The Beauty of Circularity

Made to be remade. The DESSO® Origin Collection is a truly circular product, designed to be disassembled so its components can be easily recycled into raw materials for new carpet tiles.

AUSTRALIA & NEW ZEALAND

/ July 2023

June

www.tarkett.com.au

Origin

Editor’s Note

Welcome to the June / July 2023 edition of Flooring Magazine. Inside this issue you will find our annual Eco and Sustainability Feature where key industry stakeholders discuss how they are committing to reducing the carbon footprint and working towards providing an environment fit for future generations.

Our Company Profile this issue is TWO Australia, a one stop shop supplier for interior solutions specialising in a diverse range of shutters, blinds and outdoor shades. Philip Ashley explains how this company has firmly established itself as a leader in the window furnishings and outdoor shades industry an area many of our regular retailers are beginning to explore.

Please feel free to contact me directly regarding any company events, industry news and or new product information by email at – michelle@ elitepublishing.com.au

Don’t forget to check out our new website, join our growing online community and visit us on Facebook and Instagram.

Until next time, enjoy your read.

Michelle Cammiade Editor

3 Flooring June/July 2023 www.flooringmagazine.com.au Contents

Front Cover Tarkett www.tarkettt.com.au vol 41 no 3 Flooring Magazine is on: @flooringmagazineaustralia @flooringmagazineaustralia News 8 Celebrating 50 years of inspiring tomorrow Company Profile 12 Two Australia Feature 14 Eco & Sustainability Design & Trends 36 Carpet Court continue to push for sustainable flooring Focus On 40 Australian Panels Spotlight On a Franchisee 44 Andersens Warwick Insurance Matters 46 How insurance brokers help Safety 52 The Australian Made Logo – Promoting local manufacturing

RFMS users dominate Carpet Court Awards

Around 30% of Carpet Court members in Australia use RFMS, so the RFMS Australasia team were delighted that six of the eight awards at the recent Carpet Court conference in Darwin went to Carpet Court stores using RFMS business management software.

Chris Ogden, director of RFMS Australasia, said that as pleased as he was at seeing RFMS users being so well represented, he never loses sight of the fact that RFMS is not a substitute for good culture, management, and leadership. Chris went on to say that for businesses with those critical elements in place, RFMS can be the final element, streamlining processes and giving business owners access to information they would not otherwise have.

Frances Hickey says RFMS has been instrumental in the success of their business since joining Carpet Court in 2021. Frances said, “Thanks to RFMS, we were able to efficiently manage our sales, inventory, and customer relationships, ultimately propelling us to start our journey off successfully and achieve the New Member of the Year Award for our stores in Mascot and Bondi.”

Hayden Tegart says he was pleasantly surprised to receive Member of the Year NSW/ACT for Carpet Court Dubbo; he believes it shows the strength currently of the regional markets. Carpet Court Dubbo has been on RFMS for over seven years, and Hayden says it has “definitely made life easier since taking it on”.

Anthony Rechichi of Midland Carpet Court was similarly surprised to win Member of the Year WA after winning it last year. Anthony’s business has been on RFMS for nearly five years, and he says his business is a lot more efficient and profitable as a result. Anthony particularly appreciates the ability to job-cost

projects to see exactly how profitable each job is; he says, “RFMS gives me confidence in my business”.

Chris Ogden said getting this positive client feedback is encouraging for his team. Still, he reiterated RFMS is only one element of a successful business. Chris also said the Carpet Court group is a very proactive environment for flooring retailers wanting to improve their business through IT, having recently introduced a Power BI tool for group members to access information about their business. Chris went on to say that an IT-friendly group culture is very good for the membership overall.

Chris said the RFMS software has been subject to continuous development with the introduction of mobile apps over recent years. He says development has been accelerated with RFMS joining the Cyncly group last year, with significant investment in development being made.

“This will benefit our existing clients and new clients as they implement RFMS in their flooring businesses”, he said, “we look forward to seeing even more flooring businesses benefit from RFMS in this part of the world.” s

4 Flooring June/July 2023 www.flooringmagazine.com.au News

The RFMS team are delighted to congratulate the following RFMS users among award winners.

Congratulations Carpet Court 2022/2023 NMM Award Winners BEST PERFORMING NEW MEMBER OF THE YEAR Mascot and Bondi Carpet Court ____________ MEMBERS OF THE YEAR Carpet Court Dubbo – NSW/ACT Cranbourne Carpet Court – VIC/TAS Indooroopilly Carpet Court - QLD/NT Midland Carpet Court – WA ____________ NATIONAL STORE OF THE YEAR Cranbourne Carpet Court

Learn how RFMS can take your flooring business to the next level, go to www.rfmsanz.com Freephone 1800 229 427 (AU) 0800 643 012 (NZ)

Best Environmental Practice PVC product verification scheme

Following extensive consultation with stakeholders, the Vinyl Council of Australia (VCA) has launched its updated ‘Best Environmental Practice PVC (BEP) v 2.0’ verification scheme for PVC products with the VCA taking on full responsibility for ongoing development, management, and administration of the updated BEP scheme.

Launched in 2010, the BEP scheme remains the most stringent criteria and guidelines for manufacturing PVC, with participants required to meet conditions including VCM emissions targets, voluntary restrictions of additive use and stewardship requirements for end of first use of PVC products in Australia.

Under the updated BEP scheme, products that are independently verified as being fully compliant with all core and one or more optional scheme guidelines are eligible to be issued with a Best Environmental Practice PVC Licence Mark by the VCA, and included in the online product register to indicate to procurers and specifiers that the BEP PVC manufacturing guidelines have been met.

While the original BEP scheme was only applicable to PVC products used in the building and construction sector, the updated accreditation is available to all complying PVC products across the full spectrum of applications.

Following the launch of the updated scheme, it is important to note that there will be a transition period as current BEP accreditation will continue to be valid until the existing verification expiry. The updated BEP guidelines will become mandatory from 1st September 2023 onwards when companies seek renewal of their BEP accreditation, however the VCA encourages all companies undergoing the auditing process prior to this date to elect to be audited against the updated guidelines.

“The BEP 2.0 product certification scheme continues to reflect ongoing best practice

in PVC manufacturing through the core guidelines, while also reflecting societal expectations for increased focus on the environmental and social impacts of products and materials through the addition of optional criteria,” said VCA CEO Jim Coulston.

The VCA has worked closely with the Green Building Council of Australia (GBCA) to ensure that the updated BEP scheme is recognised under the GBCA’s Responsible Products Framework, which seeks to drive the supply chain to deliver transparent, healthy, low-impact products that are part of a circular economy.

To learn more about the guidelines and audit requirements involved in gaining BEP verification, go to: https://www.vinyl.org.au/ in-greenstar/achieving-best-practice-pvc s

6 The FCIA Gala Returns in 2024 2 March 2024 Plaza Ballroom VIC email info@fcia.org.au for registration details

News

Celebrating 50 years of inspiring tomorrow

Carpet Court Australia (CCA), one of Australia’s largest retail floor covering, window furnishing and rug specialists, recently held a four-day conference to bring together its Members, Suppliers and industry experts from around the country to meet, learn and engage whilst celebrating the company’s milestone 50th anniversary.

The event which took place from May 7th to May 11th in Darwin, Northern Territory, was a resounding success. With the theme “50 Years, Inspiring Tomorrow,” the conference not only honoured the company’s past and present achievements but also established a solid foundation for a prosperous future.

A schedule of engaging activities, insightful presentations and exciting announcements left Carpet Court Conference attendees inspired and motivated, ready to conquer the next 50 years and beyond.

Representing diverse locations across the country, Members of Carpet Court Australia showcased a vibrant display of unity and shared purpose. The nationwide participation exemplified the deep-rooted connection and support within the Carpet Court community, highlighting the enduring strength and resilience of the company’s membership model.

The Conference

The conference commenced with an exuberant Welcome Event at the Mindil Beach Casino Resort with 580 guests including CCA Members, their children and Supplier Partners. The atmosphere was electric as guests forged new connections and rekindled existing ones while the diversity of perspectives and experiences enriched the conference, creating a vibrant tapestry of knowledge, ideas and shared passion for the flooring industry.

One of the conference highlights, the Supplier Expo, took centre stage featuring 46 supplier booths. Each Supplier had the opportunity

to showcase their invaluable contributions to CCA’s 50-year journey, present their sustainability initiatives, and unveil new core range products. CCA Members played an essential role in shaping the offerings and strengthening the partnership between Carpet Court Australia and its Suppliers through active participation and insightful feedback. This collaboration further reinforced the sense of community and unity that permeated the conference.

Keynote Speakers

The Carpet Court Conference boasted the presence of two prominent guest speakers who captivated the audience with their expertise and insights. Giulio Bonazzi, Chairman and CEO of Aquafil Group, mesmerised attendees with his journey through the development of a closed-circle process to recover and recycle nylon and other waste. Aquafil Group's innovative approach led to the creation of the ECONYL Regenerated Nylon fibre, which is now utilised in Carpet Courts’ exclusive eco-friendly ranges. Bonazzi's presentation emphasised the significance of sustainability and showcased how businesses can contribute to a greener future.

8 Flooring June/July 2023 www.flooringmagazine.com.au News

Above: Best Performing New Member - Mascot & Bondi Carpet Court

Gus Balbontin, an engaging speaker, investor and advisor, delved into the topic of "Harnessing Innovation." Balbontin shared valuable lessons from various industries that have experienced disruption and change, offering insights that were applicable to the flooring industry. He conducted rotation sessions, encouraging CCA Members to identify business pressure points, provide solutions, demonstrate proof of concept, and test the viability of their ideas. Balbontin also highlighted the importance of testing and learning to drive innovation and enhance business practices.

Gala Event and Awards

The conference concluded on a high note with a spectacular Gala Event attended by 350 guests including CCA Members, agency partners, ambassadors, and special guests. The evening was filled with entertainment from renowned artists such as Kate Ceberano, Joe Camilleri, Linda and Vika Bull and was generously sponsored by Qantas Loyalty. The event also marked the unveiling of CCA's new brand work in celebration of its 50th year in business, creating a sense of anticipation for the official launch in July 2023.

An essential highlight of the Gala Event was the recognition of excellence through store awards. Several categories acknowledged the outstanding contributions and achievements of CCA Members. The event also paid tribute to past and present Members through induction into the Hall of Fame and acknowledgment on the Roll of Service.

Blazing the Trail - 50 Years On

The Carpet Court Australia Conference was an exceptional celebration of the company's 50-year journey, showcasing its unwavering commitment to innovation, sustainability, and excellence. By bringing together CCA Members, Suppliers, and industry experts, the event provided a platform for networking, engaging activities, and enlightening

presentations by industry leaders, leaving attendees inspired and ready to embrace the next 50 years with renewed enthusiasm.

Carpet Court Australia continues to shape the future of the flooring industry with the unwavering support and dedication of its invaluable Members. Their entrepreneurial spirit, combined with the resources and support provided through the membership model, propels Carpet Court towards continued growth and success.

Above: State Member of the Year - QLD

CARPET COURT 2023 CONFERENCE AWARDS

Best Performing New Member of the Year

Mascot and Bondi Carpet Court

Outstanding Achievement Award

Terry Bros Carpet Court Forbes

National Store of the Year & State Member of the Year - VIC/TAS

Cranbourne Carpet Court

State Member of the Year - NSW/ACT

Dubbo Carpet Court

State Member of the Year - QLD

Indooroopilly Carpet Court

State Member of the Year - WA

Midland Carpet Court

State Member of the Year – SA

Nick’s Carpet Court s

9 Flooring June/July 2023 www.flooringmagazine.com.au News

Above: National Member of the Year - Cranbourne Carpet Court

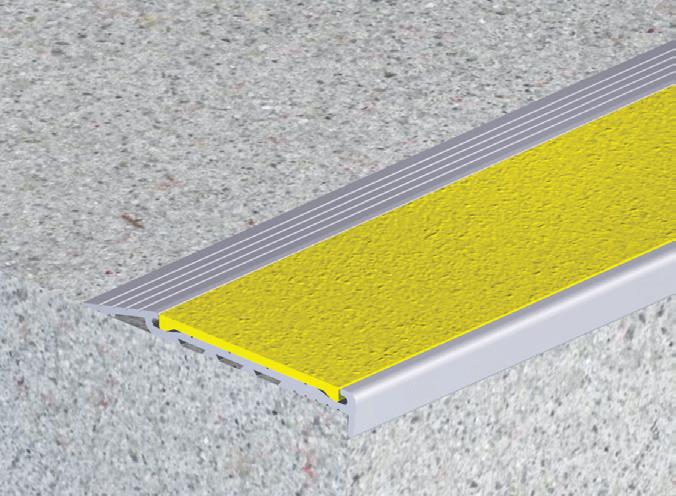

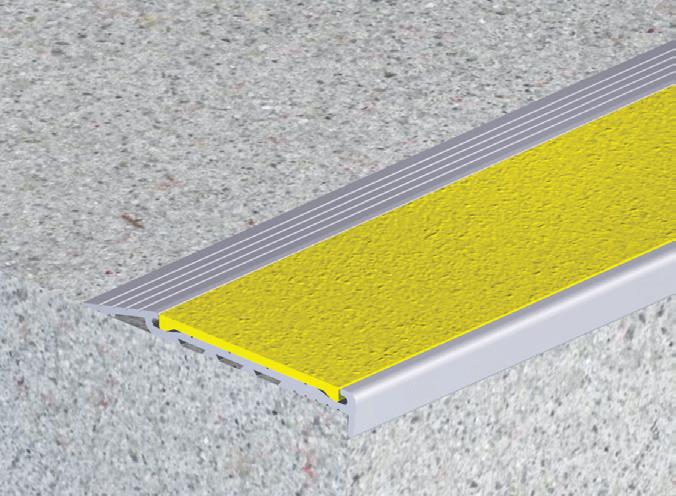

Altro Introduces Suprema

Safety flooring that combines style, durability, and easy cleaning.

Altro, the leading provider of safety floors and wall protection, is proud to introduce Suprema – a revolutionary new safety flooring that looks good, feels smooth and is exceptionally easy to clean.

Suprema offers unbeatable protection against slips, with a guaranteed sustainable P3 slip rating for its entire lifespan. Backed by a 10-year product warranty, this stylish flooring remains resilient in even the harshest environments.

Suprema's colour palette was designed with input from colour consultants, architects, and end users. Its range of 33 colours was inspired by current interior design trends, making Suprema the ideal choice for any space. Its ability to perform under harsh conditions makes it perfect for busy spaces including healthcare, education and retail.

Altro’s Easyclean technology makes cleaning simple and quick. Suprema looks good longer while remaining exceptionally easy to clean and maintain. Its unique combination of safety and style ensures that Suprema stands out from the crowd when it comes to safety flooring solutions.

“At Altro, we are committed to providing our customers with innovative safety solutions that don’t compromise on aesthetics or performance," said Tim Attard, Altro APAC Commercial Manager. "We are confident that our newest offering, Altro Suprema, will exceed expectations in all these areas."

Altro Suprema has been designed to withstand the rigours of hightraffic areas such as classrooms, hospital wards and corridors. Thanks to its durable construction and easy cleaning properties, Suprema will offer long-lasting performance without compromising on aesthetics.

Altro is committed to making safer spaces for everyone through its innovative products and pioneering technologies - Suprema is no exception. s

10 Flooring June/July 2023 www.flooringmagazine.com.au

Technical Excellence Continuous Innovation Contact us 0 7 5 5 2 6 7 3 9 9 RESIDENTIAL RESIDENTIAL & & Industry Leaders COMMERCIAL COMMERCIAL www.cleverchoice.com.au UNDERLAY H E W H E R E W E G O N D E & U N D E R O O G U S

Product Update B2B B2B B2B

Company Profile

Who is TWO?

TWO Australia believe the home is a sanctuary where people can escape in quiet moments or entertain family or friends, a place where memories are created, a place filled with laughter and peace. TWO Australia helps their customers make the most of this special place with stylish and functional products.

TWO Australia is a wholesale manufacturer specialising in a diverse range of beautiful interior and exterior shutters, interior blinds, and outdoor shades.The company has firmly established itself as a leading player in the window furnishing and outdoor shades industry.

With manufacturing facilities in the United States (TWO USA), Australia, and China, TWO Australia is committed to delivering exceptional products that meet the highest quality standards. TWO Australia empowers its partners to thrive and grow their businesses through strategic partnerships with valued distributors worldwide.

A Rich History

The journey of TWO Australia began in the early 2000s when visionaries Ian and Michele Roe, along with Cliff Stanley, identified a void in the market. Dissatisfied with the diminishing customer focus of industry competitors, the trio recognised an opportunity to leverage their extensive manufacturing, installation, and retail knowledge within the window-covering industry. Their collective expertise and Cliff Stanley's three-generation legacy in the shutter industry gave rise to Made2Trade in 2007.

From humble beginnings operating out of the Roe's garage in Redcliffe QLD, the company rapidly gained momentum and popularity among its small dealer base. As the company expanded, it evolved from The Window Outfitters to TWO Australia, a brand synonymous with innovation and dealercentric practices. Today, TWO Australia stands out as a dynamic force, revolutionising a traditionally conventional industry through its diverse product offerings and commitment to exceptional customer service.

Unwavering Dedication to Customer Satisfaction

TWO Australia places immense value on the relationships it nurtures with its partners. Recognising that homes are sanctuaries where cherished memories are made, the company strives to create products that seamlessly blend style and functionality. By offering an extensive selection of competitively-priced, high-quality products and ensuring prompt delivery, TWO Australia aims to simplify the process of doing business. The company's commitment to transparent communication and comprehensive training support empowers its dealers, fostering a mutually beneficial partnership.

Sustainability: Empowering the Future

TWO Australia recognises its responsibility to operate sustainably and strives to integrate environmentally and socially responsible practices into every aspect of its business. With manufacturing facilities in three countries (with four factories in Australia) and a growing global distribution network, the company constantly seeks avenues for improvement in sustainability. TWO Australia manufactures their outdoor shades and interior blinds in their Queensland, New South Wales and Victorian factories where they are committed to preserving resources and minimising contributions to landfill.

For over a decade, TWO Australia has manufactured its timber, aluminium, and PVC shutter products in its Chinese facility. Pioneering sustainable practices, the company remains ahead of the curve in adhering to China's evolving manufacturing improvement standards. With a heavy

12 Flooring June/July 2023 www.flooringmagazine.com.au

Article by Philip Ashley

Above: Robert Blanch and Ian Roe

Company Profile

investment in filtration systems and other environmental controls, TWO Australia ensures that its manufacturing processes minimise their environmental impact. Advanced air filtration systems, including UV lights and additional filters, eliminate emissions from spray and detailing booths, while an industrial outdoor dust extraction system filters the entire factory. Energyefficient compressors housed in soundproofed areas further enhance the company's commitment to sustainability.

curtains in a Melbourne-based facility within the next few months, which signifies TWO's commitment to expanding our offerings and providing comprehensive locally-made solutions to our dealer-base.” By capitalising on the popularity and versatility of curtains, TWO is well-positioned to meet the evolving demands of the Australian market. Homeowners seeking customisable and visually pleasing window treatments can now access a wide range of curtain options through TWO's trusted network of dealers nationwide.

TWO Expands Product Range with Curtains

In an exciting development, TWO Australia announced at the recent SuperExpo 2023 textiles and window furnishing tradeshow its plan to offer a comprehensive range of curtains nationwide. Recognising the enduring popularity of curtains in Australian homes, TWO aims to cater to the diverse needs of customers seeking versatility, decorative appeal, and effective light control capabilities. Homeowners have long favoured curtains because they can seamlessly blend functionality with aesthetic appeal.

Managing Director, Robert Blanch explains TWO’s direction, “By incorporating curtains into our product range, TWO takes a significant step towards solidifying our position as a one-stop-shop supplier for interior solutions. We aim to begin making

TWO is People

From manufacturing to customer support to innovative leadership, TWO Australia’s people come from different backgrounds with different talents. TWO believe that this diversity is what brings the wealth of knowledge and diverse thinking to their offices and factory floors, and results in the new style of business they deliver to their traditional industry. TWO is no more than the people that make up the team, and therefore it is crucial that they continually strive to improve the welfare of each individual.

Nationally Local

TWO Australia is a national company but even with their continuing growth, is committed to maintaining a local, customer-oriented focus. They recognise the modern-day demands and time constraints their commercial partners

face and have streamlined their service structure to best support those needs. With warehousing capacity and a fleet of their own vehicles and delivery teams, TWO Australia can guarantee on-time distribution of product to most Australian states, delivered in the same condition it left their production facility or warehouse.

Service Innovation

While TWO Australia’s products need to speak for themselves, the company also believe that their business is as much about service as anything else. As well as continued R&D for their product ranges, they also continue to reinvent the way they support their customers. By embracing technology, TWO know they can make things easier and minimise errors. And by breaking the mould of a traditional window treatment manufacturer-to-client relationship, they can better support their dealers to expand their businesses. This includes in-house tailored marketing support and individual guidance. Quite simply, TWO Australia know that working in partnership with their dealers holds the key to their success. s

13 Flooring June/July 2023 www.flooringmagazine.com.au

Eco & Sustainability

How do we provide a built environment fit for future generations?

Feature

Together, building and construction is responsible for 39% of total global emissions. This is the damage we are doing as stakeholders in the built environment. What as an industry do we need to do to reduce this impact?

As global leaders in commercial flooring, Interface is committed to sharing its own sustainability journey with all stakeholders within the wider industry. Over the span of more than 50 years, Interface has evolved both its thinking and approach. Originally, the focus was solely on reducing environmental impacts, but that has evolved to include social impacts and new business models.

Whole life carbon and why does it matter?

The science of sustainability can seem complicated. But one fact is simple: the planet is warming at an alarming rate. Reducing humanity’s carbon footprint is the most essential step we can take to live within the means of our planet.

The industry’s focus on reducing built environment carbon impacts has largely been the building’s operational carbon. This is the term used to describe the emissions of carbon dioxide during the in-use phase of a building. This includes the emissions associated with heating, hot water, cooling, ventilation, lighting systems and lifts.

We now have to turn our focus to whole life carbon for the structures we build.

In some ways it is like approaching an iceberg, operational carbon is the iceberg above the water, it has been clearly visible for a long time. However, upfront carbon is the rest of the iceberg hidden under the water not visible to most of the built environment.

14 Flooring June/July 2023 www.flooringmagazine.com.au

“Reducing humanity’s carbon footprint is the most essential step we can take to live within the means of our planet.”

Feature Eco & Sustainability

Implementing a circular economy business model

Net zero ambitions for the built environment will be achieved not only through use of renewable energy and low carbon materials, but also by adoption of the circular economy model whereby those products and materials are recirculated to retain their embodied energy.

“Circular economy doesn't mean that we take waste from someone else to use as a raw material for our product; circular economy for us is retaining the value of our product throughout its life,” explains Aidan Mullan, Sustainability Manager at Interface. “And, at the end of life, getting that product back is the goal. We can extend its life or dismantle it into its constituent parts for manufacturing new products. That, to us, is a circular economy.”

In short, the circular economy model focuses on designing out waste, circulating products and materials at their highest value and regenerating nature by recycling.

For Interface this means "not taking what we cannot put back." The ultimate goal is to cut the link to petrochemicals and fossil fuels. This means:

• Designing long lasting products that can be re-used

• Replacing virgin raw materials with high recycled or bio-based content

• Having a remanufacturing solution for the product at the end of its useful life

Urgency and radical collaboration

It’s not up to a government and it’s not up to just one company. Everybody must be accountable for how they procure materials

and how they design projects – the decisions we make now about the materials we use in the buildings have a lasting impact for thousands of years.

2030 is the target for emissions reduction, not 2050. With so many sustainability assessment and carbon measurement tools out there, the message from climate experts is that we need to select one and start working on it NOW.

A key pillar of

the Interface Climate

Take Back plan is the belief that we need new models of low-carbon, inclusive and collaborative business, that deliver value for everyone. Leading the industrial re-revolution by championing radical collaboration and collective will, Interface’s goal is to transform industry to build a climate fit for life.

web www.interface.com s

15 Flooring June/July 2023 www.flooringmagazine.com.au

Kerakoll, the leader in green building materials

Kerakoll is the first company in the world to offer a global solution for Green Building Materials and services as a means of building and living in harmony with the environment and wellbeing in the home.

Since 1968, when the Group was founded by Romano Sghedoni in Sassuolo, the heart of the most important ceramic district in the world, Kerakoll has continued to expand in both the Italian and international building materials markets to reach its current position as leader in green building, with an acknowledged technological primacy at an international level. From a turnover of 11 million (EUR) in 1990, Kerakoll has now reached total revenue of around 650 million (EUR) of which almost half is earned through foreign markets and can count on approximately 2,000 employees and collaborators. Today, Kerakoll has a direct presence in 12 different countries, with 16 manufacturing sites.

Representing Green Building the ‘New’ low environmental impact approach to building, Kerakoll safeguards foremost the health and wellbeing of people with respect to the environment. Kerakoll has developed and produced innovative solutions that focus on the environment and on improving both health and quality of life by using eco-friendly and naturally breathable building materials

that avoid the most common illnesses caused by indoor pollution. Kerakoll’s vision is to interpret Green Building as a new way of building that is kind on the environment, promoting higher quality homes around the world and helping people to live better.

Innovation and research with respect for the environment, concern for health and living comfort, and a pure wholesome approach are the defining tenets of Kerakoll. This has also contributed to Kerakoll being at the forefront of product innovation with the largest array of Silica free products therefore alleviating silicious in the building products industry.

Cutting edge innovation in the form of removing Petro-chemicals and substituting with plant-based latex and the removal of Portland cement with lower carbon Geobinder technology is Kerakoll’s commitment not only to people, but also to the planet.

The company has remained faithful to the values that saw it rise to 1st place in the production of Green Building solutions around the world with more than 1,700 items that are 100% eco-friendly. Our carbonfootprint, green build rating, recycling content and material quality are all synonymous with the Kerakoll name.

www.kerakoll.com.au

16 Feature Eco & Sustainability

s

Everything Carbon Neutral

Interface® is now a third-party certified Carbon Neutral Enterprise

As the first and only flooring manufacturer to achieve third-party Carbon Neutral Enterprise certification, Interface neutralised its carbon impact across its entire business, including all operations and its full value chain. The Carbon Neutral Enterprise certification builds on our history as a purpose-driven flooring company and sets the stage for our future, guiding everything we do.

For more information visit interface.com/carbonneutralenterprise

Image: © Christopher Payne Esto

Image: © Christopher Payne Esto

Feature Eco & Sustainability

Embracing sustainability in style

In an age where sustainability is no longer a mere trend but a necessary ethos, Signature Floors continues to prioritise eco-friendly design that creates sustainable flooring solutions. With their visionary approach and use of innovative Liteback technology pioneered by Välinge, you can be assured that all of Signature's hybrid flooring ranges have a light-weight impact on the planet.

Liteback features milled channels that remove 20% of the physical weight from the core, resulting in a durable and lightweight flooring solution that is a breeze to handle. Combined with Välinge’s industry-leading 5G floor locking system, installation is faster and easier than ever before. The milled material is then recycled and reused, dramatically curbing the consumption of raw materials, resulting in a lighter carbon footprint and lower cost to the environment.

Signature Floors champions recycling initiatives. By utilising the Liteback technology, which enables the removed

material to be re-used in production of new floor products, they help promote a practical circular economy. This forward-thinking approach not only diverts waste from landfills but also fosters the reutilization of valuable resources, creating a positive ripple effect for a greener future.

Liteback also provides superior acoustic performance, where the grooves help to disperse both impact sound vibrations and radiated walking sounds, significantly reducing noise transfer to rooms below, creating a haven of tranquility, ideal for use in upstairs rooms and for apartments.

Quattro, Dimension and Distinct, the hybrid ranges designed by Signature Floors, seamlessly blend breathtaking aesthetics with unmatched performance, all while minimising their ecological footprint. By choosing Signature Floors' hybrid ranges with Liteback technology, discerning customers can embrace a lifestyle that champions both sophistication and environmental stewardship.

Signature considers thoughtful home design, factoring in human experience and behaviour. In that, spaces are visually appealing, functional and comfortable – enriching and nourishing those living within them. With a solid core that contains no harmful content, a long-lasting durable PUR wear layer you can rely on, and superior noise reductionplus sustainable design - these ranges offer customers the opportunity to enhance their spaces and prioritize sustainability, creating a positive impact on our planet for generations to come.

web www.signaturefloors.com.au s

18 Flooring June/July 2023 www.flooringmagazine.com.au

Feature Eco & Sustainability

Tarkett deliver circular economy to the Australian flooring market

At Tarkett, they are taking important steps towards a circular economy. As a global flooring manufacturer and supplier, they take their leadership role in Sustainability very seriously. In 2022 they were the only flooring manufacturer to reach A- score (leadership level) at CPD, the world’s leading climate disclosure program. But what about locally in Australia?

Tarkett Australia is proud to offer local customers a truly circular solution to their flooring waste. Through local investment in processing machinery alongside key partnerships with logistics and suppliers, Tarkett Australia can collect and divert flooring offcuts and select post-use waste from landfill. This valuable resource is processed in Australia and returned to their factories to be turned back into high quality flooring, effectively closing the loop on flooring ‘waste’.

Investment in local capabilities was required to process waste flooring for both shipping efficiencies, and in preparation for recycling at their plants. This investment has been a journey involving several parties and included grant funding from the NSW Environment Protection Authority’s (EPA) Bin Trim program. The combined efforts of all parties have delivered a functional system that will allow local construction greater access to make sustainable product choices.

Key to the success of initiating Tarkett Australia’s local ReStart program were their machinery partners in Waste Initiatives. The team supported them from day one, assessing their needs, designing the right machinery, and assisting with advice on available grant funding and navigating waste export licenses.

Leveraging on GMK’s existing cardboard recycling program, Tarkett’s paper and cardboard waste is also recycled as a part of the wider local ReStart program. This extends efforts associated with the ReStart program beyond just flooring material.

The NSW EPA and Tarkett’s independent Bin Trim assessor, Theresa Troup of Cleanaway assisted in navigating the application process for the Bin Trim grant which was ultimately successful. They are proud to be part of the Bin Trim program, which is designed to divert waste from landfill, making the most of valuable resources, in Tarkett’s case through a circular recycling process.

Tarkett’s ambitious global goals are to achieve 30% of recycled content in their flooring by 2030. This goal is achievable through their ReStart program which has collected over 115,000 tonnes of flooring waste since 2010 (the equivalent of 4000 loaded trucks). In Australia, Tarkett has diverted nearly 9,000kgs of waste flooring from landfill in 2022, with that number to grow in years to come.

Their Logistics and Warehousing partner, GMK Logistics have been instrumental in setting up the operational side of the local ReStart program. As their local distribution partner, it made sense to house their recycling operations on GMK’s site to avoid double handling. GMK have worked with Tarkett to ensure their ReStart program is operated with safety being key.

20 Flooring June/July 2023 www.flooringmagazine.com.au

Feature Eco & Sustainability

Consultation with Next Gen flooring, a key committed contractor partner in Adelaide, allowed Tarkett to learn more about how to run an effective and functional recycling program in Australia. This relationship has been vital to continued learnings and system improvements that will benefit all Tarkett Australia customers.

In June 2022 their granulator was installed in Sydney after a process of site trials with Waste initiatives, including on-site training. This installation marks a key turning point for the capability of Tarkett Australia’s recycling program as they launch their pilot phase with key contractors. Flooring offcuts can now be collected from installation sites and transported to Tarkett’s Distribution partner GMK, for processing and shipping back to their factories, so the offcuts can be utilised in the manufacture of new flooring.

Marketing Manager, Stacey Smith says “Tarkett’s products are designed with recycling in mind. So, it’s great to be able to extend the ReStart recycling program to our local customers. It’s been quite the journey getting our local program up and running, but with the support of our key partners including Bin Trim, EPA, GMK and of course our flooring contractors, we are now well on the way in our local journey”.

Learnings from the pilot program will be utilised to bring improvements as Tarkett launch ReStart to all of their customers.

Tarkett is the only flooring manufacturer to pioneer post-use recycling for Carpets, Linoleum and Vinyl floors. On average, our Vinyl floors are made up of 24% recycled content, while their carpets contain over 60% and their Linoleum more than 30%. Locally, Tarkett Australia is committed to delivering real circular economy solutions to their customers.

Tarkett’s innovative circular closed-loop systems stand in contrast to linear, take-makewaste models of production. From the initial point of extraction, through to manufacturing, installation, use and recycling, Tarkett’s circular strategy effectively cuts down on waste and the emissions of greenhouse gases. This circular approach has enabled Tarkett to significantly reduce its carbon impact and achieve the lowest circular carbon footprint for its Origin collection.

Made to be remade, this collection features two complementary organic designs, DESSO Recharge and DESSO Retrace. Recharge evokes the upcycled chalk used in the manufacture of the EcoBase backing, while Retrace looks to the carpet tile recycling process itself for inspiration.

web www.tarkett.com.au s

Introducing DESSO Origin Carpet Tile collection – A truly circular product

As a part of Tarkett’s commitment to delivering sustainable flooring solutions, they are pleased to introduce the DESSO Origin collection. This collection delivers the lowest circular carbon footprint in Europe*, one that is at least 6 times lower** than the total carbon footprint of Tarkett’s competitors.

* For EcoBase-backed carpet tiles with PA6 yarn, according to the Environmental Product Declaration (EPD) S-P-05827 externally verified by Bureau Veritas, based on the total carbon footprint (Modules A-D) with a closed loop circular recycling scenario.

** Comparison of EPD S-P-05827 with the total carbon footprint (Module A-D) of each of the 19 carpet tiles’ EPDs available on internet (May 2022) for competitors with production location in the EU+UK, in the product weight range 600-699gr, Polyamide yarn and incineration as end-of-life scenario.

21 Flooring June/July 2023 www.flooringmagazine.com.au

Feature Eco & Sustainability

Leaving a lighter footprint with sustainable flooring and underlay

The Dunlop Flooring team is pushing the limits to design, produce, and distribute groundbreaking products with minimal environmental and social impact.

They aim to drive sustainability through recycling and integrating eco-friendly practices into their business. Dunlop EnviroFirst is a commitment to the planet and protecting the environment by eliminating waste and pollution through recycling and sustainable manufacturing.

Ongoing investment in the testing and certification of environmentally friendly new products has been driven by increasing consumer demand in the residential and commercial markets, ultimately driving innovation and breakthrough thinking in the hard flooring and underlay categories.

Recycling by Dunlop

Dunlop operates an industry-leading recycling program encouraging retailers and contractors to return their used underlay. These participating retailers and contractors collect used and discarded foam underlay, off-cuts and trims and return them to Dunlop Flooring. Their manufacturing facility in Sydney thoroughly cleans and sorts these materials, transforming them into a new, reusable underlay.

This new, recycled Dunlop underlay is then sold back into the market, effectively closing the loop, diverting waste from landfill and creating a circular economy.

Asthma friendly hard flooring and underlay

The Sensitive Choice was created by the National Asthma Council Australia in 2006. Sensitive Choice's goal is to help people identify products and services that are asthma and allergy friendly using the blue butterfly symbol.

Dunlop Flooring is proud to have many of its products approved by Sensitive Choice, including all their hybrid and vinyl planks and its entire range of carpet underlays. This certification means that their products have gone through a rigorous review by a panel of experts (pharmacists, chemists, GPs, allergists, lawyers and other professionals.) to prove that their product provides a potential benefit to someone with asthma and allergies. Dunlop is the sole recipient of this accreditation within the Australian industry, giving their products a bold advantage. To find out which products have the blue butterfly, visit www.dunlopflooring.com.au/ envirofirst/sensitive-choice.

Airsafe Australia – Keeping our installers safe

There has been a concerning rise in silicosis and lung cancer cases associated with high-silica products. The Lung Foundation of Australia has issued a statement urging government ministers to ban such products and strengthen workplace safety regulations. At Dunlop, they prioritise both product quality and safety through rigorous testing. In collaboration with Airsafe Australia, Dunlop proudly announces that silica is not detected in their entire Hybrid collection within their hard flooring range. This means that builders and installers who use Dunlop products can be confident that they will not be exposed to hazardous dust particles that can lead to illnesses like silicosis or lung cancer. Without action, an estimated 100,000 workers could be at risk over the next 50 years. Dunlop Flooring remains committed to safeguarding our families, workers, and customers.

The team at Dunlop Flooring are driven not only by their commitment to minimising environmental and social effects but also by their desire to make positive contributions and enhance the well-being of others in all aspects of their work. The team strongly recognises their duty to lead the industry by continuously developing products with a lighter footprint. web www.dunlopflooring.com s

22 Flooring June/July 2023 www.flooringmagazine.com.au

Sustainable flooring that leaves a lighter footprint. Discover what we’re made of. Watch our video now.

Feature Eco & Sustainability

Godfrey Hirst – Believe in Better

As the Oceanic subsidiary of Mohawk Industries, one of the world’s largest flooring companies, Godfrey Hirst belongs to a global network of leading products, brands and world-class manufacturing and they know that their future depends on the work they do today.

At Godfrey Hirst, their commitment to our planet extends beyond just products and processes: it’s how they challenge themselves to do and be better every day, how they make decisions, how they reinvest in their people and our planet, and how they define what matters most as they work to deliver value for generations to come.

Their approach to becoming a more sustainable business is all about making the world better. Godfrey Hirst captures this in three powerful pillars of People, Performance and Planet in everything they do.

Better for People

Godfrey Hirst is partnering locally and globally to improve lives where their team members, customers, and stakeholders live and work.

On the 17th of March they held their largest Take 3 for the Sea beach clean-up event to date. This now being their third beach clean-up event in as many years, as well as

continuing to be an official supporter of Take 3 for the Sea, they are proud to get behind such an important organisation.

In only one hour, their 31-person strong GH Commercial and Godfrey Hirst, team along with Take 3 for the Sea representatives collected 1,657 litter items weighing 7kg altogether. Working to remove this litter from our environment helps to protect our animals, ecosystems, and oceans.

Better for Planet

Taking real climate action as an organisation means voluntarily going above and beyond current regulations to achieve net zero carbon emissions. In addition to taking steps to reduce the greenhouse gas emissions associated with their operations and products, Godfrey Hirst Australia has achieved Climate Active Carbon Neutral organisation status and are proud to be the first Australian carpet manufacturer to do so. Furthermore, Godfrey Hirst New Zealand is also now a carbon neutral organisation. *

Better for Performance

Many of the Godfrey Hirst products hold current and relevant certifications that illustrate their commitment to transparency in their product ingredients.

Their triexta, solution dyed nylon and wool carpets are certified Declare Red List Free.1 The Living Building Challenge Red List is a register of manufacturing ingredients, such as fluorocarbons, added formaldehyde, VOC’s and phthalates.

Commitment to our planet extends beyond just products and processes: it’s how Godfrey Hirst challenge themselves to do and be better every day.

*Godfrey Hirst Australia Pty Ltd and Godfrey Hirst NZ Ltd are ‘carbon neutral’ organisations. This means that those entities purchase and voluntarily retire carbon offsets equivalent to their annual carbon dioxide equivalent greenhouse gas (GHG) emissions from sources within their organisational boundary. For New Zealand, organisational GHG emissions are accounted for in accordance with ISO140643:2018. For Australia, organisational GHG emissions are accounted for, and carbon neutral status is certified, in accordance with the requirements of Climate Active.

web www.godfreyhirst.com s

1 Red List Free products disclose 100% of ingredients present at or above 100 ppm (0.01%) in the final product and do not contain any Red List chemicals.

24 Flooring June/July 2023 www.flooringmagazine.com.au

® Taking real climate action as an organisation means voluntarily going above and beyond current regulations to achieve net zero carbon emissions. Godfrey Hirst Australia has achieved Climate Active Carbon Neutral organisation status and are proud to be the first Australian carpet manufacturer to do so. Furthermore, Godfrey Hirst New Zealand is also now a carbon neutral organisation. [1] [1] Godfrey Hirst Australia Pty Ltd and Godfrey Hirst NZ Ltd are ‘carbon neutral’ organisations. This means that each year those entities purchase and voluntarily surrender carbon offsets equivalent to their annual carbon dioxide equivalent greenhouse gas (GHG) emissions from sources within their organisational boundary. For New Zealand, organisational GHG emissions are accounted for in accordance with ISO14064-3:2018. For Australia, organisational GHG emissions are accounted for, and carbon neutral status is certified, in accordance with the requirements of Climate Active. Learn more at www.godfreyhirst.com Scan to learn more! First Australian Carpet Manufacturer to achieve Climate Active Carbon Neutral Organisation Status.

Believe in Better

Feature Eco & Sustainability

Polysafe QuickLay PUR

The looselay flooring installation market is growing at an exponential rate, and with the many practical and environmental benefits of the product it is not hard to see why Polysafe QuickLay is the choice for so many contractors and specifiers. Since the launch last year, Polyflor have been met with a great reception from consumers as the QuickLay installation method saves considerable time and eliminates the need for adhesive.

Its practical installation comes down to the specially formulated studded emboss on the underside of Polysafe QuickLay which works as a moisture barrier, controlling moisture to escape from the subfloor and facilitates installation over new concrete floors of up to 97% RH. The studded back technology means that after the installation your QuickLay flooring is going to lay smooth and flat with the unique double sided QuickLay tape to secure it in place.

learning environments. Polysafe QuickLay PUR achieves BRE Global A+ rating in the Green Guide to Specification in use areas such as education and healthcare.

a Ramp test of R11. QuickLay is also in accordance with the EN 13845 European safety flooring standard.

Polysafe QuickLay is the choice in sustainable flooring as it is 100% recyclable. As well as the fact that Polysafe QuickLay can be uplifted and re-installed as a result of the looselay installation method. Polysafe QuickLay is a temporary or permanent floor covering which yields the same results as other Polyflor collections with sustainably conscious technology and the additional benefits of adhesive free installation.

Sustainability is also at the forefront of Polysafe QuickLay’s environmentally friendly features. This product is built to last but does offer an end-of-life flexibility to uplift, re- use or recycle via Recofloor. The collection is versatile in that it is suitable for both heavy commercial and residential environments in need of a quick turnaround and with a high priority on sustainable slip resistance. QuickLay flooring technology has been utilised in key sectors including healthcare, residential care, retail, education and social housing.

Features

• Same day lay, install and walk.

• Install over a variety of existing subfloors up to 97% relative humidity.

Polysafe QuickLay is designed with a healthier environment in mind. Its odour free installation promotes excellent indoor air quality and low VOC emissions, which means your new indoor environment can be utilised immediately. It is perfect for busy commercial spaces especially those containing many people in working and

Polysafe QuickLay features a contemporary tonal colour bank of 12 shades with a matte surface finish much like the Polysafe Verona Pure Colours collection. This allows for a decoration that is suitable for dementia friendly environments and is backed by the University of Stirling Dementia Services Development Centre, with accreditation for the full collection.

Naturally with a Polysafe product sustainable slip performance is imperative in its practicality of use. Polysafe QuickLay achieves P4 on the Pendulum Test (Slider 96) and

• Embossed backing facilities moisture dissipation.

• Contemporary decoration optimised for specification in dementia friendly areas.

• Polyurethane Reinforcement (PUR) for polish- free maintenance

• Easy to remove, reuse and recycle.

• Adhesive-free ensures excellent air quality and VOC emissions.

• Gauge – 2.2mm; Roll Size – 2x20m; 12 shades; P4 Pendulum Test (AS 4586 Slider 96); R11 (AS 4586).

web www.polyflor.com.au s

26 Flooring June/July 2023 www.flooringmagazine.com.au

Polyflor Australia www.polyflor.com.au 1800 777 425 flooring design for a better environment SAFETY FLOORING FOR ADHESIVE-FREE INSTALLATION

6241

Glacier

the QR Code to request FREE SAMPLES

Scan

Feature Eco & Sustainability

A1 Rubber - contributing to a sustainable society

Sustainability and environmental responsibility have always been at the forefront of A1 Rubber’s manufacturing vision since they began manufacturing over 30 years ago. A1 Rubber specialises in upcycling waste tyre rubber to create new products of higher environmental value, including commercial and fitness flooring, acoustic underlays, playground surfacing and much more. With over 9,000 tonnes of tyre rubber upcycled into new products every year, recycled tyre rubber accounts for over 70% of the materials used in A1 Rubber’s total product output. Not only does A1 Rubber lead the drive for higher recycled content in manufactured products, but this directly impacts waste materials ending up in landfill.

In recent years, A1 Rubber has been focussing its efforts to increase the amount of Australian waste tyre rubber acquired for manufacturing in to finished flooring products. These efforts have been aided by Tyre Stewardship Australia, who are helping to strive for better recycled rubber processes, so that waste rubber is suitable for manufacturing into high quality products. The Tyre Product Stewardship Scheme administered by Tyre Stewardship Australia aims to drive sustainable outcomes for Australia’s used tyres, where stewardship is an ethical value that embodies the responsible planning and management of resources.

Tyre Stewardship Australia (TSA) has a Circular Economy Collaborator program, which is designed to celebrate organisations that conduct activities that align with TSA's vision of contributing to a sustainable society. These organisations, like A1 Rubber, are instrumental in creating new markets and jobs from Australian generated end-of-life tyres. A1 Rubber is recognised as a Circular Economy Collaborator by Tyre Stewardship Australia for playing a role in utilising Australian generated tyre derived material, contributing to a sustainable society.

believe that the TSA’s vision aligns similarly with theirs, and provides a robust, credible recognition of efforts that specifically acknowledges their contribution to reducing the impact of waste Australian tyres.

In addition to manufacturing from waste tyre rubber, A1 Rubber also re-recycles any manufacturing offcuts or defects into rubber granules that can be processed again. Similarly, A1 Rubber has a real return policy, accepting past installed A1 Rubber products to reprocess into rubber granules. These re-recycled rubber granules get put to good use, as they retain all their original properties and are perfectly suitable for acoustic underlays and other applications where they get covered over. By adding these additional recycling processes, A1 Rubber further reduces its environmental impact.

At A1 Rubber, upcycling used Australian tyre rubber is their primary focus, with the majority of rubber used in their finished products being sourced from Australia, and directly saving over 200,000 Australian tyres from landfill every month. As such, they

A1 Rubber is grateful for the ongoing support of those who choose their products over imported products - by choosing A1 Rubber you are supporting Australian manufacturing and contributing to a more sustainable society.

web www.a1rubber.com s

28 Flooring June/July 2023 www.flooringmagazine.com.au

A1 Rubber saves up to 200,000 passenger tyres from landfill every month www.a1rubber.com

Flooring industry to create circular pathway for floorcoverings

Resilient flooring like sheet vinyl, linoleum, rubber and LVT are sought after products which are seeing steady demand from the construction sector. However, much of these products are imported into Australia. So, what happens to the waste generated by these products over their lifetime? The Australian Resilient Flooring Association has been busy developing a solution and now it has an answer, ResiLoop.

ResiLoop will be the industry-led and supported process to recover and recycle waste from resilient flooring products in Australia.

It is estimated that the construction industry generates about 9000 tonnes of resilient flooring waste from installations every year and the scheme will aim to recycle at least 1000 tonnes annually. It is expected that recycling rates will increase as the scheme expands and attracts new participants and as it develops end markets for the recyclate and solutions for the more challenging end-of-life waste streams.

As managing director of Karndean Flooring, Dan Lovell has witnessed first-hand the solid growth experienced by the resilient flooring industry, but he believes that the industry must make a stand to ensure that as more resilient flooring is installed, the waste streams are considered.

“We have a duty to ensure that we are good stewards of our products and that is no mean feat given there is no current onshore avenue for resilient flooring waste at the scale needed,” he said.

Mr Lovell, who is also the president of the Australian Resilient Flooring Association said that all businesses in the flooring supply chain have a lot to gain from joining ResiLoop.

“As stewardship, waste reduction and landfill diversion are being prioritised by consumers, policy-makers and regulators, you will see more major tenders demanding evidence of recycling, meaning those not delivering stewardship outcomes will be left behind.

“In fact, the Green Building Council of Australia – the organisation which manages Australia’s green building rating system –supports the scheme and is a signatory to our collective action statement.

The scheme fundamentals

The scheme describes a process for efficiently collecting scheme members' product waste from construction sites through a network of collection points and will be funded through a levy per square metre on relevant product sales, paid by distributors who join the scheme.

ResiLoop is based on a hybrid product stewardship model, in which the scheme subsidises the collection and transportation of waste and will own collected material until its transfer or sale to a recycler.

Crucially, it will also include funding for research and development to grow onshore recycling capacity and capability, including development of products that can utilise the recycled material.

Members’ waste accepted under the scheme is collected by ResiLoop-registered installers, dropped off at registered Collection Points → 32

30 Flooring June/July 2023 www.flooringmagazine.com.au

Feature Eco & Sustainability

BE PART OF THE INDUSTRY’S CHANGE

As a voluntary industry product stewardship program, ResiLoop is creating a pathway to a circular economy for resilient floorcoverings in Australia.

ResiLoop will not only recover recyclable materials, diverting thousands of tonnes of floorcovering waste from landfill, it will help meet customer, contract and ecolabel requirements to address product waste and demonstrate circular strategies in construction.

The just-released scheme design is heading towards launch in late 2024.

And it grows stronger with each committed supplier of floorcoverings, so it needs you!

A government-funded initiative of the Australian Resilient Flooring Association

ResiLoop today – contact info@arfa.org.au or visit www.arfa.org.au/resiloop.html

Join

Feature Eco & Sustainability

and then transported by contracted logistics providers to ResiLoop-registered recyclers according to the scheme’s procedures.

These activities will be funded in two key ways. A Member Participants Levy for brand owners will be established which may be transparently passed on to end users.

At the same time, an Annual Fee will be introduced for contractors and retailers intending to provide Collection Points, which brings immediate return on investment in the form of avoided waste disposal costs and a program trademark to raise their profile as ResiLoop participants.

Industry support

Since releasing the design for the scheme in May, interest and support for the scheme has been strong.

In fact, the need for an industry stewardship scheme is widely supported by the flooring industry, with over 50 key stakeholders including manufacturers, distributors, retailers, contractors, installers and specifiers, as well as influential ecolabels and industry associations, signing a Collective Action Statement which endorses such an industrywide approach.

“ResiLoop is a timely solution and will provide a practical pathway for waste from commercial and residential construction away from landfill and towards alternative durable products. It will also contribute to Australia’s ambitious goal to transition to a circular economy by 2030,” Dan Lovell said.

“We’ve been buoyed by the incredible support we’ve had for our Collective Action Statement, which builds momentum for the scheme and its implementation,” said Dan Lovell.

” But to operationalise the scheme, we need firm industry commitment and participants.

Supported by funding from the Australian Government through the National Product Stewardship Investment Fund, the impetus for ResiLoop has been the Australian Resilient Flooring Association (ARFA), making it a truly industry led project.

ARFA members have demonstrated significant foresight to develop ResiLoop and ensure effective consultation with relevant organisations in the product value chain. The scheme design process was inclusive and solution oriented.

“Suppliers, contractors, retailers, installers and builders all have something to benefit from this program. Now is the time to step up and invest in this initiative.”

To learn more about the scheme, how it works and to show your support head to https:// www.arfa.org.au/resiloop.html

Fast facts

• ResiLoop has been developed by industry, for industry to lead the way in product stewardship for resilient flooring in Australia

• It will initially aim to recycle 1000 of tonnes of installation waste per year

• It will primarily be funded through levies on product sales which can be transparently passed on to consumers

• Phase 1 will go live in Sydney, Melbourne and Brisbane in late 2024, before expanding in later stages.

32 Flooring June/July 2023 www.flooringmagazine.com.au

web www.arfa.org.au/resiloop.html s

“ResiLoop is a timely solution and will provide a practical pathway for waste from commercial and residential construction away from landfill and towards alternative durable products.”

A NATURAL BEAUTY

Marmoleum cocoa is a collection where beauty and circularity are united thanks to the unique addition of cocoa husk; a byproduct from cocoa production giving the floor a unique, granular look and feel.

It is the perfect choice for those looking for a flooring option that is both beautiful and environmentally friendly.

Made with plant-based natural raw materials, it is CO2 positive cradle to gate, without offsetting. By saving one square metre from incineration after fulfilling its intended purpose, we can reduce pollution for the next generation, equivalent to 1.8 kg of CO₂ emissions.

But that’s not all. Marmoleum with its Topshield pro surface finish is also incredibly durable, resistant to scratches, stains and is easy to clean.

Discover the full Marmoleum story on our website

Forbo - Meeting today’s sustainability requirements

The world is transitioning towards a more sustainable future, and reducing emissions is the key focus of governments, corporations, and individuals globally.

The building and construction sector accounts for almost 40% of all annual carbon emissions from the operation and construction phases. Embodied carbon or upfront carbon, is all the emissions from the construction phases of a building, including the energy and impacts from manufacturing every finish and fitting within the building.

The Green Building Council of Australia (GBCA) and over 1100 local architectural practices have declared action against climate change and have set goals to reduce embodied carbon in new buildings to net zero by 2030. The Green Building Council sets the benchmark for buildings and products, driving change to favour supply chains that are transparent, healthy, carbon neutral and circular. The Responsible Product Framework developed by the GBCA requires

all products used in Green Star projects to meet certain requirements across both independent certification and proof of a valid and current Environmental Product Declaration (EPD). An EPD documents the full makeup and lifecycle of a product and allows one to understand the true impacts of a product across several common categories from raw material extraction, to manufacture, transport and use, and end-of-use stage.

Marmoleum - the carbon and circular champion

Marmoleum is a flooring product that is future-ready, now. A carbon champion that is carbon neutral from cradle to gate, its natural raw materials absorb more carbon during their growth phase than is required to manufacture the flooring. Marmoleum also contains a high percentage of recycled content in its makeup and end-of-life recycling options.

In addition to the product itself, for every square metre installed in Australia, our local climate partner Carbon Positive plants

native trees and shrubs to create long-term carbon sinks, not as an offset program, but rather as a regeneration of local habitat that has been cleared or damaged, restoring parts of native Australia to what it was before. Marmoleum can help lower a building’s overall embodied carbon footprint and resource consumption, thus helping to meet climate goals. Being a natural, highly plant-based material, it also improves indoor health and well-being.

Natural beauty, proven performance

Aside from its impressive sustainability credentials, Marmoleum is exceptionally hard-wearing and not dissimilar to timber floors; as it continues to harden over time, contributing to a very long lifetime. The NEW Topshield pro surface finish provides incredible protection from scratches and scuffs making floor care a breeze. Additionally, Marmoleum is naturally bacteriostatic, and allergy and asthma approved.

34 Flooring June/July 2023 www.flooringmagazine.com.au Feature

& Sustainability

Eco

Feature Eco & Sustainability

Other complete flooring solutions that contribute to Green Star and sustainable projects

Forbo prides itself on offering total flooring solutions for all areas and catering to each project’s specific needs. While PVC products will never be as sustainable or low in embodied carbon as Marmoleum, there are attributes that contribute to Green Star buildings.

Their PVC collections including Eternal general purpose vinyl, Sphera homogeneous vinyl, Step safety flooring, Sarlon acoustic vinyl, Allura LVT and Flotex resilient textile are all GreenTag GreenRate Level A and Best Practice PVC certified. While circularity for PVC still poses a large challenge, progress is being made through local and strong industry collaboration.

The NEW addition: Marmoleum Cocoa

The sustainable Marmoleum champion just got better. The Dutch region De Zaanstreek - The region where Forbo’s Marmoleum factory is located in an area where cocoa is produced and processed. This inspired Forbo to create a cocoa-themed floor covering using a combination of sustainable Marmoleum flooring and recycled cocoa husks.

Forbo’s sustainable design ethos is perfectly displayed in this collection of linoleum flooring; the use of tough cocoa husks, a waste product from cocoa production, is ground and added to the mix. The finely ground cocoa husks add a unique granular look and feel to the floor design. Not only do they use cocoa husks, but also incorporated pre- and post-consumer Marmoleum, which the team at Forbo believe achieves the ultimate challenge of circularity.

The Marmoleum Cocoa production process prevents and reduces carbon emissions while also allowing the product to be recycled or reused resulting in less pollution. In fact, every square metre saved from incineration after its lifetime saves emissions to the equivalent of 1.8 kg of CO.

If you would like to learn more about responsible products and how they fit within Green Star, please visit www. forbo-flooring.com.au/sustainability or to discover their latest Marmoleum Cocoa collection visit www.forbo-flooring.com. au/marmoleum-cocoa, email us at info. au@forbo.com or call 1800 224 471.

web www.forbo.com s

35 Flooring June/July 2023 www.flooringmagazine.com.au

Design & Trends

Carpet Court continue to push for sustainable flooring

With a mission to provide consumers with a growing selection of sustainable flooring options, Carpet Court continues to make significant progress in the flooring category with the addition of eight new carpet ranges made with revolutionary ECONYL regenerated nylon.

ECONYL regenerated nylon is made by recovering nylon waste such as fishing nets from the oceans and aquaculture, fabric scraps from mills and carpets destined for landfill and turning it into virgin quality nylon yarn for the fashion and interior industry. This innovative technology allows for infinite recycling without compromising on quality, making it an ideal option for eco-conscious consumers.

As a leading retailer of flooring solutions, Carpet Court has made a commitment to corporate social responsibility and sustainability. Demonstrating the brand’s dedication, the eight new ranges of carpets made with ECONYL yarn bolsters the brand’s existing eco-friendly offering comprising eight carpet products made with ECONYL yarn which initially launched in 2021.

The range expansion follows the success of the initial launch prompting Carpet Court Suppliers to embrace the ECONYL process. This includes new Australian Made Victoria Carpets ranges, Torpedo, Ocean and Mythic, Beaulieu Australia ranges, Epicurean, Splendor and Epitome, as well as Australian Made EC Carpets expanding their existing Textured Collection range made with ECONYL yarn to include new Alchemist and Focus ranges.

Providing a diverse selection catering to various tastes and budgets, the entire Carpet Court range of carpets made with ECONYL yarn delivers options for customers that prefer a soft and luxurious feel, durability on a budget, or rich textures in a variety of palettes to suit every interior style and scheme.

A key benefit of Carpet Court's new range is that customers can make stylish, eco-friendly selections without sacrificing quality or affordability. The versatility and range of carpets made from ECONYL regenerated nylon ensure these carpets deliver the same level of luxury, performance, and fashionforward designs as traditional nylon carpets sourced from petroleum.

Conscious consumerism has become a way of life, leading designers, and manufacturers to create beautiful, innovative, and resourceefficient products. By choosing Carpet Court's new range of carpets made with ECONYL regenerated nylon, customers can take pride in making a positive contribution to the environment without any compromise.

New Carpet Court ranges made with ECONYL regenerated nylon

Victoria Carpets

• Torpedo: Stain-resistant carpet in a wide range of versatile neutral colours, designed to prevent soil deposition and absorb spills, making it easy to clean and maintain.

• Ocean: Highly versatile carpet suitable for all rooms, featuring strong fibres for resilience and longevity. Inspired by marine life, it brings a touch of nature to your home with a soft twist pile.

36 Flooring June/July 2023 www.flooringmagazine.com.au

Design & Trends

• Splendor: Heavy-duty carpet with a protective treatment against spills and marks. Colourfast and fade-resistant, it offers allergen filtering properties and a low VOC output for a cleaner living environment.

• Focus: With its contemporary chunky loop design, this new carpet not only offers a pleasing tactile experience underfoot but also complements any interior style effortlessly, thanks to its neutral colour palette.

• Mythic: Luxurious twist pile carpet with a uniquely shaped fibre that prevents dirt from settling, creating a stain-resistant and easy-to-maintain carpet that's perfect for families.

Beaulieu Australia

• Epicurean: Australian-made carpet with a soft woven backing fabric for added comfort, stability, and insulation. Enhanced with antimicrobial protection for low-maintenance living.

• Epitome: Hardwearing carpet resistant to crushing from furniture and foot traffic. Featuring antimicrobial protection, it offers durability, resilience, and contemporary colour options for all rooms.

web www.carpetcourt.com.au s

EC

Carpets – Loop Pile Australian Made Carpet

• Alchemist: The new loop pile carpet seamlessly blends durability and style, providing exceptional resilience against heavy foot traffic while boasting an elegant tweed-inspired design that effortlessly hides everyday soiling.

37 FIND OUT MORE As a Carpet Court Franchisee you are joining our network of family-owned businesses that have been at the forefront of flooring retailing since 1973. With 50 years of experience, a strong brand identity and a professional team to support you, we’ll provide you every opportunity for success.

a confidential obligation free conversation, get in touch with us now. BE PART

SOMETHING BIGGER Join Australia’s largest and most innovative flooring retailer.

For

OF

Design & Trends

Expert design insights from floor to window treatments

The look and feel of a home’s interior is influenced by a homeowners’ individual style and their choices in building materials, furnishings and accessories. This is particularly true when it comes to flooring which accommodates a large area of a home, and window treatments which help set the tone for each room. Faced with a sea of options, homeowners can feel overwhelmed, however, the key to getting it right is to think about these aspects not as standalone choices, but as integral components of the overall design aesthetic for the home.

Good home design lies in creating a space that doesn't just look incredible, but also optimises your day-to-day living. “Every selection you make should fit perfectly within the bigger picture to cultivate a cohesive look, as well as enhance the rooms in terms of how they function and feel,” says Alessia Tripi, Andersens’ in-house designer. With careful planning and thought, flooring and window dressings can work together to transform your home from just ordinary to truly extraordinary.

Making design decisions can seem challenging, but starting early in the building or renovating stage can result in better outcomes. It is essential to visualise your home's desired style and think about your preferred design themes. Whether you are attracted to a classic Hamptons style, a modern Australian look, or the clean lines of Scandi design, your flooring and window treatments can be instrumental in solidifying that theme, each reflecting your choices in texture, colour, and material that align with your individual aesthetic.

“The relationship between the interior and exterior of your home is just as important. The right materials can seamlessly link all aspects of your design, offer practical advantages, and enhance the overall appeal and liveability

of your home,” says Alessia. Here are some insights on how you can incorporate design choices into your home, regardless of your preferred style.

Hamptons Style: Characterised by a coastal, relaxed feel with a sophisticated touch, Hamptons-style homes typically utilise light, natural materials. Whitewashed or lightcoloured timber floors such as Andersens’ Timbre in the colour Ashen Oak, luxury vinyl that mimics this look, are ideal. For window treatments, consider plantation shutters, which add a charming touch while also allowing for easy light control and works well in most parts of Australia.

Modern Australian Style: This style draws on the country's diverse natural beauty, focusing on open, bright spaces with a laidback vibe. Consider wide plank hardwood floors or high-quality laminates such as Andersens’ Clever XL Engineered Timber in the colour Gold Coast that imitate this look. Roller blinds or venetian blinds can create a light, airy atmosphere while maintaining privacy when needed.

Scandinavian Style: With its minimalistic, functional, and clean design, Scandi-style homes favour neutral colour palettes and natural materials. Light, muted timber or vinyl plank flooring works well here, for example Karndean Looselay Longboard in the colour Wheat Oak. For window treatments,

38 Flooring June/July 2023 www.flooringmagazine.com.au

Design & Trends

consider panel glides or simple roller blinds in a light, sheer material that can still let in lots of natural light.

Regardless of your chosen style, it is critical to consider the functionality and texture trends of flooring and window treatments. They should not only match your aesthetic preferences but also withstand the rigours of your lifestyle. The current resurgence in the appreciation of texture, specifically in natural materials, adds a new layer of consideration. Whether you are accommodating high-traffic areas, pets, or kids, it is crucial to find durable, texturally appealing, and stylish solutions. By doing so, you ensure your home is not only captivating to the eye but also resilient and practical for everyday living.