InconversationwithFalkoSchlottig

Since2022,theFHNWSchoolofLifeScienceshasfocused ondeepeningitscorescientificdisciplines,implementingdigital toolsandrenewingitscommitmenttoappliedresearchthatmattersto industryandgovernment.Prof.Dr.FalkoSchlottig,DirectoroftheFHNW SchoolofLifeSciences,commentsonkeyaspectsoftheschool’s strategyandvisionfor2035.

Collaborationisakeydriverofinnovation

Prof.Dr.Schlottig,whatroledoescollaboration playattheFHNWSchoolofLifeSciences?

UniversitiesofAppliedSciencesplayauniqueand importantroleinSwitzerland’seducationand economy.First,wecontributeresearchexpertise andcutting-edgefacilitiestoprojectswiththe privatesectorandgovernmentagencies,helping themaddresschallengesandanswerquestions. Second,thesecollaborativeresearchprojects offerundergraduateandpostgraduatestudents excitingopportunitiestoworkonrealworld situationsandneeds.WeadaptourBScandMSc programmeseachyear,toreflectchangeswesee inindustry.Thesuccessofourschoolisbuiltona dynamicinterplaybetweenresearchandeducation. Workingwithothershelpsusexcel.By selectingtherightpartnerstocollaboratewith, wearemoreinnovativethanwhenweworksolo. Thisphilosophyalsoapplieswithinourschool. Ourfourinstitutesworktogetheroncrossdisciplinaryprojects.Acollaborativeapproachis neededtosolvethechallengesofourtime.

Technologyfocus

Whicheducationalandscientificareashas theFHNWSchoolofLifeSciencesidentifiedas apriority?

Ourschoolismovingforwardindifferentareas. Wealwaysaimtokeeppacewithdevelopmentsin academiaandindustry.

Digitaltechnologiesarenowintegratedintoall ourBScprogrammes.We’reimplementinga combinationoflifesciencesandartificialintelligence,datascience,digitaltwins,automationand roboticsacrossourresearchareas,anddefining howstaffandstudentseffectivelyandethically workwithnewtools.Futurehealthisapriority topicidentifiedbytheFHNWthatourschoolcan makeimportantcontributionsto.

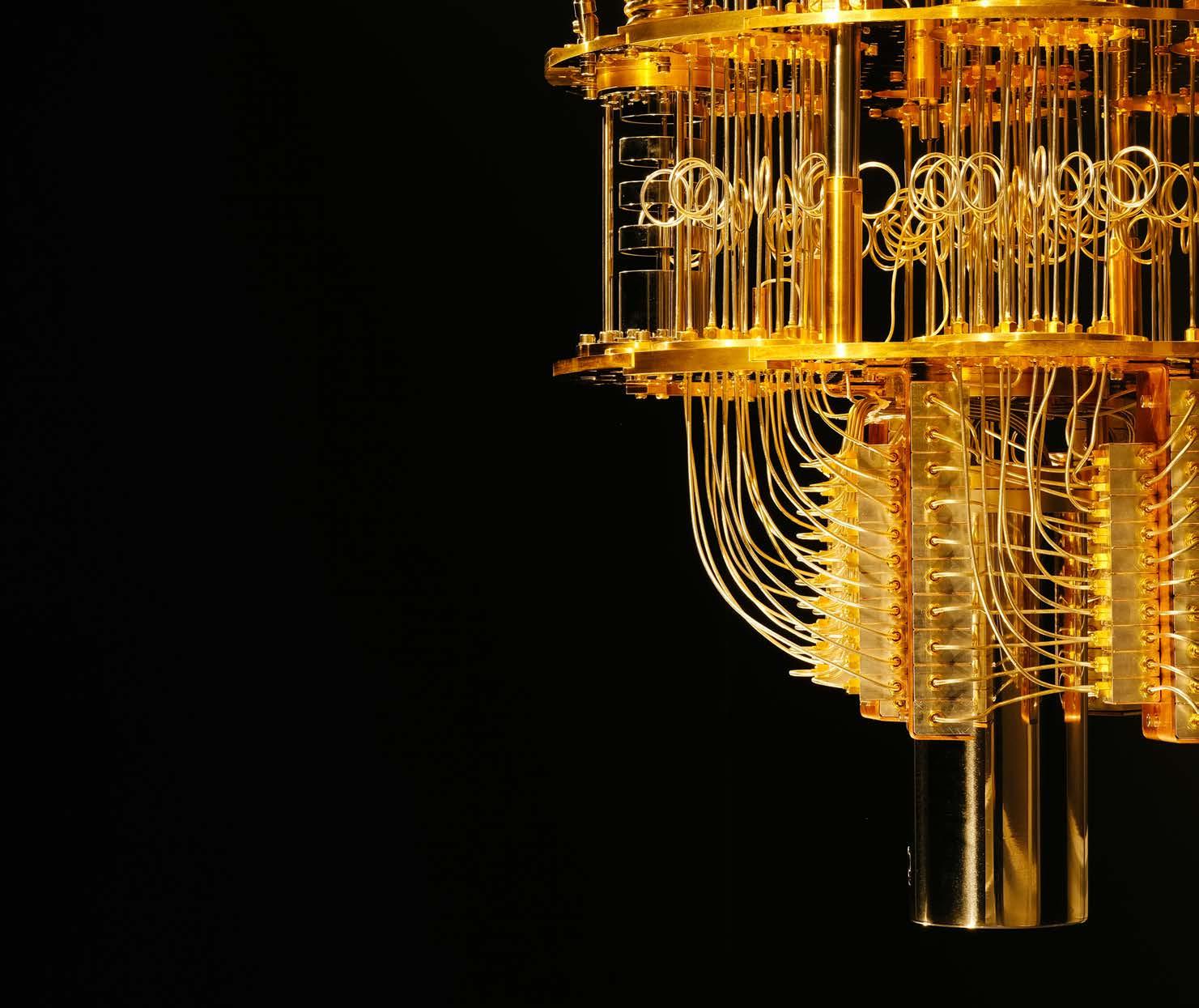

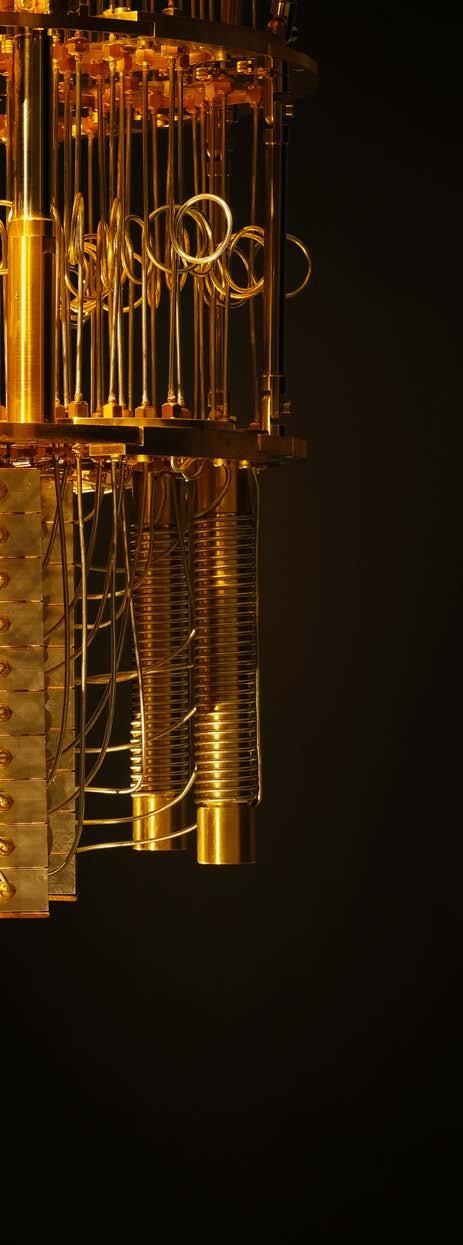

TheFHNWSchoolofLifeSciencesismoving forwardinappliedquantumcomputing.We’veestablishedanewresearchgroupinthisfield,andare workingcloselywithQuantumBaseltobring appliedresearchproblemstothetable seepage42).

Sustainablechemistryisgrowing,witha newBScprogrammeindevelopment.Several ofourresearchprojectscontributetotheFHNW’s zeroemissionpriorityandtoEUprojects.Grassrootseffortsinitiatedbytheschool’sresearchers areunderwaytomakeourlaboperations moresustainable.

It’scriticaltotakeastepforwardinapplying biobasedtechnologiesandothergreenmethods forproducingbasicchemicals.Thisisaneed sharedacrosstheindustrythatwillrequireusto beambitiousandworktogether.

Furthermore,theFHNWSchoolofLife Sciencesisstrengtheningitsactivitiesinbiotech, medtech,medinformatics,pharmatech,cell biologyanddiagnostics.

Internationalisation

WhatistheFHNWSchoolofLifeSciences‘local andinternationalpositioning?

TheFHNWSchoolofLifeSciencesoffersawealth ofinternationalstudyprogrammesandopportunitiestostudents.Beingwellconnectedtothe internationalenvironmentisourresponsibility. Manymultinationalcompaniesareestablishedin Switzerlandanddobusinessaroundtheworld. OurMScprogrammesinparticularneedto preparestudentsforthiscontext.Inparallel, UniversitiesofAppliedSciencesareattheservice oflocalbusinesses,citiesandcantons.Ourstaff andstudentsdevelopmanyvaluablebusiness relationshipsattheregionallevel.

NegotiationsforSwitzerland’sreassociationto HorizonEuropeareprogressingwell.Alreadyin 2024,researchersinSwitzerlandwereableto

Prof.Dr.FalkoSchlottigleadstheFHNWSchoolofLifeSciences.

participateintheERCAdvancedGrantscallas beneficiaries.In2025,Swissresearcherscan participateinthecallsfortheERCStartingGrant, SynergyGrantandConsolidatorGrant.Theseare allpositivesignalsthatthefullreassociationof SwitzerlandtoHorizonEuropeisaroundthe corner.Inthemeantime,ourresearchershave foundnewwaysofmakingmeaningfulcontributionstoEuropeanresearchprojects,severalof whichareshowcasedinthisbrochure.

Challengesfacingus

Thepandemicfollowedbytwowarshaveledto difficultconditionsaroundtheworld.Howhasthe FHNWSchoolofLifeSciencesfeltthisimpact? Forthemostpart,weareinaveryprivileged positionasamemberofaworld-leadinglife sciencesclusterhereinBasel.Likeothersinthe field,wewereaffectedbychangesinthepriceof energy,chemicalsandgases,aswellasother

strainsonthesupplychain.

Weareconfrontedbyuncertaintiesand changesinindustry,financeandsociety.That’s whyweaimtodevelopcriticalthinkinganda senseofself-responsibilityinourstudents. Listening,askingquestionsinordertopropose relevantsolutionsandnotbeingafraidtomakea change.Recognizingthatourresearchisimportantandhasthepotentialtomakeadifferencein theworld.

Peopleatthecentre

WhatistheFHNWSchoolofLifeSciences‘ visionfor2035?

Inadditiontothecollaborative,scientificand internationalaspectswe’vetalkedabout,akey elementisputtingpeopleatthecentre.It’sour staff’senthusiasmandideasthatdriveusforward. We’vebeenluckytoaddseveralnewteamleaders thatbringindustryexperienceandnetworkswith

“Inourcommunities, withindustry,for patientsandwith researchpeers,the peopleoftheFHNW SchoolofLifeSciences aredrivinginnovation forward.”

FalkoSchlottig

them.Ourgenderandculturaldiversityare increasing,andthisbringsagreaterrangeof perspectivestoourwork.

Harnessingourpotentialmeansempowering staff.Providingfreedomtooperateandtakingthe timetolistentoeachother.Askingourselves honestlywherewecanhavethemostimpactand settingprioritiestogetherhelpsusstayfocused. Asweembracenewworkanditsflexibility,we recognisethevalueofface-to-faceconversations andbeingpresentforourcolleaguesandclients. Inourcommunities,withindustry,forpatientsand withresearchpeers,thepeopleoftheFHNW SchoolofLifeSciencesaredrivinginnovation forward.

Inour communities

Ourworldisfacingunprecedented environmental,agriculturalandenergy challenges.TheFHNWSchoolof LifeSciencesactivelycontributesto developingsolutionsatthemunicipal, cantonal,nationalandinternational leveltofosterahighqualityoflife inourcommunities.

Waterexpertiseatthe serviceofourcommunities

Accesstocleandrinkingwaterisinequitableworldwide.About2 billionpeopleliveinwater-stressedcountries.Climatechangeand populationgrowthareputtingpressureonanalreadycritical situation.Waterresourcesarealsounderstrainfromtheagriculture industry,whichusesanestimated70%ofallfreshwaterworldwide.

Switzerland’sexpertiseinwaterconservation,managementand treatmentisinternationallyrecognised.Municipalandcantonal governmentsaswellasindustryarecontributingtotechnological advancesinunderstandingwastewaterandoptimizingitstreatment.

AttheInstituteforEcopreneurship,threeresearchgroupsare makingsignificantcontributionstolocal,nationalandglobalneeds forcleanwater.

Minimisingcombinedseweroverflow

MichaelThomann’steamisusingonlinesensors andmodellingtoexploitexistingwastewatercollection andtreatmentinfrastructure.

Incombinedsewersystems,rainwaterandwastewaterfromhouseholdsarecollectedtogether andmaketheirwaytowastewatertreatment plants.Heavyrainfallcancausethesecanalsto overflowbeforethewaterhasbeentreated.

Tocounterthis,Prof.Dr.MichaelThomann’s teamisparticipatingintheEuropeanproject StopUP,whichaimstoreducepollutioninreceivingwaters.Theteamisworkingcloselywith cantonBasel-Landschaft’sOfficeforIndustrial Operations(AIB),whichisresponsibleforsewers, wastewatertreatmentplants(WWTP)andlandfills.

AlthoughAIBmonitorstheamountofstormwaterdischargedfromtheirsewers,littleisknown aboutitsqualityandthusthepollutionload releasedintotheenvironmentduringcombined seweroverflowspills.Sewernetworksandrunoff dynamicsaresocomplexthatrepresentative samplingandlabanalysisarechallengingto implementineverydayoperation.

“Onlinesensorscancollectsufficientdata pointstocapturethedynamicsofevents.We aimtocorrelateparametersmeasuredwithour sensorswithtoxicologicallyrelevantpollutants suchasheavymetalsorcertainorganiccompounds”explainsMichaelThomann.Firstsamplingcampaignsandchemicalanalysesshowed promisingresults.Ecotoxicologytestingis

plannedin2024tofurtherunderstandenvironmentalimpactsofuntreatedwetweatherrunoff.

TheprojectalignswiththeSwissconcept tominimisetheecologicalimpactonreceiving watersthroughintegratedmanagementofthe sewernetworkandWWTP,includingoptimalutilisationofthehydraulicandbiochemicalcapacityof theWWTP.TheWWTPBirsusessequencingbatch reactorstotreatwastewater.Duringdryweather, thesereactorsexecutefullcleaningcycles.The plantswitchesintowetweathermodewhen heavyrainfallisexpected,sothereactorscan partiallytreatagreaterquantityofwater.

“Ourhypothesisisthatit’sprobablybeneficial toperformashortertreatment,evenifthat treatmentisabitlesseffective,thanhaving untreatedwaterspillover”saysMichaelThomann. “Modellingwillhelpusunderstandhowwecould furtherincreasetheinflowtotheWWTPduring rainyweatherwithoutundulycompromising treatmentefficiency.”

“Waterqualityinformationiskeyinanintegrated managementofsewernetworks,wastewater treatmentplantsandreceivingwaters”says GerhardKoch,HeadofTechnologyandDeputy HeadofAIBBirs.“TheFHNWhelpsusunderstand thisaspectbetterandtakeitintoaccountinour plantoperation.”

ResearchassociateBartoszKaweckicleanssensorsinstalled atthewastewatertreatmentplantBirs.

Communities: KantonBasel Landschaft;Europe Watersystem: Municipalwastewater Partners: 11partners Funding: EUHorizon101060428,SBFI22.00128

Prof.Dr.MichaelThomann Groupleader,Environmentaland watertechnologies +41612285334 michael.thomann@fhnw.ch

Howwelldoindustrialcompaniesknow theirwastewaters?

AtooldevelopedbyMiriamLanger’steamishelping industrybetteranswerthisquestion.

Themetal,pharmaceutical,chemical,cleaning andwastemanagementindustriesallneed tounderstandtheirwastewaterandcomplywith environmentalnorms.Whilechemicalanalyses canindicatethepresenceandconcentrationof targetedsubstances,theycannotpredictthe responsesoforganismsorcellstoacombination ofthesesubstances.Nordochemicalanalyses revealwhetherunknownsubstances,residues andmetabolitesarepresentiftheyarenot specificallysearchedfor.

Takinginspirationfromgapsidentifiedinan industryworkshop,Prof.Dr.MiriamLangerand ResearchAssociateDr.XeniaKlausfirstcollected nationalandinternationalknowledgeabout industrialwastewaterscreeningwithbioassays. Toanswerthechallengesthatcompaniesface, theycameupwiththeideatocreateapanelof biologicaltests.Theirtool,ABIScreen,combinesa time-efficientbiodegradationtestwithabattery ofrobust,broad-basedbioassays,including toxicitytothebacteriainthewastewatertreatmentplant,andeffectsonluminousbacteria, daphniaandalgae.Ifdesired,anAmes-testcan beincludedtodeterminewhethersubstancesin thewastewaterhavemutagenicpotential.

ABIScreeniscurrentlybeingdeployedinfive Swisscantons.Companiescollectsamplesof

theirwastewaterfromacombinedwaste streamorasub-streamofinterest.Theflasksare pickedupbytheInstituteforEcopreneurship andanalysedinitslabs,withthecostcoveredby theFederalOfficefortheEnvironmentandthe Swisscantonsinvolvedintheproject.Langer’s teamprovidesareadoutofkeyparametersin acomprehensiblereport,whichthecompanycan usetobothtreatandpreventproblems–orin manycases,confirmthesuccessoftheirwastewatertreatmentperformance.

Sincetheprojectbeganin2023,over50 companieshaveparticipated.Theyvaluethe informationtheyreceiveabouttheirwastewater, theconfidentialityoftheprocessandtheability totakemattersintotheirownhands.Somehave requestedfollow-upscreeningofsub-streamsso theycanzeroinonspecificissues.Thecontact betweenmembersofLanger’steamandindustry helpsstimulatedialogue.

“We’reveryhappywithwhatwe’veachieved” saysKlaus.“Companieshaverealisedthat performingbioassaysisnotaslong,complex orexpensiveastheymightthink,anditcomplementschemicalanalysisnicely.Theproject isencouragingthemtomeasuremoreoften andcheckthattheirtreatmentprocesses areworking.”

Industryclientsandgovernmentagencies agree.“Infuture,ABIScreencouldhelpusto identifycriticalsubstancesinourwastewater moreeasilyandeliminatethematsourcewherever possible”saysChristineWegmannfrom dsm-firmenich.

“Thecombinationofdegradabilitytestsand bioassaysinABIScreenenablesaholistic characterisationofaspecificwastewaterin additiontochemicalanalysesandsimultaneous evaluationofthecompany’sownwastewater treatment.Tracingtoxicandnon-biodegradable substancesinwastewaterbacktotheirsource helpscompaniestofindoutabouttherequired state-of-the-arttechniquesandtherefore representsaddedvalue”saysSaskiaZimmermann-Steffens,WaterDivision,FederalOfficefor theEnvironment.

Inthenextphaseoftheproject,Langer’steam willpublishanonymousbiotestresultsina databaseaccessibletoparticipatingcompanies, allowingthemtocomparemetricswithintheir industrysector.Thedatabaseisexpectedtogo livein2025,withadetailedanalysisofcombined resultsby2026.

Asmorecompaniesseevalueinthesetests andthevolumeoftestingincreases,theFHNW SchoolofLifeSciencesplanstotransferthe

knowhowtoprivatesectorlabs,helpingthem expandtheirserviceofferings.

“Thisprojecttrulyillustratesthevalueofthe FHNW’sappliedresearchexpertiseforSwissindustryandgovernment,andisanactivecontributiontofuturegoodwaterquality”saysLanger.

Community: Switzerland(CantonsAG,BL,GE,VD,ZH)

Watersystem: Industrialwastewater Financing/Support: FederalOfficeforthe Environment(FOEN)Switzerland,CantonsofArgau, Basellandschaft,Geneva,VaudandZurich Partners: VerbandSchweizerAbwasser und Gewässerschutzfachleute

Prof.Dr.MiriamLanger

Groupleader,Ecotoxicology +41612285883 miriam.langer@fhnw.ch

Dr.XeniaKlaus

Scientificassociate,Ecotoxicology +41612285635 xenia.klaus@fhnw.ch

TechnicalspecialistPatrikEckerttakeswastewatersamples fortheFHNWInstituteforEcopreneurship.

Asystemicapproachtosafewater

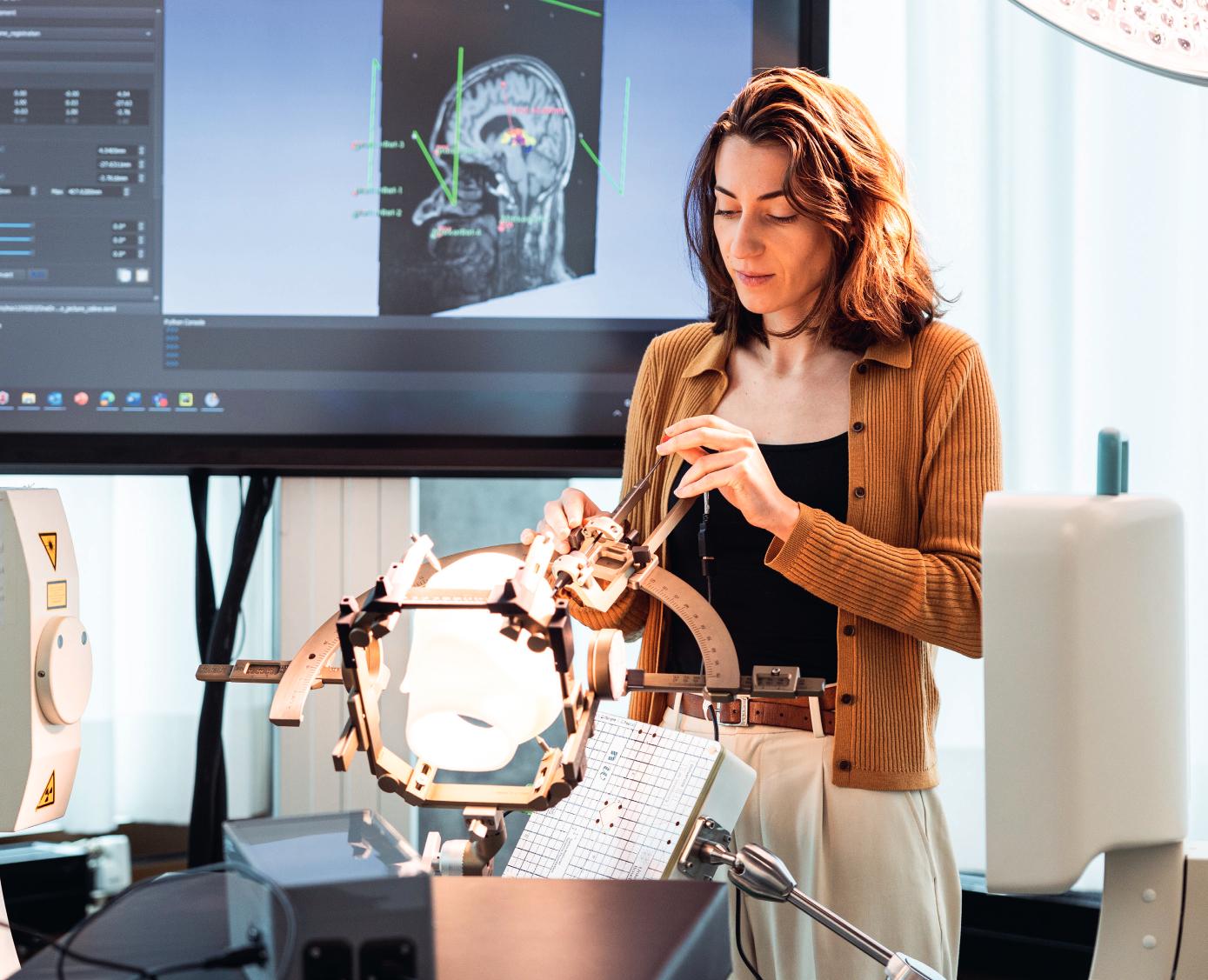

MarynaPeterandherprojectteamarepreventingdisease throughhandwashingtechnology,behaviouralscience, effectivemanagementandlong-termrelationships

Over45%ofprimaryhealthcarefacilitiesand50% ofschoolsinlow-andmiddle-incomecountriesdo nothaveaccesstohandwashingfacilities,basic hygieneandwatersupplysystemsnecessaryto preventdiseasetransmission.Inresponsetothis challenge,Dr.MarynaPeterandherteamatthe InstituteforEcopreneurshipansweredacallfrom theSwissAgencyforDevelopmentandCooperationwithaprojectcalledHands4Health.Theprojectproposesanapproachtosupportwater,sanitationandhygiene(WASH)systemsthatreduce diarrhoeaamongchildrenatschoolsandprevent transmissionofinfectionsinhealthcarefacilities. Comingfromabackgroundinenvironmental engineering,Peteristheinventorofagravitydrivenmembranetechnologythatfilterswater andremovespathogenicmicroorganisms.Itcan beusedfortreatingdrinkingwater,butalsoto recyclewater.Gravit’eausystemsusethis technologyforhandwashing,reusingthesame

waterforseveralweeksbeforeitisreplaced.By providingasourceofwaterforhandwashingonly, thetechnologyhelpsconservedrinkingwater, whichisimportantduringemergenciesandin water-scarceareas.Peter’snot-for-profitassociationGravit’eauoffersthedesignunderopen accesstocommunities,wholearntoproducethe systemthemselveswiththesupportofassociationmembers.WhenPeterjoinedtheFHNW SchoolofLifeSciences,shenotonlybroughtthis technologicallegacywithher,butalsothevision todeployitusingasystemicapproach.

TheHands4Healthprojectsheleadsjointly withherWASHteamisactiveinMali,BurkinaFaso, NigeriaandPalestine.TheconsortiumiscomposedofresearchersfromtheFHNW,theSwiss TropicalandPublicHealthInstitute,ÉcolePolytechniqueFédéraledeLausanneandthe PalestinianPolytechnicUniversity.Alongside themarenon-governmentalorganisationsTerre

deshommes,CesviandSkatFoundation,aswell asprivatesectorpartnersRanasandMartin Systems.Theteamworkscloselywithlocal governmentsandcommunityrepresentatives, focusingonimprovingwater,sanitationand hygieneservicesatoff-gridschoolsandhealth carefacilitieslocatedinconflict-affectedareas.

Thefirststepisdevelopingasharedunderstandingofthecontext-specificchallenges anddefiningacommongoaltoworktoward. “Eachsituationisdifferent,andit’scrucialto engagelocalstakeholdersattheoutsetsothat wecanprioritisetheneedseffectivelyand sustainablyandunderstandthebarriers”says Peter.“NGOslikeourpartnersTerredeshommes andCesvihavelong-standingrelationshipswith communities,localgovernments,schoolsand healthcarefacilitiesandhelpusbuildtrust.”

Akeypartneroftheproject,Ranas,iscontributingtheirmodelofbehaviourchangeto

SchoolchildreninaprimaryschoolinMaiduguri,BornoState, NigeriauseaGravit`eauhandwashingsystem.

“Ourgoalisbroadpublic disseminationofasystemic approachtocommunities andNGOs,sotheycantest andimplementittoincrease sustainabilityandimpactof theirWASHprogrammes.”

MarynaPeter

understandmotivatorsforandbarrierstohandwashinginschoolchildrenandhealthcarefacility staff.Factorssuchasriskperceptions,attitudes, normsandvalues,abilitiesandself-regulationare importantdriversofbehaviour.Foreachcountry, behaviouralfactorsthatcanimproveconsistency ofhandwashingpracticeswereidentified.Correspondingbehaviourchangeactivitiescanthenbe selectedfromactivitycataloguesthatare preparedwithintheproject,specificallytargeted totheschools’andhealthcarefacilities’contexts.

Peter’steamiscontributingoverallproject leadershipaswellashardwareinterventions, monitoringtechnologiesandimpactevaluation. Theyareevaluatingsensorsforthehandwashing stationsthatmeasurewaterlevel,andsupporting NGOsandauthoritiesinestablishingeffective monitoringprocessesusingKobo based datacollectionappslinkedtodashboards.Finally, theyoffersimplehow-toguidesforplanning

improvementstowatersystems,maintaining watertanksandchlorinatingwater.

“Thisprojectisnotonlyaboutgettingscientific results”saysPeter.“Ourgoalisbroadpublic disseminationofasystemicapproachtocommunitiesandNGOs,sotheycantestandimplement ittoincreasethesustainabilityandimpactof theirWASHprogrammes.”

Since2021,Hands4Healthhasworkedin26 schoolsand24healthcarefacilities,withadditionalimplementationsplannedin24healthcare facilitiesand26schoolsbytheendof2024, reachingnearly100,000people.

Communities: HealthcarefacilitiesandschoolsinMali, BurkinaFaso,NigeriaandPalestine Waterandsanitationsystems: Recyclingwater forhandwashing;Chlorination;Rehabilitationof infrastructure;Behaviourchange;Digitalisedmonitoring andimpactevaluation

Partners: 10partners

Funding: SwissAgencyforDevelopmentand Cooperation Transform2020

Dr.MarynaPeter Groupleader,Water,sanitation andhygiene(WASH) +41612285792 maryna.peter@fhnw.ch

Letthesunshinein

Ensuringsustainabilityofnew photovoltaicmaterials

Perovskites-Didyouknow?

Perovskiteisamineralcomposedofcalcium titaniumoxide.Itscrystalstructurehasinspired thedevelopmentofaclassofmaterials,also calledperovskites,whichfeaturetwopositively chargedionsandthreenegativelychargedions.

Perovskitesolarcells(PSCs containcompounds withtheperovskitestructure,mostoftenmethylammoniumleadhalides.Theyofferahighabsorptioncoefficientcoupledwithsimplicityandlow productioncost.IncorporationofcarbonelectrodesinPSCscanfurtherimprovetheirsustainability,usingfewercriticalrawmaterials.However, therearealsovoicesexpressingconcernsabout environmentalcompatibilityduetotheirlead content,whichislowbutpresent.

Perovskitesolarcellscanbeprintedasthin, flexiblefilmsforapplicationsinbuildings,vehicles andelectronicdevices.Intandemperovskitecells, aperovskitecellislayeredontopofatraditional siliconcell,whichsignificantlyboostsitsenergy conversion.PSCscanalsobeusedalonetopower smallvehiclessuchasdrones.Assolarpanelsize, locationandenergyneedsvary,PSCscanprovide newoptionstohelpdiversifythesolarmarket andmeetcleanenergytargets.

Netzeroby2050 thisgoalisattheheartofthe EU’sGreenDeal.Toachieveit,thedeploymentof solarphotovoltaictechnologiesmustbescaledup exponentially.Newmaterialsofferaleapforward inthecapacityofsolarpanelstoabsorband convertenergy,butit’simportantnottolosesight ofsustainabilityconsiderationsrelatingtotheir production,useandendoflife.

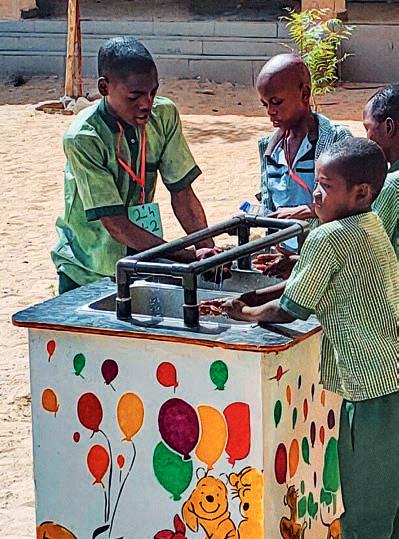

Dr.MarkusLenzandhisteamattheInstitute forEcopreneurshipareleadingthechargeininvestigatingthesustainabilityofnewphotovoltaic materials.Specializinginthecirculareconomyof metalsandminerals,theyareparticipatingintwo EUHorizonprojects,namelyNexusandPearl, toexamineifperovskitescanbesafelyusedinthe nextgenerationofsolarpanels.Inparallel,they areworkingonrecyclingperovskitessothatthey willnotbecomeawasteprobleminthefuture.

Perovskitecellscontainminimalamountsof lead,withaprotectivelayerofglassorplastic designedtocontainit.Lenz’steamisconducting outdoorleachingteststodetermineifthecellsare hermetic.Todothis,theyinstalledseveral perovskitepanelsontheroofoftheFHNWSchool ofLifeSciencesinMuttenzthatareexposedto real-lifeweatherconditions.Temperature,light, moistureandwindvarythroughouttheyear,and thepanelsaresubjecttomoreextremeweather

eventssuchashail.Metalquantificationtests performedonrainwatersamplescollectedfrom thepanelshaveshownverylowpredicted environmentalconcentrations,comparableto thosepermittedindrinkingwater.Withinthe Nexusproject,furtherfacilitiesarenowbeing installedinBolzanoandValenciatoensurethat perovskitescanbesafelyoperatedunder differentclimateconditions.“Wecurrentlysee littlereasontobeconcernedaboutthepossible environmentalimpactsofleadduringtheuse phase”saysLenz.

Butwhatifthecellweretobedamaged?To findout,Lenz’steamsimulatesmoreextreme weathereventsinacontrolledenvironment.Inthe Pearlproject,theyexposeperovskitemodulesto higherUVradiation,createdefects holes usinga laser,andlookatwhetherbacteriacoulddamage protectiveplasticlayers.

Andwhenthemodulesreachtheirendof life?Recoveryandrecyclingofcriticalmineralsis keytosolidifyinganindependentEuropean supplychainandensuringsustainabilityofsolar andbatterypower.Usingtheirexpertisein hydrometallicrecovery,Lenz’steamhasdemonstratedforthefirsttimehowwateralone issufficienttorecoverpureleadiodide(PbI2) fromperovskites.

Lenz‘steamconductsoutdoorleachingteststoassessthesafetyofperovskite photovoltaicpanelsinstalledontheroofoftheFHNWCampusinMuttenz.

Therecoveredleadiodidecanbeusedto producenewperovskitematerials,whiletheold cellsarenolongerconsideredhazardouswaste,a win-winsituation.

InnovativesolarfirmsparticipatingintheNexus andPearlprojectsaregratefulfortheenvironmentalfatetestingandmaterialrecyclingdone byLenz’steam.

OxfordPV,whosetaworldrecordinenergy conversionof28.6%fortheircommercialsizedperovskite-on-silicontandemsolarcellin January2024,isworkingtowardatargetof>30% formodulepowerconversionefficiencyinthe Nexusproject.

SauleTechnologies,whoisparticipatingin thePearlproject,specialisesinprintingperovskite solarcellsonthin,flexiblesubstratesatlow temperatures.

“Inthepastdecade,perovskitePVhasgone fromalabcuriositytoapowerhousewiththe

potentialtodemocratisecleanenergy.AtSaule Technologies,werecognisetheurgencyofthe climatecrisisandarecommittedtoharnessing thistechnologyresponsibly,minimisingenvironmentalimpactsateverystageofdevelopment andproduction.ThroughthePEARLprojectwe aregainingcrucialinsights,ensuringasustainable futureforthecleanenergycomingfromour perovskitePVtechnology”saysDr.Konrad Wojciechowski,ChiefScienceOfficeratSaule.

“Ourroleisneithertoengageingreenwashing, nortogeneratealarmism”saysLenz.“Inthese projects,we’reprovidingscientificfactsthatcan helpmanagepossiblerisksofperovskites,determinetheirenvironmentalandsocialacceptabilityandfacilitatetheiradoption.Wealso hopeourmethodscontributetoscaling-upand broadlydeployingrecyclingprocessesfor criticalminerals.”

“We’reprovidingscientific factsthatcanhelpmanage possiblerisksofperovskites, determinetheirenvironmental andsociallyacceptability andfacilitatetheiradoption.”

MarkusLenz

Community: Europe

Financing/Support:

Nexus:HorizonEurope(GA101075330)andSERI (22.00314)

Pearl:HorizonEurope(GA101122283)andSERI (23.00383)

Partners:

Nexus:12partnersincludingOxfordPV Pearl:10partnersincludingSaule

Dr.MarkusLenz

Groupleader,Appliedcircular economy +41612285686 markus.lenz@fhnw.ch

Inthemix

Combiningbiocharandcompostto rehabilitatedegradedsoils

Biochar-Didyouknow?

Biocharisaformofcharcoalobtainedbythermally decomposingbiomassattemperaturesbetween 400and700°Cwithoutoxygen,aprocess knownaspyrolysis.Over2500yearsago,Amazoniansusedasimilarprocessofsmouldering agriculturalwaste,bones,brokenpotteryand otherorganicmattertocreatehighlyfertileTerra preta,whichmeansdarkearthinPortuguese. Today,mostbiocharisproducedfromwoodyand grassybiowastes.

Pyrolysisofbiomassresultsnotonlyintheproductionofsolidbiocharbutalsoinbiofueland syngas.Plantsproducingbiocharmayusethe syngastheygeneratetofuelpyrolysis.

Biocharcanprovidestablecarboninsoilfor hundredstothousandsofyears.Itsporosityhelps soilretainwater,nutrientsandorganicmatter.It canalsoreducenitrousoxide(N2O)emissions duringcomposting,whichhelpscountergreenhousegasemissions.

Ifyouhaveavegetablepatchinyourgardenor flowersonyourbalcony,youknowthebenefitsof usingcomposttomaintainorincreasethequality ofyoursoil.Materialsaddedtosoiltoimprove itschemical,physicaland/orbiologicalproperties arecalledsoilamendments.Onesoilamendment generatingsubstantialinterestisbiochar,aform ofcharcoalobtainedfrombiomass.

IntheAgrocompositprojectconductedas partoftheEuropeanJointProgrammeonAgriculturalSoilManagement(EJPSOIL),scientists fromtheInstituteforEcopreneurshipandAgroscopearecollaboratingwithresearchersand practitionersinNorwayandHungarytocombine biocharwithcompostingofdifferenttypesof biowaste.Theyaretestingthepotentialof compositesoilamendmentstorehabilitate degradedsoils,increasenitrogenuseefficiency alongtheentirevaluechainandreducegreenhousegasemissions.

InSwitzerland,FHNWresearchersarecocompostingbiocharwithanaerobicallydigested greenwasteandtheorganicfractionofmunicipal solidwastefromananaerobicdigestionplant. InNorway,researchersarecombiningaquaculture biowastewithbiochar,whileinHungary,a mixtureofsewagesludgeandbiocharisbeing investigated.

First,theteamisproducingcompositesoil amendmentsfromdifferentbiowastesandwith varyingbiocharconcentrationsinthelab,and testingthesemixturesinpotexperimentson wheatandmaizeplants.Theyaremeasuringthe levelofnutrients,carbon,tracemetalsand polycyclicaromatichydrocarbon(PAH)inthe compositesthemselves,inthedifferenttypesof soilstheyareappliedtoandinthecrops.These resultswillbecomparedtopotsthatcontainno amendments,digestedwasteonly,biocharonly andtraditionalmineralfertilisers.

Next,theteamwillapplyitsfindingsoutdoors inlarge-scalefieldtests,toquantifythepotential ofthecompositesoilamendmentstoimprove degradedsoilsatspecificsites.Theywilldeterminewhichcompositeamendmentshelpenhance soilpropertiestosupportagroecologicalfunctions,includingincreasedcarboncontentand improvedwater-holdingcapacity.

“Fieldtestsarechallenging,withalarge numberofvariablesthatcan’tbefullycontrolled, buttheyareessentialtotranslatinglabresults intoapplication.Weareexcitedtogeneratenew insightsintobiowastevalorisationroutesfor healthieragroecosystemsinEuropethroughthe applicationofbiochar-compostcompositesin real-worldsituations”saysGross.

ThomasGrossusesadrumcompostertogenerateanewcompositesoilamendmentthatincludesbiochar, anaerobicallydigestedgreenwasteandtheorganicfractionofmunicipalsolidwaste.

Findingpromisingcompositesoilamendments isnottheonlyaim.Theprojectcollaborateswith severalfull-scalebiowastetreatmentfacilitiesand farmsinSwitzerlandandEuropetoexplore environmentallyandeconomicallysoundbiowaste valorisation.Toquantifytheenvironmental footprint,Gross’teamisconductingsubstance flowandlifecycleanalysistocalculateenvironmentalimpactsfromresourceuseandemissions alongthebiowastevaluechain.Combinedwith ecotoxicologicalassessmentsconductedbyother consortiumpartners,thiswillprovideasolidbasis todetermineiftherearerisksforsoilhealthand cropsafety,andwhethertheadditionofbiochar tocompostisjustifiedintermsofyield,environmentalimpactsandeconomiccosts.

Agriculturalandenvironmentalagencies requirethistypeofdatatoestablishregulations andprovidesoundguidancetofarmers.The SwissFederalOfficeoftheEnvironmentiscalling

formoreknowledgefromresearchbeforebiochar canberecommendedforuseinSwisssoils, particularlywithregardtotheeffectsonsoil organisms.Concernsregardingbiocharhavebeen formulatedinthefollowingfactsheet:Biocharin Swissagriculture-risksandopportunitiesforsoil andclimate[inGerman:Pflanzenkohleinder SchweizerLandwirtschaft RisikenundChancen fürBodenundKlima].

Attheintersectionofbiowastevalorisation, agricultureandbioenergy,thisprojectcanhelp generateknowledgeaboutthesafetyandefficacy ofcombiningbiocharwithcompost,andinthe longrun,contributetodrivingtheSwissbioeconomy.“Ultimately,wehopetohelpcloseresource cycles,reducethedependencyonnon-renewable fertilisersandprovidenewsolutionstorehabilitatedegradedsoils”saysThomasGross.

“Ultimately,wehopeto helpcloseresourcecycles, reducethedependency onnon-renewablefertilisers, andprovidenewsolutions torehabilitatedegradedsoils.” ThomasGross

Community: Switzerland,Europe

Financing/Support: SNSF31SL30_214524

Partners: Agroscope;BudapestUniversityofTechnology andEconomics;NorwegianInstituteofBioeconomy Research;InstituteforSoilSciencesofHungary

ThomasGross Researchassociate,Sustainable resourcesmanagement +41612285654 thomas.gross@fhnw.ch

Trustedpartner forindustry

Swisscompaniesofallsizesseekus outasatrustedpartnerforapplied research.WithakeyroleintheBasel cluster,ourcompetencesandstateof-the-artfacilitiesareanassetforboth bigpharmaandSMEs.Innosuisse projectfinancingisavailableforfirms whocollaboratewithustobringtheir ideastowardthemarket.

Biologics–anewgeneration ofmedicinesthatrequire newsolutions

Biologicshaveestablishedtheirplaceasanewgeneration ofmedicinesthatprovidemoretargetedtreatmentoptions forcancer,autoimmunediseases,metabolicdiseases andgeneticdisorders.

Today,biologicmodalitiessuchasantibody-drugconjugates, bispecificproteinsandcellandgenetherapieshaveopened upevenmoreavenues,yettheypresentuniquechallenges inbiopharmaceuticalproduction.Meanwhile,someestablished biologicsaremovingfromclinicaltohomesettings,where patientscanadministerthemthemselves.Thiscreatesnovel considerationsforbiologicsstorage,injectionandalternative deliveryroutes.

TwoteamsattheInstituteforPharmaTechnologyandBiotechnologyarecollaboratingwithindustrytofindsolutionsto newchallengesacrosstheentirebiomanufacturingprocess, fromcelllinedevelopmenttoculture,purification,formulation, fill,finishandqualityassuranceoftechnicalandpreclinical trialmaterial.

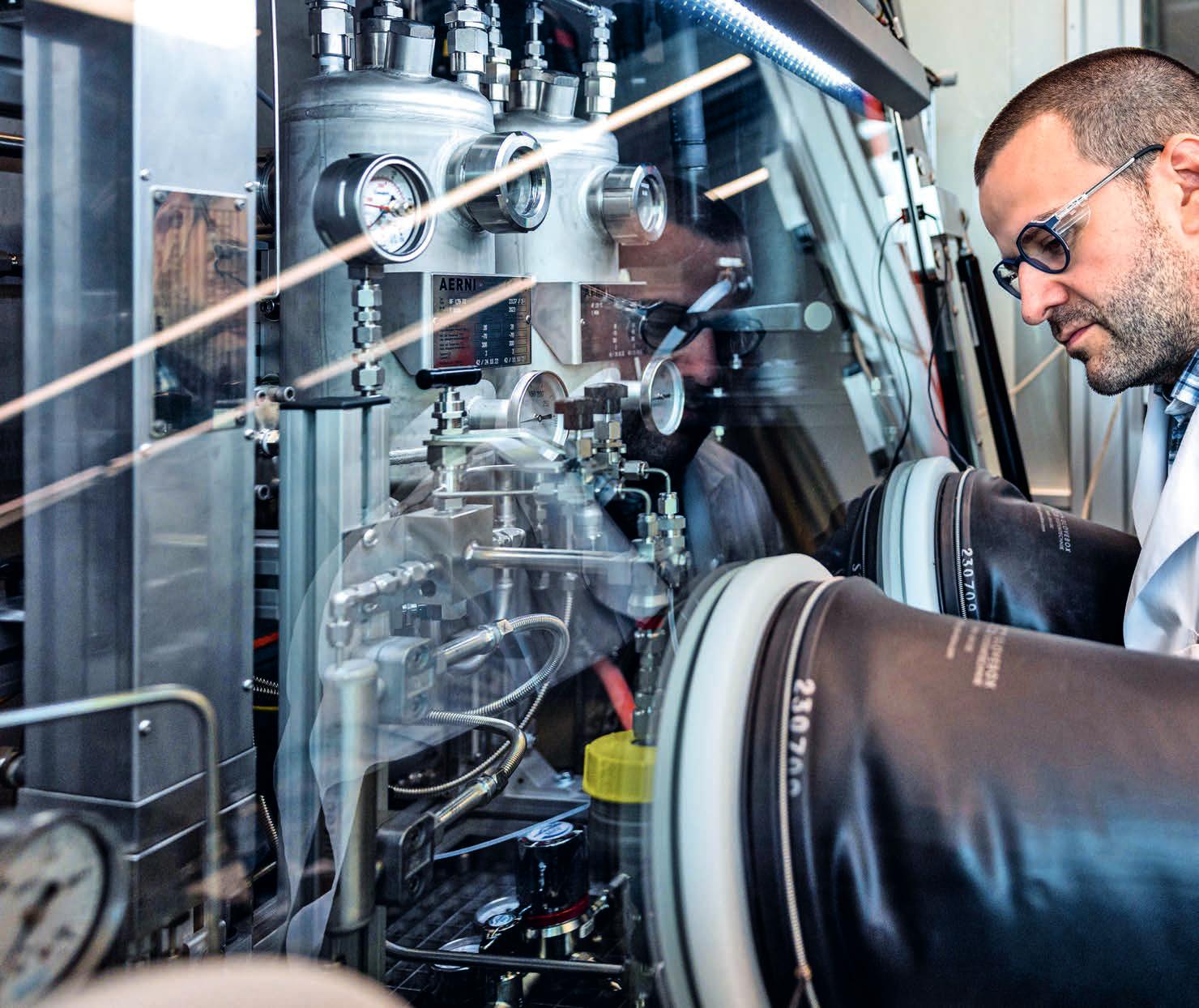

Cellculture

MammalianhostcelllinessuchasChineseHamster Ovary(CHO)orHumanEmbryonicKidney(HEK) cellsactaslivingfactoriestoproducebiologics. Understandingwhatishappeninginsidethe bioreactorduringdifferentstagesofcellcultureis keytoobtaininghighyields.

Ramanspectroscopy,includinganalysers, probesandsoftware,canenablereal-time analysisofnutrients,metabolites,productquality andcellviability,helpingmanufacturersgain controloftheprocessandmakedecisionsabout whentofeedtheculture.However,itswide-scale implementationiscurrentlylimitedbycalibration modeldevelopment,whichrequireslabour-intensiveandtime-consumingexperimentalsetups aswellascomplexITinfrastructure.

InanInnosuisseprojectcalledRamanReady, researchersfromtheInstituteforPharma TechnologyandBiotechnologyaredeveloping

Endress+Hauser,aleadingproviderofRamansystems, isimplementingcalibrationmodelsdevelopedattheInstitute forPharmaTechnologyandBiotechnology.

ready-to-usecalibrationmodelsforRaman spectroscopyinbioprocesses.

“BycombiningRamantechnologywithmachine learningexpertise,weaimtocreateversatile andaccuratemodelsthatareapplicablefora widerangeofbiologicsandprocesses”saysProf. Dr.ThomasVilliger,GroupLeader,Bioprocess Technology.

Theproject’simplementationpartner,Endress+ Hauser,isaleadingproviderofRamansystems whobelievesintheimportanceofdelivering high-qualitysensorstoitsclients.

“Weareconfidentthattheworkwearedoing withtheFHNWwillhelpmakeRamansystemsmore accessibletoourclientsandbroadentheapplicationofthispowerfultechnology”saysLukasJegge, SeniorSalesEngineeratEndress+Hauser.

DoctoralresearcherSherinPanikulamperformschromatographytopurifybiologics,andanalyseswhetherhostcell proteinsremainafterpurification.

Purificationofantibodies

Afterproduction,biologicmodalitiessuchas antibodiesproducedfromahostcellneedtobe separatedfromtheculturemediuminwhichthey weregrown.Centrifugation,membranefiltration andproteinaffinitychromatographyarethemost commonstepstocaptureandpurifythetarget biologics.However,smallamountsofprotein impurities,knownashostcellproteins(HCPs,may remainafterchromatographyandcancause concernsforproductquality,safetyand/orefficacy.

Inalarge-scalestudyconductedwithNovartis, SherinPanikulamfromVilliger’steamanalysed 23biologicsafteraffinitychromatography.The goalwastofindoutwhattypesofHCPsremained andunderstandwhytheyhadbeencaptured alongwiththebiologics,tobetterguideprocess development.

Ofthe449HCPsidentified,mostwerecapturedalongwithfewerthan3biologics.However,

someHCPsremainedidentifiedinmanybiologics. Usingproteinnetworkanalysis,Panikulamshowed thatprotein-proteininteractionisanadditional mechanismforHCPco-elution,resultinginfailure toremovethembychromatography.

“Ourfindingsmayhelptoguidehostcellline development,forexampleknockdownorknockout oftheprimarybindingpartnerintheCHOcellline. Wealsohopethatnewpurificationstrategiescan bedevelopedtopreventcertainhost-cellproteins frombringingtheirfriendstothepartyandbeing capturedwithtargetbiologics”saysPanikulam.

“Nowadays,weneedabetterknowledgeof residualimpuritiesremaininginbiologics.These resultsarekeytounderstandinghowHCPs behaveduringthepurificationprocessofadrug, andsupportprocessdevelopmentincaseaproblematicHCPisspotted”saysNicolasLebesgue, PrincipalScientistinAnalyticalCharacterization atNovartis.

DoctoralresearcherJuliaMüllerdevelopsnewcontinuouspurificationstrategiesforviralvectorsusedingenetherapy.

Purificationofgenetherapeutics

Ingenetherapy,arepairDNAsequenceis packagedinsideaviralvector,alsocalleda capsid,thatdeliverstheDNAtothenucleusofa cell.Manufacturinggenetherapeuticsiscomplex andtimeconsuming,asthetraditionalproduction processrequiresthreeplasmids,growthofhost HEKcells,introductionofthethreeplasmidsinto HEKcells,productionbytheHEKcellsofviral capsidsthatcontainthetherapeuticDNAsequence,andseparationofcapsidsfromthe materialusedtoproducethem.

Notallviralvectorsproducedcontainthe therapeuticDNA.AfterproductioninHEKcells, about50-80%ofcapsidsareempty.Captureand polishingchromatographystepsareusedto obtain80-90%fullcapsidsandtoensuretherapeuticefficacy.Purificationprocessesforviral vectorsarenotaswellestablishedorstandardisedasthoseforantibodies,especiallyat

largerscale.Thisisacriticalbottleneckto makinggenetherapiesmoreaffordable andavailable.

InaprojectwithYMC,aleadingdeveloper ofchromatographicstationaryphasesand purificationequipment,JuliaMüllerfromVilliger’s labisworkingoncontinuouspurificationstrategiesforadeno associatedviralvectors(AAVs

“InsteadofcapturingAAVsonasinglecolumn andlosingsomeduringloading,weareusingtwin columnstotransfertheflow-throughfromthefirst columntothesecond,givingAAVsasecond chancetobecaptured”saysMüller.Afterwards, thefirstcolumnisemptiedandreintegratedinto theprocess,pickingupthebatonwhenthe secondcolumnisfull,andsoonuntileverything hasbeenpurified.Continuouspurificationnotonly capturesmoreAAVs italsouseslessmaterial andenergythanbatchpurificationandiseasierto characteriseforqualityassurance.

“Continuouschromatographyoffers greatpromiseforachievinghigher yieldsingenetherapymanufacturing,whileincreasingsustainability andreducingcosts.”

ThomasMüller-Späth,CEO,YMC

Similarly,duringpolishingtoseparatefull andemptyAAVs,thepurestfractionoffullAAVs centrecut isextractedfromthefirstcolumn, whilepartiallypuresidecutscontainingboth emptyandfullAAVsarerecycledonasecond column,resultinginincreasedyieldoffullAAVs withoutcompromisingpurity.

“TheresultsgeneratedbytheFHNWdemonstratethatcontinuouschromatographyoffers greatpromiseforachievinghigheryieldsingene therapymanufacturing,whileincreasingsustainabilityandreducingcosts”saysThomasMüllerSpäth,CEOofYMC.

Surfactants,whichhaveahydrophilicheadandhydrophobictail,areusedinbiologicsformulationtopreventaggregation.

Biologicsdrugproductformulation

Biologicscanbecomedestabilisedbyconditions duringtransport,storage,andhandling,whichcan leadtolossofefficacyorunwantedimmune reactions.Withbiologicsadministrationmoving fromthedoctor’sofficetothehome,patientsare becomingpartofthecoldchainandsharing responsibilityforconsistentrefrigerationand properhandlingoftheirbiologics.

Topreventdamagetotheirstructure,biologics areformulatedwithsurfactants,amphiphilic moleculescomposedofahydrophilicheadanda hydrophobictail.Surfactantspreventbiologics aggregationbyblockingtheiradsorptionat air-waterinterfacesencounteredduringmanufacturing,storage,transportanduse.Onlythree surfactantsarecurrentlyusedincommercial biologicsformulation,andtheyfacechallenges whenitcomestodegradation.

Inaprojectconductedincollaborationwith

Novartis,Prof.Dr.OliverGemershausandhisteam helpedassess40newpotentialsurfactants, includingexistingmoleculesandnovelsurfactants synthesisedbyNovartis.Theyfirstexamined biophysicalpropertiesofthecandidates,followed bytheirabilitytopreventagitation-induced aggregationwhenformulatedwithdifferenttypes ofbiologicsincludingadisorderedprotein,a fragmentantigenbindingregion,monoclonal antibodiesandafusionprotein.Mostimportantly, thechemicalandenzymaticdegradationpropensityofthenewsurfactantswasinvestigated.

Theteamidentified2finaliststhatoffered comparableorbetterbiologicsstabilisationand significantlylesssurfactantdegradationcomparedtoexistingformulations.

“ItwascrucialtohavetheexpertiseofFNHWat ourdisposalwhenselectingtheabovealternative surfactants”saysKarolineBechtold Peters, DirectorScience&TechnologyatNovartis.

“Wewillcontinuetoexplorenewsurfactants together.”

CapabilitiesattheInstituteforPharmaTechnologyandBiotechnologyhavebeenbeneficialin twootherprojectswithNovartis:Microdownscale modelstoevaluatethefreeze-thawstabilityof biologicalagents;aswellasPhysicalassessment andmodelstoevaluatethesiliconeoildepletion activityofbiologicalagents.Bothareessentialfor productsinpre-filledsyringes.

“Earlydownscalemodelsandsimulationsenable speedtofirst-in-humanandhelpaccelerate thedevelopmenttimeline”saysBechtold-Peters.

PhDstudentIliasAmaraproducesartificialreferenceparticlesusingtwophotopolymerisation.

Particlecharacterisation

Afterbiologicshavebeenproduced,purifiedand formulated,theyundergoqualityassuranceto ensuretheymeetestablishedstandardsforinjectabledrugformulations,includinglimitsofvisible andsubvisibleparticles.

Particlestypicallyrangefromnanometers tohundredsofmicrometers.Theymaybe extrinsictothenormalmanufacturingprocess,for examplecellulosefibersfromcleaningprocesses. Theycanalsobeintrinsic,havingemanatedfrom normalmanufacturingprocessesorthecontainer closuresystem,ortheymaybeinherent,originatingfromformulationexcipientsortheactive ingredient,forexampleexpectedaggregates orhazes.

Calibrationofinstrumentsusedforsizingand countingsuchparticlesisdonewithperfectly sphericalreferenceparticlesthatofferhigh opticalcontrast.Intrinsicproteinparticles,onthe

otherhand,poseachallengeforinstrumentsdue totheirirregularshapeandtranslucentnature.

Toaddressthis,Germershaus’groupfabricatedirregularlyshapedparticlesrepresentativeof subvisibleandvisibleparticles,inacollaboration projectwithRoche.Createdbytwophoto polymerisation(2PP)printing,theseartificial particlesmayserveasnewreferencematerial mimickingthemorphological,opticalandphysical propertiesofproteinparticles.

Intheirstudy,theycomparedthenew referencematerialtocurrentlyusedpolystyrene spheres,standardparticlesfromtheNational InstituteofStandardsandTechnologyandactual proteinparticlesgeneratedbyexposingmonoclonalantibodiestovariousstresses.

“Wearecurrentlyworkingtowardsbroad evaluationofthesuitabilityoftheprotein-like particlestandardswedevelopedwithstakeholdersinthepharmaceuticalindustry,withthe

ultimategoalofharmonisingsubvisibleandvisible proteinparticlecharacterisationacrosslaboratoriesandorganisations”saysGermershaus.

ScientificassistantYasminGretherconductstestsintheFHNW‘sProcessTechnologyCenter, wherecompaniescandevelopnewfillfinishformatsandprotocols.

Packagingandadministration

Oncebiologicshavebeenformulatedandcharacterised,theyundergofillfinish,whichinvolves transferringthebiologicdrugsubstancetoa sterilevialorsyringe,stoppering,inspectionand labelling.Somebiologicsarelyophilisedbefore stopperingtoincreasetheirstability.TheProcess TechnologyCenterattheFHNWCampusMuttenz featuresacleanroomwherecompaniescandevelopnewfillfinishprotocols,fillreferencesamples ormanufacturebiologicsforpreclinicaltrials.

Increasingly,biologicsarebecomingavailable forpatientstoadministerathomeusingpre-filled syringes,autoinjectorsorpatchpumps.These productsofferpatientsconvenienceandautonomy,andaredesignedtohelpovercomeneedle phobiaandincorrectadministration.

Pre-filledsyringescontaintherightdosage, andthepatientcancontroltheinjectionspeed.

Autoinjectorsaresemi-automatic,withabuttonto

starttheinjection,ahiddenneedleprotectedbya safetycoverandaudibleclicksthatindicatewhen theinjectioniscomplete.Patchpumpsandother wearabledevicesarethenewest,mostadvanced optionsforbiologicsself-administration.The latestdevicesfeatureinnovationstoreconstitute lyophilisedbiologicsandenabledeliveryoflarger volumesbysubcutaneousinfusion.

Germershaus’teamiscollaboratingwith companiesfromthepharma,packagingand devicesectorsfocusingonthedevelopmentof newinjectiondevices.Thesubcutaneousdelivery oflargervolumesiscurrentlyanimportanttopic. Studiesrangefrominvestigationofthecompatibilityofdevices e.g.patchpumps withbiologic drugproducts,tofillingofnovelpackaging formats e.g.cartridges underasepticconditions. Fillingcanbeperformedmanuallyorautomatically inbatchsizesfromsingledigitunitnumbersupto 1000unitsperhour.

Financing/Support: RamanReady:Innosuisse114.286IP-LS DevelopmentofaMobileDosingPumpforthe AdministrationofBiologics:25721.1PFLS-LS Partners: Endress+Hauser,Novartis,Roche, YMCChromaCon,SensileMedicalAG

Prof.Dr.ThomasVilliger Groupleader,Bioprocesstechnology +41612285246

thomas.villiger@fhnw.ch

Prof.Dr.OliverGermershaus HeadofInstituteforPharma TechnologyandBiotechnology Groupleader,Formulations anddevicesforactivechemical andbiologicalsubstances +41612285526

oliver.germershaus@fhnw.ch

Overcomingfrontiersin brainmedicine

Ourbrainisprotectedbyalayeroftightlywovenendothelial cellsthatlinethebrain’sbloodvessels,calledtheblood-brain barrier.Thesecellsblockforeignagentssuchaspathogens fromenteringourbody’scommandcentre.Atthesametime, nutrientsthatthebrainneedsareallowedtopass,viaaprocess calledreceptormediatedtranscytosis(RMT).Receptorson thesurfaceofendothelialcellsrecogniseandbindtonutrients, andcarrythemintothebrain.

Thebarrieralsopreventssometherapeuticsfromreaching diseasetargetsinthebrain.Medicinesthatcansuccessfully enterthebrainincludeanesthetics,antidepressantsand antipsychotics.Agreatneedremainshoweverfortherapiesto treatAlzheimer’s,ALS,Parkinson’s,braincancersandmore. Biologicdrugscouldofferhope,butstrategiesmustbedevised tosneaktheselargemoleculespastthebarrierusingRMT.

TeamsattheInstituteofChemistryandBioanalyticsare workingonengineeringnanomedicinesthatcanenterthebrain, aswellasnewmodelsoftheblood-brainbarrierthatcanbe usedbypharmaceuticalcompaniestotestwhether medicinescancross.

Bighopesfornanomolecules

Nano-engineeredshieldforenzymereplacement therapycouldhelpitreachtargetsinthebrain

Enzymesareproteinsthatspeedupchemical reactionsincells.Theybreakdownfoodand toxinsinourdigestivesystemandliver,andhelp DNAunwindduringcelldivisionandreplication forexample.Beyondtheirroleinourbodies,their propertiesascatalystsmaketheminterestingasa greeneralternativetochemicalcatalystsfor chemicalreactions.

In2016,scientistsattheInstituteforChemistryandBioanalyticsdevelopedaninnovative methodtoengineerenzymesinsidenanoparticles, makingthemmoreresilientforapplicationsin biocatalysis.TheyspunoffthecompanyInofea, focusedonprovidingsolutionsforstable,active andpureenzymesforchemicalreactionsand productionprocesses.

Enzymescanalsoactastherapeutics,in caseswhenthebodyisnotproducingenoughon itsown.Buildingontheirenzymeengineering technology,Prof.Dr.PatrickShahgaldianandhis teamdevelopednano-architecturestoprotect sensitiveenzymetherapeuticsfromdegradation inthebody e.g.intestinaltract.Theteam designedanorganic-inorganichybridthatenables enzymestostayaliveandreachtheirtargetsin thegut.Thiscansignificantlyreducethepill burdenforpatients.Forthetherapeuticapplicationsoftheshieldingtechnology,Shahgaldian

spunoffPerseoPharmain2019.Thefirmis currentlyconductingpreclinicaltestingoffour digestivetherapies,aswellasinvestigatingifa similarapproachcouldbeusedtodelivera cocktailofenzymesthatpreventsmetabolic activityincancercells.

ThenextfrontierforShahgaldianandhisteam isanotherdifficultenvironmentformedicines:the brain.Thistime,they’reworkingonsolutionsfor lysosomalstoragediseases(LSD),alargegroup ofmetabolicdisorderscausedbyenzyme deficienciesinthelysosome.About50-70%of LSDsaffectthecentralnervoussystem.Enzyme replacementtherapiescanhelpaddresssome oftheseconditions,butunfortunatelytheydonot crosstheblood-brainbarrier.

Shahgaldian’steamisseekingtoovercome thisproblembydesigninganouterenzymeshield thatwillnotonlyprotecttheenzymes,butmore importantly,bindtoreceptorsontheblood-brain barriertoallowtransportacrossit.

“Bydecoratingtheenzymeswithstructures thatthebrain’sendothelialcellsrecognise andbindto,itmaybepossibletodeliverenzymes tothebrain.Wehopeourapproachwillcontributetonewtreatmentsforlysosomalstorage diseasesaffectingcentralnervoussystem targets”saysShahgaldian.

ResearchassociateCongyuWuperformsscanningelectron microscopytocharacterisenanomoleculesdesignedtobind totheblood-brainbarrier.

Anotherstrategythattheteammayexplorein thefutureisthedesignofnanoparticlesforintranasaladministration.Nosetobrainisapromising routethatavoidssomechallengesassociated withtheblood-brainbarrierandforwhichnanomoleculesareparticularlysuited.

Financing/Support: SwissNanoscienceInstitute Partners: PerseoPharma

Prof.Dr.PatrickShahgaldian Groupleader,Molecular nanotechnology +41612285487 patrick.shahgaldian@fhnw.ch

Testingbrainmedicinesinthefastlane

New invitro modeloftheblood-brainbarrierhelps pharmaidentifypromisingcandidates

ResearchassociateFlorianaBurgioseedsbrainmicrovascular endothelialcellsinanOrganoPlate 3lane Mimetas tocreate amodeloftheblood-brainbarrier.

Theneedforbraintherapeuticsisgreat,andmany pharmaceuticalcompaniesaredevelopingdrugs. Totestthesenovelmedicines,clinicallyrelevant modelsthatmeasuretheirabilitytocrossthe blood-brainbarrierareneeded.

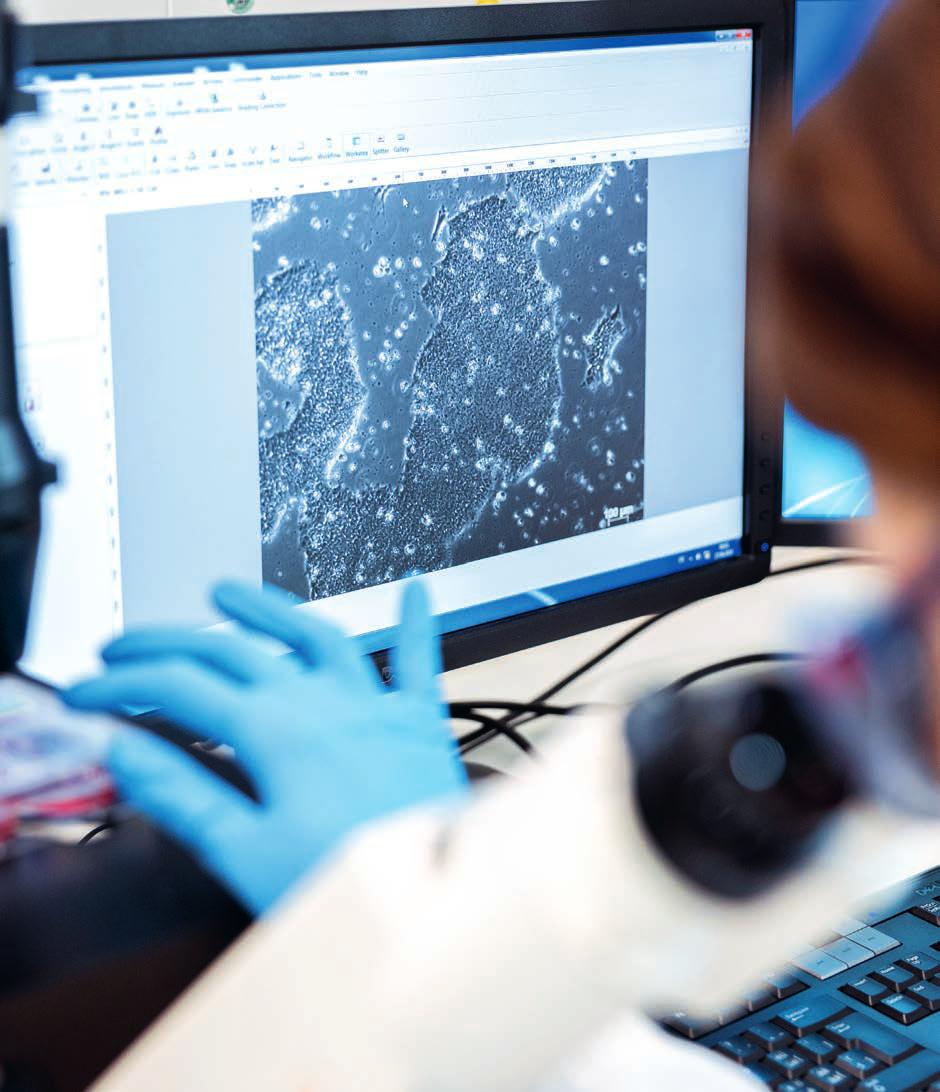

Invitro modelsarecellsgrowninsideaspecial devicethatmimicshowanorgan,orpartofit, functions.Prof.Dr.LauraSuter-Dick’steamatthe InstituteforChemistryandBioanalyticshasdeep expertiseindevelopinglivermodelstotestthe safetyofnewmedicines,whilereducingand replacingtheneedtouseanimalsforexample.

Backedbythisstrongfoundationinadvanced invitro modelsandnewapproachmethodologies (NAMs,postdoctoralresearcherDr.Floriana BurgiofromSuter-Dick’scellbiologygroup,in collaborationwithscientistsfromUCBPharma Belgium,setouttocreateamodelofthebloodbrainbarrierusinginducedpluripotentstem cells iPSC).Theseimmaturecellscanbedifferen-

tiatedintoanycelltype,makingthemversatile forresearch.

ThemodelimplementedbyDr.Burgiofeatures asinglecelltype:brainmicrovascularendothelial cells(BMEC)derivedfromiPSC.Shegrewthe modelinanOrganoPlate®(Mimetas andconductedteststoconfirmthatitmimicsbarrier tightness.Themodelfeaturesatopchannelwith endothelialcells,amiddlechannelwithextra-cellularmatrix,andanemptybottomchannel.Test moleculesareperfusedintothetopchannel; thosethatbindandpassarecollectedinthe bottomchannel.Thesystemiscompatiblewith automatedfluidhandlingandallowstheevaluationof40chipssimultaneously.

“WhentestedinourBBBmodel,weshowed thatamoleculewhichbindstothetransferrin receptorhasan11-foldincreaseincrossingthe barriercomparedtoacontrolmoleculethatdoes notbind”saysBurgio.“Thisestablishedthatour

modelexhibitsfunctionaltransferrinreceptormediateduptakeandtranscytosis.”

Theprojectwasconductedincollaboration withUCBPharmaBelgium,aleaderinmedicines forneurological,immuneandrarediseases.

“TheFHNW’smodeloftheBBBrepresentsa greatstepforwardtowardstestingtheabilityof potentialdrugcandidatestoenterthebrain.Inthe end,suchamodelcanimprovepreclinicaltesting offuturemedicinesfrombothanefficacybutalso asafetypointofview”saysRainerClass,AssociateDirectorof Invitro ADME,UCBPharma.

“Notonlydidthisprojectenableustodevelop amodelthatUCBPharmaBelgiumcanuseaspart oftheirdrugscreeningprocess;italsoallowedthe FHNWSchoolofLifeSciencestobreaknew groundindesigning invitro modelswithinduced pluripotentstemcells,propelledbythelatest microfluidictechnologies”saysgroupleaderProf. Dr.LauraSuterDick.

“TheFHNW’smodelofthe blood-brainbarrierrepresentsa greatstepforwardtowardstesting theabilityofpotentialdrug candidatestoenterthebrain.”

RainerClass,AssociateDirector ofInvitroADME,UCBPharma.

Partners: UCBPharmaBelgium

Prof.Dr.LauraSuter-Dick Groupleader,Cellbiologyand invitro toxicology

+41612285659

laura.suterdick@fhnw.ch

Burgioassessesiftheinducedpluripotentstemcellsaredenseenough tostartdifferentiationintobrainmicrovascularendothelialcells.

Safetyfirst!

AndreasZoggbringschemicalengineeringcompaniesand studentstogethertomakesharedadvancesinprocesssafety

Managingethoxylation–Didyouknow?

Ethoxylationisachemicalreactionofethylene oxidewithanalcohol,acidortriglycerideoil.The reactionisperformedtoproducesurfactants, whichareusedinlaundrydetergents,surface cleaners,cosmetics,agriculturalproducts,textiles andpaint.

Performingethoxylationasacontinuousreaction ismoresustainableandcost-effectivethan runningitasabatchreaction,buttheexplosive natureofethyleneoxiderequiresmasteryof reactionsafety.

Properlymanagingandscalinguphazardous continuousreactionsincludes: reactioncalorimetry:measuringheatreleased fromthereaction,determiningheatandgas removalrequirementstocontrolthereaction. thermaldecomposition:knowingthe temperatureatwhichasubstancechemically decomposes. explosionpressure:measuringthereaction’s pressuretodetermineitsriskofexplosion. pressurerelief:providingamechanisminthe reactortoreleaseexcesspressure.

Prof.Dr.AndreasZogghasapassionforprocess safety.HejoinedtheFHNWSchoolofLife Sciencesin2018afterservingasSafetyexpertat Novartis,andProcessdevelopmentchemistat F.Hoffmann LaRocheandCibaSCforseveral years.Nowheleadstheprocessdevelopment groupattheFHNW’sProcessTechnologyCenter. Heisfounderandpresidentoftheassociation Miniplant4.0.

“Threedriversofinnovationintoday’sSwiss chemicalindustryaresafety,sustainabilityand quality”saysZogg.“Ifyouaskme,safetyalways comesfirst!”

Manychemicalreactionsperformedto produceingredientsfordetergentsandcosmetics poseadangeroffireandexplosion.Transitioning frombatchorsemi-batchreactionstocontinuous flowchemistrycanprovidesafetyadvantages.

Second,ascompanieslooktoreducetheir energyconsumption,theyseetheopportunityto conductsomereactionsincontinuousmodeto avoidcostlyenergypeaks.Thisiscreatinga demandforcontinuousreactorsystemsdeployed atsmaller,decentralisedproductionsites.

Finally,asthepriceofchemicalsmanufacturedinSwitzerlandishigh,theirqualitymustbea differentiatingfactor.Scalingupflowchemistry helpspromotethefinechemicalssectornationally.

Zoggisaddressingallthreeelementsinan InnosuisseprojectcalledSimulation-basedsafety conceptforthescale-upofsafety-related demandingcontinuousprocesses,performedin collaborationwithMScstudentsfromtheFHNW SchoolofLifeSciencesandindustrypartners.

Zogg’steamiscontributingamodeltoscaleup acontinuousethoxylationreactionanddetermine whenanexplosionislikelytooccur.Theinitial modelisbuiltondatainscientificliteratureabout thermodynamicsandreactionkinetics,combined withsmall-scaledifferentialscanningcalorimetry (DSC)measurementscollectedintheFHNW’s ProcessTechnologyCenterexplosionreactor.

Todeterminewhentheethoxylationreactionis likelytocauseanexplosion,Zogg’steammodelled twoscenariosandperformedthemwithina uniqueexplosionreactor,usingtheresultingvapor liquidequilibriumdatatorefinetheirmodel. Althoughtheyhadmodelledamaximumexplosion pressureof12bar,thereactionwasperformedup to20barbeforeexploding.

Furthermore,Zogg’steamconceptualisedthe basicdesignofthecontinuousethoxylationplant, includingacomprehensiveriskanalysis(HAZOP).

Finally,theyperformedtheflowreactionina safetygloveboxthattheydesignedspecifically forthispurpose.Theboxprovidesanitrogen

“Theprocesssafetymodels developedbyFHNWareenabling safer,moreenergyefficient reactionsthatproducehighquality surfactants.Welookforwardto applyingthemodelstoscaleup productioninourfacilities”

RolandBorner,Schärer&SchläpferAG

MasterstudentsThisZahndandBenediktBrönnimanngaindirectexperienceinmodelling andmanaginghazardousprocessesincollaborationwithindustrypartners.

atmosphere,monitorsoxygenandethyleneoxide levelsandfeaturesanintegratedsafetywasherto destroyethyleneoxidesteamleakage.

Fluitec,adesignerandmanufacturerof reactionsystems,iscontributingasmall-scale continuousreactioncalorimetertotheproject. Thisspecialiseddevice,whichsitsinsidethe safetyglovebox,measurestheheatreleased fromthereaction.Thereal-timedatacollected usingFluitec’sdeviceisusedtoadjusttheFHNW’s processmodel.

“Deployingourflowcalorimeterinanexperimentalsettingandcontributingtonewmodelsfor flowchemistryscale-upprovidesvaluableinsights abouthowthecalorimeterperformsatsmalland productionscale"sayssaysMarliesMoser,Fluitec.

TheFHNW’smodel,strengthenedbydata collectedbyFluitec’scalorimeter,willbeapplied bytheproject’simplementationpartner,Schärer &SchläpferAG,aproducerofsurfactantsfor

thepharmaandchemicalindustry.Thegoalisto enabledirectscale-upfromlabtoproduction volumes.

“Theprocesssafetymodelsdevelopedbythe FHNWareenablingsafer,moreenergyefficient reactionsthatproducehighqualitysurfactants. Welookforwardtoapplyingthemodelstoscale upproductioninourfacilities”saysRolandBorner, Schärer&SchläpferAG.

Inadditiontoindustrialinnovation,theproject provideshands-oneducationalopportunities.Two part-timeMScstudents,ThisZahndandBenedikt Brönnimann,areworkingontheInnosuisseproject whilecompletingtheirMaster'sinChemical Engineering.BScstudentsinchemicalengineeringalsocarryoutaportionofthework.The FHNW’sMiniplantfacility,includingitsunique explosionreactorfortestingthethermalprocess safetyofexplosivereactions,providesstudents withdirectexperienceinhazardousprocess

modellingandmanagement.

“EspeciallyforstudentsattheMaster'slevel,it enablesthemtodeepentheirknowledgein real-lifesettingsbeforetheygraduateandfully transitiontoindustry”saysZogg.“Atthesame time,itallowsustoadvanceknowledgeonhowto safelyscale-upflowchemistryprocessesto promotetheiradoptionbyindustry.”

Partners: Fluitec;Schärer&SchläpferAG

Financing/Support: Innosuisseproject62273.1IP-ENG

Prof.Dr.AndreasZogg

Groupleader,Processengineering andreactiontechnology +41612285825 andreas.zogg@fhnw.ch

Progressfor patients

Healthcareisprogressingfromthe clinictothehome,andfromgeneralised treatmentstopersonalisedmedicine.

Adeeperunderstandingofthehuman body,diseaseandhealth,coupled withtechnologicalbreakthroughsand intelligentuseofdata,areproviding newoptionsforpatientsandmedical professionals.

Navigatingthebrain

Intelligentelectromagneticnavigationsystemforprecise implantationofdeepbrainstimulationelectrodes

Deepbrainstimulation-Didyouknow? Inthelate1980s,aFrenchbreakthroughin neurosurgery,deepbrainstimulation(DBS), openednewavenuesforthetreatmentofmovementdisorders.DBSinvolvestheimplantation ofelectrodesandtinyneurostimulatorsin thebrain.Thesedevicessendsignalstospecific targetsinthemotorregions,tohelpalleviate motorsymptoms.

DBSwasapprovedbytheFDAin1997forthe treatmentofParkison’sDiseaseandessential tremor.Itisnowalsousedtotreatdystonia,some obsessive-compulsivedisorders,epilepsy andchronicpain.Itmaybecombinedwithtaking medicines,orofferanalternativetothem.

Thesuccessofdeepbrainstimulation(DBS) dependsonprecision,bothinpositioningthe electrodesandstimulatingspecificbrainregions. Currently,pre-operativeimagingandstereotactic techniquesarethegoldstandardfortheinsertion ofDBSelectrodesintothebrain,buttheydonot offertrackingduringsurgery.

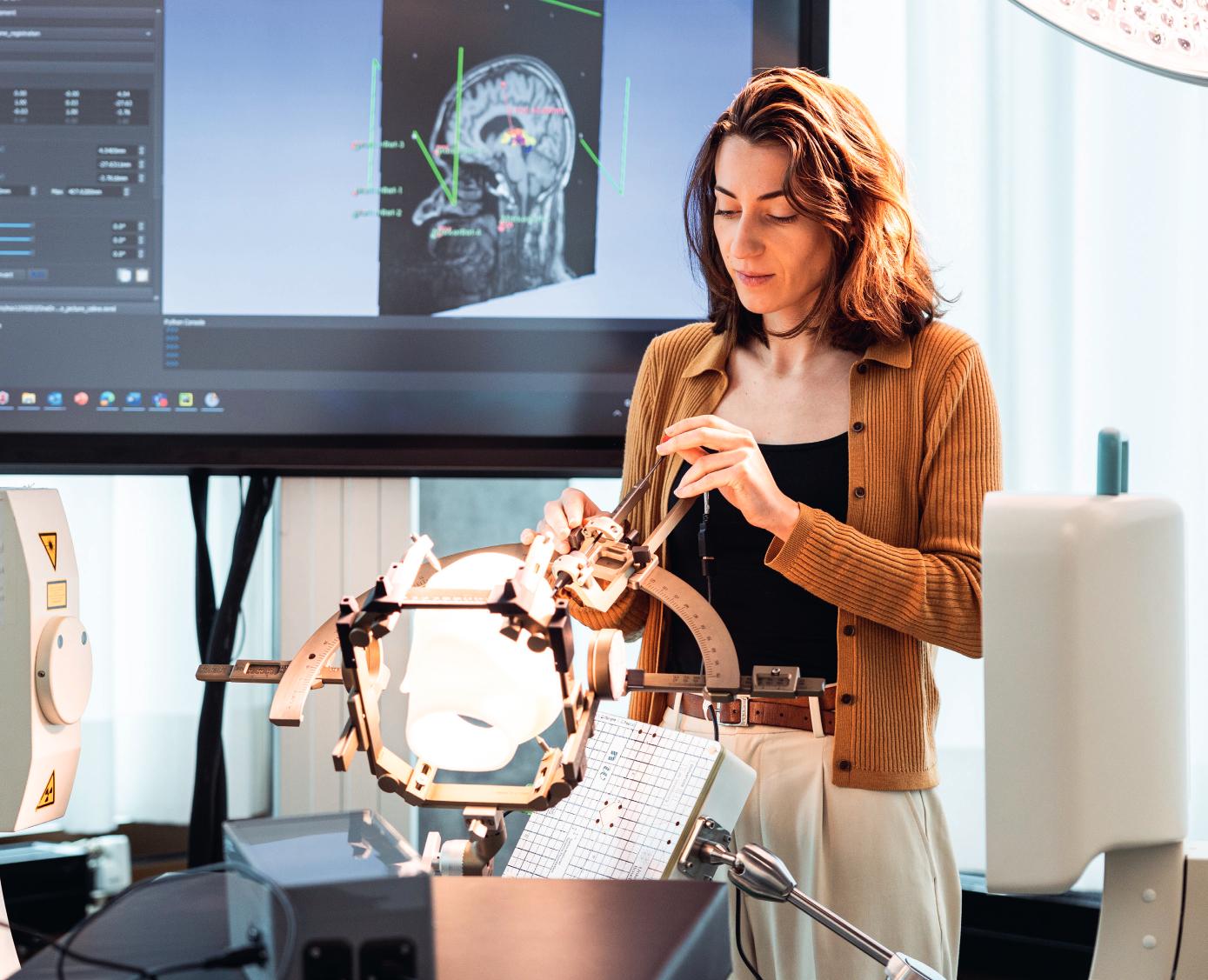

CélineVergne,whoiscompletingaPhDatthe InstituteforMedicalEngineeringandMedical InformaticswithajointenrolmentattheUniversitiesofBaselandStrasbourg,hasdevelopedan electromagneticnavigationsystemaimingatthe precisetrackingofelectrodesduringtheirimplantation.“Thechipintegratedintothestimulation device,coupledwithourvisualisationsystem,will allowsurgeonstoseetheangleandpositionofthe DBSelectrode”saysVergne.

Shefirstintegratedatinymagnetometerinto theelectrode.Lessthan1mmacross,themagnetic sensorcanbedetectedbygeneratinglowmagnetic fieldsandusingatrackingalgorithmtodetermine itsposition.Prof.Dr.JorisPascal’steamcontributedtothesensor’sdevelopment,whileProf.Dr. SimoneHemm’steamwasresponsibleforthesystemset-upandtestinginthesurgicalenvironment. IncollaborationwiththeUniversityofStrasbourg, Vergneisinvestigatingmachinelearningalgorithms tooptimisethesensor’strackingperformance.

Vergnethensetouttoensurethecompatibility ofherprototypewiththesurgicalenvironment.In theoperatinglabattheFHNWSchoolofLife SciencesinMuttenz,sherecreatedaDBSsurgical set-upusingaheadphantominsideastereotactic headset.Fortheelectromagneticnavigation system,calledManaDBS,sheaddedasystem controlunit,amagneticfieldgeneratoranda sensorinterfaceunitconnectedtotheDBSlead.

Electromagneticperturbationsfromthe magneticfieldcanthrowofftracking.Toaddress this,Vergneappliedanewtrackingprincipleto limitelectromagneticdisturbancesandensure correcttrackingoftheelectrode.

Implantationtrialsonaneggplantsimulating braintissuewereperformedinarecreatedDBS surgicalsetup.Thisgaveaninitialideaofthe sensor’sperformance.Thefinalstepbefore transfertotheclinicalenvironmentisuser-friendly softwaretovisualisetrackingintheoperatingroom.

ThesystemwillthenbetestedattheUniversity HospitalBaselduringasurgicaldressrehearsal. Thisenvironmentcansimulatethecompatibilityof thetechnologywiththeuniqueDBSoperatingtheatre,helpingtranslatetheprototypetotheclinic.

Ifsuccessful,ateamofneurosurgeonsatthe UniversityofBaselwilltestthetechnologyin patients.Ultimately,thesystemmaygothrough

medicaldeviceapprovals,ledbyaproducerof neurosurgicalornavigationinstruments.

“It’sveryexcitingtohavethreefieldscoming togetherinthisproject:electronics,computer scienceandneuroscience”saysVergne.“This multidisciplinaryapproachandcollaborationwith partnersaredrivinginnovationforward.”

“Thiselectromagneticnavigationsystemisa promisingtoolforthelocalisationoftheDBS electrodes.Wearehopefulthatitwillbeintegratedintothesurgicalprocedureandbringadvantagesforbothpatientsandmedicalteams”says Dr.EthanTaub,NeurosurgeonattheUniversity HospitalBaselandexternalexpertoftheproject.

CélineVergnetestsherelectromagneticnavigationsystemforlocalisationofelectrodesin thebrain,usingaheadphantominsideastereotacticheadset.

Patients/TargetGroups: Parkinson’sdisease,essential tremor,dystonia,epilepsy,chronicpain

PartnersandPhDCo-Directors:

UniversityofBasel:Prof.Dr.med.RaphaelGuzman, Chairman,DepartmentofNeurosurgery

UniversitédeStrasbourg:Prof.Dr.MorganMadec, Simulationandelectronicssystems

Financing/Support: SNSFprojectgrant204448

CélineVergne PhDstudent

Neuroengineeringandsensor systemsfordiagnosisandtherapy +41612285945

celine.vergne@fhnw.ch

Prof.Dr.JorisPascal Groupleader,Sensorsystemsfor diagnosisandtherapy +41612285647

joris.pascal@fhnw.ch

Prof.Dr.SimoneHemm-Ode Groupleader,Neuroengineering +41612285689

simone.hemm@fhnw.ch

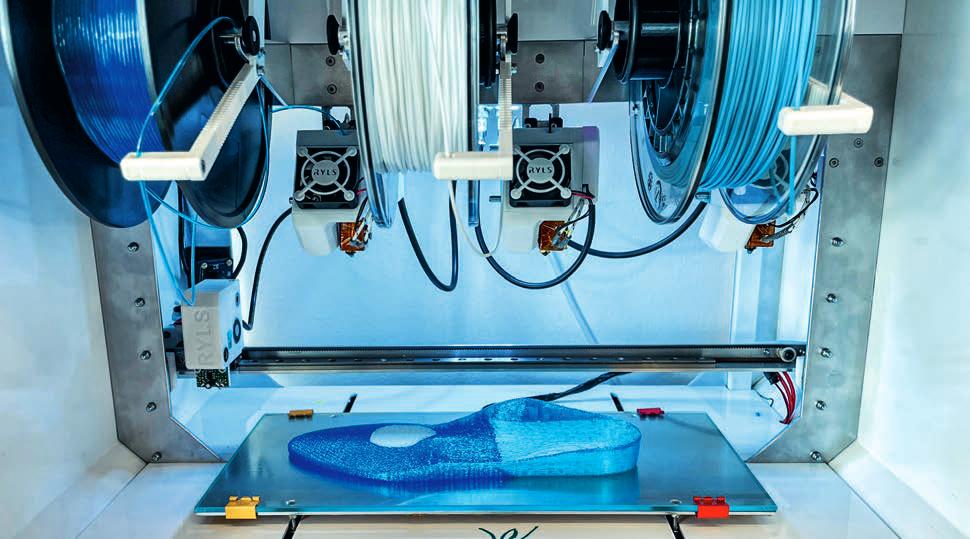

Steppingup3Dprintingof orthopedicinsoles

DanielSeiler’slabisrevolutionizinghowpersonalised orthopedicinsolesaremade

Orthopaedicinsoleshelpredistributepressure andrelievesensitiveareasofthefeet,makingit morecomfortableforpeoplewithfootmisalignmentstowalkandperformdailyactivities.

Orthopaedicinsolesarealsoacrucialtoolfor patientswhosefootnerveshavelostsensitivity, whichcanunknowinglyleadtopressuresoresor evenamputation.Innon-medicalapplications, insolescanhelpincreasecomfortandstabilityfor adults,offersupporttopeoplewhospendalotof timeworkingontheirfeet,andboostperformance inrunningandothersports.

Eventothisday,personalisedinsolesare primarilyproducedusingcomputernumerical control(CNC)machinesandarefine tuned manually.Thistraditionalmethodofmillinginsoles isnotonlyenergy-intensivebutalsogeneratesa substantialamountofnoise,dustandchipwaste.

Theshifttoward3Dprintingofpersonalised insolescanreducewasteby95%.However,the keychallengeistheprinter’sabilitytomanage severaltypesofmaterialswithdifferenthardness levelsandproperties.

InanInnosuisseprojectperformedincollaborationwiththecompanyOrthopodoMalgaroli, DanielSeiler’slabattheInstituteforMedical EngineeringandMedicalInformaticshasdevelopedanautomateddigitalproductionprocess

processfor3Dprintingofpersonalisedorthopaedicinsoles.

“OrthopodoMalgaroliapproacheduswitha desiretomaketheirproductionprocessmoredigital,efficientandsustainable”saysSeiler.“This involvesnotonlyashifttoward3Dprinting processes,butalsonewmethodsinscanning patients’feetandarrivingattheoptimalinsole design.Weenvisionanend-to-endsolutionfrom footscanningtoinsoleoutputthatcanrevolutionisehowpersonalisedinsolesaremade.”

YvesLetzandRomanSantschifromSeiler’s teambeganbydesigningafuseddeposition modeling(FDM)3Dprintercapableofmanaging atleastfourdifferenttypesofsoftmaterialsthat canhelprelievepressure.Theyengineerednew printheadstoaccommodatematerialswith degreesofflexibilityrangingfrom60to90shore A.Theprintercanautomaticallyswitchmaterials andprintheadsbasedontheinsoledesignsit receives.Theseinnovationsenablethe3Dprinter toproduceinsolesthatmeetdiversecomfort andsupportrequirements.

Butlet’stakeastepback:howarepersonalisedinsoledesignscreatedinthefirstplace?A 3Dscanofthefootcombinedwithdynamicfoot pressuremeasurementsareusedwithclinical datasuchasvarus/valguslegsasinputforthe

insoledesign.Basedonthreedecadesofreal dataandexperiencefromOrthopodoMalgaroli, Seiler’steamisdevelopingartificialintelligence modelsandalgorithmsthatcanautomatically designcustomisedinsolesforpatients.

“Oursharedvisionisforpatientstocomeintoa clinicorastore,scantheirfeetandhavethe computercreatea3Dinsolemodel.Theinsolewill thenbeproducedbythe3Dprinter.Withinone hour,patientscanwalkoutwearingtheirnew custom-madeinsoles”saysSeiler.

Thinkingahead,thepartnershaveconceptualisedauser-friendlyinterfaceforthefootmeasurementandprintingplatformforpoint-of-care andpoint-of-salesettings.Astackabledesignwill accommodatemultipleprintersvertically,for clinicsthatproducemanyinsoleseachday.Finally, Seiler’steamisrefiningasecurecloudsolutionfor patientorcustomerdatastorageandprocessing.

“The3DprinterdevelopedbytheFHNWnow givesustheopportunitytoproduceorthopedic insolesquicklyandsustainably”saysMario Malgaroli,ownerofOrthopodoMalgaroli.“Inthe future,itcouldbeusednotonlyinouroffices,but alsoindoctors’offices,bypodiatristsand physiotherapists,andinshoeandsportsstores.” Seilerbelievesitcouldalsobeusedtotriage normalsupportrequirementsfrommedical

ResearchassociatesYvesLetzandRomanSantschidesignedafuseddepositionmodelling3Dprinter capableofmanaginguptofourdifferentsoftmaterialsrequiredforinsoleprinting.

3Dprintingofpersonalizedinsoles canreducewastebyupto95%.

conditionsthatrequiretheexpertadviceof podiatrists,actingasadiagnosticdevice.

Thetransitiontoautomateddesignand3D printingofinsolesisaparadigmshiftfororthopedicfirms.“TheFHNWhashelpedOthopododerisk thetransitiontoManufacturing4.0bymaking advancedknowledgeaccessibleandworkablein practical,real-worldsituations”saysSeiler.

Inthenextstepoftheproject,atrialis plannedtovalidatetheeffectivenessandaccuracyoftheautomatedinsolemanufacturingprocess. Thiswillinvolvetestingthe3D-printedorthopaedicinsolesinreal-worldconditionstoensurethey meetpatientorcustomercomfortrequirements.

Seiler’sgroupisalsostartinganewproject financedbytheForschungsfondsAargautorefine thesoftmaterialfilamentsusedtoproducethe insolesandgivethemantimicrobialproperties.This workisbeingconductedincollaborationwiththe InstituteforChemistryandBioanalyticsand

theInstituteofPolymerEngineering.

Lastly,theteamisaimingtoreducethe amountofglueneededbetweenlayersofdifferentmaterialsbyintegratingtheglueintothe printingprocess.Theyarealsodesigningnew softmaterialsthatwillberecyclable,twofurther stepstowardincreasedsustainabilityof customisedinsoles.

Patients/TargetGroups: Footmisalignmentpatients, Adultswithreducedbalance,Standingoccupations,Sports Partners: OrthopodoMalgaroli

Financing/Support: InnosuisseProject107.955IP-LS

ForschungsfondsAargauProject20220930_17

ForschungsfondsAargauProject20240331_03

DanielSeiler Laboratoryleader, Medicaladditivemanufacturing +41612285848

daniel.seiler@fhnw.ch

Improvingwoundhealing afterC-sections

RetoWildhaber’steamhasdevelopedavisualisationtechnology tobetterilluminatecorrectivesurgeryaftercaesariansections

InSwitzerland,32%ofbabiesaredeliveredby caesareansection.Whilehospitalsareworkingto reducethenumberofproceduresthatarenot medicallynecessary,Switzerland’srateremains oneofthehighestinEurope.

Caesareansectionsposeseveralriskstothe mother,oneofwhichispoorhealingoftheuterine scar.Unknowntissuefactorscanleadtohampered woundhealingandgapsintheanterioruterinewall. Thesegaps,alsocalledniches,weakentheuterus inasubsequentpregnancy.Itcantake1-2years forwomentoobservepainandothercomplications fromimproperwoundhealing,whichmightrequire follow-upcorrectivesurgery.Chronicpainand multiplesurgicalinterventionscanpreventwomen fromperformingchildcaredutiesandreturningto theworkforce,andcanconsiderablyreducetheir qualityoflife.Ifthenichebreaksduringasubsequentpregnancy,therearesignificantrisksfor bothmotherandbaby.

SurgeonsattheUniversityHospitalZürich approachedProf.Dr.RetoWildhaberwiththeidea ofintegratingalightsourceintoauterinemanipulator,atoolusedduringgynaecologicalsurgery. Currentlaparoscopictoolsandcamerasystemsfor imagingtheuterusduringcorrectivesurgeryemit lightonlyoutsidetheuterus,andprovideanunclear viewofdifferentlayersoftissueinsidetheuterus.

Wildhaber,whospecialisesinsignalanalysis anddigitalbiomarkers,cameupwiththeideato useapulsinglightthatisinsertedintotheuterus throughthevaginaandcervix.Hesupportedthe developmentofthefirstprototypewhileworking attheBernerFachhochschule(BFH).In2021he joinedtheInstituteforMedicalEngineeringand MedicalInformaticsandcontinuedtoworkonthe projectincollaborationwithBFH,withwhomajoint patenthasnowbeenfiled.

First,Wildhaber’steamtackledthephysical challengesofrefiningtheprototype.Theyselected thematerialandprocesstoproducetheinstrument tipwherethepulsingredLEDlightsourceis housed:3Dprintedbiocompatiblepolymethyl methacrylate.Thetipsweresubjectedtomechanicalforcetestingtoensuretheycanbendduring surgerywithoutsnapping.

Tofacilitatesterilisation,theinstrumentcanbe disassembledintocomponentsandlaidflatinan autoclave.Theconicaldesignofonecomponent actsasa‘plug’forthecervix,stabilizingtheinstrumentandpreventinggasinjectedintotheabdomenduringsurgeryfromescapingtheuterus.

Tokeepthetipoftheinstrumentcooland preventdamagetouterinecelltissue,fibreoptic cablesareusedtotransmitlightfromthepulsing redLEDsintotheuterus.

Theteamthenputmathematicsintoaction, developingadigitalenhancementequationthat exploitsthedifferencebetweenthepulsinginterior lightemittedbytheprototype,andtheexterior lightemittedbylaparoscopictools,tocreatean imageoverlayonthesurgicalmonitoringscreen.

The2Daugmentedrealitywillhelpguide surgeonsbydisplayingtheboundaryofdifferent tissuesintheuterusandthelocationofthe surgicaltool.Itwillenablethemtoseetheniche andpreciselyremovescartissue.

Overall,theinstrumentprovidesanintrauterine lightsourcethatallowsdirectlocalisationofthe nichewhilestabilizingtheuterus,andiscompatiblewiththeDaVincirobotthatassiststhecorrectivesurgery.Thesmallcomputerrequiredto performthedigitalenhancementequationsand thescreenthatdisplaysthe2Dvisualisationcanbe easilyintegratedintoexistinglaparoscopicset-ups.

Thevisualisationtechnologyunderwenta proof-of-conceptpilotstudyinWildhaber’slabin thesummerof2024,whichwillbefollowedby clinicalstudiesattheDepartmentofGynecology attheUniversityHospitalZürichafterapprovalby Swissmedicandthelocalethicsauthorities.

“Webelievethatwomenwithlowerabdominal symptomsandwomenwithanichethatwishto conceiveasecondchildwillprofitfromthenew

ApulsingredLEDlightinthetipoftheinstrumentisusedin digitalenhancementequationstogeneratea2Daugmented realityduringsurgery.

device”saysProf.Dr.med.CorneliaBetschart Meier.“Wearelookingforwardtoapplyingthe so-calledscarlightdeviceinafirstclinicaltrial.It willenhancethesurgicaltechniqueandweexpect itwillyieldagoodoutcomeformothersand children.”

“Thisdevicehasthepotentialtosimplifya medicallynecessaryprocedure,andmakeitsafer andmorereliable,thankstotoday’stechnology” saysWildhaber.

Ifclinicaltestsaresuccessful,aspin-off companyatUSZcouldbeformed,orthetechnologycouldbelicencedtoasurgicalorimaging instrumentsfirminordertobringittothemarket.

Patients/TargetGroups: Gynaecologicalhealth Partners: UniversityHospitalZürich, FachhochschuleBern

Financing/Support: Innosuisse(101.964IP-LS)

Prof.Dr.med.RetoWildhaber

Groupleader,Signalanalysisand digitalbiomarkers +41612286125 reto.wildhaber@fhnw.ch

Intelligentdrugformulation

TwoteamsattheInstituteforPharmaTechnology andBiotechnologyareadvancingresearchonintelligent formulationoforaldrugs

Predictingsolubilityandformulation compositiontoreduceanimaltesting About80%ofexistingandneworaldrugsarepoorlysolubleinthegastrointestinaltract.Assessing theperformanceoforalformulationshaslargely reliedonanimaltesting,whichisincreasingdespite theEU’scommitmenttoreducinganimalsinresearch.

Tooffernewsolutionsandreduceanimaltesting,researchersattheInstituteforPharma TechnologyandBiotechnologyareparticipatingin theEUprojectInPharma.Theprojectaimsto developanend-to-endmodellingapproachtothe formulationofdrugsfororaladministration.

Prof.Dr.MartinKuentz,TeamLeaderinOral FormulationofChemicalDrugs,isleadingthe project’sworkpackage1,Computationaltoolsto developoptimaloraldrugformulations.Thegoal oftheworkpackageistofindsuitableexcipients andformulations,forexampleusingquantum chemicalmethodsandmolecularsimulation.

“Artificialintelligenceandmechanistic modellingareincreasinglyshapingthedevelopmentofdrugproducts”saysKuentz.

InPharmaactivelycontributestotraining13 early-stageresearchers,whoarecompletingtheir EuropeanIndustrialDoctoratesaspartofthe project.Kuentzissupervisingtheworkperformed bytwooftheseearly-stageresearchers.

OneofthemisShaidaPanbachi,whois collaboratingwiththefirmZentivaontestingthe industrialfeasibilityofnoveldeepeutecticsolvent formulations.Forthefirstpartoftheproject, Panbachiusedcomputationaltoolssuchas moleculardynamicssimulationstopredict physicalandchemicalpropertiesofdeepeutectic mixtures,whichshecompletedattheFHNW SchoolofLifeSciencesinMuttenz.

ThenPanbachitravelledtoPraguetoworkon capsulecompatibilityandprototypedevelopment withZentiva,aleadingmanufacturerofgeneric medicines.UnderthesupervisionofDr.Josef Beranek,Panbachiisstudyingthe invitro release propertiesofinnovativedeepeutecticformulations,whichbridgesovertoWorkpackage2led bytheUniversityofAthens.

ShaidaPanbachihasalreadypublishedafirst scientificpaper,whichcontributestotheoverarchingprojectobjective,topromoteformulation innovationusingcomputationaltoolsand invitro teststoreducepreclinicalanimalstudies.

MartinKuentzandhisteamanalysenew liquidformulationschemically.

Financing/Support: EUHorizon2020InPharma955756 PartnersandBeneficiaries: 18organisations,including Zentiva

Prof.Dr.MartinKuentz

Groupleader,Oralformulationof chemicaldrugs +41612285642

martin.kuentz@fhnw.ch

Aquarterofpeoplewhoare65andoldertakefiveormoremedicinesperday.Inthefuture,personalisedformulationsmade usingmicropelletswillhelpeasethepillburdenandmaketreatmentmoreeffective.

Precisionpharmaceuticals

Livinglongerisabenefitofmodernsociety,yetour lifestyleandageincreaseourdiseaseburden.A quarterofpeoplewhoare65andoldertakefiveor moremedicineseveryday,cocktailsthatsometimes haveunexpectedadverseeffectsorlittleefficacy.

Understandinghowwemetabolisedrugs individually drug geneinteraction,andhowthe drugsinteractwitheachother(drug-drug interaction,becomesincreasinglycomplexthe moremedicineswetake.

Across-disciplinaryteamfromthreeinstitutes iscollaboratingtodevelopprecisionpharmaceuticalsthatpredicttherightdosesoftherightdrugs attherighttimes.

Real-worlddrugcombinationsfromproton-pumpinhibitors,bloodthinners,anti-hypertensives,statins,painkillersandmorearetested inorgan-on-chiphuman invitro modelstostudy theirinteractionswhenabsorbedandmetabolised.

Thosemodelscomprisepatient-derivedcells withdifferentmetaboliserprofilestoreflectthe heterogeneityofourpopulation.

Feedingthisdatainto insilico modelsallows predictionofdosageadjustmentstoachievethe besttreatmentswiththefewestsideeffects.

Inthenextphaseoftheproject,theteamwill joinforceswithdrugmanufacturerstoworkon thenextgenerationofmedicinesthatcanbe individuallydosed.Insteadoffixed-dosetablets, drugswillbeformulatedinso-calledmicropellets, whichareeasytoswallowandperfectfor personaliseddosages.

“Imagine!Inthefuture,patientscangototheir pharmacy,andbasedontheirpharmaco-genetic profileandprescriptions,receiveprecision pharmaceuticalsthathavebeencustom-madefor them”envisionsProf.Dr.JohannesMosbacher, whoisleadingtheproject.Asitoncewasinthe past,pharmacistswouldbethosewhoprepare

themedicinesforpatients,thistimewithhelpof 3Dprintersormicropelletsortingmachines.

Patients/TargetGroups: Olderadults,peopletaking multiplemedicines

Partners: DOPPLSA,GlattGmbH

Financing/Support: StiftungFHNW,Innosuisse44386.1

Prof.Dr.JohannesMosbacher Lecturer,InstituteforPharma TechnologyandBiotechnology +41612286149 johannes.mosbacher@fhnw.ch

Technologyin focus

Artificialintelligence,datascience andquantumcomputingaredeveloping atanexponentialpace.Thisrapid evolutionisgeneratingopportunitiesto harness,aswellasresponsibilitiesto shoulder.Attheforefrontofthesechanges, theFHNWSchoolofLifeSciences providesscientificvisionandethical leadershiptodevelopthedigital technologiesofthefutureandapplythem toresearchquestionsinlifesciences.

Qubitsandbits withClémentJaverzac

In2022,theFHNWSchoolofLifeSciencesmadetheboldmove toestablisharesearchgroupfocusedonappliedquantumcomputing, becomingthefirstUniversityofAppliedSciencesinSwitzerlandto enterthequantumspace.LedbyClémentJaverzac,thegroupisona missiontoapplyquantumcomputingtolifesciences.

Itstartswitheducation

Prof.Dr.Javerzac,tellmewhat’shappening attheFHNWSchoolofLifeSciencesinquantum computing?

We’restartingwitheducation:makingstudents andfacultyquantumaware.Weheldafirstcourse intheMaster'sinMedicalInformaticsin2023, whichgavestudentsthecouragetotacklewhat canseemlikeacomplextechnology.In2024,a quantumcomputingmodulewasincludedinboth BScandMScprogrammes,andweheldasummer schoolattheFHNWonthistopic.

Youdon’tneedtobeamathematicianora physicisttotryquantumcomputing.Thereare user-friendlytoolsandpackagesliketheIBM QuantumComposerthatcanhelpyougetstarted. Whatyoudoneedisanunderstandingofwhich typesofproblemsquantumcomputingis goodatsolving.

Bringyourproblems

Howdoyouidentifytherightresearchquestions toapplyquantumto?

Workingalongsidelifescienceresearchersprovidesanexcellentopportunityforinterdisciplinary exchange.Iaskpeopletobringmetheirproblems! ButIdon’tguaranteethatquantumcansolve themall.

Oneapplicationweareworkingonissimulatingnuclearmagneticresonance(NMR)spectra thataretoocomplexforclassicalsupercomputers. Quantumalgorithmscanbeusedtodecodethe compositionofmatterfornewmaterials,for exampletoidentifythebeststructurefora materialthatcancaptureCO2

Quantumsensingismorematureandpromisingformedicalapplications,forexample,diagnosingfunctionallyrelevantcoronaryarterydisease fCAD).Theheart’stinymagneticfieldcanbe measuredwithquantumsensors.Togetherwith JorisPascalfromtheInstituteforMedicalEngineeringandMedicalInformatics,wearedevelopingamagneto cardiograph(MCG)asapoint of caredevicepoweredbyquantumsensors,in collaborationwithCSEMandtheUniversity HospitalBasel.

Thequantum-AIhandshake

Whattypesofproblemsshouldquantum computingstayoutof?

IncontrasttoAI,quantumcomputingisnot goodatsolvingproblemsthatinvolvebigdata, becauseitisslowtoloadit.Quantumisidealfor solvingcombinatorialproblemswherethereare fewvariablesintheinput,andmanypossibilitiesin theoutput.Thinksupplychainandlogistics,

schedulingshiftworkorDNAsequencing. Withhybridalgorithms,youcangetthebestof bothworlds:youcanaskAItosolveapartof theproblem

veryfast

,andquantumtheother

veryhard

Quantumcommunities

WhichquantumcomputersistheFHNWSchoolof LifeSciencescurrentlyaccessing?

Webookcomputationtimeonthebestinfrastructuresintheworld,includingIBM’squantum computersintheUnitedStates.Thisprivileged accessismadepossiblethroughourpartnership withQuantumBasel.

We’realsoexcitedaboutbuildingEuropean capacityinquantumcomputing.IonQisestablishingaEuropeanquantumdatacentreincollaborationwithQuantumBasel,consistingoftwo systemswith35and64algorithmicqubits respectively.ThiswillpositiontheBaselregionas oneofthemostpowerfulquantumcomputing centresintheworld.

Javerzac‘steamdevelopsquantumsensorsfor newmedicaldevices.

Quantumforeveryone?

Classicalcomputersusedtotakeupentire roomsandbeusedbyspecialists.Nowtheyfit inourpocket.Doyouseeasimilartrajectory forquantumcomputers?

Idon’tthinkquantumcomputerswillreplace currentcomputers,becausedifferenttypesof processingunitshavedifferentfunctions.

Centralprocessingunits(CPUs makeupthe coreoftoday’slaptopsandmobiledevices.

Graphicprocessingunits(GPUs firstappeared forgraphicdesignandvideogameapplications, andarenowusedtotraindeeplearningmodels.

Tensorprocessingunits(TPUs anddata processingunits(DPUs arethenextgeneration ofprocessorsdesignedspecificallyforbigdata applicationsandcentres.

Quantumprocessingunits(QPUs arebestfor solvinghard,combinatorialproblemswithout replacingclassicalcomputing.

Beforequantumcomputerscanmakeittoprime time,weneedtoincreasetheirsize:notonlythe numberandqualityofqubits,butthenumberof operationstheycando,whichiscalledcircuit depth.TheNationalCenterofCompetencein Research:SpinQubitsinSilicon(NCCR-SPIN)is workingonalternativewaferscalequantumcircuitsthatcanbefabricatedbythesemiconductor

Atomicvaporcellscanbeusedtomeasuretinymagnetic fieldssuchastheoneemittedbythehumanheart.