Upgrading your control system to the

Upgrading your control system to the

The performance and flexibility of a CNC machine tool have a major role to play in the unceasing advance of technological development. The control system, the heart of the machine, has proved to be a key factor in the delivery of efficient, high-quality production. One current example of this technological development is upgrading of SIEMENS 840 controller to the SINUMERIK ONE.

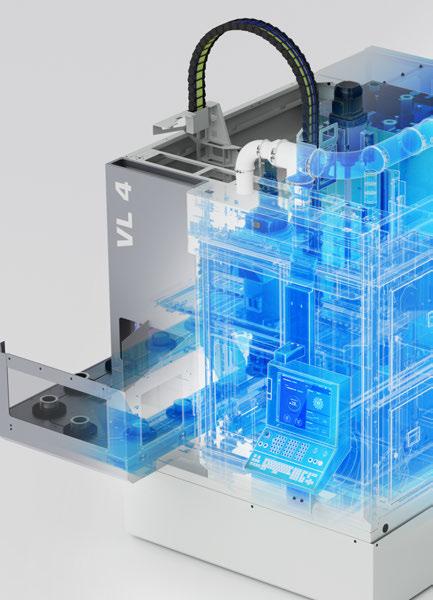

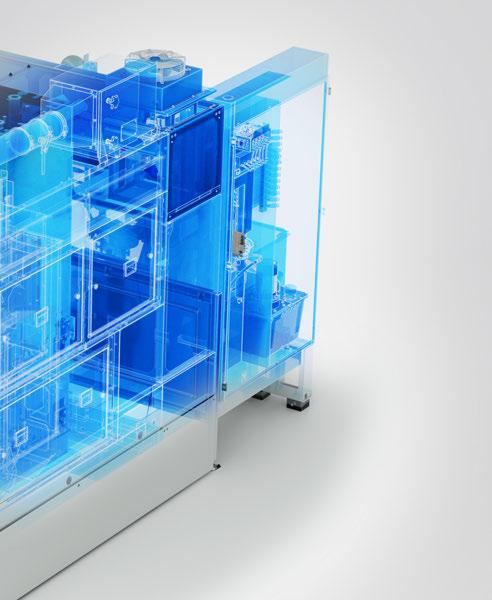

The mechanical components of a CNC machine tool can function well for a long period of time without requiring major modifications, but control technology continues to develop at a rapid pace. Thanks to the improved computing capacity of the new controller, the machine can perform more dynamic processes, energy consumption is reduced and the machine can be networked with higher level production networks (IoT After Sales). Furthermore, the standardization of the control concepts means that the risk of operator error can be reduced.

EMAG also offers control system upgrades to the SINUMERIK 840D sl and Fanuc 32i. One of the major benefits is the standardization of the control concepts. Not only is a standard control concept easier to learn, but it also reduces possible error sources. Furthermore, EMAG can provide a future-safe spare parts supply if you upgrade to these control systems. That means that spare parts and support is guaranteed for many years to come. This is a major benefit, particularly in comparison to older systems which have restrictions in terms of spare parts and support.

To ensure that the control system can be upgraded smoothly, however, a number of adjustments have to be made to the existing drive units, tool systems and measuring units. EMAG can provide its customers with a comprehensive range of services for control system modernization. This ranges from new cabling and the installation of a new control cabinet, the integration of a new CNC controller and the installation of modern control units. All this work can also be carried out very quickly, if necessary, and perfectly planned at the customer’s premises so that the machine downtime is minimized.

This is where the specialists carry out mechanical, electrical and complete retrofits on machine tools. And, the aim of every retrofit is to return machines to the same standard as a new machine.

In addition to mechanical retrofitting, EMAG can also modernize and upgrade machine tools with up-to-date control systems.

Upgrading the control system to the SINUMERIK ONE is a major step towards modernizing ageing machine tools and can significantly increase the productivity and quality of the manufacturing processes.

The costs for upgrading the control system to the SINUMERIK ONE depend on a range of factors such as the age and type of machine, the control system that must be installed and the extent of the work required. However, upgrading the control system is generally a lower cost alternative to buying a new machine.

We will be delighted to advise you about the possibilities of upgrading your control system.

The SINUMERIK ONE is the latest generation of CNC controllers from Siemens and has a number of major improvements compared to its predecessors, the 840 controller series. These include the following:

The SINUMERIK ONE is faster and more powerful than the 840 controller series, making faster and more efficient processes possible.

The control and programming of SINUMERIK CNC systems (including the SINUMERIK 828) is completely compatible – identical CNC language, identical technology cycles and identical ShopTurn graphic programming software.

Users who are familiar with SINUMERIK systems will immediately feel at home with the SINUMERIK ONE. The range of functions of the SINUMERIK ONE is identical to that of the SINUMERIK 840D sl.

The availability of spare parts and software updates is another benefit of the SINUMERIK ONE controller. You can obtain spare parts for your control system without any problem even after many years of use. In addition, Siemens delivers regular software updates for the SINUMERIK ONE, containing new functions and improvements.

Furthermore, the SINUMERIK ONE provides improved connectivity due to a series of interfaces to ensure its easy integration into the corporate IT or linking to IoT systems.