On The Road Again

Custom farming keeps the Petersens on the move

Custom farming keeps the Petersens on the move

Cereals, pulses, fertilizer and now... OILSEEDS. The Convey-All OilSeed Series takes all the features that makes a Convey-All the most durable, functional, and reliable conveyor on the market, and adds the versatility of handling oilseeds such as canola or hemp.

The addition of scrapers keeps the fine material on the belt and prevents build up. Unlike other ‘Canola Approved’ options where capacity is sacrificed, the OILSEED Series offers 7,900BPH, keeping your operation running.

08

A Farmer’s Viewpoint Farm Support Should be More Targeted by Kevin Hursh

12 Grain Market Analysis Gene Editing Technology and its Implementation by Scott Shiels

22

Soil Testing Precision Agronomists Let the Fields do the Talking by Becky Zimmer

32 Farming Your Money Is it Time to Rethink AgriStability? by Paul Kuntz

36

Those Wily Weeds Sub-Groups or Super Groups? by Tammy Jones

Angela Lovell

39

Spraying 101

What is Spray Quality, Anyway? by Tom Wolf

44 Seed Plan Plan Your Fall Seed Program by Lisa Kopochinski

46

From the Farm Farm to Fork is a Colossal Catastrophe by Jake Leguee

50

Nitrogen Practices

Fertilizer Reductions Continue to be a Topic of Discussion by Becky Zimmer

Welcome to the world of GFL Ag, a company dedicated to transforming compostable food into innovative fertility products for enhanced crop performance. We’re here to enrich the sustainability of modern agriculture—with the next generation of sustainable fertilizer. Using what we have. Creating more of what we need. And growing the biggest and best crops possible.

Learn about Bio-Sul Premium Plus, and how our newest next-gen nutrient source helps maximize crop performance, at gflagri.com.

Kevin Hursh, P.Ag.

Kevin Hursh is one of the country’s leading agricultural commentators. He is an agrologist, journalist and farmer. Kevin and his wife Marlene run Hursh Consulting & Communications based in Saskatoon. They also own and operate a farm near Cabri in southwest Saskatchewan growing a wide variety of crops. Kevin writes for a number of agricultural publications and serves as executive director for the Canary Seed Development Commission of Saskatchewan and the Inland Terminal Association of Canada (ITAC).

Twitter: @KevinHursh1

As farmers, we often complain about all the government policies, rules and regulations that cost us time and money. The list is long and many of the complaints are legitimate. However, we should also take time to consider all the taxpayer money that’s poured into the agriculture sector and whether the money is all being spent appropriately.

The biggest of the business risk management programs is crop insurance or AgriInsurance. The two levels of government cost share the premiums with producers and also pay the administration. As someone who farms in the Palliser Triangle and has had back-to-back serious droughts, crop insurance has been a huge support.

I wonder how much money some of the mega farms receive from crop insurance. If a farm has 20,000 or 40,000 acres or more and is a highly profitable farm business buying and renting more land every year, is a government subsidy on all of its crop insurance a good use of public money?

Instead, might it be reasonable to have a cap on government contributions, such as the cap that exists for AgriStability and AgriInvest?

As an example, what if the crop insurance cap was $5 million? That would cover a 10,000-acre farm, assuming coverage of $500 an acre. Above the $5 million in liability, the farm could still buy crop insurance but it would no longer be subsidized by government.

AgriStability has been criticized for years as being unreliable. Many producers have dropped out of the program. Although premiums are relatively inexpensive, for most there is also a cost to have an accounting firm submit the information in the required format.

With crop insurance coverage high due to strong insured prices, AgriStability doesn’t usually trigger. That could change for next year if prices continue their downward trajectory. For now, however, AgriStability is a much smaller government expenditure than crop insurance.

Farming For Tomorrow is delivered to 90,720 farm and agribusiness addresses every second month. The areas of distribution include Manitoba, Saskatchewan, Alberta and the Peace region of B.C.

The publisher does not assume any responsibility for the content of any advertisement, and all representations of warranties made in such advertisements are those of the advertiser and not of the publisher. No portion of this publication may be reproduced, in all or in part, without the written permission of the publisher. Canadian Publications mail sales product agreement no. 41126516.

Then, there’s the highly popular AgriInvest. Free money is always welcomed and I’m in line for my share just like everyone else. For a government running huge annual deficits and in a society where health care is in continuous crisis, it’s difficult to argue that AgriInvest is justified.

is coming to the following regions this fall!

Southern Saskatchewan

October 23 to 27

Watch for locations, dates and times for 20 single day events

Vancouver Island & Fraser Valley, British Columbia

October 2 to 13

Watch for locations, dates and times for 7 single day events

Check out Cleanfarms.ca – see “Unwanted/Outdated Products” under “What to Recycle & Where”

The money comes based on your net farm sales and although a matching contribution is required, there’s no restriction on how or when the money is used. Unlike crop insurance, the program is capped with annual contributions at a maximum of $10,000.

Some producers pull the money out each year. Others let it build into an emergency fund or a fund to help buy land that may come for sale.

You get the money even if you’re highly profitable. In a farming operation, $10,000 a year doesn’t go very far, but consider what that sort of money would mean to a family living in poverty.

Then there’s the cash advance program where the interest-free portion has risen from $100,000 to $250,000 and now $350,000. I’m not aware of any concerted farm lobby that asked for the increases; it will be hard for the federal government to ratchet down the number in subsequent years.

Cash advances probably made more sense back in the days of the Canadian Wheat Board (CWB) when wheat and durum delivery opportunities were often restricted. At least there was a way to get some cash with your stored grain as security. While the CWB is long gone, cash advances are flourishing.

With high input costs and the rise in interest rates, the program is more popular than ever, but what other businesses or sectors of the economy receive a similar perk? And what other businesses have anything comparable to the farm fuel tax exemption?

Grain farming has gone through some long periods of limited profitability, where everyone scraped by. Remember the old joke about how leaving the farm to your kids should be considered a form of child abuse?

The last 15 years have been different. Established producers have been profitable – and often very profitable with dramatically rising asset values. Yet farm programs continue to dole out money as if we were still struggling to make ends meet.

Don’t get me wrong. Young producers and those with heavy debt loads still struggle. However, government support is largely untargeted. It’s going to everyone whether they need it or not.

I don’t see the gravy train ending any time soon. Politicians are loathe to rein in spending. While the number of farmers continues to dwindle, government likes to be seen supporting agriculture. It’s funny how we rarely think about how much support we actually receive.

Scott grew up in Killarney, Man. and has been in the grain industry for 30 years. He has worked with Grain Millers Canada for 10 years and manages procurement for both conventional and organic oats for their Canadian operation. Scott is an elected board member for Farm and Food Care Saskatchewan and sits on several other committees on both the organic and conventional sides of the oat industry. Scott and his wife Jenn live on an acreage near Yorkton, Sask. Find out more at www.grainmillers.com.

On May 3rd, The Honourable Marie-Claude Bibeau, minister of agriculture and agri-food, announced newly updated guidance for seed regulations that provides direction for breeders, primarily regarding gene editing technology and its implementation in the plant breeding process moving forward.

While the Canadian Food Inspection Agency (CFIA) and Health Canada have deemed gene edited plants to be completely safe, the fact remains that in many parts of the world gene edited equates to “genetically modified.” This correlation means that we could be in some danger of losing potential export markets, especially in the organic agriculture sector.

However, the potential benefits that gene editing can bring to the breeding of new crop varieties are significant enough that we will see this technology used to some extent in nearly every plant breeding program. Using this method for plant breeding can possibly result in better yields, disease resistance, drought tolerance and many other attributes that would otherwise potentially take decades to develop. All of this will obviously be very appealing to producers, as those all contribute to a better bottom line at the farm gate.

Because of these changes, we are most likely going to see an increased focus on variety identification when it comes to marketing crops. Currently, the Canadian Grain Commission requires that producers sign a declaration stating that the grain they are delivering is a registered variety in Canada. Moving forward, I feel that it is more than likely that buyers will require affidavits identifying the variety sold. This level of transparency and traceability will allow Canadian processors to market products that contain gene edited variety materials separately from those that can be marketed as non-gene edited.

If we do move forward and introduce gene edited varieties to the crops that currently do not use gene editing or GMO technology, it will necessitate segregation and documentation at the buyer level, which will ultimately come at a cost. On the other side of that coin, there is potential that this opens up a whole different market on the store shelf for products either produced with, or produced without, gene edited crop ingredients. More than likely, as we have seen with GMO/ non-GMO, the consumer will likely be looking for non-gene edited ingredients; but if this is marketed correctly, there shouldn’t be much uproar around it.

On the organic side though, neither gene edited nor GMO seeds are allowed to be used in the production of organic crops, so this is where things get a little tougher. As plant breeding moves forward, potentially with gene editing technology being used, varieties will theoretically improve significantly. This would put organic producers at a disadvantage, one that could potentially cost acres and market share for that sector. Part of the minister’s announcement outlines a new database that will be used to track breeding methods. This database, and its efficiency, will play a big role in maintaining organic integrity on the seed end of things.

There is a lot more to all of this and far more to come. I am not taking any side on this – nor is a lot of the industry, it seems. What we are looking to do is make sure that producers are fully informed about the gene editing process and what it could possibly mean to the future of the crops they grow.

Until next time…

the

the

For the past 25 years, Lee and Dana Petersen and their family have not only farmed 3,500 acres of grain land near Hodgeville, Saskatchewan, they’ve also run a 100-head cow/calf operation and a custom combining business that takes them away from the farm for most of the summer and fall.

Being that diversified involves a lot of management and organization, and it can definitely get a little crazy in the spring.

“Basically, we plant our crop in the spring, we get it sprayed and then we’re gone until harvest,” Lee says. “We don’t see our own crop. We try to monitor it remotely. That causes some challenges but it’s something we’ve worked with.”

By mid-May there’s a lot going on besides the usual work of preparing the tractors and machinery for seeding. The combine crew is doing maintenance on the machines to get them ready for the season while the Petersens deal with the paperwork to get their work visas and other documents in order to head down to the United States, all the time keeping in touch with their harvest customers in Oklahoma, Kansas and Colorado about how the crops are shaping up.

“Certainly, at that time of year you have got to wear two or three different hats and sometimes you wear them all the same day,” Lee says.

Lee’s three children grew up helping out on the farm. They have been heading out on the road every summer and have been part of the harvest crew ever since they could legally operate the machines. Tyson, the eldest son, at 22, is now working full-time on the farm along with his wife, Brooke. Their newborn, Wells, will be six months old when he goes on his first harvest run, following in the footsteps of his dad who was two weeks old when he had his first combine ride in Flagler, Colorado.

Tyson’s sister, Tilynn (20), who just graduated from Lakeland College with an agribusiness diploma, will help out again this summer, as well as his brother, who is 19 and just finished his first year of mechanical engineering at university.

Lee’s 81-year-old dad, Lloyd, who still helps out with the day-to-day chores, purchased the farm in the early ’60s. In 1968, he and his brother began custom combining for farmers in the United States. Although Lloyd got out of custom work after a few years, his brother continued until 2006. It wasn’t until the early ’90s that the idea came around again.

“We started doing some custom work just for a few neighbours to supplement the farm and make better use of the machinery that we had at the time,” Lee says. “Then, we had the opportunity to go to the United States to do some

jobs in 1998 and it has grown from there. Now it’s an integral part of the operation.”

The Petersens currently have three combines on the road and the combine crews (that usually include an extra three or four seasonal employees besides the family members) harvest in the United States from early June until August, then come back to do jobs in Canada for September and October. Sometimes they will go back to North or South Dakota to harvest fall crops into November.

They work on farms from 40 acres to 40,000 acres and all those farms have different needs. In some cases, they complete the entire harvest operation, including hauling the grain. Other farms have their own combines and just need some extra capacity for a week or two to help out. Some farms have never owned a combine and don’t intend to. All are family-owned farms and in most cases, they are repeat customers. Some have worked with the Petersens for so long, they are now dealing with the next generation.

“We may have dealt with dad for 15 years and now we are dealing with the son or daughter,” Lee says. “It’s nice to see.”

Over the years, the Petersens have developed ways to manage all these multiple enterprises at once and if necessary, remotely.

“Dad stays home on the farm all year round, so he certainly does a good amount of it as far as checking everything. We also have a full-time employee at the farm to check the pastures and help with haying and things like that, but we rely a fair bit on the local agronomists and specialists that we deal with,” Lee says. “If we’re talking to the neighbour and there’s a pest in the crop or something that’s causing some problems, we’ll lean on somebody to do some scouting and get their opinion.”

The juggling doesn’t stop for them on the road either, with timing of the custom jobs often being a bit of a squeeze play.

“It can be a battle to get one job done because the next farm is going to be ready tomorrow,” Lee says. “We do have a pretty good network of other Canadian custom harvesters that we know and we help each other out if we need to. You do rely on your friends a bit too.”

“We may have dealt with dad for 15 years and now we are dealing with the son or daughter; It’s nice to see.” - Lee PetersenLee Petersen says many of the farms he works with have been customers for generations. Tyson Petersen and his wife Brooke are dedicated to helping to keep the family business thriving. Their son Wells will go on his first harvest run at just six months old.

It felt like time stood still when she was born. And every day has flown by faster ever since. She’ll be all grown up before you know it. You can never be completely ready for your little girl to take over the family farm. But you can make sure that she will be.

And you can make sure that when the time is right, your farm will be ready, too.

Typically, the Petersens do not have trouble finding employees but ever since the mandatory training for truck drivers has come into effect, it is a bit more of a challenge. Over the years, though, they have had young people from as far away as New Zealand and Ireland who were eager to sign on for a season.

“It’s more than just farm work because it’s an adventure with the harvesting and the travelling,” Lee says. “We have two fellows from Switzerland working for us on our crew this year, and they just want to go out and see the world. They both got a hold of us through people that worked for us in the past; a majority of our employees the last few years have come as a result of word of mouth.”

Obviously, the Petersens know a thing or two about diversification and they have developed their own way of managing their complementary businesses, but the driver behind every decision they make is economics.

“You stand back today and see all the grain prices are high. There’s opportunity there but you still have to look at the big picture,” Lee says. “Harvesting is no different than farming. We’ve had good years and years that aren’t as good but everything comes around if you make a decision based on the economics. You can be too diversified. You can be putting too much energy into part of your operation that’s not paying for itself.”

A good example of that was the family’s decision to reduce their cow/calf herd from 300 to 100 head recently.

“We have some marginal land that the cattle are the best fit for but we only need a certain number of head to use that most efficiently, so that’s why we backed off a bit on our cattle side, simply because of economics,” Lee says.

Lee believes that custom work is a good thing for farmers to get into if they are trying to diversify.

“If you’ve got a tractor or you’ve got an implement that you’re underutilizing, you can look at doing a little bit of custom work with it,” he says.

But that advice comes with a caveat; it is vital farmers know exactly what their costs are going in so they can get a true picture of whether their investment is making them enough of a return to be worthwhile.

“With the price of machinery and the depreciation on the machinery, you’ve got to make sure that if you’re out there running it on somebody else’s farm, it needs to be paying for itself – or you’re going backwards,” Lee says. “You think you’re making money but you’re really depreciating the implement faster than you are earning money.”

Lee, who is 47, has seen a lot of people trying to get into custom work make the same mistake: over-investing at the very beginning.

“I’ve seen people decide they are going to be a custom harvester and spend a bunch of money to buy fancy machinery when they don’t have the work to back it up,” he says. “Or, they have a year when there isn’t a lot of work and two years down the road they’re dejected because they can’t make any money at this. It’s like any other business. You have got to watch your cost going into it and grow it over time. Everything doesn’t need to be new and shiny year one or two or maybe even year 10.”

Spending so much time on either side of the border means Lee sees agriculture from both sides. One of the biggest differences he has noticed is that Canadian farmers seem to be more adaptable than American farmers.

“Canadian farmers are a lot more adaptive to change and technology even with things like crop rotations and different varieties of crops,” he says. “The average farm in Western Canada grows at least four to six different crops, anything from

“With the price of machinery and the depreciation on the machinery, you’ve got to make sure that if you’re out there running it on somebody else’s farm, it needs to be paying for itself – or you’re going backwards. You think you’re making money but you’re really depreciating the implement faster than you are earning money.”

- Lee Petersen

CONNECTING PEOPLE, MACHINES, AND TECHNOLOGY TO GIVE YOUR OPERATION A COMPETITIVE ADVANTAGE!

SEE HOW TECHNOLOGY IS CHANGING THE WAY FARMERS OPERATE

• DATA MANAGEMENT

• REMOTE MANAGEMENT

• GUIDANCE

• OPERATIONS CENTER DIGITAL MANAGEMENT

· ABILITY TO MONITOR YOUR EQUIPMENT IN REAL-TIME

oats to canola to flax, and you may see a bit of that as you come farther north, like in northern Montana, but not to the extent you see here. We have customers who grow wheat and have summer fallow and they’ve done that for 50 years. I had a middle-aged farmer from Iowa who stopped by a field in Kansas we were combining because he had never seen wheat harvested before. On his farm all they ever grow is corn and soybeans.”

Lee admits he doesn’t know why that is, but he does have a few theories.

“Perhaps it’s how their crop insurance programs work compared to ours. I think maybe we’re a step ahead with our crop rotations, with watching disease and all the other agronomic reasons that we do crop rotations. However, I don’t have a firm reason to say, ‘this is why it’s different,’” he says.

Lee has seen a lot of changes in the industry over the past quarter decade, in the types of crops and of course the equipment, which has got bigger and heavier over the years. There is a lot of new technology, although the basics haven’t changed that much.

“If you’ve got a combine that’s brand new or one that’s 10 years old, they’re not drastically different,” he says. “We have autosteer and things now we didn’t have when we started but we’re still harvesting the crop and hauling it to the elevator. The technology has made it easier and more convenient with things like apps on your phone to track the loads to the elevator and to link your scale and your cart to your phone but we’re still doing the same job.”

With the next generation coming on board and a farm that offers opportunities on so many different fronts because of how diversified it is, the Petersens are working, in the short term, on defining what everyone’s role will be going forward.

“Right now, everybody can do everything but as you get into the next generation, it’s about figuring out where everybody fits and where we need to grow our business to fit that,” Lee says. “I could see, as the opportunity arises, certainly growing the farm and we could also grow the harvesting side, running another crew, that kind of thing. We’re basically there now; we can do that now, but that’s something that could easily develop in the future for sure.”

The X-Treme® 19-Series features a front-folding design with enhanced forward reach for greater unloading visibility. The 60-Series of single-auger grain carts maximizes side reach with a side-folding design. The 20-Series of dual-auger grain carts offers a pivoting vertical auger, rubber-cushioned tongue suspension, low-profile design with large carrying capacities and fast unloading speeds. To get your crop to the bin quickly and safely, rely on the 30-Series lineup of durable grain wagons.

Five agronomists are sitting in a bar. One asks the others a question. A fight breaks out. Tables get overturned. RCMP are called. This hypothetical scenario happened all because of one question: what is the best way to soil test a field?

Thoughts are mixed about how much soil testing even takes place in Western Canada, besides the best techniques that get farmers the best results.

According to Statistics Canada’s 2021 Farm Management Survey, a fair amount of soil testing is being done across Canada but not to a satisfying degree for local agronomists, including Marilyn Kot, president, Green Acres Tech; and Dale Steele, owner, Steele Ag Insight.

“In 2021, 94 per cent of field crop (oilseed, grain and pulse) farms that applied fertilizer tested their soil for nutrient content and varied their fertilizer application rate,” says the report. “This represents a four per cent increase compared with 2017. Among these farms, 42 per cent tested their soil every year.”

However, according to the description of the sample size, 18,000 farms were selected to be representative of 81 per cent of Canadian production and, “small farms were automatically excluded; large ones were considered ‘must take’ because of their national influence on farm practices.”

“Steele Ag Insight Ltd. in southern Alberta serves larger operations,” says Steele, and even this owner sees a lack of soil testing in Western Canada.

As part of the Analysis of Precision Agriculture Adoption and Barriers in western Canada Survey, the first benchmark study of precision ag adoption rates completed in 2017, Steele was a huge part in surveying Western Canadian farmers on their precision ag practices. With 261 responses representing almost

“In 2021, 94 per cent of field crop (oilseed, grain and pulse) farms that applied fertilizer tested their soil for nutrient content and varied their fertilizer application rate.”

- Statistics Canada’s 2021 Farm Management Survey

We noticed quite quickly we were saving about 10% in our fuel use per hour... using Dieselex Gold.

DEAN HUBBARD Silverwood Ventures Ltd.

DEAN HUBBARD Silverwood Ventures Ltd.

one million acres of cropland across Western Canada surveyed for the study, 63 per cent of those acres were soil tested. With layoffs and a lack of research funding available, Steele says there is even more testing that needs to be done with very few people trained and operating to do it. While he and his crew are kept busy, he’s always looking for more clients, 100 per cent of which come his way through referrals.

Back 20 years ago, Kot, president of Green Acres Tech Inc. in southern Saskatchewan, would estimate the number of fields being tested at 10 per cent. Now she estimates that number at around 30 per cent.

With 44 years in the industry, Kot says the hypothetical bar scenario is the easiest way to start an argument among agronomists. While Kot has her own tried and tested methods, she knows that those methods can vary among agriculture professionals.

“Every agronomist has their own viewpoint and I don’t question them because every agronomist works in their own area and they should know what works best for them. At the end of the day, it doesn’t really matter as long as they understand how to interpret the sample and they can do the service for the client.”

Kot has had clients with her for over 15 years who have tracked the data and improved their operations through soil testing but some farmers do not see the benefits, she notes.

“When clients match the nutrients going out of their field to what they are putting back in, soil testing shows those numbers,” she says. “Farmers see those returns on investment in two ways: farmers get more bushels per acre and save on those inputs when the field doesn’t need them. I’ve proved time and again that if we pay attention to what the soil test is telling us, the history of the field, the crops being grown and we work the rates according to the field, they get that much more grain off it over time. Or at the very least, they save fertilizer.”

Just like many agronomists in the industry, Kot knows how she is collecting those samples and how to properly get them to a testing facility. It works for her organization and she knows what she is looking for when she sends that sample in, paying attention to the historical data just as much as the recent test results.

For Kot, she decides on a square acre by acre benchmark as a representation of the entire 160-acre field and marks that spot using GPS, consistently coming back to that point year after year.

After that, she lets the field tell her where and how to sample by zone, turning that one benchmark sample into six to 10 precise zones where, again, she consistently takes samples.

One question debated by the industry is how big the sample should be. Through Kot’s experience and research, she takes, at minimum, 15 core samples from ground level down to 24 inches, with some exceptions due to manure application. Following that, she is separating the cores by depth since there is a difference between what is going on at that surface to six inch depth down, to what is going on at that farthest point.

One thing Kot also does is freeze the sample for transport to maintain its integrity.

“If the sample gets exposed to some warm air, it’s going to start mineralizing. This means the lab result for nitrogen will include what was present in the soil as well as what was mineralized in the sample bag. Therefore, the test results will not be a true representation of what was in the field the day the sample was taken.”

With more year-over-year samples, Kot has a better understanding of what the numbers are telling her. Making a plan for nutrient management, the lowest number is going to dictate crop yields and for a few bucks, Kot encourages farmers to look beyond nitrogen to see what other micronutrients are lacking.

Steele Ag Insight does a number of services for large operations, including soil sampling, satellite imagery, irrigation scheduling, crop scouting and multiple rate fertilizer prescriptions. How often farmers take on these services is up to them, says Steele.

“Prior sampling inaccuracies have caused farmers to doubt those benefits of soil sampling,” he says, “but done properly, it can provide a lot of valuable information for farmers. That lack of soil sampling also comes from a place of belief in using a single rate of fertilizer for every field. Even though we see topography differences and low spots and hilltops and sandy

“Every agronomist has their own viewpoint and I don’t question them because every agronomist works in their own area and they should know what works best for them. At the end of the day, it doesn’t really matter as long as they understand how to interpret the sample and they can do the service for the client.” - Marilyn Kot

There’s a future on the land in Alberta and it’s in good hands. Like those before them, the next generation of producers will drive innovation and change, nourishing and protecting the land while feeding the world.

PROUD TO GROW AGRICULTURE IN ALBERTA

AFSC.ca

spots and different yields, they’re not doing anything about it. It’s like, well, I’m just going one rate to fertilizer. I don’t need to know what’s in every field or different parts of the field.”

He continues, “Actions taken from testing results come from what the farmer wants to do with this information. Are they wanting to mine, maintain or build up the nutrients and organic matter in their field? There’s not a right or wrong answer to this question but the answers are more accurate with multiple years of testing. How do farmers know what they are doing is the right thing without going back and testing again?

“If you’re asking for an average of the field – a composite or benchmark – I’ll request your prior sampling points. It’s funny how very few farmers can ever give me those; they always appear to be lost or missing. So, we’ll create new points with our trained technicians.”

For Steele, the best results come from composite sampling in the winter without including those hill and valley outliers that would skew a more realistic average of the whole field, he says.

Farmers need time to make decisions and winter sampling paints a more accurate picture without the mineralization that takes place in October and November, April and May, with time to plan for spring seeding. It is also safer for his staff since it is easier on the equipment and teams and for contending with less mud. Also, there is less risk of a service truck burning up on stubble.

“When taken correctly, samples will offer the same readings from one lab to another,” says Steele, “but there may be differences in how they are presented, i.e. Celsius versus Fahrenheit.”

“There is history in the agriculture industry of cognitive biases and that fear of ‘snake oil’ but there is also a wealth of techniques that have worked on Prairie farms for decades.

According to Steele, finding a trusted agronomist is the key to identifying the problems and finding the solutions to the all-important question of how to improve yields.

“There is history in the agriculture industry of cognitive biases and that fear of ‘snake oil’ but there is also a wealth of techniques that have worked on Prairie farms for decades.”

- Dale SteeleMarilyn Kot takes core samples by hand but also uses a Wintex automated sampler to collect soil at varied levels. Photo Credit: Marilyn Kot

INNOVATION. EDUCATION.

2023 August 1 & 2

Join us to learn about the latest in agriculture and the ways you can prepare your farm for the future.

GET YOUR TICKETS AT AGSMARTOLDS.CA

Featuring the Field Crop Development Centre Field Day August 2 Celebrating 50 years of variety innovation.

Produced By:

Ag Tech STEAM is a project based in south central Alberta, near Acme. The project was founded by 17-year-old Luke Silinski just five years ago.

With the aim to educate rural and underserved youth about agriculture technology and coding and help them gain access no matter where they live, Silinski is utilizing real life and digital tools to craft, create and cultivate interest.

He says the idea for Ag Tech STEAM started at the Emerging Agriculture Hackathon in 2018, an event where groups of software developers work at an accelerated pace.

“I had started building a Lego model of DOT (which is the autonomous farming platform from SeedMaster, now known as Omni by Raven) and was invited to the Hackathon. I and my partner, Megan, won the MacGyver Award. That’s how Ag Tech STEAM started. It was mostly an online idea but with some industry support, we started building and sending out Ag Tech STEAM boxes the next year.”

Silinski, who comes from a long line of farmers and innovators in agriculture, was inspired by his rural school experience to bring Ag Tech STEAM to rural and underserved students across Canada.

“I love running equipment, doing agronomy with my dad and learning about seed science with my friends at 20/20 Seed Labs, as well as so much other cool ag tech with other great organizations.”

20/20 Seed Labs Inc. is Canada’s first fully accredited, independently owned seed testing laboratory with facilities in Alberta, Manitoba and Chile. The lab has been serving customers in local and international agriculture operations for three decades.

Silinski says STEAM, which stands for science, technology, engineering, art (or agriculture) and math is sometimes called STEM.

“I added the ‘A’ because we need more art and ag! Coding is a huge part of ag tech and there are many jobs coming that will

require an understanding or interest in both ag and coding. Ag tech has a wide diversity and so many interesting roles that support or are directly involved with primary production and other important sectors in agriculture.”

Silinski says there are many ways to learn with Ag Tech STEAM, such as the physical and online content packs that cover everything from seeds (germination, planting seeds and seed treatment) to entomology, weather and data management –with experiments for all of the letters of STEAM.

Each content pack has components and activities that provide learners with insight into how farmers use those exact same skills and tools to grow food, fuel and fibre across Canada and around the world.

“It’s everything from math to data management, agronomy to entomology, seed analysis to understanding the impacts of weather. All the activities are scalable. Younger learners can do seed germination and drag and drop coding, while more mature learners can do advanced experiments.”

Ag Tech STEAM also offers an exploration of future career options, such as agronomy, seed analysis and entomology, in addition to coding and managing data.

“We want to give learners an opportunity to develop skills and gain a broader understanding of ag tech and see what appeals to them to open doors to careers,” he adds.

As for what the next few years hold for the project, Silinski says they will be expanding other areas to keep supporting the Ag Tech STEAM program.

“We’ll be building more interactive content packs, adding more games and building add-on boxes that cover other areas of ag tech, including the new build-a-bug, sprayers and robotics. We’ll also be doing more speaking engagements and team-building activities using Lego, as well as working to support virtual learning for agriculture with the ag lab that is coming soon.”

Project gives young people an opportunity to develop skills and gain a broader understanding of agriculture technology

Whatever

Despite the United States being home to an estimated 7 billion tons of accessible potash, the nation shockingly relies on imports for 95% of its potash needs in the agricultural sector This heavy dependence on foreign sources for a mineral that is critical to crop growth is both surprising and illogical, given the significance of potash in promoting food security and supporting agricultural efforts Recognizing this glaring discrepancy, industry veteran Peter Hogendoorn and his team took the initiative to address the issue headon by launching Sage Potash Corp Dedicated to advancing domestic potash production in America, Sage Potash firmly believes in the viability of the project and is committed to meeting the clear demand for a local potash supply

In mid-March of 2023, Sage Potash made its highly anticipated debut on the TSX V (TSXV:SAGE), publicly asserting its confidence in the project's feasibility and its dedication to meeting the demand for a local potash supply As the CEO of Sage Potash, Hogendoorn takes great pride in leading the charge towards enhancing domestic potash production to promote North American food security

Sage Potash boasts an extensive portfolio of mineral rights in the abundant Paradox Basin, situated in Southeastern Utah Currently, the Paradox Basin is estimated to house approximately 2 billion tons of accessible potash,

yet contributes a mere 3 5% of the total potash demand in the United States Sage Potash aims to significantly expand production by tapping into these valuable reserves

Historical resource mapping conducted in the past has indicated a high likelihood of discovering thick, high-grade, and horizontally oriented potash beds within the Paradox Basin. These beds were initially deemed inaccessible due to their depth, rendering conventional mining methods impractical However, recent advancements in drilling and mining technologies have paved the way for more effective exploration and extraction from these reserves Sage Potash also employs a solution mining model, which offers greater efficiency and sustainability compared to traditional mining methods

The significance of American farmers having access to a domestic potash supply cannot be overstated It not only protects against costly disruptions in the supply chain but also fosters productive agricultural practices, which are essential for North American food security Modernday farmers face numerous challenges beyond their control, including operating in an unforgiving landscape with thin profit margins that are heavily influenced by commodity prices, environmental factors, and global politics The list of obstacles that

can hinder a successful farming season seems endless, underscoring the resilience required in this industry Nonetheless, agriculture remains crucial for the survival of society, and those involved demonstrate a fortitude not for the faint of heart

The Sage Solution

Sage Potash aspires to be a part of the solution by empowering farmers with greater control over their industry. Providing a local supply of accessible potash shields them from the financial burdens associated with importing approximately 95% of their required potash, including costly duties and transportation fees Furthermore, a domestic potash supply instils a sense of security among all North Americans, knowing that they have control over the production of food, a resource critical to survival

Having accumulated over thirty years of experience in the mineral exploration and mining sector, Hogendoorn is no stranger to the inherent risks of being an early investor His confidence in the Sage Potash project stems from the team's clear vision and the viable path they have identified to achieve production and fulfil an essential need in a resource-rich region With Sage Potash leading the way, the prospect of significantly boosting domestic potash production to benefit the North American agricultural community appears brighter than ever before

95%

of US potash requirements are imported

40%

of the world's potash supply comes from Belarus and Russia, both of which are currently sanctioned by Canada and the US tons of potash resources are estimated in the Paradox Basin

2B

"Reliable and local supply chains are key to achieving national food security in this post-Covid and inflationary era."

Discover the Sage Potash Opportunity today and learn about the benefits of investing in food security:

www sagepotash com

The Paradox Basin contains more than 25% of US potash, yet only produces 3.5% of US potash demand. To encourage local production, the US Government has approved the spending of half a billion dollars on projects aimed at increasing American potash and fertilizer production

Head to our website via the QR code to discover more about potash production advancements.

With spring in the books and harvest time quickly approaching, maintenance is often top of mind. Orders are made for fuel and chemicals. Oil is changed and air filters swapped on equipment, repairs get made. A big part of preparing for the next season is making sure that all the equipment is ready to go so that costly breakdowns during critical times can be avoided.

The one piece of equipment that is often forgotten, or neglected, is our own physical body. With a thousand thoughts, each fighting for priority and taking up headspace, it is easy to forget that the human body is the farm’s most versatile and critical machine. While it does not need an oil change, it is important to make sure that it is in top condition to avoid breakdowns.

Physical fitness is about keeping the body safe and healthy so that it is in the best possible condition to handle the physical and mental stress of a busy, challenging season. As is the case with farm equipment, a well-maintained body will be around for a long time and have fewer breakdowns.

Are you confident that you have been healthy enough that YOU will not break down this coming season?

It is a sad truth that producers often take better care of their tractors and equipment than they do the human bodies that operate them.

Start by conducting a quick lifestyle assessment and ask yourself, “Do I get enough sleep each night?”, “Do I choose healthy foods… most of the time?”, “Do I drink enough water per day?”, “Do I exercise regularly?”, and “When was the last time I spoke to a medical professional?”.

A good night’s sleep can lead to more energy, increased ability to handle stress and may improve overall well-being. Sleep does not cost anything extra and provides benefits such as heart health, concentration, and higher cognitive functioning; strengthens the immune system; and aids in weight management.

You would never choose sub-par fuel or oil for farm equipment. Eating a wide variety of fruits and vegetables while limiting, sugars, fats, and alcohol will ensure that you are refueling with the good stuff. Keep in mind - sugars are often hidden in ‘healthy’ drinks and be cautious of ‘energy drinks’. Drinking sufficient water can help stave off fluid loss and heat exhaustion on especially hot days.

You may have a mechanic look at the tractor, or other equipment, to ensure it is running at peak performance before critical harvest time. Likewise, consider consulting a physician routinely to ensure that your body is performing at peak performance as well. Research shows that regular physical activity can help reduce the risk for several diseases and health conditions, improving overall quality of life. Always consult a doctor before beginning any new fitness plan or weightlifting program.

As preparations are being made to ready the equipment, take some time to consider how your personal lifestyle tune-ups may impact your operation.

Since 1955, the Saskatchewan Safety Council, a non-profit registered charity, has been dedicated to the prevention of injury in Saskatchewan... at home, at play, and at work.

Many producers that I talk with have a negative feeling toward AgriStability but I think it is time to rethink this program. If you are not in it, you should look at joining and if you are in it, you should understand the changes that have been made and how it could work for your farm.

The negative feelings toward AgriStability are founded. The program changed in 2012 and became very hard to claim. Also, it did not protect your farm very well. This was the first issue with the program. The government went on to make additional changes to make it even harder to get money out. When producers did qualify for a claim, the process seemed to take forever to finally get cash. All of this did not sit well with farmers.

Although there have been changes to the program and market conditions that make AgriStability better, I still caution livestock producers about joining. Perhaps if you are a hog operation or a feedlot, there may be a place for it. Breeder operations like cow-calf producers will not gain much protection. The program pays out when there are large swings in income/expenses and these operations rarely experience this. You have heard me joke before that cow-calf operations are financially boring. Each year a cow has a calf and you sell most of them. Rarely are all the cows open or the calves die. Rarely does every cow have a twin. The income is static and so are the expenses. This program will never pay out in those circumstances.

Grain producers, however, are a different story. Yield can go way up and it can go way down. Grain prices can be very low and then very high. This is where AgriStability can help out.

There have been rule changes in the past few years that have enhanced protection. The first rule that was changed was the elimination of the Limited Reference Margin.

AgriStability works by taking your previous year’s financial history and seeing what your margin was. Margin in the AgriStability world is your revenue less eligible expenses. Eligible expenses are fertilizer, seed, chemical, fuel, labour and a few others. In the past before the rule changes, if your farm had great revenue and you kept your expenses low thereby having a great margin, the program reduced your margin through the Limited Reference Margin rule. This was a penalty against efficient producers, which seemed wrong. They took this out a couple years ago. Now, if you have great revenue with low expenses, you will have great margins, meaning your reference margin will be great as well with no reductions.

Many producers are making the switch to linear box affordability with the versatility to accurately plant high yielding primary crops as well as cover crops that produce valuable nitrogen and protect against soil erosion. Cover crops require the same seeding accuracy and depth control as primary crops. Achieving this requires the accuracy of the exclusive Fluted Seed Meter and the industry’s first Pneumatic Down Pressure opener system. From 10’ through 50’ widths, the ruggedly built Landoll 5000 Series Drills deliver linear box affordability with unmatched standability.

Call us for more information or visit us online at www.Landoll.com

The other rule that was changed was the amount of the payout. This gets a bit confusing. AgriStability pays out when your claim year margin falls below the reference margin by 30 per cent. Once you are in a claim, the program now pays out $.80 for every dollar you are in claim. It previously paid $.70 for every dollar you are in claim. It is important to note that you still only trigger a claim at the 70 per cent level of your reference margin. This has not changed.

Here is an example. If your farm has a historical Reference Margin of $150/acre, you would be in claim if your Claim Year Margin dropped to $105. This is a 30 per cent drop in your margin. If your Claim Year Margin was $75, you would be in claim from $75 to $105, which is $30 and you would receive 80 per cent, which is $24/acre.

The changes to the program are worth looking at to see how they will affect your farm.

If your farm has suffered from production losses in the past few years, this next section is not for you.

Where this program can really make a difference is if your farm has been fortunate enough to grow an average crop during the last few years. The increase in grain prices has driven your margin through the roof. Another interesting aspect is the increase in the allowable expenses.

If we look at the increase in grain prices, this has had a dramatic effect on margins in the program. We often think of the reference margin calculation as an average of the past five years but this is incorrect. AgriStability uses the Olympic averaging system, which takes out the highest and the lowest numbers and then averages the three remaining years. This three-year average calculation can skew your numbers to your benefit. If your 2021 was a great year and your 2022 was also a great year, they can only take one. If you had a wreck in the past five years, they take out that low year. This results in your reference margin being very strong. I am seeing many of my clients doubling their reference margin for the 2022 year.

The other side to this equation is the increase in the cost associated with the allowable expenses. Although there has been some softening in prices recently, if we look at what we spent on just fertilizer, chemicals and seed in 2023 as compared to 2018, 2019 and 2020, it is much higher.

All of this can lead to a situation that looks like this:

The 2022 year will be removed because it is the highest and the 2020 year will be removed because it is the lowest. The remaining three will average out to $292. If your reference margin is $292, your trigger point to be in a claim is ($292 x 70 per cent) $204. If your 2023 allowable expenses are $300, you would be in a claim when your revenue goes below $504. Three of your last five years produced revenue below this amount, making a claim very likely.

That is the reason why you need to look at your AgriStability – to see what your numbers are.

AgriStability has gotten a bad rap for paying out late. This can be avoided. AgriStability needs two sets of information to process your claim. The first is your income/expenses. If you are not incorporated and farm as a sole proprietor or partnership, then AgriStability will receive your income and expenses directly from Canada Revenue Agency when you file your taxes. If you are incorporated, you or your accountant will have to submit that information.

The next thing AgriStability needs is called supplementary information. This includes year ending inventory, production numbers, deferred income, prepaid input, etc. You can supply all of that information the day after your year end. If you have a December 31 year end, on January 2 you can submit your

supplementary information. You can file your taxes by the end of February. If AgriStability receives all of your information by March 1, they will most likely have your file processed in 30 days because very few other producers will have their information in to them at that time.

The deadline to submit supplementary information is September 30. Normally, what happens is you finish up harvest in October of 2022, your year end is December 31, 2022, your accountant files your taxes on April 15, 2023, and sends AgriStability the supplementary information in August 2023. The admin staff at AgriStability receive most of the paperwork at this time of year; they are busy and it takes a few months to get your claim processed. It could be October 2023 before you are looking at a payout for your 2022 crop. That is not the fault of AgriStability.

I would also recommend that you send in your own supplementary information rather than have your accountant do it. If you are incorporated, I would suggest your accountant send the income/expense information. But I would recommend you send in your own supplementary information because you know that best. This is information like your seeded acres and the yield. You know this better than your accountant.

The cost to be in this program is very inexpensive. Understand what the program can do for your farm and make a decision based on real information.

Where this program can really make a difference is if your farm has been fortunate enough to grow an average crop during the last few years. The increase in grain prices has driven your margin through the roof. Another interesting aspect is the increase in the allowable expenses.

Tammy Jones completed her B.Sc. in crop protection at the University of Manitoba. She has more than 15 years of experience in the crops industry in Manitoba and Alberta, with a focus on agronomy. Tammy lives near Carman, Man., and spends her time scouting for weeds and working with cattle at the family farm in Napinka.

The science of herbicide resistance management continues to evolve with new technological developments and better understanding of plant processes. As we continue to identify herbicide resistance in more weeds and in different combinations, there needs to be some contemplation of how best to use herbicide groups to manage weed issues. While herbicide groups based on mode of action provide some insight, how best can this information be used to maximize the utility of all herbicide actives, when it seems that weeds are developing resistance mechanisms much faster than herbicides can be developed?

A cornerstone of the best management practices for reducing the risk of herbicide resistance development is to rotate herbicides based on their mode of action. The mode of action of a herbicide is a description of how the herbicide acts in a susceptible plant to control it. The mode of action may describe a biological process (disrupting cell membranes), the enzyme in the plant that the herbicide interrupts (ACCase enzyme) or the symptomology (bleaching). Rather than expecting every farmer and agronomic advisor to become chemists, organizations like the Herbicide Resistance Action Committee (HRAC) and the Weed Science Society of America (WSSA) to name a few, developed classification systems in the 1980s. These classification systems incorporated cutting edge science on the site of action and symptomology of herbicides to develop less than 30 groups of chemicals encompassing hundreds of active ingredients to make herbicide rotation more approachable.

HRAC developed a letter-based classification system while WSSA utilized a numerical classification. Since the 1980s, there have been new active ingredients introduced, some with new modes of action and not surprisingly, research developments have helped to better understand the modes of action of herbicides already on the market. Periodical updates have been performed on the mode of action classifications with the most recent updates completed in 2010 and then another revamp in 2020, which has led to both systems now utilizing the numerical classification to be globally relevant and allow for more herbicide groups to be added in the future. And, while this system will allow for additional herbicide groups in the future, HRAC

and WSSA adjusted the way they categorized several herbicides based on new scientific evidence.

A notable change for Western Canada was the reclassification of Group 8 herbicides (which included Triallate and EPTC).

HRAC and WSSA determined that the mode of action previously represented as Group 8 has a similar mode of action to the Group 15 herbicides. It is interesting to note that Triallate is not new; it was introduced to Western Canada in 1961 and utilized in formulations of Avadex and Fortress. After all these years of use, the reclassification was slightly surprising and at the same time, concerned growers who were utilizing the Group 8 herbicides since it was considered unique based on the mode of action. Did the elimination of a herbicide group mean the loss of a rotational tool?

HRAC and WSSA noted that in the reclassification of the Group 8 herbicides, “Although the modes of action of Triallate and EPTC have been relocated to Group 15, rotation of Triallate and EPTC with historical Group 15 herbicides is still aligned with HRAC and WSSA recommendations for

the Group 15 herbicides are believed to impact on multiple sites or multiple enzymes and there will need to be further research to identify specific target sites. Current weed resistance reports for Group 15 herbicides are limited and cross-resistance patterns haven’t been clearly identified within the Group 15 herbicides; so, mixtures or sequential application

As we continue to identify herbicide resistance in more weeds and in different combinations, there needs to be some contemplation of how best to use herbicide groups to manage weed issues.

patterns within the sub-groups of each herbicide group. In certain cases, all or most herbicides within a mode of action may be rendered ineffective by a particular occurrence of herbicide resistance. However, knowing which sub-groups or specific active ingredients remain effective may help to manage the population in combination with other weed management strategies. This would require in-depth testing of the sub-groups of a herbicide group on a specific weed biotype to identify any effective tools that remain. This could be time-consuming and costly, and there is no certainty in how long those tools would remain effective.

The opposite approach was recently suggested in the Pest Management Science Journal by Dr. Philip Hulme. Dr. Hulme proposed that by “clustering” modes of action based on herbicide resistance patterns, better recommendations could be made to sustain the efficacy of the various herbicide groups. Utilizing the data provided by the International Herbicide Resistant Weed Database, specifically the linkages demonstrated by weeds with resistance to more than two modes of action and herbicide groups with more than 10 different weeds having developed resistance, Dr. Hulme has proposed that there are three clusters of herbicide groups (or super groups) that could be used to rotate or mix between clusters rather than within the cluster to minimize further development of herbicide resistant weeds. For example, Group 2, 4, 5 and 9 herbicides were identified as having several commonalities in herbicide resistant weeds, so rather than using mixtures from these groups, it would be better to use one of these groups in combination with herbicides from other clusters.

The concepts of looking within a herbicide mode of action (the sub-groups) or considering several herbicide groups as a “cluster” (super groups) to thwart further herbicide resistance development are quite complicated and require much more investigation. There are no easy answers. While herbicides can provide farmers with an effective and economic weed control tool, there is no doubt that weed control will continue to become more and more complicated with the increased frequency of multiple herbicide resistant weeds.

There are no easy answers. While herbicides can provide farmers with an effective and economic weed control tool, there is no doubt that weed control will continue to become more and more complicated with the increased frequency of multiple herbicide resistant weeds.

Tom Wolf grew up on a grain farm in southern Manitoba. He obtained his BSA and M.Sc. (Plant Science) at the University of Manitoba and his PhD (Agronomy) at Ohio State University. Tom was a research scientist with Agriculture & Agri-Food Canada for 17 years before forming AgriMetrix, an agricultural research company that he now operates in Saskatoon. He specializes in spray drift, pesticide efficacy and sprayer tank cleanout, and conducts research and training on these topics throughout Canada. Tom sits on the Board of the Saskatchewan Soil Conservation Association, is an active member of the American Society of Agricultural and Biological Engineers and is a member and past president of the Canadian Weed Science Society.

It’s often been said that droplet size is the most important factor governing spray operation success. Both spray drift and pesticide efficacy depend, to a large degree, on droplet size. For something this important, the information ought to be accessible and easy to understand.

There are a few problems to overcome before we get there.

The first is the difficulty in measuring droplets in the first place. In the early days of spray technology research, sprays would be captured on a surface and individual droplets were measured and counted under a microscope. A common approach was to use magnesium oxide coated glass slides. The magnesium oxide layer was soft and an impinging droplet left a telltale crater behind, much like those found on the moon’s surface. This allowed the analysis to be done after evaporation. Water-sensitive paper is the modern version of this concept, but magnesium oxide still does a better job with smaller droplets.

Impingement methods are easy to use but one needs to know the spread factor to calculate the size of the in-flight droplet. The spread factor depends on droplet size, velocity and formulation. In addition, the overall droplet density has to be low enough to avoid overlaps or coalescence. One way around this was to spray into a dish containing an oil. The water droplets would sink to the bottom and stay their original size but they still needed to be counted under magnification. Needless to say, droplet size data was hard to obtain before the 1980s.

In the 1970s and 1980s, we saw the development of laser-based droplet size measurements. With these, a spray simply needed to be directed into such an instrument. This very quickly determined the diameter, and in some cases the velocity, of the droplets. The principles employed by various laser instruments differed and although one could now rapidly obtain data in situ, the numbers among the instruments didn’t always agree.

I recall when I started as a spray technology agronomist with Agriculture and Agri-Food Canada in 1989. Our lab had purchased one of the first such lasers, the Aerometric Phase Doppler Particle Analyzer (PDPA), which was invented by Will Bachalo, originally of Portage la Prairie, MB. We would spray a specific nozzle through the intersecting laser beams and were able to measure tens of thousands of droplets in a matter of minutes. It was absolutely amazing. We learned a great deal. But when we compared our data with other labs using the same device, the numbers didn’t agree exactly. Equipment principles, setup and software versions were important. Everybody had their own true numbers.

All these comparisons ushered in a new approach, that of using reference nozzles.

Rather than argue about whose instrument or measurement method was correct, experts decided to allow each lab to use their tried and true methods. However, they would need to report their data relative to a set of reference nozzles that were carefully selected and distributed to labs on request. These reference nozzles defined the boundaries of spray qualities and were measured by the lab at the time they tested other nozzles. When a nozzle of interest produced a spray whose parameters fell between two reference nozzles, the spray quality was thus defined. In this way, the peculiar results of a certain measurement approach became irrelevant. All that mattered was where the result lay within the reference nozzles.

Credit is due to members of the British Crop Protection Council, who pioneered this result in the U.K. in the mid-1980s.

Thus, the term “spray quality” was born and after various incremental revisions, these were named extremely fine, very fine, medium, coarse, very coarse, extremely coarse and ultra coarse. A colour code was assigned for easy identification.

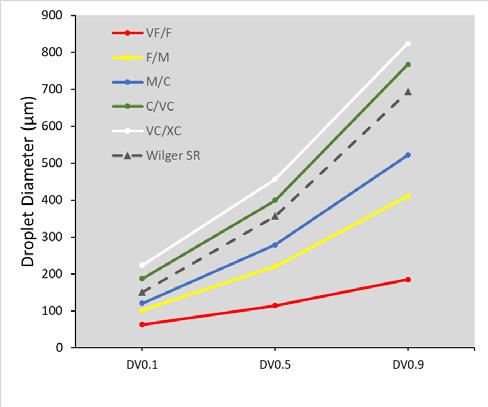

Figure 2: Symbols and colours used to designate spray qualities according to ASABE S572.1 and S572.2. Photo Source: Hypro

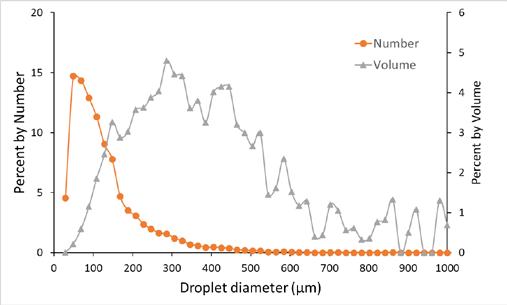

From the beginning of droplet size measurement, the question of descriptive parameters has been debated. Upon the very first measurement of spray droplets, it became obvious that hydraulic sprays were polydisperse, meaning they were comprised of droplets of very many different sizes. A modern nozzle, for example, will produce droplets ranging from about five µm to over 2000 µm. There isn’t one droplet size.

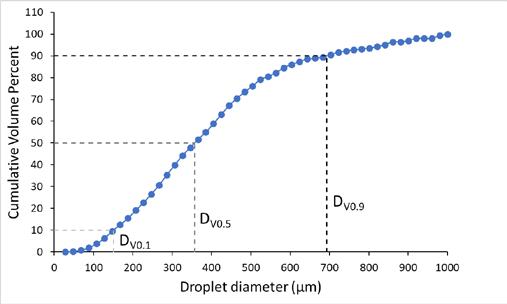

A second observation was that the vast majority of droplets were small. In any sample, about 80 per cent to 90 per cent of the total number of droplets were less than 150 µm in diameter. This held more or less true for both fine and coarse sprays. As a result, using an average weighted droplet diameter was not useful as a descriptor as the abundant sizes would always bias the outcome. There was no way to improve this; any other numerical descriptors such as mode (the most frequent size class) or median (the size class above and below which were an equal number of droplets) were equally flawed.

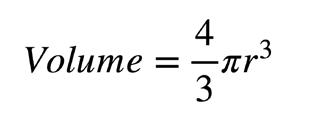

To solve this problem, diameters were converted to their volume equivalent using the formula:

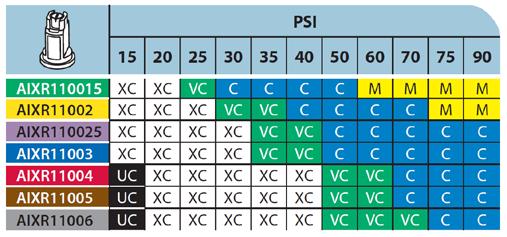

Nozzle manufacturers have a responsibility to publish the spray qualities of their nozzles and they do so on their websites or catalogues. This makes it much easier for applicators to select the right nozzle for the job. With spray quality, the nozzle brand becomes less important.

Where r is the radius of the droplet.

The VMD is the benchmark value. It can be thought of as the diameter around which the majority of the dose is delivered. The DV0.1 is more of a drift index, describing the diameter that contains the smaller droplets. Higher DV0.9 values indicate that more of the spray may be lost to large droplets that will likely rebound.

Thus, we arrive at a volumetric distribution, where each diameter is described by the proportion of the total spray volume it represents. That volume represents the dose of spray. Now we have some practical meaning of the numbers.

By dividing the cumulative distribution into benchmark values, we can get values that differentiate various sprays. The key ones of interest are the 10th, 50th and 90th percentile. The 10th percentile, known as the DV0.1, is defined as the diameter below, which is 10 per cent of the total volume of the spray. DV0.5 and DV0.9 likewise describe the diameters below, which are 50 per cent or 90 per cent of the spray volume. The former is more commonly known as the volume median diameter (VMD). Recall that the median is the value that divides a distribution in half by number, therefore the 50th percentile is also the median.

Figure 5: ASABE reference nozzles showing spray quality boundaries. Note that the Wilger SR tip falls between the medium/coarse and the coarse/very coarse border nozzles, making the spray quality “coarse.”

A laboratory that measures spray qualities would start by running the ASABE reference nozzles on their instrument. They would then calculate the three parameters we just described and plot them as shown in Figure 4. Next, the lab would atomize various nozzles of interest to see where their parameters fall with regard to the reference nozzles and make a spray quality designation. In the example we’ve been showing, the Wilger SR nozzle is in the “coarse” category using this approach.

Nozzle manufacturers have a responsibility to publish the spray qualities of their nozzles and they do so on their websites or catalogues. This makes it much easier for applicators to select the right nozzle for the job. With spray quality, the nozzle brand becomes less important. In fact, nozzles that produce the same spray quality can be expected to have very similar performance. Various nozzle models still have important distinguishing features, such as pressure range, fan angle, pattern tilt, etc. But a 110-degree air-induced nozzle that produces a “coarse” spray quality should perform very similarly to a different manufacturer’s 110-degree nozzle that also produces a “coarse” spray quality.

Note that the spray quality categories are quite broad. Within any given spray quality range, we might see a twofold range of drift potential, for example. It remains important to have a sense of where one is operating within the spray quality range.

A recent development is the creation of a new standard that has implemented new boundary nozzles for the coarser sprays. This standard, ASABE S572.3, coincides with the new ISO standard 25358 and has been implemented by TeeJet in their new catalogue. A way to determine if one is dealing with the new or older standard is to look at the colours of the coarse

and very coarse categories. In S572.1 and S472.2, coarse is blue and very coarse is green. In S572.3 and ISO 25358, these colours are reversed.

Regardless of these recent changes, spray quality will likely remain a very useful way to communicate expected drift and coverage information for agricultural sprays.

Note that the spray quality categories are quite broad. Within any given spray quality range, we might see a two-fold range of drift potential, for example. It remains important to have a sense of where one is operating within the spray quality range.

Planning your fall seed program definitely sounds easier than it is. There are a number of key considerations that must be taken into account before planting winter wheat and fall rye for the 2023/24 season.

Timing, optimal seeding depth and density are just a few factors that must be evaluated closely, in addition to fertility application, weed and pest treatments. If that isn’t enough, growers need to be on the watch for new varietal developments and input products.

“When it comes to harvesting a successful fall cereal, it is all about being able to rely on a proper establishment,” says Nathan Penner, commercialization manager for FP Genetics, a Saskatchewan-based seed company with territories in Alberta and Manitoba. “The expression, ‘well-sown is half-grown’ really does have merit with fall seeded crops. We are asking these cereals to survive in Canadian conditions for nearly a year, so you want to give the seed the best possible start.”

Some key considerations involve high-quality seed, field selection, fertility, timing and for the seeding operation to ensure the field is well-established and uniform heading into winter. Conversely, if the field is poorly established, there will be increased weed pressure, lower yield and, with fall rye, potentially more ergot in the grain sample.

“When selecting a field for fall rye, ideally it should be well-drained, so there is minimal standing water in spring,” Penner explains. “We recommend not seeding low areas that

are known to flood in the spring as that is where you’re most likely to have winter injury. As always, watch for herbicide carry over from the preceding crop.”

As with anything in life, timing is everything. For fall rye, early seeding is typically the best option. For most areas of the Prairies, FP Genetics recommends seeding between midAugust and September 10.

“These dates vary a bit by region, but generally the later you seed–even by 10 days to two weeks–can make a significant impact on yield, ergot and weed control,” says Penner. “Essentially you have a less vigorous and competitive crop in the spring if it is seeded too late. It is possible to compensate somewhat with a higher seeding rate adding five per cent-to-10 per cent per week after about September 5. This can help maintain the plant density when conditions are not optimal.”

For hybrid fall rye, FP Genetics recommends 0.8 units per acre, which is 800,000 seeds per acre. Units are calculated using seed size and germination to ensure the grower is purchasing based on live seeds. This seeding rate equates to 18 plants per square foot. This is a significantly lower seeding rate compared to open pollinated (OP) rye. The hybrid rye exhibits more aggressive rooting and tillering than OP varieties of rye, and this means less seeds are required to produce an optimal yield.

“Optimal seeding depth is three-quarters of an inch with proper packing,” explains Penner. “The importance of the

seed depth goes back to giving the field the best start. Keeping the seed at three-quarters of an inch helps achieve a uniform emerging field.”

When it comes to fertility application, weed and pest treatment considerations, in order to get the best results from the hybrid fall rye, the inputs need to be adjusted to yield expectations. Due to the extensive rooting of hybrid fall rye, the plants are highly efficient at converting inputs into grain, but it can be difficult to achieve top yield potential without adequate fertility.

“So much depends on location, soil moisture and residual fertility,” stresses Penner. To achieve a 100 bushel per acre hybrid rye crop, guidelines generally suggest 120 lbs. of nitrogen, 30 pounds. of phosphorus, 50 pounds. of potassium and 15 pounds. of sulphur. “An agronomist in your region can help adjust for your specific field conditions.”

While many growers prefer to put all their fertilizer down in the fall, other growers will split apply the nitrogen, but it is vital to have that extra nitrogen applied very early in the spring. Since fall rye begins developing once the soil is barely above zero degrees Celsius, winter wheat needs warmer soils at four-to-six degrees Celsius.

“This means fall rye’s yield potential is set much earlier than

winter wheat,” says Penner. “This also means that in most areas of the Prairies, the nitrogen needs to be available late April or very early May.”

One of the advantages of fall rye is there tends to be lower input costs. Well-established fields have a significant impact on input costs. With a pre-seed burn off and a fall herbicide application for any perennial or winter annual weeds, a well-established field doesn’t always need spring herbicides.

“We still highly recommend scouting the field in the spring to determine if a spring application is warranted,” says Penner. “Hybrid fall rye varieties have good disease tolerance and rarely need fungicides. Since fall rye flowers early, it tends to be done flowering before the prime fusarium infection period for cereals. However, testing is ongoing to determine if spraying for fusarium is economical.”

While there are occasional years that winter cereals can be impacted by true armyworms, scouting fields by mid-to-late June is prudent. However, it is a rare occurrence to have a season with widespread damage.

Over the next few years, FP Genetics plans to launch some exciting new rye hybrids in Canada. “We’re also focused on market development to bring growers more opportunities to sell grain from these new varieties,” says Penner.

“The expression, ‘well-sown is half-grown’ really does have merit with fall seeded crops. We are asking these cereals to survive in Canadian conditions for nearly a year, so you want to give the seed the best possible start.” - Nathan Penner

By Jake Leguee

By Jake Leguee

When I was young, agriculture was not a common news story. The times that ag was mentioned in the news (we were one of those families that always had the six o’clock news on), it was a story about an old elevator getting knocked down, farmers complaining about this or that, how difficult it was to survive farming and so on. I so wished for ag to feature more prominently in the news. I so wished people could see the amazing technological advancements we were making, even 20 years ago. I so wished people saw farming the way I did!

I believe the phrase goes something like, be careful what you wish for….

Well, we got what I asked for. Agriculture is definitely a prominent subject these days. In fact, farming has found itself more in the spotlight than I ever could have imagined it would. Unfortunately, it isn’t there for the reasons I’d hoped.

Like the energy industry, agriculture continually finds itself in the cross hairs of the environmental movement. Apparently, we are a major contributor to greenhouse gas emissions; we degrade and damage our land; we apply dangerous pesticides and fertilizers that harm the environment; we grow nutritionally sparse, calorie-dense foods that are causing a crisis in obesity; and on and on.

Recommendations usually include switching to organic or at least regenerative (whatever that means), cutting or eliminating pesticides and fertilizers or in the case of the Netherlands in certain areas, just shutting down the farm completely.

The European Farm to Fork strategy is a microcosm of this movement to “transform” food systems. You might have heard of it – it’s a key part of Europe’s “Green New Deal.” Here are its core tenets, at least as far as agriculture is concerned:

• Reduce the overall use and risk of chemical pesticides by 50 per cent and the use of more hazardous pesticides by 50 per cent by 2030.