A HOLISTIC APPROACH TOCONTAMINATION CONTROL

THE IMPORTANCE OF TECHNOLOGICAL INNOVATION

IS COATING AS EFFEICIENT AS IT COULD BE?

July/Aug 2023

DIGITISING LOGISTICS AND DISTRIBUTION

FOR FASTER, SAFER CELL AND GENE THERAPIES

THE NEW FE CPS CONTINUOUS MANUFACTURING REINVENTED Discover how Continuous Manufacturing can be compact, fast, flexible, easy to use and efficient. The FE CPS offers standardized and widely applicable Continuous Manufacturing technology. Visit our website for more information: fette-compacting.com

REGULARS

5: EDITORS DESK A Fresh Start.

6: A SMALL DOSE

A brief round-up of some of the latest industry developments.

12: COVER STORY

Matthew Lakelin, co-founder, and VP Scientific Affairs & Product Development at TrakCel argues the case for digitising logistics and distribution.

FEATURES

8: CONTAINMENT

Catherine Jomary, ATMP Technical Lead at IPS explores a hollistic approach to contamination control.

14: LOGISTICS & DISTRIBUTION

Richard Harrop, Product Director, Topa Thermal looks at a new concept in thermal packaging that is reducing costs and CO2 emissions.

18: SUPPLY CHAINS

Rex Clements, CEO at Centrient Pharmaceuticals, sheds light on the company’s efforts to contribute to a sustainable global supply chain for antibiotics.

22: COATINGS

Prashant Deshpande, ACG, discusses the critical process parameters of film coating and the measurement, monitoring and recording of tablet bed temperature in batch manufacturing.

30: CONTINUOUS MANUFACTURING

Niklas Jungnelius, Process Modeling Leader at Cytiva helps find your “why?” in continuous manufacturing.

34: CLEANROOMS

Elizabeth Makin, Marketing Manager, Dycem presents polymeric solutions for particle level control.

July/Aug 2023 | Volume 23 Issue 4 Contents

12 8 18 30 34 14 22

HEAD OFFICE

No. 3, The Office Village, Chester Business Park, Chester CH4 9QP

Tel. +44 (0)1244 680222

Fax. +44 (0)1244 671074

www.pharmaceuticalmanufacturer.media

EDITORIAL

editor Jai McIntosh jai.mcintosh@rapidnews.com

publisher duncan wood

PRODUCTION

head of studio and production sam hamlyn

ADVERTISING

robert anderton tel: +44 (0)1244 952359 robert.anderton@rapidnews.com

vp sales & sales talent

Julie Balmforth julie.balmforth@rapidnews.com

SUBSCRIPTIONS

subscriptions@rapidnews.com

qualifying readers

Europe - Free, ROW - £249

outside qualifying criteria

UK - FREE, ROW - £249

please subscribe online at www.pharmaceuticalmanufacturer.media

A FRESH START / A NEW WORLD

Address changes should be emailed to subscriptions@rapidnews.com

European Pharmaceutical Manufacturer is published by Rapid Life Sciences Ltd. European Pharmaceutical Manufacturer is distributed in electronic and print formats to a combined readership of 14,000 pharmaceutical manufacturing professionals.

Volume 23 Issue 4 July/Aug 2023

While every attempt has been made to ensure that the information contained within European Pharmaceutical Manufacturer is accurate, the publisher accepts no liability for information published in error, or for views expressed. All rights for European Pharmaceutical Manufacturer are reserved and reproduction in part or whole without written permission is strictly prohibited.

2052-4811

And so each venture is a new beginning.”

T.S Eliots words have been perhaps more relatable than ever given the nature of my stop-start year. Having found myself sleeping in the north-Indian desert, wandering the streets of Kyoto, and attempting to drive a motorbike across Thailand, I would have been hard pressed into believing that, come Summer, I would have to be introducing myself to a new collection of readers, in a completely new industry. Moving from sports and fashion into pharma may not be a well-worn path,

nonetheless, the significance and importance of the pharma industry far outweighs the faux importance of my former subjects. The industry is designed to help keep people safe, healthy, and happy. Yet, when I sat down for my first week in the office, keen as ever to get as well acquainted as possible with an industry so vast, I was left slightly dismayed that I was greeted with the depressing drivel of former Health Secretary Matt Hancock casually noting that the UK government came “within hours” of running out of intensive care medication during pandemic.

EDITOR’S DESK

JAI MCINTOSH

Amongst the almost constant floundering, Hancock went on to attempt to defend the government’s handling of COVID-19 and the subsequent fallout across the medical and pharmaceutical supply chain, in large part due to the mishandling of Brexit, stating that “when it comes to the question of the overall impact of Brexit, absolutely the paperwork is very clear

that some of the preparation work was stopped, and a small number of people would move off that work. On the other hand, we were better prepared in terms of supply chains.” Evidently, an understanding of the medical and pharma supply chains was considered enough to move certain individuals over to aid in Brexit planning. Clearly this failed to work, and the industry itself is still working through multiple supply chain issues that Hancock helped create.

The grey cloud that is Matt Hancock was eventually replaced by the optimistic rays of sunlight that is Donanemab, a potentially game-changing drug in the dementia fight created by Eli Lilly. The study, first reported in JAMA, highlighted that the drug has shown significant abilities in slowing the pace of cognitive decline by up to a third, a hugely significant step. It is worth mentioning at this point that the drug itself is not a cure, only working on Alzheimer’s disease not other dementia types. However, global health outlets and charities have hailed this is a landmark moment, with the UK’s drug watchdogs sounding out the new drug for potential use throughout the NHS.

Recently, aducanumab, another antibody Alzheimer’s drug, was rejected by European regulators due to lack of effective evidence and patient safety concerns. The hope this time is that donanemab sails through the required regulatory tests and is approved to provide those in need with quality, trusted support.

As the world of pharma continues to develop and innovate, so do we. There is plenty to do, so let’s get started. I hope you enjoy the issue.

ISSN No -

BPA Worldwide Membership

5

“

A small dose

NOVO NORDISK RESPONDS TO EMA REVIEW OF GLP-1 DRUGS

NovoNordisk’s diabetes and obesity medication, specifically Ozempic (semaglutide) and Saxenda (liraglutide), have come under scrutiny following two reports of suicidal thoughts and one case of self-harm in Iceland. This has prompted a European Medicines Agency (EMA) review into both drugs.

The aim of the review, conducted by the Pharmacovigilance Risk Assessment Committee, will explore the casual links between Saxenda and Ozempic to determine whether there is a link between taking the medication and the potentially adverse effects that some patients have experienced.

GLP-1 treatments have increased in popularity over the last few years due to their ability to encourage dramatic weight loss. A recent report from BMJ suggested that: Among patients with weight measures available, 33.4% and 43.5% achieved clinically meaningful weight loss ≥5% of baseline weight at 12 and 24 months, respectively. At 24 months, 59.2% and 64.7% of patients with T2DM were adherent to or discontinued GLP-1 RA therapy, respectively.

Given that the risks attached to the use of semaglutide (Ozempic) for those with mental health difficulties, predominantly use of semaglutide (Wegovy) for weight loss,

should be avoided in patients with a history of suicidal attempts or active suicidal ideation, there is a likelihood that the drug may face harsher scrutiny. Worthwhile remembering that the EMA have suggested that it may expand its review to encompass an analysis of all GLP-1 drugs.

Having reached out to Novo Nordisk for comment, a spokesperson stated: “Patient safety is a top priority for Novo Nordisk, and we take all reports about adverse events from use of our medicines very seriously. GLP-1 receptor agonists have been used to treat type 2 diabetes for more than 15 years and for treatment of obesity for 8 years, including Novo Nordisk products such as semaglutide and liraglutide that have been on the market for more than 10 years. The safety data collected from large clinical trial programs and post marketing surveillance have not demonstrated a causal association between semaglutide or liraglutide and suicidal and self-harming thoughts. Novo Nordisk is continuously performing surveillance of the data from ongoing clinical trials and real-world use of its products and collaborates closely with the authorities to ensure patient safety and adequate information to healthcare professionals. EMA continuously monitors for safety signals and so does Novo Nordisk. Novo Nordisk remains confident in the benefit risk profile of the products and remains committed to ensuring patient safety.”

Alnylam

Reports Updated Positive Interim Phase 1 Results in Development for Alzheimer’s Disease and Cerebral Amyloid Angiopathy

Alnylam Pharmaceuticals have announced an updated positive interim result for the ongoing single ascending dose portion of the Phase 1 study of ALN-APP, an investigational RNAi therapeutic targeting amyloid precursor protein (APP) in development for the treatment of Alzheimer’s disease and cerebral amyloid angiopathy (CAA). ALN-APP is being developed in collaboration with Regeneron Pharmaceuticals. The results were presented at the 2023 Alzheimer’s Association International Conference (AAIC) being held July 16-20, 2023, in Amsterdam, The Netherlands. ALNAPP is the first clinical-stage program using Alnylam’s proprietary C16-siRNA conjugate platform for central nervous system (CNS) delivery and the first investigational RNAi therapeutic to demonstrate gene silencing in the human brain.

Twenty patients with early-onset Alzheimer’s disease have been enrolled in three single-dose cohorts in Part A of the ongoing Phase 1 study. In this study to date, single doses of ALN-APP, which are administered by intrathecal injection, have been well

The Medicines and Healthcare products Regulatory Authority has provided regulatory approval to see whether a novel psilocin prodrug can treat major depressive disorder when combined with therapy. The trial, designed by Clerkenwell Health, will be delivered in their London facility. The treatment will enable patients to stay on their antidepressants for the trial.

The trials will combine dosages of the psilocin-based drug with specialist therapy, delivered by Clerkenwell’s own trained therapists.

The trials come at a time when innovative ways to treat depression are sorely needed. Statistics show that one in four people taking antidepressants in the UK have done so for more than five years.

Tom McDonald, CEO at Clerkenwell Health, said: “We are incredibly excited to

be given the green light for this trial to explore this innovative treatment and help millions of people. Our work with Mindset is part of a suite of trials we’re planning to undertake in the next 12 months, to test the potential of psychedelicsrelated medicines for complex mental health and central nervous system.”

The drug being used in the trial, titled MSP-1014, has been designed by Mindset Pharma, a drug discovery and development company focused on creating optimised next-generation psychedelic medicines to treat neurological and psychiatric disorders with unmet needs.

MSP-1014 is anticipated to exert similar efficacy to psilocybin in improving symptoms of depression.

Preclinical studies comparing MSP-1014 to psilocybin suggest that the tolerability of MSP-1014 may be superior to psilocybin.

6

tolerated. All adverse events were mild or moderate in severity. Cerebrospinal fluid (CSF) white blood cell count and total protein levels showed no remarkable elevations from baseline. Routine laboratory assessments (hematology, serum chemistry, liver function, urinalysis, coagulation) as well as preliminary data for the exploratory biomarker neurofilament light chain (NfL) did not reveal any significant abnormalities. Patients treated with a single dose of 75mg ALN-APP experienced a rapid and sustained reduction in cerebrospinal

fluid of both soluble APPα (sAPPα) and soluble APPβ (sAPPβ), biomarkers of target engagement, with maximum reductions of 84% and 90%, respectively. Mean reductions in sAPPα of greater than 55% and sAPPβ greater than 65% were sustained at 6 months after a single dose. Additional results can be seen in the presentation on Capella. “We’ve known for decades that mutations that increase APP production, or alter its proteolysis, cause early-onset Alzheimer’s disease, early-onset CAA or both,” said Dr. Sharon

Cohen, MD, FRCPC, Neurologist and Medical Director, Toronto Memory Program. “These Phase 1 results show that a single dose of ALN-APP can rapidly reduce APP production and that this effect is sustained at 6 months. Given the critical need for new and better treatments for AD and CAA, these results are promising, and the approach warrants further study.”

Further exploration of single doses of ALN-APP is ongoing in Part A. In addition, the safety review committee has recommended initiation of Part B, the multiple-dose part of the

study. Part B will enroll patients from Part A and has already received regulatory approval to proceed in Canada, where the majority of the Part A clinical trial patients were enrolled. The multiple dose part of the study remains on partial clinical hold in the U.S. due to findings observed in prior nonclinical chronic toxicology studies.

In addition to ALNAPP, Alnylam and Regeneron have named 10 targets in the CNS as part of their exclusive collaboration established in 2019 to discover RNAi therapeutics for eye and CNS diseases.

WE HAVE THE SOLUTION! Our bene ts: Isolator has automatic adjustable height No need for SBV: Spray Dryer discharge in isolator (100 ng/m3) WWW.FPS-PHARMA.COM - INFO@FPS-PHARMA.COM Spray Dryer integrated in isolator How to safely discharge a Spray Dryer and mill the potent API ? Milling done inside the isolator: no product transfer No need for PPE: 400 gowns saved/month Free Webinars Don't miss our webinars on the world of containment: visit our website!

www.pharmaceuticalmanufacturer.media 7

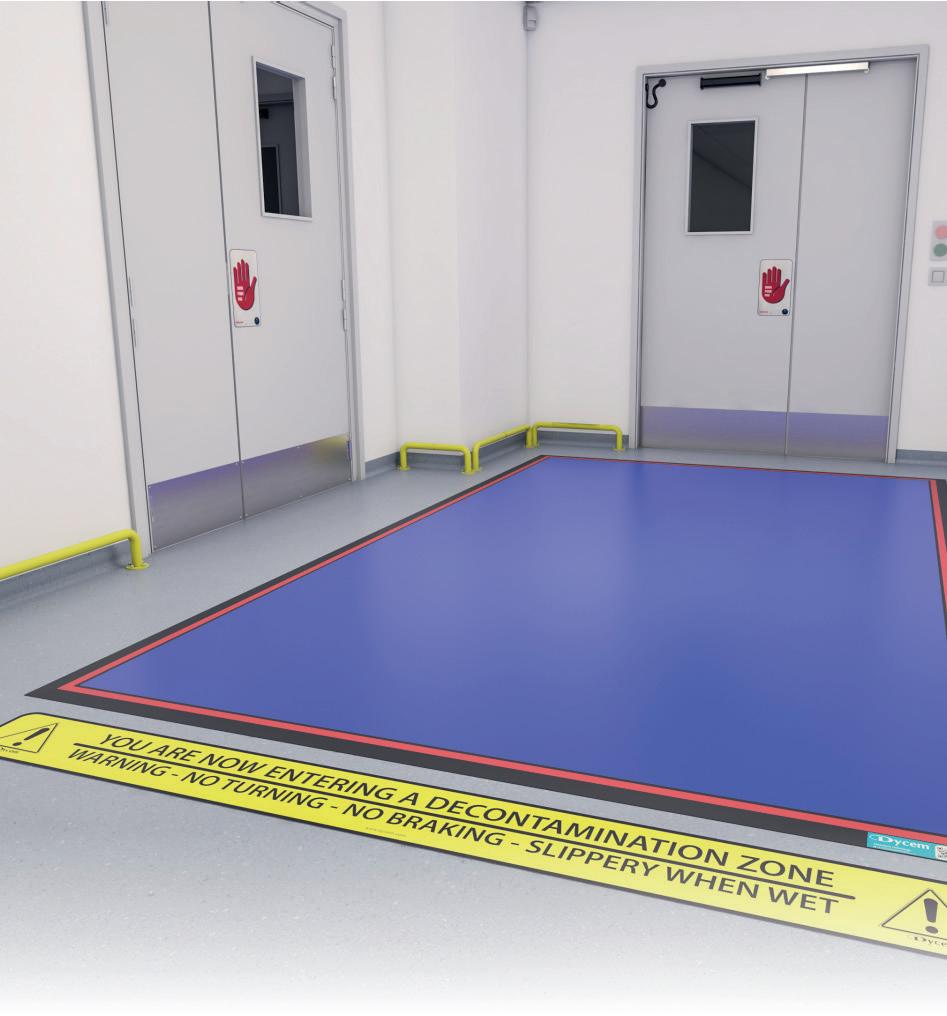

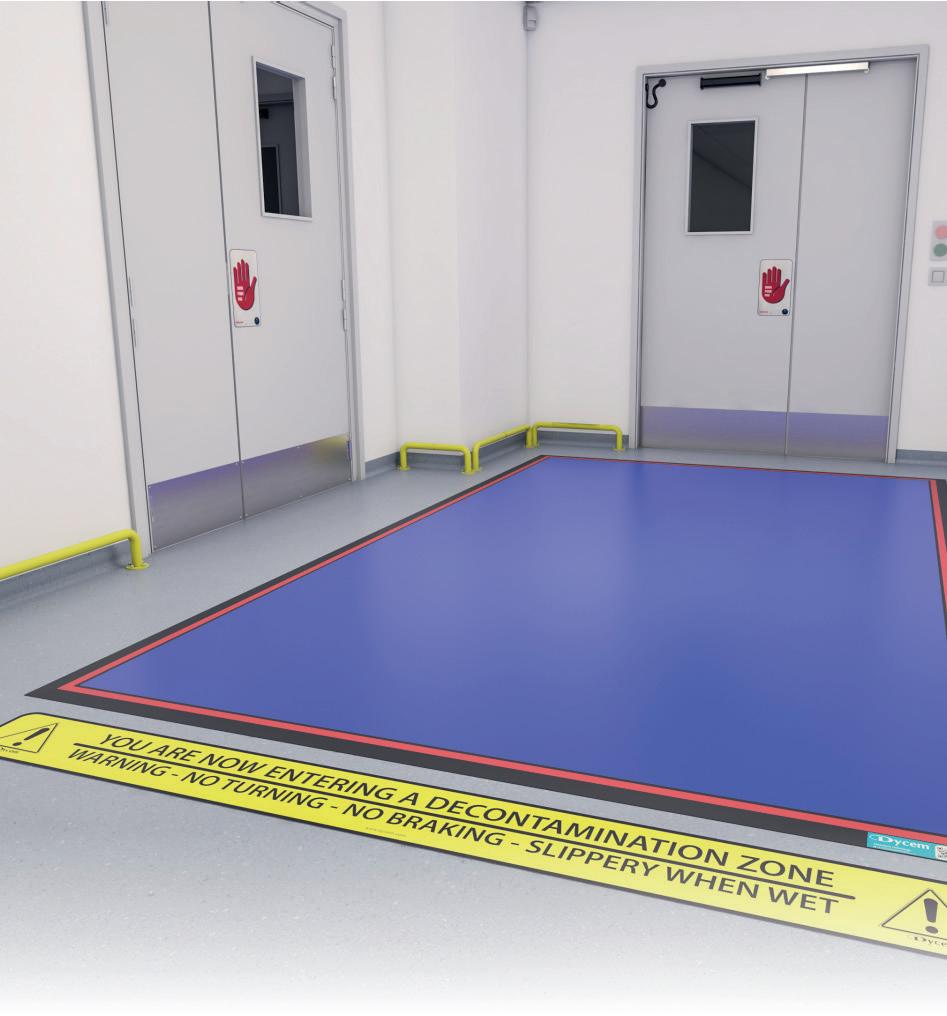

PREPARING FOR THE ANNEX 1 REVISION: A H LISTIC APPROACH TO CONTAMINATI O N CONTROL

Catherine Jomary, Ph.D., ATMP Technical Lead at Integrated Project Services (IPS), reframes the understanding of contamination control under the EU GMP Annex 1 regulatory revision, which takes e ect in August 2023, to fully encompass the human and technological processes involved in the interconnected nature of modern pharmaceutical manufacturing.

Author: CATHERINE JOMARY ATMP Technical Lead,

As we prepare for Annex 1 to take effect, it is important to understand the big picture and recognise the benefits of this regulatory revision. I tell clients that, in many ways, this is an excellent tool for us. Previously, the regulatory strategy of GMP (good manufacturing practices) was deliberately vague and open for interpretation which allowed the industry to excuse certain practices as “good enough.” In terms of contamination control, “good enough” seemed to achieve good customer safety results. Over time, the nature of the pharmaceutical product required more attention to contamination control. In this age of cell and gene therapy (or Advanced Therapeutic Medical Products, as they are commonly known outside of the US), the call for purity in our products is even more critical because the consequences of failing to act are more dire.

Annex 1 is built on mitigating risk. It is a compilation of the best contamination control practices currently in operation in facilities across the globe. Since the release of the first drafted Annex 1 revisions, I have worked with clients across the industry to understand how these regulations might impact their operations.

Annex 1 calls for a holistic understanding of the manufacturing process. Under Annex 1 regulations, we must thoroughly understand the relative risks involved in introducing contamination into any aspect of our facilities, from the flow of raw materials and personnel throughout the facility to air handling, the cleaning of manufacturing surfaces, and the egress of waste materials. Nothing is left to interpretation, and everything must be accounted for in your risk-assessment analysis.

This analysis extends to every corridor and every room across the facility. It impacts the worker experience from the moment they enter the building.

WHAT DOES IT REALLY MEAN TO HOLISTICALLY ASSESS YOUR FACILITY?

It is important to read the Annex 1 revisions and understand what is being asked of the industry. Many companies often skim these revisions and believe that they are already compliant, and no changes will be needed before August. Many often fail to realise the inherent risk of that line of thinking. It all returns to the notion of a holistic approach to understanding risk across the facility. Without a thorough facility audit regarding Annex 1, you simply do not know what process needs to be reconfigured to come into compliance or what technological changes need to be incorporated

8 CONTAINMENT

IPSIntergrated Project Services

Follow us here!

Your Thermal Packaging Specialist

Reliable Pharma Needs Reliable Thermal Protection

When you’re confident in your cold chain distribution, you know your temperature sensitive pharmaceuticals will be kept completely safe - carefully protected, at the right temperature.

From off-the-shelf high-performance thermal packaging and components to custom and fully optimised distribution systems, Topa Thermal helps pharmaceutical manufacturers protect their products as they are shipped worldwide.

2°C to 8°C; 15°C to 25°C; 2°C to 25°C; <-20°C protection

Parcel to Pallet, Freight Optimised Systems

Pre-qualified or Custom-made

24 to 120+ Hours Duration, Designed & Tested to Your World Challenge

For thermal packaging you can rely on, visit topathermal.com

100 years dedicated to packaging excellence

(and tested and re-validated). Wise organisations will employ a diverse team to audit their facilities, with experts from inside and outside their company to leverage their expertise and challenge each others’ assertions.

To regulators under Annex 1, the safety of patients has no cost. There is no economic argument for excusing risk, and with contamination risk for potential patients comes greater financial risk for pharmaceutical manufacturers.

Contamination control is a combination of human procedures and facility technology. Technical solutions should complement procedural changes. There is often a technical solution that will reduce risk in certain aspects of manufacturing, however, we can also evaluate human behaviour, activity, and traffic flow within a facility to make simple changes in process design that complies with GMP.

These two elements work in tandem. Workers can follow the processes and procedures to the letter, but it will not matter if your ventilation system, for example, is substandard or if there is no way to remove waste without interacting with the manufacturing line.

For example, I worked with a company that had developed an impeccable mitigation strategy against cross-contamination. On paper, they did everything correctly regarding procedures and the flow of materials and workers throughout the facility, except for one important thing: a waste pipe along the side of a corridor built at about knee height. It would only take a small seal failure or an accidental stumble to cause a

small, barely perceptible leak to begin, which could then be tracked across the facility.

Modernising your production facilities could cost time and capital expenses. However, few things may cost a manufacturer more than a regulatory shutdown, whether that is the loss of a batch or the losses that accrue every moment a production line is closed.

Come August, Annex 1 regulators want to see you have done your work. They want to know that you have read the regulations and evaluated your facility. They want to see what you have done to mitigate contamination and that you have generated the numbers to back your assertions.

Your greatest asset to meet this challenge is a simple spreadsheet.

EVALUATING YOUR FACILITY BY ROOM

A modern facility is a wonder of science and engineering. It is, of course, complicated and difficult to perceive in its entirety. Breaking the process down into smaller steps makes evaluation manageable.

Take any given room in your facility. It is a tab in your spreadsheet. What is the purpose of the room? What is the flow of people, and how do they get in or out? Is it bidirectional or unidirectional?

The risk is different for each scenario, of course. Is there an airlock? How does raw material flow into the room? How about utilities? How do you clean it? How often is it cleaned?

What is the cleaning process? How do you manage the waste? Where does the waste go? Does it conflict with the flow of people? Is there a potential for risk there?

Asking these questions will achieve a complete, holistic understanding of this room’s problem. Then you solve these problems where conflict occurs. That might be procedural –a bi-directional hallway becomes unidirectional –or a technological solution might be achieved by rerouting pipes or exchanging machinery for something that can be put through an autoclave.

Then, this process is repeated for every room and corridor in your facility. It does not end there, however, as now you have multiple tabs on this spreadsheet, and you must make sure your contamination strategy for one tab does not conflict with another.

GOOD ENOUGH WILL NEVER BE

The EU GMP Annex 1 revisions will dominate the regulatory

world come August. This is a tremendous opportunity to conduct a risk assessment and either improve your production techniques or gather evidence to support your contamination strategy to regulators.

At this stage, hesitancy to act will have dramatic consequences, and many small manufacturers might be gambling on whether their assumptions will be enough to convince regulators. For Annex 1, “good enough” will never be enough, and your only defence will be a global, holistic understanding of your contamination risks.

10 CONTAINMENT

Wise organisations will employ a diverse team to audit their facilities, with experts om inside and outside their company to leverage their expertise and challenge each other’s assertions.

Logistics is a critical factor across biopharma, but the rapidly growing cell and gene therapy (CGT) industry is currently working through extreme supply chain complexities that therapy manufacturers have never before faced. These therapies are often personalised, such as autologous cell therapies where each batch manufactured is made for and suitable for one specific patient, but even some allogeneic therapies are matched or partially matched to a very small number of potential patients.

Large-batch manufacturing isn’t an option, and production capacity is struggling to meet the rising demand, so each patient becomes a batch in themselves, with their own manufacturing events or slots. This means that all of the events in the patient’s journey need to line up with the manufacturing schedule, which can tie up a slot for weeks, and the logistics must flow seamlessly to support this. Autologous products will be made from a sample of the patient’s own tissue or cells, which ties the ‘raw material’ element to the patient schedule as well as the dispatch of the final treatment.

Unlike biomanufacturing for traditional therapies, advanced therapies often need to be matched to individual patients by the dose. Matthew Lakelin, co-founder and VP Scientific A airs & Product Development at TrakCel, discusses the unique logistical challenges in the space, and how digitising COI and COC can make processes scalable.

Author: Matthew Lakelin, co-founder and VP Scientific A airs & Product Development at TrakCel.

DIGITISING LOGISTICS AND DISTRIBUTION FOR FASTER, SAFER CELL AND GENE THERAPIES

12 COVER STORY

Most eligible patients are critically ill and are receiving these as lastresort therapies, adding more complexity to the timing. They must be well enough to undergo cell collection, and their status can change at short notice. Once collected, the living cells must be transported to the manufacturing site via careful, temperature-controlled shipping and handling, and where processes dictate that the cells are transported fresh. To maintain the viability of the cells, the logistics timelines may be only 48-72 hours for materials that are not cryo-preserved.

In addition to this, the shipments need to be traceable to the patient they are intended, and the cells handled in compliance with local human tissues and cells legislation. Each dose is linked to an individual, there are additional considerations around patient privacy and protection of personal data within the supply chain, as well as the flow of in silico data. Some therapies may require multiple samples or manufacturing exercises. More recently, the various reimbursement aspects for commercially approved therapies have exacerbated this complexity.

DIGITAL SOLUTIONS TO MANUAL PROBLEMS

All of the above combine to create a very delicate supply chain for each patient that only magnifies as the patient numbers begin to scale up. Managing quality, forecasting, managing demand, and working towards best utilisation of manufacturing resource is complex and volatile. But the urgency is clear: these are life-changing, often curative therapies with growing applications beyond hematologic cancers including rare disease, solid tumour cancers and autoimmune conditions. If the potential of CGT is to be harnessed, then managing the efficient scale up of the supply

chain will be essential to supporting better patient access to what are already costly therapies.

Technology has made possible the automation of processes and rules, data analysis and agile, collaborative information sharing between supply chain partners. Advanced therapy developers are turning to specifically designed digital orchestration solutions to act as a central control and coordination point. These allow them to strengthen processes and scale-up, whilst protecting safety and quality, empowering supply chain partners to manage their resources with simplicity.

The sector has come to realise the value of undertaking this digitalisation process early, often from first-in-human testing, to make clinical trials easier to manage, and to be ready to progress to the next stages more quickly.

To ensure that personalised medicines reach the correct patient, the industry has endorsed the Chain of Identity (COI), a record created at patient registration/enrolment that then permeates every step of the process, to ensure that cells and medicines for that patient can always be matched back to them. Recent industry standards ensure that each patient gets a unique COI number that will be on all related materials and records for full traceability, key for both data protection and patient safety. The consequences of being treated with the wrong medication may prevent them from receiving further CGT treatment, and could even trigger a fatal immune response.

Orchestration systems ensure that this COI number can be monitored and tracked throughout the process.

As manual systems are

cumbersome to manage, vulnerable to error, and hard to validate, many developers are looking to software solutions that can help to manage other complexities within the supply chain process. Modern digital orchestration solutions can generate compliant COI references, enforce uniqueness and connect them easily and securely to partner reference numbers where required. They can also transfer this information to labels, shipping documentation and reports, to help visibility and minimise errors.

Throughout the process, who handles cells and samples (and how) is tracked through Chain of Custody (COC). This is necessary for ensuring adherence to timelines and optimal storage conditions, but also mandatory for regulatory compliance. Human tissues and cells are subject to very specific handling regulations, and it is necessary for supply chain partners to prove that these have been followed.

This COC record is critical for visibility within the supply chain. It documents each time a sample changes hands, and often includes a quality check at the point that the transfer is made. Key partners, such as couriers and manufacturers, are able to see if the status of a shipment has changed and adjust as needed. The value of these products -- both financially and in terms of their potential impact – necessitates being able to trace where materials are and to intervene quickly in the event of a process breakdown

is exceptionally valuable. It also offers accountability in the event of a process failure.

Using a digital orchestration system to manage COI and COC gives all of the permitted parties within the supply chain access to the information that they need as it is entered. It also notifies when tasks are due or as statuses change, relieving time pressures, simplifying processes and removing the administration associated with collaboration.

LEVERAGING DATA FOR THE FUTURE

Given the rapid changes in the CGT industry, there will doubtless be even more development in the future to support these complex supply chains. The collection, collation, and analysis of the data available can contribute to solving these challenges – for example, helping to facilitate more reactive and flexible scheduling in order to improve resource use and efficiency.

Digital orchestration solutions are already capable of creating detailed and customised reports to support COI and COC. But there are many other insights that can be leveraged from the data they collect, particularly in this space, where they are central to an integrated supply chain eco-system, sending and receiving data from partner systems in real time. Advanced analysis of the data collected within the supply chain has the potential to help inform forecasting and manufacturing management, as well as risk mitigation within the day-to-day processes.

www.pharmaceuticalmanufacturer.media 13

e sector has come to realise the value of undertaking this digitalisation process early.

FAST CUTS FOR PHARMA: HOW A NEW

THERMAL

Topa Thermal’s new bulk shipping solution heralds greater e ciency and sustainability for cold chain drug distribution.

In just one year, companies across many healthcare sectors have cut freight costs and reduced CO2 impact by simply shipping their pharmaceutical products in a different type of bulk thermal packaging.

Pharmaceutical manufacturers, wholesalers, and distributors alike have found that using a Connex Overwrap thermal shipper to protect and transport their products in bulk has reduced their freight costs by as much as 40%, lowered the CO2 impact of their distribution by 31% and even halved packing time. The new pallet shipper has brought many other benefits to their logistics operations too.

A MORE EFFICIENT, CHEAPER, AND SUSTAINABLE SUPPLY CHAIN

Connex Overwrap was introduced to the market in 2022 by Topa Thermal, the Netherlands-based thermal packaging innovator, offering a more sustainable, logistically efficient, and economic solution for shipping temperature-sensitive healthcare products in bulk.

Compared to traditional thermal pallet packaging systems, the slimline, special coolant-wall design of the Overwrap creates additional payload capacity but from a much smaller, lighter container. With an impressive 55% loadable shipping ratio it has the highest payload vs outside dimensions ratio of all passive and active shippers in the market.

Richard Harrop, product director at Topa Thermal: “The Connex OVERWRAP thermal shipper has a unique size-CO2 efficient design that makes your temperature controlled distribution more efficient, cheaper and sustainable. No matter where you sit in the supply chain.”

Here are three success stories where the Connex Overwrap has already made a difference.

€600K ANNUAL SAVING FOR PHARMA MANUFACTURER

Firstly, using the Connex Overwrap thermal shipper, saved a major pharmaceutical manufacturer €600,000 in freight costs and lowered CO2 emissions by 31%; the CO2 equivalent of over 100,000 cars in one year.

The manufacturer wanted to lower the CO2 impact of their logistics, but at the same time maintain the same performance and thermal protection of products during transit. “We applied a total cost of ownership approach to their distribution using the Connex Overwrap,” says Richard Harrop. “The space and CO2-saving attributes of its design reduced CO2, and cut freight costs significantly due to lower volumetric weight per shipment. Consequently their whole logistics operation is faster, lighter, and more efficient.”

PACKING TIME HALVED FOR PHARMA WHOLESALER

Secondly, in the case of a wholesaler shipping temperature sensitive pharmaceuticals from Europe to Canada, the company needed a bulk thermal packaging solution that met the thermal and durational performance demands of international shipping, at the right price.

Richard Harrop, Product Director, Topa Thermal

14 LOGISTICS AND DISTRIBUTION

CONCEPT IN

PACKAGING IS QUICKLY REDUCING LOGISTICS COSTS AND CO2 IMPACT FOR COMPANIES ACROSS THE PHARMACEUTICAL SUPPLY CHAIN.

By using the Connex Overwrap thermal shipper, they cut shipping costs by 40% and nearly doubled shipping duration from 4 to 7 days. They also halved packing time because the Overwrap is very light, has fewer components, and can be assembled by one person. “We needed a costeffective thermal shipper that performs at 15°C - 25°C for +120 hours. Connex Overwrap gives that and much more” added Harrop. They also reduced the overall CO2 impact of their distribution due to the Overwrap shipper’s light-weight, high capacity design made from sustainable and reusable materials.

FREIGHT COST DOWN 35% FOR LOGISTICS COMPANY

Thirdly, the benefit for pharma distribution also extends to the logistics side of the

lifesciences cold chain. A 3PL customer needed an alternative thermal packaging solution to deliver temperature sensitive pharmaceuticals safely and cost-effectively from the UK to the US.

Richard Harrop: “Connex Overwrap is 35% smaller than conventional quarter PMC solutions, but has the same payload capacity and is also much lighter. This means that we were able to cut the billable weight of each shipment by a third and cut freight costs even further by shipping more product per load.” Also, the new thermal shipper gives the added benefit of handling efficiencies, quicker packing and is size-optimised for direct-to-rollerbed loading.

Announced as a BSMA Sustainability Supply Chain Award Finalist in 2022 (“Smart Thermal Packaging Solution for Improved Impact on CO2 Emissions in Bulk Pharma Distribution”) the last 12 months has seen the Connex Overwrap qualified for safe delivery of bulk pharmaceuticals, going from user trials and early adoption to use in commercial and international freight channels.

In just 12 months, Connex Overwrap has proven economic, logistical, and environmental benefits for the pharmaceutical cold chain. Ultimately its superior load efficiency means more life-saving products can reach more patients more efficiently.

www.pharmaceuticalmanufacturer.media 15

ABOVE: Topa Thermal’s new bulk shipping solution is helping manufacturers and logistics companies cut freight costs and CO2 impact.

Laura Johnson, Loftware Senior Director, Life Sciences Sales.

THE IMPORTANCE OF TECHNOLOGICAL INNOVATION IN PHARMACEUTICAL MANUFACTURING

In the ever-evolving landscape of pharmaceutical manufacturing, technological innovation has become paramount for enabling compliance, ensuring product safety, and facilitating supply chain transparency. With rising global demand for advanced therapies, industry leaders are recognising the vital role of cloud technology in the development, manufacture, and distribution of pharmaceuticals. The Healthcare Information and Management Systems Society reports that 83% of pharmaceutical companies are leveraging cloud services, and Gartner reveals that 49% of life sciences CIOs plan to invest in cloud platforms this year.

Balancing innovation with human health, compliance, and supply chain agility is crucial. The swift, accurate provision of pharmaceutical products is vital, and there is no margin for error or inaccuracy.

The rise of counterfeit pharmaceutical goods being traded using e-commerce platforms is a pressing issue. These products pose significant risks to consumers. Therefore, pharmaceutical manufacturers must reassess their digital transformation initiatives. Cloud-based labelling and serialisation technologies offer a solution, providing end-to-end traceability of drugs. In essence, the label acts as a product’s passport throughout its entire cycle - both upstream and downstream. In many instances, without proper and accurate labelling, human health is put at risk, production lines stop, productivity is impacted, and business is lost. Mislabelling can also cause items to be rerouted and ultimately can result in product recalls and fines.

SAFEGUARDING THE PHARMACEUTICAL SUPPLY CHAIN

Counterfeit medication has become a global concern, despite the tightening of regulations. Fortune Business Insight reports that the anti-counterfeit market is expected to grow by 45% from 2018 to 2026. Pharmaceutical companies are recognising the need for robust brand protection and are turning to cloud-based radiofrequency identification (RFID) serialisation. This stringent approach to drug authentication assigns a unique serial number to each product unit, containing information about the product’s origin, batch number, and expiry date.

By printing this code on the packaging, a product can be tracked and traced throughout the supply chain, offering greater accuracy and traceability. The RFID reader device compares the information on each tag to a central database, thereby authenticating and verifying each drug package.

Cloud-based RFID technology offers an efficient approach to identify and eliminate counterfeit products within the pharmaceutical supply chain. The increased visibility facilitates prompt detection of counterfeit attempts and identification of tampered packages.

ENSURING COMPLIANCE

Furthermore, serialisation technology can help pharmaceutical manufacturers achieve regulatory compliance. Cloud-based platforms securely store and access data, facilitating regulatory audits and demonstrating adherence to stringent compliance standards.

Regulatory bodies such as FDA, EMA, and WHO require certain documentation – serialisation technology allows them controlled access to the data in their jurisdictions. The secure cloud-based environment in which this RFID data is stored ensures

only authorised individuals or devices can access this information, meaning pharmaceutical manufacturers can rely on the cloud’s secure infrastructure to protect their critical data assets while also meeting the requirements of key regulations.

MINIMISING LOGISTICAL DISRUPTIONS

Cloud-based RFID technology helps prevent logistical disruptions within pharmaceutical supply chains. RFID tags on drug packaging enable real-time tracking and monitoring at every stage of the supply chain. The collected data, transmitted to a cloudbased platform, provides comprehensive visibility of the supply chain processes. This visibility enables early detection of potential bottlenecks, and proactive measures can be taken to mitigate disruptions, ensuring a smooth flow of products.

Pharmaceutical companies can promptly address issues such as inventory shortages, transportation delays, or storage discrepancies, minimising the risk of disruptions. Cloud-based RFID technology empowers companies to proactively manage their supply chains, optimising logistics and maintaining efficient flow. Pharmaceutical manufacturers must be at the forefront of technological innovation. Adopting cloud-based labelling and serialisation technology safeguards operations and future-proofs businesses, aligning them with regulatory requirements and ensuring sustainability in the evolving landscape.

16 LOGISTICS & DISTRIBUTION

Lacking the resource to implement process change? We can fill in the gaps.

Would you benefit from a Change Management program for cleaning and disinfection regime change in your cleanroom?

Let Ecolab’s experts carry the burden of process change for you with a customised change plan, managed from end-to-end.

Speak to your Ecolab account manager or email infols@ecolab.com to arrange a call with our Technical Services team.

ecolab.com/changemanagement

Risk Assessment Supplier Approval Product Selection Validation Implementation

11486.02 © 2023Ecolab USA Inc. All rights reserved. 05JULY23/EU GLOBAL EXPERTS IN CONTAMINATION CONTROL

RESPONSIBLE MANUFACTURING IN THE AGE OF ANTIMICROBIAL RESISTANCE

Rex Clements, CEO at Centrient Pharmaceuticals, sheds light on the company’s e orts to contribute to a more sustainable global supply chain for antibiotics.

At Centrient Pharmaceuticals, we see responsible manufacturing as an integral part of our duty of care to our stakeholders. These include our employees, for whom we strive to provide a safe working environment, as well as the communities in which we build and invest. Likewise, we have a duty to our investors to ensure we act responsibly as well as profitably, and to uphold the policies and values of our local and regional government stakeholders.

As a leading supplier of betalactam antibiotics and other vital medicines, we also have a responsibility to our customers and, by extension, to the millions of people around the world who rely on our products. The first time our industry touches a patient’s life is often at the age of two or three months, when they are treated for their first small ear or throat infection. From that point on, they will have a lifelong relationship with our industry. Over the course of their lives, they may need access to

antibiotics for routine surgery, childbirth, chemotherapy or a variety of other reasons. Given this fact, I believe the products we make are truly the foundation of healthcare.

Patients place their trust in our industry in other ways, too. They trust that the medicines they are prescribed are not only safe and e ective for their own use, but also created in a way that does not cause harm to the environment or society. At Centrient Pharmaceuticals, we are working to repay that

18 SUPPLY CHAIN

Author: Rex Clements, CEO at Centrient Pharmaceuticals.

trust – for example, through our focus on sustainable manufacturing technology. With our proprietary enzymatic antibiotics manufacturing platform, we have succeeded in reducing the carbon footprint associated with antibiotics production by up to 65% compared to traditional chemical-based processes, while eliminating the use of solvents and other chemicals. Our target is now for Centrient to become fully carbon-neutral by 2030.

STRONGER TOGETHER

However, simply taking responsibility for our own activities will not ensure the long-term sustainability of our industry as a whole. With this in mind, we have recently started to license our enzymatic technology to other pharmaceuticals manufacturers, in line with our commitment to support the transition to a lower-carbon antibiotics supply chain.

Similarly, we are committed to being at the forefront of the industry’s fight against antimicrobial resistance (AMR). Without a concerted, consistent, industry-wide approach to this growing global healthcare problem, our products will eventually cease to work. In recent years, we have taken concrete steps to minimise our own contribution to AMR by improving wastewater treatment and effluent analysis methods at all our global manufacturing sites. And in 2021, we achieved our goal of meeting Predicted No-Effect Concentration (PNEC) targets for all of our oral antibiotic wastewater streams.

But ultimately, it makes no difference whether an AMR hotspot occurs at a Centrient Pharmaceuticals site or at one of our competitor’s facilities: either way, the long-term efficacy of finished dosage forms is compromised. The greatest weapon we, or any company, have in the fight against AMR is partnership. Centrient was a founding member of the AMR Industry Alliance (AMRIA), which now represents approximately 30% of the global human health antibiotics supply chain. Importantly, AMRIA has developed an Antibiotic Manufacturing Framework, which sets a benchmark for good manufacturing practice based on PNEC targets. In June of this year, I also welcomed the launch of an independent standard and certification scheme by AMRIA in partnership with the British Standards Institution (BSI).

The adoption of a common set of global criteria for sustainable antibiotic production is essential, taking this step ensures clear, consistent standards and a level playing field for all members of the value chain. Nevertheless, manufacturers like us still have a duty to monitor our own supply chains and audit them from top to bottom, as it is too easy for irresponsible practices to slip through the net. For example, a supplier may source its ingredients from a fully regulated, PNEC-compliant facility supplying Western Europe. But if that same company operates unregulated sites in other parts of the world, they may still be contributing to the spread of AMR. The onus is

on us to take responsibility for what is taking place upstream; we need to understand the exact origin of the ingredients used in our products and only source from suppliers that are PNEC compliant.

WALKING THE WALK ON COMPLIANCE

Authenticity is key. Talking about becoming a more responsible industry is all well and good, but to be of consequence, the steps we take to limit AMR and environmental degradation must be measurable, sciencebased and verifiable. Most importantly, our policies must be applied consistently, wherever we work and whomever we work with.

I am proud to lead a company that is fully embracing this approach. In May last year, Centrient Pharmaceuticals became the first member of the industry to publicly announce PNEC compliance for our entire oral antibiotic product supply chain. Perhaps more than any other achievement, this demonstrates our

commitment to the responsible manufacturing of antibiotics. It also shows the role that sometimes lesser-known members of the pharmaceuticals value chain – in our case, a medium-sized, European-based manufacturer – can play. Given our influential role at the centre of the chain, it is important that we continue to make our voices heard by actively promoting best practices in sustainable manufacturing and sourcing. We must continue to encourage stakeholders at each point in the chain to join organisations such as AMRIA and participate in standardised, industry-wide certification.

The first step in solving a problem like AMR is to ‘own’ the fact that our industry is both part of the problem and part of the solution. By taking responsibility collectively and cohesively, we can help to build a sustainable future for antibiotics – ensuring they remain the foundation of healthcare for generations to come.

www.pharmaceuticalmanufacturer.media 19

e rst step in solving a problem like AMR is to ‘own’ the fact that our industry is both part of the problem and part of the solution.

R&D REVOLUTION: A NEW PARADIGM OF SOURCING AND LANDSCAPING FOR THE PHARMA INDUSTRY

Author: Dr Robin Knight, co-founder & Co-CEO of IN-PART, discusses the emerging importance of outsourcing ‘landscaping’ activities within the pharmaceuticals industry and the benefits of adopting an openly innovative approach that pools sources of innovation from a wide variety of areas.

In the dynamic world of biopharmaceuticals, where groundbreaking discoveries emerge at an unprecedented scale, larger, more established pharma companies are finding themselves in an unfamiliar and precarious position. As nimble biotech start-ups and university spinouts enter the market backed by significant investment and astonishing financial rounds, big pharma’s competitive edge could be under threat.

Many newcomers have the distinct advantage of being able to pivot in response to market and patient demands, and quickly adopt the latest technologies such as genomics and artificial intelligence to capitalise on emerging trends and scientific breakthroughs. That is why top technology venture capitalist firms continue to throw big money into life science start-ups. They can map out research opportunities at speed and at scale, take hidden treasures to clinical trials faster, all while being more open to and adept at forging fruitful partnerships with academic institutions around the world.

To remain at the top of their game and flourish at a time of fierce competition, wellestablished pharma firms need to embrace and adapt to the disruptive potential of start-ups and spinouts and be on the ball when it comes to finding new opportunities and nurturing interdisciplinary collaboration.

LOOKING BEYOND THE WALLS

With the pharmaceutical industry being highly R&D intensive, it is true the next project, drug trial, or innovative

20 R&D

therapy could be ‘just around the corner.’ But rather than taking the saying literally and only searching within academic institutions in close geographical proximity, established pharma companies need to widen their net and adopt a more global outlook to find the right collaborator that will help give them that competitive edge.

There have been many great and long-term corporateacademic collaborations in biomedical sciences, for example, Harvard University and Swiss pharmaceutical company Novartis developing biomaterial-based cancer immunotherapy technology, and on another occasion together with the Broad Institute, they collaborated on research to find out how Zika virus attacks the brain of developing foetuses. A researchintensive pharmaceutical company based in Germany teamed up with Newcastle University a few years ago to triage proprietary early-stage compounds for the treatment of fibrosis.

When traditionally R&D teams and technology scouts would go out to conferences, book meetings in-advance with academic representatives to discuss projects and read countless medical journal articles to identify new opportunities, today’s challenges of stretched budgets and human resources can endanger the effectiveness of those approaches. Whilst it is certainly still important to ‘get out there’ and have a presence in the physical spaces of partnering, scouting for new opportunities in person may not be possible at the same desired frequency. And it is certainly not scalable. Not to miss an innovative solution to a priority disease for cost and time reasons, pharma companies need to adopt an approach that pools sources of innovations from a wider variety of different areas.

THE EVOLUTION OF OUTSOURCING

Outsourcing landscaping and scouting activities within the pharmaceutical industry is emerging as the most promising, efficient approach to identify hidden gems at scale. By leveraging the expertise and agility of external entities such as universities and biotech companies, biopharma R&D teams can significantly save time and resources by streamlining the process of identifying potential collaborations. Outsourcing can involve engaging specialised agencies, consultants or technical offices who solely focus on the task of research scouting on behalf of biopharma firms, but it can also entail pushing out global calls for research on online channels, forums and platforms.

Organisations that embrace the outsourcing ‘open innovation’ approach online can reap a wide range of benefits, such as increased efficiency and faster access to specialised crossdisciplinary expertise. Outsourcing facilitates a more diverse portfolio of R&D projects at various stages of development, making biopharma firms one step closer to taking the next viable medicine breakthrough to market. This includes clinical trials or providing valuable connections to novel research that may have been inaccessible.

Being proactive and outsourcing landscaping and scouting activities means established biopharma organisations can always have their finger on the pulse and comfortably compete with agile market newcomers. It also helps to mitigate risk as engaging external partners in the process means they can conduct due diligence and thorough evaluations of potential research opportunities, including scientific validity, market potential, commerciality benefits, intellectual property landscape and legislative considerations. This helps to mitigate risks and reduces the likelihood of investing resources in collaborations that won’t align with a biopharma firm’s goals or vision.

COLLABORATION IS ESSENTIAL TO INNOVATION IN PHARMA

New collaborations between academia and pharmaceutical companies are an opportunity to spearhead breakthroughs and combat a variety of global health challenges and unmet medical needs. The most successful partnerships are built around a common goal and similar ambitions or

outcomes in mind. Clarifying priorities early-on helps to avoid unnecessary back-andforth or misunderstandings when it comes to timeliness or frequency of communication and puts the differences in working cultures behind for the good of science and patients.

Given the dynamic nature of drug discovery and development, the approach of outsourcing landscaping activities exposes well established biopharmaceutical companies to faster innovation in potentially life-saving strategies. By embracing and reviewing a global pool of knowledge, they have much more insight to work from, heightening the chances of achieving meaningful progress, be it a new treatment for rare diseases or a faster diagnostic for cancer. With nimbler biotech start-ups already open to global partnerships and accelerating the creation of life-changing medications, well-established pharma companies cannot afford to fly solo, or too locally, for much longer if they are to remain competitive and contribute to solving significant human health issues.

www.pharmaceuticalmanufacturer.media 21

Organisations that embrace the outsourcing ‘open innovation’ approach online can reap a wide range of bene ts, such as increased e ciency and faster access to specialised crossdisciplinary expertise.

Film coating is an important stage in the manufacture of pharmaceutical tablets, powders and granules. In addition to controlling drug release, it can be used to mask bitter tastes, enhance product appearance, appeal, and the colour. Film coating is mostly opted for to help identify and enhance a market brand. All these factors improve patient compliance.

Coating also improves a product’s stability and shelf life. Considered a vital process, coating reduces the abrasion of the extremely fragile surface of an uncoated tablet, and therefore also helps to mitigate dusting of the product during handling, packaging, and dispensing.

Film coating is widely used in the pharmaceutical and nutraceutical sectors and has largely replaced the once popular but labourintensive sugar-coating process, because it offers far greater flexibility. Smart coaters are widely used for film coating. These have been popularised over other conventional methods of pan coating.

CRITICAL PROCESS PARAMETERS

Film coating is a complex process. It involves the spraying of coating dispersion with specialty polymers, pigments and plasticisers. In the smart coater spray, nozzles spray coating dispersion on to the rolling tablet bed in the perforated coating drum to achieve a thin, uniform film coating. The requirements of the drug release and release rates determine the choice of coating formulation.

The critical process parameters in the coating include:

• Inlet temperature and relative humidity of process air

• Spray rate & pattern

• Atomisation air pressure

• Revolutions per minute (RPM)

• Airflow across the tablet bed

The spray pattern, coating dispersion droplet size, and nozzle configuration are important aspects of the coating process. Precise control of these parameters is crucial to achieve uniform coating on the substrate. A concurrent flow of heated, clean process air assists in the controlled drying of the coating.

The spray rate, in conjunction with atomisation air pressure control the droplet size and droplet size distribution of spray, ensuring that it is not too large or too fine to cause defective surface coating. If the droplet size is small and fine, it will air dry too quickly and generate dust.

FILM COATING OF ORAL SOLID DOSAGE FORMS: THE CRITICAL PARAMETERS

Author: Prashant Deshpande, Head, Process & Technology Support at ACG Engineering, discusses the critical process parameters of film coating and the measurement, monitoring, and recording of tablet bed temperature in batch manufacturing.

22

COATINGS

The requirements of the drug release and release rates determine the choice of coating formulation.

Achieving the optimal spray rate is also vital in preventing coating defects. These range from blistering, chipping, colour variations, and smudging, through to logo bridging and the rejection of entire batches due to non-complying product standards and specification. Physical appearance is one of the quality tests as a standard in the specification for pharmaceutical products. Too high a spray rate may result in coating defects such as picking, sticking, and twinning. At the other end of the scale, a low spray rate can cause spray

drying and a reduction in coating efficiency.

Spray rates are monitored and controlled precisely by defining process variables in the batch manufacturing process. They are continuously monitored with a display showing the flow of the coating and its dispersion via the transfer pump.

MANAGING EXTREMES

Generally, for a process developed and designed based on the QbD principle, each critical process parameter is

defined, ranging from lower to higher limits. Overheating or underheating can lead to a defective product profile such as surface irregularities, twin tablets, or product non-complying standard specification. To monitor and control process parameters, several temperature sensors are incorporated in the equipment, including:

- Resistance Temperature Detector (RTD) - a sensor that measures and senses the temperature of the tablets during the coating process. The RTD’s resistance increases as the temperature of the sensor increases.

- Infrared temperature sensor (IR) - it is important to note that this sensor will sense and measure the temperature of the top layer of tablets and not the bulk of tablets with the help of IR light’s wavelength that falls on the surface of the tablet.

OPTIMISING TABLET BED ZONES

In the smart coater the rolling tablet bed is divided into two distinct zones - the coating zone and the drying zone. The temperature of the tablets in each zone varies by just a few degrees depending on the formulation, solvent system, and process. Typically tablets in the spray zone are at a lower temperature than tablets rolling in the drying zone, which is inside the perforated coating drum.

Process airflow plays a key role during the process in the coating drum, where the product is coated and dried simultaneously. The drying process is a function of the volume, velocity, temperature, and relative humidity of incoming airflow. The negative

pressure in the coating drum is maintained and monitored during the process. Optimised process parameters ensure final product coating is uniform and smooth in appearance.

MONITORING TEMPERATURES

Measuring, monitoring, and recording tablet bed temperature ensures that operators work within a validated range to impose a limit for the product temperature. The limit is defined based on the principle of risk analysis during the development stage.

Others work on process control, based on the adjustment of inlet temperature to maintain the required exhaust temperature. This measure is widely used as it is assumed that it closely resembles the tablet bed temperature.

The exhaust temperature is one of the process parameters that is monitored during the process. In the absence of tablet bed temperature data, the exhaust temperature provides a reasonable estimate. The temperature of the exhaust air flowing across the tablets is measured by a sensor kept near the tablet bed, outside the perforated coating drum.

Whether the manufacturing process adopted is based on the measurement, monitoring and, recording of the tablet bed temperature, or a process control based on the inlet and exhaust temperatures, during the batch manufacturing process, there will always be a margin of error for either practice. However, such small variances in product or exhaust temperature do not have any impact on the critical quality attributes of the film-coated tablets. The critical process parameters are spray rate, pattern, atomisation, drum revolutions per minute (RPM), inlet air temperature and airflow across the tablet bed.

www.pharmaceuticalmanufacturer.media 23

GEODIS – THE ROLE OF THE PHARMA FREIGHT FORWARDER

The Global pharmaceutical supply chain is constantly growing. An ever-increasing stream of medicinal products moving around the world until finally reaching their end destination. Drugs are moved from A to B, quick hop on an Aeroplane, Truck or Ship and away it goes. Sounds easy right?

The pharmaceutical supply chain is complex and if you’re a named Responsible Person within a wholesaler or manufacturer then you will be well acquainted with the plethora of GDP regulations applicable to your country, region, and scope. Despite all the regulatory guidance, rules, symposiums, trainings, guides, or country there just never seems to be enough information on what happens to the medicinal product during the global distribution

process. The easiest way to move ANY cargo is to subcontract a Freight Forwarder. That’s where GEODIS come in.

Regardless of commodity, the role of the Freight Forwarder within any supply chain is vital. In simplest terms, the Forwarder is an expert company who manages your cargo from the minute it leaves your warehouse to the moment it’s handed over to your customer, wherever in the world that may be. We handle the carriers, sub-contractors, export/import documentation, customs, and warehousing on your behalf, using our global offices for end-to-end network connectivity.

Pharmaceutical cargo is distributed on passenger and cargo aircraft just like any other commodity;

and there are a hundred ways this can result in temperature excursions, security threats, damage to product, contamination… the list goes on. Once the cargo has been handed over to the carrier, neither the Forwarder nor Shipper are in physical possession of the goods, but we are both still responsible for maintaining the integrity of the product throughout.

‘How do we achieve this?’, I hear you ask. How do we keep a medicine, travelling to the other side of the world in a 39°C climate wearing nothing but a thermal blanket within product storage conditions? I’m not going to go into too much detail because that would be akin to Grandma sharing the secret family recipe but what I can do, is give you a brief overview of how controls and

risk mitigation implemented at origin can make a world of difference to ensuring pharmaceutical cargo arrives in optimum condition.

When a pharmaceutical shipper comes to us and asks to book a pharmaceutical shipment, we don’t simply go out to our carriers and see who comes back with the best price. There is a raft of information that we need to ascertain before we can think about the logistics:

● At what temperature do the goods need to be stored?

(See page 182 of our favourite Green Guide)

● What temperature management packaging is being applied to this shipment?

● Is the shipper applying the temperature management packaging or will GEODIS apply it?

ADVERTISEMENT FEATURE

● If the shipper applies the temperature management packaging, what is the validated time/transport period and under what conditions is it validated for?

● Where is the customer located in terms of nearest Airport?

● Has the customer requested a temperaturecontrolled collection?

● Do we have an approved route risk assessment in place for this shipper on this lane?

● Who are our carrier options?

● What are the Ground Handling capabilities at global hubs?

● What is the climate at the carrier hubs planned in the routing?

● Does the shipment contain controlled-drugs or Dangerous Goods?

● Does the requested destination come under export-control regulations?

● Are shippers applying data loggers?

● Do the loggers contain lithium-ion batteries that come under the IATA DGR?

All this information is then pulled together to create a distribution solution for pharmaceutical export/import. For every single shipment. We will then proceed to book the appropriate pharma & temperature-control service with the carrier using the most direct route with the lowest risk to product. What this means is the pharmaceutical cargo will be stored under temperature-controlled conditions where possible. It looks like this (simplified version):

1. Pick-up from customer (temperature-controlled truck)

2. Cross-docking and export labelling at the Forwarder warehouse (controlled facility)

3. Delivery to the Ground Handling Agents at Airport (temperature-controlled truck)

4. Storage at the GHA awaiting flight (controlled facility)

5. Transfer to the apron (uncontrolled in most circumstances)

6. Loading Aircraft (uncontrolled)

7. Flight (controlled providing animals aren’t on board)

8. Unloading Aircraft (uncontrolled)

This is for one transport leg and direct flights aren’t always available, so steps 4-8 above could be repeated more than once depending on the destination, and the capabilities of temperaturecontrol will differ throughout the global airports. We manage global carrier and GHA capability using an expansive route risk assessment programme tailored to each customer individually. This is then shared with our customers to create ‘approved’ lane programmes. Exporting to Sydney in August will have different risk considerations than exporting to Toronto in December and risk must be managed accordingly using climate data, temperature management packaging and process-controlled distribution. A collaborative approach between Forwarder and Shipper is essential for supply chain success and GEODIS will provide

comprehensive route risk assessments allowing the Shipper to make evidencebased decisions that are underpinned by risk management.

GEODIS has been ahead of the pharmaceutical distribution game for some time now, growing pockets of excellence, honing technical expertise, and tailoring ultrabespoke solutions for some of the biggest names in the pharmaceutical industry. Over the past two years, we have taken this another step further as an organisation and implemented IATA CEIV Pharma throughout our Global Network in 26 hubs over 21 countries and heavily invested in temperaturecontrolled infrastructure to accommodate the everexpanding pharmaceutical market.

I am the Responsible Person named on the UK WDA(H) licence and manage GDP for Europe, with a background in pharmacy. If you would like more information on anything I’ve discussed here, please feel free to contact me.

JENNA CORDERY

Responsible Person –WDA(H) 43825

Regional GDP Manager –Europe

Jenna.Cordery@Geodis.com

GEODIS Freight Forwarding Geodis.com

ADVERTISEMENT FEATURE

IS COATING AS EFFICIENT AND ECONOMICAL AS IT COULD BE?

Author: Oscar Benedi, Laboratory Manager, Romaco Tecpharm.

Coating is an integral part of pharmaceutical tablet and pellet production. Nevertheless, some problem areas have not been adequately solved so far, although they entail economic losses. To a certain extent, this is due to a presumed lack of viable solutions – but they do exist. A new generation of tablet coaters is addressing these challenges in an innovative way. When talking about challenges in coating, there are three areas involved: the quality of the coating result, the productivity of the coating process, and the flexibility of the tablet coater.

QUALITY

Among the first things that come to mind when thinking about product quality is the prevention of defects. Preventing such defects is always a matter of stabilising the coating process by regularly checking parameters and adjusting them if necessary. The common method for increasing this process control is currently to improve the technical feedback and leave the interpretation and reaction to the operator.

This approach leaves a greater risk for errors and inaccuracies because the regulation and control of the coating process is dependent on the operator. What if there is no suitably trained operator available? And even if a fitting operator is available, it is not always easy for them either to get the ideal

coating settings and keep track of all the parameters, especially with batch size changes, complex coating processes or demanding products that are, for example, sensitive to humidity or temperature.

The solution to this systemic uncertainty is to automate the coating process to a larger

extent, including the fully automatic adjustment of the relevant parameters where required. The TPR Optima perforated coating pan from Romaco Tecpharm can do so. It monitors parameters such as temperature, humidity, flow rate and tablet bed level, set up the predefined optimal coating conditions for the

specific product and thus minimises the risk of losing parts of or entire batches. One could say the TPR Optima tablet coater creates the reproducible coating process –irrespective of the complexity. This automatic self-regulation can be exemplified very well in the context of the second main problem area, where

26 COATINGS

automation is also the means of choice for optimisation.

PRODUCTIVITY

The deficiencies in the productivity of the coating process are partly accepted as a given. As an example, it is currently common to plan for 50 per cent more suspension than is theoretically needed to coat a product, because a loss of up to 40 per cent is considered normal. With functional coatings this can result in major financial losses. But even with standard coatings there are hidden costs in the form of cleaning, disposal and logistical expenses.

Here, especially the automatic adjustment of the suspension application and drying is the answer. This is implemented in the TPR Optima as follows: Using sonar technology, acoustic wave sensors continuously measure the distance between the spray nozzles and the tablet bed, which may vary depending on the process that is conducted. If modifications are required regarding the ideal spray distance or the set spray angle, the intelligent system carries them out by means of a nozzle arm with a three-point extension mechanism during the ongoing process – the machine does not have to be paused for this purpose.

An automatic set of air exhaust flaps, which can be opened individually and continuously allows precise regulation of the path taken by the air flow through the tablet bed, ensuring maximum drying effi ciency. With these new possibilities of the coating technology from Romaco Tecpharm only 10 to 15 per cent more coating medium is needed instead of 40 per cent. The associated more efficient drying and the possibility to adjust without interrupting the coating process also reduce process times by hours.

FLEXIBILITY

Coatings must deal with scale-up and scale-down procedures. For example: - when producing for different market requirements - when validations have to be carried out - when producing under contract, where a wide range of batch sizes must be processedor when the switch from laboratory to production scale is pending.

But why is this a challenge? Firstly, it means that companies currently need at least two machines, one for producing smaller batch sizes and one for larger batch sizes, as most coaters do not have a large enough batch size variability. Usually, they can only go down to 40 per cent of the maximum batch size at the most. This need for several machines is associated with high investment costs, energy expenditure and, space requirements. In addition, the parameters cannot simply be transferred from one machine to another – not even if they are the same type and brand. Consequently, a relatively large number of manual adjustments must be made, and here again the problem of ensuring high quality and uniformity across all products arises. Not to forget, of course, the time and work that goes hand in hand with manual adjustments.

With the ability to monitor and adjust to batch sizes, the TPR Optima achieves a batch size range from true 10 to 100 per cent filling volume with the same drum. This eliminates the need for multiple machines just because of different volume requirements, the time and workforce it takes to set up the right parameters for different systems, and the risk of errors and imprecisions. What is more, this also applies to volume changes within a single coating process, such as coatings with multiple layers.

CONCLUSION

There is significant optimisation potential in coating that can be exploited through a higher degree of automation. Shorter process times, continuously high product quality, time and cost savings and resource conservation are just some of the gains. Tablet coaters like the TPR Optima with these technological capabilities will certainly represent the future of coating and are already supporting innovation.

www.pharmaceuticalmanufacturer.media 27

One could say the TPR Optima tablet coater creates the reproducible coating process –irrespective of the complexity.

Tim Lin, Director of the Technical Services Department at Bora, discusses the benefits of utilising Wurster coating technology, laying out steps to help overcome challenges and optimise controlled-release profiles for e cient and e ective drug delivery.

LEVERAGING WURSTER COATINGS FOR CONTR LLED RELEASE

Afinal drug formulation influences the therapeutic activity of an active pharmaceutical ingredient (API) in the body. Each excipient has a purpose — from increasing solubility to improving taste — and the coating or capsule of a solid dose formulation is key. When exposed to the harsh conditions of the gastrointestinal tract, the coating or capsule will break down to release the drug substance over time. These systems remain a favoured option as the drug is slowly released over time, these controlled-release products can also reduce off-target toxicity.

Encapsulation of a drug protects the API from environmental factors such as moisture and oxidisation, extending product shelf life. With a range of options, choosing the right coating or capsule for a drug product is crucial to ensure a high-quality product. The prevalent choice within the pharmaceutical industry is Wurster coatings.

HARNESSING COATING TECHNOLOGY AND OVERCOMING CHALLENGES

Wurster technology is a frequently used particle coating method that produces uniformly coated particles for controlled product release. The coating process involves loading the substrate into a fluidised bed chamber, spraying with the coating substrate suspended in a solvent and drying.

Compatible with a wide range of particle shapes and sizes, this method can be used for a variety of drug compositions. This process is suitable for automation, leading to a cost-effective method that can be easily scaled.

Even though it is used as a tool to produce high-quality, stable and effective controlled-release profiles, the Wurster coating method is subject to limitations, including:

• Incomplete coating: This can lead to an uneven final coating, resulting in inconsistent drug release profiles and unpredictable therapeutic outcomes.

• Agglomeration: The particles may stick together during the coating process, which reduces the surface area, leading to incomplete drug release and reduced bioavailability.

• Material loss: A coating that is too thin can lead to substrate loss, lowering the final product yield and increasing production costs.

FOUR STEPS TO A TAILORED WURSTER COATING SOLUTION

To minimise the impact of product characteristics on the coating process, the Wurster coating method can be tailored to the desired product by following four key steps:

1. Complete preformulation studies: Confirm understanding of the physicochemical properties of the product.

2. Adapt coating composition: The coating solution can be

optimised to ensure compatibility with the drug product.

3. Optimise the coating process: The process parameters for applying the Wurster coating can be redesigned to suit the new coating composition and the drug product.

4. Build in quality control testing: Incorporate quality control testing measures to ensure the final formulation meets the desired specifications.

By implementing these steps into practice, a highly effective controlled-release formulation can be developed using Wurster coating methods. As this process requires specialised technology, partnering with an expert can provide insight into this process, helping to tailor this flexible method to the product for the optimum therapeutic effect.

MEETING CONTROLLEDRELEASE STANDARDS