For the first time, industrial ethernet enters ABB instrumentation with the ProcessMaster and CoriolisMaster.

ABB flow measurement is connection made easy! Gain quick access to meters with a standard browser on a laptop, tablet or mobile device in parallel to PLC – secure and via the same cable. abb.com/measurement or contact us at instrumentation@ca.abb.com

Let’s

AGAWIN

GILLETT

Archis Ambulkar OCT Water Quality Academy

Gary Burrows City of London

Patrick Coleman Stantec

Bill De Angelis Metrolinx

Mohammed Elenany Urban Systems

William Fernandes City of Toronto

Marie Meunier John Meunier Inc., Québec

Tony Petrucci Black & Veatch

Science & Engineering

a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales Second Class Mail Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Environmental Science & Engineering 220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727-4666

www.esemag.com

Mommas, don’t let your babies grow up to be meteorologists

Report applauds COVID-19 wastewater surveillance

Editorial Comment

CSA Group develops how-to guide for municipalities to integrate water standards

Decanters provide smooth operation for military base’s WWTP

Using cartridge filtration systems to remove PFAS contaminants from drinking water

Quebec mining firm fined $15M for Fisheries Act violations

Investigating the source and age of nitrate in drinking water wells

What is the real mixing limit for mixed liquor?

Hamilton tackles major problem caused by residential wastewater pipes mistakenly connected to storm sewers

Collingwood, New Tecumseth to update costs of pipeline drinking water agreement

Using Python can help Canadian water utilities cope with vast amounts of data

UWaterloo leads new PFAS investigation into seven Ontario water systems

Ensuring peace of mind against leaks when lining above ground storage tanks

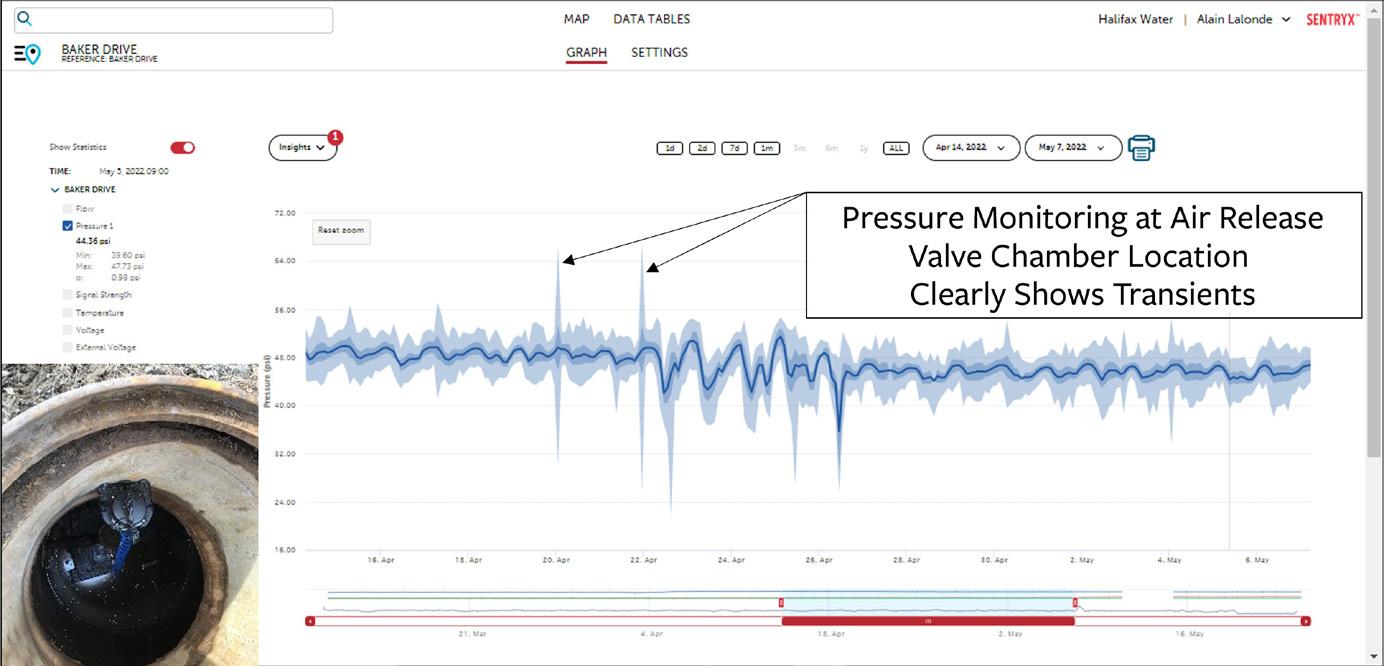

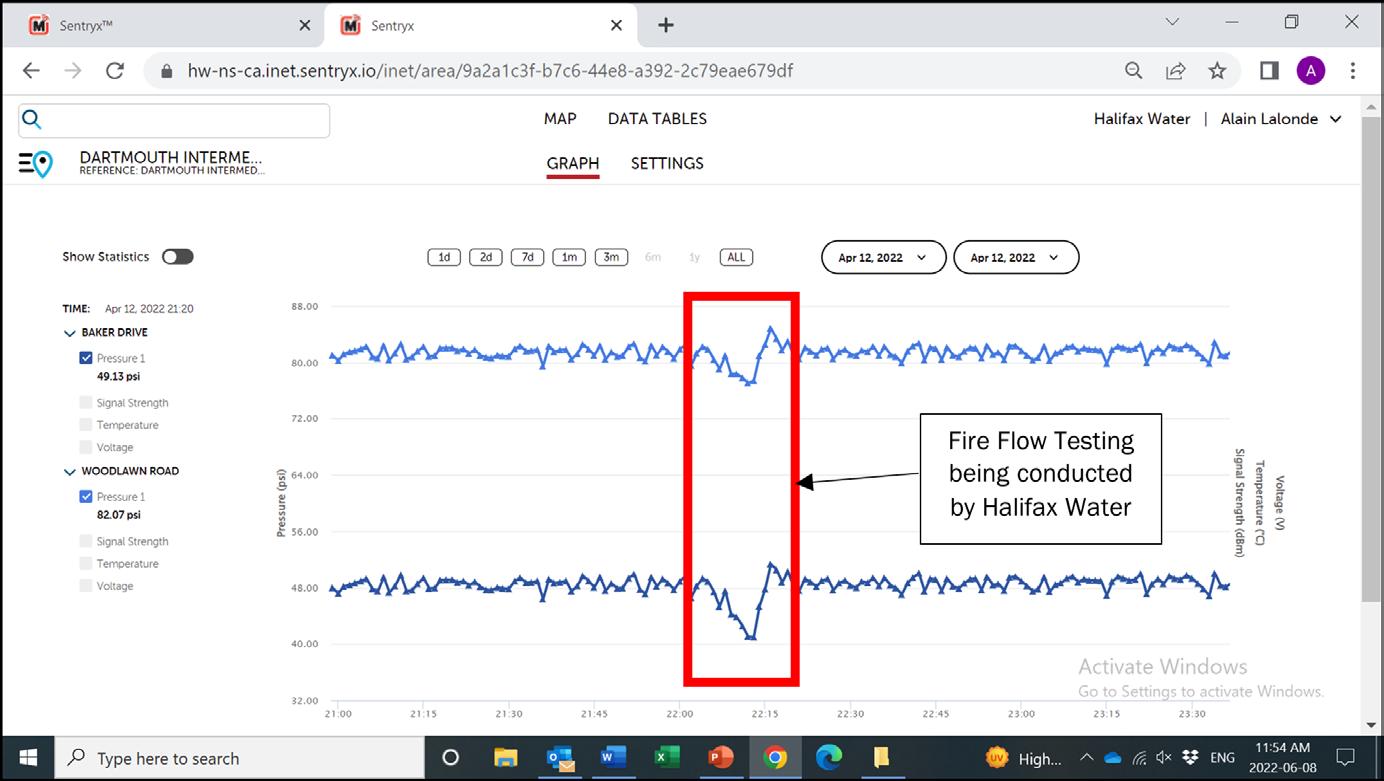

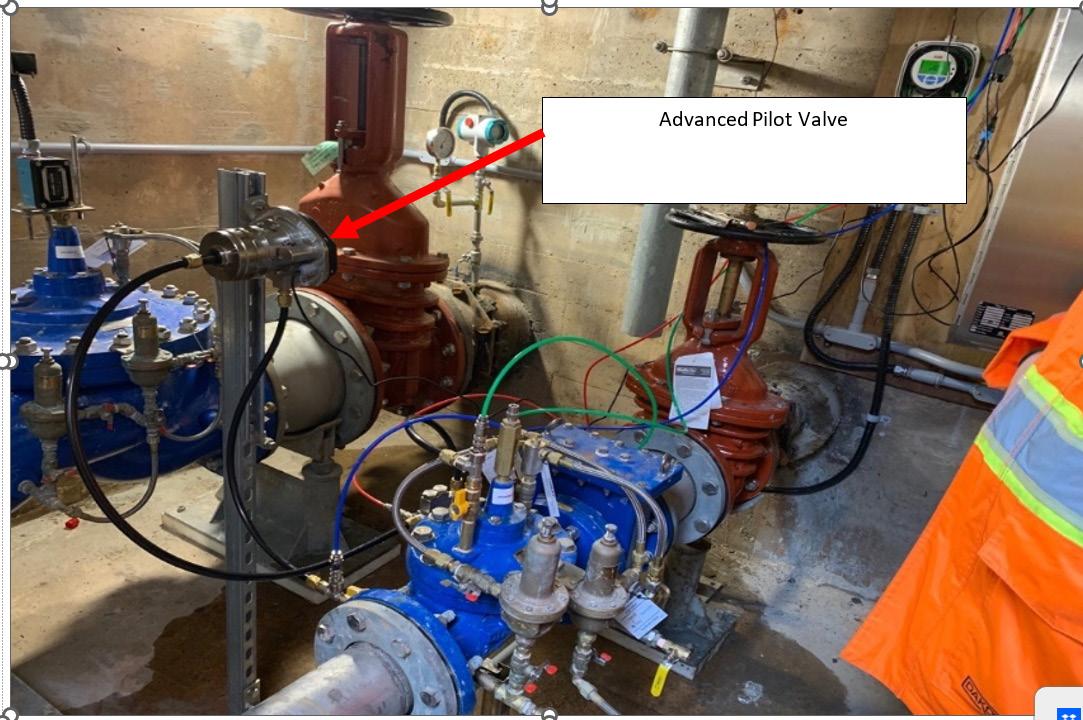

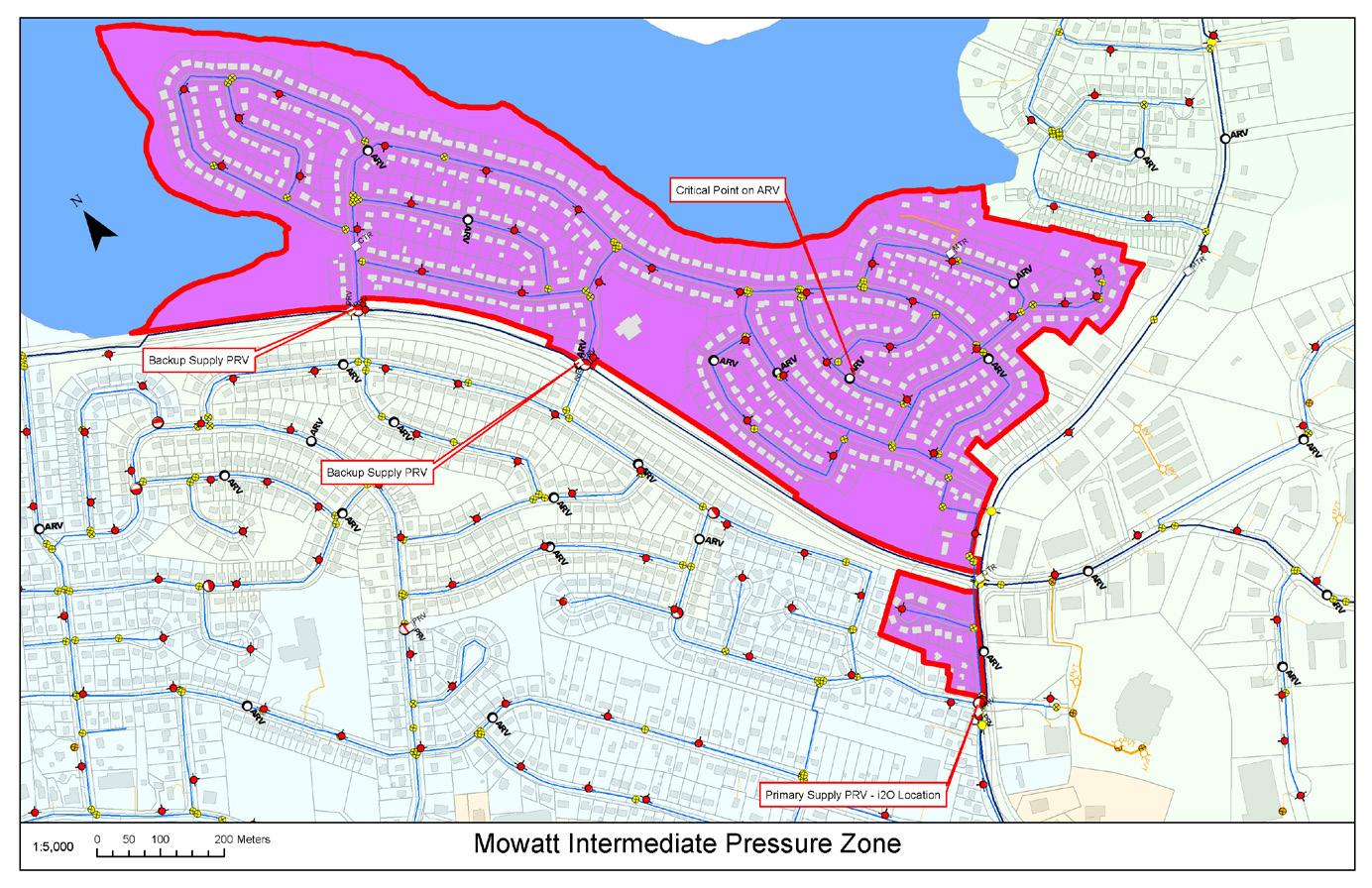

Halifax Water uses advanced pressure management pilot to reduce leakages

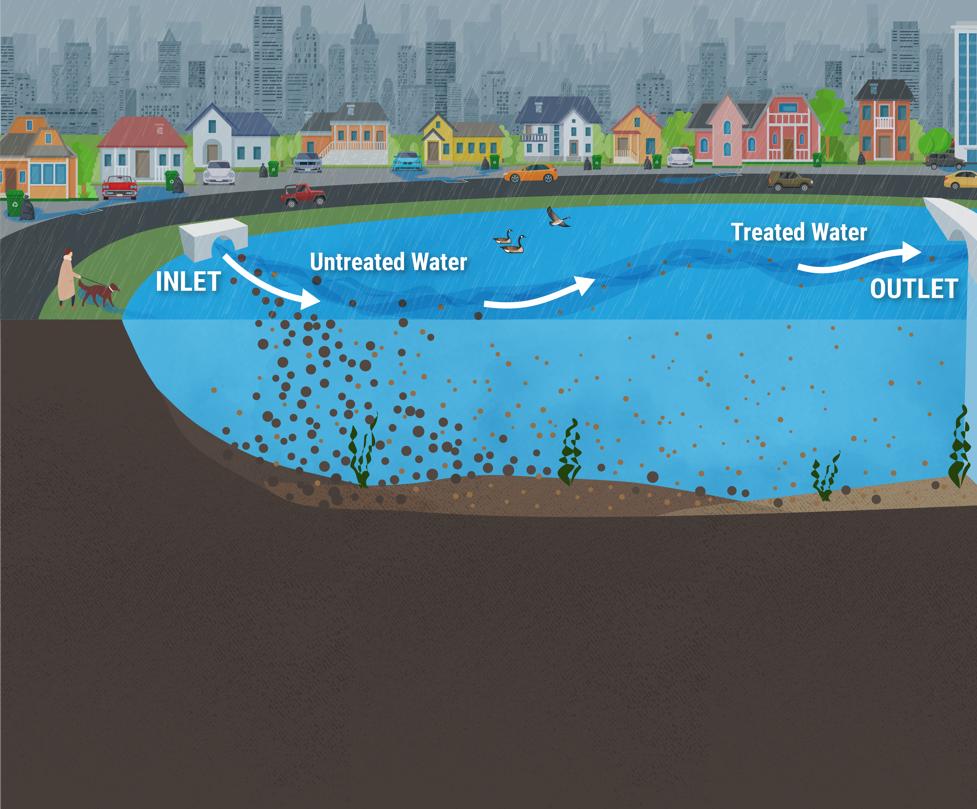

Challenges, opportunities for reuse of stormwater management pond sediment

Maximizing process, energy efficiency of heat exchangers for wastewater applications

problem with PFAS waste incineration

monitoring as a community health indicator

York Region wins award for sewage forcemain upgrades using microtunnelling

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circu r, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

•

Rotary Lobe Pumps & Grinders

• Disinfection UV, Ozone

• Tertiary Filters Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Condi tioning, In line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gather ing & equipment control

Sludge Treatment, Transport & Stor age

Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

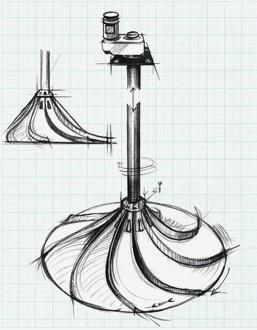

StationsPump&StormwaterCSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

Digester Gas Gas Holders, Gas Condi tioning: chilling; compressing; and remov al of moisture, sulphur, carbon dioxide and siloxane, complete Co Generation facilities

Despite the title of this piece, let me set the record straight; I have noth ing against meteorologists. I know some, they’re nice people, about 60% of the time.

I mean, where else can you work and be correct 60% of the time and still have a job?

But I do feel badly for people in that profession because, after government workers and politicians, they get blamed for all the horrible weather evils that come our way.

Weather records throughout the world that have been around for a long, long time, are being smashed on a reg ular basis and the pace doesn’t appear to be slowing down. Many countries around the world, including Canada, Australia, the U.S. and Europe have all experienced extreme weather events that are pushing boundaries and resources to the brink.

There is no country on Earth that has not felt the effects of climate change to some degree. The worldwide climate-re lated mortality rate is increasing, pri marily in areas where the most vul nerable live. Each passing summer day brings more extreme thunderstorm and heat warnings.

In the meantime, climate modelling predictions from numerous high-level institutions disagree with each other on what’s happening, or what’s in store for us in the future. The next 20 or so years will prove whose model was right. For now, much of humanity must find ways to adapt to the ever changing and ever unpredictable weather extremes that are being seen around the globe.

For decades, the “hundred-year-storm” has been used as the benchmark for weather events. What it means, in effect, is that you should expect a storm of a particular intensity every 100 years or so.

However, just in Southern Ontario, over the last 20 years, there have been

It’s always been tough to be a farmer; climate change is just making it all the tougher.

five or more breaches of the hun dred-year benchmark for rainfall alone. That, too, tells us that the weather par adigm has shifted dramatically, and in less than 100 years. When it comes to weather today, we often find ourselves in uncharted territory, and things are very uncertain.

The new “tornado alley” in Canada is now the Barrie/Ottawa/Gatineau area.

During the last 50 years, tornadoes in this area have resulted in widespread property damage and many fatalities. In general, storms everywhere are becom ing more intense due to the excessive amount of energy released from over heated, moist air as it is cooled, even slightly.

During all stages of history, the collection of weather data has been extremely important. The collection of weather observations is critical in that it helps us identify changes and through those changes, hopefully patterns will emerge. It takes years to establish reli

able patterns, but the last 50 years’ worth of data has revealed distinct increases in air, land and sea temperatures around the world. The scientific world has embraced this reality and is trying its best to understand where it is taking us. Climate change deniers now exist pri marily in the conspiracy theory camps.

One of the most concerning changes that has been observed with increased global temperatures is increased drought. This not only affects food and livestock crops, but also causes extremely dry conditions in our forested areas. Dry forests are easily ignited by lightning strikes, which are also increasing glob ally due to more intense thunderstorms created by excessive heat. Hot air con tains immense amounts of energy and when that energy is released it can be catastrophic at times.

The main debate now is whether or not humanity can halt or even roll back the damage caused by CO2 emit continued overleaf…

Credit: Budimir Jevtic, stock.adobe.com

ted through the burning of fossil fuels. Nobody knows for sure if we are reach ing the “point-of-no-return”, or whether we’ve already passed it.

As we learn through our experiences, it turns out that carbon dioxide may not be our biggest concern, but it certainly plays a major role it what is happen ing. Science has been telling us (for a long time) that carbon dioxide is what is causing the “greenhouse effect”. Car bon dioxide is causing the atmosphere to heat up beyond what it would if levels were lower.

The trapped heat is having profound effects on global water resources, due to elevated evaporation rates from the surface of the Earth and bodies of water. Hotter air is able to hold more moisture and when it is released it is often in a violent form.

Hurricanes are getting more frequent and more intense, likewise for torna does. Droughts are lasting longer, lakes are drying up, the Arctic and Antarc tic poles are melting at an alarming rate. Yet, only a small percentage of the global population are committed to greening their lifestyles. The rest are clinging to the fossil fuel economy, which many people feel has been the root cause of the current climate problem.

Often forgotten is the fact that, throughout the Earth’s 4.5-billion-year history, the climate has always been changing. Five planetary ice ages tell us that. The last ice age lasted two and a half million years and only left us 12,000 years ago.

Ice core samples also tell us that car bon dioxide levels on the planet have been as high as 4,000 ppm (parts per million) during the Cambrian period, 500 million years ago. During the Qua ternary glaciation period, two million years ago, levels were as low as 180 ppm, which coincides with the lower plane tary vegetation level due to the ice age.

Global CO2 levels in 2022 are in the range of 415 ppm.

Much speculation is put into trying to understand how organic life adapted during those prehistoric conditions. The clues are few, and tough to find.

When it comes to forest fires, we are seeing fires like we have never seen before. The epic Australian fires recently

burned over 12 million acres of land and killed over a billion animals. Many of the animals that perished were domes tic animals and more than 2,000 homes were destroyed. Thirty people died, some of whom were firefighters.

The summer of 2022 saw the Yukon and Northwest Territories fighting mega fires that resulted in many evacuation orders and relocations, largely affect ing First Nations people. This came on the heels of two consecutive winters of near record snowfalls, followed by two consecutive springs of record flood ing, especially in the lower-lakes region south of Whitehorse.

The Arctic and sub-Arctic areas are warming at more than twice the rate in the south. This warming is causing per

derstorm warning where some areas received up to 100 mm of rain within a matter of a few hours.

This type of precipitation benefits farmers very little as it tends to run off to the nearest river or lake without hav ing the chance to soak into the ground properly. Torrential rainfalls can also cause fields to be torn up by water as it rushes toward ditches, resulting in fur ther crop loss. It’s always been tough to be a farmer; climate change is just mak ing it all the tougher.

Right now, there are more questions than answers. Are we moving toward greening our energy supply quickly enough? Are we moving too slowly to rid ourselves of our dependency on fossil fuels? Is nuclear energy going to

Often forgotten is the fact that, throughout the Earth’s 4.5-billion-year history, the climate has always been changing. Five planetary ice ages tell us that. The last ice age lasted two and a half million years and only left us 12,000 years ago.

mafrost to melt, which in turn is releas ing methane gas that has been trapped in the frozen ground for millennia. When it comes to greenhouse gasses, methane is 84 times more damaging than carbon dioxide. Increased methane in the atmo sphere is dramatically enhancing the greenhouse effect, and more permafrost is melting all the time.

The summer of 2022 in southern Ontario also saw extremely low precip itation rates in most areas. Coupled with several days well in to the mid 30s, some farmers saw an 80% decrease in yield for many of their crops. Earle and Sha ron Clugston, who have owned Shearlea Acres in Lynden, Ontario, since the early 1970s, advised me that lettuce and cucumbers were particularly hard hit along with sweet corn and other waterthirsty vegetables.

When it did rain, which was seldom, it was generally under a severe thun

make a big comeback? Is there going to be a solid path forward or will changes in world governments constantly plague progress?

But the biggest question of all is: Are we making the right choices and are we making them in time?

We have a lot of great minds work ing on solutions and I think they need to hear our cries of support and not our cries of indignation. Their job is not an easy one.

So, mommas, don’t let your babies grow up to be meteorologists. Let them grow up to be scientists, so we can all work toward a permanent climate change solution that will benefit man kind into the future and beyond.

John Smythe is with NOVA Training and Development Inc. Email: contact@nova-td.net

By ES&E Staff

By ES&E Staff

Anew report from the Royal Soci ety of Canada (RSC) makes a series of recommendations based on expert analysis and lessons learned from wastewater surveillance during the COVID-19 pandemic, which had caused some 6.4 million deaths worldwide, as of the end of July 2022.

The report views wastewater surveil lance as an objective and independent window that provided a valuable dataset on the persistence of COVID-19 infec tion as indicated by virus-shedding in the population through faeces.

One of the keys that made wastewater surveillance of SARS-CoV-2 RNA effec tive, the RSC found, was the level of col laboration among public health agencies, local wastewater treatment plant opera tors, and academic research laboratories.

“Many public health officials were initially skeptical about whether or not actionable information could be pro vided by wastewater surveillance for SARS-CoV-2,” states the RSC report. “However, previous experience has shown that public health surveillance for a pandemic has no single, perfect, all-purpose tool to characterize all the important features of what is happening in a timely manner,” the report adds.

The report views wastewater surveillance as an objective and independent window that provided a valuable dataset on the persistence of COVID-19 infection. Credit: Felipe Caparrós, stock.adobe.com

Ultimately, organizations such as the Public Health Agency of Canada, the World Health Organization, as well as the European Commission and the U.S. Centers for Disease Control and Preven tion, recognized wastewater surveillance as an important tool in the pandemic.

The wastewater surveillance option also provided a much less expensive option on a per capita basis than other testing methods, the report states, par ticularly as clinical testing was over whelmed in the face of variants, such as Omicron.

Although initial emphasis was on mon

itoring at WWTPs serving large commu nities, researchers successfully monitored sewers directly serving priority locations such as long-term care facilities, hospitals, university residences, as well as industrial and correctional facilities.

Wastewater surveillance was also use ful in capturing signals from asymptom atic individuals, the report states.

In April 2020, RSC established a task force to equip Canadians with accurate information about the country’s response and recovery to COVID-19.

Some of the key recommendations made in the report include the need to create structures and capacity to sustain capability and develop rapid response to future public health threats, as well as to build upon existing infrastructure and programs.

In addition to designing frameworks for surveillance programs, the report also recommends new frameworks for interpretation of the data. Maintaining and promoting academic partnerships and communication networks that will help identify new opportunities and threats is also considered a priority.

For more information, email: editor@esemag.com

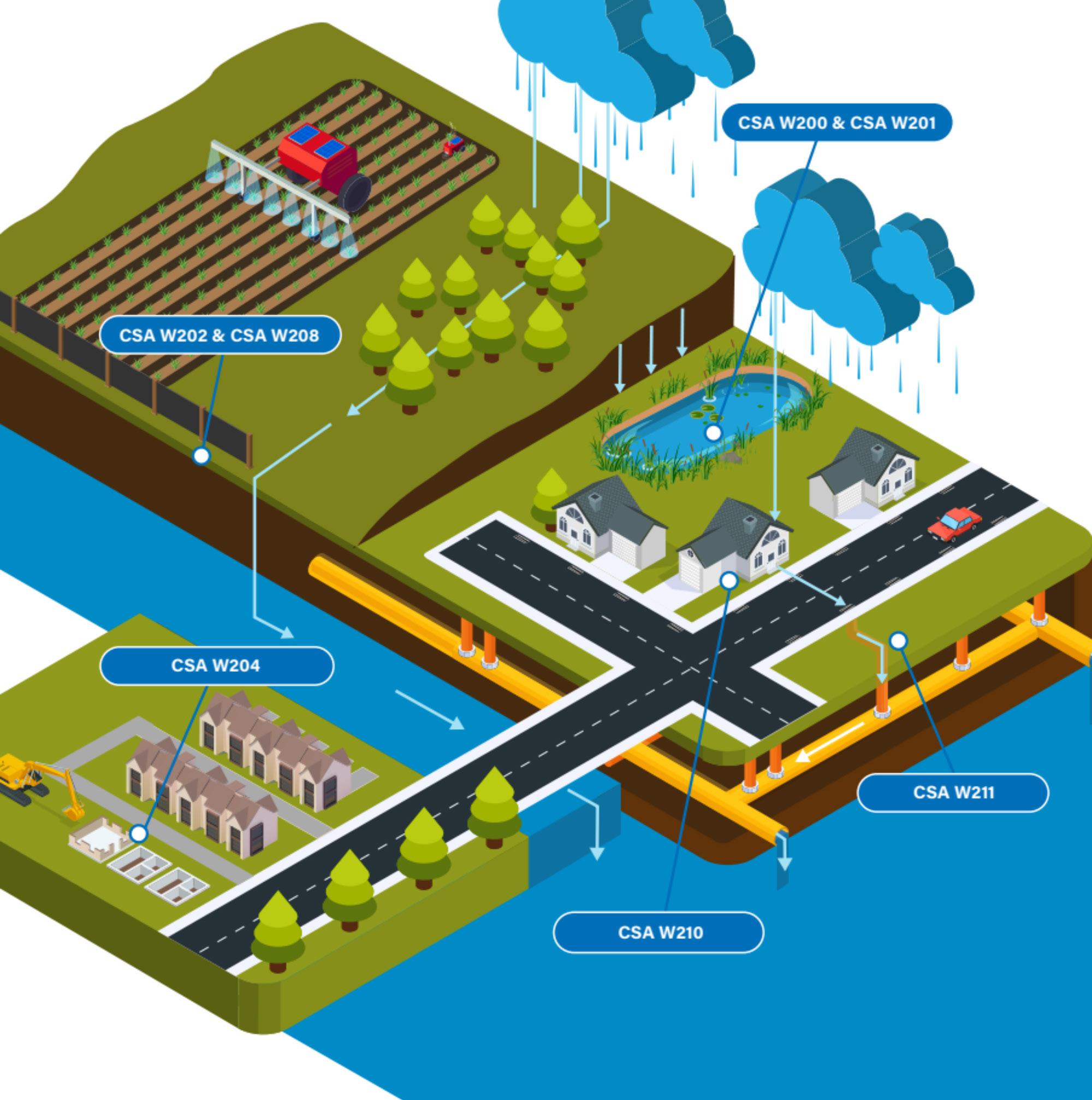

Standards development organiza tion CSA Group has published a municipal how-to guide for local officials to maintain high commu nity water standards in the face of grow ing threats from climate change.

CSA says that municipalities “shoul der the burden of responding to these events and their aftermath,” and need help. Focusing on flood resiliency, storm water, bioretention systems, as well as erosion and sediment control, the new guide highlights a three-step process to integrate CSA standards into municipal planning.

“Our ultimate goal is to have networks of resilient communities supporting each other,” announced Michael Leering, director of environment and business excellence at CSA Group, in a statement. “For a municipality to truly be resilient, their neighbouring municipalities must also be working towards the same goals and implementing the same standards,” he added.

In step one, the CSA guide recom mends that municipalities assemble a “toolbox” that takes stock of elements already in place, such as existing munic ipal bylaws and other strategic docu ments. The guide suggests taking advan tage of established CSA standards for stormwater management), bioreten tion system design, and flood resilience design, to name just a few.

CSA views step two as finding gaps where new tools in the toolbox, or stan dards, can be implemented. This can come through the municipality’s leaders answering a series of questions. Exam ples of these could be: Does your munic ipal zoning bylaw or land use bylaw limit development in areas subject to flood ing? Does your municipality’s storm water management plan encourage low-impact development and/or green infrastructure for stormwater manage ment? Or, does your municipality (or conservation authority) require devel

opers to prepare and submit an erosion and sediment control plan? The guide then links local officials to the relevant CSA standard when answering these types of questions.

The third and final step recommended by the new guide is for municipalities to integrate these standards by reference into existing policies and guidelines or develop new ones. For instance, the CSA Community Water standards can be implemented under community plans, zoning bylaws, subdivision agreements, and many more.

The guide also suggests ways to imple ment certain requirements, such as bio retention standards, directly into new contracts and requests for proposals.

To develop the guide as a resource for

urban planners, managers, and elected municipal officials, CSA collaborated with four Canadian municipalities impacted by flooding in recent years: Colwood, Brit ish Columbia; High River, Alberta; Lake shore, Ontario; and Cambridge, Ontario.

“The launch of a guide to support municipal uptake of CSA Group stan dards provides an important tool for interpretation and decision making,” announced Lisa Prime, chief planner for the City of Cambridge, in a statement. “Municipalities can benefit from further opportunities to meet technical perfor mance requirements for development through standards,” she added.

For more information, email: editor@esemag.com

A graphic from the new how-to guide for local officials illustrates how CSA Group Community Water Standards can be integrated into the municipal planning process. Illustration: CSA Group

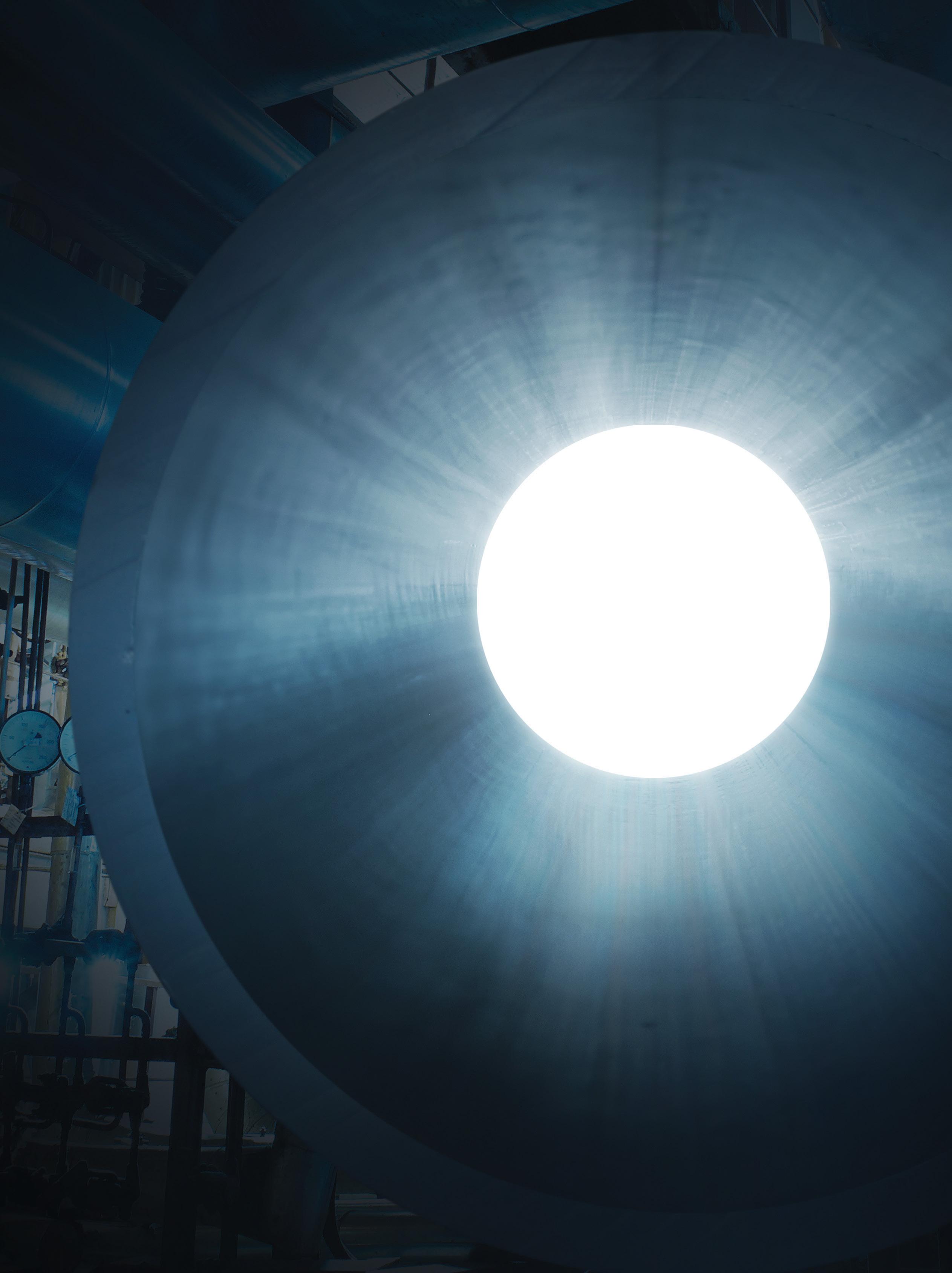

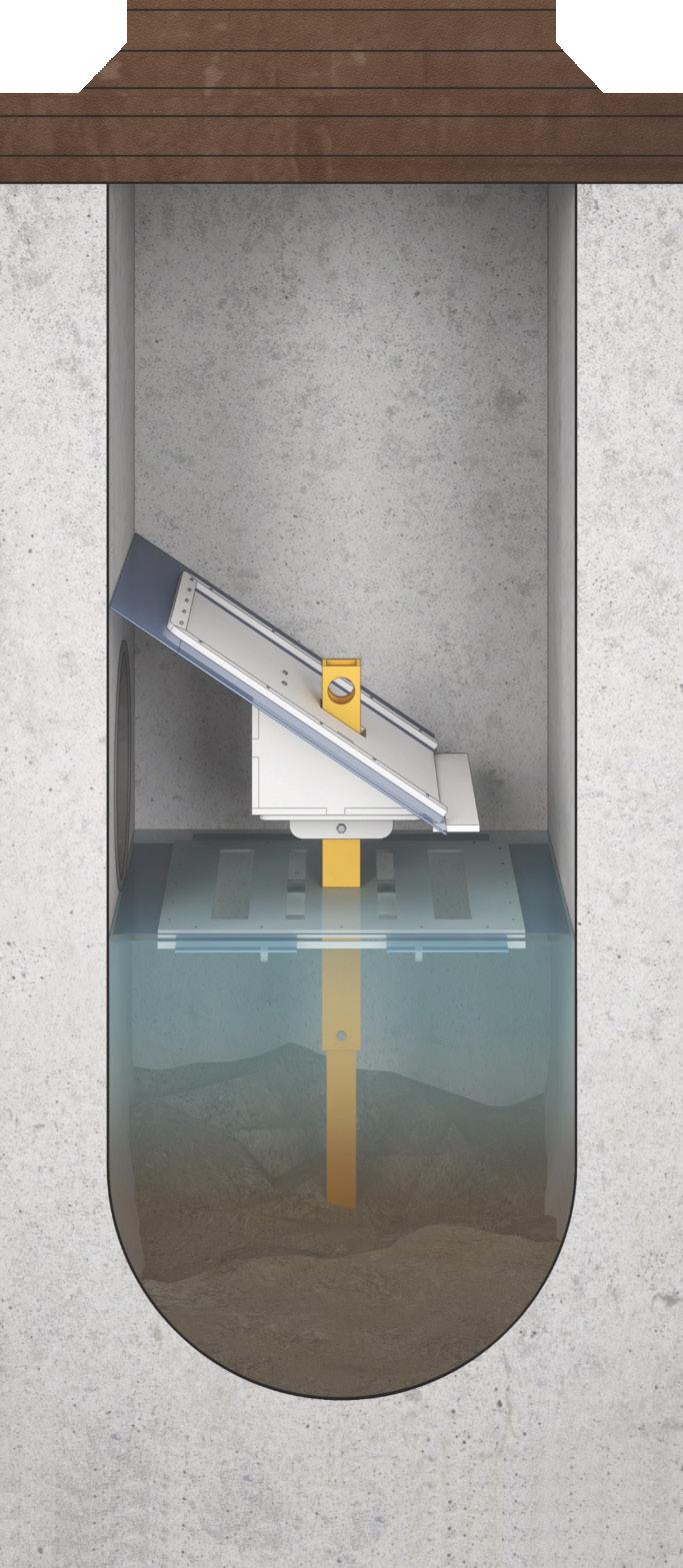

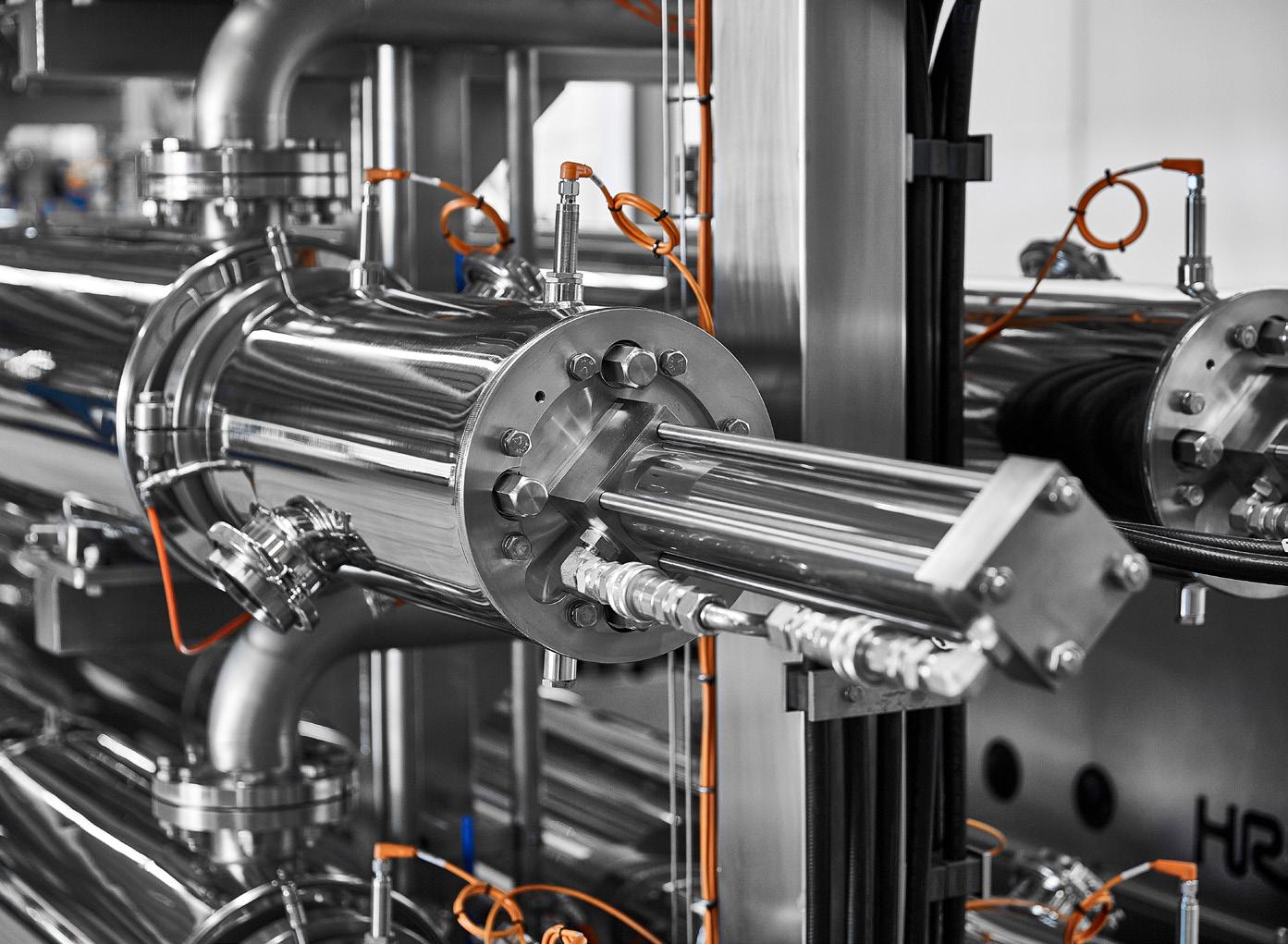

In 2014, the Northern Wastewater Treat ment Plant of Marine Corps Training Base Camp Pendleton in Southern California, was designed with purpose and efficiency in mind for its migra tory population of around 200,000 peo ple, which includes 18,000 troops, plus employees and their families. The $66 million plant was built to consolidate all the pump stations and lift stations of 12 treatment plants down to just the North ern and Southern Treatment Plants, cov ering some 85,000 hectares.

While the Southern plant kept its older equipment, the Northern plant was outfitted with new Flottweg centri fuge decanters and 3.2 megawatts of solar power. The base supplies the power, but the solar power feeds the facility. Excess power returns to the base’s grid. There is a 2,000 kW generator for backup. The plant produces a megawatt of produced power every two to three days that returns to the main grid at the base.

The centrifuge runs once or twice a month on average, according to Chief Plant Operator Phil Starks. “At times the centrifuge must be used multiple times a week,” he said. “Digestion is over 200 days sludge retention time (SRT) with good sludge concentrations. We have excellent aerobic sludge digestion avail able with a lot of volume reduction and two extremely large digesters. One is kept about half full at all times. When the level gets high, the decanters are run to bring the level back down.”

With constant sunshine, the plant is able to spread out the solids to naturally dry them. The primary goal for the oper ation of the centrifuges is not for the percentage of solids produced. Instead, the focus is on the centrate going back to the plant. “I want the cleanest centrate possible because neither drying nor vol ume is an issue,” Starks explained.

“We have absolutely no problems with the centrifuges. The only issue has been

an experiment to see how the centrifuge would react to a thicker solid coming in from the digester. It operated great, but we didn’t flush the unit appropriately with the thicker solids, causing just a few minor adjustments.”

Clean water is becoming an increas ingly valuable raw material, which is why the importance of municipal waste water treatment continues to grow. Slud ges resulting from drinking water and wastewater treatment must be separated as efficiently as possible. For the dewa tering and thickening of sewage sludge, industrial centrifuges are now consid ered the state of the art. They are cost-ef fective, energy-saving, and efficient.

The most important goal in dewa tering is to maximize the reduction of the volume of sewage sludge. The rea son for this is that every tenth of a per cent increase in dry solids in the sludge reduces the costs of sludge disposal. The dewatering decanters of the Flottweg

C-series and X-series reduce operat ing costs and energy consumption and achieve a higher dry solids content.

During thickening, a high degree of separation and a low polymer con sumption are extremely important. Both relieve the burden on subsequent pro cesses and improve the overall perfor mance of the wastewater treatment plant.

A decanter can be regarded as a sed imentation tank that is wound around an axis. In the sedimentation tank, the solid particles, which are heavier than the liquid, move to the bottom by grav ity and form a sediment (solid phase) at the bottom of the tank. For example, a wine decanter can be understood as a kind of sediment vessel. In a centrifuge, the solid and liquid phases are separated by means of centrifugal acceleration.

In the rotating bowl of the centrifuge, the solid particles, which have a higher density and are therefore heavier than continued overleaf…

The Northern plant was outfitted with new Flottweg centrifuge decanters.

the liquid, move outward because of cen trifugal force. Sediment is formed on the inner wall of the centrifuge bowl. Since centrifugal forces of approximately 3000 g are exerted in a centrifuge as opposed to 1 g in a gravitational field, the separa tion of the solid particles from the liquid is much faster and more efficient.

Product is fed into the inlet chamber of the decanter scroll through the cen trally arranged feed pipe. From there, after gentle pre-acceleration, it passes through the distributor openings into the decanter bowl.

The decanter bowl has a cylindrical/ conical shape and rotates at a pre-set speed optimally adjusted to the appli cation. The slurry rotates within the bowl at the operating speed and forms a cylindrical layer at the bowl wall. Due to the higher density, the solids contained in the product settle on the inner wall of the bowl under the action of centrifugal force. The length of the cylindrical bowl section and the cone angle are selected to meet the specific requirements of an application.

The decanter scroll rotates at a slightly different speed than the bowl and con veys the separated solids toward the conical end of the bowl. This differen tial speed determines the residence time of the solids in the decanter bowl. Res idence time is a critical factor for cake dryness. It can be adjusted by changing the differential speed of the scroll, and therefore providing optimal separation. Depending on the application and task, the scrolls are designed differently.

Settled solids are ejected through ports at the conical end of the bowl into the solids housing and fall through the discharge chute.

The clarified liquids (fluid phase) flow to the cylindrical end of the bowl where they exit over weir plates. In these open ings there are very precisely adjustable weir plates (overflow weirs) with which the pond depth (liquid layer) in the bowl is adjusted. The liquid is collected in the drain housing and discharged without pressure.

As an alternative to the overflow weir, the clarified liquid can also be dis charged via an impeller and discharged from the bowl under pressure in a closed system. This eliminates the need

The decanter scroll rotates at a slightly different speed than the bowl and conveys the separated solids toward the conical end of the bowl.

for a separate chamber pump. A further developed variant, the adjustable impel ler, allows infinitely variable adjustment of the pond depth during the run. This allows a fast and fine adjustment to changed conditions without having to take the centrifuge out of operation.

At the Northern Camp Pendleton Plant, Starks said the centrifuge works smoothly and requires little maintenance. “It’s doing exactly what it’s intended to do,” he said. “The equipment operates with little to no issues. It takes about 30 min utes to an hour for the unit to settle into a nice rhythm after a few adjustments are made with the variables like tem perature and solids concentration.

“A centrifuge is like a moving dart board. It is three dimensional, and you’re always trying to hit that exact right spot. It takes experience, combined with high quality equipment. As long as every thing is set with the variables, these units just have to start up, and then we really don’t have to do much.”

According to Starks the sophisticated decanters have many features that make finding that sweet spot easier. “Instru mentation is key and getting the feed back on the screens is essential,” he explained. “I control the unit by scroll torque. It also has differential controls, but I don’t need to use them as much. The scroll torque is much more respon sive. I can also make adjustments with the feed rate of the polymer. There are so many adjustable parameters, you could

over adjust if you’re not patient. It’s important to make one adjustment and then give it 15 or 20 minutes and then check on it. Then you can make another adjustment from that point.”

With a small staff, Starks said another advantage is that one person can eas ily operate the equipment and little to no maintenance is required. “Having maintenance free separation is just the best thing for a plant like this,” Starks explained. “You don’t want to contin uously have to take things apart and fix them. The Southern Plant is con stantly having issues because it was not designed with purpose. This is actually a very boring plant. The plant just runs so well, we rarely ever have any issues. Sometimes we are running so smoothly, we can help out at the Southern half.”

The Northern Plant is designed to handle a much larger population and this could double or even triple easily in the future without breaking capacity.

Daniel Lakovic is with Flottweg Separation Technology. Email: dlakovic@flottweg.net

By Cyndi Benson and Alfredo Rizo-Patron

By Cyndi Benson and Alfredo Rizo-Patron

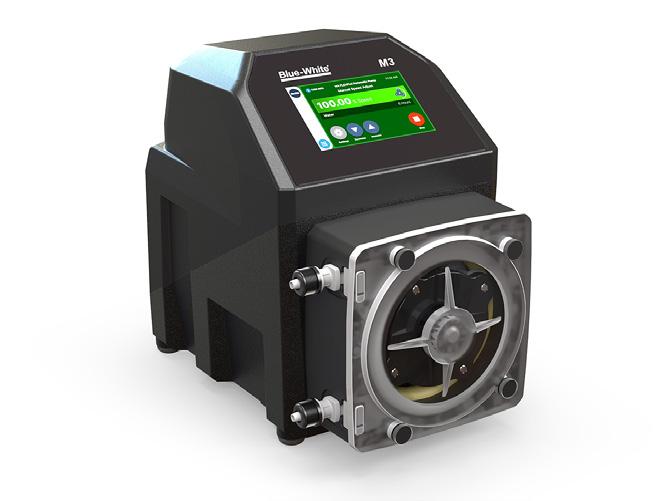

End user households and municipal water utilities are increasingly grappling with the need to address perand polyfluoroalkyl substances (PFAS) once they are detected in source water. Also known as forever chem icals, because they are among the most persistent toxic com pounds in existence, even low doses of PFAS have been linked to serious health problems.

Because drinking water standards are a moving target, while treatment options are limited and can represent a mas sive expense, addressing PFAS can be especially challenging for small water systems such as housing communities and single-family homes. The key to finding an optimal solution requires a thorough investigation of solutions.

High-pressure membranes, such as nanofiltration or reverse osmosis (RO), have been extremely effective at remov ing PFAS. Research shows that these types of membranes are typically more than 90% effective at removing a wide range of PFAS, including shorter chain PFAS.

While RO is highly effective, it comes with steep capital and operating costs, which include the handling of the contami nated waste stream.

Another treatment option is anion exchange treatment, or resins. Ion exchange resins are made up of highly porous, polymeric material that is acid, base, and water insoluble. One benefit of this treatment technology is that there is no need for resin regeneration, so there is no contaminant waste stream to handle, treat or dispose of. However, it is still not the most economical solution in many cases.

Granular activated carbon (GAC) can be the most economi cal solution for PFAS treatment in individual applications and smaller utilities. This includes the use of carbon-bedded sys tems and carbon cartridges, each of which fit inside a larger cell. GAC is a filtration media that is not selective for only PFAS, meaning that other organic contaminants in the water will also be removed.

Determining the most efficient and cost-effective GAC sys tem requires further investigation into specific applications. One example is the Harmsco WaterGuard Filtration System which combines activated carbon, cartridge filtration ultra violet neutralization, and patented “up-flow” technology in a compact filter housing design. Its large carbon block cartridge is significant because the larger surface area promotes longer contact times. The up-flow feature allows self-purging to elim inate entrapped air. Additionally, the WaterGuard offers quick filter changeout times and a self-purging design.

One small public water utility that currently follows a PFAS

Harmsco water filtration systems combine activated carbon, cartridge filtration ultraviolet neutralization, and patented “up-flow” technology in a compact filter housing design.

standard of 13 ng/L, detected elevated PFOA and PFAS con centrations in one of its wells (average combined PFOA and PFAS concentrations were approximately 37.5 ng/L).

Because the utility has had extensive experience with car tridge filtration for the removal of iron and manganese par ticulates, it began pilot testing the Harmsco activated carbon cartridge filter for PFOA and PFOS treatment. The goal was to determine its efficacy in applications throughout its ser vice area.

The pilot consisted of two parallel cartridge filters, with an average flow rate of 113.5 litres per minute total. Sampling included raw, entry point, and pre/post-filter changeouts. A removal rate of 65.3% was required to comply with internal proposed standards. Results of the pilot are expected soon.

Because of its effectiveness at a lower cost, private homes and other utilities may find cartridge filtration a viable option to address PFAS in similar circumstances.

Cyndi Benson and Alfredo Rizo-Patron are with Harmsco Inc. For more information, email: sales@harmsco.com, or visit: www.harmsco.com

Quebec-based iron ore mining com pany ArcelorMittal Canada Inc. has been fined nearly $15 million for 93 offences related to conceal ing the extent of toxic substances that entered waters near the Moisie River after a dike rupture.

The 2012 incident where the depos its took place involved lakes Saint-Ange and Webb and their tributaries which flow into the Moisie River, a proposed aquatic reserve and one of the biggest Atlantic salmon rivers in North America. Investigating the impact of the depos its from the dike breach, Environment and Climate Change Canada (ECCC) officials said that they were left with an “inaccurate and altered overview of the situation,” as the mining company made false and misleading statements to the environment officers, in violation of subsection 63(1) of the Fisheries Act.

ArcelorMittal Canada, the Canadian subsidiary of the Luxembourg-based steel giant, had been found guilty in late 2021, but appealed the decision. Ulti mately, the court upheld that Arcelor

A 2012 dike rupture led to deposits in the SaintAnge and Webb tributaries, which flow into Quebec’s Moisie River, pictured. Credit: Lkovac, Wikimedia Commons

Mittal Canada Inc. was found guilty of 93 charges and numbered company partner 7623704 Canada Inc. was found guilty of five charges for violating the Fisheries Act and Metal Mining Effluent Regulations (MMER).

According to ECCC, the inves tigation took place at the company’s Mont-Wright mining complex in Fer mont, Quebec, which opened in 1974. It

uncovered 33 unauthorized deposits out of the normal course of events of toxic substances made in water frequented by fish between May 25, 2011 and May 14, 2013, in violation of subsection 36(3) of the Fisheries Act. The criminal investiga tion resulted in the filing of charges on July 19, 2017.

Environment officials stated that they used Daphnia magna, a small freshwa ter crustacean of the suborder Cladoc era, as a test organism to determine the impacts of the lubricant oil. According to a statement by ECCC: “These water fleas are sensitive to a broad range of aquatic contaminants and are used in many countries to test toxicity.”

ArcelorMittal Canada Inc. and 7623704 Canada Inc. were also found guilty of failing to conduct the testing required during deposits out of the nor mal course of events. The firms violated paragraph 14(1)(b) and subsection 17(1) of the MMER. In addition, ArcelorMit tal Canada Inc. was found guilty of fail ing to submit quarterly effluent mon itoring reports within the prescribed time frame, in violation of subsection 21(1) of the MMER. Both companies have been added to the Environmental Offenders Registry.

For more information, email: editor@esemag.com

In the April 2019 issue of Environmental Science & Engineering Magazine, we published an article titled “Environ mental Isotopes Help Solve Ground water Issues” (Vakili and Sklash, 2019).

In it, we explained that environmen tal isotopes are naturally-occurring iso topes (versions of atoms) that we can use to help solve groundwater problems. The controlling factors for environmental isotopes in the hydrosphere are different from the typical groundwater investiga tion methods, which employ concepts like Darcy’s Law and groundwater flow directions and/or the interpreting dis tributions of chemicals in groundwater. Therefore, the addition of environmen

tal isotope data helps to build a more defendable conclusion than using tradi tional methods by themselves. In some cases, environmental isotopes can pro vide insight into hydrogeological prob lems without resorting to the expense of installing monitoring wells (e.g., Sklash and Mwangi, 1991).

In Vakili and Sklash (2019), we dis cussed the application of four environ mental isotopes: oxygen-18 (18O), deu terium (2H), tritium (3H), and nitro gen-15 (15N) to help understand ground water recharge, nitrate distributions in groundwater, and nitrate sources at a commercial dairy. In this article, we have summarized a recent preliminary

isotopic investigation we conducted on the source(s) and age of nitrate in groundwater in drinking water wells in a small community.

The ratios of heavy to light stable iso topes of hydrogen (2H/1H) and oxygen (18O/16O) in water molecules are largely controlled by temperature. Concentra tions of 18O (oxygen-18) and 2H (deute rium) are measured in specialized labo ratories using mass spectrometers. Con centrations of 18O and 2H are expressed in standard delta notation (δ) of the ratio of the heavy isotope to light isotope in a water sample compared to a standard water. For example, the concentration of oxygen-18 in a water sample is expressed as:

δ18O = [ {(18Osample/16Osample) –(18Ostandard/16Ostandard)}/ (18Ostan dard/16Ostandard)] x 1000 ‰

where: “δ” is read as “delta” or “del,” the standard is “SMOW” (standard mean ocean water) and “‰” means parts per mille (or mil). δ2H is deter mined similarly comparing ratios of 2H/1H. δ18O and δ2H analyses cost about $50.00 for the pair, which can be used for the following:

• Identify the age of groundwater (recent or glacial age).

• Identify recharge mechanisms (direct infiltration versus infiltration of evapo rated water from ponds, infiltration of ponded water into groundwater, etc.).

• Identify whether mixing of ground water occurs in, or between, aquifers.

• Determine travel time through thick aquitards.

• Determine the percentage of current rainfall in storm runoff in a stream.

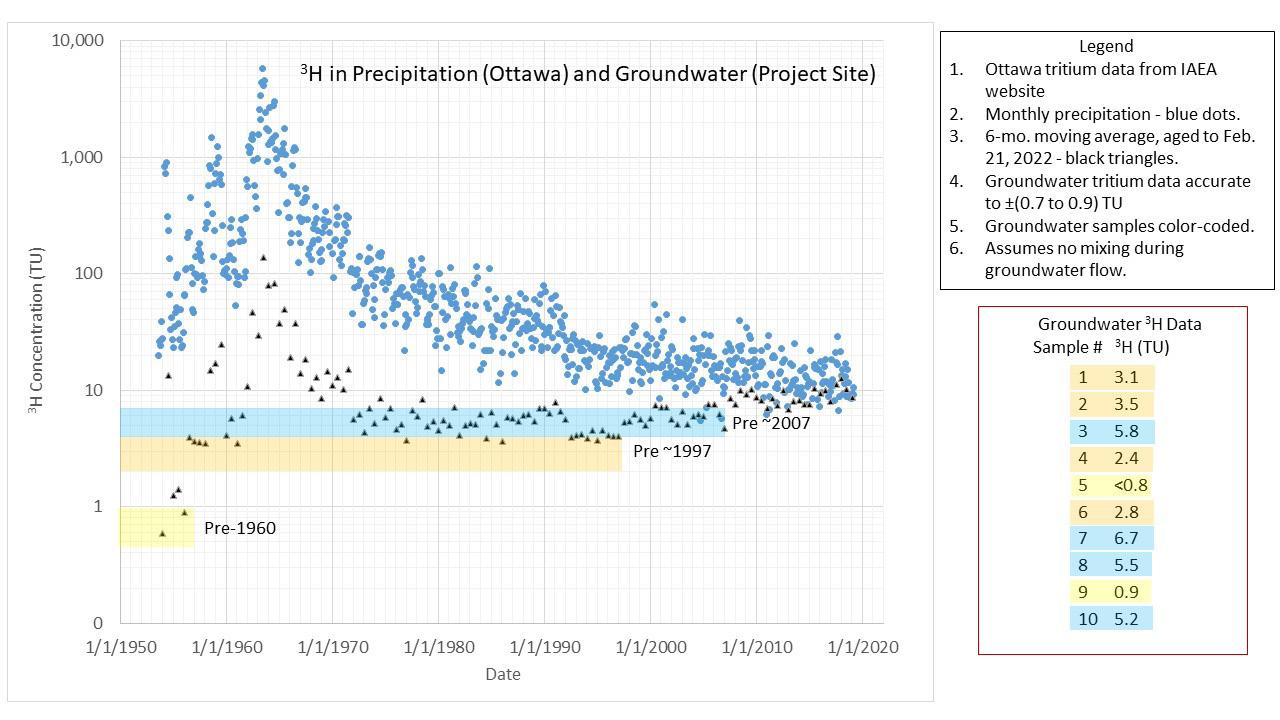

Tritium (3H) is a radiogenic isotope of hydrogen, whose concentration in groundwater depends on when the groundwater was recharged. Concen trations of tritium are measured in spe

cialized laboratories using scintillation counters. Concentrations of tritium are expressed in tritium units (TU) where 1 TU means one tritium atom in 1018 pro tium (1H) atoms. 3H analyses cost about $200. The basis for tritium aging of groundwater is:

• Groundwater takes on the tritium concentration of the precipitation that recharges groundwater.

• Before and during the early 1950s, nat ural tritium concentrations in precipita tion were thought to be 10-25 TU (there were few measurements at that time).

• During the 1950s and early 1960s, tri tium concentrations in precipitation increased greatly (to 1000s of TU) due to atmospheric testing of nuclear bombs; the explosions created “bomb tritium.”

• In 1963, the USSR and the USA signed an atmospheric test ban treaty. Subse quently “bomb tritium” in precipitation was greatly reduced.

• Tritium is a radiogenic isotope with a half-life of about 12.3 years. This means that the concentration of tritium spon taneously is reduced by half about every 12.3 years.

• After 1963, the tritium concentrations in precipitation gradually diminished.

• Recent precipitation in the temperate areas of North America contains about 10 TU of tritium.

As a result of these factors and assum ing no mixing in the groundwater flow system following recharge (that would mix the tritium concentration of the groundwater), groundwater recharged in, or before, the early 1950s now con tains less than 1 TU. Groundwater recharged in about 1963 would now con tain about 90-100 TU, and so on.

During the past several decades, iso tope hydrogeologists have used the ratios of 15N/14N and 18O/16O in nitrate dis solved in groundwater to differentiate between sources of nitrate, such as chem ical fertilizer, soil nitrogen, and animal waste (manure or septage waste). Con centrations of 15N and 18O in nitrate are also measured in specialized laborato ries using mass spectrometers. The ratios of 15N/14N and 18O/16O in nitrate are continued overleaf…

During the 1950s and early 1960s, tritium concentrations in precipitation increased greatly (to 1000s of TU) due to atmospheric testing of nuclear bombs; the explosions created “bomb tritium”.

expressed in δ-notation in ‰; however, different standards are used for 15N/14N.

Fogg et al. (1998) clearly demonstrated how groundwater below test areas used exclusively for/with cattle, chemical fer tilizer applications, no treatment, and septic systems, had characteristic δ15N values. Spalding et al. (2019) show nitrate source fields using dual isotope plots of δ 15N versus δ18O in nitrate to identify source types.

We recently conducted a preliminary investigation of the source(s) of nitrate in groundwater in the drinking water wells in part of a rural village in the Great Lakes area. Data from the two previous years indicated that some of the drink ing water wells had groundwater nitrate concentrations in excess of 20 mg/L. The drinking water criterion is 10 mg/L.

We used existing water well records for drinking water wells in, and around, the village to estimate groundwater flow directions and hydrostratigraphy (geo logic strata and their associated hydrau lic properties). These data indicated the groundwater flow direction was generally from northwest to southeast, which is con sistent with published regional mapping.

According to the regional hydrogeo logic information for the area, the over burden consists primarily of glacial till. Local water well records indicate the bed rock surface in the study area is between about 28 to 47 feet below ground level (fbgl). Records also indicate the drinking water wells are cased through the over burden and into bedrock and are com pleted as open boreholes in carbonate rock, generally between about 100 and 160 fbgl.

Ten target wells were selected for isoto pic testing. We intended to establish one well transect aligned in the groundwater flow direction (to determine where the nitrate source might be) and one transect transverse to the groundwater flow direc tion (to evaluate the width of the ground water body containing elevated nitrate).

In February 2022, we collected ground water samples from the 10 target wells and evaluated these water samples for nitrate, water isotopes, nitrate isotopes, and other water quality parameters.

The highest nitrate concentrations we

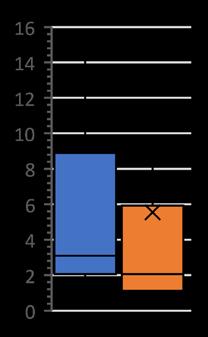

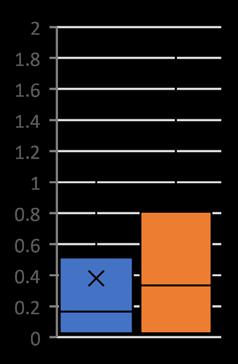

Figure 1. Plot of δ18O versus δ15N in nitrate in groundwater.

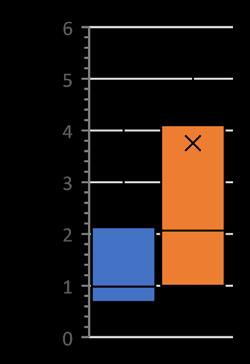

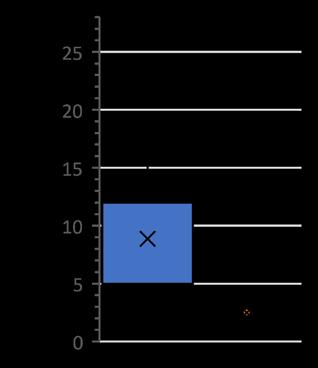

Figure 2. Plot of tritium concentrations in precipitation (Ottawa) and in groundwater (project site).

observed in the groundwater were in the area previously identified by the client as a high nitrate area. Our preliminary groundwater flow and nitrate data indi cate the high nitrate groundwater occurs in a narrow band aligned in the ground water flow direction.

Figure 1 is a plot of the δ18O versus δ15N in the nitrate in groundwater and includes the “nitrate source” fields pro vided in Spalding et al. (2019). It clearly shows that seven of the 10 wells had groundwater nitrate that originated from animal/human waste. Two wells had groundwater that may have had some animal/human waste. Figure 1 also indicates that chemical fertilizer was not a significant source of the nitrate in the groundwater in the study area.

Figure 2 is a plot of tritium in monthly precipitation at Ottawa, Ontario, since

about 1950. These data are from the International Atomic Energy Agency (IAEA) and Ottawa has the longest tri tium record available for North America.

We reduced the number of data points for easier graph-reading by calculating a six-month moving average of the tritium concentrations in precipitation, and then “aged” these precipitation data to February 2022, based on when the pre cipitation fell and the half-life of tritium.

Assuming there is no mixing in the groundwater once the precipitation recharges into the groundwater, we colour-coded the data into “age” groups. The colour-coding in Figure 2 indicates the following:

• None of the groundwater samples contained about 10 TU of tritium; there fore, none of the groundwater was exclu sively post-2007 groundwater.

• Two groundwater samples (#5 and #9) contained less than 1 TU of tritium. This groundwater must have recharged before 1960.

• Four groundwater samples (#1, #2, #4, and #6) contained between 2 and 4 TU of tritium. This groundwater likely recharged before about 1997.

• Four groundwater samples (#3, #7, #8, and #10) contained between 5 and 7 TU of tritium. This groundwater likely recharged before about 2007.

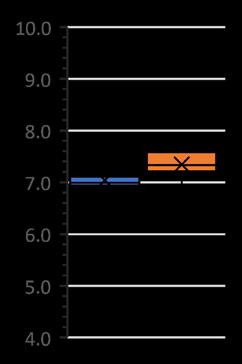

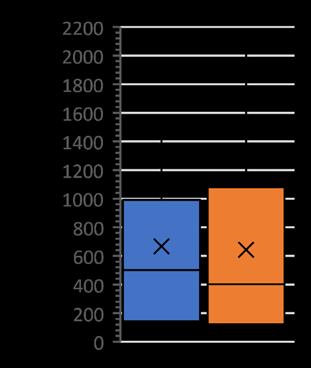

The oldest (#5 and #9) and newest (#7) groundwater samples (based on tritium) had δ18O and δ2H values that were sig nificantly different (Figure 3). The differ ence in δ18O and δ2H values between the older and newer groundwater may be related to a local, progressive tempera ture increase between the mid-1950s and 2020 from about 6°C to 8°C (43°F to 47°F). These data suggest that δ18O and δ2H may be used as a less expensive method of age-dating groundwater in this area.

The highest nitrate concentrations align along a narrow band in the ground water flow direction that coincides with the youngest groundwater. Nitrate iso tope data indicate that the majority of the groundwater samples contained nitrate that originated from animal/human waste.

Finally, all of the groundwater sam ples evaluated during this investigation contain “legacy nitrate” that entered the groundwater before about 2007.

Figure 3. Plot of δ2H versus δ18O in groundwater.

In order to remedy a groundwa ter quality problem effectively and effi ciently, one must delineate the spatial extent of the problem and understand how the problem began. This case study involved a preliminary environmental isotope investigation of groundwater in a small community where the ground water was known to be impacted by nitrate in certain areas.

Without drilling new wells for the investigation, we now have a sense of where the elevated nitrate in ground water originated geographically (some where northwest), when it originated (pre-2007), and that it originated from

animal/human waste.

The next step in “fixing” the problem includes investigating up the groundwater hydraulic gradient (that is, to the north west) from the observed “high nitrate from animal/human waste” groundwater to the source.

References available upon request. Mike Sklash and Fatemeh Vakili are with Dragun Corporation. Email: msklash@dragun.com or fvakili@dragun.com

Across the world, utilities are striv ing to minimize the use of electri cal power associated with waste water treatment, in an effort to reduce operating costs and greenhouse gas emissions. The industry is beginning to demonstrate how the traditionally energy-intensive water resource recov ery facility (WRRF) can become energy neutral, or even energy positive.

Typically, these achievements are made through fundamental changes to process operation, i.e., co-digestion of imported substrates, operating at low dissolved oxygen (DO) concentrations, de-ammonification, etc. The potentially significant reduction in airflow has led some to propose adding mixers in down stream aerated zones to ensure that the mixed liquor remains in suspension.

Doing so would add significantly to cap ital expenditure as well as operating and maintenance efforts and costs.

Engineers and plant operators can make changes to reduce the energy foot print of conventional wastewater treat ment by rethinking traditional design

and operating guidelines for activated sludge mixing.

Aeration is typically where most power is used in a WRRF. Minimum aeration power is determined by mixing requirements, while mixing of unaer ated zones adds to power use. Tradi tional rules of thumb are often used to determine how much power is needed to keep mixed liquor in suspension.

These are summarized in Table 1. At first glance, it appears confusing that mix ing the same material (activated sludge) requires such a variety of (at times con flicting) approaches and empirical design assumptions.

These design criteria likely origi nated from full-scale design and perfor

Well flocculated mixed liquor at a power level of 0.11 W/m3 (Schauer & Kobylinski, 2010).mance experience. While adopting such published design guidelines is safe, the drawback is that these guidelines tend to be set based on the worst-case (failed) designs and as a result tend to increase over time.

Indeed, the recommended mixing power requirement increased from 13 –26 W/m3 (Metcalf and Eddy, 1972) to 15 – 30 W/m3 (Ibid, 1979) to 19 – 39 W/m3 (Ibid, 1991) to 20 – 40 W/m3 (Ibid, 2003 and 2014). This is progress of the wrong kind, suggesting that the efforts our industry has made during the past three decades have resulted in ever less effi cient mixing systems.

Table 1 also highlights that, depend ing on basin dimensions, the results are surprisingly similar around 6 W/m3 or an air flux of 2.2 Nm3/h.m2. How ever, when one considers optimum mix ing intensities that were experimentally determined for flocculation, one finds that these translate to much lower energy intensities, between 0.23 and 1.2 W/m3, continued overleaf…

Mixing intensity expressd as Source Nm3/h.m2 (scfm/ft2) W/m3 (hp/mil gal)

Fine bubble aeration

Coarse bubble (20 scfm/ kcf)

- SWD = 13 ft (4.0 m) - SWD = 20 ft (6.1 m)

Channel aeration (2 scfm/ ft)

- Width = 5 ft (1.5 m) - Width = 15 ft (4.6 m)

Mixer power in unaerated zone

Velocity gradient, G - Optimum flocculation

- Minimum tested

2.2 (0.12) 6.0 (30) 77

4.8 (0.26) 7.3 (0.40) 13 (66) 20 (100) 114 141

7.3 (0.40) 2.4 (0.13) 20 (100) 6.6 (33) 141 81

2.9 (0.16) 5.0 (0.28) 8.0 (40) 14 (70) 89 117

0.15 (0.008) 0.58 (0.032) 0.083 (0.0045) 0.037 (0.002)

Table 1: Comparison of different mixing criteria.

0.40 (2.0) 1.6 (8.0) 0.23 (1.2) 0.10 (0.50)

20 40 15 10

or almost two orders of magnitude below some of the other criteria.

Presumably the mixed liquor needs to stay in suspension for flocculation to occur. The flocculation results suggest that optimization would allow mixing power to be much lower than indicated by traditional design guidelines.

This article includes a comparison of several full-scale mixing system case studies where operators experimented with lower power intensities. These illus trate the value of conducting a site-spe cific evaluation of the actual minimum power required to maintain adequate mixing of mixed liquor for facility own ers and operators. Also, they provide a template for how to conduct these kinds of investigations. This allows any facility operator to experimentally determine the actual minimum mixing require ments, without risking affecting WRRF performance, or the exceedance of efflu ent limits due to insufficient mixing.

Aeration is typically where most power is used in a wastewater treatment facility. By determining the actual mixing and aeration requirements for each application, operators and design engineers can save power and potentially avoid unnecessary investments. Credit: Umpawan, stock.adobe.com

Schauer and Kobylinski (2010) tested the impact of impeller speed of an axial flow, top-mounted mixer in an irreg ular-shaped anoxic zone. Their results show that, in the second anoxic zone, reducing the mixing intensity from 4.5

to 0.11 W/m3 resulted in the maximum MLSS concentration difference increas ing from 3.4% to 5.5%. This suggests lit tle was lost in terms of homogeneity.

This is equivalent to reducing the air flux from 1.7 to 0.040 Nm3/h.m2, which is in line with some of the lowest power levels tested for flocculation and is a reduction of almost 98%. At the same time, the mixed liquor took on the appearance of extremely well flocculated solids.

They were not able to achieve the same results in the first anoxic zone. This suggests that the blending of the mixed liquor return flow and the efflu ent from the upstream anaerobic zone, introduced a few metres apart, limited the homogeneity of the mixed liquor at low power intensities.

Operators at one plant noticed that high DO concentrations in the down stream aerated zones were reducing the denitrification efficiency in the anoxic zones. It was determined that the aer ation system in these zones often oper

ates at mixing limited set points. To test the rule of thumb (2.2 Nm3/m2.h), one zone was operated overnight at an air flux of only 1.1 Nm3/m2.h. The next morning, profile MLSS measurements at multiple points in the zone revealed no distinguishable MLSS gradient.

As a result of these observations, the operators plugged diffusers in the second and third aeration grid, to make lower aeration fluxes viable without exceeding diffuser limitations. Then, they reduced DO set points in all aeration grids. They also decided to cycle mixer operation, so that each mixer only operates 30 min utes every 24 hours.

Thanks to these changes, and other sys tem improvements, the effluent total inor ganic nitrogen concentration dropped from 15 mg/L to 8.5 mg/L, while saving almost 2,100 kWh/d.

The same techniques can be used at any facility. There will usually be at least one aeration grid where airflow is main tained at the traditional mixing limit of 2.2 Nm3/m2.h, resulting in high DO

concentrations and potentially inhibit ing denitrification in upstream anoxic zones. By gradually allowing lower air fluxes, and leaving the system at these settings long enough for the solids pro file to stabilize, typically overnight, the impact of lower air fluxes on the solids profile can be determined experimen tally, using a Kemmerer sampler or a portable handheld TSS probe.

Before adding a mixer in an aerated zone with low oxygen demand, one would want to use this method to con firm that additional mixing is needed, and the expense is justified.

The same approach can be used to track changes to the solids profile after the mixer in an unaerated zone has been switched off, to determine the feasibility of cyclic mixer operation.

These examples illustrate that it is possible to improve effluent quality while saving power and operating cost. Depending on the plant loading and

operating conditions, significant blower power may be saved. Cyclic operation of mixers may be used to reduce over all power cost or to minimize demand charges by minimizing mixer operation during daily peak rates. If the floccu lation of the mixed liquor shows a sig nificant improvement, one might even increase secondary treatment capacity.

Instead of accepting traditional rulesof-thumb at face value, there is an oppor tunity for plant operators and design engineers to determine the actual mix ing requirements for each application and use these to save power and poten tially avoid unnecessary investment.

References available upon request. Coenraad Pretorius and Jeremy Kraemer are with GHD. For more information, email: jeremy.kraemer@ghd.com

Hamilton is a port city on the west ern side of Lake Ontario with a population of 550,000. The Niag ara Escarpment runs through the middle of the city across its entire breadth, producing roughly 148 km of watercourses that flow through Hamil ton and feed into Lake Ontario.

Hamilton has two types of sewer sys tems. One is a separated sewer system, which has one pipe for sewage that gets treated at the wastewater plant and one pipe for stormwater that flows out to the natural environment. The other is a com bined sewer system that exists in older parts of the city where one pipe collects both stormwater and sewage, which goes directly to the wastewater treatment plant. Once the wastewater is cleaned it is discharged into Hamilton Harbour.

The city has nine large storage tanks that can hold 302 million litres of diluted wastewater in the event of extreme rain or snowmelt, so it is rare that wastewater treatment plant operators have no other option than to release diluted wastewa ter into the harbour.

At the end of 2001, the Ontario Min istry of the Environment, Conserva tion and Parks notified the city that there was E. coli present in the Red Hill Creek. Given that rainwater washes ani mal waste into streams and rivers, it is not uncommon to find E. coli in water courses when there are big rain events.

Calvin Huizinga, project manager of the sewer lateral cross connection pro gram for Hamilton Water, said: “It was important that we understood where this E. coli came from, so we ran a series of tests in storm sewer outfalls upstream of Red Hill Creek to determine if human waste was a factor in this E. coli discov ery. Unfortunately, the results indicated this was the case.”

Cross connection repair completed. The coloured pipe is a sanitary sewer lateral and the white pipe is a storm sewer lateral.

The city discovered that part of the problem was cross-connected sewer lat erals, from residences where builders had mistakenly linked sewage outputs to the storm sewer system. In addition, there were partial cross connections that typically occur from homeowner ren ovation projects, with new plumbing fixtures being connected to an internal stormwater drain.

The city immediately launched a sam pling program in 2002. “The starting point was easy, as we investigated the surrounding catchment area for Red Hill Creek,” said Huizinga. Crews sampled the storm sewers, and upon a positive result, they deployed CCTV into the storm sewer system during dry weather to look for the source of entry for human waste.

Once the source was determined, the

homeowner was contacted to advise them of the situation so that the city could gain access to their internal plumbing. This would allow crews to run a definitive dye test and another CCTV inspection to identify where the cross connection took place. Twohour on-site investigations cost the city around $650.

In two years, 153 storm sewer outfalls were investigated that were part of the two most significant (and environmen tally sensitive) watershed areas in the city: Cootes Paradise and the Red Hill Valley. They identified concerning levels of E. coli in 31 streams, indicating a high probability for cross connection con tamination.

“Unfortunately, we were met with some resistance from residents to

gain access into homes for dye test ing. Homeowners were concerned that they would be found at fault, resulting in fines and costly repairs. Our primary concern was to stop the flow of this raw sewage through the drains as it posed a serious health risk and environmental contamination at its final harbour des tination. So, in 2009 the city chose to waive owner liability, which significantly improved resident cooperation in giving us access for the final confirmation of what we suspected,” said Huizinga.

The city looked for ways to expand the program by identifying other hot spots, conducting regular testing and fixing the cross connections wherever they occurred. In 2009, the sewer lateral

one of Canada’s oldest water systems, so we have learnt how to get creative to get the job done. One corrected cross con nection diverts approximately 225,000 litres of sewage out of watercourses and into the treatment system each year. This has a significant impact on the health and safety of our residents and the health of surrounding ecosystems, which is why the city stepped up to fix these cross connections at a cost of $7,200 per resi dence for the full repair and restoration.”

Partial cross connections represent 10% of all identified cross connections in the city. Since the repair is required within the household, the city is not able to fix the connection. “We are still look ing at ways to deal with partial cross

sewer system. The city has conducted more than 615 dye test investigations, positively identified 376 homes with complete cross connections and con ducted 376 repairs. This amounts to one repair for every 750 m of inspection. This translates to more than 84.6 million litres of sewage being redirected from watercourses and the natural environ ment each day and into the city’s waste water treatment facilities.

In addition to field investigations and repairs, the city has also made changes to the building inspection program and created new bylaws to help prevent future cross connections. New subdivi sions are now required to dye test pri vate sewer laterals to ensure they are

including Hamilton Harbour and Lake Ontario. The city is committed to fixing this legacy issue and has identified and repaired a number of cross connections across Hamilton.”

In 2017, municipalities in Canada and the U.S. with cross connection issues were contacted to complete a survey for industry review. Participants were given an overview of the City of Ham ilton’s program and were asked to pro vide information about their own pro grams. Of the returned survey responses, only the City of Toronto and the Bos ton Water and Sewer Commission had well-established programs in place.

“This was definitely surprising to us, as cross connections are not an uncom mon problem. Yet it was clear that our relatively small city already had a mature program in place. Furthermore, we dis covered that we had corrected twice the number of cross connections per staff and at 12% less cost,” said Huizinga.

Hamilton also partnered with Redeemer University’s Environmental Studies pro

gram as they began actively monitor ing water quality in the Chedoke Creek watershed in 2012.

“Our students collect and analyse samples for a variety of biological and chemical contaminants. Nitrates, E. coli, total coliforms, phosphorus, chlorides (from road salt), and several others are being studied. It only makes sense that we share our findings with the city as we all have the same vested interest in restoring the health of Hamilton’s water sheds” said Edward Berkelaar, professor of chemistry and environmental science for Redeemer University.

The city, in turn, provided some fur ther insight into the civil side of how collection systems operate. “Environ mental stewardship is all of our respon sibility and the students of Redeemer are our future policy makers, water sci entists, operators and engineers. Part nerships like this accelerate a successful outcome,” said Huizinga.

An independent research project started in 2018 by a Redeemer University

student is looking specifically at “Micro bial Source Tracking of Fecal Contamina tion in Hamilton’s Chedoke Watershed”. Using cutting-edge lab equipment, the student was able to perform quantitative polymerase chain reaction (qPCR) lab procedures to isolate and amplify specific characteristics of the DNA to identify if the bacterial contamination was human or otherwise. Two of the seven sample locations registered human fecal con taminations of 10% and 13% of the total E. coli and five of the locations registered indiscernibly (<3%) small amounts.

“While the methodology and appli cation of this technology is fairly new at Redeemer University, we are all keen to better understand the sources of con tamination within our watersheds and to quantify the positive environmental impact of repairing cross connections,” said Huizinga.

The city has already inspected 25% of the storm sewer system, and plans to continue inspecting 46 km every year, until the entire separated sewer system has been reviewed. In addition, they have expanded the scope of the pro gram to include other potential sources and causes for sanitary sewer cross con tamination. With over 300 km of coded CCTV storm sewer footage as a result of searching for cross connections, it makes sense to leverage this data for a deeper structural pipe condition assessment.

“We plan to work with environmen tal engineers to use this data with addi tional infrastructure records and inno vative software to pinpoint other poten tial sources of sewer cross connections, such as improperly abandoned sewer lines or sewer exfiltration. 84.6 million litres of sewage diverted from the envi ronment every year is something we are very proud of, but with human E. coli still present at outfalls we still have lots of work to do,” concluded Huizinga.

Dave Alberton and Donald Young are with Hamilton Water.

dave.alberton@hamilton.ca,

New Tecumseth is ready to confirm how much it will pay for the expansion of the Raymond A. Barker Water Treat ment Plant in Collingwood, Ontario, which has piped drinking water one hour south for more than 20 years as part of a collaborative agreement.

The towns, which have worked together since the expiration of their previous agreement in 2020, recently formed a new draft 10-year agreement to better position each municipal ity as their populations continue to grow and require greater water capacity.

The pipeline, which connects to a local reservoir, essentially began to support the construction of the sprawling Honda manufacturing plant expansion in Alliston, Ontario. The Town of Collingwood owned a rail line between Collingwood and Utopia and agreed to grant an easement over part of the railway lands to accommodate the transmission of water.

An announcement from the Town of Collingwood noted that the new agreement will include “an updated supply rate structure” that is “consistent with the principles of water rate setting by the American Water Works Association,” including cost recovery and asset management into the future.

“Collingwood has supplied water to the Town of New Tecumseth for over 20 years, and a new agreement will ensure that the best interests of both communities continue to be met in a transparent and financially responsible manner,” announced Sonya Skinner, Collingwood’s chief administrative officer, in a statement. “This collaboration will achieve greater efficiencies and enable growth for both communities,” she added.

The new rate will begin in January 2023, with a four-year transition period. It was established with the aid of Hemson Consulting Group. The rates range from $0.5 to $0.58 per cubic

metre in 2023 and increase to $0.62 per cubic metre by 2026, assuming a 2% consumer price index.

Until the new water treatment plant is built in Collingwood, New Tecumseth must purchase 9,000 cubic metres on average per day, up to a maximum of 9,500 cubic metres. In 2027, the minimum quantity will be 13,400 cubic metres. A new admin istration fee of $0.04 per cubic metre will commence on com missioning of the newly expanded water treatment plant.

In the terms of the transfer of pipeline ownership, New Tecumseth will be expected to pay $6.5 million to Colling wood in exchange for an 18.5% interest in the pipeline.

The two municipalities will also form a joint water commit tee to review planning for future expansions, maintenance and capital budgets, as well as supply rates.

“Both municipalities have been committed to working together to address our water supply needs for today and in the future,” said Blaine Parkin, New Tecumseth’s chief admin istrative officer, in a statement.

For more information, email: editor@esemag.com

The Town of Collingwood owned a rail line between Collingwood and Utopia and agreed to grant an easement over part of the railway lands to accommodate the transmission of water.

Kristjan, stock.adobe.com

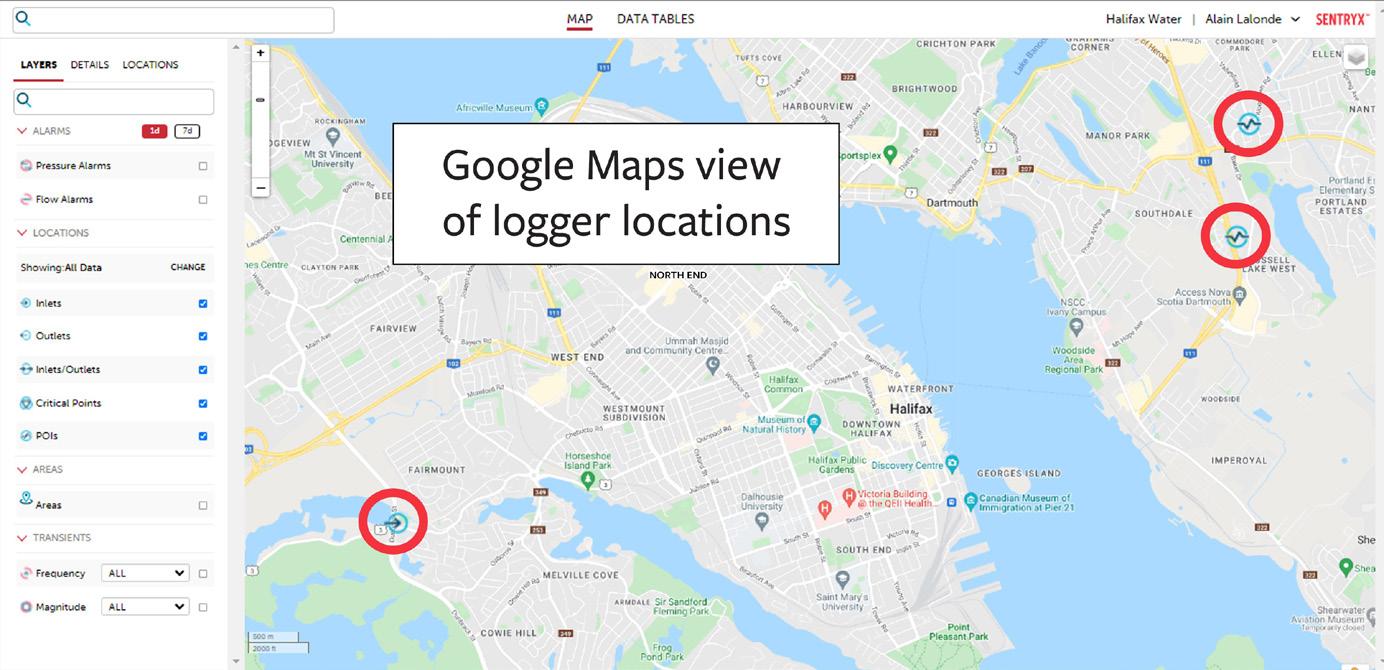

Digitization has arrived as a bat tle cry in the daily operations of Canadian water utilities. Thou sands of sensors are pumping out millions of time-series data points, ven dor solutions compete to provide reams of analytic reports, and vast amounts of public data beckon that can inform wastewater flows, moisture impacts and other vital parameters.

There’s a ready, willing and able army of data-driven engineers armed with Python, Julia and R programming skills, keen to use predictive analytics and machine learning (ML) automation to tackle the challenges wrought by climate change-induced storm events, urban population concentration and ageing infrastructure.

It’s worth noting Python’s popular ity in particular. With a name inspired by the surreal TV sketches and mov ies of the British comedy troupe Monty Python, Python is a high-level opensource programming language. It was conceived by the Dutch programmer Guido Van Rossum in the late 1980s, during his Christmas break at university!

While he has since pursued a brilliant technical career working in the coding armies at Google, DropBox and most recently, Microsoft, he shouldered lead developer responsibilities for Python as “benevolent dictator for life”. This title was bestowed upon him after he passed his torch in 2019 to a five-member steering council that now leads the Python project.

The August 2022 edition of InfoWorld

With face pro, users can do things like convert measurement units, define lookup tables for weirs, flumes, and pipe cross-sectional areas, create rolling averages and sums, etc. Credit: dusanpetkovic1, stock adobe.com

reported that “unstoppable Python” topped the chart as the world’s most popular programming language. It reg istered a 15.42% market share, which is an all-time high for the language. It’s the only programming language besides Java and C to hold that No. 1 position.

Python courses are ubiquitous at Canadian college and university engi neering programs, not to mention those at MIT, Stanford and Carnegie Mel lon. And, the Coursera “IT Automation Python Professional Certificate” has a current enrollment of over 450,000 stu dents who pay an average of US$300 to complete that course in six months.

Python power and popularity has been built with extraordinary open-

source Python libraries for data science that are used by programmers every day in solving problems. For the uniniti ated, Python libraries are collections of modules that contain useful codes and functions, eliminating the need to write them from scratch. There are tens of thousands of Python libraries that help ML developers, data scientists and data visualization engineers, and more.

Python is the preferred language for machine learning, because its syn tax and commands are closely related to English, making it efficient and easy to learn. Compared with C++, R, Ruby, and Java, Python is one the simplest lan guages, enabling accessibility, versatility, and portability. It can operate on nearly any operating system or platform.

As an example of vast Python resources, Scikit-learn is an actively used library for ML. It includes easy integra tion with other ML programming librar ies like NumPy and Pandas. Scikit-learn comes with the support of various algo rithms such as classification, regression, clustering, dimensionality reduction, model selection, and preprocessing.

Built around the idea of being easy to use but still flexible, Scikit-learn is focused on data modelling. It is con sidered sufficient enough to be used as an end-to-end ML toolkit, from the research phase to the deployment.

Pandas is another notable Python library. It is primarily used for data manipulation and analysis. Pandas make working with time series and structured multidimensional data effortless for machine-learning programmers. Some

of the great features of Pandas when it comes to handling data are dataset reshaping and pivoting, merging and joining of datasets, handling of missing data and data alignment, hierarchical axis indexing, fancy indexing, and data filtration options.

As founder of the company that brought the flowworks flow monitor ing, analysis and reporting software platform to life in over 70 Smart City water utilities including Los Angeles County, Toronto, Seattle, and Dallas, I led a $4-million Digital Supercluster R&D consortium project that brought our technical team deep into Python’s potential for ML and other advanced data calculation applications.

The Fresh Water Data Commons project, now deployed in Andersen Creek in the Columbia Basin near the City of Nelson, British Columbia, uses an ML-enhanced version of the flow

works platform to transform data using Python scripts to build real-time analyt ics, predictive analytics and ML models.

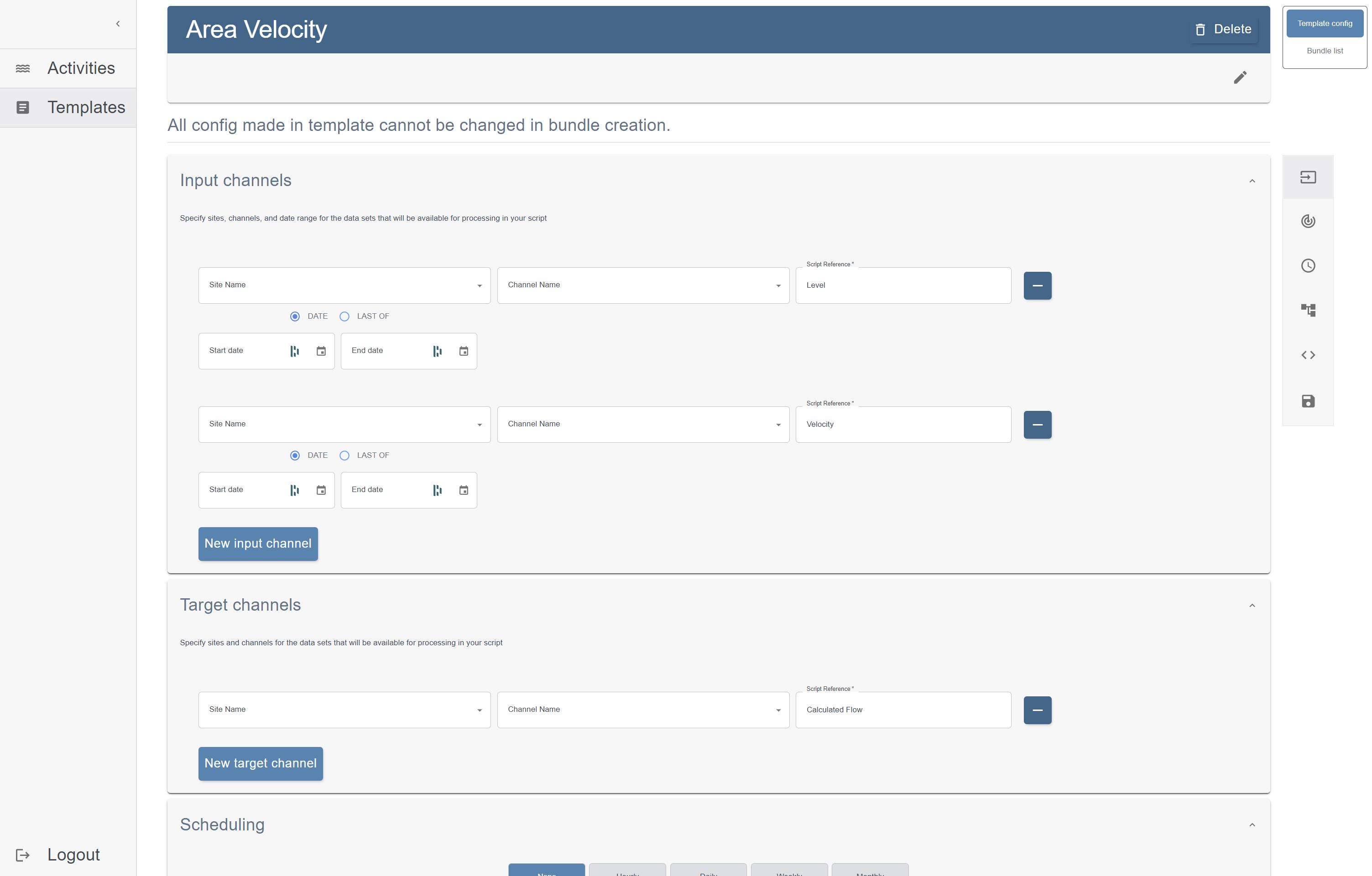

The objective of the Canadian Fed eral Government’s Digital Supercluster initiative is to identify global indus try leaders and where Canadians bene fit from the prosperity and growth that comes from creating new products and services that are meaningful across the country and around the world. We did precisely that with a product launched at WEFTEC 2022 called face pro. Some of our Beta customers refer to it as “the Python tamer”.

A well-used toolset within flowworks, face stands for “flowworks advanced cal culation engine”. Using face pro, munic ipal engineers can create, edit and com bine data channels with mathematical functions. This allows them to create and define new datasets from incoming raw channels, using advanced math, statis continued overleaf…

tics and logic equations. Users can create, edit, delete and combine data channels with powerful mathematical functions for sophisticated real-time analysis.

With face, users can do things like con vert measurement units, define lookup tables for weirs, flumes and pipe cross-sec tional areas, create rolling averages and sums, build time-weighted averages of irregularly spaced data, and move data forward or backward in time to compare it with previously collected datasets.

Infinitii face pro, as the name suggests, takes advanced calculations and related automation to another level.

Users can literally cut and paste Python (or Julia or R) scripts into flow works production systems and then sec onds later, ML algorithms defined by those scripts are running system wide. After a recent demo of infinitii face pro, a senior software developer working at one of our flowworks engineering ser vices partners declared that “I can do my entire job inside this software!”

With infinitii face pro, flowworks users can easily deploy existing algorithms and calculations from the vast Python libraries technologists use every day. It’s as simple as cutting and pasting Python code into an intuitive interface, and then minutes or even seconds later seeing that code run in production systems.

Use cases for this Python-taming calculation engine include forecasting, anomaly detection, predictive mainte nance and failure prediction. The types of advanced calculations easily performed with infinitii face pro include Soil and Water Integrated Model (SWIM) calcu lations that track and predict climate and land use change impacts at a regional scale, and evapotranspiration (ET) cal culations used to estimate soil-moisture storage based on precipitation deficit and the maximum water-holding capac ity of the soil.

Working alongside the flowworks platform, infinitii face pro provides a utility-wide data monitoring and report ing environment with state-of-the-art streaming data calculations that take advantage of the latest ML algorithms available in the vast Python libraries or created in-house to solve very spe cific problems. Significantly, flowworks “plays well with others,” and breaks down versus puts up barriers to working with data provided by other vendors.

Flowworks accepts all types of data from any source. Real-time, historic, wireless, satellite, SCADA, public data sets including USGS, NOAA and weather forecasts. It doesn’t matter where the data originates or from which sensor. You can connect it. Customers use flowworks daily to monitor water flow, rainfall, and other vital parameters in thousands of collection system metering points.

Eric Corey, the smart wastewater net work project manager at Core & Main, has stated that with flowworks: “We now

Infinitii face pro input data channel and target output data channel for area velocity.have the unique ability to treat data like data, not like countries.”

He continued, saying “given the com plexity of the Smart Wastewater Net work and the number of different soft ware solutions being utilized, what flow works provides us is a data Switzerland.

“This neutrality gives a required level of comfort to our other technology and manufacturing partners that allows us to truly innovate with their technolo gies versus being locked in or locked out from utilizing strategically import ant data.”

Infinitii face pro users working with the flowworks platform can build ana lytic models and transform raw sensor data in order to generate new data or output events in near real time. They can simultaneously filter, aggregate, enrich and analyze high volumes of time-series data from multiple sources, then present it using flowworks graphing and geo graphic information system (GIS) map ping tools like K2 Geospatial’s JMap.

Flowworks alarming and notification tools are readily employed, and infinitii face pro can also leverage Microsoft Power BI dashboards.

Greg Johnston is with infinitii ai. For more information, visit: www.infinitii.ai

Infinitii face pro area velocity results graph calculated from new data channel.The University of Waterloo is lead ing an interdisciplinary research team that hopes to unlock key information that will inform Cana dian water systems about potential PFAS contaminants and treatment options that could impact millions of Canadians.

Per- and polyfluoroalkyl substances (PFAS) will be monitored through the treatment process of seven Ontario water supply systems under the new research. The project will determine which PFAS are present in Ontario waters, as well as the chemical and physical processes underpinning treatment technologies.

This project will see water samples taken throughout the treatment process to determine which PFAS are present in Ontario waters. Credit: madamlead, stock.adobe.com

new water and wastewater treatment technologies,” said Scott Hopkins, project lead and professor in Waterloo’s Depart

Traditional water treatment methods are ineffective at destroying these chemi cals, added Hopkins, who says the carbon fluorine bond formed in PFAS is one of the strongest in chemistry. His team will focus on the detection, characterization, and use of machine learning models to predict the physicochemical properties of PFAS and the transformation products generated by the treatment processes.