Arctic water system innovations for freeze protection

Decentralized and distributed wastewater management

Stopping PFAS migration at the source

Arctic water system innovations for freeze protection

Decentralized and distributed wastewater management

Stopping PFAS migration at the source

Styrene-Free Structural Liner for Sewers and Culverts

The need for a durable and cost-efficient pipe rehabilitation solution has never been more paramount. The engineers at IPEX recognized this need and have responded with NovaForm™ PVC Liner, a product that brings the lasting benefits of factory-made PVC pipe to the North American trenchless pipe rehabilitation industry.

Disruptions Available in Sizes 6” to 30”

To learn more, call or visit us at:

|

With their modular design, intelligent diagnostics and full approvals, our AWT420 advanced water transmitters offer a flexible, high performance solution for a wide range of industrial applications, from water and wastewater through to chemical and petrochemical. Packed with a host of features including Bluetooth® connectivity, dual PID control and EZ-Link™ sensor connection, water analysis has never been easier. abb.com/wateranalysis

Measurement made easy.

The versatile solution that works the way you want it to work.

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

TECHNICAL ADVISORY BOARD

Archis Ambulkar, OCT Water Quality Academy

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors. Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales

Second Class Mail

Product Agreement No. 40065446

Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com

6

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering

220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727 4666 www.esemag.com

57

www.esemag.com

37 UBC explores hydrothermal liquefaction to extract phosphorus from wastewater

38 Taking a closer look at the material of water system valve seats

40 Simplify wastewater DO monitoring with flexible, low-maintenance sensors

42 Post-flood, source water risk review and water system recovery plan for Merritt, B.C.

44 Water infrastructure upgrades funded for B.C. and N.B.

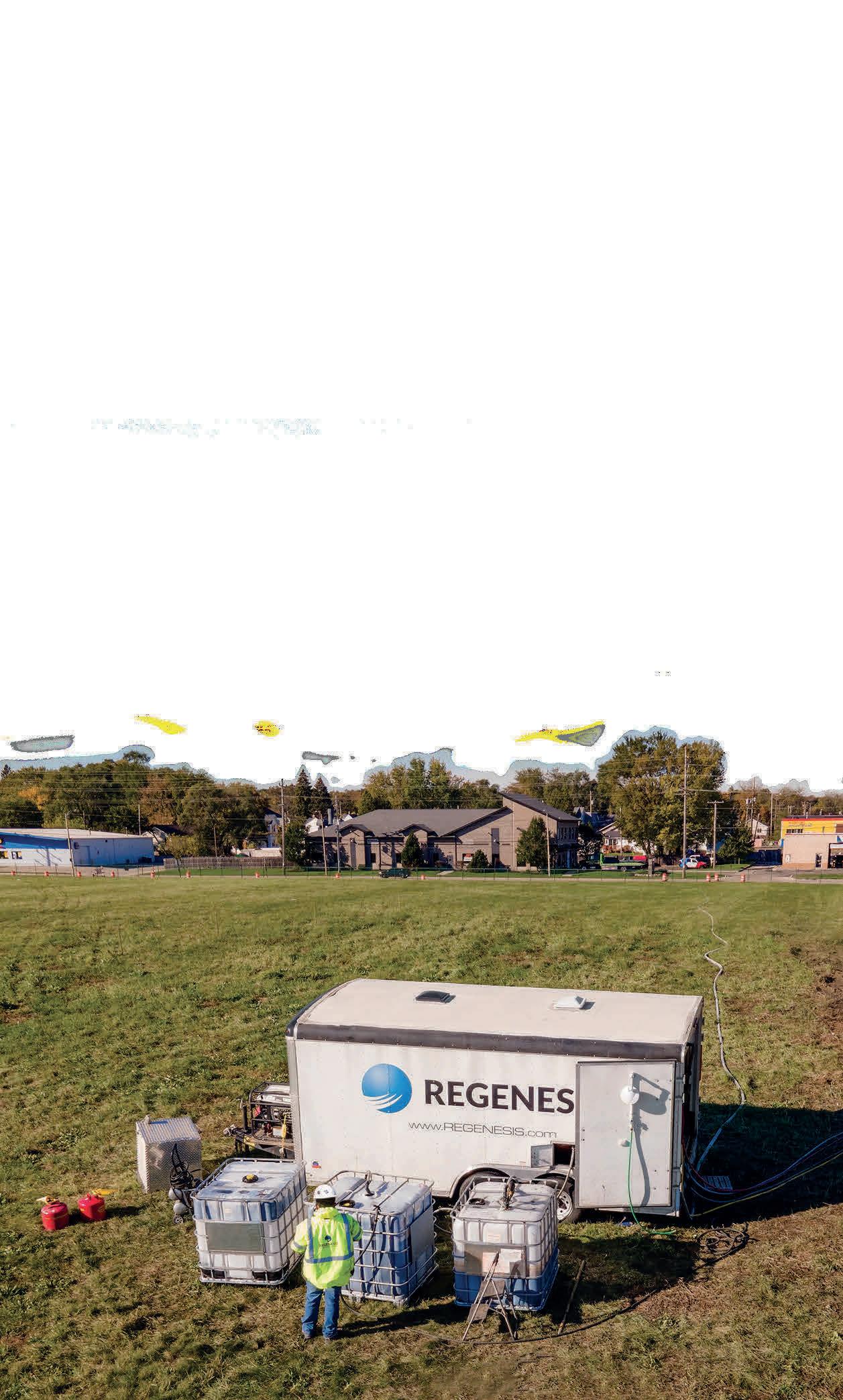

45 Nova Scotia flash floods damage water infrastructure

46 Dealing with diapers – the dirty little secret of organics diversion

48 What makes butterfly valves unique?

50 Stopping PFAS migration at the source to protect water supplies and prevent exposure

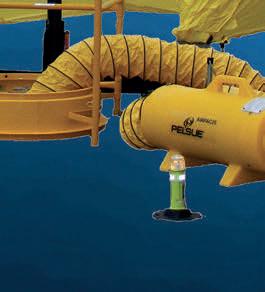

52 Cover Story: Canadian Arctic water system innovations for freeze protection

56 BC sets new controls for LNG sector to cut emissions, fast-track clean energy projects

60 Reports question financial feasibility of municipal PFAS removal at WWTPs

62 Laval releases ambitious $276M climate plan to cut GHGs by 33%

a co mple te range of ma rket ve pro du cts. Let u s sh ow you

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

•

tiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recovery

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – snoitatS pmuP & retawmrotS ,OSC

Primary & Secondary, Circular, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dry Systems

Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vortex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

In the spring of 2023, I made the most important discovery of my career (and that is saying something). Canada’s National Plumbing Code does not require trash cans in women’s toilet stalls. Our industry has been messaging for years that toilets are not trash cans, but women’s toilet stalls are not provided with trash cans! Women’s toilet stalls look exactly like men’s, except that there is a very small, metal box attached to the wall (sometimes recessed), which contains flimsy paper bags.

Presumably (and there are no instructions, by the way), we are meant to remove soiled products, get them into this flimsy bag, carry it out of the stall to the public part of the washroom, and deposit it into the trash can by the sinks.

I can tell you that I have never seen a woman carry a soiled paper bag out of the stall to do this. This is not socially acceptable, even in women’s washrooms. I have been asking women about this since my discovery, and nobody else has either.

But, I do see women cram the paper bag with soiled product back into this small metal box, right beside the stack of clean paper bags. How unsanitary. How preposterous. How disrespectful.

When the Codes were written about 75 years ago, women’s washroom requirements were not considered. Menstruating women require a sink, counter, paper towel and trash can in the toilet stall.

Rough calculations show that 51% of the population is female, about 50% of women are of menstrual age (based on the City of Toronto population distribution), and women are away from home 10 to 12 hours a day (assuming working outside the home). Then, there are evening activities like taking the kids to hockey, going to the gym, eating at restaurants, etc.

Women menstruate 25% of the time, which means millions of tons of menstrual products are being flushed every year.

We need 30% of toilet stalls to be equipped for menstruators. These can easily be combined with the accessible stall in most washrooms. They would also be helpful for women with children in diapers, adult incontinence products, etc.

Now, private businesses (restaurants, gyms, etc.) sometimes install a trash can in the stall and post a flimsy sign on 8.5 x 11 paper, made up by the owner, asking women not to flush menstrual products. Presumably, they have done this because they experience private-side sewer pipe blockages and wish to avoid them.

My question is this: why are private business owners, who know nothing about sewers, expected to educate the public? Surely this is the purview of municipalities who own and

operate sewer systems.

The National Plumbing Code needs to be rewritten (not “updated”). I observed that when gender identity issues began to be better understood, the Codes were updated to require single user toilet stalls in certain cases. These do contain all the facilities required by menstruators. It is difficult to understand why our female population has not been treated with similar respect.

Making changes to the National Plumbing Code can be a long process. The Codes are administered by the National Research Council (NRC) and updated periodically. Anyone can submit a Code Change Request to be considered every five years or so. However, for urgent needs, Code changes can be made sooner than that. I am taking steps to initiate this personally, but the rewrite needs to be done by plumbers, not engineers.

However, engineers need to understand Building Codes, as they relate to sewers. How can we solve private-side inflow and infiltration (I/I) without understanding the regulations that govern it? The Ontario Building Officials Association (OBOA) offers a course in house plumbing, which would be a great starting point

Why is this essential for the engineering industry? Most menstrual products are being flushed when women are away from home, because we have no choice. While we wait for this essential rewrite of the Code, women continue to flush menstrual products, flushable wipes, incontinence products, etc., when away from home.

These deleterious items that are flushed provide a place for continued overleaf…

When the Codes were written about 75 years ago, women’s washroom requirements were not considered. Credit: wittayayut, stock.adobe.com

fats, oils and grease (FOG) to stick, causing blockages and fatbergs. The advent of the flushable wipes industry has greatly exacerbated the formation of fatbergs, which cause blockages in laterals (private and public side), and public-side sewers. Many residents (and businesses) discharge FOG into their kitchen sinks, which also contribute to fatberg formation and blockages.

As well, when combined sewer overflow situations occur, flushed materials are discharged directly into streams, and other water bodies, and cause an unsightly and unhygienic mess in harbours, beaches and shorelines.

Obviously, these products do not belong in sanitary sewers. All of it must be removed at pumping stations and at wastewater treatment plants (WWTPs).

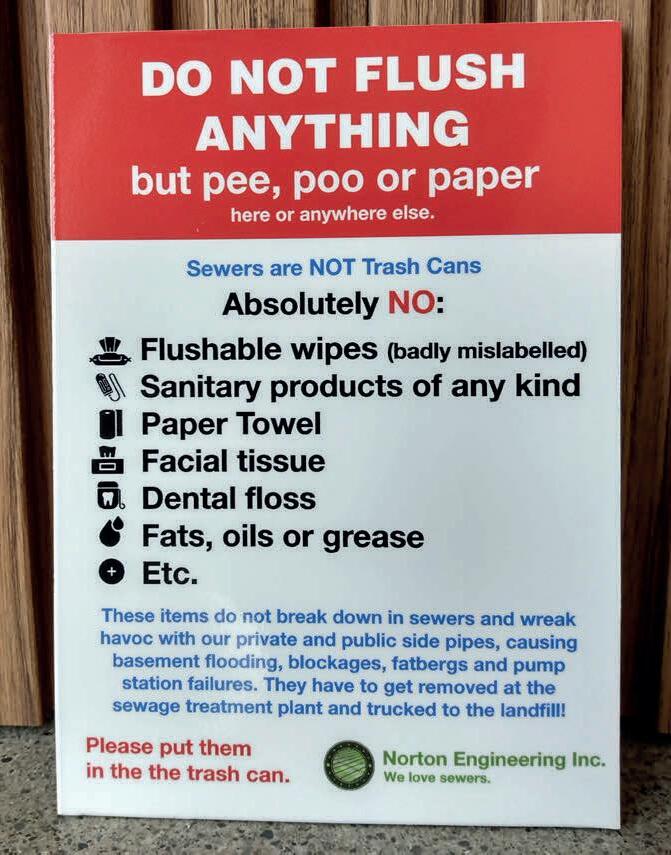

So, how can we educate the public about all of this? Not only that toilets are not trash cans, but that sewers are not trash conveyers. Norton Engineering has developed a simple, efficient, and cost-effective solution. We need to get trash cans in all toilet stalls, including men’s, as they also flush wipes and incontinence materials.

Public toilet stalls are a perfect place to educate and constantly reinforce the messaging, to men and women, about what to flush. Just telling them not to flush menstrual products is not enough. Why not cover all the things that should not go into sewers, such as FOG, dental

Signs like this should be

owners everywhere, to replace flimsy paper ones.

floss, condoms, etc.? We need to explain why this is important everywhere.

I have developed a stall-sized sign that is designed to cover all this information. It briefly and succinctly explains what not to discharge into sewers. It is designed to be installed in every public toilet stall (men’s and women’s) explaining this. This solution reinforces the messaging every single time someone uses a public washroom. Signs like mine should be provided to business owners everywhere, to replace flimsy paper ones.

Changing the National Plumbing

Code will not change behaviour (though equipping stalls will help a great deal). The general public understands almost nothing about sewers, even the fact that they own one if they own a house!

That is where the engineering industry can help. We are the ones who understand sewers and WWTPs, and the risks that flushed materials pose to them.

This brings me to public education. I speak very widely to generally educated, but not technical, residents. After five years of doing this, I can tell you that the public understands almost nothing about how to operate and maintain their sewer and drainage systems, including sump pumps and backwater valves. They tell me that while they have heard of what not to flush, they do not really understand the reasons why.

Many municipalities have been diligent about trying to message this. Many have sent bill inserts and have information on their website. But, based on my extensive experience with the general public, these methods have not been particularly successful.

However, I have found that if we carefully explain to residents that flushing certain materials at home increased the risk of their own sewer getting blocked, they pay careful attention.

Barbara Robinson is with Norton Engineering Inc. Email: nortonengineeringinc@gmail.com

provided to business

provided to business

Water treatment system operators rely on the accuracy of a flow meter’s readings, particularly for chemical dosing and other low-flow processes. Accuracy in metering depends on a range of factors, from the types and quality of liquid being metered to the meters themselves.

Generally, the two most accurate meter technologies are static meters (i.e., those without moving parts), which includes ultrasonic and magnetic flow meters (mag meters). Both have their advantages, but the right fit will depend on the application. This makes it important to understand the pros and cons of each technology before making a purchase.

Ultrasonic meters detect and measure flow using sound waves in one of two ways. Doppler ultrasonic meters send out a signal and measure the change in frequency as it bounces back to determine the flow rate. To do this often requires bubbles, particles or a high concentration of solids that will reflect the sound wave back.

By comparison, transit-time ultrasonic meters send two signals, one upstream and one downstream. The difference between them is proportional to the velocity of the liquid. However, bubbles and large solids will cause inaccurate readings.

Mag meters create a magnetic field and measure the voltage of any conductive material passing through the field. The major downside to this technology is that it requires liquids with specific properties or impurities. Mag meters work well with water with some natural mineral content (such as most drinking water), as well as acids and caustic liquids.

Mag meters and ultrasonic meters both have comparable accuracy under ideal conditions. The exact level of accuracy

will depend heavily on the manufacturer and the application.

As mentioned, air bubbles can either aid or hinder a meter, depending on the technology. Mag meters, for example, will read air bubbles as flow and may read high if there is too much air in the fluid. On the other hand, Doppler ultrasonics rely on air bubbles for their reading, so the opposite is true in that the absence of air can cause inaccuracies.

For transit-time ultrasonics, air bubbles can be problematic, but there are solutions, such as including a strainer that mitigates the bubbles, and installing the meter vertically rather than horizontally. This also works with substances like sodium hypochlorite, which can offgas and cause similar problems in meter accuracy to air bubbles in general.

Both types of meters are impacted by fluid temperature. The conductivity of a fluid changes with temperature, which can cause inaccuracy for mag meters, particularly at low flow rates. Similarly, ultrasonic signals will travel faster in warmer fluid than colder fluid. Thankfully, some meters have temperature sensors and built-in algorithms that allow them to compensate for temperature changes.

Mag meters require an invasive installation, which involves welding them in-line. Ultrasonics are often welded in place as

well. Clamp-on ultrasonic meters are less invasive and easier to install, although they tend to be less accurate since the pipe itself dampens the signal.

The lowest possible detectable flow rate will depend less on the technology and more on the manufacturer and the intended application. For example, meters for administered chemicals need to have very low flow ranges. Some, such as those offered by Blue-White Industries, can detect as low as 10 mL/min. This is ideal for municipal and industrial water treatment, when operators need to be as precise as possible to avoid overdosing with a given additive.

The type of liquid and its properties matter when selecting a meter. For example, mag meters will not work well with hydrocarbons, distilled water, and non-conductive solutions, as these liquids have little or no electrical charge. Ultrasonic meters will not work with a liquid that dampens sound, which includes some polymers and dense slurries.

Mag meters tend to be more expensive than ultrasonic meters, although exact prices vary depending on the manufacturer, pipe size, application, and more.

As with flow range, specific features will vary from product to product and manufacturer to manufacturer. Features like the above-mentioned strainer to reduce bubbles and temperature compensation algorithms are only available in some models.

Water treatment professionals should be sure to ask vendors about innovations that may be advantageous to the intended application before deciding.

Amparo Burke is with Blue‑White® Industries. Email: aburke@blue‑white.com

Flow meters are an important component in water treatment systems, and operators rely on their accuracy, particularly for chemical dosing and other low-flow processes.

The Northwest Inner City area of Calgary has recently experienced unprecedented flooding, the most devastating of which was the Bow River flood in 2013. This significant event refocused the city’s priorities in this area on drainage improvements. As such, in 2016, Associated Engineering updated the city’s Northwest Inner City Community Drainage Improvement Study.

Subsequently, in 2019, the City of Calgary initiated three community drainage improvement projects with three different consultants (MPE Engineering, GHD, and Associated Engineering) within the same geographic area. A year later, the city received funding through the Municipal Stimulus Program to design and construct the recommended drainage improvements. These were designed to mitigate risks to the communities, which were at the highest risk of flood recurrence.

The Municipal Stimulus Program funding stipulated that construction had to be completed by the end of 2021. To take advantage of the funding, the city had to reduce the detailed design and procurement schedule from one year to approximately six months.

To meet the tight schedule, the three consultant teams were directed to work with Associated Engineering, who would serve as lead consultant and manage the delivery of three community drainage improvement projects.

As lead consultant, Associated Engineering was responsible for aligning the designs and preparing templates to produce a single, cohesive request for proposal (RFP) for procurement of a contractor. The RFP would ultimately become the contract document, including special conditions, construction drawings, and technical specifications to deliver the overall project, while also considering and incorporating project specific elements.

The challenge was to deliver this work safely, minimizing community impacts and achieving the city’s design standards, while managing three consultant design teams, each with their own unique personality, design processes, and work environment. Viewing the projects as an overall program, defining project requirements, and considering the overlapping impacts and risks helped achieve the city’s goals.

When the provincial funding support was announced, the individual projects were already in various stages of design and construction document preparation. Adding to the program’s complexity were public safety measures related to the COVID-19 pandemic. The design teams had to transition to working remotely and using virtual communication tools and collaboration platforms for project meetings and document control. This virtual environment, project management, leadership, prompt decision making, and

clear communication helped to keep the project and development of the RFP on schedule.

The city received bids from three contractors. Employing evaluation criteria developed by Associated Engineering, it selected a contractor and awarded the construction contract for approximately four kilometres of storm system improvements valued at almost $30 million.

The project was successfully delivered in a challenging urban environment, overcoming pandemic-related supply chain constraints, and a compressed schedule. Key to the success of the project was the collaborative design and construction environment fostered between Associated Engineering, the three consultant design teams, the City of Calgary, and the contractor.

The project’s construction included approximately four kilometres of storm system improvements and was valued at almost $30 million.

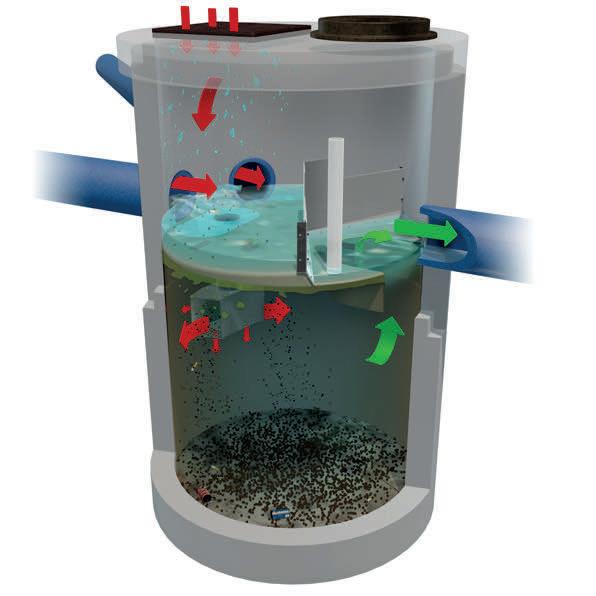

For most of the past 100 years, the predominant model for wastewater management has been the centralized wastewater treatment (CWWT) facility. In most developed economies, the benefits of such professional and effective sanitation have been enormous.

However, as our communities are embracing the need for greater sustainability, infrastructure security, and resilience, it may be time to evaluate and implement a more local alternative. This can be a distributed network of decentralized wastewater treatment (DWWT) and resource recovery facilities.

While the benefits of CWWT facilities are significant, there are inherent weaknesses. Servicing a large catchment area, they require an extensive network of large sewer lines that are costly to install and maintain, and are susceptible to increasing levels of leakage as they age.

By servicing myriad residential, commercial, institutional and industrial clients, a highly complex stream of raw sewage is discharged into an end-ofpipe treatment facility. This may make it

extremely difficult to recover resources (including water). Also, potential water reuse clients may be many kilometres from the plant.

Traditionally, CWWT facilities tend to be designed for a 25+ year horizon. This may often over-estimate or under-estimate the population growth within the community, and often places a significant financial burden on the community.

By its nature, a CWWT facility is a single point of vulnerability that could bring down all sanitation services to a large part of the community, should the operations be compromised by extreme weather events, power outages, operator error, physical or cyber terrorism, military conflict, etc.

Owing to its size and embedded cost, there is a level of inertia within the CWWT in terms of ability to evaluate and implement newer, more advanced treatment technologies beyond initial piloting activity.

DWWT refers to the practice of locat-

ing treatment equipment and processes close to points of wastewater generation. These include:

• Residential developments, including apartment buildings and small clusters of homes, up to the size of a rural village.

• Commercial and institutional facilities such as office buildings, shopping centres, schools, hotels and resorts, sports facilities, prisons, highway rest stops, etc.

• Light industrial facilities such as craft breweries and wineries, artisanal cheese producers, and similar (although these may also be described as pre-treatment operations when discharging into a municipal sewer system).

The overall vulnerability to disruptions in service from natural or man-made events would be limited to a relatively small group of clients, or mitigated completely, by shared service mechanisms. The system could also be brought back online faster with less cost or impact.

Superstorm Sandy in 2012 proved the resilience of distributed systems. The New York/New Jersey area was hit

Hotchkies, M.Eng., P.Eng.hard and flooding knocked out many of the low-lying sewage treatment systems. But, the dozens of on-site, distributed wastewater recycling systems in the region were all back up and running on generators 24 hours after the storm.

Grey and black water discharges can be treated at (or adjacent to) the point of generation for immediate reuse within or around the development for a range of non-potable applications. This significantly reduces the overall water footprint of the community.

Community development can progress faster and at a lower capital outlay. Development does not have to wait until connections are made to an existing sewer line (if one exists), or until new sewer services are run to the area. Smaller, local service area facilities can be constructed quickly and at lower cost with a shorter horizon, then expanded in modular increments to match development as required. Smaller diameter and shorter sewer lines would reduce the cost of deployment and would be better tailored to actual wastewater flows to the treatment works.

Today, many DWWT systems are modular and standardized around a range of flow-based sizes, with resulting benefits including:

• Lower upfront capital expenditure, with the ability to defer downstream expansion costs until supported by revenue from development charges.

• Faster and simpler construction.

• Smaller mechanical equipment, with the possibility of sharing spares and stand-by units with neighbouring DWWT facilities.

Billions of people around the world lack access to safe and effective sanitation, let alone sewage treatment, with significant health, economic, social, and political consequences. In these areas, the rapid deployment of smaller, affordable DWWT systems offers the only viable solution to approaching the United Nation’s Strategic Development Goal (SDG) 6: “By 2030, achieve access to adequate and equitable sanitation and hygiene for all and end open defecation, paying special attention to the needs of women and girls and those in vulnerable situations.”

Balancing these potential benefits, arguments against radical decentralization have held sway for many decades. In the past, small privately-owned and operated plants have tended to be staffed with less qualified operators in some areas. Multiple small, independent plants across a community may create more complex overall control issues.

Advanced treatment technologies may be more affordable and manageable at a large, centralized facility. Some resource recovery technologies have a return-on-investment threshold that favours larger treatment facilities. Poorly designed and constructed decentralized plants can be an expensive burden to the community if abandoned by an independent operator. Significantly, an entire design community, product and service supply chain, and regulatory approvals mechanism has evolved over many decades around the large CWWT utility.

Despite these arguments, DWWT systems have recently improved, with advances in product and process technology, remote monitoring, and systems management. There is also an urgent global need to address sustainability and resilience. As such, it may be time for the water sector to look at emulating the successful migration away from the monolithic utility model that we have seen happen within the energy and communications sectors.

Today, we no longer require the technical, physical and financial mass of a CWWT facility to ensure our communities have reliable, effective and affordable sanitation. Rather, with easy access to advanced technologies from a global supply network, and by leveraging the developments in communications and inter-connectivity, we can access these benefits while enhancing our water security and resource optimization.

continued overleaf…DWWT solutions offer many potential benefits, especially for communities considering new greenfield wastewater treatment facilities, and for upgrading existing decentralized municipal treatment works to meet new loading and/ or effluent discharge criteria. Centralized utilities can extend coverage into an expanded urban or peri-urban envelope.

However, in order to extract the maximum benefit, the deployment of DWWT infrastructure should be carefully planned, coordinated and executed according to best practices.

Borrowing from the IT sector, regional utilities may consider exploring distributed decentralized wastewater treatment (D2WWT) wherein a network of DWWT facilities are owned, operated and managed by a central entity, in a hub and spoke arrangement.

This would involve common, standardized designs, construction and operating parameters, interchangeability of parts,

load sharing where interconnection with small diameter pressure lines is practical and beneficial, and centralized monitoring, operations management, and back-office services.

It is important to segregate sanitary and process (industrial) streams and only allow process streams that have been fully pretreated to typical sanitary wastewater characteristics into any community treatment works. All industrial clients would need to treat all internal wastewater streams to a quality level suitable for direct in-house reuse, and to transfer any “non-treatable” effluent to an off-site, industrial wastewater management facility.

It is also important to establish a realistic set of final effluent quality criteria to be achieved by any DWWT facility within the catchment area. For any single on-site DWWT facility or for any community network of DWWT facilities, develop a water footprint reduction strategy that maximizes on-site and/or local water reuse.

For any network of DWWT facilities where each individual site may be too small to adopt resource recovery technologies (such as phosphorus recovery), consider establishing a hub and spoke model, wherein a centralized recovery facility can be established to aggregate feed from the treatment nodes for cost-effective recovery.

Any DWWT facility external to a centrally managed network will need the following:

• A n operating system that can be continually monitored, or will send out alerts when key functional parameters are exceeded.

• On-site stock of spares for all key mechanical, instrumentation, or other process-critical equipment.

• A cloud-based log of required analytical data (as required by the system vendor), and permit criteria fully accessible by the permitting agency.

• An operations and maintenance protocol and log that reflects the base requirements of the system vendor, updated annually to reflect application, or site specific conditions.

In some cases, the advantages and benefits of the CWWT facility will continue to outweigh any other alternatives. But, for many communities and applications, advances in technologies, processes and products have now overcome many of the barriers or objections to the deployment of widespread DWWT systems.

These systems represent a viable option to address our growing concerns over water scarcity, infrastructure security and resilience, and the urgent need to provide access to safe and effective sanitation for the billions of people around the world without any infrastructure.

This article was adapted from a whitepaper written by the author entitled “Decentralized and Distributed Wastewater Management”, for the Ontario Society of Professional Engineers (OSPE). OSPE assumes no liability or responsibility regarding adaptation from the original content. References are available upon request.

VEGA’s commitment to providing the best process measurement solutions means more than just producing precise and reliable instrumentation; it means being there whenever you face a challenging measurement application. That’s why VEGA is proud to now o er direct sales and support to the Atlantic Provinces. SOME

Per- and polyfluoroalkyl substances (PFAS) are a broad category of fluoropolymer, synthetic substances that are widely used in the manufacture of non-stick cookware, water-repellant textiles, stain-resistant carpets, chrome-plating, and semiconductors. Due to their strong fluorine-carbon bonds, PFAS have been repeatedly demonstrated to be pervasive and persistent environmental contaminants, aptly earning the name “forever chemicals”.

Their significance, however, is not limited only to environmental degradation but extends to their contentious effects on human health. Exposure to the hazards and toxicity of PFAS in drinking water has been a worrisome reality worldwide. As such, many methods have been used to test its presence in human biological fluids, including whole blood, blood serum, breast milk, as well as hair.

At this stage, Ontario has not yet regulated these compounds under the current site assessment structure. However, this will likely change in the coming years, given the extent to which these types of chemicals exist in the environment due to human activities. Most environmental remediation summits and conferences now touch upon how environmental professionals are planning to mitigate the effects of these chemicals on humans in the future.

Blood serum testing for PFAS has been the dominant method for quantitative analysis. However, it comes with a set of challenges. Traditionally, a larger volume of whole blood is drawn from a patient’s vein and safely transported to a laboratory, where the serum is separated. This is a time and cost-ineffective process.

The other approach is extracting and analyzing whole blood from minute dried blood spots. However, this results in a loss of accuracy, because volumes of whole blood present in these spots can vary significantly.

To overcome these challenges, Eurofins Scientific has developed a sampling approach introducing a new generation of specialized volumetric absorptive micro samplers (VAMs). These are equipped with a proprietary absorptive hydrophilic polymer that precisely measures 30 µL of whole blood extracted through a single finger prick. This design was specifically developed for the ease of self-collection, packaging and transport for quantitative analysis.

A study was performed to evaluate this novel VAMs approach against other sampling methods. It concluded that it is well suited to characterize a variety of PFAS concentrations in the blood with high accuracy.

While VAMs seems like a promising sampling option for

epidemiological studies of PFAS in large-scale biomonitoring programs, or for individuals interested in knowing PFAS levels in their blood, it is uncertain as to how much of the population will endeavour to ascertain these concentrations.

It may require medical professionals to urge such tests to be routine as a part of annual physicals, etc. The reason being that it is expected that a very large swath of the human population may have significant concentrations of the subject chemicals that, if left unchecked, will impact our collective health down the road.

Beniz D’Souza is with the City of London. Email: dsouza.beniz@gmail.com. Sajjad Din is a professor at Centennial College. Email: ofotd1@gmail.com

Reference: Self-Collection Blood Test for PFASs: Comparing Volumetric Microsamplers with a Traditional Serum Approach. Courtney C. Carignan, Rachel A. Bauer, Andrew Patterson, Thep Phomsopha, Eric Redman, Heather M. Stapleton, and Christopher P. Higgins. Environmental Science & Technology 2023 57 (21), 7950-7957.

Blood serum testing for PFAS has been the dominant method for quantitative analysis. Credit: muhammad, stock.adobe.com

Maintaining an efficient and reliable sewer system is a critical task for any city. As urban areas grow, the capacity demands on sewer infrastructure increase. To meet these challenges, innovative technologies are being employed to streamline maintenance processes and reduce costs.

One such technology is acoustic inspection, which is a fast, low-cost, and highly effective method for assessing small-diameter gravity sewer lines. Already being used across Ontario, aggregated data suggests the device has helped utilities cut costs while increasing inspection efficiency.

The Sewer Line Rapid Assessment Tool, or SL-RAT®, by InfoSense Inc., is comprised of a transmitter and a receiver. The transmitter is placed atop an open manhole and emits a series of tones. These acoustic waves travel into the airspace within the sewer pipe. Positioned on the adjacent manhole, the receiver listens for these known tones and assigns a score to the pipe segment based on how much sound it transmits.

Scores range from 0 to 10, with 0 indicating a completely obstructed pipe and 10 representing a pipe with excess flow capacity. By utilizing acoustic inspection, cities can shift from traditional reactive or time-based maintenance strategies to a more efficient, condition-based approach.

Instead of allocating resources evenly or waiting for a

problem to arise, this method first determines general blockage locations and then focuses cleaning efforts on pipes that require immediate attention. As a result, this proactive strategy allows for targeted maintenance, lowering costs while reducing risk in one’s system.

Since 2017, nine cities in Ontario have adopted acoustic inspection as a condition-based maintenance strategy. These cities have collectively measured over 3,500 kilometres of gravity sewer lines using the SL-RAT.

Looking at over 52,000 measurements taken during the sixyear period, the data shows a large majority of each city’s collection system is unobstructed. Over 75% of all the lines measured were scored as “good” by the SL-RAT. Pipes receiving this rating have excess flow capacity and require no further maintenance.

By identifying these unblocked pipe segments, attention and resources can be redirected toward addressing lines that

A RATS team can inspect a larger portion of a system in a shorter amount of time compared to other methods.the SL-RAT scored low. In the case of Ontario, less than 10% of lines scored below a 4. This totals around 275 kilometres between all nine cities.

With a cost of cleaning ranging from $3.00 to $5.00 per metre, the total cleaning cost for every blocked line can be estimated between $825,000 to $1,375,000. Comparatively, it would cost between $10,000,000 to $17,000,000 to clean all 3,500 kilometres measured with the SL-RAT.

The data also shows increased efficiency. On average, the nine cities could measure 750 metres per hour. As InfoSense CEO, Alex Churchill, puts it: “One key benefit of SL-RAT is an increased inspection scale. You are only going to find problems where you are looking.”

Since SL-RAT measurements take less than three minutes without flow contact, a two-person SL-RAT team can inspect a larger portion of their system in a shorter amount of time compared to more traditional inspection methods.

The efficacy of the acoustic inspection device has not been limited to Ontario alone. Hundreds of communities worldwide have embraced this technology. By

By identifying unblocked pipe segments, attention and resources can be redirected toward addressing lines that the SL-RAT scored low. In the case of Ontario, less than 10% of lines measured scored below a 4.

employing it, cities can make informed maintenance decisions, maximize their resources, and ensure the longevity and efficiency of their vital sewer systems. As technology continues to evolve, acoustic inspection paves the way for more sustainable and resilient infrastructure management.

Chase Mendell is with InfoSense Inc., who are represented in Canada by Rapid Assessment Technology Services (RATS) Inc. For more information, email: sales@ratsinc.ca

By ES&E Staff

By ES&E Staff

Aformer Smiths Falls water treatment plant with two heritage designations was severely damaged in a May fire. Now, local officials of the eastern Ontario town are weighing demolition versus stabilization, which both have a “similar order of magnitude,” according to an engineering report.

G. Douglas Vallee Limited presented its structural pathology engineering report to the Smiths Falls council in late July. It estimates that the ballpark figure of $500,000 would be a reasonable starting figure for either razing the property or stabilizing it and restoring damaged masonry walls.

The three-storey sandstone building along the Rideau Canal dates back to 1868 when it was built as a grist mill. The town

purchased it in 1910 as a waterworks and made several additions. Ultimately, it was decommissioned in 2010 after providing drinking water for more than a century. The Smiths Falls Waterworks Building Complex was designated as a heritage property in 1977 for its historic and architectural value.

“The option to stabilize and restore the masonry improves the safety of the site while protecting the heritage integrity of the buildings,” states the engineering report. “This option is similar (same order of magnitude) yet understandably more expensive than demolition. If there is a foreseeable vision for the future development of this site and the will to preserve the historic structure, this option is feasible and economically responsible in the long term if the heritage value of the site is considered.”

Leaving the Smiths Falls structures as is was not recommended as a course of action, primarily considering that the report states that there are “environmental events that could cause partial collapse of the stone masonry wall.”

Redevelopment plans for the historic building had been well underway prior to the spring 2023 fire, the cause of which remains unknown. Plans that had been in the works include maintaining the historic elements of the architecture while converting the site into a wedding and meeting venue, as well as condominiums, with construction starting as soon as 2026.

The Smiths Falls municipal heritage committee has expressed a desire to preserve what is left of the site after the fire.

Local officials had previously commissioned a separate engineering report that had recommended “immediate demolition,” but decided to seek out a second opinion before tearing down the site.

For more information, email: editor@esemag.com

The Smiths Falls Waterworks Building Complex was designated as a heritage property in 1977 for its historic and architectural value.

Credit: G. Douglas Vallee Limited

The Smiths Falls Waterworks Building Complex was designated as a heritage property in 1977 for its historic and architectural value.

Credit: G. Douglas Vallee Limited

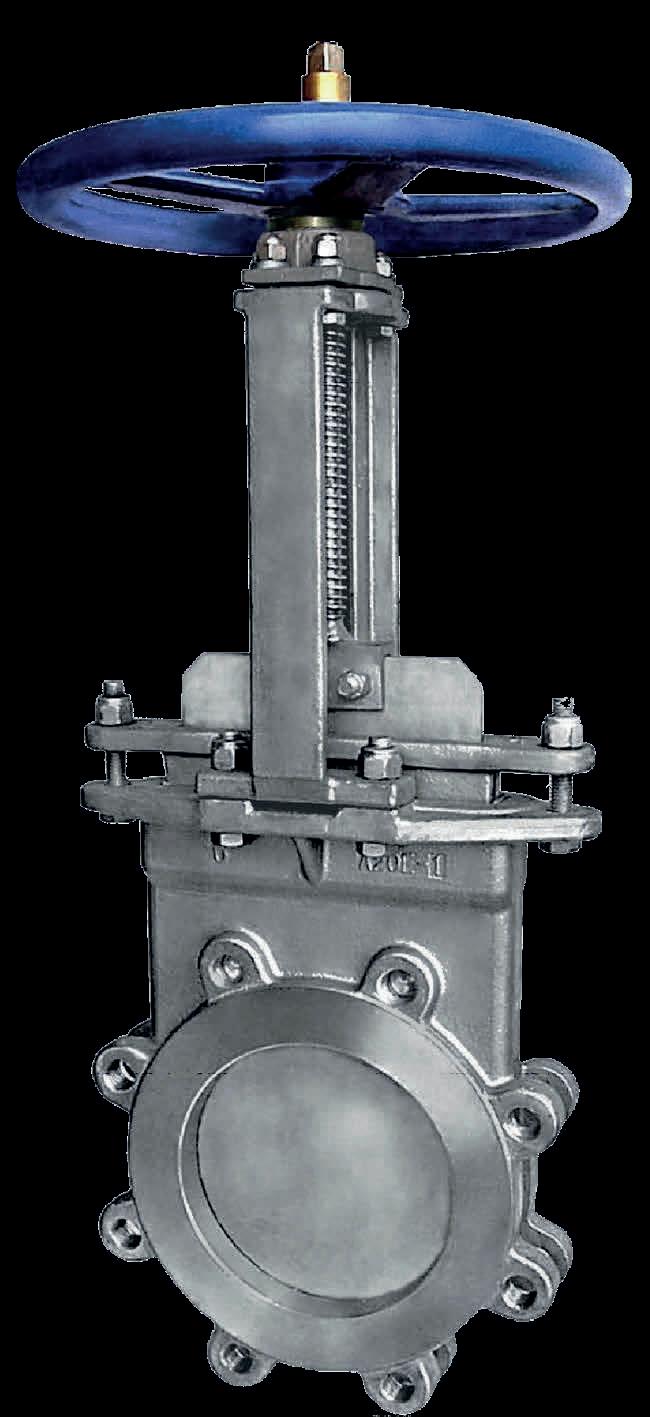

Equipped with superb sealing capabilities and built to meet the rigorous MSS-SP-81, AWWA C520-10, and TAPPI-TIS 405-8 standards, the Pratt® Knife Gate Valve is the ultimate solution for a range of applications in industries, including mining, chemical, food/beverage, and pulp and paper.

Specifically engineered to handle tough slurries and abrasive materials with ease.360 degree wrap-around packing with first row elastomer seal Gate reinforced by a PTFE bearing incorporated into the seat Seat loads into the body through the packing chamber VISIT

Heat regeneration (or heat recovery) is the mechanism whereby heat from a process, which would otherwise be lost or wasted, is recaptured and used for useful heating purposes. Heat regeneration should not be confused with “regenerative heat exchangers”. These are a specific type of heat exchanger in which the product and service fluids flow alternately, and the heat is stored in the structure of the heat exchanger.

When we talk about heat regeneration, we mean the recovery of as much surplus heat (or cooling capacity) as possible after the primary function of the heat exchanger has been performed. This can then be reused to either improve the efficiency of the heat exchange process or used elsewhere. Recovery and reuse of industrial waste heat is an attractive concept that could simultaneously reduce energy costs and CO2 emissions.

Given the importance of energy efficiency in reducing the use of fossil fuels and greenhouse gas (GHG) emissions, it can be argued that it is imperative to employ heat regeneration and recovery at every opportunity. As at least one research paper has pointed out, the use of excess heat could also be important to improve the economic and climate footprint feasibility of new processes, by avoiding the addition of new heat production capacity.

Heat recovery improves the energy efficiency of heat exchange processes, so the greatest benefit of heat regeneration (recovery) is that less energy is required for a particular heating or cooling operation. This obviously provides financial benefits, but is also better for the environment compared to systems without heat recovery.

Repurposing recovered heat can also reduce the amount required for certain processes. For example, if a material is

pre-heated with recovered heat, then it may be possible to complete the necessary heating (for example, pasteurization) using hot water from another source or part of the factory. This is instead of requiring a dedicated boiler to provide the necessary temperature rise.

By increasing the energy efficiency of the heat transfer process, heat recovery can also make it possible to reduce the size of the heat exchange equipment required, or reduce the necessary processing time.

One example can be found in food processes, where products such as cream need to be heated to the necessary temperature to achieve pasteurization, then rapidly cooled to maintain shelf life and quality. Such systems involve the use of

two heat exchangers. One uses hot water to raise the temperature, while the second uses chilled water to cool the cream down again.

The cooling process produces warm water which can be discarded, cooled for reuse, or cooled with some of the heat contained being used to pre-heat the cream before the pasteurization process. This last option utilizes heat recovery or heat regeneration, reducing the amount of new energy required for the subsequent first heating phases.

As another example, many biogas plants use heat exchangers to pasteurize the digestate produced during the anaerobic digestion (AD) process. The “surplus” heat which is generated after the system has been running can also be used to pre-heat the digestate, reducing total heat load and improving overall efficiency.

Water which has been heated by cooling food products can be used to pre-heat the same product ahead of pasteurization, reducing the overall energy requirement.Heat recovery can also be used in gaseous applications. Whether it is using the heat from the flue gas of a biogas combined heat and power (CHP) engine to pre-heat digestate, or a large gas-togas heat exchanger to capture waste heat from chemical processing, there is no reason to waste the heat present in gaseous products or waste streams.

Perhaps the most common use of heat regeneration is demonstrated in multi-effect evaporation systems, where several heat exchangers are combined. In HRS’s DCS digestate concentration system, the first evaporation stage heats liquid digestate and uses a cyclone separator. Steam produced from this first cycle is then used as the heating media for the second effect, whereby the process is repeated. The subsequent steam is then used as the heating media for the third cycle.

The number of effects is determined by the level of dry solids required and the amount of surplus heat available, up to a maximum of four cycles. After the final stage, the steam is condensed back to water and this heat is used to pre-heat the incoming product before the first stage of evaporation. In all, the heat is regenerated up to four times in the process.

To determine the potential value of waste heat, and what it can be used for, it is necessary to know the process temperature, the product and heating (or cooling) medium being used, and the performance of the heat exchange process in terms of heat transfer area and flow rate.

It is therefore important to consider energy regeneration or recovery as early as possible. Heat recovery systems can be retrofitted to many processes, but their design is often a compromise. As such, retrofitted solutions may involve excessive pipework and other connections.

To maximize the benefits of heat regeneration, it is important that waste heat is transferred to the storage media (e.g., water or thermal transfer fluid such as glycol) as soon as possible after its source. This is particularly true where waste heat is in the form of a gas. It has a much greater energy constant than liquid, meaning that the heat is lost much faster. By considering all these factors, it

will be possible to calculate both the additional capital costs associated with specifying heat regeneration in a project, together with the savings in running costs and energy. Then, the return on investment for the project can be calculated. Although capital costs may be higher, the longer term financial and environmental benefits will make

the use of heat regeneration in heat exchanger projects highly attractive.

Matt Hale is with HRS Heat Exchangers. Email: info@us.hrs he.com

We understand the challenge of finding the right balance between plant efficiency and compliance with industry standards and legal requirements.

Hamilton became a city in 1846 and was the second one in Canada to create its own water system. Up until 1955, lead water services were used in plumbing, and lead was the standard material used in soldering up until the 1990s. When the health risks associated with lead became known, the city anticipated that this would be an issue with so many old homes and old infrastructure.

Nick Winters, director of Hamilton Water, said: “Lead plumbing material is an issue for the City of Hamilton, our residents, and our industrial, institutional and commercial customers as well. So, we knew it would take multiple approaches to identify the extent of the problem and different tactics to mitigate the effects of lead as quickly as possible.”

The city has 154,352 water service lines and about 20,000 homes built before 1955 that may have a lead water service line connecting them to the municipal water supply. Determining the extent of the issue involved identification of lead plumbing, sampling, education, and if necessary, replacement. As this cost is the homeowner’s responsibility, service line replacement can be challenging for some residents.

The city conducted a lead sampling program that confirmed that more than 10% of the lead samples taken from residential plumbing systems with water service lines exceeded 10 micrograms of lead per litre (μg/L). The maximum acceptable concentration (MAC) for lead set by Ontario Regulation 169/03 is 10 micrograms per litre. In 2019, the acceptable level set by Health Canada was lowered from 10 micrograms per litre to 5 micrograms per litre.

While there are no lead watermains in the city, there are lead service lines on public property that need to be identified and should be replaced. Dealing with both residential and municipal identification and replacement would take years, even though the city was committed to starting work right away.

“We recognized that we needed an interim solution that would have a more immediate effect while the replacement program was underway, and this led to the implementation of a corrosion control program (CCP),” said Winters.

In November 2018, the city started adding a phosphate-based inhibitor in the Woodward Avenue Drinking Water Sub System (DWSS), where lead sampling results exceeded the MAC by Ontario Regulation 169/03. Orthophosphate creates a protective barrier inside pipes, which reduces the release of metals such as lead and copper from household plumbing. Phosphorus is an essential nutrient and an approved safe additive to drinking water. The estimated average requirement of phosphorus for adults is 580 mg per day. The city’s addition of orthophosphate amounts to an increase of no more than 1 mg/L.

The city spent $987,000 on the design, and $6.2 million on the construction of the orthophosphate addition building at the Woodward Water Treatment Facility. The ongoing cost of maintaining the CCP is about $311,000 per year.

To monitor the effectiveness of the program the city did pre-implementation sampling, so they had a baseline, and then post-implementation sampling to monitor the effectiveness of the lead control.

The city installed three lead pipe loops in the Woodward Avenue DWSS as an additional tool to monitor the effectiveness of the corrosion control. Monthly lead samples showed an overall decreasing trend. Post implementation, the lead values at all three locations were below the Health Canada limit of 5 µg/L.

Winters said: “We expect the lead levels will continue to decrease as the scale thickens and strengthens from continued exposure to orthophosphate. The CCP results have been very effective in a short period of time. It is an important program as it helps protect residents who can’t afford to replace the private-owned portion of their lead pipe, and those properties that don’t have lead supply pipes but still have leaded-brass fixtures and lead solder in their internal plumbing.”

Secondary impacts stemming from the addition of orthophosphate were also observed in the distribution system. Although pre-filter orthophosphate dosing has contributed significantly toward reducing treated water aluminum levels, precipitation of orthophosphate with aluminum was observed within the distribution system. This impact was controlled through flushing and

Use PROMO CODE “ESE15” to get 15% OFF registration fees! Learn more and register today: www.canect.net

November 14 – 15, 2023 Vaughan, ON and Virtually

The Fall CANECT Essentials Conference features practical and interactive courses, led by experts in environmental regulations, best practices and due diligence.

Always on the cutting edge of new regulations and policies, CANECT’s courses are consistently being updated and renewed with fresh content every six months to ensure that only the most up-to-date information is delivered.

Constant re-evaluation by the editors and staff at Environmental Science & Engineering Magazine and CANECT session chairs ensures that our

faculty of expert speakers, the topics they present, and the handout materials they develop reflect the highest standards of relevance and practical application.

That’s why CANECT’s courses continue to be the #1 choice of both experienced environmental practitioners, speakers, partners and sponsors, as well as those new to the field.

did not contribute to aesthetic impairment noticeable to customers.

The city estimated that there was a total of 20,000 substandard/lead water service lines (LWSLs) within the Woodward Avenue DWSS at the end of 2021. It has had a sub-standard water service line replacement program for over 30 years to address customer requests related to pressure or other concerns (such as undersized services or leaks). Over the last 10 to 15 years, as the awareness of health risks associated with lead became apparent, the focus of the program shifted from poor pressure to sub-standard/LWSL replacements.

In this program, the city replaces the sub-standard material up to the property line (public portion), when the homeowner replaces the privately-owned portion.

“There are potential health impacts that can result from mixed plumbing types, and also the possibility that a new 25-mm public water service line can cause

increased flow and pressure on a private service line. As such, we are opposed to replacing the public water service line prior to the private water service line replacement. From 2017 to October 2022, we have replaced over 4,589 sub-standard service lines,” said Winters.

The first step for residents was to understand the health risks associated with lead and what they can do about it. The city completed a 29,498 mailout to all homes built before 1955, or that had a known lead service line, or an unknown service type. In true transparency and to reach every resident, the city also inserted lead awareness pamphlets into all billing statements and their newsletter and launched an advertising campaign. To help homeowners determine if they have lead pipes, the city made an informative identification video. Residents are also able to call the city and book a free inspection.

All this information is available on the lead awareness website (www.hamilton.ca/

leadpipes) and the corrosion control website (www.hamilton.ca/corrosioncontrol).

“Our goal was to ensure every resident knew about the risk associated with lead and were aware of what we were already doing, but more importantly what we still need to do together to protect all residents,” said Winters.

On August 11, 2022, a change was made to amend Hamilton’s Property Standards By-Law, backed by a staff recommendation, that obligates Hamilton homeowners to switch out their portion of lead water service line to match the city’s current standards.

Winters said: “In order for us to eliminate all the lead service lines in Hamilton, we need the remaining homes to have their lead pipes replaced. This new by-law will help us achieve this goal in protecting all our residents. While we can’t cover the costs of upgrading private infrastructure, we have provided a loan program to

make it more affordable for homeowners.”

The city offers a $2,500 interest-bearing loan for property owners who would like to replace their lead water line. To make it easy, the loan, including interest, is transferred to the owner’s monthly water bill for a maximum 10 year repayment period. In addition, homeowners who have qualified for low-income energy customer support programs such as LEAP (low-income energy assistance program) or OESP (Ontario electricity support program) are eligible for a zero-interest loan to cover the cost of the replacement. The loan remains interest-free unless the customer defaults on payments.

Roughly 175 to 200 loans are issued every year to homeowners to replace their lead lines.

The city also has a program that provides tap filters approved for lead removal by the National Sanitation Foundation (NSF/ANSI53). These filters are provided to any residents that have a lead line

and after each private water service line upgrade. This allows the resident to minimize any impacts resulting from mixed plumbing types until the public portion is replaced.

Currently the public water service lines are being replaced approximately four to eight weeks after the private side is completed due to backlog. When the program started in 2017, 221 lead filter kits were handed out, since then more than 125 kits have been provided to residents by the city. In 2020, the city amended the program to provide a jug and three filters to homeowners when a lead filter kit is requested.

The cost of the lead program to the city is approximately $3.5 million dollars a year, which includes water service line replacements, education, sampling, testing and pilot testing.

The corrosion control plan results are extremely good and pipe replacement is accelerating. “Initially we expected

it might take 30 to 40 years to find and replace all the lead lines in the city. But, with the public on our side and over $1.38 million already committed in our loan program, we have effectively reduced this time frame by 10 years, since we started in 2017. We also had to manage the pandemic during this time, so we are optimistic that reducing this time frame further is still possible,” concluded Winters.

Hamilton’s water is tested over 46,000 times a year to ensure residents can trust that is safe to drink and that the city is continuing to be proactive to keep it this way.

Susan Girt and Dave Alberton are with Hamilton Water. For more information, email: susan.girt@hamilton.ca, or dave.alberton@hamilton.ca

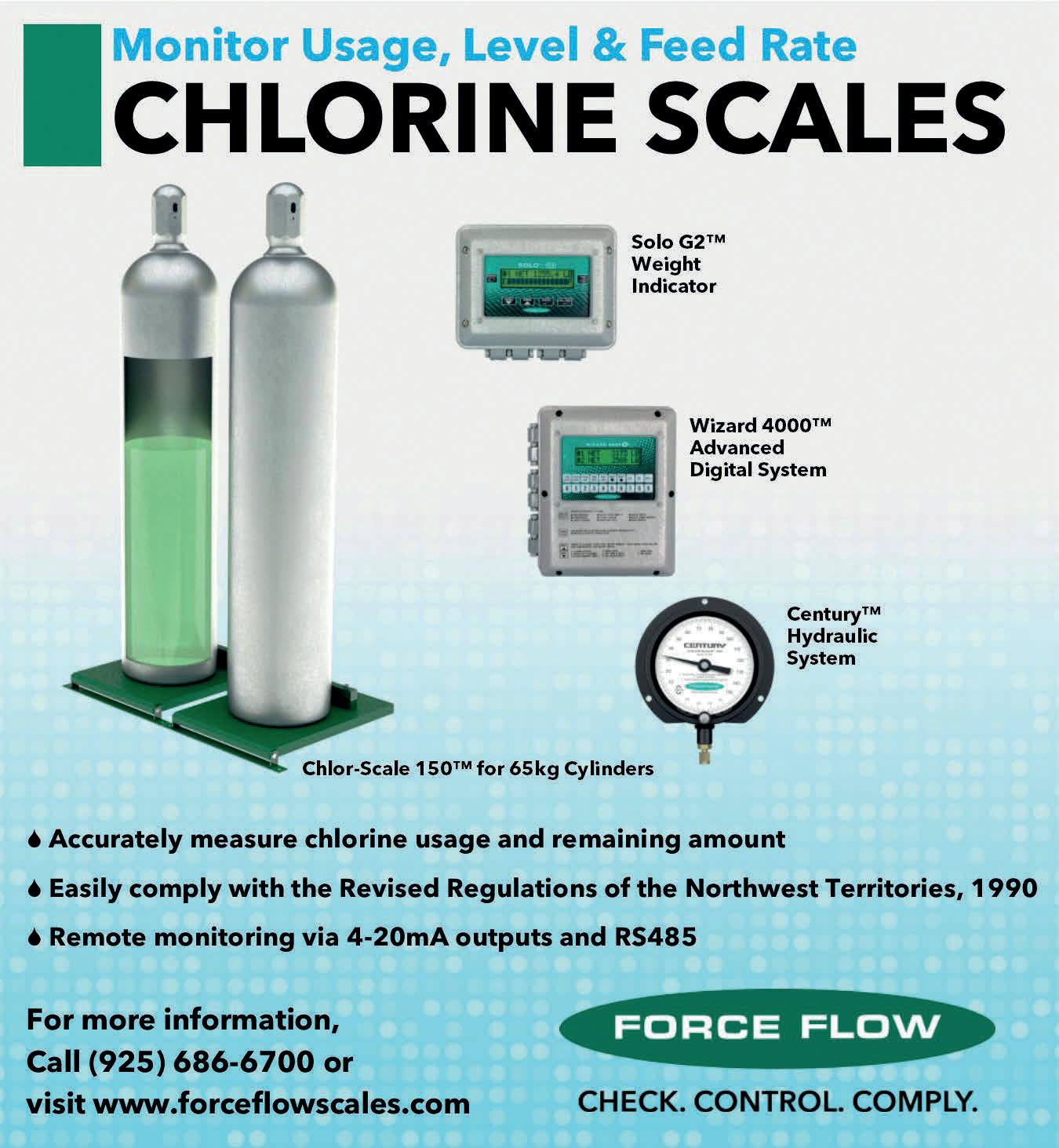

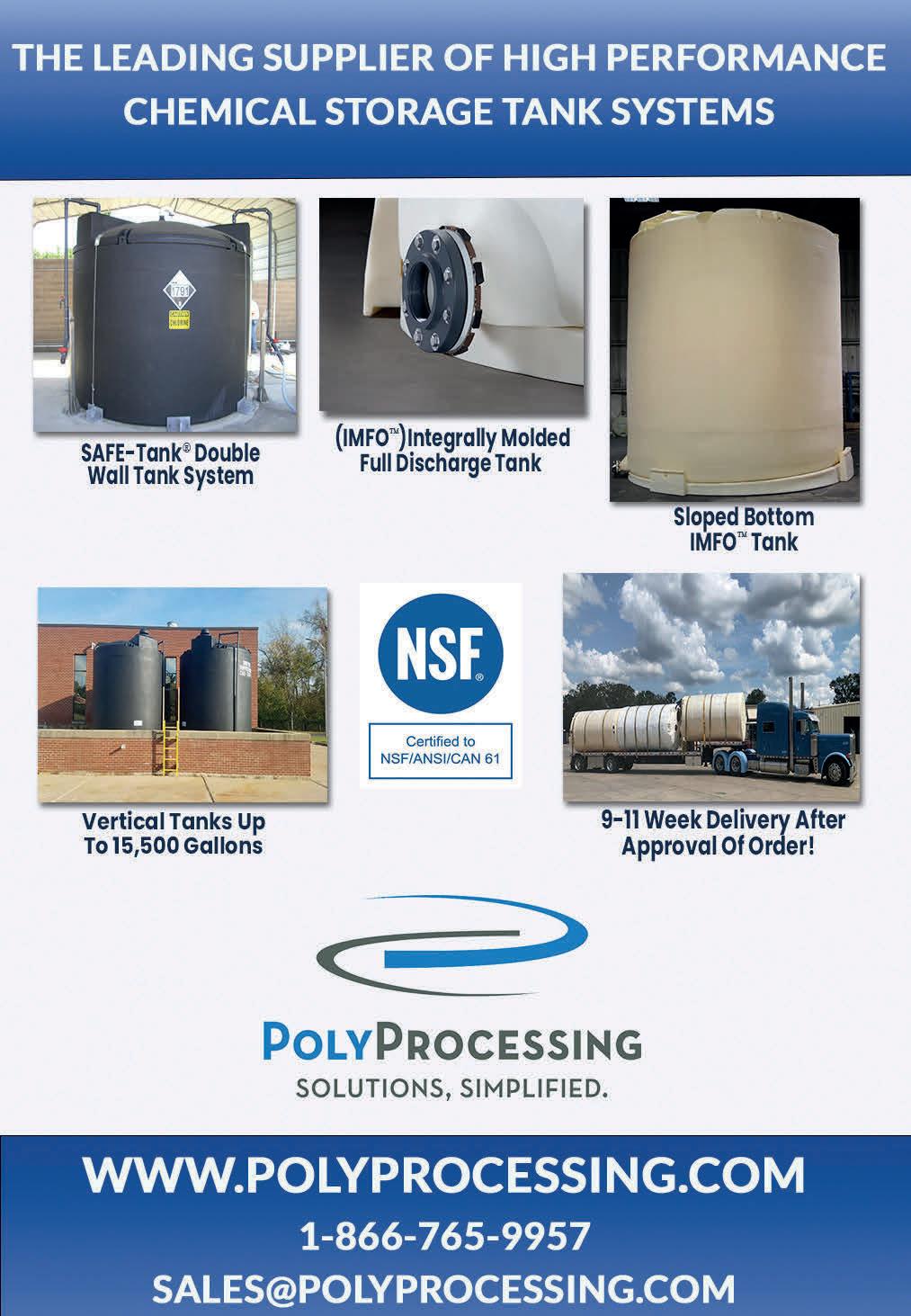

In addition to physical and biological treatment, wastewater treatment requires aggressive usage of large amounts of chemicals, so safe storage of them is always an important consideration.

To facilitate the removal of solid particles within wastewater, chemicals such as ferric chloride, polymers and alums are used to produce positive charges. These are intended to neutralize negatively charged solid particles. As a result, the solid particles clump together, making removal easier. Since more solids exist in wastewater than municipal drinking water, more chemicals are required for this coagulation process.

Neutralization, or the adjustment of the pH levels of wastewater with the addition of an acid or a base, is common in wastewater treatment. Either sulfuric acid or another base chemical (typically sodium hydroxide) may be added to the water to achieve optimal pH balance.

The collection and treatment of industrial wastewater can result in some unpleasant odours. Chemical treatment is used to control them, in addition to activated carbon and wet scrubbers. It is very common to see sodium hydroxide, calcium nitrate and hydrochloric acid used in these processes.

To prevent the spread of disease, microorganisms that are pathogens must be destroyed or removed from wastewater. A common, relatively safe, and inexpensive disinfecting chemical is sodium hypochlorite.

Finally, a polymer chemical is typically used to remove water from sludge to reduce volume, making transporting the sludge to the landfill easier and less expensive.

is built should start with the chemical involved. Thoroughly understanding the nuances of the chemical’s properties is vital to maximize the operation and performance of the chemical delivery system, as well as the longevity of the chemical storage tank.

The storage tank is the headworks of the system, so it is a critical component of the overall process involving the use of the chemical. If the design of the storage tank is wrong, it could lead to serious problems. If you simply design a tank based on generic factors such as size, material and capacity without defining the chemical used, you risk getting a non-optimal tank.

and flow meters—all essential parts for proper operation—could potentially be compromised.

Sodium hypochlorite is one of the most common chemicals used to eliminate bacteria and viruses, especially towards the end of the process, in the disinfection stage.

It presents several major chemical storage challenges, including breakdown under UV light exposure; the fact that it tends to contain transition metals such as nickel, iron and copper that accumulate in the tank and create off-gassing exposure; and that it aggressively oxidizes.

Since sodium hypochlorite is an aggressive oxidizer, the opportunity for it to escape the storage tank must be lim-

Every chemical storage system that continued overleaf…

Also, it is important to consider the effect that chemical properties have on the other component parts of the storage system. Valves, fittings, pumps

If you simply design a tank based on generic factors such as size, material and capacity without defining the chemical used within the tank, you risk getting a non-optimal tank.

Sewage sludge dewatering offers a wide range of potential savings for operators of wastewater treatment plants. The cost of transport and disposal of dewatered solids can amount to as much as 80% of the operating costs of mechanical dewatering. Since dryer solids result in less volume for disposal, the decision to invest in an efficient, reliable and, above all, peakperforming dewatering system is critically important to reducing operating costs.

“The Flottweg centrifuges and the dryer biosolids they produce have saved us about $900,000 annually. Our plant was able to incinerate the dryer sludge without the aid of natural gas, which equated to our high savings. The Flottweg centrifuges also produce cleaner and more consistent centrate.”

ited through wetted connections and side fittings. This will reduce leak paths that can cause damage. In addition to oxidation, sodium hypochlorite is sensitive to transition metals found in some common tank fittings. These will quickly degrade the chemical, while causing off-gassing and even more aggressive oxidation.

One key to storing sodium hypochlorite is to use carbon black, white, or gray compound cross-linked polyethylene (XLPE) resin to dramatically reduce UV degradation of the chemical, as well as mastic coatings and insulation. XLPE is excellent for strength and chemical compatibility, and using an antioxidant inner resin prevents oxidation. This combination seamlessly bonds the engineered interior antioxidation resin with a maximum strength outer surface.

To prevent the potential buildup of transition metals in the tank, a molded, full discharge fitting like the Poly Processing IMFO® system must be used. This special, integrated flange is molded into the tank, preventing chemical con-

tact with any surfaces other than polyethylene. It also allows for full discharge/ drainage of the tank, which can greatly increase the half-life of the chemical. Any additional fittings should be PVC.

Any gaskets should be made of EDPM or Viton GF to meet NSF-61 Certification. Should bolts be needed, titanium is a good choice, in order to mitigate the risk of off-gassing.

Sulfuric acid is the most commonly used acid in the world, and is often used during wastewater neutralization. Proper storage presents two main challenges: the weight of the chemical, and its nature as an aggressive oxidizer.

The inherent weight of sulfuric acid requires a strong material to withstand the static load pressure pushing on the bottom third of the storage tank. When storing sulfuric acid, it is important to verify the hoop stress rating and understand specific gravity ratings, ensuring the resins used in the storage tank provide a mar-

gin of safety. Volume changes and temperature variations affect the tank walls as well. In addition, the concentration weight will limit the size of the storage tank.

Sulfuric acid is also an aggressive oxidizer, meaning safeguards are required to prevent structural degradation of the tank’s polyethylene material. Such damage can result in leaks or failure of the tank.

The molecular strength of XLPE and thicker tank walls can provide the structural support required for storing this heavy chemical. These aspects are particularly important in the bottom third of the tank, where high levels of load are concentrated.

If secondary containment is present, a molded full discharge fitting instead of mechanical fittings, will maximize the tank’s structural integrity. Combining this tank design with an antioxidant resin system will reduce oxidation dramatically.

If secondary containment is not present, a double wall system is recommended. Along with containing the chemical from its surrounding environment, these double-walled tanks greatly lower the risk of hazardous contact of sulfuric acid with water.

Polymers are used in the headworks of wastewater treatment to facilitate flocculation. They also aid in the dewatering of digester cake, thus reducing the volume of waste materials needed to be disposed of.

Because polymers are very slippery chemicals, there is always a danger of slips and falls resulting from spills or leaks. In addition, polymers can be an environmental stress crack agent.

A full discharge fitting system is ideal for sludge control and ease of cleaning, since the tank drains at its true bottom. Heat pads and insulation can help keep the chemicals at the optimal temperature, greatly reducing the chance of separation and settling.

Using XLPE tanks will allow for greater expansion and contraction, while maintaining structural integrity, and thus lessening the risk for tank failure. A mixing system can also be installed to keep the chemicals from separating.

Tanks for these types of chemicals require titanium bolt material, while stainless steel bolts should be used for aluminum sulfate and various other polymers. A SAFE Surge® manway cover is recommended on pneumatically loaded systems to support tank longevity.

Sodium hydroxide is commonly used in wastewater treatment to adjust or neutralize the base pH levels. Similar in use to sulfuric acid, it can balance the wastewater pH. Sodium hydroxide is another “slippery” chemical that tends to find weak points under storage. It is also highly corrosive to human skin and toxic if ingested, making exposure to workers a potential danger.

In addition, if sodium hydroxide is not stored at appropriate temperatures, the chemical will crystallize and turn into a solid. This results in unnecessary chemical waste and damage to the storage system itself.

The key to storing sodium hydroxide properly is strong, safe containment. Since the chemical is so corrosive, secondary containment is a must. If secondary containment is available, a full discharge tank is recommended. Full discharge fitting systems are ideal for sodium hydroxide systems because their flange is a molded part of the tank and not an insert that could leak or fail.

A full discharge outlet eliminates the

need to drill into the sidewall of the tank to install a mechanical fitting, which can create a maintenance issue for this chemical, thus ensuring long-term performance of the overall system.

When secondary containment is not available, a properly designed double wall tank like the Poly Processing SAFETank® can meet this requirement. This double-walled tank extends the margin of safety by providing 110% secondary containment. These tanks can be double-wall piped safely, using a transition fitting with a built-in expansion joint.

Hydrochloric acid is a pungent liquid with highly corrosive properties. While hydrochloric acid has several different applications, in wastewater treatment it is used to control odours that come from industrial wastewater.

With an extremely low pH, it is highly corrosive and can generate toxic fumes that can be harmful or fatal. These fumes also present a maintenance issue, as entering the tank for cleaning must be avoided and parts replacement minimized.

An integrally molded flanged outlet (IMFO®) allows for complete drainage of the tank, which eliminates the need to enter the tank for cleaning. It also reduces the chances of having to replace parts, as the drainage system is part of the tank’s mold. This is imperative when dealing with such a strongly fuming chemical.

Rotary Lobe Pumps & Macerating Technology for Sludge (Primary, WAS, RAS, Digested, Thickened, etc.), Biosolids, Grease, Sewage, Scum, Lime Slurry, Alum Sludge, Permeate, Polymers, etc.

www.boerger.com

Municipal Representatives:

Scrubber systems are used to control the fumes. No restraint or ladder attachment bands circumscribing the tank are allowed. Cable restraint systems must pass cables over the top of the tank. Hydrochloric acid requires the use of flexible connections with fittings on the lower third of the sidewall.

When it comes to protecting your equipment, your personnel, and your chemical supplies, cross-linked polyethylene tank systems are second to none. Not only are they a smart financial investment, but they can also outperform other tank options for reliability, safety and longevity.

Marshall Lampson is with Poly Processing Co. Email: mlampson@polyprocessing.com

The future of our communities relies on the commitments we make today. EPCOR’s annual ESG report covers progress on the North American utility’s sustainability journey along with stories on innovative projects that are helping pave the way. This story shares how combining the power of the sun with new energy management technologies at the kīsikāw pīsim solar farm helps deliver safe, reliable water to communities in Alberta’s Capital Region.

By Curtis GillespieThe kīsikāw pīsim solar farm at EPCOR’s E. L. Smith Water Treatment Plant in Edmonton is an undertaking that tells us much about our past, present and future.

Located on former reserve lands of Enoch Cree Nation, the Cree name was gifted to EPCOR by the Nation, and means “daylight sun.” Today, the site is used as both a resource for the community and place of ceremony for the Nation.

The renewable energy solar farm and battery system help power one of two plants that provide Edmonton and more than 90 communities and counties with clean potable water.

The project is also a glimpse into the future.

EPCOR’s Distributed Energy Resource Management System (DERMS) is an innovative way to manage electrical energy. Solar panels produce energy, but where that energy goes depends on the needs of the moment. It first needs to be collected, converted, and then conveyed. When the plant needs power, the energy is directed there. When

there is surplus power and battery capacity, the batteries can be topped up. If the plant and batteries don’t require solar energy, the surplus can go to the provincial grid.

EPCOR’s DERMS-enabled system acts as an air traffic controller overseeing water plant operations, solar generation, battery storage and the grid. DERMS directs electrical traffic in real-time, managing supply and need.

Chris Chapelsky is EPCOR’s senior manager for grid transformation. “At its heart, DERMS is a computerized

control system,” he says. “We can model, monitor, forecast, and leverage distributed energy resources across our entire grid.”

Trina Manning is senior manager of sustainability with EPCOR, and adds that: “What’s innovative is how the pieces of the system talk to one another and how decisions are made. DERMS changes the way the grid functions in directing electricity to the plant, to batteries or to the grid. And it happens every second of the day.”

Nathaniel Papay, an electrical

engineer, has been with EPCOR his entire career, the last decade as a project manager. What makes DERMS unique, he says, is the integration and coordination. The solar farm and battery are technically twin systems arranged side by side, allowing for critical redundancy.

“There are two electrical cables coming into the water treatment plant,” he says. “We basically have two solar farms and two systems. So, if one cable fails, we can still run the plant.” This helps protect Edmonton’s primary

source of clean drinking water, while also supplying it with clean energy.

DERMS controls it all not just for EPCOR, but as part of the larger system. “We use it to monitor distributed generation across the grid,” says Papay. “It can ‘see’ how much power we’re using, storing, and sending to the grid, but it also allows for us to be integrated with the entire regional system.”

Solar, wind, and other carbon-free energy sources are a big part of our energy future, but having many different systems across the grid means

a more complex flow of energy. Making the most of what is available, DERMS is key to grid transformation and how we are going to manage our energy future.

The day will come, says Manning, when people will be generating their own electricity to supply their own battery systems. “DERMS is going to play a really important role. When everyone plugs their car in at the end of the day, how do we shift loading to where it’s needed? It’s not just about one water treatment plant, it’s about millions of people.”

DERMS is a way to make sure the switch flip of the future produces electricity. EPCOR’s goal is to be a net-zero entity. That means doing the technical work, but also bringing people along for the ride.

“Helping people see that a new system is more reliable is going to be critical,” says Manning. “We have a vision for rethinking utilities to reduce our environmental footprint, but we have to be patient, too. Different perspectives are important. Community engagement is how everyone benefits.”

“DERMS is really all about what’s next,” says Papay.

Which in some ways is the point. Yes, DERMS oversees the regulating, storing, and directing of electricity. But it’s also a tool to help us prepare for the future.

Discover more about EPCOR’s sustainability journey at EPCOR.com/esg

By Marc Hunt

By Marc Hunt

Many industries use water either when producing commercial products or for cleaning activities during the production process.

Different industries produce different types of wastewater. Metal finishers produce sludge (liquid waste) containing heavy metals, which can harm the environment and people’s health. Industrial laundries can contain oil, grease, heavy

metals, and volatile organic compounds (VOCs). Steel and iron production uses water for cooling metals and separating byproducts, which can be contaminated with ammonia, cyanide, and waste acids. Food processing produces waste that

can contain pesticides, fertilizers, and different types of organic matter.

Wastewater management is an essential component of running a commercial or industrial enterprise. Government regulations require the removal of organic and inorganic pollutants from industrial sewage. Management includes the treatment of effluent before the water is discharged back into the land or water supply or reused in commercial operations. As a result, companies must invest the appropriate resources in their waste management.

However, the landscape is changing, and companies that produce industrial wastewater must keep pace. They can no longer discharge it to the sewer for treatment at a municipal plant. Dwindling water resources, stricter government monitoring and reporting requirements, and discharge processing limits are forcing companies to reassess their water footprint.