Introducing Carbophalt ® G from Simpson Strong-Tie — a reinforcement grid made of durable, high-tensile-strength carbon fiber that strengthens asphalt roads and highways. Unlike other asphalt reinforcement products, its open-grid design is fully saturated with bitumen, helping it form a powerful, long-lasting bond between asphalt layers. Our innovative grid distributes loads more evenly, increases load-bearing capacity and makes roads more resistant to cracks, potholes and rutting. Ideal for new construction or resurfacing, this grid is tested and proven to extend the service life of paved surfaces, delivering greater economic value over time. And, it’s easily milled and recycled, making it reusable and highly sustainable. Installation is fast and easy with our grid machine, which is available with complete training for operators. Take asphalt performance further.

To learn more about Carbophalt G asphalt reinforcement grid, contact your Simpson Strong-Tie representative. Visit go.strongtie.com/asphalt or call (800) 999-5099.

At Gencor, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. From the award winning Ultraplant® to the Green Machine, our record is unrivaled in innovative design. That’s the kind of leadership you’ve come to expect from Gencor.

The Trusted Choice!

Call 407-290-6000 or visit www.gencor.com

As experts, manufacturers, and the regulatory side of the industry push for ever-stricter emissions standards, producers benefit from electrification and digital precision. | 18

PRODUCTION NOTES

10 Hot Products

A variety of industry products on the market now.

12 Wide Open Spaces

How technology improves safety and accuracy on this family-owned business South Dakota paving project.

18 Bridge the Construction Trade & Talent Gap

The industry is experiencing an ongoing hiring drought, and the challenge of hiring has led to a loss of business for many contractors.

JOBSITE INNOVATIONS

30 Detroit I-375: Removal, Redevelopment, and the Legacy of Urban Renewaln

The complicated history of city-planning, progress, racism and road-building through the lens of one community’s effort to be reconnected.

38 Growing Our Way Off Oil

Using bio-based binders and rejuvenators to lessen our dependence on petroleum, lengthen the lifespan of our pavement, and protect our planet.

IN EVERY ISSUE

8 Editor’s Perspective

50 Last Exit

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December, with an additional Buyer’s Guide issue published in August by AC Business Media, 201 N. Main Street, Fifth Floor, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 60065-3605.

Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies

Dodge Data & Analytics recently published two economic insight reports, one listing the top 25 U.S. infrastructure projects in the planning phase and the other listing the top 25 infrastructure projects recently started.

Read more at: https://asph.link/bw9pm6

There’s good news and bad news for the road ahead, the coming year, and the decade too

Read more at: https://asph. link/xctp42

Barry Ruffalo is no longer president, chief executive officer, or a member of the board of directors. What does the shakeup mean for the stories Astec brand?

Read more at: https://asph. link/6ga7bl

Technology in the form of accounting software, project management software and AI has changed the construction processes and is constantly increasing the production for construction companies at their sites.

Read more at: https://asph.link/ aqegtf

BOMAG equipment technology is not only crucial to road building success, but also essential for operators and the future of the industry.

Read more at: https://asph. link/400ypk

Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page: Facebook.com/ Asphalt.Contractor/

As a decades-long leader in asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems.

Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

MARCH 14-18, 2023

• LAS VEGAS, NV

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Brandon Noel, Editor

Brandon Noel, Editor

bNoel@ACBusinessMedia.com

234-600-8983

This month’s issue is full of some amazing articles! There are numerous forms of technology and/or software on the market, and more coming to market every month, that can improve different facets of your business, operations, and performance. In addition to the in-depth cover story specifically covering asphalt plant technology, there’s a keen focus on emissions reduction. Experts from four major manufacturers of asphalt plant technology weigh in on what works to cut emissions and improve efficiency.

However, don’t miss our features on utilizing tech to bridge the skills and talent gaps for your workforce, as well as our article outlining software to better manage you fleets and load tracking using real-time data.

To round out the issue, there’s a piece I’m really proud of, investigating one of many new federally-funded projects that focus on the reconnection of communities once divided up by mid-century city planning and infrastructure. Such projects have a lot of potential to not only create new types of projects for contractors, but, also to see how powerful the road building work is for the people in these cities.

I took on the role as editor of Asphalt Contractor only seven months ago, and since Day One there has been talk about CONEXPO, and it has continued to loom larger than life over the past half of a year. This year’s trade show will undoubtedly be one for the history books, due to the fact that the last show was cut short by the pandemic, and everyone was sent home early. In-person events have steadily been coming back ever since, all the while CONEXPO has been in its normal cycle of off-years.

Advanced details about new and updated products from all the biggest names in the industry have been coming in. Those details will be made available in next month’s big CONEXPO preview guide, along with a map layout for the booths, products and demos you wont want to miss out on.

The 2023 CONEXPO will be the first one for several of our editorial team, and we’ve been in the trenches since late October, planning our team coverage. Whether or not you are able to be in Las Vegas this March, you’ll be able to stay on top of the latest and greatest.

Not to mention that our parent company AC Business Media (ACBM), that houses all of the print magazine brands, as well as ForConstructionPros.com and IronPros. com, will have a booth of it’s own! If you find yourself at the North Hall, come visit me and the rest of the ACBM team at booth #N12839. Myself and the other editors will be there from time-to-time when we aren’t out covering the show for you!

NAPA Annual is in Miami this year, and I’m very excited about the list of events scheduled during the three-day gathering. Beyond the fact I’m from Ohio, getting to step out of the frigid heart of my state and into the balmy sands of South Beach, this will be my first time meeting personally with members the infrastructure and road building industry.

One of the biggest areas of journalistic interest for the year ahead lies in the federal and state level projects funded by the Inflation Reduction Act (IRA) and the Infrastructure Investment and Jobs Act (IIJA), and the updates on their effects and progress.

EDITORIAL Editor Brandon Noel bnoel@acbusinessmedia.com

Contributed Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Digital Content Director, IRONPROS Wayne Grayson wgrayson@acbusinessmedia.com

Managing Editor ............................................................... Gigi Wood gwood@acbusinessmedia.com

Technology Editor .............................................. Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger ........................................ Cindy Rusch crusch@acbusinessmedia.com

Art Director ............................................................... April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer....................................................Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR @ASPHALTCONTRCTR

@ASPHALT-CONTRACTOR-MAGAZINE

There are lots of ways technology can help your company succeed, but finding the right piece of tech for your company is the key.

PaveScan 2.0 can be used to uncover problems that occur during the paving process, including poor uniformity and significant variations in density, to help avoid premature failures such as road raveling, cracking and deterioration along joints.

• Sensor design built specifically for the extremes of the asphalt paving environment

• Foldable deployment arms with high-visibility for work site safety

• Warm-up time of under one minute when ambient temperature is over 70° F

Road Widener ‘s patented FH-R material placement attachment features a remote-controlled design that allows the operator of the host machine to control the attachment via remote control, enhancing safety by eliminating the danger of additional workers standing along the jobsite. The FH-R is a solution for material placement, dispensing topsoil, gravel, asphalt, limestone and more, all with an attachment compatible with common machines. The remote-controlled attachment connects to most skid-steers, compact track loaders, road graders and wheel loaders, operating off the host machine’s engine and hydraulics. The attachment is designed for a variety of tasks including backfilling, road widening, road shoulder repairs, remediation and aggregate placement.

AgEagle, a company specializing in drone technology, offers the eBee TAC for government projects and reliable surveying applications. This product offers 90 minutes of flight time and can be operated by one person. Deployment time is approximately 3 minutes.

Each eBee TAC system features NDAA compliant drone, sensors and active components, Blue sUAS registration, secure extension, Endurance activation, two Endurance batteries, one Pitot Pro-kit, two micro SD cards with adapters, AES256-bit encryption, pixel camouflage and an IP67 hard transport case with STANAG military standard certification that is lightweight, rugged and dust and water resistant.

Increases the versatility of the Offset Vibratory Roller attachment. The accessory fits on all Offset Vibratory Roller attachments and aids in suppressing dust particles, compacting aggregates and preventing clumping when rolling hot mix asphalt. Allows contractors to compact a variety of materials including asphalt, stone, gravel and topsoil.

Doosan Infracore North America offers Concept-X, a smart control solution, for construction vehicles on busy jobsites. It can survey worksite topography via 3D drone scanning, establish operational plans based on that data and operate heavy construction equipment without human intervention. Concept-X technology paves the way for the worksite of the future with equipment-driven construction sites, freeing human personnel to tackle complex data analytics.

Durex offers numerous urethane, rubber, and wire screen media options, allowing fine-tuned production and increased tons/hr. Available in modular snap-in, pinstyle, knock-in and bolt-in systems. Livewire Screens: A self-cleaning screen, and many more.

Border States Paving (BSP) is a family-owned general contractor that operates two permanent asphalt plants, as well as a one portable plant, which produce asphalt for the paving projects that they complete throughout the Dakotas, Wyoming and eastern Montana. In addition to the traditional paving tools that they use daily, BSP crews have adopted technology, one of which is FleetWatcher telematics, to eliminate over trucking,

streamline their operations and eliminate the waste of traditional paper tickets with e-ticketing

Early in 2022, they integrated their FleetWatcher e-ticketing with OnStation to determine exact locations more precisely for each load of asphalt placed. On a paving project along U.S. Highway 12 in South Dakota, this technology integration not only increased their accuracy, but it also made their jobsites a lot safer.

BSP crews were tasked with paving Highway 12 eastward from Thunderhawk, South Dakota. Material was produced at a portable plant located near Shadehill, South Dakota,

approximately 20 miles away.

The plant was running 450 tons of Q3R an hour, from sun up to sundown. There were 20 company-owned trucks on the project, all equipped with FleetWatcher telematics hardwired into them, and an additional four third-party trucks equipped with FleetWatcher through portable devices. A total of 32,000 tons of asphalt was laid for the 13-mile project on both eastbound and westbound lanes of the two-lane highway.

In addition to keeping the trucks staged, thus eliminating idle time at the plant or paver, the telematics helped in other numerous ways. Most notably, the use of telematics deeply improved

There’s always something new at Eagle Crusher. Eagle Crusher consistently leads the industry in new product innovations and 2023 will be no exception. Join us at CONEXPO-CON/AGG, and see our newest equipment and technologies on display, including the UltraMax®1600X-OC Portable Impactor Plant and the 8x20 Screen Plant with Integrated Feed Conveyor and Blending Gates.

Learn about the many plant options for asphalt producers from our expert personnel in the booth. Outstanding plant options include onsite RAP systems for crushing and precise screening, allowing product consistency with a minimum of white rock and a minimum of fines. Also available are highly portable plant options for larger-sized jobs with high volumes of material at- or near-spec, allowing most to be removed before crushing to increase overall production and reduce wear.

communications, according to BSP technology coordinator Lukas Slotten.

“If there were issues on the road or at the plant, these guys are figuring out the problems and starting to fix them,” said Slotten.

That eliminated over trucking, allowed BSP to get more production from fewer trucks, and, also, improved the consistency of the asphalt being produced.

“The plant manager can see that they are coming up on a bridge, so he can start slowing down the plant ensuring that our hot spots aren’t as severe. We can keep the drum turning and make our materials more consistent,” Slotten said.

In addition to keeping the

gradations more consistent on the materials, this eliminates any unnecessary wear and tear on the plant.

Previously on BSP projects, a single person collected the tickets, which contain the latitude and longitude of the dump location, and then estimated how far they were from the Station.

“You’ve got your stations every 100 feet,” explains Slotten, “and the ticket taker would estimate Station plus 50 feet. It was just a guess.” Slotten figured there had to be a better way.

“We started talking back and forth between BSP, FleetWatcher and OnStation, and the South Dakota

DOT to see if we could use everyone's technology and convert it into one,” recalls Slotten.

“We'd still have our checker on the side of the road writing down station numbers just to see how accurate they actually were.”

As it turned out they were not very accurate.

“Before, we were getting estimates - now we’re accurate to within a couple feet,” says Slotten.

This new functionality automatically tracks the load from the time it is fully loaded at the asphalt plant, all the way through to its dump into the paver on the jobsite. The exact Station location becomes a part of the digital e-ticket, with no operator intervention required. Operators and transportation agency officials can know precisely on a jobsite where a specific load of asphalt was laid, so that if a future problem arises, they can investigate other parameters around that location, including core tests, density, drainage or others, to determine the scope of the problem.

When a FleetWatcher equipped truck enters a jobsite geozone, the vehicle’s

Easy to change timing belt — only 2 working hours needed

Drum shell is made of highly wear resistant Hardox® steel, ensuring many hours of trouble free running

Record number of passes, potion, temperature and compaction value in real time with Dyn@Lyzer

Eco Mode and automatic idling saves up to 15% fuel while lowering noise level

latitude/longitude is sent to OnStation. After verifying that it is part of the project, OnStation return the station, alignment, and offset where the load is deposited, which then becomes part of the e-ticket. The e-ticket then flows normally through to the DOT and BSP crew personnel. The process occurs automatically and replaces manual tracking and estimating by the BSP ticket taker, which they discovered was often erroneous.

Additionally, this stationing information for each load is maintained in Fleetwatcher indefinitely for future use. Though there haven’t been issues requiring the locating of a specific load of asphalt placed on the Highway 12 project, Slotten knows that if one arises in the future, it can be easily found.

Due to the fact BSP removed the person alongside the paver, walking up to trucks, collecting paper tickets, and then estimating locations, they are safely out of harm’s way.

“Now we’ve got a person off the road in a pickup. It’s just one less person out there to worry about when you’ve got big iron going down the road,” said Slotten. “We were testing out the technology to see how well it works and how accurate it is. We found out that it’s way more accurate than what we were doing. And we’re hoping to eliminate a person collecting the material because its already in FleetWtacher.”

It is much more efficient for the project engineer to determine yields, as a result, thanks to the seamless integration of FleetWatcher and OnStation. Now, all of the needed information is already placed on the e-ticket, accessible by smartphone. There is no more collecting manual tickets then looking through them to figure yields, so the process is simpler.

Another area where BSP is using technology to enhance their performance is with Intelligent Compaction or IC. A thermal camera on the back of the paver captures the

temperature of the load and feeds this data to the inline rollers, which are all equipped with IC, allowing them to achieve more uniform compaction. This was especially important on the Highway 12 project, which was completed on October 22, as the South Dakota temperatures were in decline for the winter season.

BSP certainly had all the traditional paving tools on hand to get the job done. But their use of technology allowed them to do the job more accurately, efficiently, safely and more consistently than ever before. It removed another person from the process by eliminating the ticket-taker function, and further enhanced the efficiency and cost effectiveness of the technology.

For more information visit http://asphalt.com/kk3fi1

And a world of experience to build that road. A s the global leader in road construction and minerals processing technology, we‘ve seen just about everything there is to see. I n every climate, every condition, every twist, turn and terrain. And we put that world of experience in your hands, so you can experience exceptional performance and results at every phase of the road construction cycle.

very

wirtgen-group.com

The conversation around asphalt plant emissions can be highly technical, and sometimes confusing. However, with the passage of new legislation like the Inflation Reduction Act, there are more direct incentives than ever to bolster your production efficiency, evaluate weaknesses in the systems you use, and either upgrade or retrofit them to reduce your carbon footprint and overall emissions.

In a memo request for comments on energy security tax credits for manufacturing posted to the IRS government website, (2) Section 48C(c)(1)(A)(ii) adds to the list of eligible projects any

that re-equips an industrial or manufacturing facility with equipment designed to reduce greenhouse gas (GHG) emissions by at least 20% through the installation of certain systems, including through the installation of energy efficiency and reduction in waste from industrial processes.

The National Asphalt Pavement Association (NAPA) has set a highly publicized goal of net zero carbon emissions by 2050, and it's an admirable, if not ambitious goal considering some of the technological innovations such a leap might require, from where the industry stands today. Also, it's not purely about innovation, it's also about adoption. NAPA concluded as much in the industry emissions inventory it released in June of 2022.

"Cradle-to-gate GHG emissions could be reduced by up to 24% relative to 2019 emissions by implementing certain environmentally preferable technologies and practices," the report continues. "Even with widespread adoption of readily available technologies and practices, the 24% reduction in GHG

emissions is not sufficient to achieve net zero GHG emissions. New technologies and additional innovative practices will need to be developed and implemented to achieve more significant GHG emission reductions."

When facing the task of reducing plant emissions, there's a somewhat innocuous question that comes up, that may seem obvious on the surface, but when you closely consider it, the answer isn't so straight forward. Are all plant emissions controllable through technological (either by mechanical or chemical) means?

"It is important to distinguish between types of emissions from a facility – process and fugitive. We must also distinguish between carbon emissions and all other emissions," said Catherine Sutton Choate, IPS Director of Product Documentation and Environmental Compliance at Astec Industries. "We can effectively control all types of emissions through application of suitable technology and implementation of

As environmental experts, manufacturers and regulators push for ever-stricter emissions standards, while producers benefit from electrification and digital precision.

recommended operational procedures."

Process emissions means those from industrial processes themselves involving chemical or physical transformations. This includes all gases discharged from the exhaust stack. Fugitive emissions are those unwanted and undesired releases of gasses, fumes, and/or other particulates not intended as part of that regular transformation process. Think blue smoke, dust, and other fines that can escape and be blown around the environment of the plant. The primary process emissions controlled are:

• nitrogen oxides (NOx)

• carbon monoxide (CO)

• carbon dioxide (CO2)

• particulate matter

In addition to these, sulfur dioxide (SOx) are primarily caused by oxidation of fuel-bound sulfur and volatile organic compounds (VOC) are caused from unburnt asphalt fumes when liquid asphalt is introduced into the drum mixers.

There can be multiple sources for these emissions throughout any asphalt plant, but generally, the largest

contributor of these emissions is from drum mixers, due to the dryer burners and the fuel they consume. This means both the type and volume of fuel consumed. Hot oil heaters, the plant's exhaust stream, and, those emissions from the heated asphalt cement binder and final asphalt mixtures due factor in. However, according to Choate, "Overall emissions from the asphalt binder associated with silo filling and truck loading are more prevalent than emissions from the hot oil heater, even if it operates year round."

If the drum mixers and their burners are the primary source of green house gasses, then what can be done about it? A large amount of heat is needed to dry aggregates allowing for the proper production of asphalt pavement.

This is the foundational concept behind understanding emissions and GHGs.

The fuel used to heat the asphalt mix, to power the burners, is the front line in the emissions battle. Some fuel sources are better and cleaner than others. What fuels are better at bringing down the threshold?

"The lowest levels of NOx are achieved using natural gas. It burns cooler than oils and has no nitrogen in it, making it inherently a lower producer of NOx," said Gencor's Dennis Hunt, Senior Vice President.

In fact, according the NAPA inventory, the asphalt production industry is already the leader of all industrial sectors when it comes to natural gas fuel consumption as a percentage of overall adoption. But their study showed there's still room for significant improvement.

NAPA said that when natural gas is not

available, plants typically burn used oil or diesel fuel instead. However, there is a growing market for using liquid natural gas (LNG). From their baseline evaluation, on average, plants were utilizing 69% natural gas in overall fuel consumption, and sees the longterm goal as shifting that needle towards 90%.

Hunt continued, "The use of low NOx burners, and low NOx burners with flue gas recirculation introduced into the highest flame temperature region reduces the flame temperature from the burner and effective burner controls are the current tools in place that are now effectively used to meet the most stringent air quality districts rules for NOx emissions."

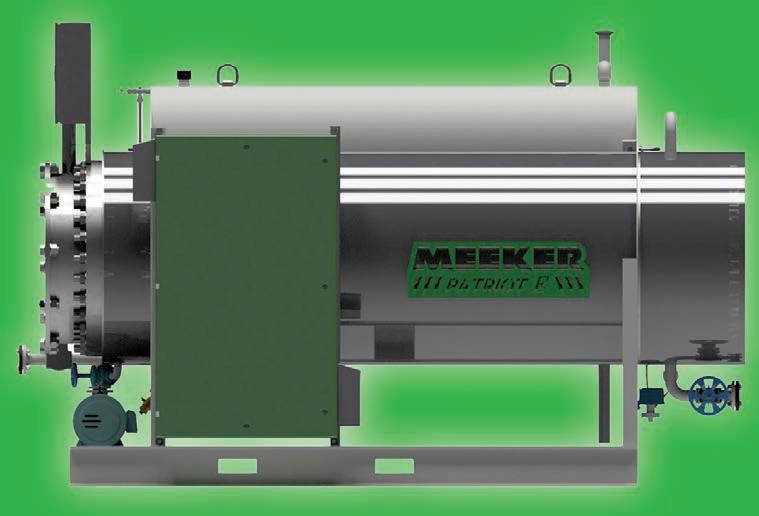

These burner controls are extremely important, in fact, just as important as the type of fuel you choose. Jeff Meeker, President of the Meeker Equipment Company said, "The industry has really tightened down on initial requirements for the asphalt plant. Which means the burners and the burner controls are very critical to the asphalt plant."

The modern burner controls are such that all of the ignition points across a plant can be digitally stored so that as the burner opens up and starts to produce more emissions, it tries to keep the optimal emissions for that specific burn, bringing it back within a desired range.

Hydrogen is poised to be a major player in more ways than one. As an alternative to EVs, hydrogen powered trucks,

“New technologies and additional innovative practices will need to be developed and implemented to achieve more significant GHG emission reductions.”

-NAPA

excavators, and other heavy construction equipment can reduce overall carbon footprint for a plant's operations. According to some experts, by 2030 the amount of permissible hydrogen content in existing natural gas lines could increase by up to 20%.

This is far from a "new" technology, it's a clean fuel, and it can reduce GHG emissions. Hydrogen is light, energydense, and produces no direct emissions of pollutants and no greenhouse emissions. "[However], when hydrogen is added to natural gas above 5% by volume the flame temperature will increase with a resultant increase in GHG emissions from the burner, Hunt warned that, "Mitigation efforts will need to be introduced to compensate, such as flue gas recirculation, water injection in the low NOx burner technology."

Producers who are able to take advantage of the increases in hydrogen will be in a more flexible position, and should stay aware of their state and local regulations regarding its use as the rules continue to evolve.

In the January 2023 issue of Asphalt Contractor, in the article "The Heat is On," it covered one of the best ways to improve energy consumption. From that article, "When choosing energy for asphalt heating, it’s important to look at the entire picture. Cost-per-unit of energy to heat asphalt and oil is certainly part of the puzzle — but it is not the only cost. Also important is the heater’s thermal efficiency. A small difference in efficiency can make a big difference in how much fuel a heater burns over its lifetime."

Jeff Meeker mentioned a forthcoming product from his company, to be shown at CONEXPO later this year, "Electrically heated, heat transfer oil is a product that we know is going to be good for the industry in terms of planning missions," he said. "Plants are permitted based upon total emissions. They add up the hot oil heater, as well as the main aggregate burner. This will substantially reduce the hot oil heater emissions as opposed to gas or oil fired burners."

ALmix, as well as Astec, offer versions

of the electrically heated systems for AC storage systems, which does increase the amperage draw for plant. "Electric heating elements are used to maintain the AC temperature in the tanks," said Ryder Harman, Sales Manager at ALmix. "Pumps and piping can be heated with heat trace cables and insulated, or hot oil systems heated by scavenger heat can also be utilized in these electric applications, depending on customer preference." ALmix also offers these types of electric heat systems on portable AC tanks as well. These electric heating systems allow for a reduction in emissions from the hot oil heater burner they replace and are often simpler to run and maintain than traditional hot oil heaters.

When talking about becoming more energy efficient, however, there are lots of capital investments available on the market today. Variable frequency drives (VFDs) for motors, pumps, and fans can substantially decrease electricity consumption, according to NAPA. Gencor, Astec, ALmix, and Meeker, as well as others, are able to equip their own versions of VFDs which aim to improve the overall fuel needs of the main burners, making the heating and drying of aggregates more efficient, thus resulting in a subsequent decrease in the electricity needed, because the volume of air managed by the baghouse fan is lowered. Even a small reduction in air volumes can yield significant results.

In a more detailed explanation how VFDs are utilized in today’s modern asphalt plants, the ALmix's Insignia Control System offers benefits at multiple junctions in the production process, that cumulatively provide even better efficiency and needed flexibility at the plant, allowing the plant to run efficiently at various production levels.

• Drum Mixer: Allows producers the ability to adjust the rotational speed of the drum mixer. Useful during the production of high percentage

RAP mixes and Warm Mix Asphalt to allow the changing of aggregate veiling characteristics.

• Drag Conveyor: Controls the speed of the inclined drag slat conveyor allowing for a reduction in conveyor wear by running at slower speeds during slower production runs. This also maintains the level of mix in the slats, the mass, and as a result, better maintains the mix temperature.

• Baghouse Exhauster: No need for a fan damper. The baghouse fan is adjusted with the click of a button. The fan runs at the exact speed needed for desired pressure drops across the baghouse.

• Burner: The burner turbo air blower can be set to track specific process temperatures and automatically adjust output as necessary based on realtime data from the plant, including mix temperature, baghouse inlet temperature and stack temperature. Similarly, Astec utilizes a system called V-Pack Stack Temperature Controller which enhances production efficiency by varying drum rotational speed to maintain desired stack temperature during production. Facilities using this system can enhance heat transfer with the drum and significantly increase RAP usage. Another process efficiency improvement is their StackPack Heat Exchanger for hot oil heaters that reduces fuel consumption by preheating combustion air to the burner.

In addition to their VFD systems, Gencor has a drum mixer flight design system, Converta Flight, which maximizes drying efficiency in which drum speed controls are not normally needed.

This is a good point to bring up the mix itself, because there are three major aspects of the asphalt mix that have been mentioned in passing thus far, but not really highlighted or explained in detail. None are revolutionary, but, perhaps one or more of them aren't

being utilized to their maximum potential at your facility. As mentioned previously, there's never been a better environment to tweak, retro-fit, or improve your process. Take advantage of the government incentives while they're available, and get ahead of the curve.

The three aspects of the mix that can most effect emissions are warm (WMA) versus hot mix asphalt, virgin aggregate moisture content, and RAP. According to NAPA, WMA technologies have been demonstrated to reduce burner fuel consumption by 1,100 Btu/°F/ton, and WMA alone can account for a reduction in asphalt mix temperatures by at least 30 degrees F. Design mix temperatures can be reduced from 300 degrees F down to 260-270 degrees F, reducing fuel consumption by as much as 20%, now setting the standard for the industry. Less fuel means significant lower stack emissions of CO2, NOx and VOC.

"The Astec Green System, which mechanically foams liquid asphalt, not only enables lower fuel consumption and reduces carbon footprint, but the resulting reduced production temperature also lowers the 'blue smoke' hydrocarbon emissions," explained Trevor Wagoner, Product Manager of Sustainability for Astec Industries.

The ALmix WarmWare Warm Mix System operates in a similar fashion, and can also yield contractors additional benefits such as a reduced odors at the plant, improved workability of the mix, and extended hauling distances for mix transport.

Switching to WMA confers many other production benefits in addition to emissions improvements, according to Hunt. "It turns out to be a great tool to ensure coatings of hard to coat mix designs like large rock," they said. "The Gencor Ultrafoam process is a tool to improve workability of high RAP mixes, that are considered to be 'hard mixes' at normal mix design temperatures or reduced temperature mixes. Plant blue smoke emissions are reduced and it highly reduces laydown emissions on the road, while improving worker comfort and safety.

Perhaps, one of the most surprising aspects of energy consumption and, thus, overall emissions control is the proper storage and care of virgin aggregates and RAP. In fact, it may drive the largest benefit to cost ratio. For example, the June 2022 study by NAPA reported that for every 1% reduction in aggregate moisture, the average energy intensity for asphalt mix production was lessened by 27,100 BTU/ton.

Drive by any asphalt plant facility and you are likely to see huge piles of RAP stored wherever they can fit. More attention should be paid to these details

"One of the best 'technologies' that is available to an asphalt producer is good stockpile management," said Wagoner. "Reducing the moisture in the aggregates feeding an asphalt plant can result in significant improvements in the heating energy required from the burner."

Common ways to aid in the reduction of aggregate moisture is to slope the grade and include a drain under the storage piles, lay pavement under them, and/ or build structures that cover or house them. When this is combined with some of the other process related controls like we've discussed can mean a reduction in necessary heat by at least 20%.

Gencor takes this one step further with the Ultradrum Advanced Rap Entry technology. "It utilizes the convective heat of the combustion zone to preheat and advance the release of internal moisture in the recycled pavement," said Hunt, "This release of moisture in the RAP offers an increase in energy efficiency, by allowing the RAP material to move through the combustion zone absorbing conductive, radiant and convective energy while controlling and preventing overheating. It permits 50% RAP capability with lower aggregate temperatures."

It might feel like a long time ago, but at the start we discussed the difference between process and fugitive emissions at asphalt plants. Obviously, the process emissions are a varied and the ways to reduce them are numerous and growing. Technology continues to evolve, and

need further innovation to achieve the goals set by the industry for net zero carbon emissions. But we can't ignore the other side of the coin, because there are plenty of improvements available for you plant today.

"Dust and fine particulate matter emissions have been controlled by baghouses for years," said Harman. "The ALmix baghouses use a reverse air rotary cleaner to clean the bags during production, which allows for gentle cleaning of the bags without the need for compressed air. We offer nearly limitless dust metering, storage, and return options to help contractors manage different volumes and types of dust at the plant. Different states have different requirements for dust handling, but the overall goal here is to keep the dust and fine particulate matter out of the air around the plant and reuse as much as possible in mix products."

In parallel with that, Gencor has the Ultraflo baghouse filtration system meets and beats some of the most strict and rigid dust collection rules and requirements for PM 2.5 and PM 10 particulate emissions.

What's Still on the Table Research shows that, even with all of this technology, there's still a lot to overcome.

According to NAPA's report, "From a raw materials perspective, asphalt binder production is the most significant contributor of upstream GHG emissions in an asphalt mixture, comprising 94% of the emissions associated with raw materials (A1) and 53% of cradle-to-gate emissions."

In addition to this, 63% of GHG emissons associated with the binder production come from the extraction of crude oil. The heart of the matter is still the reliance on fossil fuels. The asphalt industry, NAPA, and its goals are admirable. With the vast majority of America's roadways being paved in asphalt, perhaps that will mean continued sustainable asphalt innovation.

For more information visit https://asph.link/wmjikv

Colorbiotics® asphalt solutions are ready to change the asphalt industry as much as they change the molecules inside asphalt. That’s because our solutions attack the effects of aging at the molecular level and transform recycled material from the inside out.

Low bid? Best value? Win contracts either way with the first technology that truly reacts and restores asphalt. You can take RAP content beyond the 50% threshold and make pavement that’s good for the planet — but even better for your bottom line.

Give us a call to use more of your RAP than ever before.

Arecent report from the U.S. Chamber of Commerce

Commercial Construction Index indicated that 92 percent of contractors reported difficulty finding construction workers. Of those, 42 percent said that this has caused them to turn down projects and work.

According to the Associated Builders and Contractors, the tight labor force is expected to continue, due to inflation, federal spending, an aging workforce and persistent shortages. As we combat these obstacles, it becomes necessary to prioritize recruitment, retention, employee training and workplace safety. Investing in technology solutions is key to the construction industry’s success.

Construction is known to be a physical profession, which creates real issues problems as individuals age out of the workforce. According to the Bureau of Labor Statistics, the average age of a construction worker is about 42 years old, and 36 percent are between the ages of 45 and 64. Advanced technology solutions help to elongate the careers of construction workers and retain this crucial segment of aging talent.

The stress of making decisions on the fly that impact quality, schedule and cost is alleviated when technology provides certainty via real-time data. For example, before paving a section of

The industry is experiencing an ongoing hiring drought, and this persistent challenge has led to a loss of business for many contractors.

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

asphalt, digitally verifying installation progress, mix-quality and dimensional layouts would enable the identification of errors and omissions relative to the plans, grades and designs. Subcontractors can then use that data to make relevant corrections before asphalt is paved and compacted, and utilize it as a source of certainty for the future. This precision eliminates decisions based on second-guessing, that is inherent in manual quality control processes, and leads to increased productivity and schedule acceleration.

Technology that increases construction accuracy and reduces mistakes will unlock the potential for a higher degree of communication, certainty, schedule and cost. Accurate, real-time data equips teams to identify errors, gain heightened accountability and collaborate better because the insights show where attention is needed now, rather than having to tell a team member what mistakes were made after the fact. This eliminates fingerpointing when an error is identified and creates a more positive environment that boosts morale and employee retention.

The early adoption of technology, such as plan verification software that provides real-time actionable insights on a project, will improve the construction work environment and potentially attract more professionals in the near future. A new superintendent typically needs up to six years of field

management work to become fully trained in how to forecast errors. With technology-enabled data, contractors can cut that process down to as little as two years. The checks and balances provided by data-informed reports identify a variety of issues and alert field mistakes as they happen, equipping the superintendent with the knowledge of what to look for and getting them up to speed in the field quicker.

Trade schools were once seen as a “fallback” option in the 1980s and 1990s but are now more attractive for those who graduated high school mid-pandemic. According to ECMC Group, a teen’s likelihood of pursuing a four-year degree decreased 23 percentage points between May 2020 and September 2021, down to 48 percent from 71 percent. Given the tools to succeed, construction can become a more attractive job option for recent graduates.

When we equip trades with cuttingedge tools, the construction industry becomes a more attractive career path,

especially for younger individuals who have an easier time adopting new technology. While we train the future workforce to use data effectively on the jobsite, we’re teaching them how to adapt to new technologies and better prepare them for their future.

Accurate data-based technology allows management to accelerate lessons learned for employees before it’s too late, showing them solutions rather than just problems. If a worker is repeatedly improperly grading slopes or over/under compacting, real-time documentation allows the project manager to identify where retraining is needed. Documenting errors along the way equips the team to improve work processes and instruct workers on how to succeed moving forward when reporting mistakes.

Over 40 percent of American workers report experiencing increased mental distress due to the pandemic, and over 85 percent say that work impacts their mental health, according to the National Safety Council. Prolonged workplace distress causes fatigue and impacts worker safety. The risk this presents extends to construction trades. According to the U.S. Occupational Health and Safety Administration (OSHA), decreased alertness from worker fatigue has factored into industrial disasters, prime examples being the 2005 Texas City BP oil refinery explosion, the 2009 Colgan Air Crash, the explosion of the space shuttle Challenger, and the nuclear accidents at Chernobyl and Three Mile Island.

©raisondtre

©raisondtre – stock.adobe.com

The most significant contributor to construction workplace safety incidents is unplanned work, with an estimated 70 percent of safety incidents happening during rework. When workers aren’t in a planned workflow, like during the rework process, they are contending with heightened risk and stress. The uncertainty leaves them more vulnerable to making mistakes that can cause financial losses within the project or, even worse: increase the likelihood of injury. With the proper tools and actionable data insights that catch problems before they happen, general contractors avoid rework and improve the well-being of trades.

Contractors orchestrate a project according to a schedule, and when a schedule slides, it affects costs and penalties and limits their teams from moving on to the next project.

By leveraging technology and data, industry professionals will streamline the construction process by speeding up tasks, ensuring better quality, and protecting budgets.

For example, asphalt pavement density can be complicated to inspect and ensure quality control if you’re inexperienced. Any sections of pavement left not up to spec, could see a quick decline in integrity, and ultimately fail well before it should. Digital verification platforms enable confirmation of every square inch of the exterior without supervisors having to do it manually. By shifting the weight of this obstacle to data-informed technology, contractors can reduce risk and eliminate errors, saving time and resources through greater efficiency and accuracy. This process allows contractors and managment to more precisely understand how to budget for contingency time, which should be reserved for unavoidable circumstances like weather delays. Through this

heightened efficiency, industry leaders maximize the productive time of workers, freeing them from endless hours of manually checking every detail and allowing them to focus on more significant parts of the work.

Data-driven processes better equip construction decision-makers to combat the prevalent labor shortage through tools that improve worker retention, training, and worksite safety. Whether improving workplace morale by providing certainty and eliminating errors or streamlining the construction process by freeing up the team to complete more meaningful tasks, technology is the key to bridging the construction trade and talent gap and accelerating the industry forward.

For more information visit https://asph.link/b5kz0x

Heavy-viscosity, abrasive-filled asphalt? Bring it on. It’s no match for the fierce quality and reliability of Gorman-Rupp rotary gear pumps. Loaded with patented performance features and rugged, heavyduty components —from high-strength iron gear sets for handling higher viscosity, pressure and torque to thermal jacketing for temperature control — our rotary gear pumps are engineered to stand up to abuse and last longer.

An investigation into the complicated history of city-planning, progress, racism and road-building through the lens of one community's effort to be reconnected.

This story is different than what you might normally find in this space. Some of the information and ideas presented might be uncomfortable to some people. It is uncomfortable for a good reason.

This story is the culmination of important questions that arise about the industry. If the work the industry does is build roads, and the work the magazine does is to write about that, then stories like this are just as important as as those about the latest innovative technology to hit the market.

Roads aren't built in a vacuum. They are built in places where people live. Where they are built effects that area in complex ways. Grappling with the context and impact of the work of this industry is valuable and worthwhile.

Bringing it into the conversation can only enrich the work we all do.

What does it mean to be a community? It depends largely on what defines the community, or how the community chooses to define itself. Its identity is drawn, just like a map, atop the space where a community gathers. One word for these spaces is a "neighborhood." A place where people live, work, raise families, start businesses, and meld together into something greater, as a whole, than their individual selves.

This emergent group of people cannot be separated from the physicality and the geography where they live. They are inexorably linked. This includes the infrastructure and the city planning decisions that transform a community over time, as well as the ways some

profit from those transformations, while others are negatively impacted by them. It includes how, in the name of progress, a community can be torn apart, wither away, and be seen as nothing more than collateral damage. Or, conversely, how a community can be resurrected and thrive when different decisions are made.

This is part one of a new series that attempts to examine specific communities, their history, how they were effected by large-scale city infrastructure changes, and focuses on the new nationwide trend to see these communities restored. In each case study, the conditions are different, but there is a common thread tying them all together. A city, its people, its economy and infrastructure are all part of a system.

If we want to see American cities truly come back-to-life, it's going to require rethinking 70 years of how to do things, and not repeat some of the mistakes of our past.

To better understand new solutions to our current problems, we can benefit from examinations of previous solutions, their broader ramifications and, ultimately, how they succeeded or failed.

Right in the heart of the city of Detroit, in the shadow of the General Motors tower and the stadium where the Tigers play, is interstate-375. A four-lane freeway south of the I-75 interchange, where it widens to six lanes. At only 1.062 miles in length, it once had the distinction of being the shortest signed

Interstate Highway in the country, from the time it opened on June 12, 1964 until 2007. At the time it began construction, in 1954, it cost roughly $50 million. This amounts to approximately $477 million in 2022 dollars.

It was an expensive, major urban area project, that was part of a wave of largescale public projects in the post World War Two, Eisenhower administration effort to greatly expand the country's interstate system. These efforts ended up cutting wide gashes of freeway through city neighborhoods all across the United States1.

As was often the context for these expressways, there were two major talking points to justify the eminent domain seizure of property and redevelopment. The first was "urban renewal", where

zoning changes and real estate ratings deemed current structures condemned or labeled whole blocks as part of city "blight". The second, and still often cited in our modern era, was in regard to high daily traffic volumes that would flow in from the affluent, and mostly white, suburbs to downtown jobs.

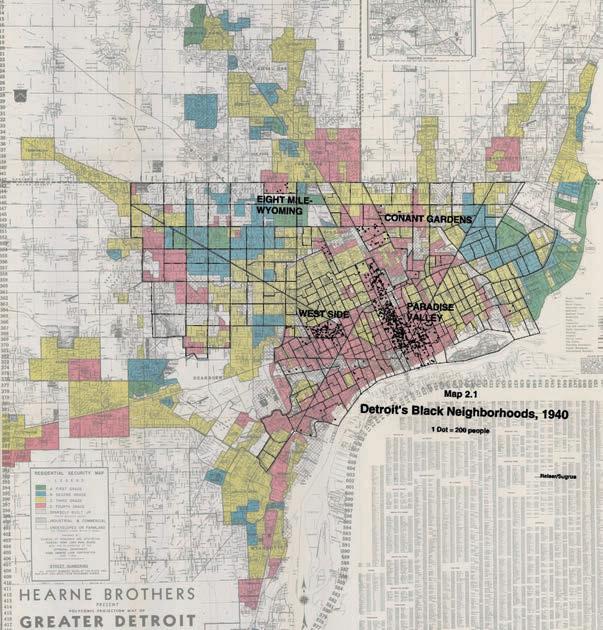

Such were the areguments for the neighborhood of "Black Bottom", where I-375 was built. To better understand the negative impacts on the community, we first have to look at the specific history of this part of downtown Detroit.

The neighborhood of "Black Bottom" is one of the very oldest in the city of Detroit. It gets its name from the soil, a dark, rich earth beneath the surface, as described by the French explorers who founded it. In the early decades of the 20th century, Black Bottom was a thriving center of African American business, culture, and prosperity. Famed musicians like Duke Ellington and Ella Fitzgerald, among others, played at the Castle

Theater in the Paradise Valley entertainment district.

It was so successful, in fact, that the son of prominent Black Bottom businessman, Sidney Barthwell, said in a 2013 interview with the Detroit Free Press, "It was indeed a paradise for black entrepreneurial business. The Detroit black community in its heyday was absolutely fantastic. It was better than Harlem." The Barthwell family owned and operated a chain of drug stores and ice cream parlors that were decimated after the construction of the freeway.

In an article about the enduring legacy of the I-375 project, published in July of 20202 , author Nithin Vejendla wrote about how demolition and the resulting fallout impacted the region. "Highway planners sold the demolition programs as part of an 'urban renewal' campaign designed to help residents by replacing

A map that shows in dots the concentrations of African American population in the city, and the lowest rated quality of housing in red. From the city of Detroit archives

older homes and apartments with new construction," said Vejendla.

But how it was presented and how it functioned were two different things.

Vejendla continued, "Predominantly Black and poor residents displaced by the demolition were left to find new housing without government assistance, at a time when demand in the city’s segregated housing market far outstripped supply. Instead of moving into better living conditions, a majority of those displaced ended up within a mile of the new superhighways, in homes that were commonly no better than the ones they had left. The better rated residential areas, such as Lafayette Park, became mostly white enclaves. In addition to inner-city red lining, and restrictive deed covenants, there were legal methods of preventing black families, no matter how affluent, from moving into or even buying into white suburban neighborhoods.

While the once prosperous neighborhood of Black Bottom was literally demolished, they were locked out of the kind of improved living conditions city planners had sold urban renewal upon. And even as restrictive laws were gradually changed on paper, intimidation and acts of violence took their place.

Other parts of the city's projects did similar damage to surrounding neighborhoods, hundreds of homes and more than 2,800 buildings were displaced for other new freeway construction. However, Black Bottom was hit the hardest. Not a single structure was left standing from the original neighborhood where more than 300 black-owned businesses made their home in 1930.

While many of these structures were extremely old, and in need of heavy repairs or rebuilding, rather than investing the millions of dollars into projects that could have updated housing and utilities, the city spent its money to more directly benefit the new suburbanites who could now get to work in ten minutes.

Rather than allow for the neighborhood to continue to flourish into the latter half of the century, it essentially robbed the future from that local generation. The wealth of those families was wiped out while simultaneously (if indirectly) transferring the potential of that wealth to those who fled the city.

As Nithin Vejendla described, "[It] concentrated poverty in the inner city", in the ensuing decades as business owners and companies took advantage of cheap suburban land and moved the last remnants of decent jobs out of the city, "Highway-assisted suburbanization effectively locked a generation of black Detroiters out of middle class employment."

One of the contemporary city planners from the I-375 project, Ed Hustoles, when interviewed by local journalist John Gallagher in 2013, had this to say when reflecting upon the work he had done so many year ago, "We thought we were doing good. We were taking blight away and giving people decent, safe, and sanitary housing, and we were rebuilding the city. In retrospect, you can always do some things differently."

Nothing happens quickly. Even when a piece of infrastructure has aged out

of its usefulness, as many in the early 2000s agreed I-375 long had, and the cost of upkeep exceeds getting rid of it. It has been seventeen years since the earliest discussions, and almost ten years since the start of the official removal process. Not a foot of road has come up, yet.

In April 2013, the Michigan Department of Transportation (MDOT) made public its considerations, still in very early stages, to either spend an estimated $80 million to conduct essential repairs to the roadway, or remove it and convert it into a boulevard or some other communityfocused resource. Local businesses and members of the impacted community were invited to participate in a study, comment on the process, and submit alternate project bids.

In June 2014, six different proposals were revealed to the public. Their

price tags ranged from $40 million to $80 million, and varied between full rebuilds, full removals, and everywhere inbetween. By January 2016, with no final decision in sight, the city announced that the project was on hold indefinitely.

Enter John Lurie, the senior project manager at MDOT, and the environmental assessment of May 2017. This was a turning point.

"It's a type of change or solution that doesn't happen overnight," Lurie said. "The Downtown Development Authority, in partnership with the Riverfront Conservancy, did a planning and environmental linkages study. It looked at this segment of freeway and its future and whether [the community] was better served by a boulevard or other type of roadway configuration."

At the conclusion of the assessment, it was announced only two potential projects remained viable, and both were removal and redevelopment based.

Lurie described some of the impacts and considerations, now that the pathway forward was more clear. "It's changing from a freeway to a boulevard, because it still serves a large volume of traffic. We had to take that into account," he said. However, there are many benefits the change offers.

"The freeway didn't really have that riverfront connection, and that area has

been a huge investment for the city," Lurie said. "Also, we wanted to make sure the new development incorporated multimodal components. So, we have a cycle track on the east side that connects down from the riverfront. Twenty-two-foot-wide paved sidewalks will go in on the central business district side so that there's room for the pedestrian activation."

These assets are in addition to potential future benefits for nearly thirty acres of excess property, the subject of an upcoming land-use survey, that will most likely be earmarked for green space redevelopment and/or new businesses. But the I-375 removal has immediate positive outcomes for the city infrastructure too, especially relevant in a year where urban rainfall has seen multiple major city highways across the country submerged under water.

Lurie explained, "All the drainage for I-375 and the freeway segments to the north drains into our combined sewer system. We have this opportunity to get the new connection to the riverfront, to provide a separate outfall, and treat the stormwater and release it. Now, it won't burden our combined sewer system. This could decrease the propensity for those combined sewer overflows that we see with these intense rains we're getting more frequently."

Restoring these communities is gaining more support on the state and federal levels. Michigan Gov. Gretchen Whitmer actively campaigned on a platform to, "fix the damn roads." This might hint at how dire the situation and condition of public roadways was in November 2021 when she wrote a letter3 to the secretary of transportation, Pete Buttigieg, thanking him for the administration's work on the Infrastructure Investment and Jobs Act (IIJA) and the $1 billion set aside for "Reconnecting Communities", a pilot program aimed to fund the planning and capital investments needed to restore historically-segregated communities devastated by racially-targeted projects exactly like I-375.

In a statement, Whitmer said, "As we build up our roads and bridges, we also have to take a closer look at the unjust legacy of so many of our freeways, including I-375 and the I-75/ I-375 Interchange, that were built decades ago by demolishing black neighborhoods, splitting up key economic areas, and decreasing connectivity between families, communities, and small businesses."

Michigan expects to receive an extra $250 million to $350 million a year, on top of the $1 billion annually it was already receiving before the new infrastructure law was passed5

According to the federal government's website for the program, it is described as, "The first-ever federal program dedicated to reconnecting communities that were previously cut off from economic opportunities by transportation infrastructure. The funding supports planning grants and capital construction grants, as well as technical

assistance, to restore community connectivity through the removal, retrofit, mitigation, or replacement of eligible transportation infrastructure facilities."

The eligible types of infrastructure include a highway, road, street, parkway, or other transportation facility, such as a rail line, that creates a barrier to community connectivity, including barriers to mobility, access, or economic development, due to high speeds, grade separations, or other design factors." 4

While city planners, contractors and businesses can be justice-minded in their decision making in the present, a question still looms about justice for the past. If the government is willing to admit to the racial factors and history of urban development projects like I-375, and set aside hundreds of millions of dollars to invest in their restoration, what about restitution for the human beings effected? People were harmed by

the system, indisputably. So, what does that system owe their descendants?

In a news segment for WDIV Channel 4 in Detroit, Stephen Henderson, from Detroit Today, spoke in more detail about what justice for the families of Black Bottom and the history of the area could look like.

"If you really want to solve the problem of connecting downtown, you will need to do more mass transit, build more affordable housing for people downtown, and deal with issues of race and equity, but this will help," Henderson said.

When pressed about whether or not Black Bottom and Paradise Valley could ever be truly brought back to its former glory, Henderson responded, "Can't we go find the families who lost houses and businesses, and ask, 'What would you like to do?' or 'How can we make you whole from what we took?' but this is an exercise we aren't entirely comfortable with. But we are doing it right now in the city anyway. We've got a reparations commission studying ways we can make up for the things that the city did. I think here at I-375, it's kind of ground zero for that discussion." 6 In this case, the victims and their families were not so long ago that there exists no records to be able to offer reasonable proof of impact.

Others have written about the removal project more skeptically, and with good reason. Wayne County Executive Warren Evans, wrote an opinion on September 22, 2022, and said, "It boggles the mind that anyone could have the audacity to say this project will in any way rectify what happened to the families and business owners of Black Bottom and Paradise Valley all those years ago — especially when you consider that many of them were only given 30 days to relocate once the decision had been made to demolish their homes."

In Evan's opinion, the media and the government have not painted a clear and accurate picture, given the history of the area. He said, "I want to make clear that I am not opposed to the new project.

Perhaps, you look at this case study, this particular context and situation thinking that it is not clear to you how the road building industry is involved with this story. What does one simple freeway project have to do with today, with your business? What does this have to do with anyone? There are many ways to discuss answers to that question, but, for now, let us focus on two of them: community and justice.

The industry, the contractors, the bids they put forward, can participate best when they have these two concepts in mind. To be community minded requires one to be invested in an area, understanding the dynamics and the history of the places where their work is done.

These jobs and bids are a part of the community itself, and become a link in the chain of its history. Attending city council meetings can be helpful, as well as, being aware of open comment periods for locals where you can go to listen. Talk to the people who live there. To have the support of a community is good for business, because, at the end of the day, you are building that community.

Make no mistake, there is money to be made in the business of jobs like the I-375 removal and redevelopment. Not only are there billions set aside by the IIJA, but the Inflation Reduction Act (IRA) includes hundreds of billions of dollars more. The market is flush with tax dollars, and there is no shortage of projects on the table. Many are just like this one, and some that we will cover here in future installments of this series.

To be community conscious and have a business ethic focused on justice doesn't mean there is no profit. However, the legacy of those profits earned can be seen in the light of history as it moves forward. Of course, it isn't always clear. The city planners of 1950's Detroit thought they were doing

something good. This highlights the importance of diversity in these kinds of decisions, which can offer insights and perspectives that might be overlooked at first glance. Every choice made has a ripple effect, and the opportunity exists, not just in Detroit but all over the country, to participate in positive ways.

We cannot hope to make for ourselves a better future if we continue to carry on the work we do in this industry, as if it is, "just a job." It is more than just a job for those who do it, and it is more for those who live in the places the work is done. It matters deeply to the people on both sides of the orange cones.

This industry, the manufacturers, and the contractors too, all have parts to play in this much larger system. It is important to take ownership of those roles, and see how each has a power to effect things in a community. Projects like the redevelopment of I-375 are opportunities to reconnect formerly severed areas, and make something brand new in the process.

For more information visit https://asph.link/6iycs3

1. The Detroit Free Press · Sunday, December 15, 2013: When Detroit Paved Over Paradise (John Gallagher) pg. A17-A18

2. https://www.freep.com/story/opinion/ contributors/2020/07/05/detroitfreeways-racism-segregation-whiteflight/5366081002/

3. https://www.metrotimes.com/newshits/archives/2021/11/24/whitmerrequests-federal-funds-to-fix-thedamn-i-375-citing-its-racist-legacy

4. https://www.transportation.gov/grants/ reconnecting-communities

5. https://www.route-fifty.com/ infrastructure/2022/08/big-surgetransportation-funding-state-decidesits-spending-priorities/375630/

6. https://www.youtube.com/ watch?v=kwpzee5q9Co

7. https://www.freep.com/story/opinion/ contributors/2022/09/19/opinioni-375-demolition-detroit-neighborhoods-black-wealth/69499351007

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to success for contractors across North America. Weiler material transfer vehicles, commercial pavers, road wideners, windrow elevators, compactors, soil stabilizer, rock drills, grader, screeds and tack distributors are engineered with proven features to increase productivity while reducing operating costs. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America, providing unmatched support with factory trained technicians and readily available parts to keep your operation up and running.

weilerproducts.com

The asphalt manufacturing industry has experienced increasing demand over past five years, despite challenges caused by the COVID-19 pandemic. Increasing prices of substitute materials, such as cement, caused demand for this industry's asphalt paving products to rise slightly, as well, during the current period, boosting industry revenue.

Now, however, skyrocketing oil prices have made asphalt—and all petroleum byproducts—almost obscenely expensive. And the inflation of all products and goods reliant on transportation is painfully familiar to everyone.

In addition, a recent study by Yale University suggests, “fresh asphalt is a significant, yet overlooked, source of air pollution. In fact, the material's

Using bio-based binders and rejuvenators to lessen our dependence on petroleum, lengthen the lifespan of our pavement, and protect our planet.

“OUR

contribution to one kind of particulate air pollution could rival or even exceed that of cars and trucks.”

Not that asphalt production—or paving—is going away anytime soon.

About 93% of the 2.2 million miles of paved roads and highways in the U.S. are paved with asphalt. Most road construction is funded by states, counties, or other federal programs. Thus, demand for asphalt and road oils are largely dependent on the level of funding available. During the recession

most local governments collected less revenue and could not afford investment in infrastructure. However, everyone is keenly aware of how that then changed.

President Biden’s Bipartisan Infrastructure Law calls for allocating $110 billion to modernize 20,000 miles of highways, roads, and main streets. Funding improvements to roads, bridges, railways, and other infrastructure has been a central piece of President Biden’s recovery plans. This is good for us in the asphalt industry and good for the nation. We have an opportunity before us.

Overall, our industry is not suffering

that badly, and it’s clear we’ll be around for the long haul. But we need to do better. If our roads and streets can be built more resiliently to last longer, we need to pursue ways to make that happen. And if we can pave with less-toxic materials, we must do that too.

In the past decade, technologies have been developed to help us address each of these issues to make asphalt paving more sustainable. And it would appear the solutions are rooted in our agricultural industry.

From the Holland-based Biobased Press: “In the Netherlands there are now testcase bio-based roads and cycle paths, paved with a bitumen-like product made from the natural binder lignin. These include a section of road on an industrial site – used daily by cars and heavy trucks, some minor roads, and a cycle path at Wageningen University & Research, which is in three sections, each produced using a different lignin-based bio-bitumen.

'We already built eight demonstration roads in the Netherlands with this type of new binder, so 50% lignin, 50% bitumen,’ explains Richard Gosselink, from Wageningen Food & Biobased Research. 'We now have four years’ experience with that, and it looks very good.’”

Back in the US, the New Mexico Department of Transportation (NMDOT) manages a 12,000-mile road network with limited funding and takes pride in utilizing innovative paving techniques to repair aged roadways. Indulin emulsifier chemistry enables the milling, rejuvenating and replacement of asphalt highways, which makes the process better for the environment, faster and less expensive, and creates longer lasting roads.

Since 2018, the Minnesota Department of Transportation (MnROAD) has been testing biobased rejuvenators, including some developed by agricultural conglomerate Cargill and aggregate supplier Hardrives – a substance that, “promises to reverse the effects of aging when the existing asphalt roadway

is recycled back into the new road,” Ben Worel, MnROAD research operations engineer and project manager for this partnership, said in a statement.

The New Mexico Department of Transportation (NMDOT) has been utilizing Indulin emulsifiers, a key ingredient in successful pavement preservation techniques across the globe. The unique Indulin formulations enable paving managers to work with asphalt technologies that are water-based, rather than solventbased, which means significant cost and energy savings from the elimination of traditional asphalt heating, mixing and transportation demands. And there are tremendous upsides:

• Roads can be reopened to traffic 40% sooner

• Cost 50% less to construct

• 90% reduction in GHG emissions

Iowa State University’s Institute for Transportation’s research project Development of Bio-Based Polymers for Use in Asphalt states, “Soybean oil is the world’s most abundant vegetable oil and currently costs 40 percent less than butadiene, which is commonly used as an asphalt binder. Supplanting butadiene

with a soy binder would translate into lower costs of polymer-modified asphalt. Polymerized triglycerides are also intrinsically renewable, environmentally friendly, and safer to handle than butadiene.”

With future implementation of the developed biopolymers, soybean oil can be utilized to produce polymers for use in the asphalt industry. This can create

improved economic opportunities for soybeans, resulting in economic value to soy farmers and further maintaining soil qualities through a balanced crop rotation with corn. This is a significant opportunity for both farmers and asphalt contractors. Utilizing this scientific techonology, some transportation agencies, local municipalities, and private parties alike, significantly lengthened the lifespan of asphalt paving through the use of

Since 1892, Homestead continues to be the most reliable manufacturer of asphalt valves. With cast iron and ductile iron material options, we offer a complete source of valves for any liquid asphalt application.

Our full line of hot-jacketed 2-way shutoff & 3-way diverter valves provide a ready solution to meet your flow requirements.

Homestead’s cutting-edge actuation design allows you to easily add actuators to your existing Homestead valves, in-line, without modification

Our fully stocked warehouse of valves and actuators offers you security in knowing that the valve you need is only a phone call away.

RePlay. Which is a soy-and-recycledStyrofoam-based asphalt sealer that’s 100-percent nontoxic, can double or triple the lifespan of asphalt pavement, contributes no VOCs, and can cure as quickly as 30 minutes. This soy byproduct can also be applied at night and goes on clear, so that restriping isn’t necessary. Which is a potential time and budget saver, that is, also, environmentally conscious.

A 2019 study conducted by the National Center for Asphalt Technology at Auburn University found that “rejuvenating fog seals are a low-cost option for preventing or retarding the surface deterioration of pavements, practical in use since they do not require specialized equipment, and can be effective for restoring the surface condition of an existing pavement.” Out of seven different rejuvenators (of various makeup) tested, RePlay and BioRestor® received an A-grade.

There’s no shortage of soybeans in the US, and the soy industry’s markets are expansive, at this point, mostly devoted to feedstock. Right now, the two biggest producers of soybeans are the US and Brazil, which tells us if soy becomes a major player in pavement preservation, it will potentially help ease our nation’s reliance on foreign oil sources.

With our country’s increased federal budget for infrastructure—a large part of which is road construction—it only makes sense to preserve what we build. It’s a sustainable solution that’s better for the environment and saves precious dollars, both public and private.