BUY AUSTRALIAN MADE BUY SURTECO AUSTRALIA

German technology, Australian know-how.

SURTECO Australia are committed to creating the highest quality product through local design, materials and manufacturing for the Australian climate. We are a one-stop-shop. www.surteco.com/au | www.shop.au.surteco.com

Editor’s Note

Welcome to the May / June 2023 issue of Supplier Magazine. This issue we mourn the enormous loss of our founding partner and publishing trailblazer, Vicky Cammiade. Supplier Magazine and Vicky have been a huge part of the development of modern furniture manufacturing in Australia. Vicky was passionate about the industry and the work she did. It was a personal privilege that Vicky was not only my mum, but my mentor and her legacy will continue to inspire the work I do each day. Read Philip Ashley’s tribute to an industry Icon, Vale Vicky.

Inside this issue you will also find our coverage of Interzum and Ligna where features such as resource efficiency, smart materials, renewable energies or recycling and upcycling were key to many of the innovations exhibited. Along with the two megatrends of sustainability and digitisation. Read our stop press coverage on page 20 for everything you need to know about the return of these two international industry events.

Please feel free to contact me directly regarding any industry news, company events, training and or product information you would like us to publish at – michelle@elitepublishing.com.au

Take a look at our new website and don’t forget to join our growing online community by visiting us on Instagram and Facebook.

Until next time, enjoy your read.

Michelle Cammiade Editor

Michelle Cammiade Editor

Vale Vicky Cammiade

Supplier Magazine regrets to announce the passing of Vicky Cammiade, longtime friend and valued colleague to many in the furniture, flooring and stone industries. Vicky passed away peacefully at her home in April. Many will know Vicky as publisher of Supplier Magazine but her legacy of service and support of the furniture and allied industries extends far beyond her role as a successful businesswoman.

Vicky’s involvement in the industries she served started in the 1980’s, a time of rapid adoption of technology. The industry was coming of age and Vicky was there with her business partner Maureen Horne to kick start what is today a vibrant, advanced contributor to the Australian economy.

It may not be widely known, but Vicky and Maureen organised the very first AWISA fair in Sydney, an event that is now a fixture for manufacturers in Australia and throughout Oceania. John Tiddy, chairman of the association wrote to Vicky and Maureen, “(We) convey to you our delight and appreciation for the positive and professional presentation of AWISA’88. We feel that our joint efforts can only produce the start of bi-annual exhibitions for the whole industry…bringing the industry together.”

A member of the International Woodworking and Furniture Supplier Magazine Association; Vicky is recognised around the World as the face of Australian furnishing media. John Legg of Furniture and Joinery Production U.K. described Vicky as a ‘pioneer’. Stephen Powney of Wood Based Panels International said, “I know she was highly regarded in the international furnishing print media.”

Vicky established the highly valued Gold Star industry awards in 2012 that are displayed in the head offices of parent companies throughout Europe alongside some of the World’s most prestigious industry awards. Vicky has always loved the industry and the work she did. “Its diversity, the products, the people are fantastic” she always said.

Supplier Magazine and Vicky Cammiade have been a huge part of the development of modern furniture manufacturing in Australia. Always welcoming with a warm and genuine smile, Vicky knew how to listen and always gave her clients what they wanted. Vicky’s contribution to the entire industry has formed what it is today and if there is ever a book written about it, Vicky’s name will certainly be amongst those who shaped its future. ❚

Vicky’s contribution to the entire industry has formed what it is today and if there is ever a book written about it, Vicky’s name will certainly be amongst those who shaped its future.

Silica Risk Update

On 28 February Commonwealth, State and Territory work health and safety ministers met and agreed on significant measures to advance stone processing safety in the workplace. WHS ministers agreed to implement National awareness and behaviour change initiatives; implement regulation of high-risk crystalline silica processes for all materials (including engineered stone) across all industries; and further analysis and consultation on prohibition of use of engineered stone including consideration of silica content levels and other risk factors, and a national licensing system for products that are not subject to a ban or legacy products.

Safe Work Australia have been tasked to review three options for a ban on the use of engineered stone. A decision was planned to be made no later than July 2024. Those options included:

1. Prohibition on the use of all engineered stone described in Option 6 of the Regulation Impact Statement;

2. Prohibition on the use of engineered stone containing 40% or more crystalline silica, and;

3. Prohibition on the use of engineered stone containing 40% or more crystalline silica and licensing of PCBUs working with engineered stone containing less than 40 % crystalline silica.

Master Builders Australia are concerned that any blanket ban that is not risk proportionate would send the wrong message to businesses that are innovating and investing to continuously improve products and processes to minimise risk. It is clear MBA do not support option one, a total ban on the product.

At least one supplier of engineered stone has made a public statement that they believe Safe Work Australia will recommend option three, a silica content of 40% or less, as well as National licensing facilitated at a state level. Their statement says “Any material containing silica, from engineered stone to concrete and natural stones like granite and sandstone, poses risks if not handled properly. The risk of silicosis can be avoided if proper equipment is used and proper safety controls are followed, like wet-cutting to suppress dust.”

The CFMEU has urged Federal and state ministers to commit to option one, banning engineered stone. The construction union has also stated they will take the extremely rare step of banning engineered stone in July 2024 unless federal and state governments

act first. The Australian Workers Union (AWU) has welcomed the NSW Labor government’s move to reform workplace safety laws to prevent workers from contracting silicosis.

Kate Cole, president of the Australian Institute of Occupational Hygienists, likens the risk of exposure to silica to that of asbestos and says ‘high-silica’ stone products should be banned as soon as possible. Federal workplace relations minister, Tony Burke said planning would be brought forward by six months following a warning by the construction union in November that it would ban the use of the material. Minister Burke acknowledges that not all engineered stone products pose the same risk, an indication that item 3 is a government option. ❚

Dementia Research Community - Bondi2Barossa

In March this year an epic nine day cycling adventure took place. Starting in Bondi and riding to the Barossa Valley in South Australia the ride covered a staggering 1,400km.

Twenty-six riders including four ride captains took part in the fully supported event which included lead and rear escort cars, a mechanic, and a medic to raise awareness and funds for a cure for Dementia.

The charity event raised $175,000 for this ride specifically and over $1,000,000 in funding so far for the Bondi2Berry charity.

Innovync has been a major sponsor of the Bondi2Berry ride since 2016 and every multi day ride since. They are the only company to achieve this and will continue to sponsor this great charity doing wonderful things for the dementia community.

Dementia statistics Australia 2023

• Dementia is the second leading cause of death of Australians

• Dementia is the leading cause of death for women

• In 2023, there are more than 400,000 Australians living with dementia. Without a medical breakthrough, the number of people with dementia is expected to increase to more than 800,000 by 2058

• In 2023, there are more than 28,650 people with younger onset dementia, expected to rise to more than 42,400 people by 2058. This can include people in their 30s, 40s and 50s

• In 2023, it is estimated that more than 1.5 million people in Australia are involved in the care of someone living with dementia

• 2 in 3 people with dementia are thought to be living in the community

Bondi2Berry is a challenging, yet beautiful ride covering 155km in distance, and an elevation of 1,700m. Starting at the North Bondi Surf Life Saving Club, they ride out of the Eastern Suburbs and travel through parts of the Royal National Park to Wollongong and Kiama before finishing in Berry on the NSW south coast.

The ride is an open road event. It adheres to normal road rules and is sanctioned by AusCycling. Please note that only road bikes are able to be utilised (no TT / triathlon or mountain bikes). There will be support vehicles for each of the groups, as well as first aid and bike mechanics on the course.

For more information and to register your interest visit: https://www.bondi2berry.com/ waitlist/ ❚

forget this:

enjoy this:

DUST-FREE WORK ON THE CNC WITH LEUCO

LEUCO „AEROTECH System“

1 SYSTEM – 2 FUNCTIONS: Clamping device and extraction turbine at the same time

Dust-free nesting and routing with all the benefits for

Tool

Production

Energy efficiency

Health!

| different designs depending on your application and material (MDF, Fibre )

| machine manufacturer approved versions available

CONTACT US

DIRECTLY

Your LEUCO technical advisers

T (61)-02-8708-4900

ONLINE PRODUCTS

LEUCO tools online catalog www.leuco.com/products

ONLINE NEWS www.leuco.com

Product Update

Recycling made easy with new 4-Bucket Concelo

Gone are the days when we put all our waste in one bin and don’t give the environment another thought. No body likes the idea of their waste needlessly polluting the environment, which is one of the main reasons why separating waste is important. Waste that isn’t separated just ends up in landfill, whereas separating our waste correctly allows more to be recycled, allowing precious materials to be reused again. With a growing number of city councils now collecting four separate types of waste and recycling, there is an increasing need to separate waste conveniently within the home.

Hideaway Bins are proud to introduce the new Concelo CR600 models, their first ever 4-bucket-in-one waste bins. These have been developed to allow waste to be easily separated into four waste and recycling buckets in one convenient unit which fits into a standard 600mm wide kitchen cabinet. Sorting waste within the kitchen avoids the nasty task of sorting through and separating recycling later. A 2015 report on managing household waste in Europe showed

separating our waste increases the quality of material collected. That’s because it’s easier for people to sort out the different materials than for machines, particularly food and the complex packaging we have today.

right hand buckets are available for recycled items. The Active Lid is totally hands free and is compatible with electronic push to open systems like Blum Servo drive or Grass Sensomatic.

The new Concelo CR600 is available in a range of model and bucket sizes, and in white or cinder colour options.

The smaller CR600-413 offers four 13 litre buckets, which can sit behind a 50/50 drawer front split, offering 52 litres total capacity.

Each bucket in the CR600 is supported by an individual Clip’n’Clean tray, which can be removed for easy cleaning in warm soapy water. Moulded from durable polypropylene, these trays resist staining and will not rust, providing a durable hygienic waste bin.

To control odours and moisture, the Concelo Active Lid has been positioned to close over the two left hand buckets, perfect for waste or food scraps buckets, while the two

For larger families there are two options, which both can sit behind a 60/40 or 2/3 to 1/3 drawer fronts. The CR600-416 has four 16 litre buckets, for 64 litres of total capacity. Or if you want to mix bucket sizes to match the volume of waste generated, choose the CR600-213-216 model, which offers two 13L and two 16L buckets. For total flexibility the buckets can be configured in any position within the bin unit.

The CR600 is designed to fit a standard 600mm wide cabinet using 16mm board. Like all Concelo waste bins, it is designed to suit System 32 drilling specifications, and is provided with a drilling template to make installation straight forward.

To learn more, visit hideawaybins.com.au or contact one of Hideaway’s distribution partners – Hafele, Nover or Galvin Hardware. ❚

Product Update

Introducing the NiRo collet chuck Premium by Leitz

High quality on workpieces can only be guaranteed with high-quality tool clamping technology. The clamping device must combine consistently high holding forces with great precision. However, these requirements are in the context of increasingly complex work tasks, in which the overall system of clamping device and tool must ensure high machining results in the long term, even under difficult production conditions. For example, the functionality of a clamping device must be guaranteed even under high air and/or material humidity. After all, the machining quality should remain permanently and consistently high and the tool life should be maintained at a maximum. Tool breakage and damage to the workpiece must also be prevented.

Concentricity with high balancing quality

With the NiRo collet chuck Premium, Leitz has developed a new clamping system with hollow shank taper that combines high changing repeat accuracy with flexibility and durability. Made entirely of stainless steel, the chuck guarantees corrosion-free finishes for life and precise, functionally reliable tool clamping, even with high air and material humidity. The high concentricity (max. 0.003 mm) is fine balanced to G2.5 at 25,000 rpm. With a taper angle of 2°52', the OZ collet enables the transmission of higher torques than an ER collet with an 8° taper angle. The longer taper length of the Niro Premium also offers greater angular stability. At the same time, the ball-bearing clamping nut ensures low friction losses between the nut and collet and enables safe use in right-hand and left-hand operations. In conjunction with the optimized trapezoidal thread and the increased guide length, this ensures aboveaverage holding forces with a comparatively low tightening torque of 80 Nm.

Above: NiRo – durable, precise and powerful

New key system, slim contour

Depending on the application, the collets of the premium chuck can be easily and quickly changed to adapt to a wide variety of drills and cutters. The available collets cover the range from 6 mm (or ¼") to 25 mm (or 1") safely and precisely. Thanks to the machine-side connection via the HSK-E-63 adapter, speeds up to a maximum of 24,000 min-1 are possible. The high concentricity and balance quality of the Niro Premium ensures a long tool life and permanently

high machining quality on the workpiece. In addition, the collet chuck features a particularly slim design, which improves accessibility to the workpiece and due to the reduced interference contour, allows optimized 5-axis machining. Leitz has also revised the Premium's key system for easy mounting of collets and tools. The optimized key surfaces not only ensure safe operation during clamping and releasing, but the contour of the system is also up to 15 percent slimmer than comparable chucks.

All in all, this new solution in new dimensions shows why Leitz simply offers more. Knowledge and reliability for more productivity, efficiency and quality in clamping resulting in better safety and perfect machining results in CNC machining.

https://www.leitz.org/en-au/highlights/nirocollet-chuck-premium

Product Update

Introducing the Hafele Déco Collection 2023

Functionality and aesthetics go hand in hand – with an elaborate result.

With the 2023 Déco collection, Häfele is presenting a compendium of innovative design ideas. From soft, hand-caressing to unique handles in the harsh industrial style, to icons in the style of a modern classic.

As multi-faceted as the designs are, they combine the intention of bringing together design and functionality at the highest level. Be it fashion, your own home or innovative furniture designs – it is not only the balanced interplay of design and materials which appeals to our senses. It is often the smallest details which make the difference,

Peka storage solutions

Choosing the perfect kitchen unit is not enough to guarantee you the perfect storage space. Only by selecting the right units for your kitchen layout and the right interior fittings to match can you be sure of enjoying maximum accessibility and convenience. Peka’s corner unit and larder unit pullouts make full use of the space in your kitchen units and keep all your utensils and ingredients within easy reach.

Combining smart innovative storage solutions with Swiss quality since 1964. Peka is one of the top market providers of larder unit pullout, slide-out corner systems, and ecologically designed waste sorting systems. The Peka range includes kitchen larder pull-outs,

extendo shelf systems, corner cupboard pullout, base unit systems, Pegasus high shelf liftdown, Riverso drawer systems, laundry Sesam standard, cleaning accessories and more.

triggering a feeling and reinforcing our sense of wellbeing.

The Hafele 2023 Deco collection, which was designed by well-known designers, Sacha Sartory, Francesco Buzzo and Serena Lambertoni, perfectly combines outstanding usability with modern aesthetics. References from the past decades are present – yet every handle is a contemporary design of the 21st century.

For more information scan the QR code attached or call your nearest, Häfele sales office or account manager for a personal demonstration.

www.hafele.com.au

Peka’s sleek, stylish unit and shelf systems lend kitchens, living areas, bedrooms, and offices a touch of understated elegance, as well as offering breathtakingly original ways to use space more effectively than ever before.

Longevity and environmental sustainability are absolutely central to the development of Peka products. Peka understands that the longer products can be used, the less harm they do to the environment. That is why they use only high-quality and durable materials manufactured using the latest, environmentally friendly processes, and guaranteeing a long service life for products.

Peka is available exclusively through Nover. ❚

Product Update

Traditional bathroom fixtures reimagined

Artedomus, Australia’s pre-eminent supplier of bathroom and architectural surfaces, has been proudly bringing Agape’s stunning bathtubs, tapware and bathroom accessories to Australian shores for several years. They are delighted to now expand the range with Agape’s new Memory collection of tapware and accessories.

Designed by the highly regarded Italian architectural and design practice Benedini Associati, the Memory collection of tapware and bathroom accessories is inspired by the elegance and atmosphere of traditional 20th-century bathing spaces, reimagined for today. As with all Agape designs, every piece is made in Italy to exacting production standards.

Reflecting the current focus on wellness in interiors and the subsequent repositioning of the bathroom as one of the most important rooms in the home, these new designs evoke a timeless and breathtaking beauty, while elevating your bathing experience.

A perfect fusion of past and present, the collection pays homage to the curved,

undulating forms of traditional 20th-century tapware, reinterpreting them with clean, sharp and modern lines, along with a fresh and revitalised take on the classic four-spoke handle design.

Tapware for basins, baths and showers includes benchtop- and wall-mounted mixers, floor-standing spouts and shower heads, in a range of sizes and with single or double controls. There are various finishes available to suit different bathroom aesthetics, including chrome, brushed burnished brass and natural brushed brass.

A progressive mixer is a unique addition to the range. The single-handle mixer allows precise control of water temperature from cold to hot without affecting the flow rate, ensuring comfort throughout the wash.

To allow for a seamless and cohesive look throughout your bathroom, a range of complementary accessories are available as part of the Memory collection. This includes an exquisite floating shelf featuring softly curved lines and optional marble inserts. Available in sizes from 120 millimetres to 700 millimetres in length, the Memory shelf

provides a beautiful and practical spot to store soap and bathroom essentials.

You can also choose matching mirrors, available in rectangular, circular and square shapes and two different sizes, both framed and frameless. The framed mirrors, which come in a black or white lacquered finish, give you the option to include concealed LED lighting, while the frameless mirrors feature an elegant, polished edge.

There are also towel rails, wall hooks and WC accessories, all available in the same range of finishes as Memory tapware so you can create a seamless aesthetic throughout your bathroom.

Artedomus is Australia’s pioneer in truly exceptional bathware, tiles, stone, architectural surfaces and furniture. The new Agape Memory collection is a perfect example, transforming the look and feel of your bathroom and elevating your cleansing ritual to the next level.

Agape Memory tapware and accessories are available exclusively in Australia at Artedomus showrooms. ❚

Product Update

Concreet – celebrating individuality

For each project, the team of experts at Concreet carefully select the shape, texture and colour, taking into account the characteristics of the architectural project and the customer’s needs.

Sculpting imagination

Immerse yourself in the world of architectural design innovation with Concreet’s S-1 Series. A revolution in design and construction. The engineered concrete compound is more than a material – it is an embodiment of versatility and uniqueness, offering boundless creative possibilities. The Series S-1 ensures enduring robustness while redefining design boundaries, setting every Concreet creation apart as a statement of bespoke design.

Versatility

The S-1 Series showcases remarkable versatility, regardless of the projects size, it lends itself to a broad array of applications. From crafting bespoke feature walls and handmade rocks to moulding simple reliefs and intricate sculptures. The S-1 Series even serves to create unique pieces of furniture, transforming environments into artistic masterpieces.

Exclusivity

Dive into the artistic expanse of the S-1 Series, offered exclusively by Concreet in Australia. This unique compound opens up possibilities for crafting diverse custom projects, functional art, furniture, distinct décor and architectural centrepieces. The S-1 Series is more than just a construction material – it is about sculpting narratives, creating works of art and personalising spaces.

robust resistance against wear and tear including from a variety of environmental conditions like high humidity. Constructed from natural materials, the S-1 Series reflects Concreet’s commitment to environmental responsibility.

Durability

The S-1 Series combines aesthetics with outstanding resilience, embodying the Concreet commitment to durability, safety and environmental sustainability. It provides

Partners in creativity

The team at Concreet turn visions into reality. Rather than just create walls or décor they sculpt stories, setting new design standards each time. Engage with one of the Concreet design specialists today and let them help bring your vision to life, transform your space, impress your clients and set a new standard in design with the power of the S-1 Series.

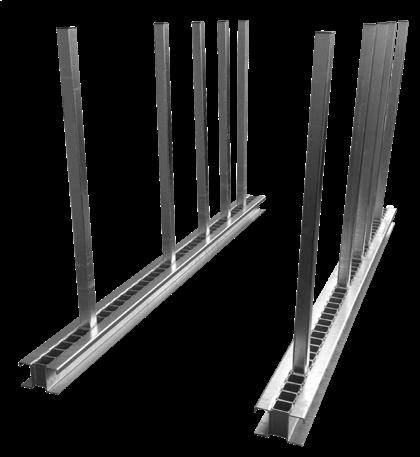

Surteco Australia invests $2.5 million in its ABS edgeband facility

Surteco Australia, the only local manufacturer of ABS edgebands for the cabinet-making industry, is boosting stock supply and delivery timeframes with a $2.5 million investment in its NSW plant. A warehouse extension coupled with a new production line will provide more capacity and offer exciting new products to the Australian market.

“Our German parent company has invested heavily in the Australian business for the past 30 years,” says Aldo Borazio, Managing Director of Surteco Australia.“We manufacture ABS Edgebands in Australia - purely for the Australian market and conditions.

“We have our own product formulations and testing processes, and we go to great lengths to improve UV resistance and maintenance of colour to deal with our hot summers.”

Surteco produces a range of ABS melamine and thermoplastic edgebands in various sizes and thicknesses and is one of the world’s largest manufacturers of the décor papers that are supplied to local fabricators for the production of laminated surfaces.

“The unique position that Surteco Australia holds is that it is the only company that can take designs developed for décors through to edgeband and other related products.” Borazio says. “All other companies in our field are either décor or edgeband manufacturers. Surteco does both, resulting in a perfect match between décor and edge, and enhancing the surface technology.”

Surteco leads the way with choice for their customers with the ability to offer not only ABS edgeband but Digital print, Fusion edgebands in different thermoplastic solutions such as ABS, PVC, PP and Acrylics, with all options either manufactured or stocked in Australia ready to be supplied when customers need.

Surteco was established in Germany some 140 years ago and opened its Australian plant more than 30 years ago.

While Australian manufacturing processes are tailored for the local market, the equipment and technology used to further improve product quality and efficiency are based on decades of German engineering know-how.

For example, ongoing research is carried out on the most effective means of adhering edge bands to different types of boards.

The benefits of buying locally made, extend beyond the product specifications, Borazio says.

With more than 30 years of manufacturing experience in Australia, Surteco colour matches and manufactures quickly and effectively, and supports the market with branches and sales representation nationally.

Surteco is a one-stop shop for all products associated with edgebands, including adhesives, Release agents and cleaners.

The company provides decorative surfaces, with Surteco Australia offering a large portfolio of products including decorative paper, release paper, finish foil, skirtings, roller shutters and technical profiles.

The fusion of innovation and creativity

“Surteco Australia offers customers absolute freedom of design,” says Borazio. “They

can take advantage of international trends or incorporate their own designs, then choose from countless decor and embossing variants, and various gloss levels and materials.”

“A premium combination of decor and embossing is guaranteed, and we have a very diverse range of edges to ensure the right fit for material and design.”

Spectacular Deko Metal finishes

One of Surteco Australia’s ranges is the Deko Metal collection, made with real metal and matched with edgebands.

“Cabinet makers who want to make a really dramatic statement in a kitchen are incorporating these metal surfaces to great effect,” Borazio says. “The edgebands can also provide a very striking contrast

to benches and cupboards when used as a pop of colour in a more subtle décor.”

The Deko Metal collection is available in brushed and mirror finishes, four board thicknesses and five luxurious colours in Surteco Australia’s stock collection. Colours are Brushed Bronze, Brushed Copper, Brushed Gold, Brushed Titanium and Brushed Silver. Deko Metal edges are available in 23mm wide by 1mm thick to perfectly match the metal surfaces. Deko Metals are stocked in Sydney.

Other trends in decorative finishes

After having their domestic lives turned upside down during the Covid-19 pandemic, and adjusting to working from home, many Australians are now seeking a sense of serenity and peace.

There has been an influx of natural materials and earth-inspired colour tones, along with a big emphasis on tactile decorative surfaces and finishes that mimic natural textures.

Super matt interior surfaces are also proving popular as they provide a sense of calm and softness both visually and to the touch.

Surteco’s Deko+ range has a velvet touch with low light reflectivity, making it a very appealing super matt laminate for calming interior spaces.

Sustainability

Surteco has established a global sustainability team that works closely with the company’s engineers in Australia. There is a growing focus on selecting sustainably compliant products that are environmentally sound and long-lasting.

Surteco Australia is Greenguard and Greenguard Gold certified for all Australianmade edgebands.

“We are looking at every possible action we can take with regards to sustainability,” Borazio says. “, We continually are trying new materials both here in Australia and globally to always improve our product whilst ensuring Surteco takes a leading position with sustainability initiatives.

The Surteco website is a major creative and technical resource for cabinet makers wanting information and inspiration on new designs and products, services and support. Products can also be ordered online.

Stop Press – interzum and Ligna

The head of the World Health Organisation has declared an end to the COVID public health emergency saying most countries have “Returned to life as we knew it in 2019.” This was evident this May when the two international trade shows interzum and Ligna resumed to great visitor numbers in Germany.

Approximately 62,000 trade visitors (74,000 in 2019) from some 150 countries attended the leading international trade fair for suppliers to the furniture and interior design industry at interzum in Cologne, Germany. Held 9th to 12th May, 1,600 exhibitors, down slightly from 1,806 in 2019, displayed a wide range of product with a central theme of sustainability. Aspects such as resource efficiency, smart materials, renewable energies or recycling and upcycling were key to many of the innovations exhibited.

The fair’s organisers scrutinised interzum’s own carbon dioxide (CO2) emissions, ranging from event technology and energy to logistics and waste disposal along the way through to

food service. These emissions were reduced wherever possible. Any emissions that could not be reduced were be offset by financing two certified, internationally recognised climate protection projects in India; the first a wind energy generation scheme in Gujarat. The second, a reforestation scheme in Karnataka.

There was no stronger demonstration of sustainability than the stand of the ownermanaged storage solution company Vauth Sagel. Spanning 832 square metres, the Vauth Sagel exhibit, designed as a polygonal garden landscape clearly indicated the direction in

which Vauth-Sagel is heading: “We have grown because we have made lots of good decisions; and we can continue this tradition by making lots of good decisions for the future”, claims CEO Claus Sagel.

This year, Häfele will celebrate 100 years with a display focus on ‘Maximising the value of space.’ Displays included theme worlds of kitchen, caravan, micro living, office, and hotel, with additional displays featuring their extensive lighting products, and their ‘We Care’ service. Interesting products from Häfele included onefix plus, a connector based on minifix, and slido F-Flush57, their innovative twin-panel sliding door system. Häfele’s Connect Light Experience won an interzum award for high product quality.

Salice, a brand we’ve known for decades impressed with the innovative Conecta concealed hinge for either wooden or aluminium-framed glass doors. The product received an interzum award for high product quality. Their Exedra pocket door system has been further developed and a new 70kg drawer runner F70 features soft, decelerated closing of the drawer.

Titus celebrated their 50th anniversary at interzum. Highlights showcased the Titus T-type hinge that now features a tool-free hinge cup fixing system. The Push Latch RV is the latest addition to the range of push locks and handles from Titus, designed to provide secure locking of cabinets during transit for a variety of applications in recreational vehicles, boats, and yachts.

Interzum presented to the international trade audience as an active shaper of change. Three ‘Trend Forum’s’ were presented at this year’s interzum; Materials and nature, Textile and machinery, and Function and components. The forum ‘Materials and nature’ concentrated on "Neo-ecology" and in particular on the transformation towards a circular economy, making optimal use of the available resources.

Stop Press, Ligna.

Awarded ‘Best of the Best’ at the interzum award 2023: FurnSpin from Hettich brings elegant dynamism to high-end furniture design. A flick of the wrist turns the carcase from the closed to an open position. FurnSpin synchronises two forms of movement: swivel action as well as rotation through 180 degrees. Benefiting from refined kinematics, the cabinet body moves along a defined path, preventing any collision between furniture edges. FurnSpin cancels out centrifugal force; torque is balanced so carefully that even very light objects don't fall over or slip about in the cabinet but stay firmly in place during the spinning movement.

The trend ‘Function and components’ focused on furniture in change, shifting boundaries. Häfele displayed a new drawer system where it is possible to disassemble the drawer into its individual parts. All materials are checked in order to reassemble them in such a way that the individual components can be easily recycled at any time.

If you wanted to talk about how much carbon each manufacturer had removed from the atmosphere you certainly could, but more tangible methods to help the environment is the industry push to a circular economy, re-using as much material as possible and assisting in minimising pollution. The next fair will build on these piers of responsibility because industry can always do better. The next event will be held on 20–23 May 2025

From Monday 15th to Friday 19th May, 1,300 companies from 50 different countries presented their solutions for the wood industry, the furniture-making industry, the woodworking trades and the forestry sector at Ligna in Hannover, Germany. The focus was on the two megatrends of sustainability and digitisation. The response from Germany and all over the world was equally high. 80,000 visitors (90,000 in 2019) from 160 countries took advantage of the opportunity to inform themselves about smart machines and resource-saving production processes.

Dr. Bernhard Dirr, Managing Director of VDMA Woodworking Machinery said, “The show demonstrated that the woodworking and wood processing industry offers its customers the necessary technologies for competitive, and at the same time, sustainable production. In view of the uncertain situation currently confronting the woodworking and wood processing industry, the success of LIGNA 2023 speaks volumes for its status as a source of momentum. Not only is it a driver for the industry in good times, but above all, it delivers solutions for the challenges ahead.”

Achim Homeier, Senior Director Global Marketing & Product Management, HOMAG Group said, “It was surprising how many people came because after four years, nobody knows what’s really going to happen. But we are very satisfied with the result.” Oliver Kunzweiler, Director Central Marketing Weinig Group said, “It was absolutely crazy to be here at LIGNA 2023. The place was crowded.”

A Few Ligna Highlights

Altendorf Group displayed their ‘Hand Guard’ system for sliding table panel saws they showed us a prototype of at the last Ligna show. Altendorf claim this is a globally unique early detection system with two cameras and is the world’s first and only Aiand camera-based safety assistance system for sliding table saws.

Biesse Group showcased a new visual identity that represents the corporate renewal process and actively expresses the group’s values and identity – centred on

multi-materiality and being inherently international – while preserving the features that distinguish the various sectors in which it operates. In their preview area, Biesse presented a crowd-stopping edge banding machine where hydrogen is used to power the laser edge applicator. One litre of water produces 1.5 kilometres of panels!

Felder Group presented their solution for panel saw safety with PCS (Preventive Contact System) and their revolutionary PUR-edge banding without a glue pot using a PUR glue strip with ‘GlueBox.’ An interesting innovation was the positioning of vacuum pods on CNC machines using with augmented reality glasses, available as an option with Felder’s ‘Format4 F4Integrate’ software solution.

The IMA Schelling Group (WoodTech Australia) is introducing the first production lines with homogenous software developed in-house: aimi will enable visualisation and control of the machines and entire plant from anywhere. With implementation projects already underway, IMA Schelling is reaching an important milestone on the way to achieving this.

Jan Kurth is Managing Director of the furniture industry's VDM and VHK associations and said,“The EU Commission is currently working on several legislative projects aimed at the transition to a circular (sustainable) economy.” A circular economy designs out waste and pollution, keeps products and materials in use, and regenerates natural systems. To the sustainability megatrend add increasing digitisation, or ‘Industry 4.0’ and soon to include Ai (artificial intelligence) and you have a fair that anticipates a ‘transformation of the wood industry.’

With the NiRo collet chuck Premium, Leitz launched an innovation that combines several processing needs. The clamping system is entirely stainless steel, has a long lifetime and is process-reliable in the event of high air or material humidity. Optimized key flats ensure safe operation during clamping and unclamping. Due to a ball-bearing ring, the power transmission to the tool shank is significantly higher than with common chucks and as a result provides the optimum hold for maximum precision during machining with twice the holding force.

The unusual DIACURVE nesting cutter from LEUCO incorporates end-to-end arc-shaped cutting edges and large gullets. The tool delivers high cutting quality without chip congestion. Its diameter remains constant which makes it uncomplicated. Its overall appearance and design of the diamond tips underline the innovative and patent pending construction. With fewer diamond tips and two alternating shear angles per cutting edge, the tool achieves precise and chip-free results. The extra-large gullets enable higher feed speeds.

Homag Group’s always interesting ‘innovation centre’ gave us a look into the group’s future with Ai measuring panels for stress. Systems will display arrows on panels to indicate the next manual movement. Edge bander Ai will measure ambient temperature and adjust glue for best adhesion. Dust extraction and vacuum systems can automatically be turned off when the machine does not require it.

SCM Group presented their awardwinning ‘Blade-Off.’ This new, anticipatory safety system for SCM sliding table circular saws eliminates accidental contact between the operator's hand and the saw blade. The system intervenes before the saw blade is accidentally touched or dangerously approached by the operator. Intelligent sensors detect parts of the human body and distinguish them from actual materials. Another feature of the SCM exhibit was the SCM Maestro

connect Digital Service platform that ensures machine status monitoring, maintenance optimization, rapid support for issue management, suggestions on spare parts and augmented reality support.

Weinig Group demonstrated a large-scale system for the complete manufacturing process from raw material to finger-jointed lamellae and solid wood panels. In a cross-cut finger jointing line a robot with a vacuum unit stacks boards onto the line. Jean-Philippe Hildebrand of Luxscan technologies explained these are assessed using the CombiScan Sense scanner with Ai technology, and any identified defects are cut out by an OptiCut 450 Quantum, the world’s fastest high-speed cross-cut saw. Up to 240 good parts per minute are automatically transferred to the HS 200 finger jointing line.

LIGNA 2023 was not only a platform for presenting new technologies, but also a venue for knowledge transfer and networking. Smart, connected machines, systems and processes that make costs and production more efficient were particularly popular with the visitors. There was also strong demand for automation and processoptimizing solutions to cushion the impact of the shortage of skilled workers. Supplier will cover both interzum and Ligna in more detail in the next issue. The next LIGNA runs from 26 to 30 May 2025. ❚

Stone Safety

Article by Philip AshleyFeature

The manufacture of stone products presents unique and serious safety risks to workers. From slabs falling and crushing workers to airborne dust, working with stone requires a commitment to health and safety from the business owners and all workers in the production facility.

Silica dust is generated in workplace processes such as crushing, cutting, drilling, grinding, sanding, sawing, or polishing of natural stone or man-made silica containing products. Every stone product can include a small amount of silica and should be treated with care. Silica dust can be generated and found during manufacturing and construction, and when mining or tunnelling.

We should know later this year whether or not engineered stone will be banned and what licensing arrangements will be put in place if a decision is made to allow material with a silica content of 40% or less to be used. If a total ban is imposed by the unions

as promised, then the very serious issue of silicosis will largely go away.

Another safety issue found when people work with stone is falling slabs. People have been killed and crushed by heavy slabs, either falling from a store, or when being transported and craned to and from stone processing machinery. Flying debris from modern machinery is not a big issue but if stone is cut with manual machinery like saws, it can be.

Other more general safety issues include manual tasks with heavy loads or repetitive movements; machinery or equipment with moving parts; and hot or cold temperature extremes. General safety risks can be controlled by eliminating a dangerous process; substituting a dangerous process for a safer one; engineering controls like isolating workers from dangerous machinery movements; administrative controls like training and changing the way people work, and as a last resort, personal protective equipment. ❚

Unloading stone slabs from containers

Article by Worksafe

What is the problem? Workers have been trapped and crushed while unloading stone slabs from shipping containers. The problem is often due to one or more slabs toppling (i.e., falling from vertical), often as a consequence of a slab moving more than expected or in an unintended way. For example, a slab might tilt to a greater angle than anticipated.

What are the risks?

There have been a number of serious crushing incidents where toppling slabs have trapped a person against the floor or wall of a shipping container or other structure or between slabs. These have resulted in fatalities, amputations and musculoskeletal injuries affecting the trunk, back, shoulders and arms. Some incidents have occurred when attempting to remove single slabs from either A-frames or crates standing vertically. Causes of incidents include inappropriate packing methods, excessive number of slabs being moved and the use of equipment such as forklifts and lifting attachments not specifically designed for the task. While movement of the slabs may be intended, the speed, forces and extent of movement are commonly underestimated, and once the falling load topples, there may be no opportunity for escape.

What are the solutions?

When ordering stone slabs:

• Where possible, stone slabs should be ordered and delivered in open top containers that allow individual slabs to be accessed for mechanical lifting while the person is outside the container (i.e., not in the fall shadow).

• All containers should be inspected prior to unloading – open top containers make inspection easier.

• Loose slabs should be placed on a central A-frame rack.

• The A-frame sloping arms should be leaning at an angle of between 4º to 8º.

• The angle of the base or leg should be 90° to the A-frame arms to minimise the likelihood of the slabs moving during transport.

• Any packing between stone slabs must not reduce the angle of slabs to less than the A-frame angle.

• There should be sufficient space to sling and remove the A-frame, with slabs attached, from the container.

• Crated slabs that stand vertically should be braced to prevent movement during transport.

When inspecting the container:

• Ensure the container is level to prevent the A-frame angle being reduced on one side or a crate not standing vertically.

• Before opening any container, check the outside for any damage that may indicate the load has shifted.

When unloading stone:

• Before stone slabs are released from any transport restraints, ensure that no person is in the fall shadow of any slabs or crates at any time.

• Provide temporary restraints such as straps, chains or purpose-made mechanical devices to restrain slabs that are not being removed and to limit movement of slabs being removed only to vertical. These temporary restraints must be able to be placed and controlled from outside the fall zone and must not impede separation of slabs for removal.

• Separate individual slabs from the end closest to the container door so people are not moving into the fall shadow. Use either wooden or proprietary brand wedges designed for the task.

• Use a gantry or bridge type crane fitted with a vacuum lifter or lifting clamp to unpack stone slabs from open top containers. ❚

Discover the benefits of Corian Solid Surface

A safe and versatile material for your next project.

Technical expertise is crucial in any industry, but especially when it comes to manufacturing and installation. It is essential to ensure that the products produced are of the highest quality, durable, and safe for use. Corian Solid Surface is a leading zero silica benchtop solution that is safe to manufacture and install in homes and businesses across Australia.

Silica is a naturally occurring mineral commonly found in many engineered and natural stones used for benchtops. When these materials are cut or drilled, they release tiny particles of silica dust into the air, which can be inhaled and cause serious respiratory problems, including lung cancer.

Corian Solid Surface is different. It contains zero silica, which means it is safe to manufacture and install without the risk of releasing harmful silica dust. This makes it a responsible choice for both workers and consumers.

In addition to its safety benefits, Corian Solid Surface is a versatile material that offers a range of design possibilities. With a wide range of colours and finishes available, it is easy to create unique and stylish surfaces that are both practical and aesthetically pleasing. It is also a highly durable, non-porous material that is resistant to bacteria, stains, and impact damage, making it ideal for high-traffic areas. Corian is easy to clean and maintain and is backed by a 10-year installed warranty.

To ensure that the highest quality and safety standards are maintained, Corian offers a comprehensive fabricator training course. This course is suitable for both beginners and experienced professionals who want to learn more about working with solid surface materials. The course covers everything from fabricating to fitting and finishing, giving participants a thorough understanding of the process from start to finish.

At CASF, they understand that every project is unique. That's why they offer small-group training sessions that are tailored to meet the specific needs of their customers. Their hands-on training approach ensures that participants have plenty of opportunities to practice the skills they learn in a real-world setting, giving them the confidence they need to work with Corian Solid Surface.

Whether you're a professional fabricator or someone looking to start a new career in the industry, their fabricator training course is the perfect place to start. Their experienced trainers will guide you through the process, sharing their expertise and knowledge along the way.

By choosing Corian Solid Surface, you can be part of the movement to protect our tradespeople and create a safer, healthier work environment. It is a material that meets your needs and exceeds your expectations in both design and safety.

For more information visit the website or call 1300 795 044. https://bit.ly/3B793Hm web www. casf.com.au ❚

Respiratory protection by Sundstrom Examples of construction dust

Many professions may be exposed to harmful dust in a construction environment. Anyone who inhales construction dust should be aware of the health risks this may cause.

Regular inhalation, of even small quantities of construction dust, can damage the lungs and respiratory airways over the course of time. Diseases can develop quite quickly, but in many cases, it can take 10 to 30 years before symptoms become apparent. Unfortunately, by the time the problem is noticed, irreparable damage is often done, and it can be difficult or impossible to treat.

What is construction dust?

Construction dust is a broad term, as there are many different types of dust one may be exposed to in a construction environment. The largest particles, which are visible, are captured by the body’s natural defenses, and remain, in most cases in the nose, mouth and throat. The small particles, which are invisible to the human eye, are the most dangerous, and can cause scarring of the lungs and even enter the bloodstream.

Silica dust arises during work with materials containing silica, such as concrete, mortar and sandstone.

Wood dust arises during work with softwood, hardwood and wood-based materials such as MDF and plywood.

Other types of dust arise during work with plaster, glass wool, mineral wool, marble, etc.

Health risks

Lung damage such as silicosis, lung cancer, asthma or chronic obstructive pulmonary disease (COPD), and includes diseases such as chronic bronchitis and emphysema. Construction dust can also cause allergies.

Respiratory protection

When all other measures have been taken to reduce dangerous exposure levels, respiratory protection equipment is the last, but important, means of preventing hazardous air contamination entering the body via the airways.

The choice of respiratory protection depends, amongst other factors, on the type of dust present, its WEL (Workplace Exposure Limit), and the nature of the work, i.e., the degree of physical exertion and the length of exposure.

Facial hair, such as beards, moustaches and sideburns, reduce the level of protection offered by tight-fitting respirators, and create a need for Powered Air Respiratory Protection to ensure adequate levels of contaminant reduction.

National regulations and requirements must be followed, as these may vary from state to state/territory. Check carefully which regulations apply.

Sundstrom recommendations

The filtering devices listed below for work in which silica dust (RCS) and general construction dust is present or likely to occur.

Shorter duration: For lower work rate and dust concentrations. For users who are clean shaven.

• Half mask SR100 or SR900 with high efficiency P3 particle filter SR510

• Silica Dust respirator kit – A complete respiratory protection kit

Longer duration: For heavier workload and higher dust concentrations. For users who are clean shaven, with facial hair, beard or sideburns.

• SR500 fan unit against particle and gas contaminants

• SR700 fan unit against particle contaminants only.

• Use the powered air purifying respirator (PAPR) with a suitable head top depending on the work situation: SR580 helmet with visor, SR570 face shield (Bump cap optional), SR530 soft hood, sR200 full face respirator.

Lapitec - a unique material for design and architecture

Lapitec is the material of the future: 100% Made in Italy, elegant, sustainable and highly performant.

Lapitec is one of the world’s only sintered stones: a timeless surface made from a selected mixture of natural and incredibly pure minerals, ideal for adding a touch of charm to any environment. It is a full-bodied material, meaning that its exterior and interior are identical, with no prints on the surface; it is produced in large slabs and with a range of different thicknesses. Each slab measures over five square metres and can be cut and worked on in different ways, depending on the project at hand: curve cutting, carved surfaces and various types of holes are all possible.

Lapitec can be used in a number of ways, in various environments: from kitchens to bathrooms, from wall cladding to paving for swimming pools, from spa areas to yachts.

The nature of the product

The success of the product is based on a combination of features that respond perfectly to market trends, as well as an obvious focus on sustainability, both in the raw materials used and the stages of the production process. Lapitec is a mixture of 100% natural minerals that contains no resins, inks, and other petroleum derivatives.

The versatility of Lapitec

With innovative technology supported by 25 patents, Lapitec offers design versatility, and the guarantee of an excellent aesthetic result combined with optimum technical performance.

Lapitec slabs, 3365 mm in length, are available in two collections, 14 colours and five different surface textures, and can also be customised. They are used not only as an indoor and outdoor surface covering, but also for rooftops, yachts, swimming pools and product design, from tables to consoles and from bathrooms to kitchens, where the total absence of porosity of the surface makes

Lapitec ideal in terms of hygiene and ease of maintenance.

Lapitec is a valuable material that is suitable for numerous uses, the ideal support for international architects and designers. In recent years Lapitec slabs have been used for public buildings, residential complexes, infrastructure, places of worship and marine applications, but also for the creation – in collaboration with other design brands – of kitchens, outdoor furniture, tables and next generation technologies.

Thirty years on Lapitec, the company –now run by the third generation under the leadership of Marcello Toncelli's grandson of the same name – is expanding its product range with ever more innovative solutions in the field of kitchens and living spaces. This is also through the technological partnership with the parent company Breton, a world leader in the production of plants for machining stone materials and natural agglomerates, which guarantees the reliability of the production chain.

web www. lapitecaustralia.com ❚

A Safer Stonemasonry Future

Embracing water processing and automation.

In the active work of stonemasonry, the strategic integration of water processing and automation is pioneering a new age of safety and efficiency.

With specialised machinery such as the Dal Prete water treatment system, Extra 480 CNC Bridge Saw, GMM Techni Water Jet, along with offerings from other notable brands like Comandulli, Burkhardt, Thibaut, and Cobalm, businesses can tailor-make production lines that prioritise employee safety while enhancing operational efficiency.

The essential role of water in stonemasonry

In modern stonemasonry workshops and factories, water plays an indispensable role across various stages of stone processing, including cutting, milling, and polishing. Its strategic application has not only revolutionised the industry but also significantly enhanced the safety of stonemasons.

Here's why water is so crucial.

For cooling the tool: In stone processing, the temperature of diamond tools can significantly rise, leading to accelerated wear. Water acts as an effective coolant,

TOOLS FOR SAFER STONE PROCESSING

preventing the tools from overheating and extending their lifespan. Importantly, this also reduces the risk of accidents from tool malfunction, promoting a safer environment for stonemasons.

For cooling the surface: Elevated temperatures can detrimentally impact the quality of the stone being processed, which could compromise safety. Water not only helps maintain the stone's integrity by cooling the surface but also enables the cutting of more fragile materials with ease and efficiency. This ensures a high-quality finish and creates safer conditions for stonemasons.

The integration of automation and water processing: A safer future

By bringing together specialised machinery, each with its unique strengths, businesses can create a production line that significantly improves safety and efficiency. For example, the Extra 480 CNC Bridge Saw ensures accurate and neat cuts while operating in water. The GMM Techni Water Jet enables safe and intricate crafting by submerging the stone and water jetting out a desired shape, making it suitable for tasks like sink hole cuts. Then Comandulli Musa can polish the edges to achieve the desired finish, all while capturing and filtering the water back into Dal Prete's water treatment system. This ensures sustainable water recycling and contributes to a cleaner environment for employees while saving the expense of additional water.

At the heart of this transformation is the SEKON software, which enables the interconnectivity and optimal performance of these machines. It ensures safer and more efficient operations through the automation of processes, reducing the potential for human error and workplace accidents.

By embracing the power of water processing and automation, the stonemasonry industry is pioneering a future where workplace safety and operational efficiency are paramount. This forwardthinking approach results in tailor-made production lines that not only create safer environments for employees but also streamline business operations. As the industry continues to evolve, the central role of water and automation in promoting safety and driving development is becoming increasingly evident.

web www.cdkstone.com.au ❚

For removing particles: Stone processing inevitably generates dust and particles. Water aids in removing these particles from the surface, reducing friction with the tool and ensuring a smoother, safer processing operation. By limiting dust production, water also contributes to a healthier workspace, reducing airborne particles.

How to start a porcelain revolution

Article by Tijana Trifunovich, InnovyncIn 1965, Australia’s porcelain industry experienced a monumental shake-up. Mr Serra, an Italian immigrant with a passion for quality ceramics, founded a company dedicated to importing and manufacturing quality European ceramics. In so doing, European Ceramics sparked a porcelain revolution.

The first disruptive wave began when the firm imported Italian tiles into the country. Then they imported a high-end Italian machine to cut large-format tiles on. The very first CMS waterjet in Australia, to be exact.

“Being of Italian origins, construction, design, and manufacturing have always been my passion. CMS - “MADE IN ITALY” - is a no brainer, and the fact that, in the 1980s, they were the first manufacturer of a stone

machining centre, was a simple reason to invest in and purchase a CMS Stone machine. Today in the factory, we operate an Idroline waterjet and a Maxima CNC. Both machines serve us very well in the manufacturing of large porcelain slabs,” says David Serra, the founder’s son, now European Ceramics’ Director.

Leading a team of stonemasons, technical experts, project managers, and installers, David does it all. Immersed in the operations of the business, he continues to bring top-quality tiles to Australia, while keeping an eye on global trends and new materials. Like Dekton and other sintered stone, which are notoriously difficult to work with - unless you’re European Ceramics. Their greatest success secret? A blend of advanced technology and exceptional technical support.

“We have made several changes to our CMS machines over the years thanks to Pierre at Innovync. The changeovers have been the reason why we have had a mutual and respectful relationship over several years,” says the Director.

One of those changeovers was the acquisition of a CMS Maxima. This 5-axis machining centre is capable of carving exquisite monuments from marble, granite, porcelain, and sintered stone. In the hands of Roberto Colonetti, the company’s Porcelain Artist, this machine has created true stone masterpieces. The bust of David, which Roberto crafted on the Maxima then shipped to CMS in Italy is just one example. If you attended Marmomac last year, you would have seen it proudly displayed on CMS’ stand, a testament to the detail and accuracy of their machines.

Such awe-inspiring works have earned the company great respect in the Stone industry. Their reputation for excellence in the field

Discovering Stone

of porcelain and ceramics travels far beyond Australia’s borders, positioning them as global leaders. Holding workshops all over the world, these porcelain experts teach others special cutting processes as well as manufacturing and methodology systems that lead to highquality results. The workshops are an integral part of the firm's operations, solidifying their position as leaders and guiding others through the difficult-to-navigate field of ceramics manufacturing.

Hands-on learning and constant experimentation are the foundations for European Ceramics' expertise. Cutting largeformat tiles, kitchen benchtops, vanities, and innovative new products, David and his team constantly push the envelope. With the combination of the Idroline and Maxima, they’re able to cut almost any material, then use the Maxima’s multi-axis capabilities to reach hard-to-get angles. Collaborating with architects, homeowners, and designers, the team easily fulfill orders and adapt to the challenges of a rapidly changing market.

“The most important part of our development over the past 58 years is that we have never stopped, never felt satisfied. We have always been able to change with the market demands. The saying is “don’t be a white elephant” - always move and move quickly with the times and market trends. Technology is changing, and thanks to CMS and Innovync, we have embraced these changes and invested in new machinery and technology and moved with the times,” says the Director.

This attitude has made the firm resilient, innovative, and resourceful. Their investments in the Idroline waterjet and Maxima CNC have been instrumental in keeping the business running, even when things around them stood still. Relying on Innovync for maintenance, spare parts, and technical expertise, European Ceramics weathered the COVID storm with barely a scratch to show.

“Certainly, we were very relieved with Innovync taking over CMS in Australia, as anyone who has a large operation with machinery understands that every day if your equipment is not working it is costing you money. The after-sales service of the machinery is the most important part for the initial sale of equipment. We have been working with Innovync since the re-branding of the company in Australia, which I believe to be from 2020. We have had a very mutual relationship over the years, and they have provided expert installation, maintenance, and repairs, and one item which was very important to our operations: especially during the COVID years - a fast spare part replacement. They carried stock of most spare parts in Australia, which was a very important service tool throughout the COVID period,” comments David.

With Innovync’s support and expertise to lean on, David, Roberto and others on the team are free to experiment and innovate. The security of having a dedicated, aftersales specialist who keeps machines running 24/7 is instrumental in helping European Ceramics grow and flourish. Is it any wonder then, that this unique firm is at the forefront of the Australian and global ceramics sector?

On their own, European Ceramics’ feats seem like remarkable one-off achievements. Step back in time, look at the big picture, and you’ll see that each feat is simply one pitstop on the road to a porcelain revolution. web

The new kid on the block – Measure Square Stone and Tile

Stone and tile estimation software is revolutionising the construction industry. Having the ability to quickly and accurately estimate a project’s cost and materials needed can save time and money for builders, contractors, and other industry professionals. Stone and tile estimation software provide users with powerful tools such as slab optimization, vein matching, and structural take-offs that help to ensure accuracy when pricing large multi-story kitchen bench top projects.

across multiple slabs when doing a project. This ensures a professional-looking finish on any project by allowing perfect pattern alignment between slabs. It also eliminates any guesswork involved in estimating by utilising advanced algorithms to match veins accurately with no need for trial-and-error tests or manual measurements.

Measure Square Mobile provides a simple mobile solution for anyone looking to measure, plan, estimate, and quote onsite. Measure Square Cloud provides an interface and set of tools designed to keep your team, customers, and contractors on the same page.

Slab optimisation is a feature of stone and tile estimation software that helps users optimise the number of slabs needed for any given project. This can save time in estimating by quickly calculating how many slabs will be required as well as their sizes and shapes. Additionally, it allows users to view 3D visuals of the entire project before ordering materials to make sure they are correct.

Structural take-offs are an additional feature of stone and tile estimation software that allow users to quickly calculate the amount of material needed for any project. By using this tool, users can input job specifications such as sizes, shapes, types of stones or tiles used and have accurate calculations in seconds instead of hours or days if done manually. This not only saves time but also helps keep estimates accurate by eliminating potential errors associated with manual calculations.

Measure Square Suite

Measure Square provides detailed documentation, video tutorials, and training resources to get customers up to speed quickly with their products. Whether it's a single-user license or a multi-user subscription plan, Measure Square has an option for everyone's needs. With cloud-based collaboration tools, customers will never miss out on any project changes or updates from other users in their team. Detailed reporting features allow customers to track their progress over time and measure their success. With Measure Square, customers can easily manage their projects from start to finish with the help of a dedicated customer local support team that is available for any troubleshooting or technical assistance needed.

JobTrakr- Live site project management solutions

Vein matching is another useful feature found in stone and tile estimation software that helps users match natural stone veins

Measure Square is designed for all estimation professionals across the flooring and construction industry. Measure Square suite provides digital tools to significantly improve efficiency, reduce mistakes, increase profit, and establish clear communication and collaboration pipelines designed to keep any team on the same page. Designed for commercial estimation processes using simple take-off functionality from architectural drawings in PDF, IMG, and CAD formats, Measure Square is the industry's top-rated tool for flooring and construction businesses.

JobTrakr is the must-have project management software for flooring and construction businesses. With JobTrakr intuitive dashboards, you can quickly manage projects from start to finish. Easily track general tasking and installation tasking, assign tasks to other users, add notes and documents, review compulsory worksite processes, and much more. Built-in reporting tools let you analyse project performance in real time so you can stay on top of your projects without the hassle.

Visit www.measuresquare.com.au or give us a call +61 7 3166 9128 to find out more. ❚

TRIED, TESTED AND TRUSTED

The one partner you need for stone with exclusive and innovative suppliers from around the world. Expand your capabilities and reach your business potential with CDK Stone.

The many applications of natural stone

Natural stone is an incredibly versatile material that can bring beauty and durability to a surprising range of applications, from kitchens to pool surrounds, and furniture to fireplaces. Stone can be cut to virtually any shape and thickness for creating floor tiles, tabletops or wall cladding, or it may be used purely for its aesthetic appeal to provide subtle and stylish visual accents.

With 40 years of experience, CDK Stone has become the leader in premium Natural Stone in Australia. Selecting slabs from the finest quarries around the globe, CDK Stone’s quality, knowledge and service are unparalleled. CDK Stone’s dedicated stone consultants can help you select the perfect stone for each application.

Elegant and enduring surfaces

Kitchens and bathrooms are natural places to take advantage of stone’s physical characteristics. For these areas, marble, limestone, granite, dolomite and quartzite are popular. Benchtop surfaces and splashbacks are natural stone’s most typical use in the kitchen. It can also be used as cladding for the cabinetry or rangehood, and as a surface for built-in dining. Quartzite and marble are the most popular choices for kitchens.

For bathrooms, stone is ideal for vanity surfaces, splashbacks, and matched cladding on vanity cabinetry. It can be used in showers, as a bath surround and on bathroom floors and walls. Small but striking design features can be created in wall cabinets and mirrors with marble and limestone dominating this space.

Natural stone is a great choice for fireplace surrounds, where it captures and showcases the warmth of the hearth. Granite and marble both make for beautiful, enduring hearths and fireplaces.

Bringing warmth and beauty to living spaces

Natural stone has been used as flooring both indoors and out for millennia. It can be cut to form tiles at whatever size is required and serves just as well for making stairs. Just as with floors, stone brings its natural strength and durability to walls, either as a feature or as cladding on an entire wall, both internal and external. Stone’s beautiful natural colours and patterns can be used as a design element to great visual effect while remaining functional.

At home both indoors and out

As one of nature’s most hard-wearing materials, different types of natural stone are perfectly at home among the elements, making it great for outdoor applications such as barbecue areas, pool surrounds, paving and outdoor seating. Harder stones such as granite, dolomite and bluestone are commonly used, with Super White Dolomite and Viscount White Granite two of the most popular choices.

Whatever the application, natural stone can help bring together different functional elements of a home, unifying floors, work surfaces, fittings and furniture. No matter where or how it is used, natural stone will continue to provide classic style and enduring function for decades.

Discover CDK Stone’s range of premium natural stone today by booking a stone viewing appointment at www.cdkstone.com. au/appointment. ❚

HOW

Tooling

Three timber industry trends to revolutionise your business

As with all industries, it’s important for cabinetmakers and shopfitters to adapt to design trends in order to remain relevant and competitive, and meet the changing demands of consumers. Taking the trend theme even further, today, we look at three trends that one supplier, the Stirling Group, has identified in the industry, and how they’re connecting their customers with innovative solutions.

Trend 1: Custom tooling

Fraser Killen, Co-Founder and Co-Director at Panel Tools, says keeping up doesn’t have to be an expensive proposition. The official tooling partner of the Stirling Group, Panel Tools is leading the way in providing quality custom tooling solutions across the cost spectrum. As Fraser explains, any business using a CNC machine has the capability to produce an almost infinite array of products, simply by employing the right tool.

“We can create a one-off custom TCT router bit in less than three weeks for under $200 and with no minimum order,” he says. “This provides an opportunity to expand a business’s offering exponentially, even if the trend they’re accommodating turns out to be only short-lived.”

The example Fraser touches on is cabinet doors. “At the moment, there’s been a big run on cove and ribbed cabinet door profiles. We’ll prototype something that will give the customer a pilot version of what they want. We look at cost-effective solutions for them to produce something quickly and easily and then, if their volume grows later through demand, we can come up with a higher end solution.”

Indeed, for higher-volume output, Fraser says a diamond tip would be more appropriate. “The important thing to know is that you don’t have to over-capitalise on tooling. You

may want to do a one-off job or test the waters on an emerging trend and do a smallrun batch. But if the initial trend becomes fully adopted, you will want to gain more efficiencies from this profile, and you want tooling that will be able to cope with that.”

Trend 2: 5-axis CNC machines

While Brad Anderson, CNC Product Manager for the Stirling Group agrees that a 3-axis CNC machine is impressive in its versatility, he also sees a growing shift towards 5-axis machines.

“Some of our customers are taking their manufacturing to the next level and investing in 5-axis machines, which are another huge trend in our industry,” he explains. “As new designs become more complicated and more difficult to manufacture, these machines really step up to elevate a business’s capabilities by far.”

Trend 3: Clamex

Clamex is a type of hardware system, growing in popularity, which requires a specific profile to be grooved in the side of panel. It requires an arced groove, to be produced with a blade or a router bit in a sweeping motion. 5-axis machines allow this process to be automated and applied at any angle.

Brad says the Clamex furniture connector system is just one example of how 5-axis capabilities are helping businesses surge forward and outpace competitors. “At the Stirling Group, we’re always on the lookout for ways we can help our customers to increase efficiencies and profitability. What we’re currently seeing is 5-axis machines becoming more and more desirable. Connecting customers with advanced technology puts them ahead of the curve.” ❚

Achieve perfection with your projects

MACHINERY I TOOLING TOO LIN G I MAINTENAN C E I TRAININ G

The Stirling Group is dedicated to the growth and innovation of the Australian and New Zealand Timber Industries. As industry leaders, we aim to uniquely position ourselves with our customers to deliver customised solutions for machinery, tooling, automation, training and nished products. Contact the team today to discover how The Stirling Group can unlock your potential.

1800 077 862

thestirlinggroup.com.au

Recently, lnterzum Cologne 2023 successfully concluded, bringing together top hardware brands from around the world. DTC, with its innovative hardware products and solutions, took part in this grand event, applauded by industry elites from over 90 countries.

From the north entrance to the east entrance, at the gate of Hall 7 and Hall 8 on the boulevard, from the visitor guidebook to the internet platform, DTC images were widely seen and welcoming our guests.

At booth A068, Hall 8.l, our team together with colleagues from our distributors have presented our key products.

This year, with the theme of "Time to Cooperate", we demonstrate our approaches to collaborating with woodworking companies, hardware distributors and furniture retailers.

Our cooperation partners cover 120 countries, working with us for decades. During this lnterzum event, we have celebrated with our Australian partner Nikpol for the cooperation of lO years and we look forward to a stronger partnership for the years to come.

To share some of our latest innovations:

PURE-PRO Kitchen Storage System: A brand new system made to optimise the function of various kitchen cabinet units based on the DTC glass-boxsided and metal-boxsided drawer system.

PURE-PRO Wardrobe Storage System: