATED BUSINESS AND ARE PROUD OF OUR 20-YEAR REPUTATION. WE PERFORM A HIGH-LEVEL OF QUALITY WORKMANSHIP, SPECIALISING IN CUSTOM WELDING, METAL FABRICATION AND ENGINEERING SERVICES FROM OUR PERTH WORKSHOP AND OUR FAST METROPOLITAN MOBILE SERVICES.

• WELDING & FABRICATION

• SPECILISING IN ALUMINUM & STAINLESS STEEL

• MARINE FABRICATION & BOAT REPAIRS

• CUSTOM TRAILERS & REPAIR WORK

• ALI SLAT FENCING, PRIVACY SCREENS, AUTO GATES, CARPORTS & PATIO’S

• CUSTOM PROJECTS ALUMINUM & STAINLESS

• BARS & BARRELS

Our team is highly efficient and customer focused and our reliability is what our business is built on. We only use quality parts and products combined with very high attention to detail and finishing. No Job too big or too small. Contact us today for a quote.

Over the holiday break I spent some time enjoying using this boat with my family. I also found time to make some much needed repairs and improvements. This 2nd restoration article covers some interesting problem-solving issues.

The bow thruster was not working and after a couple of marine electricians investigated this issue, it was not clear what the actual problem was. After replacing the three 12V batteries with Delkor M31 maintenance free, deep cycle Marine batteries, the bow thruster started working. The old batteries couldn’t hold enough charge to run the bow thruster.

Half of the instrument cluster gauge light globes were not working so I upgraded all of the original globes to LED globes which operate at a much lower temperature. I did the same to the instrument cluster on the 1978 Camaro that I recently finished restoring.

Richard (Flano) at Blue Steel Welding and Fabrication did a great job custom fabricating and fitting a pair of 316 Marine Grade Stainless Steel Stern Rails that he set up to hold a cookout BBQ to this boat.

The ‘before & after’ photos of new seat trim & floor covering, dinghy davits and more will be included in our Q2 2023 edition boat restoration article. Kindly contact me at len.fretwell@diggingdrilling.com with any queries or suggestions.

Article and Images: Len Fretwell