Argentina Made 2nd Final Sunset Review of Anti-dumping Measures on Carbon Steel

The Ministry of Productive Development of Argentina issued a report numbered 573/2021 on September 22 regarding the second final sunset review of anti-dumping measures on carbon steel fasteners from China, stating to carry on the anti-dumping measures confirmed in a report numbered 1181 back in 2015 which continue to set the minimum FOB price at USD 4.67 per kilogram. This translates to imposing an anti-dumping tax which is the balance of minimum import price and landed price on the involved products. The measures are effective for 5 years from the date of the announcement.

The products involved are standard or thick carbon steel fasteners with outer diameters between 60.3 mm and 323.8 mm and manufactured to ASME B16.9, ASTM A234 and equivalent standards such as IRAM 2607, not including 180-degree elbows, reducing elbows and carbon steel tees under tax numbers 7307.19.20 and 7307.93.00 by MERCOSUR.

In early September, China issued an energy consumption policy that sets the targets for controlling total energy consumption by provinces, autonomous regions, and administrative regions of municipalities, to monitor and audit all government levels. Restrictions on the steel industry are taken up a notch across many government segments and measures to reduce production are implemented in many places. Guangxi, Jiangsu, and Yunnan governments require many large steel companies to cut down another 20% of the production planned for September, thus leading to prominent initial results. According to the statistics by China Iron and Steel Association, the first half of September recorded daily crude steel production of 2.04 million tons, down 0.38%, and daily steel production of 1.93 million tons, down 7.61%.

Recently, steel plants in various places have been implementing production control. Harbor stocks are reducing at a lower pace and hence there is serious harbor congestion. Supply is

expected to increase steadily. There is not enough momentum for iron ore price to turn upwards with the backdrop of stronger supply and weaker demand. The iron ore price is expected to continue downwards after September.

2021 sees the U.S. and Europe reopen markets in tandem with the increase of vaccination. Countries are in full throttle to reboot economy and infrastructure construction. Benefitting from this trend, the steel and fastener industry is warming up. However, the export will be subject to impact as the EU announced an anti-dumping investigation on certain steel fasteners imported from China. The investigation covers wood screws, self-taping screws, other screws, bolts with head shapes and bolts with washers.

According to statistics by General Administration of Customs of China, China exported around 3.06 million tons of fasteners in 2020, down 3.47%, and the export value was USD 6.97 billion, up 2.05%. China’s fastener import was more stabilized in 2020, totaling around 272 thousand tons, up 1.87%, and the import value was USD 2.79 billion, down 6.06%. Overall, the added value and average export price of China’s fasteners were lower. The average export price was USD 2.33 per kilogram, and the average import price was USD 10.83 per kilogram which was nearly 5 times the average export price.

5.67%

4.46%

The U.S. and Europe are important markets for China’s fastener export, but the export has shrunk as a result of the anti-dumping measures by the EU and the trade war between China and the U.S. Because of low concentration in the fastener export market, the Chinese fastener industry could take a further step in the future in developing markets that fall within the Belt and Road Initiative, considering that the increased ties in the relationship between China and African countries can help develop the Belt

and Road Initiative and provide the fastener industry with an advantageous point. The first factor is the support via China’s preferential policies and clauses, and an example is the new industrial parks under construction in Uganda and Kenya. The second factor is that the products sold in these countries are not at low prices and it provides a price edge for China’s fasteners. Additionally, the infrastructure in these countries require a large amount of fasteners, hardware, machines, high-end equipment and automotive parts. The market is huge and so is the profit margin. Perhaps for the Chinese fastener companies, it is worth considering the benefits of Belt and Road Initiative and working on developing diversified export markets.

According to statistics by General Administration of Customs of China, China exported RMB 316.58 billion worth of autmotive components in the first 8 months of 2021, up 34.6% from the same period fo 2020 and up more than 9 times the value recorded in 2019 (RMB 31.22 billion). Despite the fact that global automotive production is declining, China’s autmotive components export in the first 8 months of 2021 increased over 30%. One of the factors is increased orders, and another is lower invetory rate in overseas user markets; therefore, the second half of 2021 sees apparent increase in orders across the whole market.

The world’s automotive production is decreasing as a result of shortage of semiconductors in the U.S. and Europe. Carmakers’ demand for automotive components are less but the demand remains strong in the new energy car and after sale markets. The After Sale Components Division of China Automobile Dealers Association points out that OEM service is decreasing because car sales are dropping. With the conversion to new energy cars, many components will go through a change. Engine and transmission gear related product sales will go downwards with the development of new energy cars, while chassis, electrical engineering, battery and electronic control will go up. The after market is on a fast growth path with the aging of cars and their popularization as well as their capacity.

According to statistics by Shanghai Customs, RMB 96.6 billion worth of automotive components have been exported from Shanghai’s harbors, up 36.4%, mainly to the U.S., the EU and Japan. Although the number of orders for China’s automotive components has exploded and factories are busy with production, local companies are excited but also worried about the surging material and freight prices. Therefore, their universal solution is to pursue innovative R&D and increase product prices.

The Government of Russian Federation has announced to impose the export tariffs of at least 15% each on steel, nickel, aluminum, and copper since Aug. 1st, 2021 and this measure officially comes into effect and will be effetive through the end of this year. According to the measure, copper is subject to a tariff rate of US$1,226 per ton; nickel is subject to a tariff rate of US$2,321 per ton; aluminum is subject to a tariff rate of US$254 per ton; however, rates for steel products differ from each other, and in the “hot rolled steel” category, it is at least US$115 per ton.

The measure is aimed at protecting national defense and construction industries in Russia from the impact of hiking material costs. As the aluminum output of United Co Rusal International represents around 10% of the global total and the nickel output of Norilsk Nickel represents around 20% of the global total, and Russia itself is also the world’s 3rd largest steel exporter (mainly shipping to Europe), it is expected that such a measure will cause a significant impact on the global metal supply market.

Some analysts also estimated that, since several consumers in Taiwan and Asian countries import steel scrap, semi-finished steel billets, and hot rolled steel from Russia, plus the recent plunge of China’s export, the capacity to supply Asian market may be become tighter.

The U.S. International Trade Commission (USITC) determined that revoking the existing antidumping and countervailing duty orders on imports of steel nails from Korea, Malaysia, Oman, Taiwan, and Vietnam would be likely to lead to continuation or recurrence of material injury within a reasonably foreseeable time. As a result of the Commission’s affirmative determinations, the existing orders on imports of this product from Korea, Malaysia, Oman, Taiwan, and Vietnam will remain in place. Chair Jason E. Kearns, Vice Chair Randolph J. Stayin, and Commissioners David S. Johanson, Rhonda K. Schmidtlein, and Amy A. Karpel voted in the affirmative. Today’s action comes under the fiveyear (sunset) review process required by the Uruguay Round Agreements

Act. The Commission’s public report Steel Nails from Korea, Malaysia, Oman, Taiwan, and Vietnam (Inv. Nos. 701-TA-521 and 731-TA-1252-1255 and 1257 (Review), USITC Publication 5200, May 2021) will contain the views of the Commission and information developed during the reviews. The report has been available on June 18, 2021 and can be accessed on the USITC website at: https://www.usitc. gov/commission_publications_library.

According to the data of Vietnamese Customs, Vietnam's steel export reached 980 thousand tons at an export value of USD 833 million this May, down 4% in volume and up 8.2% in value from this April. The total export volume reached 4.88 million tons in the first 5 months of 2021 at a total export value of USD 3.61 billion, up 61.6% in volume and up 117% in value from the same period last year. The EU, China, Cambodia, Malaysia and Mexico are the top 5 destinations for Vietnamese steel products. In the first 5 months of 2021, Vietnam grew 500% (at 713 thousand tons) in steel export to the EU, 200% to China (at 1.1 million tons), and 250% to Mexico (at 293 thousand tons).

The significant growth in Vietnam's steel export to the EU could be attributed to the European UnionVietnam Free Trade Agreement (EVFTA). This also means that Vietnamese companies have acquired standardized production lines and are capable of meeting the stringent requirements and demand by the countries they export to.

According to the database by China Credit Information Service, of all entrants to the “2021 Top 1,000 Taiwanese Companies in China”, four are fastener and/or hardware companies. The overall net profit margin of the thousand entrants turned from negative to positive after two consecutive years (2018 and 2019) of negative growth, and hit a record high with a 5.76% pre-tax profit margin. Additionally, the four Taiwanese fastener and/or hardware companies have all moved up in the ranking. Regarding revenue growth, Walsin Lihwa and Hama Naka Shoukin Industry exhibit a growth exceeding 30%. The pre-tax profit margin of Hama Naka Shoukin Industry is the highest at 40% and exhibits high competitiveness.

Fastener price and volume increased in 2020. Taiwanese companies face the challenge of a business paradigm shift during the U.S./ China trade war in the aftermath of the pandemic, seeking vibrant market demand in China. They will gradually break from the pattern of emphasizing foreign trade over domestic sales and pivot towards balanced domestic and overseas sales.

McLaren Automotive Distribution (Shanghai) recalled 9 vehicles imported in 2020 under the models 570s Spider, 720s (Coupe and Spider), 600lt Spider and GT, manufactured between July 2 2019 and February 13 2020. The affected vehicles may have been assembled with banjo bolts lacking holes for hydraulic fluid to flow into the calipers. There would be no braking effect on the affected corner of the vehicle. The vehicle could pull to the left or the right, increasing the risk of collision especially in braking at high speed.”

McLaren will check the banjo bolts for the recalled vehicles for free, and if McLaren spots incorrect assembly, the bolts will be replaced to eliminate safety concerns. As an alternative solution to an emergency, if the driver spots the vehicle pulling to one side when braking, the driver should stop using the vehicle immediately and contact a sales agent to handle the issue.

Taiwan's OFCO reported its consolidated revenue in June at NTD 362 million, up 327% from the same month last year. The consolidated revenue for the first 6 months of 2021 was NTD 1.7 billion, up 283.09% from the same period last year.

OFCO said, due to the fact that Chinese steel fasteners are recently subject to import registration in the EU, the EU'S AD investigation against Chinese fasteners, short supply and surging demand in the global steel market, and steel prices being pushed to new heights, OFCO is now seeing a strong growth in order acceptance. To cope with increased orders, OFCO has ordered 11 sets of fastener forming machines and 11 sets of threading machines from Chun Zu, which is expected to increase its monthly capacity by 10%-15%. According to OFCO president, OFCO's main fastener business is expected to continuously perform quite well in the second half of this year.

PT. NITTO ALAM INDONESIA starting with 30 employees was founded in 1985 with the investment value of 700 million Rupiah. Its second plant inaugurated in Bekasi on August 2018 is dedicated to introducing automated production to provide automotive and other industry clients with high quality and shorter lead times. The so-called automated production system means that the plant has the equipment for heading, threading, heat treatment, electroplating, inspection and packaging. It took the plant 3 years to establish a vertically integrated production system, helping shorten lead time by around 30%. The plant will target the Japanese manufacturing cluster in Bekasi on the outskirts of Jakarta, and provide them with screws, bolts, anchors and other special cold forged products.

The wire rod price adjustment for the third quarter of 2021 announced by Taiwan CSC is lower than what the market had expected, giving Chun Yu an upper edge in cost competitiveness and a boost in its revenue and profit gains. With the outlook of a gradual increase in the global fastener demand which is expected to peak before Christmas, the orders placed to Chun Yu is expected to continue through the fourth quarter of this year.

Chun Yu President Huei-Jeng Lin said that the strong post-COVID demand in the U.S., Europe and China as well as reshoring of many Taiwanese businesses helped drive up the steel demand. The second quarter of this year continues with a rise in both wire price and volume as well as a large amount of fastener and wire orders placed to Chun Yu's 3 major manufacturing bases in Taiwan, Indonesia, and China. The company's revenue set a new high in May at NTD 970 million.

Meanwhile, the leading industrial & automotive fastener supplier, Boltun, benefiting from the same cost competitiveness, also sees its manufacturing already scheduled through the fourth quarter of this year. Another wire

orders through the fourth quarter of this year.

The summer of 2021 marks a new milestone in the history of Bülte. The Bülte Group, which has been active in the manufacture of plastic fasteners and protection products since 1956, is now extending the scope of its activity by acquiring the specialised plastic fasteners division of the company Werit in Germany. Negotiations were concluded at the end of June 2021 between Mr Schneider (Werit) / Mr Stein (Werit) and Stefan Bülte, President of the Bülte Group. The acquisition represents a strategic turning point in BÜLTE's business policy and a new direction for the future.

With this investment, Bülte is expanding its tooling range which will enable the company to further improve both quality and manufacturing efficiency. It will also strengthen its position in the Eastern and Northern European markets. Bülte will continue to maintain its current production facilities, mainly in Germany, thus maintaining and confirming its "made in Germany" criteria for ever greater quality, flexibility and reactivity.

Like Bülte, the Werit Group is a family-owned company with production sites throughout Europe. Founded in 1949 by the engineers Wilhelm Schneider and his son Helmhold, the company with its headquarters in Germany is celebrating its 72nd anniversary this year. Another similarity to Bülte, which is celebrating 65 years of continuous existence this year. Specialising in thermoplastics for injection moulding and blow moulding technology, Werit will concentrate on its other business areas. The BÜLTE Group will further strengthen its market position in the field of plastic fasteners by taking over a longstanding market companion.

Triangle Fastener Corporation (TFC) is excited to announce the acquisition of GLR Fasteners Inc., located in San Jose, California. GLR is a distributor of fasteners used in roofing and glazing applications and has serviced the San Francisco Bay area since 1977. This acquisition expands its coverage in the Bay Area by providing customers with local access to the complete line of Triangle Fastener products and services.

GLR will immediately become TFC's 24th branch. To ensure continuity, Gloria Rubalcava and her entire GLR team will continue to run the daily operations. The branch is located at 1425 Koll Circle #104, San Jose, CA 95122.

They look forward to serving and partnering with all current customers of Steel City Bolt and Screw. Operations of Steel City Bolt and Screw will be consolidated into the production facility at their corporate headquarters in Birmingham, Alabama. In doing this, the level of service they can offer their valued customers will be increased. Customer service remains paramount at Birmingham Fastener; in-turn, all Steel City Bolt and Screw customers will become valued partners of Birmingham Fastener and be serviced as a top priority.

The National Fastener Distributors Association is pleased to announce the 2021 recipient of its Fastener Professional of the Year award is Jim Derry of Field (Machesney Park, Illinois). The Fastener Professional of the Year award was created by NFDA to honor individuals and companies that make a substantial positive impact on people’s lives.

Jim and his brother Bill purchased Field Fastener in 1990. As president and CEO, Jim focuses on Field’s long-term strategic plan and ensures that their partners love Field. He is dedicated to enhancing Field’s world-class culture that creates an environment that allows their team members to thrive and that is a competitive advantage in the marketplace. Field’s culture has been recognized by Great Places to Work and Inc. Magazine as being one of the best small places to work in America. The culture at Field is critical to the growth of the company, averaging 19% per year growth since 1990 and has been on Inc. Magazine’s fastest-growing private companies eight times in the past ten years. The overall goal of Field’s 10-year strategic plan is to improve lives, and Jim is committed to improving the lives of the Field team members, their families, Field’s customers and suppliers, and the communities in which Field operates. Under Jim’s leadership in 2020, Field created the Do Good Team. This initiative allows their team members to volunteer up to 40 hours per year focusing on charities of interest to them. The focus of this benefit is to allow their team members to spend a significant amount of time volunteering in the communities they operate.

Birmingham Fastener is delighted to announce their recent acquisition of Steel City Bolt and Screw.

Jim along with Bill Derry founded The Derry Foundation, which supports educational initiatives. The foundation provided funds toward the engineering building at Rock Valley College located in Rockford, Illinois. It also helps fund Rock Valley’s scholarship program. Jim is also a current board member and past president of Carpenter’s Place, which provides the tools necessary for rebuilding the lives of the homeless. He is a Six Sigma Black Belt and believes strongly in lean principles to drive efficiency, continuous improvement, and innovation. Jim has a mechanical engineering degree from the University of Illinois. Jim received his award at the Professional Fastener of the Year Virtual Celebration on September 10. Nominations for the next Fastener Professional of the Year award will open in January 2022.

The Belebeevsky plant Avtonormal (BelZAN), managed by RT-Capital of the State Corporation Rostec, under a contract with JSC AVTOVAZ for developing and supplying fasteners for passenger cars in the Vesta and XRAY series, has started manufacturing products. Deliveries have begun in August 2021.

In a short time, the plant created design documentation for developing 34 new types of auto fasteners for models of the LADA Vesta and XRAY series, worked out the manufacturing technology of parts and carried out a fullscale preparation and mastered production. By the end of this year, BelZAN plans to supply up to 10 million units of fasteners with increased corrosion resistance, which will be used in the assembly of bodies and the installation of units on cars.

“Last year, the plant concentrated its efforts on expanding the range of products and passing certification by leading domestic and foreign car manufacturers. Confirmed conformity of the company's products to the highest quality standards allowed us to receive new orders this year and already increased the production of components by 15% compared to the same period in 2020. After passing the quality audit of AVTOVAZ, the plant received an order to develop new types of automotive fasteners for cars of the Vesta and XRAY series. Today, the share of BelZAN's products supplied for these models is about 15%, and it will double after delivery,” said Kirill Fyodorov, General Director of RT-Capital LLC.

In the Russian market the share of BelZAN’s fasteners for the automotive industry is about 36%. The plant is the main fastener supplier for KAMAZ, AVTOVAZ, Volkswagen, GAZ Group, Aurus and others.

T.Sh. Galiakhmetov, Director for Technical Development of BelZan, introduced plans to master the production of fasteners in new steel grades 36MnB4, 32CrB4 and 42CrMo4 to the participants in the conference “Fasteners. Quality and Responsibility”. Manufacturing pilot batches of fasteners is planned for the current year. He noted the need for mastering the production of fasteners of strength classes 8.8 and 10.9 in Russia. It is economically and technologically expedient to use two steel grades for long parts in the automotive industry.

In the case of the introducing export duties on metals from August 1, the profit of the companies will decrease by tens of billions of rubles, and the contributions to the budget will be noticeably reduced, said the group of companies "Russian Steel". Metallurgists, who were previously accused by the government of "screwing up" the state, also threatened that the development of the situation could eventually "increase social tension in the regions."

The group estimates in accordance with two scenarios - if the current market conditions persist and prices decline. In the first case, according to the group's calculations, exports will decrease by a million tons, or about 40 billion rubles, and profits by 150 billion. The total deductions to the state budget will fall by 30 billion rubles, according to the association.

In the second case, the decrease in export supplies should reach 2.5 million tons, or about 75 billion rubles. In this case, the profit will fall by 180 billion, and the budget will miss about 51 billion, "Russian Steel" emphasized.

The group also stated that the introduction of duties will reduce the investment attractiveness of the sector and hinder job creation, various social programs and the modernization of enterprises. "Russian Steel" believes that the decision on duties should be finalized and clarified together with representatives of the industry, "in order to reduce the negative impact on the development of domestic ferrous metallurgy".

On June 25, the government approved of temporary duties on the export of metals, effective August 1 to December 31 this year.

The Group of Ferrous Metallurgy Enterprises "Russian Steel" unites the largest producers of metallurgical products in Russia. The Association was founded in 2001. The current members of the group are: EvrazHolding LLC, NLMK PJSC, MMK PJSC, OEMK OJSC (Metalloinvest Management Company LLC), Mechel PJSC, OMK AO , PAO Severstal, PAO TMK and OOO UK PMH.

Hilti and OSPAZ have begun negotiations to agree on a contract under which the Oryol plant of the Severstal hardware group will produce threaded rods.

“Our company operates in accordance with quality and environmental management standards and strictly monitors all processes, while we are always open for cooperation and ready to improve production. Compliance with the high standards of a Western brand and the start of cooperation with Hilti is yet another proof of the quality of our work”, - comments Alexei Erenichev, director of the Oryol Steel Rolling Plant.

“Localization not only helps us to be competitive in terms of price and flexibility, but also creates new jobs, increases the expertise of local manufacturers and improves our position in the field of sustainability by optimizing logistics,” commented Gemil Polat, Head of Contract Manufacturing at Hilti Russia.

The Cherepovets enterprises Severstalmetiz, Severstal Kanaty and the Oryol Steel Plant have mastered the production of 81 new types of products. "Severstal-metiz" mastered the production of new types of wire, fasteners for railways. The company also modernized the galvanizing unit, which allows simultaneous production of galvanized and phosphate wire. Oryol Steel Plant in the first six months of 2021 added 40 new products, 85 percent of which are fasteners.

“The development of new types of products is the result of our work on import substitution, entering new markets and constant dialogue with customers. Severstal-metiz products meet not only the needs of customers, but also all the necessary industry norms and standards, which is confirmed by our certification documents," commented Denis Tavrikov, commercial director of Severstal-metiz.

Severstal-metiz put into operation new lines for the production of railway fasteners. Severstal-metiz has extensive experience in the production of railroad fasteners of various types. Also, Severstal-metiz is the exclusive supplier of Vossloh rail fastening elements. “The new lines will allow us to provide all our customers with the required volume of products”, comments General Director of Severstal-metiz.

Director of Khimsintez LLC (Dzerzhinsk, Nizhny Novgorod Region) V. Chumakov told the participants of the Conference “Fasteners, Quality and Responsibility" on the development of the Russian industries regarding the application of zinc coatings. He gave information on the new coating, Netoks Zn LF. There was a marked increase in the use of zinc coatings in Russia. The speaker presented domestic equipment for applying zinc coatings. The company "ArtTron" (Dzerzhinsk, Nizhny Novgorod region), with the consulting support of LLC "AntikorTech" (St. Petersburg), has created the first centrifuge in Russia for applying zinc coating. Launching a small coating installation that does not require a laboratory, treatment facilities, or a large staff of employees is a fairly convenient solution for fastener manufacturing companies.

MMK-METIZ carried out standard tests of bolts for railway in accordance with GOST 16017-2014. The products have passed the tests.

As part of the investment program for 2020-2025, MMK-METIZ has launched a fully automated line for galvanizing small fasteners in diameters from 6 to 12 mm. The capacity of this line is 250 tons per month.

The Russian Ministry of Construction approved the Applied Scientific Research Program for 2021. It includes a study of the operation of high-strength steels C390 and C440 in bolted joints. At present, as noted in the Program, there is no unified and standardized method for determining the mechanical properties of bolted joints made of high-strength steel C390 and C440; C390 and C440, therefore, the properties of rolled products at low temperatures

When erecting reactor buildings, builders use flexible anchor stops from Oryol Steel Rolling Plant. “When constructing such structures, the main thing is reliability and safety. For the production of flexible stops, we use special steel - hard, but at the same time plastic, we carefully select the annealing temperature to increase strength. The fasteners that we supply for the nuclear power plant have already been tested by time and have been used in the construction of many infrastructure facilities”, - comments

Ended the first half, the Brazilian Ministry of Industry and Commerce recorded more than US$ 457 million worth of imported fasteners (in steel, iron, and other metals). The total import value was 32.1% higher than the same period in 2020. In volume, it was 98,650.51 tons, 59.3% higher than the same period last year.

Migrating from Portugal to Brazil at the age of 12 in 1954, João Marques Castelhano worked for some important Brazilian fastener companies in his youth, such as Fibam (closed) and Elbrus. After he resigned from Elbrus, he founded Jomarca at just 28 years of age in 1969.

Currently, Jomarca is one of the biggest fastener manufacturers in South America, with more than one thousand employees and a capacity to produce more than 50 thousand fasteners per year.

On December 5th, the Portuguese João Marques Castelhano will be 80 years old. João will announce his retirement on the same date.

The life of João and Jomarca as well as his family and successors are written in a book, which he started at the 50th anniversary of the company in 2019 and completed in 2021.

Throughout 2020 the value was US$ 683.63 million in value and 125,068.4 tons in volume.

In value, China remains at the top among the ten largest fastener supplier countries, with a share of 23% in Brazil, followed by USA, 16%; Germany, 11%; Japan, 9.9%; Italy, 9.7%; France, 4.4%; Taiwan, 3.9%; South Korea, 3.2%; Sweden, 3.0%; India, 2.3%.

Meanwhile, in the first half the Brazilian fastener export reached US$ 66.31 million, up just 1.5%. However, due to currency depreciation, the export volume grew 246.5% to 35,744.99 tons.

Brazil exported 26,925.62 tons of fasteners in 2020, with an export value of US$ 136.81 million.

Among the ten largest fastener export destinations for Brazil, Argentina was the largest in value, accounting for 28%. USA was second with a share of 18%. Paraguay was next, 11%; France, 6.7%; Germany, 4.6%; Bolivia, 3.9%; Uruguay, 2.9%; Mexico, 2.8%; Chile, 2.5%; Colombia and India were tied at 2.4%.

With an annual GDP near US$ 1.9 trillion, and a predicted production of more than 2.5 million automotive vehicles and 1.1 million motorcycles up to the end of December, Brazil has given no trade fair for two consecutive years.

However, Automec, the International Auto Parts, Equipment and Services Trade Show has confirmed to take place on November 9 to 13, held in the Expo Center North pavilion, in São Paulo city, SP, according to the official Press Office.

The 15th edition of Automec perhaps is going to be the first and unique trade show in the country since 2019.

Meanwhile, the event will include some fastener companies with industrial plants and/or offices in Brazil, such as Caillau (France), Growermetal (Italy) and the Fey, Metalmatrix, Naschold and ZM.

However, as things get better with vaccination in progress, local exhibitors will form teams and purchase booths to participate.

On 04/22/2021, the State Court of Justice in São Paulo State in São Paulo City (Brazil) released a report closing the judicial review involving the company Indústrias Gerais de Parafusos Ingepal Ltda., a process which was started in 2013.

That was great news for the Brazilian fastener industry, above all for Ingepal as one of most important manufacturers of bolts, nuts, and other similar special parts.

"Motoboy" is a nickname used commonly in Brazil to identify who provides home delivery service including almost everything bought by people, such as food, electronic devices, books and others. These services generally are done by younger people around 18 - 35 years

age old who use motorcycles as transport vehicles.

Most of motoboys use motorcycles, whose engines are 100cc up to 190 cc, models that correspond to around 80% of Brazilian production in total.

As these services have risen – so much so that the online food ordering and delivery platform Uber Eats has increased globally in income by 224%, just in Q4 2020 – this delivery service probably is one of the reasons for the recent production growth of motorcycle makers in Brazil.

Despite the pandemic and shortage in raw materials, parts and pieces, from January to April 2021 the domestic motorcycle production (part of them operating under the CKD system) reached 359,621 units, but it could break 377 thousand units if April didn't have 3 workdays less because of the holidays, according to the Abraciclo (the Brazilian Association of Manufacturers of Motorcycles, Mopeds, Scooters, Bicycles and Similar).

However, during the first 4 months of 2021 there was a 2.28% fall, compared with the same, and normal period in 2019 (367,986 units), but there

was a rise of 20.16% compared with 2020 (299,278 units).

Currently certified to ISO 9001:2015 and IATF 16949:2016, Ingepal composes itself as a strong provider in the supply chain covering automotive (buses and trucks), solar energy, roads and agricultural machines, railroad-subways, construction and mainly mining industries.

Currently, its annual fastener capacity is more than 1,000 tons per month, especially because during “those hard days” the heritage was carefully well maintained, including its modern machines by Chun Zu, National Machinery, Nedschroef and Sacma, as well as a sophisticated laboratory, all installed on its own industrial unit spanning 30 thousand square meters in which 14 thousand meters comprise the building.

The closing judgment reached the newsroom of Revista do Parafuso (The Fastener Brazil Magazine) through an enthusiastic message from Dra. Laura Melle Santiago and José Roberto Santiago, both directors from the company founded in 1960, and right now they are back to the fastener game.

News provided by: Sergio Milatias, Editor of Revista do Parafuso (The Fastener Brazil Magazine) milatias@revistadoparafuso.com.br www.revistadoparafuso.com

If this trend is to sustain throughout this year, the total production can go further to 1,060,000 units until the end of this year.

The Metalbo fastener company family said goodbye to Gerhardt Böving on May 15, 2021, in Rio do Sul town, Santa Catarina State, Brazil.

In 1960 Gerhardt Böving and Edgar Arnold joined to run Rex Máquinas, a machinery industry provider for local fastener manufacture companies. After a rename came Industrial Rex. From 1967 to the 1970s, the company became a fastener manufacturer.

The company has been separated since 1987. Currently, there are two most important fastener companies in Brazil: one is the Industrial Rex Ltda., managed by the Arnold family; the other is Metalbo Indústria de Fixadores Metálicos Ltda., managed by the Böving family.

In 2021 the world sees multiple countries lowering social restrictions that lead to purchasers scrambling to buy fasteners and related products, as well as manufacturers trying to get their goods into the only few containers left available for export. The explosive demand as such is expected to persist into next year and probably much beyond. Hisener is one of the top fastener traders and manufactures in China and provides European, Russian, U.S. and South American customers with over 4,000 types of fasteners. Eyeing this extraordinary demand, Hisener is underway towards intelligent manufacturing and high capacity. By doing so, it is planning to grow beyond its current 17% growth rate and exceed its current capacity of 87 thousand tons in order to secure its position as one of the world's largest fastener suppliers.

The company has 150 partnering suppliers who are carefully chosen to help speed up delivering products to buyers. It also offers inventory service dedicated to Chinese clients. You can count on the quality, too, because Hisener is certified to CE EN14592 on structural fasteners and CE EN 14566 on mechanical fasteners and is well-acclaimed by European clients. Its Timber Screws sell well in the European DIY market. All the production process is certified to ISO9001 and re-audited and adjusted every year to strictly monitor and control via a digitalized ERP system.

It has dimension measuring instruments, metallurgy analyzers, mechanical testers and surface analyzers in its laboratory for quality inspection to secure product quality for clients. It also has its own fastener factory, a packaging line for DIY products and a warehouse. The packaging line’s monthly output can fill about 50 containers. Hisener can do the best to provide what clients need.

The company is able to connect each production process by continuously upgrading and improving the automatic inventory and scanning system. This greatly reduces logistics costs and improves the plant’s operating efficiency, making products more cost-competitive. Hisener will continue on its evolution into a smart plant by increasing investment in R&D, production and DIY packaging.

The company purchased heading machines, thread rolling machines, thread cutting machines, bit forming machines and other equipment from Taiwan in order to add capacity. Now with a great prospect on the surge in business opportunity after yearend, the next milestone for Hisener is a new 26,000-square-meter plant to be completed around the end of 2021, and by then the capacity can reach 1,500 tons per month.

In this special time when the price for everything goes up, Hisener has what it takes to tackle market turmoil. The company will do the best it can to secure clients’ benefits, uphold its commitment on quality, capacity and punctual delivery to become the one that clients can count on.

Contact: General Manager Simon Liang E-Mail: simon@hisener.com

“If you wantDean Tseng, Fastener World

T he N. America’s largest industrial fastener, fastening tools, and related machinery B2B trade show, International Fastener Expo (IFE) has been successfully held at Mandalay Bay Convention Center on Sep. 22-23 this year and has been the first physical event since it was held virtually last year due to the pandemic. The number of participants was around 2,000. Most of them were manufacturers, distributors, traders, and retailers from USA, Canada, and Mexico expecting to establish connection with potential buyers and expand sales. Exhibits included various sorts of fasteners for industrial, construction, aerospace, and automotive applications, electronics fasteners, special fasteners, tools & machinery, hand/power tools, and related solutions. Fastener World was also present with our latest issues (incl. Fastener World / China Fastener World/ Hardware & Fastener Components / Emerging Fastener Markets) to discover more local business opportunities for advertisers.

According to statistics of the organizer, 88% of attendees this year were from USA and more than 61% of them were distributors of fasteners and/or related products. Over 70% of exhibitors said that IFE was a must-attend event every year. In addition to offering a networking place for visitors and suppliers, the organizer also held several sessions on surface finishes, post-covid supply chain, factory environment improvement, AI, e-commerce, pricing model, etc. in order to offer exhibitors and visiting buyers diverse attending experience. IFE will take place again on Oct. 18-19 (exhibition), 2022. For more exhibition info or latest U.S. market updates, please contact us at foreign@fastener-world.com.tw.

A s the world's largest manufacturing country, China traded RMB 24.78 trillion worth of goods in the first 8 months of 2021, up 23.7%, among which the export grew 23.2% to RMB 13.56 trillion and the import grew 24.4% to 11.22 trillion. The trade took a drastic upturn in the middle of 2020 (roughly 15 months ago) and went on. The third quarter this year maintained a double-digit growth, and the same goes with the trade in July as well as August.

Narrowing down to the fastener industry, it shows that China exported 2.65 million tons of fasteners in the first 7 months of 2021, up 20.9% from the same period last year; the export value arrived at USD 5.97 trillion, up 22.2% showing strong export momentum in the first half of 2021. China’s fasteners are irreplaceable for their price, output, and speed of production which continue to drive a high level of demand from the world regardless of the pandemic. There is one distinction though, and that is logistics issue after the COVID outbreak, along with business owners’ gut-wrenching cost pressure, transport barriers, and heightened price posing as a tall wall bumping against the burst of China’s export.

On September 15 this year, China Containerized Freight Index reached a record high at 3,079.04 points, up 1.9% from the previous period and up a whopping 269% from the lowest point of 834 last year. Freight rate has been variating on a daily basis since the second half of 2020. It used to be RMB 30 to 50 thousand but now it just morphed into USD 30 to 50

thousand, and there are times when it goes beyond the goods price. Skyrocketing sea freight rate is devouring 30-50% of profit off Chinese companies.

T he companies stands to cope with 3 challenges which are heightened material cost and freight rate, transport barriers and high inventory load, and they have to tighten their belts on cash flow more than ever. Some small and medium enterprises have begun to suppress production. The point for the time being is to secure abundance of corporate cash flow. Taking too many orders or excessively expanding capacity could end up meeting a fist from the post-pandemic-outbreak era.

C hina produced 16.16 million vehicles (up 11.9%) and sold 16.55 million vehicles (up 13.7%) in the first 8 months of 2021, keeping a stable growth. It is worth noting that new energy car production and sales in August both broke 300 thousand vehicles for the first time. The sales grew 18.6% which was fast and apparent, setting a new record in history. New energy car sale in the first 8 months was 1.79 million, up 21.7% from the same period last year. Sales were looking optimistic.

Regarding automotive components, the export value in the same period grew 34.6% to RMB 316.5 billion, up an astonishing 900%

b y D e a n T s e n g, Fa s t e n e r Wo r l dcompared with the lowest point in 2019. The reason can be traced back to the recovery of international market demand starting in the middle of last year. The current orders taken have increased over 80% and orders are visible 3 months ahead.

In the backdrop of those 3 challenges, the domestic and overseas markets for automobiles and automotive components could provide fastener companies with a solution for the current phase in the post-pandemic era. In addition, Southeast Asia could offer another opportunity for fastener companies.

The virus sweeps the U.S. and Europe and on to Southeast Asia like a hurricane this year. Broken supply chains caught ASEAN countries off guard. This July, factories in Indonesia, Malaysia, Vietnam, and Thailand witnessed a two-month consecutive drop in capacity and number of orders taken. The manufacturing industry index dropped to below 50 (on a scale of 100). This means local Southeast Asia factories and foreign ones closed as a result of the

pandemic, which caused a sudden loss of supply source for the U.S., Europe and other countries. A large number of these countries redirect their orders to China which provides Chinese fastener companies with a route to business opportunities. However, this is a double-edged sword. As orders swarm into China, the issues with jam-packed sea ports dictates that the inflow of orders will lift the freight rate of export on Chinese fastener companies, and the pitfall is that it could exacerbate the 3 challenges mentioned above. As such, it will be necessary to count the pennies on the profit margin of standard fasteners as well as the possibility of withholding cash flow on the current corporate scale.

T his August 20, Thailand’s Ministry of Commerce and China’s Department of Commerce of Hainan Province singed a mini-FTA that seeks to enhance extensive collaboration in trade and investment. This perhaps came at the right time for local fastener companies.

T he pandemic boosts the world's awareness on health care and sports, along with environmental protection. BMW took a step forward and developed the 100% recyclable concept EV named “BMW i Vision Circular” based on the four principles of “RE:THINK, RE:DUCE, RE:USE, and RE-CYCLE”. The car body uses recycled steel and recycled aluminum, and all components on the car are recyclable. The goal is to reduce the use of components and use recycled materials. The car avoided using quick-release fasteners and other connecting components to facilitate convenience in disassembling and components recycling. BMW goes on to announce to use reusable components on all new vehicles under its brand by 2025. If this design concept is brought into reality in the future, it could force the fastener industry to readjust automotive fastener supply.

M id-term and long-term business plans must be deliberately evaluated upon available capacity and the budgets for product development. It also calls for stabilizing cash flow, workforce, and containing the spread of virus. It further requires foreseeing the possibility for your products, service model, logistics and cash flow to coexist with the virus in the next 5 years in which the virus reoccurs periodically as a new normal. As the future unfolds with the world treading slowly past the “blocking” phase, “coexistence” and “horizontal collaboration” across the supply chain will be the key capabilities determining if a company will be able to sustain through the next phase.

PD400UR Screw Driving Device is certified to "UR+" by Universal Robot. Nitto Seiko is the first Japanese company of its industry to have acquired the certificate with a screw driving device. The company successfully developed the URCap "NS SD600T" plug-in software which can be installed to the Universal Robot teach pendant from which the user can manage fastening torque and the driver's turning speed. Enter the target torque and the easy mode will automatically calculate the fittest turning speed, or select the detailed mode to allow for individual parameter configurations.

The Device is equipped with NX-T3 Driver Series/SD600T controller for high precision. Different torque values and turning speed can be set for each fastening spot, and 16 configuration sets can be stored to cope with various conditions. The user can choose to have the device pick up screws either magnetically or via vacuum suction.

"Zero Chromate" developed by Kamiyama Tekkosho in Japan can provide surface treatment for the company's self-drilling and self-tapping screws or can be used for OEM purposes. Since Geomet and other surface treatment solutions may affect the fit of screw recess and the tapping performance, the company has developed the nextgeneration Zero Chromate technology which is chrome and cobalt free and highly resistant against corrosion. The features include:

1. A 1µm Zero Chromate coating layer covers the top of an 8µm zinc coating layer to form a coating layer as thin as just 9µm. Its anti-corrosion performance has been confirmed in a salt-spray test to be 10 times better than that of a uni-chrome coating layer.

2. At almost the same cost as trivalent chromium.

3. Value of use between uni-chrome coat and Geomet.

4. Thin, environment-friendly and corrosion-resistant.

Simpson Strong-Tie, the leader in engineered structural connectors and building solutions, announced that its SET-3G™ highstrength epoxy anchoring adhesive is code listed for anchoring installations in submerged holes and in saturated concrete or water-filled holes.

Formulated to yield superior performance in threaded rod anchor and rebar dowel installations in cracked and uncracked concrete, SET-3G high-strength anchoring adhesive is the latest innovation in epoxy anchoring adhesives from Simpson Strong-Tie.

The two-component, one-to-one-ratio, epoxy-based anchoring adhesive formula dispenses in a uniform gray color to match surrounding concrete surfaces, and can be easily installed in downward, horizontal and overhead orientations. In addition to providing exceptional bond strength, SET-3G adhesive has been proven to outperform other products on the market. SET-3G is code listed to work with the Speed Clean™ DXS dust extraction system, which saves hole preparation time and complies with updated OSHA Silica Dust Compliance Regulations to keep workers safe from hazardous airborne dust.

“When a project requires underwater anchor installation or if weather may impede progress on a job, SET-3G provides contractors with the flexibility and versatility to continue their job,” says Simpson Strong-Tie market segment manager for concrete construction products Corey Clark. “Now code listed for underwater applications, SET-3G delivers ease of installation in the best and worst environmental conditions.”

Nord-Lock Group is celebrating the launch of the new Typhoon+ hydraulic bolt tensioner which has been developed to meet the technical and environmental demands of the wind energy market, where high bolt load and restricted access applications are common challenges.

• Part of Nord-Lock Group, Boltight has developed a deep understanding of hydraulic bolt tensioning and is working hard to deploy the latest technology and advanced bolt tensioning solutions that permanently eliminate the risk of loose or over tightened bolts.

• The robust Typhoon+ design ensures reliability during frequent and repeated use necessary on wind turbine projects, both on and offshore, for low radial clearance applications. The new design offers:

• Ease of use – a fast automatic spring-return design using a single reaction allows a full return to zero stroke piston retraction, and removes the need for manual input.

• Improved seal technology - reduces seal changeouts and enhances general performance throughout the high cycle usage.

• Safety - Over-stroke prevention removes the possibility of over-stroking the pistons. Internal fail-safe technology keeps the tensioner on the bolt in the event of puller bar failure, ensuring user safety.

• High Life Cycle - Long service intervals, not restricted by a fixed number of cycles thanks to high grade material puller bar.

• Low Maintenance – due to an improved spring-loaded auto engagement gear driven nut rotating socket with a geared drive, and it's easy to use.

• Durability - a unique surface finish provides long lasting protection in harsh environments.

When asked about the launch of Typhoon+, Boltight’s Commercial & Projects Manager, Gavin Coopey said, "We're delighted to be launching this new solution to our overall product offering. We feel confident that the Typhoon+ will play a crucial role by making the process of using hydraulic bolt tensioners on wind turbine bolts much quicker, improve durability and reduce downtime”.

Continued supply chain disruptions and spiking demand muted the FIN Fastener Stock Index in the second quarter of 2021 even as the U.S. economy made strides to fully reopen.

The FINdex halved its brisk pace in the second quarter, gaining 4.9% compared to a 6% gain by an index of related industrial stocks. In the opening quarter of 2021, the FINdex grew 9.6%.

Grainger achieved the highest stock gain during Q2, rising 20.5%. In Q1, Grainger sales rose 2.8% to $3.1 billion.

Other fastener companies with rising share value during Q2 included Chicago Rivet (up 2.2%); Dorman Products (up 1%); Fastenal (up 3.4%); ITW (up 0.9%); Howmet Aerospace (up 7%); Lawson Products (up 5.1%); Nucor (up 19.5%); Park-Ohio (up 2.1%); Simpson Mfg. (up 6.5%); Stanley Black & Decker (up 2.7%); and Tree Island Steel (up 10.2%).

Fastener stocks losing value during the second quarter included Carpenter Technology (down 2.2%); EACO - Bisco Industries (down 0.5%); and MSC Industrial (down 0.5%).

During the first half of 2021, the FINdex grew 15.1% compared to a 13% gain by an index of related stocks.

Fastener companies recording first-half gains included Carpenter Technology (up 38.1%); Chicago Rivet (up 14%); Dorman Products (up 19.4%); Fastenal (up 6.5%); Grainger (up 7.3%); ITW (up 9.6%); Howmet Aerospace (up 20.4%); Lawson Products (up 5.1%); MSC Industrial (up 6.3%); Nucor (up 80.3%); Park-Ohio (up 4%); Simpson Mfg. (up 18.2%); Stanley Black & Decker (up 14.8%); and Tree Island Steel (up 90%).

FINdex companies losing share value in the first half of 2021 included EACO - Bisco Industries (down 4.7%) and TriMas (down 4.2%).

During 2020, the FINdex increased 10% during the year, lower than the 12.8% rise in stock value by an index of related industrial stocks.

The seasonally adjusted June FDI (55.8) moderated from May’s 61.8 as widespread product shortages constrained sales growth for some respondents. The sales index declined to 71.4 compared to 72.2 in May. Higher pricing continues to be a significant contributor to growth, as 87% of respondents saw higher point-of-sale pricing y/y (vs. 86% in May) and 84% m/m (vs. 76% in May). That said, given the magnitude of supplier price increases, other inflationary pressures and difficulty passing these on to customers fully, some respondents are seeing margin erosion.

FLI also moderates. The seasonally adjusted FLI came in at 71.1, retreating vs. May’s 76.0, although still elevated relative to historical levels (average FLI reading over survey history is 55.3). Compared to May, the FLI employment index, respondent inventory levels and six-month outlook all weakened, while lower customer inventory levels were a partial offset. That said, a 70+ FLI continues to point to strong market conditions ahead despite June’s softening.

Employment levels slightly weaker. The FDI employment index came in at 62.9 vs. 70.3 in May. Thirty-five percent of respondents saw employment levels as above seasonal expectations vs. May’s 49%. We believe this reflects continued challenges in finding/retaining qualified labor amid a strong job market and enhanced federal/state unemployment benefits. Looking at the broader economy, the June jobs report showed a better-than-expected gain of 850,000 jobs coming off two straight soft reports. This solidly exceeded economist expectations for +706,000, and economists are encouraged this could perhaps mark a turning point in easing widespread labor constraints. Unemployment is still elevated, however, at 5.9% compared to the prepandemic level of 3.5%.

Inflationary pressures and supply chain constraints key topics of focus. Supply chain disruptions again showed no signs of abating in June, and shortages appear to be extending towards many commonly stocked items. Said one respondent, “Importers are not only out of common items, but are quoting December ETA's. I have never seen shortages as widespread.”

Given the strong demand, widespread shortages, and inflationary commodity markets, respondents continue to see significant inbound price increases: “Ocean Freight continues to run way behind schedule. Transportation Costs are skyrocketing. We are passing through as much of this cost as possible.” Echoing this, one respondent commented, “The price of everything is increasing every day.”

While inflation is clearly helping revenue growth, some respondents are seeing margin pressure due to transportation cost increases that are eating away at the incremental profit opportunity: “While we are raising our pricing 5% (higher on some items), we are losing margin because we have to pull inventory (if it is available) from all over the USA. UPS and Fedex Ground are eating up any additional margins we are getting by raising prices.”

Engineered Fastening organic growth at Stanley Engineered Fastening climbed 26% in the second quarter of 2021 as strong automotive and general industrial markets were partially offset by weaker aerospace demand in addition to automotive OEM production impacts from the global semiconductor shortage.

Consolidated Stanley Black & Decker sales during Q2 jumped 37% to $4.3 billion from volume (+31%), price (+2%) and currency (+5%) gains. The gross margin was 35.9%. Capital and software expenditures rose significantly to $105.1 million during Q2.

First-half Industrial segment sales, including fastener results, climbed 13.7% to $1.26 billion, with segment profit more than doubling to $163.6 million.

Fastenal Co. reported fastener daily sales grew 28.4% to $503.6 million (33.6% of net sales) in the second quarter of 2021, driven by higher manufacturing and construction demand. Fasteners represented 26% and 34.5% of net sales in the second quarter of 2020 and the second quarter of 2019, respectively. Net sales decreased 0.1% to $1.5 billion in Q2 as PPE and sanitation products sales plummeted. The overall impact of product pricing on net sales in the second quarter of 2021 was 80 to 110 basis points.

“We continue to experience pressure related to product and transportation cost inflation,” the company announced. “Pricing actions taken in the first and second quarters of 2021 contributed to the increase in the impact of net pricing on sales in the second quarter of 2021.”

Brighton-Best International unveiled its new vending program.

Proferred Vending solutions utilizes coil and locker machines to offer customers 24/7 access to essential products.

“Delivers the power of automated distribution by reducing supply cost, controlled product usage and state of the art technology,” the company stated.

As the largest fastener importer in the U.S., BBI is poised to influence the distribution market by utilizing technology to leverage its market position.

BBI joins major fastener distributor Fastenal, which created its FAST Solutions industrial vending program in 2009, revolutionizing its growth model from stand-alone stores to installed machines distributing products on demand within customer facilities.

Currently Fastenal has installed approximately 81,000 vending devices.

Owned by Ta-Chen International, BBI is a master distributor and importer supplying 7,000 distributors through 31 locations in six countries, including the U.S., Canada, Mexico, Brazil, Australia and the UK.

The company’s global headquarters is in Taiwan, and the U.S. headquarters is at 5855 Obispo Ave., Long Beach, CA 90805.

KYOCERA SENCO Industrial Tools is expanding its 500,000 sq ft facility in Newtown, OH, with a 32,000 sq foot addition and an 8,000 sq ft renovation of existing space.

The expansion will add offices for sales, marketing and administrative staff, bringing all Cincinnati-based employees under one roof and making the Broadwell Road facility KYOCERA SENCO’s official worldwide headquarters.

“This is a great move for us to bring all our employees back together after working in separate buildings for decades,” stated CEO Cliff Mentrup. “We see a great benefit in putting our U.S. manufacturing and Cincinnati-based business operations under one roof.”

Scheduled for completion by the summer of 2022, the project includes an employee cafeteria serving hot meals and a training, product education and innovation center.

“Part of our management philosophy at KYOCERA SENCO is to provide opportunities for the material and intellectual growth of all our employees,” Mentrup added. “It is our hope that creating a campus-like environment that encourages our team to collaborate and innovate furthers that goal.”

Parent company Kyocera Corp. of Japan, which acquired SENCO in 2017, has invested millions of dollars in the Broadwell Road facility to support manufacturing equipment and R&D projects over the past three years.

Established in 1948 by Albert Juilfs, SENCO designs and manufactures fasteners and power fastening tools for residential, commercial, manufacturing and construction applications. SENCO’s manufacturing and marketing are concentrated in the U.S. and Europe, with products sold in more than 40 countries.

Fastener Industries Inc., subsidiaries, Ohio Nut and Bolt, Buckeye Fasteners Co. and Modern Fasteners Co. recently installed a new ERP system. The new Microsoft Navision (NAV) system is helping the fastener companies streamline and automate in house processes as well as improving communications between the companies and their customers. The system took roughly one year to install. It went live in June 2020. There has now been enough time elapsed in the new system to call it a success story. The Employee Owners of Fastener industries Inc., the parent company to the Fastener Group (Modern, Ohio, Buckeye), are now working with customers to tailor the new system to meet supply chain challenges and streamlined scheduling.

Tesla recalled nearly 6,000 U.S. vehicles because brake caliper bolts could be loose, potential causing a loss of tire pressure, Reuters reports.

The recall covers certain 2019-2021 Model 3 vehicles and 2020-2021 Model Y vehicles. Tesla's filing with the National Highway Traffic Safety Administration (NHTSA) said it had no reports of crashes or injuries related to the issue and that the company will inspect and tighten, or replace, the caliper bolts as necessary, according to Reuters.

Tesla said that loose caliper bolts could allow the brake caliper to separate and contact the wheel rim, which could cause a loss of tire pressure in “very rare circumstances.” The company said if vehicle damage from a loose or missing fastener occurs, it would arrange for a tow to the nearest service center for repair.

The filing with NHTSA said Tesla was made aware in December of a field incident involving a 2021 Model Y vehicle with a missing fastener on the driver-side rear brake caliper.

The company has since taken measures during assembly to prevent loosening of the bolts, Reuters reports.

In related news, Tesla also issued two recalls covering nearly 8,000 vehicles with potentially faulty seat belts.

One recall covers certain 2018-2020 Model 3 sedans, along with certain 2019-2021 Model Y crossovers. That recall covers 5,530 vehicles with front seat belts that may be improperly secured to the b-pillar (the vertical section between a car’s front and rear windows).

The second covers 2,166 2019-2021 Model Ys where the second-row seat belt retractors may be improperly fastened to the car's body.

Both occurred due to problems fastening seat-belt components to the correct torque specification during manufacturing.

MW Industries, the Charlotte, NC, USA-based precision component manufacturer, announced that it is bringing together 21 of its businesses under a single umbrella, MW Components. The new division is on a mission to help manufacturers accelerate and simplify the entire process of creating, buying and managing the complex task of getting the precision parts they need. It means that, whether a customer wants to create a custom component for a specific application or order a stock part from one of the country’s largest inventories, they can do so from a single trusted supplier. MW Components will be led by Chris Fillmore, an industry veteran with over 15 years’ experience in delivering high-precision components for demanding industries including aerospace, medical and oil and gas. The combined business has over 100 highly-skilled engineers on hand to provide feedback on design for manufacturability, cost and performance. And specialist production capabilities span a wide variety of precision components including high-performance springs, fasteners, bellows, wire forms and virtually any customdesigned parts manufacturers require. MW Components brings together experts from industry leaders including Century Spring, Accurate Screw Machine and USA Fastener Group into a single expanded team dedicated to doing whatever it takes to help customers succeed. It will enable a more holistic view of customer needs, opening up valuable access to greater knowledge, expertise and innovations from right across the division’s 20-plus facilities.

Jon Caven will lead company sales nationally in his new role as Director of Market Development. He brings sales and business development experience from his 30 years as a sales professional and business owner. In his new role with LeJeune Bolt, Jon will implement sales, marketing, customer retention, and overall market development strategies, interface and build on relationships with key accounts, identify new and emerging market opportunities for existing legacy product lines, and create and penetrate new and existing market opportunities for LeJeune’s exclusive F3148 TNA® Fastening System. LeJeune Bolt, Burnsville, MN, USA, with a west coast office in Chino, CA, USA, is an international distributor of structural grade fastening systems, installation tools, and related fasteners for the commercial steel and concrete construction, bridge building, and transportation markets.

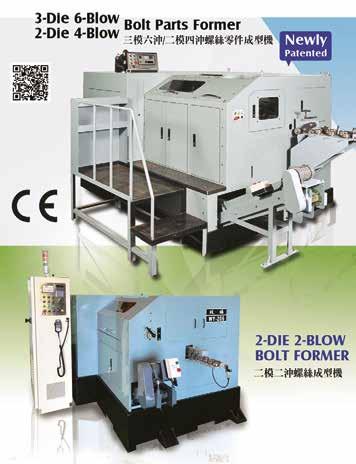

Optimas Solutions, Wood Dale, IL, USA, a global industrial manufacturer, distributor and service provider, announced the acquisition of Chun Zu and Formax four die, four blow cold header manufacturing machines that will increase Optimas’ capabilities to deliver larger format diameter fasteners and free up existing cold headers. “The addition of these machines puts us on a higher playing field that few in the industry can match,” said Marc Strandquist, CEO of Optimas. “The efficiency of these cold headers will allow us to increase our ability to make larger diameter fasteners while freeing up other machines to produce smaller diameter fasteners, all helping us improve our output at all sizes. Most important, it helps our customers struggling to get products given stress on the supply chain and inventory shortages.” The Chun Zu machine will increase production by three million additional complex parts per month within the diameter range of 12 to 18 mm.

This will allow Optimas to further focus on industries that require large diameter complex parts such as agricultural equipment, automotive, construction equipment and heavy-duty trucking. The Formax will improve Optimas’ manufacturing competencies of fasteners up to 18 mm in diameter. It adds to Optimas’ production on the company’s existing large diameter Formax machines, reducing lead times.

Peak Innovations Engineering is honored to congratulate its Principal Engineer, John Medcalf, as he was selected as the Chair of ASME B18 Subcommittee 4–US TAG to ISO/TC 2. This subcommittee coordinates and represents the USA position in the International Organization for Standardization Fastener Standards Committee (ISO/TC 2). The American Society of Mechanical Engineers (ASME) is the globally recognized source of standards used around the world. Medcalf has served as a member of the subcommittee since 2013 including serving as one of a handful of delegates to the international standards committee meetings. In addition to leading the subcommittee to coordinate USA positions on ISO fastener standards, Medcalf’s role will see him act as the head of the USA delegation at international meetings. Peak acknowledges Medcalf as a great asset to Peak Innovations Engineering and the industry.

At an awards ceremony held during the 2021 Annual Meeting of the Industrial Fasteners Institute (IFI) in Scottsdale, AZ, USA, the IFI Soaring Eagle Technology Award was presented to Chad Larson of Lejeune Bolt Company, and the IFI Soaring Eagle Meritorious Service Award was presented to Laurin Baker of The Laurin Baker Group. Chad Larson serves as the President of Lejeune Bolt Company in Burnsville, MN, USA. Chad Larson’s career in the fastener industry has spanned some 30 years and he has worked in manufacturing, distribution, sales, production, quality assurance and now executive management.

Chad Larson is recognized for his service and ongoing contributions to the fastener industry, especially in the field of structural bolting. He initiated and led a massive undertaking to combine six divergent ASTM structural bolt standards into a single coherent standard that has vastly improved standardization of structural fasteners.

Laurin Baker is recognized for his many years of outstanding service to the institute representing and protecting IFI’s interests. Laurin’s expertise in navigating international trade, tariffs, environmental and tax policies has greatly benefited the interests of the Institute’s member companies, their employees and fastener users the world over. Laurin Baker’s tireless work in coordinating and leading the coalition of IFI members, fastener distributors and North American fastener users resulted in the significant reform and improvement of the Fastener Quality Act.

Vertex Distribution owner Houston Wire & Cable Co. was acquired by OmniCable for $91 million cash. “Offering both brands allows our customers a choice and to work with their preferred partner,” stated OmniCable CEO Greg Lampert. The combined company also will continue Vertex, HWCC’s fastener redistribution business.

Houston Wire & Cable acquired Vertex Distribution in 2016. Vertex Distribution distributes corrosion resistant products including inch and metric corrosion resistant fasteners and alloy fasteners, blind rivets, hose clamps and security screws to industrial distributor markets. Attleboro, MA-based Vertex has branches in California, Florida, Georgia, Illinois, North Carolina, Ohio and Texas.

MacLean-Fogg Component Solutions acquired the assets of Formetrix, LLC of Mansfield, MA, for an undisclosed sum.

The deal includes Formetrix’s metal powder intellectual property portfolio that will broaden MacLean Fogg’s capabilities to service new and existing OEM, Tier 1 and 2 customers, as well as tool and die makers in automotive, EV, industrial, agriculture, heavy truck and construction markets.

The new business entity will be known as MacLean Formetrix and will be based in the Detroit suburb of Macomb Township.

The unit will be led by GM Greg Rizzo. Harald Lemke, formerly of Formetix, has joined MacLean Formetrix as product management director.

“As a previous customer of Formetrix, we were able to implement technical cost break-throughs with their material and process innovations that others in the additive manufacturing business claimed were impossible,” stated CEO Duncan MacLean. “We couldn't be more excited to continue to make their innovations available for our internal users, as well as serve other innovative manufacturers and tool makers.”

These materials, combined with advanced 3D printing processes, allow for tool-and-die makers and manufacturers to realize cost, time, and weight savings, as well as tool-to-tool repeatability by replacing traditionally fabricated hard tools with durable printed steel tools and inserts.

Additionally, with the multi-dimensional design and manufacturing freedom that 3D printing allows, tool designers can realize new coolant channels and shapes.

A division of the MacLean-Fogg Co., Mundelein, IL-based MacLean-Fogg Component Solutions manufactures fasteners, engineered components and plastics for automotive, heavy truck and other diverse industries.

Birmingham Fastener, Birmingham, AL, USA, announces the acquisition of Steel City Bolt and Screw. With over 100 years of combined fastener production, the acquisition strengthens Birmingham Fastener’s product offering, equipment depth, and most importantly it allows us to add teammates to our world class staff. Brad Tinney, Owner of Birmingham Fastener says, “With this acquisition we continue to double down on domestic manufacturing and provide our customers with a domestic solution on any fastener requirement they have. This equipment will assist in our expansion into the Carolinas and continue to expand our east coast footprint. Our customer base is second to none and we will ensure their needs are met and expectations are exceeded.” Operations of Steel City Bolt and Screw will be consolidated into the production facility at corporate headquarters in Birmingham. In doing this, the level of service Birmingham Fastener can offer its valued customers will be increased. Customer service remains paramount at Birmingham Fastener, and in-turn, all Steel City Bolt and Screw customers will become valued partners of Birmingham Fastener and be serviced as a top priority. Birmingham Fastener continues to invest in the future and make strategic moves and acquisitions that will yield long term benefits for our customers. The plan is to take this 100 years of customer service and turn it into 200 years of outrageous service for the entire family of customers. Customers will see a lot of information in the coming days and Birmingham Fasteners says it will build and strengthen new partnerships with the customers of Steel City Bolt and Screw.

News provided by: John Wolz, Editor of FIN (globalfastenernews.com) Mike McNulty, FTI VP & Editor (www.fastenertech.com)

◢ G r o w e r m e t a l S r l h a s b e e n c e r t i f i e d f o r y e a r s according to the IATF 16949 standard for the automotive s e c tor and no w, af ter DN V- GL cer tif ie d it s pr o duc tion p r o c e s s a c c o r din g t o th e EN 910 0:2 018 s t an d ar d , th e Italian manufac turer aims to enter the aerospace sec tor as an of ficial supplier.

The IAQG (International Aerospace Quality Group) through the EN 9100 standard has established a quality management system directly controlled by the aerospace industry itself, to define the strict requirements necessary to operate in the sector and Growermetal considered the achievement of the certification the starting point for being successful in this market. The EN 9100 standard is based on the ISO 9001 standard and the primary focus is on quality, safety, reliability and effectiveness of the production processes, covering all areas of this industry and its supply chain.

“Achieving a certification of this level was just the result of a very professional internal team work, with the goal to create new procedures and more efficient processes fully oriented to the prevention and reduction of the risk. We thank all Growermetal’s staff for the passion and dedication shown” says Paolo Cattaneo, CEO of Growermetal. “Being certified to the EN 9100 standard also gives us a great opportunity to be included in the Online Aerospace Supplier Information System (OASIS) database, from which the most important players of this industry can select their suppliers.”

◢ Hilti Group closed the challenging Covid-19 pandemic year of 2020 w ith an oper ating profit of CHF 728 million (-7% dow n on 2019) and a decline in s ale s of 9 6% compared to the prev ious y e ar - to t al ing CHF 5 . 3 bil l ion. Ne v er thel e s s , in v e s tment s in s tr ategic initiati v e s continued as pl anned to ensur e the longterm success of the company

CEO Christoph Loos commented: “2020 was a turbulent business year, which shows in our figures. Overall, we came through the pandemic year with a black eye and were able to avoid compromising the financial stability of our company. At the same time, we continued to invest into our strategic priorities.”

At the end of March 2020, Hilti launched a four-pillar program to cope with the Covid-19 impact. A strong emphasis was put on protecting the health and well-being of all employees, particularly those with direct customer contact. Additionally, a hiring freeze was imposed, indirect costs were optimised, and temporary savings measures were implemented. At the end of the year the number of team members stood at 29,549, a decrease of 1.5 percent compared with the previous year. Hilti adjusted its structures only very selectively in certain markets and avoided a more extensive restructuring. Despite the pandemic, the Hilti Group launched 74 new products and services onto the market. Expenditures for research and development reached CHF 358 million (-2.5%), a share of 6.7% of sales.

For the current year, the Hilti Group expects a moderate economic recovery, which will vary from region to region and depend heavily on the course of the coronavirus pandemic in the coming months. Despite these challenges, the company is adhering to its strategic objectives and will continue to invest significantly in innovative solutions and the digitization of its portfolio and its internal processes.

notice per

until September 2021 at the most Bengt Liljedahl, chairman of the board, commented: “Since its IPO in 2014, Bufab has shown strong profitable growth and developed into a leading company in its industry. Through investment in new customer solutions, international expansion, efficiency and acquisitions, the company has strengthened its market position and global presence. Turnover and profit have more than doubled. The company now has a strong base for further growth.” The Board and Bufab's management are now focusing on continued profitable growth while recruiting a new CEO.”

◢ Bontempi V ibo SpA has acquired 100% of Mi Me Af shares, a historic company from the Lecco area of Italy that specialises in the produc tion of special design fastener s

Mi.Me.Af. SpA has a turnover of about €6 million per year and is recognised for its high-quality and great ability to customise its products in the most varied sectors, from automotive to household appliances, as well as the locks and compressors sector. The acquisition of Mi.Me.Af. SpA is just one of the operations that are part of Bontempi VIBO’s industrial growth plan, with the company setting itself the goal of achieving €80 million revenues by 2025. This plan, which will involve targeting not only the Italian but also the European market, will be developed through selected acquisitions of solid and innovative companies, thanks to which the Bontempi Group will expand its production range - reaching new strategic sectors.

For instance, the acquisition of Fram in 2019 enabled Bontempi VIBO to increase its production, now boasting one of the largest product ranges in Europe in the fastener sector, and the company was able to continue its constant growth, finding an outlet in new markets.

Speaking about the strategy, Raoul Bontempi, CEO of Bontempi VIBO SpA, explained: "We want to get out of the industrial ‘dwarfism’ that has characterised Italian SMEs and prepare the company to be increasingly a protagonist in the challenges that we will face in the fastener sector.”