Kevin Hursh

Scott Shiels

Kevin Hursh

Scott Shiels

Kevin Hursh, P.Ag.

Kevin Hursh is one of the country’s leading agricultural commentators. He is an agrologist, journalist and farmer. Kevin and his wife

Marlene run Hursh Consulting & Communications based in Saskatoon. They also own and operate a farm near Cabri in southwest Saskatchewan growing a wide variety of crops. Kevin writes for a number of agricultural publications and serves as executive director for the Canary Seed Development Commission of Saskatchewan and the Inland Terminal Association of Canada (ITAC).

Twitter: @KevinHursh1

My nephew, a lifelong farmer, passed away back in March after battling cancer for more than a year. Darren Titemore was only 49. He had been a robust, healthy man who enjoyed working out in the local gym. He should have been farming for another 20 years. His funeral drew a large crowd and it’s still hard to believe he’s gone.

His passing is a reminder that no one has a contract on health or lifespan and, for that reason, all farms should make contingency plans in the event of disability or death.

Farming is an aging profession with lots of active senior citizens who, in many cases, are still serving as the key driver or primary decision-maker of their operation. Health issues can appear at any age, but become increasingly likely as we age.

I’m now in the senior citizen category and have a few relatively minor health issues I like to complain about, but I see farmers younger than me needing hip and knee replacements. Scheduling procedures becomes an issue, particularly for producers with both grain and cattle. It can be hard to come up with a good time of year to be out of action and yet you don’t want to pass up the opportunity for an operation when you finally get your turn.

While many aspects of farming aren’t as physically demanding as in decades past, a strong back is still useful. Some farms have younger family members or employees involved and these folks can assume the jobs requiring more brawn.

Personally, I approach tasks differently than I used to. I’m less likely to jump down from equipment and I’m more likely to get the tractor and front-end loader for moving heavier items.

A beach getaway may be closer than you think.

Let more profitable cereals take you there.

When we say more profitable cereals could take you further, we mean it. Sphaerex® fungicide delivers stronger, longer-lasting efficacy on leaf disease and outstanding control of FHB. It also helps preserve your grain’s grade with its best-in-class DON reduction. This exceptional level of protection leads to increased quality, yields and profits. Now just imagine where all that might take you. Visit agsolutions.ca/sphaerex to learn more.

Always read and follow label directions.

Sometimes it’s the body that wears out first, but other times, it’s cognitive ability. Unfortunately, all too often, disability or even death occurs unexpectedly, giving little time for the farm operation to adapt.

Heights didn’t use to bother me, but I’ve grown more cautious when climbing bins. I can still handle 50-pound bags of mustard or canola seed, but I’d rather not dump scores of them unassisted.

At the same time, I swear the writing in instruction books is getting smaller. So are the tight spaces you sometimes need to squeeze into when servicing equipment. Also, I’m happier with low-tech stuff, rather than high-tech.

In an ideal world, aging occurs gradually and farming activities can adjust accordingly. Sometimes it’s the body that wears out first, but other times, it’s cognitive ability. Unfortunately, all too often, disability or even death occurs unexpectedly, giving little time for the farm operation to adapt.

What if it’s the person who does the bookkeeping that’s incapacitated? I’ve heard of situations where the family didn’t even have the password to access the farm accounting software after the person responsible for this task was unable to continue.

The only way to make provisions for the unexpected is to ask all the what-ifs despite this being uncomfortable. Does more than one person on the farm team know how to run the sprayer? Does anyone else have a clue about debits, credits and filing GST returns?

What grain is in what bin and how much? What production contracts have been signed? Could a custom operator be hired to help the farm get through a busy season? Is there a current will and a viable succession plan?

Dealing with shock and grief can make coping with everything else much more difficult. As much as possible, it’s best to have contingency plans in place just in case the unthinkable happens. Those plans shouldn’t just be in the head of one person. They need to be written down and shared. And while it’s natural to complain about old age and the limitations it brings, growing older sure beats the alternative.

Publishers

Pat Ottmann & Tim Ottmann

Editor

Lisa Johnston

Design

Cole Ottmann

Regular Contributors

Kevin Hursh

Tammy Jones

Paul Kuntz

Copy Editor

Tom Wolf

Nerissa McNaughton

Sales

Pat Ottmann pat@farmingfortomorrow.ca 587-774-7619

Nancy Bielecki nancy@farmingfortomorrow.ca 587-774-7618

Chloe MacEachern chloe@farmingfortomorrow.ca 587-774-7622

/farming4tomorrow

/FFTMagazine

/farming-for-tomorrow

/farmingfortomorrow

WWW.FARMINGFORTOMORROW.CA

Farming For Tomorrow is delivered to 90,720 farm and agribusiness addresses every second month. The areas of distribution include Manitoba, Saskatchewan, Alberta and the Peace region of B.C.

The publisher does not assume any responsibility for the content of any advertisement, and all representations of warranties made in such advertisements are those of the advertiser and not of the publisher. No portion of this publication may be reproduced, in all or in part, without the written permission of the publisher. Canadian Publications mail sales product agreement no. 41126516.

AFSC has your back with a personalized portfolio of livestock and crop insurance, farm income stabilization, and lending products to protect you from the unexpected … and move you to brighter days.

PROUD TO SUPPORT AGRICULTURE IN ALBERTA

Scott Shiels

Scott grew up in Killarney, Man. and has been in the grain industry for 30 years. He has worked with Grain Millers Canada for 10 years and manages procurement for both conventional and organic oats for their Canadian operation. Scott is an elected board member for Farm and Food Care Saskatchewan and sits on several other committees on both the organic and conventional sides of the oat industry. Scott and his wife Jenn live on an acreage near Yorkton, Sask. Find out more at www.grainmillers.com.

In this issue, I want to talk about how public perception can potentially affect grain markets, and even your farming practices. This winter, the oat industry in particular, came under attack by the media in the U.S., our main export partner of the staple.

Back in the middle of February, the Environmental Working Group (EWG) published an article regarding the chemical chlormequat, more commonly known as Manipulator, a plant growth regulator that is registered for use on cereal crops here in Canada. The study they conducted found trace levels of chemical residue in some oat products, as well as in some human subjects tested over a period of time. The article states that while the chemical is not registered for use on crops in the U.S., it is allowed on imported products, such as oats, from Canada. Now, while the article did go on, at the very end, to state that the levels found in the products and the people tested were many, many times less than the maximum residue limits set by the EPA, the damage had already been done. Within hours of the release of this information, food companies were reaching out to the milling industry with questions about the safety of oat products coming from Canada. Shortly after the release of the EWG report, major publications began to share the story, or at least the “scary” parts of it, leading with headlines like “Pesticide linked to reproductive issues found in Cheerios”; “80 per cent of Americans test positive for chemical found in Cheerios”; and “Chemical found in Cheerios, Quaker Oats may cause fertility issues.” These headlines are the epitome of fear mongering and take the most miniscule facts and blow them up into major issues. In fact, at time of writing, both Quaker and General Mills are facing class action lawsuits in the U.S. based on this report. How is that for getting the public up in arms over nothing?

The facts, which some of the articles either twisted or left out, are actually supportive of how safe our foods made with Canadian oats are! The levels found in the oat products were 384 times smaller than the maximum levels set by the EPA. However, as we all know, fear sells, and in this day and age of social and electronic media, the bad news travels at light speed.

Now, I am not trying to put this story on trial here, but since it is front and centre in our world, I want to make an example of how something so trivial can be twisted to say whatever fits their narrative. As an industry, we need to be proactive when it comes to what we are doing and how safe it is. Linking our side of the industry to the consumer side is imperative, so that as time goes on, more and more consumers will read articles like these and either search for the truth and facts, or dismiss them entirely. Organizations such as Farm & Food Care, the Canadian Centre for Food Integrity, and Ag in the Classroom are leading the charge when it comes to advocacy for the safety of the food we are producing on our side of the border. I would urge you, if you haven’t done so already, to learn more about what these groups are doing for all of us in the Ag industry across the country. It would be far easier to educate consumers rather than having to spend the time, energy and money defending ourselves at every turn.

Until next time…

Introducing Zetigo™ PRM, a dual mode of action fungicide, with Adavelt™, a brand new Group 21 fungicide active ingredient. Zetigo PRM provides powerful disease control and elevated resistance management in pulses.

Add Zetigo PRM to your pulse disease management plan to Protect Today and Prosper Tomorrow.

Paul Kuntz

Paul Kuntz is the owner of Wheatland Financial. He offers financial consulting and debt broker services. Kuntz is also an advisor with Global Ag Risk Solutions. He can be reached through wheatlandfinancial.ca.

I love working with farmers and I think they are the highest calibre people. If I had to pick one issue I have with them, though, it is that most farmers pay little attention to inventory.

Producers focus on income and expenses. They like to know what the dollar per bushel number is or the gross revenue per acre. Livestock producers often talk about their gross revenue per head. All farmers talk about the costs they incur. They love to comment on the cost of fertilizer and how expensive a new tractor is.

What many producers do not realize is the importance of proper inventory numbers and how that affects their financial statements. There are other areas like AgriStability that can also be impacted by improper inventory numbers.

When financial statements are created incorrectly, it can cause issues with your banker and input suppliers who offer credit. They rely upon these numbers to adjudicate your file and assess your credit worthiness.

Most important to me, incorrect inventory numbers give the producer incorrect information about the farm’s financial status. This can lead to improper planning and incorrect decision-making.

A wise man once told me that when a farmer says there are 5,000 bushels of canola in a particular bin, what you know with 100 per cent certainty is that there are not 5,000 bushels of canola in that bin. It might be 5,122 or it might be 4,965, but it definitely will not be 5,000. We all know that there is some level of generalization regarding inventory and that is most likely fine.

What I am referring to is the farmer who forgets they had that 5,000-bushel bin of canola. Or the farmer who says they have 5,000 bushels, but forgot it was actually sold. That is the incorrect information I am referring to.

Livestock producers seem to have the same tactics. When I ask cow/calf producers how many cows they have, it is always a round number. “We have 300 cows” or “we have 700 cows.” I very much doubt the actual number of cows is a round number.

Following are some examples of how improper inventory numbers can affect producers.

Let’s look at a 5000-acre grain farm as an example. At year end, they declare they have $1.5 million in inventory on hand. They also declare they have $800,000 in current liabilities, such as a line of credit. They started the year with $1 million in inventory and they had grain sales of $2 million. The actual accrued income for that farm would be: sales ($2 million) less opening inventory ($1 million) plus closing inventory ($1.5 million) which would total $2.5 million or $500/acre. Their current ratio would be $1.5 million/$800k=1.875:1, which is good.

But once we dig deeper, we realize that when we account for dockage, bins that are not full to the top, and perhaps a mix up on writing down a few bins that were emptied, the actual inventory is only $1.3 million. This now means their accrued income for the year was only $2.3 million or $460/acre. The current ratio is only 1.62:1.

Another example is to see the devaluation not accounted for. If this farm had 62,500 bushels of canola worth $16=$1 million – and they had 50,000 bushels of wheat values at $10=$500,000 – in reality, the canola is $14 and the wheat is worth $8 which is now $1,275,000.

Grain farmers can have grade issues as well. If the durum listed as No. 1 is now a No. 4, that valuation will change.

Cattle producers have similar challenges. If the animals do not go through the chute, producers are just guessing. If animals are run on large acre pastures, there can be losses unknown. The biggest issue I see with cattle producers is classification of calves. A ranch might declare they have 500 calves. However, that definition of “calves” is not much of a description. Five

All producers will be at different stages regarding their inventory management. I recommend reviewing what it is that you do and determine how you can do it better. Most importantly, you need to understand how vital it is to have accurate numbers.

hundred heifer calves that weigh 400 pounds is a much different value than 500 steer calves that weigh 800 pounds.

Your marketing plan is another reason to have a good inventory system. When producers go to sell animals or bushels of grain, they need to know what they can sell.

There are apps and programs that can manage inventory. Depending on the size of your farm and complexity, you may want to look at these. For livestock, you can use RFID tags and employ the use of electronic tag readers. What I recommend is to have something. It needs to be accessible to all who affect inventory so they can record what has happened. It needs to be updated regularly. It needs to be accurate.

Whatever system you decide to employ, just make sure you follow through. You can take inventory management to extreme levels. Our grain producers have grain carts with scales on them. They can determine exactly the bushels put into their bins. When we sell grain, it is always weighed, so it is possible to know the exact weight of the grain that went into the bin and the exact weight of what was already hauled out. Many cattle producers have scales, so the exact weight of feeders can be determined. If you can manage your inventory at that level and keep it up consistently, I would applaud your operation. If you are currently keeping track of everything in your head, you do not need to switch to the most sophisticated system. What you need to do is switch to a better system than keeping track of it in your head.

All producers will be at different stages regarding their inventory management. I recommend reviewing what it is that you do and determine how you can do it better. Most importantly, you need to understand how vital it is to have accurate numbers.

Once you have your system, review your numbers often, and use that information to make better decisions.

Great job recycling your empty pesticide and fertilizer jugs, drums and totes. Every one you recycle counts toward a more sustainable agricultural community and environment. Thank you.

2024 COLLECTION SITES OPEN APRIL 1.

Ask your ag retailer for an ag collection bag, fill it with rinsed, empty jugs and return jugs, drums and totes to a collection site for recycling. In Alberta and Manitoba, ask your ag retailer if it’s a jug recycling location. Details at cleanfarms.ca

NEW! Return empty seed, pesticide and inoculant bags for environmentally safe management. Find a collection loc ation ne ar you at cleanfarms.c a

info@cleanfarms.ca

@cleanfarms

Harvey Chorney is in a unique position.

Farming with his brother north of Winnipeg, they both have the engineering background and equipment knowledge to do most of their own repairs on their tractors and combines. They know the common cracks, failures and wear points that should be checked and maintained during the off-season before hitting the field in the spring.

Farmers, like Chorney, have been doing it this way for decades, but as a retired vice-president of Manitoba operations at Prairie Agricultural Machinery Institute, Chorney says even he is finding benefit in the preventative maintenance packages that equipment dealers have been developing over the last decade. With preventative maintenance costs becoming a common service add-on, whether farmers are purchasing new equipment or adding coverage to old machines, Chorney says he is spending pennies and saving dollars in terms of breakdown costs.

“Sometimes they find things, sometimes they don’t, but you know when they do the inspection and everything is good, you’re good for the season,” he notes.

Even though he farms with many colours of equipment, Chorney says his farm has been part of John Deere’s Greenlight Inspection program for the past decade, while his neighbour has been seeing similar benefit through Case IH with checks every year on their two Quadtracs. They haven’t had an in-field incident since, he adds.

While some equipment dealers offer quick and guaranteed service during the busy seasons, including offers for a replacement machine for unexpected issues during the season, Chorney states preventative maintenance in the off-season has saved in-season headaches while avoiding the need to use a different machine.

Finding a similar model and converting monitors and hookups could put anyone down for up to three days. With the production window small on the Canadian Prairies, many farmers can’t afford the time, energy and money those breakdowns incur, let alone the time to fix a machine. Both Chorney and his local dealership benefit when they deal with these issues during the off-season.

“The dealerships get the advantage of work during the down season. Otherwise, they are trying to think what to do with their mechanics during the down months to make their time useful.”

Every machine has an expected lifespan. Chorney clocks it at around 5,000 hours for a combine and around 10,000 for a four-wheel drive. Preventative maintenance information and service, he believes, has ensured his machines make it to that point.

For John Deere, farmers are financing that maintenance right into the payment plan for their machines, meaning no unexpected costs later when something has to be fixed. According to Jason Wiens, Alberta’s precision ag lead for Brandt Group of Companies, this has been a way to digitize

what they already do with their own maintenance and checks, with concrete numbers for a part’s failure history.

“Based on the hours of the machine, it will trigger those events for the customer, alert them that the maintenance is due on a certain piece and then give them all their part numbers and fluid amounts at that interval,” explains Wiens.

Through Massey Ferguson’s GenuineCare plan, dealerships and farmers can be proactive about their maintenance. Frank Amato, program manager of commercial services at AGCO Corporation, says this is especially true for the current generation of machines plus one generation back. Through their AGCO Protection, they’ve been able to provide extended service programs going back through nine generations of tractors.

Farmers want and need that predictability, he adds, and connecting farmers with the dealerships through their Fuse technology means someone has their back during those stressful times.

“For the machines that are connected, dealers are able to see, ‘Hey, my customer is coming up on this 500-hour service.’ So, we’re going to get proactive; we’re going to reach out and schedule maintenance with them,” notes Amato.

Chorney still does as many of his own repairs as possible, and dealers incorporate this into their service plans for other DIY farmers. However, not every farmer is in the same boat with the same access and understanding to interpret the data as he has been doing in his professional life.

“When you’re looking at dealers, companies have all the data of all the machines running in Western Canada, knowing which have high potential failure points that need to be inspected. The average farmer doesn’t know that,” says Chorney. “It’s not available.”

Coding and technological advances make this more difficult for some farmers, and sometimes Chorney even needs help from the dealership to assist with his own interpretations and troubleshooting.

“We’ve relied on dealer input … where we’ve had to phone the dealership and say, ‘OK, I’ve got an error code, three-four digits long. Can you tell me what it is?’ and then try to troubleshoot.”

So, where is all this information coming from? Good data has been the driving force behind the development of these programs.

If dependability is something you value in life, look no further than Ace brand pumps. Every Ace pump features state-of-the-art design, advanced components and uncompromising quality control. The end result: pumps you can count on for years of reliable service. To learn why an Ace pump is your best friend, please visit us at www.acepumps.com, or contact your nearest Ace Pumps distributor.

“This is kind of the next level where data is key,” says Chorney. “If you know where the weak points are, where the failure points have been happening with like models in your area, that’s gold information.”

Data collection is not a new thing. Many equipment brands have their own way of connecting their machines to a wider network.

The JDLink program connects with their machines using 3G and 4G networks, starting with their tractors in 2010, and reaching full connectivity for their full production line in 2018. Since 2021, they have been equipping all machines 2012 and newer for free. With that connectivity comes data collection to not only provide their customers with predictive maintenance plans, but to also harvest those machines for valuable analytics that could help with production improvements and failure predictability.

According to Wiens, they’ve been analyzing this data for patterns. If a failure consistently triggers after a certain amount of time, or two failures initiate a third, they can use that information as an early warning system for dealerships to connect with farmers. “The dealer has the opportunity to do some remote diagnostics, confirm that it is going to fail, and then we can alert the customer. All that data is coming from the tractor back to us.”

Connectivity – and whether to take update advice – has been entirely in the hands of the farmer, especially with some concerns about what is done with that data and who will have access to it. With a focus on building and selling tractors, Wiens says they are not in the business of selling data. Farmers have full control over who sees the data and what data is being sent back to John Deere and the dealership.

“If they’re concerned about [sharing] yield data … they can turn that off, but still have that preventative maintenance expert alert,” he notes.

The data John Deere has collected over the years has been used to improve machines and address issues. “If a certain part fails on a combine, now the engineers can see anonymously, not with a customer name or anything, but they can see the load that machine was under,” explains Wiens. “Were they in 40-bushel canola or 400-bushel corn? So, the engineers can go, ‘do we have a problem here or not?’”

Connectivity continues to be a challenge across rural Canada. If 3G service is cut off in favour of 4G and 5G networks, certain machines won’t be able to connect anymore, warns Wiens. John Deere’s partnership with Starlink will mean future connectivity in these dead zones, he adds.

During harvest time, machines are also connecting with one another and forming a collective map.

“It’s really painful at harvest when we lose connectivity in a field. Deere has got quite a map of where connectivity is good and bad, so they know there’s a lot of holes in the (rural) country, in the Midwest too. And that’s what they’re hoping to alleviate with the Starlink partnership.”

With preventative maintenance becoming more and more common, there are few dealerships that don’t have something in place in terms of service contracts or the types of services they offer throughout the year.

Chorney’s advice: farmers should always talk to the dealership about which service is right for them, their operation and their equipment.

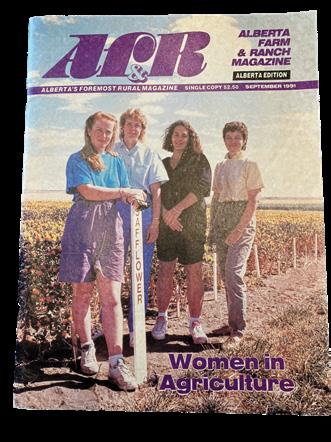

In recent years, there has been a buzz around the number of women pursuing careers in agriculture-related fields. While the demographic has steadily increased over the ensuing decades, women have always played a significant role in cultivating Canada’s soil. In 1991, Jodee Karlowsky, Dianne Westerlund and Andrea Hilderman – all working together at CARA – were featured in Alberta Farm & Ranch Magazine Today, Farming for Tomorrow continues their stories.

Back in 1991, Jodee Karlowsky was new to the agricultural industry and starting her career at Chinook Applied Research Association (CARA).

“I was trying to make a mark in the world, learning the ropes and finding my way in life,” recalls Karlowsky. “I remember being so excited about being featured in the article, and the day the writer and photographer came to Oyen to interview and photograph us. When the magazine came out, I sent it home to my parents in Manitoba. I hadn’t told them about it, but it felt like a ‘made it’ moment.”

The magazine has been tucked away in a special place over the years, but lately Karlowsky has pondered what the women would have to say about their paths today. What changes have they seen in agriculture? What advice would they give to others following in their footsteps?

To find the answers, Karlowsky reached out to some of her former colleagues and was pleased to discover many were still building careers in agriculture.

Dianne Westerlund’s tenacity, commitment and work ethic has kept CARA growing for over 30 years. With an initial aim

to connect research to the producers trying to make a living in the semi-arid and challenging soils of east-central Alberta, CARA’s program has evolved to include a broad range of small plot and field trials, including evaluation of crop and forage varieties, agronomics and rotations.

“Our program also includes conservation-related projects and a soil health initiative which grew into a Soil Health Lab about six years ago,” adds Westerlund, who serves as CARA’s manager and forage agronomist. “This ‘farmer’s lab’ is the first of its kind in Western Canada and has now processed thousands of soil and compost samples for farmers, ranchers and specific research projects. We continue to utilize a number of methods for delivering information to producers.”

Throughout it all, Westerlund has remained a constant. “I have been very fortunate to have had a supportive board (made up of local producers) during my entire career with CARA. They have guided the program, helped secure funding, but also encouraged me to be creative in developing projects and partnerships. Being a native of the special areas and understanding the challenges of the region has encouraged me to continue finding ways to improve the agriculture community. It is rewarding when I see the updates, applications and resulting benefits of the information CARA is generating and sharing.”

When asked what advice she would give to young women in agriculture today, Westerlund answers, “If you wish to pursue a career in agriculture, respect the experience and learn from the farmers and ranchers you work with; seek out and understand their knowledge and where they are coming from.” In addition, Westerlund recommends embracing learning

opportunities. “Draw on the expertise of others in the industry, seminars, conferences, etc. Don’t ever think you know it all; your formal education is just a part of the picture.”

Andrea Hilderman was one of the female agrologists working alongside Westerlund and Karlowsky at CARA during the early 1990s. Karlowsky first met Hilderman when she asked her colleague if she could help her turn on her computer.

“Since that day, Andrea has been a resource and sounding board throughout my career,” says Karlowsky. “For both myself and Andrea, our time at CARA wasn’t the result of a desire to live and work in Oyen, but it was a stepping stone to build a great foundation. One of the great things about CARA and the area is that they were willing to take us in, and accept us readily into the community.”

Even today, Hilderman stands out wherever she goes, not only for her boisterous personality, but also for her willingness to speak up and say what she thinks. Upon the completion of her bachelor’s degree in animal nutrition and biochemistry in her native Ireland, she moved to Canada in 1987 and completed her masters in weed science at the University of Alberta. “It was interesting to reread the article and look at the changes, and how I adapted and maybe even participated in

these changes over my time in the industry,” says Hilderman. “It’s a good feeling to see how far we’ve come.”

Like Karlowsky, she also comments on the passage of time. “In the beginning, I sensed myself pushing hard, thinking I could change the world, but then over time, I realized change was slow to occur,” says Hilderman, who currently serves as a category manager for Federated Co-operatives Limited. “But even so, change has happened over the years. In the beginning, a lot of women in ag seemed to be in more traditional roles –accounting, human resources, marketing – but women have moved into operationally significant positions. The industry doesn’t look like the industry I entered in respect to the representation of women and other minorities.”

According to Hilderman, many of these changes have resulted from the pure determination of women. “I think we have found our place and we continue to break down any barriers that exist. We are accepted as fully contributing members of this industry; there are no more token women.” She encourages the leaders of tomorrow to pursue agriculture careers. “This is a great industry to be a part of. There are so many aspects to it; so many different jobs within it, from running the gamut of marketing and massive budgets to being an agronomist or overseeing the whole operation. The roles are only limited by our imaginations.”

Today, Karlowsky serves as general manager of Alliance Seed, a cereal and pulse seed company that sells wheat, barley, oats and peas across Western Canada. She always recalls her experience in Oyen and how CARA was a transformational experience.

“A girl from the Red River Valley moves to the heart of the Palliser Triangle, it’s a bit like a Wizard of Oz story,” laughs Karlowsky, who grew up 50 kilometres south of Winnipeg and graduated from the University of Manitoba in 1989 with a degree in ag science. “But I wouldn’t trade that first experience for the world as it prepared me so well for my career. I loved Oyen for its close-knit community and welcoming ways. I met so many great people besides my co-workers who all have had an influence on my life.”

Karlowsky is pleased to note there’s a lot more women in agriculture than there were 30 years ago. “And not just in those supporting roles; they are participating.” Karlowsky adds diversification has increased as well. “It’s not just farm girls or veterinarians in the field, it’s women with an interest in science, women who are great at finance and those fine details that are needed in the landscape of farming today. They come from the city, they come from towns, they come from other countries … and they all contribute.”

Her advice to women entering the field: “Be open to whatever comes your way. Learn, grow, experience. And realize that not everyone is going to like you, just like you aren’t going to love everyone you meet, but respect and realize there is opportunity in every situation.”

In the past, persuading farmers to grow hemp was a bit of a hard sell. It was challenging to harvest and there was no established local market for the baled fibre. Keenly aware of these issues, a group of Alberta entrepreneurs (that included farmers) knew they would have to develop a completely different grower program if they were going to get farmers onboard with growing hemp for the 40,000-square-foot decortication facility they planned to build at Bruderheim, Alberta, 40 minutes northeast of Edmonton.

“Our model is seed, spray and walk away,” says Aaron Barr, CEO of Canadian Rockies Hemp Corporation (CRHC). “We supply the varieties and our agronomist will go do field selection and fertility recommendation. Farmers seed our hemp, do an in-crop herbicide application only if needed, and they’re done. We come in, do the cutting, raking, baling and hauling.”

Making it as easy as possible for farmers to grow the company’s single-purpose hemp (known as young hemp fibre) has been at the heart of its business model and is proving popular with local farmers.

“Farmers don’t need to buy any new equipment or figure out how to grow this crop,” Barr says. “They seed it with their conventional seeder and are essentially done. It’s been well received for farmers to grow this crop because we’ve taken harvest operations off of their plate. It has turned out to be a good fit for large grain farmers because many are overcapitalized on their seeding; they can seed more acres than they can combine, so if they don’t have to worry about doing any of the hemp harvest, the operational advantage is significant. It allows us to get more acres, but also to keep the product quality and consistency the best we can.”

The CRHC facility began processing hemp fibre in early 2023 and when it reaches full capacity, it will be able to process 50,000 acres of hemp a year, which it will source from within a 150-kilometre radius. The company has developed its own line of patented harvesting equipment that can harvest 10 to 15 acres of crop an hour. Barr and his team travelled the world to learn about different decortication technologies, which they had to adapt to process Canadian-grown feedstock.

“Our fibre is a lot tougher than that grown in Europe, for example, so there has been a lot of innovation and technology development on the decortication side that is allowing us to get high throughput capacity with minimized down time,” Barr says.

With increasing disease pressure from clubroot in canola, that is often grown in tight rotations with wheat, farmers

are always looking for additional crops to add to their rotations. That’s especially true in northern areas of the Prairies, where shorter, cooler seasons mean they can’t grow corn or soybeans. Young hemp fibre provides them with a great option because it’s a photosensitive plant that is well suited to longer days and matures quickly (about 65 days to harvest).

Barr also points to six years of extensive plant and soil research data that they have collected that has shown an average bump in yield of 20 per cent in crops that follow hemp in the rotation.

Hemp has a huge taproot. It goes two to three metres down, so it helps to break up hardpan soil, demineralizes far-down nutrients and makes them more available for the crops that follow. “Because we do the harvest, because of the soil health and soil carbon benefits, and because we’re seeing such an increase in production on crops that follow, it’s a win-win for farmers,” Barr says.

What bodes well for the hemp fibre industry in Western Canada is the versatility of the crop that produces essentially three different byproducts that all have multiple uses, with more emerging all the time.

About a quarter of the zero-waste facility’s production is hemp bast fibre that is used as batt insulation by the construction industry and in pulp, paper and textiles. Uses in the automotive industry are also beginning to emerge.

Hurd is the second raw material produced that has an established use in animal bedding, but another fast-emerging market is for Hempcrete, a building insulation material that is now approved for use in residential buildings in the U.S.

Finally, the remaining screenings and dust are captured and used in the oil and gas industry for absorption of spills as sawdust replacement.

Some farmers will remember past (failed) attempts to get decortication plants up and running across the Prairies, so what’s changed? A lot, Barr says.

There are now a number of new hemp fibre varieties available that are better suited to the western Canadian Prairies, with higher bast fibre content and higher yields, many of them coming from other hemp growing regions like Ukraine, Romania and Poland.

“The issue with growing hemp for seed or grain is they did not want tall plants or fibrous plants, so all the varieties that were existing before were the exact opposite of what we

“We are competing against wood pulp, cotton, fibreglass, polyester and those other types of raw materials, and we can sustainably produce alternative products year after year.”

- Aaron Barr

were looking for,” Barr says. “We’ve had to research and develop fibre varieties.”

There is also a huge appetite for bio products to replace things like single-use plastics and other fossil fuel-based materials. The performance characteristics of the strong bast fibre, which has a high cellulose content, means it can compete with traditional raw materials.

“We are seeing big demand on bio composites, so single-use plastic replacements and more plant-based sustainable textiles and building materials,” Barr says, adding that demand is going to spur the development of more processing facilities across the Prairies.

“We are competing against wood pulp, cotton, fibreglass, polyester and those other types of raw materials, and we can sustainably produce alternative products year after year,” Barr says. “We are talking with some automotive and textile manufacturers that are looking for volumes that would be 10 of our facilities just for one manufacturer. We are trying to model our Bruderheim facility, maximize it, and be able to duplicate it across the Canadian Prairies. Our goal in the next 10 years would be to build 10 more facilities.”

More production will provide more options for farmers to grow this low-investment crop that provides them with good returns, agronomic benefits and, in the near future, the

“We’ve done data collection on over 20,000 acres and we’re averaging around five tons of CO2 sequestered per acre in the soil. That’s a significant amount of soil carbon going back in, which is also promoting in-soil health.”

- Aaron Barr

opportunity to claim carbon credits. CRHC has done life cycle analysis and data collection over the last five years to quantify the carbon sequestration efficiency of the hemp crop.

“Farmers will have two opportunities for carbon credits for young hemp: one is soil organic carbon and the second is biomass carbon,” Barr says. “We’ve done data collection on over 20,000 acres and we’re averaging around five tons of

CO2 sequestered per acre in the soil. That’s a significant amount of soil carbon going back in, which is also promoting in-soil health.”

Above ground, farmers are averaging two-and-a-half to three tons of dried, baled biomass per acre that has a 45 to 47 per cent carbon concentration in the stalk.

“We can take that hemp stalk, put it into a building material and we’re long-term storing carbon,” Barr says. “We are very close this year to have monetized carbon credits able to compensate farmers for growing this crop.”

The future looks bright for hemp

“Young fibre hemp provides opportunities for farmers to expand rotations and promote soil health, and it’s something that we don’t just export,” Barr says. “This is a product, a raw material that we could all use. It’s such a versatile product that farmers see the tangibleness of it. They can grow it and feel that piece of paper that has their fibre in it. Farmers are risk adverse and want to see things proven, and now that we’ve had some great years of being able to grow crops at scale, harvest it and be self-sufficient and selling into the market, the farmers are really getting behind this.”

WE’VE GOT YOU COVERED. SEEDING TO SUCCEEDING

Fuel, fertilizer, forage seed and more. You depend on a lot from season to season when you’re farming.

With everything from our exclusive Dieselex Gold bulk fuel to premium lubricants, we help make sure that your equipment is ready to roll. Add to that the expertise of your local Customer Account Manager helping you make the best decisions to improve your yield, you can trust UFA to make sure you have what you need to get the job done.

Season to season, section to section, we’ve got you covered.

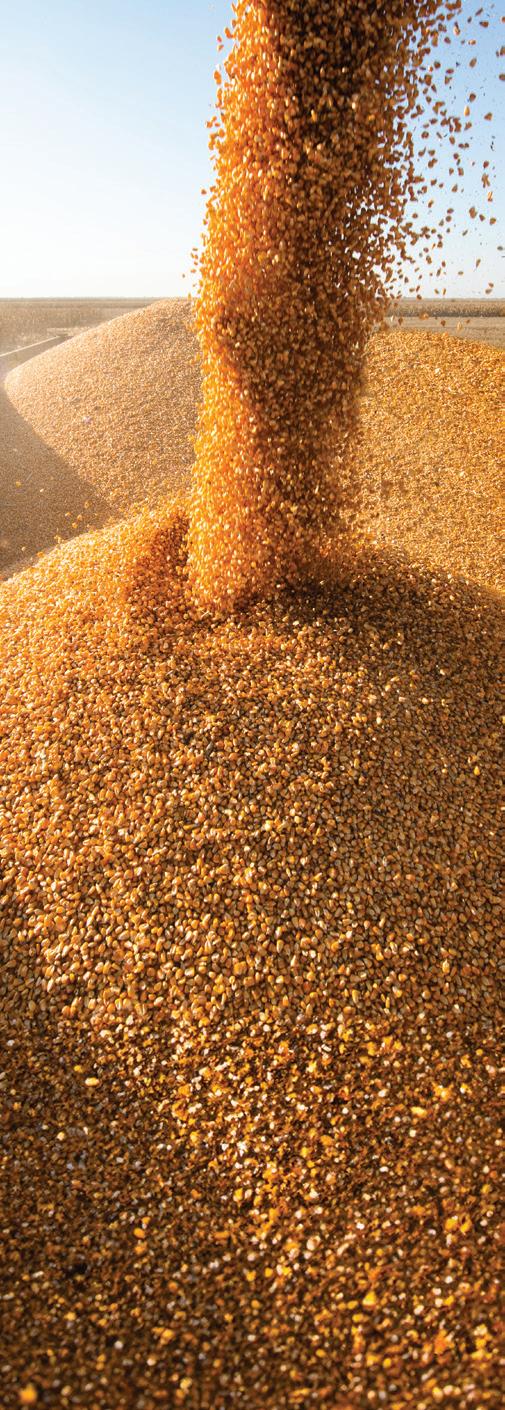

Ask any grower and they will tell you the importance of grain quality and the impact it has on profits.

This is why investing in high-quality infrastructure associated with grain storage and handling is a major component of the feed management system when rations are prepared on-site. On-site infrastructure for bulk storage and handling may also be required at a feedlot that is using commercial preprepared or premixed feed.

Corr Grain Systems – located 15 kilometres northwest of Regina – offers grain storage, handling and conditioning. Their diverse clientele is primarily situated in Western Canada and ranges from small family operations to the largest producers in the region.

“We also work with pulse and seed plants, along with major companies in the export industry,” says Lyle Muyres, vice president of marketing for Corr Grain. “Our regional sales managers assist customers in determining their grain storage and handling needs by providing product information and tailored ideas. This assistance can be provided over the

phone or through on-site farm visits, particularly for larger and more complex projects, where we help lay out comprehensive handling and dryer systems.”

When determining the best options, Muyres says the main focus is understanding their customers’ needs and ensuring product and construction services are ready for the upcoming season.

“This process is managed from our central ordering and distribution centre near Regina. Our selling season begins towards the end of harvest and continues throughout the winter. Construction typically begins in early April and slows down during winter months. We offer a range of products – from 10,000-bushel hopper bins and dryers to large flats with terminal-type handling and dryer systems. Orders for larger and more complex systems need to be placed earlier to ensure timely delivery.”

Wall Grain Handling Systems is one of the largest independent grain bin and grain dryer dealers in Western Canada. Located in Brunkild, Manitoba, the company is

Norstar’s material handling line of equipment is designed and built to handle your demands. We configure our equipment to meet your needs rather than asking you to change your needs to match our equipment. Norstar prides itself on taking the time to understand your needs for your project and what you want to accomplish with your system, from there we offer the most cost effective solution to accomplish your goals. The goal is to offer you true value for your system, we focus on more than the cost of purchase, but rather look forward with consideration of the cost of ownership in mind.

The performance of your handling system can be the difference between success and failure in your farm or agri-business. It can save or drain time and money. Planning and building an efficient handling system can help you better manage your costs. This starts with understanding your yearly through put and the specific products you’re handling, from there we look at everything for steel gauges, liners, shaft & bearing sizes, ease of installation and maintenance. It can be overwhelming with so many factors to consider. You cannot afford to make a mistake. Your profit depends on it.

When you choose Norstar for your conveyance system, our competent design team works with you; your installers and other suppliers to ensure that your site meets your needs. When your project is complete, you will have maximized your efficiency and will be able to move your commodities with confidence. At Norstar, we do more than build your conveyance equipment; we help you visualize, plan and design a handling system that is custom built to fit your needs. We partner you with experienced dealers and millwrights to fully equip and complete your system. We help make it simple to build a system that maximizes your efficiency and boosts your profit.

“We design grain bins and grain dryers and teach farmers about grain management because most people spend a lot of money on combines and tractors, but fail to put their money into management. Our main clientele are larger growing farmers that are teachable.” - Dave Wall

celebrating its 40th year in business this year and has prided itself on being a one-stop shop for grain management systems.

“We design grain bins and grain dryers and teach farmers about grain management because most people spend a lot of money on combines and tractors, but fail to put their money into management,” explains owner Dave Wall. “Our main clientele are larger growing farmers that are teachable.”

He says when his team tops a bin, they place proper air flow on it and teach their clients about grain management.

“If you do this, it can earn you a dollar or more a bushel if you cool and aerate it properly. There are a lot of things to know. You just don’t drop it in a bin and turn the fan on.”

It can be difficult for farmers to know what they need to consider for their grain storage and handling needs, particularly depending on the size of their farms. Needs will be different for a farm spanning 5,000 acres versus 25,000.

“It’s challenging to pinpoint a single answer because farms across Western Canada have diverse needs,” explains Muyres. “However, I recommend customers consider their current and future requirements when planning grain handling systems.”

Building a system that accommodates both present and future needs is crucial. For example, providing ample space for expansion is advisable, as farm size and equipment continue to grow.

With its mission to ensure the integrity and marketability of Canadian grain for the domestic and international grain trade – from producer to global consumer – the Canadian Grain Commission regulates grain handling in Canada and establishes and maintains science-based standards of quality for Canadian grain. Its research, programs and services help support Canada’s reputation as a consistent and reliable source of high-quality grain.

The Canadian Grain Commission works to deliver grain quality and quantity assurance programs for exports of Canadian grain, carries out scientific research to understand all aspects of grain quality and grain safety, and maintains Canada’s sciencebased grain grading system to ensure farmers receive fair compensation for their grain.

The Official Grain Grading Guide is a complete reference on the grading of grains, oilseeds and pulses. For more information about the guide, contact the Canadian Grain Commission at (800) 853-6705 or by email contact@grainscanada.gc.ca.

The guide can also be downloaded from its website: oggg-2023-24-e.pdf (grainscanada.gc.ca).

“We don’t just sell a bin. We show our customers how to self-vent to make it more convenient. We usually blow the grain from the dryer to the bins. We want you to combine it at 12 or 13 per cent and try not to shrink it.”

- Dave WallHe adds that blending the grain correctly can bring in more revenue. And for those farms that are large, the trucks cannot get back to the combine fast enough and you can’t hire more trucks and drivers.

“This is why we sell a lot of big bins. The bigger you go, the better with lower costs.”

Farm Action Service Team on the farm since 1953. saving you down time.

Saskatoon (306) 244-5442 | Rosthern (306) 232-4871

Prince Alber t (306) 764-5666 | Nipawin (306) 862-5543

Rosetown (306) 882-2944 | Tisdale (306) 873-3511

GOT A FARM TIRE ISSUE? OUR TEAM CAN FIX IT OR REPLACE IT ON THE SPOT

something we talk about.

It’s time to start changing the way we talk about farmers and farming. To recognize that just like anyone else, sometimes we might need a little help dealing with issues like stress, anxiety, and depression. That’s why the Do More Agriculture Foundation is here, ready to provide access to mental health resources like counselling, training and education, tailored specifically to the needs of Canadian farmers and their families.

Tammy Jones B.Sc., P.Ag

Tammy Jones completed her B.Sc. in crop protection at the University of Manitoba. She has more than 15 years of experience in the crops industry in Manitoba and Alberta, with a focus on agronomy. Tammy lives near Carman, Man., and spends her time scouting for weeds and working with cattle at the family farm in Napinka.

Sometimes things just don’t add up

One-pass weed control is often the goal of agronomists, farmers and chemical manufacturers. Herbicide mixtures employing different modes of action are often necessary to control the diversity of weeds in a field while reducing the number of passes required to do so. In addition, herbicide mixtures have been advocated for delaying or slowing herbicide resistance evolution. Factor in the development of stacked-trait herbicide tolerant crops, and it would seem logical that a one-pass weed control system should be easy to develop. Unfortunately, there are limits to herbicides and their ability to mix, beyond the obvious factor of physical compatibility.

The most optimistic result of a herbicide mixture would be synergy, where the herbicides involved would combine their effectiveness or cooperate in such a way that the results are superior to the application of each of the herbicides individually. A neutral result of a tank mixture would be that the herbicides are additive, meaning that the application of the mixture is not different than the result achieved by applying the herbicides separately. An undesirable result of a tank mixture (other than physical incompatibility) would be antagonism, whereby the mixture is less effective than separate applications, to the point where the observed weed control is lower and/or higher doses of herbicide are needed to provide consistent and effective weed control.

Unfortunately, the most frequent herbicide interaction is antagonism. When Zhang et al. (1995) summarized previous research on herbicide interactions in the paper “Antagonism and Synergism Between Herbicides: Trends from Previous Studies,” they reviewed 267 publications documenting 479 herbicide interactions with about two-thirds (67%) of those interactions being antagonistic. They noted that regardless of whether the herbicide mixture was absorbed by the same or different plant parts (leaves or roots), had the same or different translocating abilities, or had the same or different modes of action, the mixture was most often antagonistic.

In an unprecedented move, AG Direct Hail Insurance has announced that hard-working Prairie farmers will be able to purchase hail coverage for their crops at prices equal to or below 2023. We caught up with executive vice-president Bruce Lowe to find out what prompted this great news for farmers.

FFT: So, Bruce, AG Direct is offering coverage at or below 2023 prices?

Bruce: Yes, we are excited to provide coverage in about 8,500 townships across the Prairies at rates at or below last year.

FFT: Well, farmers will certainly be pleased to hear that.

Bruce: If you look at the challenges facing farmers this year, from uncertain commodity prices, high interest rates, increases to input costs and drought in some areas, we asked ourselves what we could do that would help provide some relief. We have farmers on our senior team, and they are keenly aware of all the headwinds facing farmers.

FFT: How important are rates when farmers are deciding on

Bruce: The rates are certainly a factor. Based on the millions of acres we insured last year, we know our customers find our rates attractive but it goes much deeper than that. We pride ourselves on our superior customer service and professional claims handling.

FFT: And you were the first (and only) exclusively online and direct hail insurer. How does that work?

Bruce: Simply, we don’t compensate any brokers or agents to sell our coverage. Our customers register with us and receive an email when our rates are available. Farmers enter their crop details, determine their coverage levels and deductible options, and purchase the policy, all online. It’s that simple.

FFT: How can farmers check out your rates and apply?

Bruce: They can visit agdirecthail.com or call us toll free at 1-855-686-5596. One of our team members would be pleased to answer any questions producers may have.

FFT: On behalf of Prairie farmers Bruce, thank you to you

There are several possible explanations for antagonism between herbicides:

• Biochemical – one herbicide prevents some or all of another herbicide from reaching the site of action (this could be interference in absorption or translocation in the plant).

• Competitive – the two herbicides compete for a specific binding site or metabolic pathway (this could result in a herbicide not being metabolized to the herbicidally-active form within the plant).

• Physiological – the herbicides have counteractive biological effects.

• Chemical – the herbicides react with each other.

Herbicide antagonism is not new. In 1967, S. R. Colby published an equation to calculate whether a herbicide mixture was antagonistic or synergistic. But calculating the effect of a tank mix compared to the individual herbicide applications turns out to be quite complicated. As an example from Michigan in 1987, Sorensen et al. demonstrated that a herbicide mixture (bentazon and acifluorfen) resulted in an antagonistic interaction when controlling redroot

pigweed in a greenhouse study but was synergistic in the field. Conversely, it showed synergy for control of lamb’squarters in the greenhouse but provided additive control in the field. The lack of consistency in these results demonstrates how challenging it is to predict interactions, but also demonstrates that formulation and appropriate herbicide rates can result in the successful development of a product with this mixture of actives.

Another example of antagonism is the tank mix 2,4-D (various brands) and glufosinate (sold under several trade names including Liberty), resulting in great control of many broadleaf weeds, but antagonism on volunteer cereals. Antagonism is most frequently evident in monocots or grasses. Dicamba and glyphosate tank mixes that are commonly used for herbicide tolerant soybean have also demonstrated a reduction in grass control, but have provided better opportunities for controlling broadleaf weeds.

Many antagonistic tank mixtures provide sufficient efficacy and convenience for herbicide manufacturers to register these mixtures, using rate structures and formulation components that account for a small reduction in the control of some weeds. When utilizing tank mixtures, minimizing the impact of antagonism relies on using labelled rates, applying mixtures when weeds are small and ensuring that any other nonherbicidal additions to the tank will not compromise the efficacy of the mixture. Chris Meyer and Jason Norsworthy investigated the efficacy of several glyphosate and glufosinate tank mixes on weeds in Keiser, Arkansas and concluded that antagonism was more likely to be noticed on 30-centimetre (large) weeds as compared to 10-centimetre (small) weeds.

The next step in weed management with complex tank mixtures might be a concept that is being investigated in Mississippi. A weed research team has found that a dualboom application system, where the herbicides are physically separated until the time of application, can reduce or eliminate herbicide antagonism with several different mixtures, including dicamba or 2,4-D and glyphosate. Their research shows that delaying the herbicide interaction until the herbicides land on the plant leaf improves grass control. Perhaps this is the next step in allowing complex tank mixes, but more research is required.

While herbicide mixtures are convenient and effective tools to control diverse weed populations and delay herbicide resistance development, there is just one last lingering fear with antagonism. If the herbicide effect is decreased to the point there are weeds that survive the application, this may result in herbicide resistance development. Once again, this emphasizes the need for appropriate rates, appropriately sized weeds and excellent application techniques to ensure success, for now and in future weed control efforts.

Scrap metal recycling is a win-winBy Braden Hursh

Let’s all admit it: we are bad at throwing things out or getting rid of machinery we are attached to.

We see it everywhere in the Prairie provinces: old machinery that has become a part of the landscape, ancient threshers that act as landmarks for giving directions to friends … and piles upon piles of scrap metal and junk that exists only to slowly get bigger. So, where does it all come from?

Maybe you have recently upgraded a combine or purchased a new grain truck and have decided to park the old one in the “I-Might-Use-This-Later Lineup” behind the yard. Maybe you have your grandpa’s first car parked beside your dad’s first car parked beside your own first car on the other side of a shelter belt for nostalgic reasons. Or maybe you have the skeletons of old equipment that you have been stripping for parts for years and years sticking out like sore thumbs in the place you have named “The Scrap Heap.” Whatever your reasons may be, you are likely holding onto junk you don’t need any longer.

To be fair to farmers, there are some huge hurdles to getting rid of jagged or rusty metal, old pieces of machinery or old cars that have trees growing through their engine block. Throughout the spring, summer and fall, most farmers do not have the equipment or the time to deal with these huge scrap metal piles, and even if they did, the logistics of getting this metal to a processing plant would be a nightmare. Removing generations of junk is not a one-person job by any means.

Thankfully, there is a much easier solution than grabbing out your cutting torch and work gloves. Mobile metal recycling crews have been offering services to producers, oilfields, landfills and job sites across the western provinces. Miguel Catellier, president of TruGreen Metal Recycling, states, “We bring the scrapyard to the farmer. We come to your farm with a 24-ton excavator, a demo grapple, a 40-inch magnet, whatever cutting tools we need, and a trailer that can haul 32 tons of scrap.” TruGreen will load up the metal and haul it to the nearest processing facilities

“We bring the scrapyard to the farmer. We come to your farm with a 24-ton excavator, a demo grapple, a 40-inch magnet, whatever cutting tools we need, and a trailer that can haul 32 tons of scrap.” - Miguel Catellier

across Saskatchewan, Alberta and British Columbia.

The process for having a mobile recycling crew come to your land varies. TruGreen’s typical job involves an initial phone call or conversation, and then an in-person visit from one of their eight field estimators. The estimators assess how much metal is present, how easy it is to access and the location of the nearest processing facility. The estimators will then make an offer to the producer based on their findings.

Catellier says it is important for an estimator to come in person, otherwise it is kind of like “giving a haircut over the phone.” If the farmer agrees with the estimate, they will receive a cheque in advance of the job. If, during the job, the crew finds more metal or higher quality items, they will send another cheque to compensate the farmer. Catellier states they send out dozens of cheques a week to ensure they are giving farmers fair compensation for the materials extracted.

Mobile metal recycling teams are not picky as they are essentially looking for any salvageable metals. Prices for certain metals can fluctuate depending on market conditions; for example, sometimes old autos or oversized vehicles will be in demand and other times it will be shreddable scrap.

“Really anything that’s metal is what we’re looking for and then from there we will pull out whatever other non-ferrous metals might be in there,” says Catellier. “There might also be rads or batteries and things that can be sold separately for more value.”

With over 74 per cent of new steel production coming from recycled sources, the production of recycled steel, or “green steel,” is significantly more energy efficient than raw iron ore production and also saves thousands of pounds of coal, limestone and iron ore from processing. According to Catellier, “There is a really big push around the world to make green steel because it allows for cheaper production, less emissions and because it is a more sustainable practice.” Producing new metal from recycled scrap metal compared to ore requires 90 per cent less energy for aluminum, 90 per cent less energy for copper and 56 per cent less energy for steel.

Depending on the mobile recycling crew you hire, there may be different protocols for materials they will take and will not take. TruGreen, for example, will try to be accommodating with specific items.

“When it comes to autos,” Catellier says, “we’ll load a car that

Rob Mraz – 403-308-9444

Owen Fieldberg – 403-878-0652

Rex Harwood – 587-220-5575

has got a little bit of junk in it and any tires attached to implements. But here’s where you have to be really clear with people’s expectations: some people have a lot of junk piled up. There can be wood, garbage and all kinds of stuff, but we only really want to focus on the metals because we aren’t a garbage disposal unit.”

Once the mobile recycling unit has extracted what metals they can, they will do their best to group non-metals so the producer can decide what to do with the remaining byproduct of the service.

There are a number of mobile metal recycling teams across Western Canada, so how do you find the one that best fits your needs? It is essential that you do your research before shaking hands with a company. Attend trade shows, talk to your neighbours about their experiences and go online to read reviews of happy (or unhappy) customers. One tip that Catellier gives: “Check if the company website has their Google Reviews turned on, because if they don’t, it is likely they are trying to hide dissatisfied customers.” Find the company that suits your needs, let them do the work and then cut you a cheque for your generations of junk.

Tom Wolf, PhD, P.Ag.

Tom Wolf grew up on a grain farm in southern Manitoba.

He obtained his BSA and M.Sc. (Plant Science) at the University of Manitoba and his PhD (Agronomy) at Ohio State University. Tom was a research scientist with Agriculture & Agri-Food Canada for 17 years before forming AgriMetrix, an agricultural research company that he now operates in Saskatoon. He specializes in spray drift, pesticide efficacy and sprayer tank cleanout, and conducts research and training on these topics throughout Canada. Tom sits on the Board of the Saskatchewan Soil Conservation Association, is an active member of the American Society of Agricultural and Biological Engineers and is a member and past president of the Canadian Weed Science Society.

When pulse width modulation (PWM) was introduced to agricultural spraying in the mid1990s, there was one player, Capstan; and one sprayer brand that adopted it into their models at the factory, Tyler (now Case). Fast forward 30 years and there are more than a dozen companies offering PWM valves, with most sprayer manufacturers offering it as a factoryinstalled option. New brands offer choices in features, and the most notable of these is the frequency at which the PWM valves pulse.

The original pulse frequency by the Capstan SharpShooter was 10 Hz, which was also adopted by Raven’s Hawkeye. John Deere’s ExactApply created a 15-Hz valve which they introduced in 2017, claiming improved coverage uniformity with the higher frequency. WeedIt’s spot spraying system has valves capable of 50 Hz, which introduced the concept of pulse width frequency modulation (PWFM). This system adjusted the solenoid’s frequency in accordance with the sprayer’s travel speed: high frequencies for faster speeds, slower frequencies for lower speed. The idea was to shorten the physical length of the off-cycle in the valve, minimizing the possible coverage penalty. Agrifac followed suit with a 100-Hz PWFM valve manufactured by Gevasol. Capstan, Raven, TeeJet and Precision Planting are now offering higher frequencies of 15 and 20 Hz. But are the higher frequencies necessary?

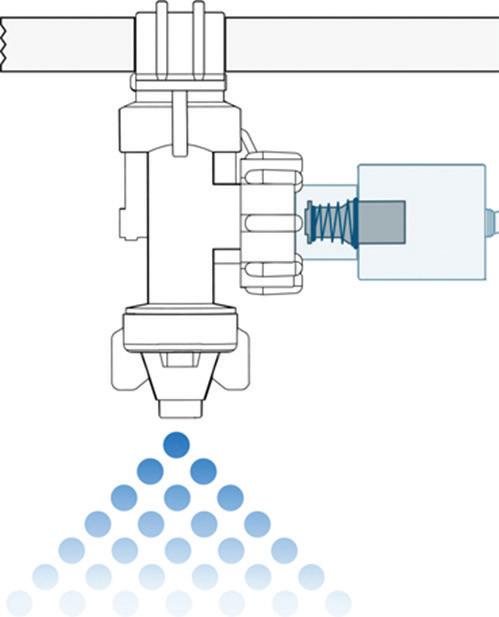

Let’s look at the design of a typical PWM valve. It’s comprised of a magnet (solenoid), a poppet containing a spring and a valve seat. It’s fairly simple, actually.

The valve seat has openings around its periphery that allow liquid to enter the interior of the solenoid, where the poppet resides. When the poppet’s spring pushes it against the central seat, the exit valve is closed and no liquid flows through the nozzle – which is the normal position. When electrical current is applied to the solenoid, the magnet pulls the poppet away from the seat and the valve opens. Liquid can now flow through the solenoid to the nozzle body where it is then atomized.

It’s obvious that smaller gaps can be obtained by increasing the solenoid frequency. Why are most systems not doing this? The reason relates to several physical limitations of the PWM valve that need to be considered.

A single sequential opening and closing of the valve is a cycle. The frequency is the number of cycles the valve undergoes per second.

Flow control with PWM is achieved by varying the proportion of the total time the valve is open. When the solenoid keeps the valve open all the time (i.e., no cycling), we are at 100 per cent duty cycle (DC) and the nozzle experiences its fullest flow. When the solenoid power is off and the valve is fully closed, again no cycling, it is at zero per cent DC. When the valve is at 50 per cent DC, it spends equal time open and closed.

The solenoid pulsing is noticeable at the nozzle orifice. Farther down the spray pattern, its effect becomes less noticeable as the spray droplets blend with each other due to their different velocities, and also mix with spray from adjacent spray patterns, which typically run on an alternating cycle. The idea is that when running at duty cycles above 50 per cent, there is never a moment when all the nozzles on a boom are off. When a nozzle is off, its adjacent nozzles are on and overlap sufficiently to cover the brief off-time. When this feature is added to the physical blending of the fast- and slow-moving droplets that form a spray cloud as it moves from nozzle to canopy, any intermittency is typically lost and is unobservable by the time the droplets reach the crop canopy.

We can calculate the physical travel distance of the sprayer during an off-cycle. At 10 Hz, we have 10 cycles per second, each lasting 100 milliseconds. At 50 per cent duty cycle, the off-duration is 50 milliseconds. When travelling at, say five m/s (18 km/h), the distance covered in 50 milliseconds is 25 centimetres. If we were to increase the frequency to 50 Hz, that distance would be reduced to five centimetres. From this calculation alone, there appears to be value in doing this.

A common error is to assume that the off-distance increases the faster we travel. This is true if the DC were held constant, but in practice, the faster we travel, the

higher the DC to maintain the application rate. As a result, the off-distance for any one application system stays constant across all its travel speeds.

Table 1 shows the calculated off-distance at two travel speeds. At four mph, the duty cycle would be, say 20 per cent with an off-distance of 14 centimetres at 10 Hz. If one speeds up to 16 mph, the DC increases to 80 per cent to increase flow and maintain the application rate. The off-distance therefore stays the same.

It’s obvious that smaller gaps can be obtained by increasing the solenoid frequency. Why are most systems not doing this? The reason relates to several physical limitations of the PWM valve that need to be considered.

The poppet inside this valve moves back and forth a few millimetres each cycle. The time it takes to make this journey has to be considered when selecting a frequency. If we ask the poppet to change direction before it has fully opened or closed, the result is a system where the poppet valve is never fully on or off, limiting its ability to affect flow rate.

Think of the shuttle run our gym teachers made us do in school. We ran from one end of the gym to the other, back and forth, as fast as we could. In this modified example, the runner is the poppet. Let’s say the teacher wanted us to turn whenever they blew the whistle. If it took five seconds to run the length of the gym and the teacher blew the whistle every 10 seconds, we had a five second rest at each end of the gym. If the whistle blew every six seconds, we’d get a one second rest. But if the teacher blew the whistle every four seconds, we wouldn’t quite make it to the end before needing to turn around unless we ran faster.

That’s what happens when we turn up the frequency. At too high a frequency, the poppet can’t physically make it to the other end of its cycle in the allotted time. The valve is therefore either not fully open or fully closed for the necessary time. If we were to change the duty cycle, we would achieve flow control only in the middle DC range, because that is the only range in which we have enough time to change the resting duration (which determines the flow rate) of the poppet.

At a very high or very low duty cycle, the poppet spends most of its time at one end of the solenoid. Let’s assume we’re driving fast and the DC is 80 per cent. It’s open 80 per cent of the time, but needs to close 20 per cent of the time as well. At a very high frequency, that becomes difficult due to the transit time. In that case, the valve is less than 80 per cent fully open. This means the dynamic range, the ratio of flows at the highest and lowest duty cycle, is reduced. High

Figure 2: The PWM solenoid is installed on a nozzle body to intermittently shut off the spray liquid flow. It does this by moving the spring-loaded poppet to and from a valve seat in the assembly. (Image source: Capstan Ag Systems.)

frequency solenoids have a lower dynamic range.

There are several ways to solve this situation. We could make the poppet lighter, allowing it to change direction faster. We could increase the strength of the spring that returns the poppet to the closed position, further increasing its speed. We would also need to increase the power of the solenoid to counteract the stronger spring.

These trade-offs aren’t easy, because the poppet needs to have a certain size (with commensurate power consumption) to allow as much liquid to flow without a significant pressure drop. We also have limited electrical power available on the sprayer. Each solenoid may consume between five and 12 watts, depending on the flow rate (larger flow rates consume more power). For a 120-foot boom with 10-inch spacing and a seven-watt solenoid, for example, that’s 1,008 watts or 84 amps at 12 volts. That’s not a trivial amount of power for an electrical system to supply and forces the solenoids to economize their power demand.

While the North American manufacturers tend to have a static frequency that can be user selected within a certain range, other systems change the frequency with speed, returning dynamic range when needed, for example, at slower speeds.

While the North American manufacturers tend to have a static frequency that can be user selected within a certain range, other systems change the frequency with speed, returning dynamic range when needed, for example, at slower speeds.

Of course, solenoid manufacturers have the ability to customize the current flow to the solenoid with each cycle. They may choose to have a stronger current at the beginning of the cycle to remove the poppet from its closed position faster, then reduce the power once the poppet is moving. These and other tricks can be employed to manage flow rates and power demands.

For the time being, there is no evidence from the field that the higher frequencies offer significant benefits. This may change as PWM is employed for spot sprays, for example, where adjacent nozzles may not be available to “blend” the spray cloud.

Solenoid valves and PWM have been one of the most important innovations in the spray industry. They provide many opportunities for increased precision and we will continue to see competition and better products. At this time, the higher frequencies add an interesting aspect, but they come at a certain cost of complexity. Because all currently available systems appear to be giving similar results, frequency should not be the main consideration when selecting a system.

June 18 – 20 | Regina, SK