DESIGN + MATERIALS + TECHNOLOGY

The innovative VS WASH® Laundry Hamper system offers a clever solution for both efficient installation and client satisfaction. Based on the renown VS ENVI Space waste bin system this new range of durable premium hamper systems designed for long-lasting performance.

Crafted with your needs in focus, the system seamlessly incorporates both quality and functionality. Featuring fully integrated soft-closing slides with syncronised over extension and hampers with precision cut ventilation holes.

Key Advantages:

• Lifetime warranty, German quality

• Efficient easy instalation

• Streamline design

• Precision cut ventilation holes - gentle on delicate laundry

• Synchronised runners with over extension for easy hamper removal

• Highly durable metal cover to trap unpleasant odours and moisture

• Integrated Soft and Self-Closing technology

Distributed by:

Welcome to the May / June 2024 issue of Supplier Magazine. Inside this issue you will find our annual Safety feature. Safety in manufacturing is particularly important because of the unique circumstances presented by fast moving CNC machinery, conveyor systems and often dangerous materials. Our feature article looks at how employers can develop a manufacturing safety checklist of best practices to protect their staff.

In our Fitouts and Trends section Philip Ashley looks at the global megatrend, neo-ecology, a blend of ecology, economics, sustainability, and consumption. With a look at how many of our advertisers, including Grass, Häfele, Kitchen King, Surteco and Titus Tekform focus on neo-ecology as a resource efficient push for social change.

Please feel free to contact me directly regarding any industry news, company events, training and or new product information you would like us to publish at – michelle@elitepublishing. com.au

Until next time, enjoy your read.

Michelle Cammiade Editor

Michelle Cammiade Editor

Multicam Systems, suppliers of the Australian made range of Multicam CNC Routing machines, recently hosted a series of in house trade expos, with great success. Held in Brisbane, Melbourne, and Newcastle during February and March, the expos attracted visitors from a wide range of industries, including shopfitters, kitchen manufacturers, cabinetmakers, engineering and fabrication companies, sign and display companies, and composite cladding companies.

At the expos, Multicam Systems showcased their latest machine models and software products.

Live demonstrations were run on a variety of machines, including a complete nesting cell with a 3600mm x 1800mm process area, automatic material loading and unloading for cabinetmakers and kitchen manufacturers.

Also demonstrated was their range of unique software products including KitchenCAD Pro, Door Manufacturer, Ezi-Panel Pro, and Ezi-Duct Pro, which offer cost-effective and versatile software solutions for kitchen manufacturers, door manufacturers, architectural cladding and ducting industries.

Visitors also had a chance to see the latest developments in CNC machinery and productivity attachments, such as special automated clamping systems, CNC rotary axis attachments, automated location and positioning systems, vacuum pods, and cutter cooling and lubrication systems. They also had the chance to interact with Multicam's representatives and technicians, who were on hand to answer any questions and offer expert advice.

Multicam also invited other great Australian companies, such as StripLox, CarbiTool, Sutton Tools, Mozaik, and Cadpro, to be part of the events and show how their products

can enable CNC machine owners to get the best from their machines. With generous contributions of patented joining systems, discounts on tooling, and incentives on a range of machinery, visiting companies were able to take advantage of the special deals on offer.

Overall, there was a great response to the events that showcased the flexibility and appeal of Multicam CNC routing machines and their ability to provide bespoke solutions based on an individual company's needs. As an Australian supplier and manufacturer, Multicam is dedicated to developing and providing solutions specific to Australian conditions and needs, making them a top choice for anyone looking to expand their capabilities and enhance their services. z

The new HAWA Concepta lll family with its wide range of variation options can provide an individual solution for any space situation. Kitchens are easy to conceal and design using the pivot and folding/slide-in hardware.

HAWA Concepta III has the complete package, with Push to Open options available from June 2024.

Key Advantages:

• Design flexibility, with or without handles.

• Functional design with movement assistance – Push to Open.

• Assemble and install in under 8 minutes with just 12 screws.

• Flush fitting design.

• Easy adjustment, saving time on site.

info@hafele.com.au

The 2024 Federal Budget’s investment to support the employment of more apprentices and trainees has been welcomed by the Independent Tertiary Education Council Australia (ITECA), the peak body representing independent skills training, higher education, and international education providers.

The Australian Government is providing an additional $265.1 million over four years in financial support for apprentices and their employers. Under the Australian Apprenticeships Incentive System apprentices and employers in priority occupations will receive an extra $2,000 and $1,000, respectively.

“This additional funding is welcome and will help aspiring apprentices and trainees plus their potential employers,” said Troy Williams, ITECA Chief Executive.

Under the revised system, from 1 July 2024 employers taking on apprentices training in priority occupations will be eligible to receive an additional $1,000 ($5,000 in total) in incentive payments, to help subsidise costs associated with employing an apprentice. Further, apprentices undertaking training in priority occupations will be eligible to receive an additional $2,000 ($5,000 in total) in incentive payments, to assist with cost-ofliving pressures and support them to finish their training.

“From construction, mining, health and hospitality the Australian Government’s investment will help more people not just into a job, but into a career,” Mr Williams said.

Apprentice payments will be restructured to be frontloaded, with apprentices receiving $3,500 in the first year and $1,500 in the second year. This will provide more assistance to apprentices when they need it most. Employers can receive up to $5,000 in the first year. Payments will be paid over two instalments, with $2,000 at six months and $3,000 at twelve months.

“The approach of the Australian Government looks to support apprentices and trainees throughout their studies has merit,” Mr Williams said.

Some employers have queried whether the additional amount will make much of a difference when it comes to apprentice and trainee recruitment and retention. ITECA notes that the Australian Government has a Strategic Review of the Australian Apprenticeship Incentive System underway that will investigate the support available to help more people start and complete apprenticeships and traineeships.

“ITECA looks forwards to ensuring that members’ views are taken into account as this review makes its recommendations to the Australian Government,” Mr Williams said.

Independent Registered Training Organisations support 50.9% of the 365,420 apprentices and trainees in training as of September 2023 according to the National Centre for Vocational Education Research (NCVER). z

Cabinetry.Online is excited to announce the Legends of the Trade initiative—a tribute to those who breathe life into the cabinet-making industry. This initiative is more than a competition; it’s a celebration of stories, individuals, and businesses that elevate our craft to new heights.

Honouring the pioneers of our industry

The team at Cabinetry.Online have been privileged to interview and publish the journeys of influential figures all across our field. It is a toast to the skilled cabinet makers, diligent business owners, suppliers, and educators who keep this industry flourishing.

The idea for the Legends of the Trade initiative sparked on a casual Friday afternoon at Cabinetry.Online. As the team relaxed with end-of-week drinks, they began sharing stories from their experiences and those of their clients. Amid the storytelling, a playful suggestion emerged: why not create a special beer for the trade? The team embraced the idea and Joinery Juice Lager was born.

“This quickly spiraled into something more when we reached out to a local brewery to see if they’d help us do a special brew,” said Justin Collins, General Manager of Cabinetry. Online. “They were willing to accommodate and even have custom can designs printed".

What started as a fun idea transformed into a full-fledged initiative aimed at celebrating the stories and achievements across all facets of the cabinet making industry.

Join the Competition: Share Your Story

As part of this initiative, Cabinetry. Online launched the Legends of the Trade competition and invites you to share your story, no matter how big or small. Whether you are a seasoned veteran or a rising star. By participating, you could win the major prize—Five free slabs of Joinery Juice Lager.

1. Visit cabinetryonline.co/legends-of-thetrade

2. Fill out the form on the page and submit your legendary entry. It could be:

• Nominating yourself, a colleague, or friend and explaining what makes them a legend.

• Submitting pictures or telling the story of an outstanding project.

• Sharing your journey or your business's growth in the industry.

Every story has the power to inspire. Join Cabinetry.Online, share your narrative, and help shape the future of the cabinet making industry.

Visit cabinetryonline.co/legends-ofthe-trade or follow Cabinetry.Online on Facebook, Instagram, and LinkedIn to discover more inspiring stories and submit your entry. z

Every so often, a development comes along that is bound to transform an entire industry. A recent innovation out of New Zealand offers cabinet makers the opportunity to significantly improve the edge quality of cabinet parts, eliminate manual cleaning and reduce edge bander maintenance, all at a surprisingly competitive price.

Quality cabinetry is largely determined by the quality of the bond of the edge tape to the panel. Since the early 1960’s, when the first edge banding machines were presented to the market, suppliers have strived to develop a more perfect joint. The invention of LASER

activated edge tape allowed for joints without visible glue lines. Zero joints not only provide the highest level of quality to the panel, but they are also more resistant to heat, humidity and bacteria than EVA glue. The original laser technology is expensive, later developed technologies are a lot more affordable but tend to require precise adjustments to get a perfect result.

And now, with Biesse, a new era of edge banding has begun with the introduction of a technology using a Hydrogen flame to activate the functional layer of ‘laser’ edge tape to produce a finish of the highest quality. The technology was developed by HyFuse and could be New Zealand’s best-kept secret, with thirty machines in that country

already using the new development. Biesse, Australia’s leading supplier of technological solutions to the cabinet industry has now partnered with HyFuse to exclusively bring this innovation to the Australian industry.

Henk van Oeveren who is one of the inventors of the Hyfuse technology explains: Hydrogen technology uses heat generated from the combustion of hydrogen and oxygen to activate the functional layer of the zero joint edge banding tape. The flame of the hydrogen-oxygen mixture is directed towards the edge band through a nozzle with a row of tiny holes to melt the functional layer. The Hydrogen is supplied from bottles sourced from standard gas supply companies.

ALPHACAM is the software-of-choice for the woodworking and stone-cutting industries, covering 3-axis right through to simultaneous multi-axis machining.

ALPHACAM Nesting software tackles complex shapes with ease, boosting your productivity. It optimises material usage by efficiently arranging parts on the sheet, minimising waste and reducing material consumption. This comprehensive solution streamlines your CNC machining and cutting operations, delivering significant material cost savings.

• Leading nesting engine

• Material optimisation

• Maximise Productivity

• Enhanced accuracy

• Reduced programming time

• Reverse side nesting

• Multi drilling unit

One D sized bottle will apply approximately 4km of tape. The required oxygen comes from an oxygen concentrator that is part of the HyFuse system. The concentrator uses on average 50 litres of compressed air per minute and is supplied through a 6 mm air hose.

The HyFuse edge banding technology comes with a virtual shopping list of benefits. First and foremost, Hyfuse makes an edge bander extremely easy to run. There are only 3 heat settings and these directly relate to the panel thickness. Heat transfer is not affected by tape colour. There are normally no different heat settings required for tape brands either.

Hyfuse technology can be retrofitted to existing edge banders. If your current Biesse edge banding machine has pre-milling, an essential prerequisite for

achieving a Zero joint between panel and edge, HyFuse technology can be retrofitted to your machine. When the time comes to upgrade to a new Biesse edge bander, the Hyfuse unit can simply be transferred to your new machine.

Switching between glue and laser is quick. If you need to change back to glue for timber or veneer edges, the change-over is as quick as flicking a switch.

Hyfuse technology is very safe. Because the flame can quickly be turned on and off as required, the Hyfuse technology is not only energy efficient, but also safe. The Hyfuse system continuously monitors gas pressures, the moving of the tape and the temperature of the nozzle which must stay below sixty degrees Celsius. Any detected anomaly will cause the shut off of the flame in less than half a second.

“Hydrogen burns differently from other gases. The hydrogen flame radiates very little heat, all transfer is through convection. This means only the functional layer gets warm but the burner stays cool even at full production. ”

The Hyfuse system does not increase the temperature in the machine.

Henk explains, “Hydrogen burns differently from other gases. The hydrogen flame radiates very little heat, all transfer is through convection. This means only the functional layer gets warm but the burner stays cool even at full production. The HyFuse system starts 10mm before the panel and stops 10mm afterwards, there is no energy used or heat generated between panels”.

The low running cost makes Hyfuse economically the best choice. Electrical power and air consumption are negligible and there is no need for a big compressor. The cost of heat activated tape is generally a little more expensive and there is a cost for the Hydrogen gas of about 4 cents per metre but this is easily offset by the savings. There is no cost for glue or cleaning agents. But the biggest saving comes from increased productivity, no more cleaning glue from panels and no more cleaning glue from parts of the machine.

HyFuse will process boards of up to 30mm thick at 20 metres per minute; the maximum panel thickness is 36mm. For faster applications Biesse has developed the Hydrogen Force System (HFS) technology. With Biesse HFS the hydrogen gas is made through the electrolysis of water, so no bottled gas is needed. With HyFuse and HFS, Biesse has a solution for all users.

Giuseppe Serpentino is Biesse Australia’s edge banding Technical Application Manager. He says, “HyFuse is exclusive to Biesse in Australia. Talk to Biesse to see if this new technology can be fitted to your existing Biesse edge bander and transferred to a new Biesse edge bander at any time in the future so there is only one purchase of this ground-breaking innovation.”

There is no doubt that zero edge technology has now become an affordable and highvalue option for all cabinet makers. The environmental implications of using Hydrogen are significant; in fact, HyFuse uses only 10% of the energy needed for other zero edge technologies, It is the greenest edge banding solution.” It truly is a ground breaking solution for the perfect edge. z

Pull-out laundry hamper systems are gaining popularity due to their space-saving design, convenience, organisation, integration with cabinetry, and contribution to home improvement efforts. As homeowners seek efficient and stylish solutions for laundry storage, pull-out hamper systems provide a practical and aesthetically pleasing option.

As Heinrich Sagel and Hermann Vauth, the founders of Vauth Sagel once said, “We want to create high-quality system solutions for living spaces. For everyone.”

Those words went on to become the foundation of Vauth Sagel, a world esteemed company known for creating its German made quality products that are at the forefront of leading home innovations.

Many of Vauth Sagel’s products are distributed by Dorset Australia, helping to close the gap between a top-quality experience, and the Australian home interior innovation market.

Co-designed with Dorset Australia; a cuttingedge upgrade to laundry layouts, integrating the latest and most advanced features available in the market. Technically and visually, the VS WASH is based on the proven waste separation systems of the VS ENVI.

Catering to the needs of both builders and clients alike, VS WASH exceeds expectations on all fronts. Engineered with an emphasis on functionality and superior quality, the system exemplifies meticulous attention to detail, leaving no aspect overlooked.

The VS WASH system has been meticulously crafted to streamline production lines and enhance efficiency for manufacturers. With its emphasis on ease of use and installation, it is equipped with a range of intelligent features designed to expedite workflows

and minimize errors. Simply clip in and go with its recessed cabinet connector, making installation, a breeze, all while maintaining a minimalist cabin interior.

The 3D Cam Shaft Adjustment feature allows for effortless front adjustment, even after installation into the cabinet, ensuring hassle-free customisation and alignment. Furthermore, the inclusion of a comprehensive full-sized installation template eliminates the need for timeconsuming measurements, maximizing efficiency and reducing the potential for errors.

Builders benefit from the VS WASH system's versatility and adaptability to various project requirements. With multiple hamper sizes available to suit different project specifications, suppliers can cater to a diverse range of customer needs. Additionally, the system's compatibility with different cabinet configurations and design aesthetics ensures broad market appeal, allowing you to address a wide customer base and capitalize on market demand.

Find a large accommodating range of Vauth Sagel products direct through Dorset Australia. Trusted in the industry, as a leading supplier in all things cabinetry and beyond, Dorset Australia provides Vauth Sagel sliding pantry systems, bin systems, base cabinet solutions, corner cabinet solutions, folding innovations and more.

Visit www.dorsetaustralia.com.au to find out more. Dorset Australia - Cabinet Hardware Specialists. z

Edencraft is an Australian boating company with a legacy that spans more than six decades. Initially starting off in the powerboat and racing category, their creations have always been in demand – which made the company a coveted buy for those in the know.

“Edecraft has been around for 35 years in Australia. Eight years ago, my dad saw an opportunity with this incredible boat that had remained largely unknown unless you're deeply involved in the industry. He had tried to buy Edencraft earlier, but the timing wasn't right. Edencraft has always been an exceptional boat. For those in the know, especially in fishing, when comparing boats of similar size, you'll find that Edencraft's perform exceptionally well offshore, every time. Historically, the company had an old-style finish on its boats, so we aimed to modernise this aspect. Our goal was to create boats that last a lifetime, replacing timber with composites. In everything we build now,

we strive to incorporate a wow factor and go the extra mile for our customers,” says Josie Maher, General Manager of Edencraft International.

When Mr Maher bought Edencraft International in May 2016, the boats were built using a mixture of outsourced manufacturing and handywork. The process was slow, with less than ideal accuracy. An R&D department was launched within the company in 2021, looking into ways to improve the process. The research all pointed to the acquisition of an in-house CNC machine.

CMS’ largest high-speed 5 axis CNC milling machine, the Poseidon, made the cut.

“It’s been about 2-3 years since we had an R&D department and decided to get a CNC machine. We worked with the Government to support getting the machine and employ the number of people we were going to employ,” says the GM.

Edencraft began with only two employees. Josie worked on the management side, while her husband began a boat-building apprenticeship to understand the ins and outs of the craft. Within just a few years, that number has grown to 40. The secret?

A great internal culture that focuses on in-house promotions, learning new skill sets, creating the best customer experience, and setting the bar high for quality. As General Manager, Josie oversees it all. She was glad to find that working with the machine was a smooth process, allowing the team to put it to use straight away.

“We started cutting our first plug on the 1st of November 2023. First, we did our new boat, which is our 255 Formula – 55 plugs and moulds, about 200 sq metres of milling. We’ve also just finished doing a pool, which was 10m x 3.5 metres and 80 square metres of milling. It was massive. We just completed two other parts for another boat-builder in Australia,” says Josie.

With a working area of 15.5m x 5m x 3m, the Poseidon is perfect for large mould manufacturing. It was a strategic investment for the company, which led to the opening of a dedicated subsidiary, Edencraft Creative. Through this division, local producers are able to take advantage of the machine’s capabilities. Orders have already come in, with demand expected to further increase as news of the massive productivity boost spreads across the industry.

“We would outsource 5 axis milling, and just get the foam outsourced then do the rest of it in-house by hand. So, the 55 plugs that we did in three months, If we were to do that the way we were doing it before, it would take over 12 months, and the quality

wouldn’t be the same. Things used to be done using timber and by hand – that took even longer and was less perfect. The machine’s really broken down the time barrier for new innovations and new boats to bring them to market.”

The 255 is Edencraft International's latest boat, brought out on the 1st of March 2024. It follows the company’s tradition of boating excellence, using updated materials for added longevity and safety. Fibreglass and Thermolite are the main composites used in the 255’s design. Fibreglass cloth, panels, and resin form a sturdy structure, while Thermolite, a lightweight composite, is used for transoms. Under the hull, the vessels are foam-filled, giving them positive buoyancy, which in turn makes them extremely safe on the water, enhancing performance.

While the Poseidon’s ability to machine these materials was an important part of Edencraft’s decision-making process, Josie and her team knew that their choice of service provider was critical. After narrowing their shortlist down, they made a strategic decision that paid off well.

“We felt more valued than we did elsewhere. They really helped us understand the Government grant process – we had to jump through a few hoops before we could get the grant. Innovync didn’t get frustrated and supported us through it. Innovync built a good foundation.”

“The main reason we went with the Poseidon was because of Innovync and the service. Buying the machine from Innovync here, we knew that we would be working with someone who could support us locally. Pierre and the team were great, especially when we went over to Italy to sign off the machine. We felt very valued when we were there.”

The care and support shown by Innovync was not a one-off occurrence. It happened from the start - even when things were not going to plan.

“We just like the way they interacted with us during their quoting and the sales process. We had a few Zooms, once we narrowed it down to a few suppliers, Innovync got CMS and us on a Zoom, and everyone was there at once. We felt more valued than we did elsewhere. They really helped us understand the Government grant process – we had to jump through a few hoops before we could get the grant. Innovync didn’t get frustrated and supported us through it. Innovync built a good foundation.”

Expect the same level of care and attentiveness at your next meeting. That is what service excellence is all about. z

Exclusive Package Deal

Biesse Jade 240 Edgebander + HyFuse

Biesse Jade 240 Edgebander +HyFuse

Flexible changeover between glue and Hyfuse

Easy to manage and to maintain

Perfect quality without the use of glue

$115,000 + GST

As a manufacturer you must, so far as is reasonably practicable, eliminate or minimise the risks associated with manufacturing. For everyone, it’s a legal requirement. For some though, it’s also about applying common sense to everything you do.

Safety is a huge issue that cannot be covered in a single article. Safety in manufacturing is particularly important because of the unique circumstances presented by fast moving CNC machinery, conveyor systems and often dangerous materials. Every situation is different and requires individual attention, not only by management, but everyone working in the production areas.

A manufacturing safety checklist of best practices will include frequent manufacturing audits and inspections. Managers should manage safety incidents and issues quickly. Your workforce should be trained effectively. You must assign corrective

and preventive actions. The necessary and required records and paperwork must be attended to promptly and stored securely until needed, either for legal issues or to learn from past issues. And most importantly, every manufacturer and every employee should develop a safety culture.

Machine safety is one aspect of workplace safety that should be fairly easy to implement but more difficult to manage. Australian Standards cover all facets of both machine and cutting tool technologies. Applying Australian Standards, keeping maintenance and incident records, enforcing machine safety rules and ensuring your machinists are appropriately trained will go a long way to protecting your company from financial penalties should an accident occur. You can use other standards, but then you would have to explain to a magistrate why those standards were better than Australian Standards…better not to go there.

The management, or enforcement of safety is a more difficult thing to manage. Management cannot be everywhere at once so the responsibility for a workers personal safety relies to a great degree on the worker. We’ll take a look at this later in this article but imagine a machine shop with fifty people all supposed to be wearing hearing protection and safety glasses and a safety inspector walks through the door. It would be your lucky day if all fifty of your employees were wearing his or her required hearing protection, eyewear and any other PPE required.

Hearing loss is an issue that creeps up on people. It’s one of the hidden dangers of manufacturing, especially with machinery. Safe Work Australia says that ‘Workers must not be exposed above 85 decibels (as an average) over eight hours at work. Machines like blenders, lawnmowers and leaf blowers are around 85 decibels. This rule changes depending on decibels and time exposed. For example, the risk at 91 decibels over two hours is the same as 85 decibels over eight hours.’ Workplaces should be checked professionally for noise levels but as an exercise, ‘Decibel X’ is an app that will give you an indication of the noise in your workplace.

SafeWork NSW states that, ‘Over the past four years more than 10,000 workers have been affected by noise-related injuries in NSW workplaces, with more than 90 per cent left permanently disabled.’ Giving your

employee a pair of earmuffs will not solve this problem in itself, as a manufacturer you must first attempt to eliminate of minimise the noise issue and this could be done using low-noise saws and cutters on your machinery. Suppliers such as Leitz and Leuco are very proficient at this.

Most modern ‘cabinetry’ is manufactured from what was commonly referred to as ‘man-made’ material. Apart from the well-documented, but often disputed (by suppliers) problems with MDF (Medium Density Fibreboard) there are few issues using boards made by human beings. For the cabinetmaker using solid timbers though, there are some nasty side effects that users should be checking for. Some examples are American / Honduras Mahogany that can cause Skin irritation, giddiness, vomiting and furunculosis (boils). Mountain Ash and Australian Blackwood are irritants, but Blackwood can also cause asthma. Other side effects include kidney damage, respiratory disorders, diarrhoea, fainting and loss of vision.

Not all air is safe to breathe. The oxygen in a certain environment may contain hazardous fumes, dust, or other contaminants. Common airborne contaminants include particulate matter (e.g. silica dust), smoke, gases, mists, vapours, and aerosols. These and other contaminants can cause shortand long-term health problems, such as asthma, bronchitis, emphysema, impaired thinking, decreased lung capacity, loss of consciousness, and cancer. For noise,

dust, and other personal protection, some excellent PPE (Personal Protective Equipment) is available but should only be used after all other safety measures have been applied. Search ‘Hierarchy of Controls’ to see the order of controls you must implement.

As a manufacturer and employer, your first objective is to eliminate the risk of accidents by changing how the work is done. A legitimate method of elimination is to get the job done by another manufacturer, basically to shift the issue to them. The second control is that of substitution and this mostly applies to toxic chemicals and the like. The third is engineering controls such as guards and lock out controls. If you have a new guard designed and installed, make sure the work is done by a qualified engineer. Fourth is administrative, where you could change the work method to something

safer. Rules and regulations come into play here. The last control is PPE and may be used in conjunction with other controls.

Work Health and Safety ministers unanimously agreed to ban the use, supply and manufacture of all engineered stone with the majority of jurisdictions to commence the ban from 1st July 2024. At a meeting held on 22nd March chaired by the Hon Tony Burke MP, Ministers agreed to draft amendments to the model WHS laws to give effect to the prohibition on the use of engineered stone from 1st July. These amendments make it clear that the prohibition applies to engineered stone benchtops, panels and slabs.

The amendments specify that all sintered stone and porcelain products (including benchtops, panels and slabs) are excluded

from the prohibition, and for the avoidance of doubt, clarify that porcelain products and sintered stone for this purpose are products that do not contain resin, and clarify that finished engineered stone products (such as jewellery, garden ornaments, sculptures, kitchen sinks) which do not require processing or modification, and pose minimal risk to the health and safety of workers, are not prohibited.

The tile industry is concerned the new regulations will be expanded in a few years to include tiles and tilers. The tile industry has questions including the inference in these amendments that resins contribute to the toxic effects of engineered stone dust.

A University of Adelaide literature review, peer reviewed by an expert from Monash University indicated in lay terms that there is no determinate evidence that resin exacerbates the health effects of airborne RCS (Respirable Crystalline Silica), and that further study is necessary.

And now to the unintended consequences of industry safety as the sole responsibility of the manufacturer. Mike Rowe is a U.S. TV personality highly regarded as a person highly committed to promoting the trades. He features in the series ‘Dirty Jobs’ and ‘Someone’s Gotta do it.’ Some years ago,

in an interview he said, “Safety First is the stuff of idiocy. It allows us to begin to believe that someone, other than us might care more about our wellbeing than we do and the minute we buy into that nonsense then we embrace the warm grip of complacency.”

Above: Mike Rowe

Mike put forward the example that the most dangerous road intersections for pedestrians are those with walk/don’t walk signs because people no longer looked right or left before crossing…someone else had taken the responsibility for their safety though the signage; in this case road safety authorities. With signage intended to ensure the safety of pedestrians, people assumed the crossing was controlled and became complacent, and without looking, walked into the path of a vehicle running a red light.

In the TAFE College I managed we were required to perform a pre-operational safety check on 60 machines every morning before anyone could use them. This check was recorded but after a while, both teachers and apprentices stopped checking the records before using the machine. The assumption

was that the machine was safe to use, based on what someone else had done (or had failed to do) and you can see the problem with that.

The result was that people assumed the machine was OK to operate and did not make the checks they used to before turning it on. Someone else had assumed the responsibility for their safety. Safety is one of the most important aspects of manufacturing, but placed above every other consideration, can end up being dangerous when operators stop thinking about what they need to do to ensure they themselves are working safely, and leave their personal safety in the hands of others.

Mike put forward the example that the most dangerous road intersections for pedestrians are those with walk/don’t walk signs because people no longer looked right or left before crossing…

Safety is a matter of common sense, and not just about following rules. The company or the person that takes responsibility for their own safety will be much safer than those who just follow a rule because someone else told them to. The rules and standards are very important but by themselves, pose a risk of complacency that you want to avoid at all costs. z

With the introduction of Australia’s first silica dust Code of practice for the construction industry last year, it highlights the importance of understanding the impact of construction dust exposure and selecting the correct respiratory protection equipment for the job at hand.

Regular inhalation, of even small quantities of construction dust, can damage the lungs and respiratory airways over the course of time. Diseases can develop quickly, but in many cases, it can take 10 to 30 years before symptoms become apparent. Unfortunately, by the time the problem is noticed, irreparable damage is often done, and it can be difficult or impossible to treat.

What is construction dust?

Construction dust is a broad term, as there are many different types of dust one may be exposed to in a construction environment. The largest particles, which are visible, are captured by the body’s natural defences, and remain, in most cases in the nose, mouth and throat. The small particles, which are invisible to the human eye, are the most dangerous, and can cause scarring of the lungs and even enter the bloodstream.

Examples of construction dust

Silica dust: arises during work with materials containing silica, such as concrete, mortar and sandstone.

Wood dust: arises during work with softwood, hardwood and wood-based materials such as MDF and plywood.

Other types of dust: arise during work with plaster, glass wool, mineral wool, marble, etc.

Health risks: Lung damage such as silicosis, lung cancer, asthma, or chronic obstructive pulmonary disease (COPD), and includes diseases such as chronic bronchitis and emphysema. Construction dust can also cause allergies.

Respiratory protection

When all other measures have been taken to reduce dangerous exposure levels, respiratory protection equipment is the last, but important, means of preventing hazardous air contamination entering the body via the airways. The choice of respiratory protection depends, amongst other factors, on the type of dust present, its WEL (Workplace Exposure Limit), and the nature of the work, i.e. the degree of physical exertion and the length of

Facial hair, such as beards, moustaches and sideburns, reduce the level of protection offered by tight-fitting respirators, and create a need for Powered Air Respiratory Protection to ensure adequate levels of contaminant reduction.

Sundström recommends:

The filtering devices listed below for work in which silica dust (RCS) and general construction dust is present or likely to occur:

Shorter duration, lower work rate and dust concentrations. For clean-shaven users.

• SR100 or SR900 half-mask with P3 particle filter SR510.

• Silica dust respirator kit, a complete respiratory protection kit

Longer duration, heavier workload, and higher dust concentrations. For cleanshaven users and/or users with facial hair, beard or sideburns.

• SR500 or SR700 fan units with P3 particle filter SR510 with

• SR580 helmet with visor or SR570 face shield (with or without bump cap) or SR200 full face mask.

SR500 Fan unit + SR580 Helmet PAPR System Combination

● Particle and/or gas/particle filter combination

● Two speeds: 175 & 240 I/min

sea.com.au

SEA.Enquiries@sea.com.au

HEAD TOP OPTIONS

SR570 face shield

SR200 full face mask

SR601 microchem 2800 hood

SR510 wet & dry particle filter

● 1,300cm2 filter area

● 99.997% filtration efficiency

● Very low breathing resistance

Can be combined with gas filters

Choosing the right adhesive is crucial for successful bonding applications, especially when working with various materials like natural stone and porcelain. In Australia, a wide variety of adhesives are available, each offering different features to suit specific project needs.

Q: What are the differences between Polyester, Vinyl Ester, Methacrylate, Epoxy and Polyaspartic adhesives?

A: Understanding the differences in adhesives is key to choosing the right one for your project. Polyester adhesives, like Diarex Poly Plus and Tenax Solid, set quickly and are cost-effective, making them ideal for fast repairs and stonework bonding. However, they can bleed into natural stones, potentially affecting their appearance.

Vinyl ester adhesives combine the best features of both epoxy and polyester adhesives, offering superior moisture resistance compared to polyester-based options. Products like Tenax Titanium exemplify typical vinyl ester adhesives. Similarly, Superior Peral provides enhanced bond strength along with better resistance to moisture, chemicals, shock, UV, and heat.

Methacrylate adhesives are valued for their rapid curing time and strong bonding capabilities. These adhesives can form both mechanical and chemical bonds, making them highly versatile for various stone surfaces, including ceramics. Products like Integra Rapid, Integra Zero, and Integra Rodding Bonder are specifically designed to optimise bonding in stone applications, making them best suited for projects requiring quick assembly.

Epoxy adhesives are preferred for the most critical bonding tasks where maximum strength is essential. Although epoxy adhesives like Tenax Domo 10 and

Megapoxy offer superior bonding strength, they have lower UV resistance compared to other adhesives and are slower to cure fully. This makes them suitable for applications where durability and strength are more important than cure speed and UV resistance.

Polyaspartic adhesives, like Integra Ultra, combine the strength and durability of epoxy with outstanding UV resistance. They cure quickly and are ideal for both indoor and outdoor applications where long-term durability and resistance to weathering are essential.

Q: What are modified adhesives?

A: Superior GOLD is an example of a modified adhesive, blending qualities from acrylics, epoxies, and vinyl esters. It has the durable backbone of an epoxy but cures quickly like polyester or vinyl ester adhesives, becoming tack-free in less than 20 minutes at room temperature. Superior GOLD is versatile in tasks like seaming, mitering, laminating, and more, with a unique chemistry that makes it suitable for indoor and outdoor applications on all material types.

Q: What is MS Polymer and why choose it over silicone?

A: MS Polymer, such as TopSeal, is chosen for its superior functionality and aesthetics compared to silicone. It creates durable, smooth joints that are easier to clean and more resistant to wear and mould. TopSeal's versatility as a sealant, adhesive,

and mounting solution reduces the need for multiple products, simplifying tasks in applications requiring instant tack, such as installing sinks and shower panels. It also offers high UV stability, mould resistance and remains flexible in dynamic environments.

Q: How can I ensure adhesives perform well in extreme climates?

A: To ensure adhesives perform well in extreme climates, proper storage and handling are essential. Keep adhesives in a climate-controlled environment to maintain their properties. In hot climates, cool both the adhesives and surfaces before application. For better handling in warm conditions, consider adhesives with higher viscosity, like Superior Gold's GV-9. In colder climates, preheat the adhesive and bonding

surfaces to ensure smooth application. Additionally, adjust the amount of hardener based on the temperature to control the curing process effectively, opting for adhesives with different viscosities tailored to each climate, except for Epoxy and Polyaspartic/Polyurethane systems, where you should always mix the specified ratio.

Each type of adhesive has unique properties that make it better suited for certain applications, and the choice of which to use should be guided by the specific requirements of the project and the materials involved.

CDK Stone provides support for stonemasons who are using adhesives in a range of applications. They offer guidance in selecting the right adhesives and provide insights on optimal application methods to ensure strong, durable bonds. z

CDK Stone

Cosentino is a pioneer in the world of architectural surfaces, setting new standards for sustainability, performance, and design.

Dekton® is Ultracompact

In a few hours, Dekton® emulates what takes nature thousands of years, through an exclusive technology (PST) that sinters mineral particles changing their internal structure.

Dekton® by Cosentino is the cutting-edge Ultracompact Porcelain Surface, known for its unmatched durability, versatility, and aesthetic appeal. A Carbon-Neutral product that redefines surface design globally, as the preferred choice for architects, designers, and homeowners.

Dekton® is Porcelain

The result is a durable surface, resistant to scratches, stains, heat, and UV rays. Maintaining its original beauty for years to come, even in the most challenging environments.

Dekton is High-Performance Dekton® surfaces are non-porous, highly resistant to liquids, easy to clean and suitable for various applications. Their exceptional performance exceeds traditional surface capabilities.

Dekton® outperforms traditional materials like granite, marble and engineered stone in key areas:

Its more durable. Maintaining exceptional strength in thinner thicknesses surpassing the need for thicker formats.

More customisation possibilities. Advanced manufacturing allows tailored applications, surpassing limitations of traditional materials.

Better Maintenance. Dekton´s almost zero porosity ensures lowmaintenance appeal.

Dekton® boasts unique advantages over standard large-format porcelain:

It´s exclusive process with a 25,000ton press and controlled sintering creates its unique properties, unlike standard porcelain made from premixed materials using lower-capacity presses and shorter transformation times.

Dekton® offers 50+ colours in various thicknesses, surpassing standard porcelain´s limited palette. It is 25% more scratch-resistant than largeformat porcelain and 30% more resistant to flexion. Furthermore, it provides users with a transferable 25year warranty.

More than 50 ultra-realistic colors, textures, and patterns for limitless indoor and outdoor design possibilities.

Dekton® goes beyond the standard in benchtops. Dekton® surfaces excel in various applications: kitchen benchtops, bathroom vanities, flooring, wall cladding, outdoor surfaces, and commercial facades.

Dekton® heat resistance suits kitchen and outdoor areas, while their nonporous quality makes them perfect for bathrooms and wet spaces. Different finishes seamlessly fit any design, be it modern or traditional.

Sensa by Cosentino® goes beyond natural stone

More than ordinary natural stone

Sensa by Cosentino® goes beyond ordinary natural stone with an exceptional range of granite and quartzites. Its innovative protective treatment ensures durability and resistance against stains, beyond traditional stone surfaces.

Sensa by Cosentino® merges natural stone’s beauty with advanced technology for a durable and maintenancefree benchtop.

In the dynamic world of interior design and architecture, materials play a crucial role in defining aesthetics, functionality, and sustainability. Cosentino, a global leader in the production and distribution of innovative surfaces for architecture and design, continues to set industry standards with its groundbreaking products. Two of their standout offerings, the Dekton the ultracompact porcelain surface and Sensa by Cosentino natural stones collection, exemplify the company's commitment to excellence, innovation, and sustainability.

The Dekton UKIYO Collection draws inspiration from the traditional Japanese art of ukiyo-e, a genre of woodblock prints and paintings that flourished between the 17th and 19th centuries. This collection is a testament to the intricate beauty and profound cultural significance of ukiyo-e, embodying its essence through modern design and advanced technology.

The UKIYO Collection reflects the serene beauty and meticulous craftsmanship of Japanese art. Each surface in this collection is designed to evoke a sense of tranquillity and timeless elegance, with patterns and

textures reminiscent of natural landscapes and traditional Japanese motifs. The subtle yet intricate designs make these surfaces ideal for creating serene, harmonious spaces in both residential and commercial settings.

Dekton surfaces are renowned for their exceptional durability, thanks to the innovative Ultra-Compact Sintered Stone technology. This process involves a combination of raw materials, subjected to extreme heat and pressure. The result is a highly resilient porcelain product that is resistant to scratches, stains, UV

rays, and thermal shock. This makes the Dekton UKIYO Collection not only visually stunning but also highly practical for various applications, including kitchen countertops, bathroom vanities, indoor and outdoor flooring, and wall cladding.

Cosentino places a strong emphasis on sustainability in its manufacturing processes. The Dekton UKIYO Collection is no exception, incorporating recycled materials and employing eco-friendly production methods. The company’s commitment to sustainability is further demonstrated by its use of renewable energy and water recycling systems, aiming to reduce the environmental footprint of its operations.

The UKIYO Collection’s versatile aesthetic and robust characteristics make it suitable for diverse design projects. Whether it’s a minimalist modern kitchen or a luxurious spa-inspired bathroom, these surfaces seamlessly integrate with various design philosophies, enhancing the overall ambiance and functionality of the space.

Sensa by Cosentino represents a leap forward in natural stone, offering a unique blend of beauty, durability, and ease of maintenance. This exclusive line of granite and quartzite surfaces is treated with a revolutionary protective treatment Senguard by Cosentino, ensuring long-lasting performance and aesthetic appeal.

The standout feature of Sensa surfaces is their proprietary protective treatment, which provides high resistance to stains. Unlike other natural stones that require regular sealing, Sensa surfaces are treated with a sealant that

penetrates deeply into the stone, creating a barrier against liquids and stains. This makes Sensa an excellent choice for high-traffic areas and spaces prone to spills, such as kitchens and bathrooms and offer a 15 years warranty.

Sensa surfaces showcase the inherent beauty of natural stone, with each slab offering unique patterns and colour variations. From the deep, dramatic tones of Black Beauty granite to the subtle elegance of White Macaubas quartzite, Sensa provides a wide range of aesthetic options to complement any design style. The natural veining and textures add a touch of luxury and sophistication to any space.

Natural stone surfaces are prized for their durability, and Sensa is no exception. The

protective treatment enhances the stone's resistance to scratches and impacts, ensuring longevity and maintaining its pristine appearance over time. Additionally, the lowmaintenance nature of Sensa surfaces means they require minimal effort to keep clean, making them a practical choice for busy households and commercial environments.

Cosentino is committed to responsible sourcing and sustainability. Sensa stones are quarried with respect for the environment, adhering to strict ethical standards. The company works closely with quarries to ensure sustainable practices, from extraction to the final product. This commitment to ethical sourcing ensures that each Sensa surface not only looks good but also aligns with the values of environmentally conscious consumers.

Cosentino’s Dekton UKIYO Collection and Sensa by Cosentino are exemplary products that highlight the company’s dedication to innovation, quality, and sustainability. The UKIYO Collection offers a fusion of art and technology, creating surfaces that are as beautiful as they are functional. Meanwhile, Sensa provides the natural beauty and durability of stone with the added benefit of advanced stain resistance and low maintenance.

Both product lines cater to the evolving needs of modern design and architecture, providing solutions that are both aesthetically pleasing and highly practical. Whether for residential projects or commercial developments, Cosentino’s products offer unmatched performance and style, making them a preferred choice for architects, designers, and homeowners worldwide.

In an industry where materials and craftsmanship are paramount, Cosentino continues to lead with products that not only meet but exceed expectations, setting new benchmarks for the future of surface design. z

In the age of Industry 4.0, manufacturing sectors such as ours are imagining and developing ever more creative and flexible solutions to seamlessly merge their physical operations and digital systems. A trend, which has accelerated rapidly in recent years, is the uptake of automated and robotic systems to address traditional workflow bottlenecks and intermittent supply chain congestion. Agile and innovative businesses are at the forefront of these improvements and, when they look to implement, turn to their partnerships with market-leading technology suppliers to ensure they are able to take the necessary steps forward to continue their long-term growth, with minimal interruption to their day-to-day lean manufacturing operations.

In the 2000s, introducing a CNC machine to your business was considered a radical decision, which (looking back) was often made without a full understanding of the possibilities and implications. Over the years since, CNC machines have saturated our industry, and are now considered to be a logical starting point for many new cabinetmaking and joinery businesses, with multiple CNCs having been a feature of medium- to large-scale enterprises for many years and several generations of machinery.

As a result, the competitive advantage that a CNC machine gave has diminished over time, prompting industry leaders to explore new avenues to stay ahead of the curve and maintain their market positions.

Nowhere has this dynamic been more apparent than in the uptake of materials handling systems and automated warehousing of stock materials.

Marquis is one such company that has embraced these principles from its inception in 1979, through to present day, under the second generation of management by the Gray family, priding themselves on combining design, quality and manufacturing technology.

At the helm of a regionally based operation in Port Stephens, NSW, with a nationalscale customer base, general managers and brothers, Allen and Phillip Gray, are extremely focused on maintaining very rapid throughput of their products. When it came to making their next technological leap forward, they knew they could rely on the expertise of their technology suppliers, Planit Australia and Woodtech.

Long-time customers of Planit Australia over the past two decades, through the CABINET VISION product range, Marquis joined forces with Woodtech in 2021. Fast forward three more years and the same teams swung into action again to deliver a new Barbaric mezzanine-based materials handling system integrated with Marquis’ CABINET VISION and enterprise management systems.

The Planit approach

“We really had to work in very closely with both Woodtech and Marquis to ensure minimal disruption to the production schedule,” says Planit Australia’s Jack Davison. 2024 has seen the introduction of new CNC machinery, as well as the construction of a mezzanine, where the Barbaric is installed. Machinery has been located beneath the mezzanine, so the Barbaric system delivers sheet material directly to two auto labelling CNC machines. This system replaced traditional board and pallet racking, yielding close to a 100% improvement in floor utilisation in this section of the factory and allowing the addition of another 36x18 Anderson CNC machine.

“Despite the scale and scope of these changes, and how important they are to Marquis, Planit Australia keenly appreciates that such changes are only possible when we work in lockstep with our customers and their machinery suppliers,” Jack continues.

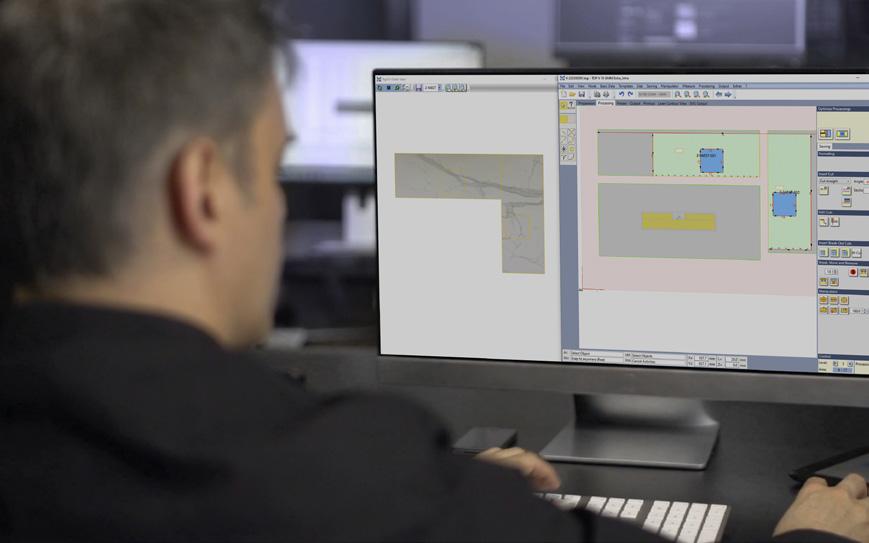

Operations manager Kyle Martin explains that “It is quite a large process, getting all these machines hooked up and getting CABINET VISION to talk to the machines. Planit Australia do a great job integrating with the machines, making the software talk to the Woodtech hardware and getting everything working seamlessly.”

Planit Australia’s senior product solutions expert, George Farrell, says that “Working with Marquis in the leadup to commissioning, and then the time I’ve spent onsite here for delivery, we’ve been developing a solution that allows Marquis to send fully optimised programs directly from CABINET VISION’s xMachining S2M Centre to the Barbaric materials handling system, which then automatically delivers materials to the machines situated beneath for auto labelling and routing”. The connection between CABINET VISION and the Barbaric is bidirectional, creating a live connection between the factory operations and back-

office stock control and ordering, helping the team at Marquis create and unlock ever greater efficiencies with their stock control and inventory.

George goes on: “Commissioning a new machine in a manufacturing facility is a huge investment for a business, and one in which we take our part very seriously. One of Planit Australia’s core values is working hand-in-glove with both our customer and their machinery supplier to make sure the solution is delivered on time and as efficiently as possible.”

“At Planit Australia, we really pride ourselves on the fact that we have deep connections throughout the industry, with players in different sectors, who we work in partnership with, like we are today with Marquis and Woodtech, to help deliver these solutions, to help push businesses further forward,” says Jack.“Planit Australia’s motto is ‘a commitment

to craft,’ and we look to reflect that in the commitment we have to our customers as well, in the commitment we have to working and collaborating with our partners across the industry.”

Planit Australia sees the future of our industry encapsulated by these types of crossdisciplinary collaborations, working closely with industry partners to discover and identify opportunities to leverage their technologies and developments to offer new and exciting ways to drive innovation and profit within our sectors.

This future will see traditional silos broken down even further, requiring ever-closer connections between technology suppliers, and Planit Australia is thrilled to be the leader pushing these boundaries further still, in their 40th year of business. z

In an era where precision is not just a requirement but a benchmark for quality, the SL Laser projector system stands out as a notable advancement.

Designed as an overhead projector solution, this innovative tool integrates computercontrolled operations with advanced software, enhancing the standards of accuracy.

Utilising a powerful green line laser, available in 5mW as standard and optionally in a 15mW version, the unique software included with the SL-Laser allows the programmer to position the suction cups on the CAD drawing and to project clear, sharp guidelines directly onto the bed of the machine.

The laser pinpoints the position of all the suction cups on the table simultaneously enabling fast and accurate positioning of all the suction cups and workpieces in one movement. As well as increasing set up efficiency an overhead projection laser improves safety for the operator by eliminating the need to enter and exit the machine to position each suction cup in turn.

CDK Stone can retrofit an SL-Laser to existing CNC machines. Other benefits include avoiding costly collisions and damage to the suction pods, as well as potentially reducing tool usage.

Key Features of the SL-Laser Prodirector 7

• Integrated Software Solution: The system works with CDK Stone’s SeKON software, as well as other CAM software, and is designed to seamlessly integrate with CNC machines. This software facilitates the precise positioning of tools and stone pieces according to CAD drawings.

• Safety and operational Efficiency: With the ability to project the position of all necessary pods simultaneously, the overhead laser enables operators to set up their CNC machines quickly and accurately. This streamlined setup process reduces downtime between operations, allowing for more projects to be completed in less time.

• Retrofitting Capability: One of the standout features of the SL-Laser Prodirector 7 is its adaptability to various machine types. It can be retrofitted to most existing CNC machines in stonemasonry, providing an upgrade in capabilities without the need to invest in new equipment. This makes

it a cost-effective solution for businesses looking to extend the efficiency and functionality of their current machinery.

• The SL Projection Laser can also be used with bridge sawing machines. When integrated with SeKON software and positioned over a saw table or loader, workpiece labels can be positioned on the slab prior to cutting.

In stonemasonry, precision and speed are crucial. The overhead projector system, such as the SL-Laser Prodirector 7, significantly enhances CNC machine performance, improving accuracy and efficiency for stonemasons.

Investing in this system can elevate your stonemasonry business, streamlining operations and increasing productivity. By enhancing technological capabilities and ensuring safety, it enables you to complete more jobs efficiently, ultimately delivering better results for your business.

web www.cdkstone.com.au z

Experience Cutting-Edge Stone Machinery and Comprehensive Automation Tools The CDK Stone range

Australia's Stone industry is experiencing seismic shifts. The dust was kicked up when news of silicosis spread across major media outlets –and it has yet to settle.

News of a potential ban on engineering stone has decision-makers keeping an eye out for alternative materials, without a definite idea of what to look for. Engineered stone was the staple for many in the industry. While the media is framing it as a major culprit, it is not the only silica-rich material being used.

“If you ban Caesarstone, the guys are still going to get silicosis from granite or quartzite, which has a silica content of 90%”, says Daniel Zovko, Director of Pacific Stone.

Daniel knows all too well how devastating silicosis is. He has met stonemasons who have suffered from the disease and takes stringent measures to keep his factory as

dust-free as possible. So much so that he had all of Pacific Stone’s CMS machines custom painted blue, making dust particles stand out for easy cleaning.

Added to that, power respirators and annual health checks form a large part of Pacific Stone’s silicosis prevention protocol. The peace of mind Daniel experiences is priceless.

“It costs us $800 per staff member, but that’s a small cost. It’s better to spend $30,000 on preventative health checks than getting a product banned. It’s a joke,” he says.

Yet, more can be done.

“Residual dust can make a major impact - what we're seeing is that factories which don't use clean or clarified water are still having issues with airborne crystalline silica levels from dust left over as the water evaporates,” says Dominik Holfter, Stone, Glass and Tooling expert for Innovync.

Strategies for setting up silicosis-free factories involve three elements. First, the cutting technology itself. The more automated, the less human exposure. Then, protective equipment and checks for workers – like what Pacific Stone implements in their factory. The third aspect is using clear, clarified water throughout the factory to stop residual dust from being kicked up.

“In Australia, we've received a lot of negative media around engineered stone and dust in

the workshop. One way to eliminate the dust in the workshop is by having clean water. Obviously, you need clean water for certain parts of the machine, but also the other water used in the workshop needs to be free of particles. Otherwise, you clean the workshop with dirty water and when it dries the dust is back in the factory. Cleaning with clean water just makes sense,’ says Dominik.

As Innovync’s Stone, Glass, and Tooling expert, Dominik works with manufacturers across Australia to provide solutions that increase efficiency and safety in the workshop. Much of the time, he sees stone shops fitted with the latest cutting equipment yet using a rudimentary system for decanting the used water. This often leads to poor quality of the ‘clear’ water. With strict regulations looming for stone shops in each state, manufacturers are now being pushed to consider other options.

Italmecc’s solutions, supplied by Innovync, solve the dirty water issue. The Italian company takes a scientific approach to water clarification, testing samples to determine the amount of coagulant and flocculant necessary for particlefree production. Shops which have the

Blucomb model, find that they need less water for processing – and that the air they breathe is much cleaner.

For many, however, step one is to upgrade the shop's cutting technology. This, as Paul Arrage from SP Stone discovered, was very worth his while.

“That’s another aspect why we went for the Speed CNC Working Centre. SafeWork were coming to our factory trying to minimise dust work. We invested in this machine to minimise manual grinding. We have been able to minimise 95% of the dry grinding. Everything gets done with water on the machine, which motivates the employees to come to work because they know there’s minimal dust. A lot of employees get scared to go to work because they feel like the environment isn’t safe. When you have machines in place, they feel like it’s a healthier environment to work in,” says Paul.

SP Stone now has two CMS machines, a Kosmos Bridgesaw, and a Speed CNC. Both were carefully chosen after lengthy discussions with Inmovync. Yet, in the end, it was the Sydney-based supplier's excellent support and after-sales service that had Paul sold.

“Innovyc’s service was guaranteed. I’ve asked a lot of stonemasons around that had the machine; they were very happy with the service. When we got the Kosmos, they guided us every step of the way. When we got the Speed installed, I was on the phone with Dominik at 11pm at night, right before Christmas,” says Paul.

While Dominik, like stonemasons themselves, is at the mercy of government decisions regarding the ban of engineered stone, he can tell you one thing for sure. There is a machine worth investing in, which cuts any material. The waterjet.

The versatility of CMS’ range allows these models to be used across every sector, without risk of dry-cutting, or putting workers in close proximity to the machines. Paired with a water clarifier, the ideal setup for a silicosis-free factory is formed. If you need the details on dust reduction and efficiency savings, just ask Dominik. He has made more than a few shops safer, cleaner, and much leaner with his attentiveness, care, and technical expertise.

web www.innovync.com.au z

For centuries, limestone has graced buildings and monuments, narrating tales of history with its timeless elegance. Today, it continues to be a desired material in modern design, offering a touch of sophistication and natural beauty to any space. Whether it’s captivating countertops and flooring or awe-inspiring facades and striking landscape features, limestone’s versatility offers endless possibilities for creating truly remarkable projects.

Limestone’s beauty extends far beyond its captivating aesthetics. It boasts surprising durability, making it a practical choice for any design. However, to ensure your limestone project remains stunning and safe for years to come, understanding its care needs is crucial. This guide unlocks the secrets to long-lasting care and safety for your limestone surfaces, empowering you to create a space that’s both beautiful and functional.

Limestone’s captivating charm lies not just in its colour palette, but also in its diverse visual appeal. It comes in a spectrum of textures, from the smooth and luxurious elegance of a honed finish to the richly textured character of an alfresco finish. Honed limestone offers a subtle sheen, perfect for creating a luxurious and sophisticated feel in living areas. Alfresco finishes, with their lightly textured surface, provide enhanced resistance, making them ideal for outdoor areas.

However, beauty often comes with considerations. Limestone, by nature, is a porous stone, meaning it can absorb liquids and be susceptible to staining. This is where understanding the specific properties if the limestone variety you choose is important. A knowledgeable stone supplier can be your trusted guide, helping you navigate these differences and select the perfect limestone for your project’s specific needs. They will consider factors like traffic flow, potential for spills, and desired aesthetic.

Sealing your limestone is the foundation of preservation. High-quality, penetrating sealers specifically formulated for limestone act as an invisible shield. These sealers repel spills, safeguarding the stone’s natural character from staining. Consulting with your stone supplier will ensure you choose the most suitable sealer based on the specific variety and application of your limestone.

Routine cleaning with a gentle touch is vital for maintaining the beauty of your limestone surfaces. Harsh chemicals, acidic solutions (like vinegar), and abrasive cleaners can damage the surface and dull the stone’s natural lustre. Opt for a pH-balanced stone cleaner specifically designed for natural stone. Simply use a soft cloth or mop dampened with the cleaning solution and gently wipe the surface clean.

While limestone offers stunning aesthetics, it’s important to prioritise safety. Limestone can become slippery when wet, especially with certain finishes.

Here are some tips to minimise the risk of slips and falls:

• Select the Right Finish: As mentioned earlier, alfresco finishes with their textured surface provide higher slip resistance compared to a smooth honed finish. Consider using alfresco finishes for outdoor applications, where the risk of slipping is higher due to moisture.

• Doormats are Your Ally: Placing doormats at entryways helps reduce the amount of dirt and grit tracked into your space. This not only prevents scratches and maintains the pristine look of your limestone floors but also minimises the risk of slips from tracked-in moisture.

• Act Quickly Against Spills: Accidents happen! The key is to act immediately by blotting the affected area with a clean, absorbent cloth to absorb the liquid. Avoid scrubbing, as this can spread the spill and potentially damage the surface.

For stubborn stains, cracks, or significant damage, consulting a professional stone restoration expert is highly recommended. Many reputable stone suppliers maintain relationships with restoration specialists who possess the expertise and tools to restore your limestone to its original brilliance.

Periodic resealing is necessary to maintain optimal protection. The protective properties of the sealer diminish over time, typically every 3-5 years depending on the type of sealer used and the environment the limestone has been installed. Your stone supplier can advise on the appropriate frequency of resealing based on your specific situation.

Choosing the Perfect Limestone: A Marriage of Beauty and Safety Limestone’s captivating beauty extends beyond just colour and texture. It offers a variety of visual appeal options, allowing you to find the perfect match for your design vision. Partnering with a knowledgeable stone supplier ensures you not only choose a limestone that complements your design aesthetic but also possesses the technical properties best suited for your specific application.

Sareen Stone is your specialist for all things limestone. Offering a curated selection of limestones in a variety of captivating colours, textures, and finishes to perfectly complement your design vision.

Their team of knowledgeable professionals are here to guide you through the selection process, ensuring you choose the perfect limestone for your project. They are also committed to providing ongoing support and maintenance advice to preserve the beauty of your limestone for generations to come. z

Most, if not all suppliers accept the increasing importance of environmental issues in the manufacture of their product. Aspects such as resource efficiency, recycling and upcycling, renewable energy, and smart materials are solutions to many of the ecological concerns important to their customers.

Neo-ecology is a blend of ecology and economics, sustainability, and consumption. It is based on rational, intelligent, and environmentally sustainable stewardship of resources. It is a major process of social change toward a resource-efficient, sustainable economy. The sustainable manufacture of products helps the environment and progressively leads to a competitive advantage for industry. Suppliers such as Grass, Häfele, Hideaway Bins (Kitchen King), Surteco and Titus Tekform, to name just a few, actively pursue NeoEcology to create added value for society and environment through entrepreneurial effort.

Interzum in Cologne last year said, “Sustainability is a global megatrend that's increasingly shaping our way of life. When it comes to homes and interior design, the main focus is on creating healthy and resource-efficient surroundings. Eco-friendly materials and components are therefore high on the agenda for suppliers to the furniture industry and interior construction sector. They are having an increasing influence on current design trends. The growing desire for closed material loops and a circular economy is also leading to new concepts in the interior design industry.”

Australian suppliers’ responses to environmental issues are very encouraging. Häfele said, “Our commitment is to minimise the use of energy, resources consumed, and waste produced while undertaking our business activities.” Kitchen King says, “We are passionate advocates for enabling better waste behaviors at work and at home.”

Kitchen King’s colour coded bins encourage users to be more conscious of waste management.

Surteco says, “Sustainability is at the forefront of the decorative finishes industry. Being an Australian manufacturer, it allows us to provide the confidence to our customers that the products they are purchasing have been manufactured with integrity, to a high quality and sustainably.” Titus Tekform says, “We are committed to meeting our customers' requirements, taking into consideration the impacts of our activities on the environment.”

Grass says, “We see the present as part of the future. For us, environmental protection is an important prerequisite for sustainable company success.”

While the all-white kitchen is still in demand for now, Australian kitchens are witnessing a vibrant transformation influenced by both global trends and local inspirations. Consumers will feel more connected to nature than ever before. According to many designers, warm woods and natural colors will make a major comeback in 2024. The NKBA, promoted as the World’s leading kitchen and bathroom organisation, said, “Greens will be the top choice. From calming sage to power-packed emerald, green is easy to incorporate into your kitchen's color scheme and has the ability to make kitchen cabinets sing.” Vogue Australia contributing designers seem to agree.

Laura Hedges, Specification Representative for SURTECO Australia says, “Earth tones such as browns and pinks are in. Softer and warmer colours that allow for more biophilia, the human tendency to connect with nature. Using earthy tones allow for a subtle connection to nature and bring the natural energy of outdoors into your space.

Our research revealed some designers feel lower cabinets need to be re-examined. They say drawers are much easier to open to pull out your plates or pots and pans. Hidden drawers, integrated step stools, charging drawers for personal devices and chargeable accessories, and toe-kick storage drawers are on the rise. Fridge drawers are trendier than ever, as a place to keep anything a family might want to grab and go. Dishwasher drawers are also becoming popular. Drawers offer as much functional storage as possible with little wasted space and are manufactured using recyclable materials. 42

Above: Surteco Brushed Gold Edge

Above: Surteco Brushed Gold Edge

Another way to save materials in the kitchen is to do away with some of the elements we’ve grown up to accept as essential. Handle-less kitchen units are part of a trend that has been on the rise over the past few years and offers homeowners upgrading their kitchens the opportunity to introduce smooth, sleek lines within the kitchen. Titus Tekform’s push-to-open cabinet solutions eliminate door handles entirely, it’s one less thing to recycle.

Manufactured (engineered) stone benchtops will take a hit due to new silica regulations imposed on the industry. Sintered stone and porcelain products are exempt and should increase in demand, as will natural stone such as Granite and Marble. A bold statement of marble in any kitchen creates a focal point and adds a touch of drama, although some designers say we will start to see fewer heavy stone slabs in kitchens, and a more sensitive, practical lightness to the space using materials that are able to be recycled in a circular economy.

Our investigation discovered that we would see more combination islands in kitchens. Over half the surface of the island will have closed storage below, while the remainder will have simple furniture-style legs and open space below to accommodate seating.

The island could incorporate workstation sinks, induction cooktops and smart storage solutions. The island would be the heart of the kitchen and the person doing the cooking wouldn’t have their back to the family while preparing dinner. Another design suggestion we found feels that island benches are changing shape and that curves are coming back in a big way.

Handle-less kitchen units are part of a trend that has been on the rise over the past few years and offers homeowners upgrading their kitchens the opportunity to introduce smooth, sleek lines within the kitchen.