At Gencor®, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. Gencor Industries remains focused on proactively serving and satisfying its customers from all aspects.

Through improved cost-effectiveness, and quality of its products and services, Gencor’s personnel are dedicated to the principle of providing the highest quality to the industry to maintain a sustainable competitive advantage for Gencor® Your Trusted Choice!

14 The Bleeding Edge of Asphalt: Data, Automation, and Beyond

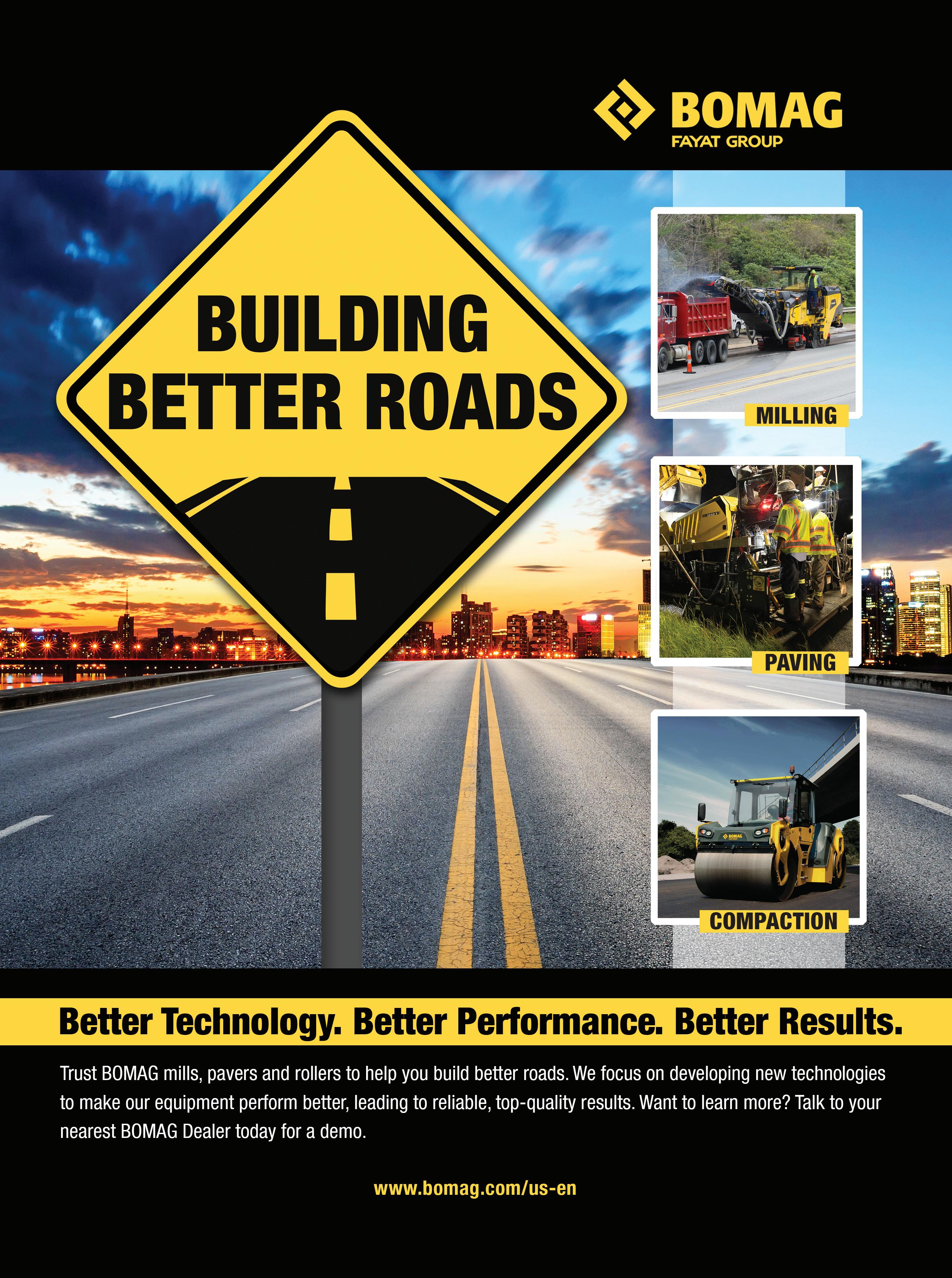

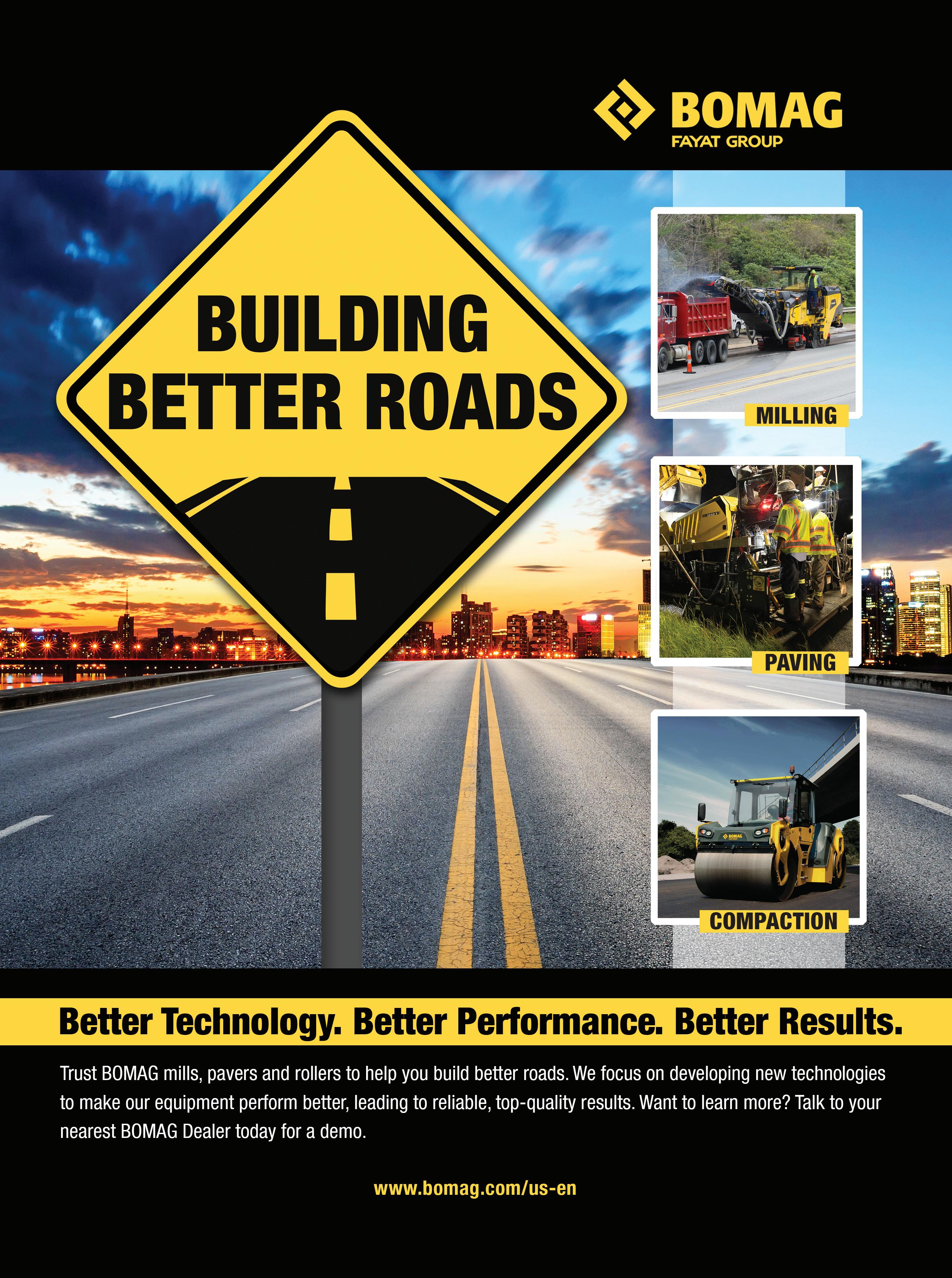

The machines that we use to pave, mill, and compact are getting smarter at an increasingly fast pace.

18 AI-Driven Asphalt Production

Could asphalt plants eventually operate themselves?

FACE OF THE INDUSTRY

32 Tech Dream Team

The technology your company employs on the jobsite should boost the effective communication and efficiency of your crew. It should reduce friction and make what you do well, even better.

38 The Fine Art of Machine & Grade Control in Construction Surface Prep

How these technologies provide precision and finesse, even for novice operators responsible for moving earth and materials to exact design specifications

44 The Biggest Hurdle Facing EV Construction Equipment

Supporting EV adoption and the bolstering of the EV charging infrastructure creates ample opportunities in several job sectors, including engineering, construction, IT, cybersecurity, and networking.

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December, with an additional Buyer’s Guide issue published in August by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 600653605. Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only)

The all-new Blaw-Knox PF-7110C tracked paver combines all-around visibility, ease of operation and a new powerful Cummins 235hp engine for the ultimate in dependability and efficiency. The turbocharged diesel engine provides more torque and less weight in a more compact package, letting you power through steep grades with confidence. Coupled with the proven Blaw-Knox durable track and automatic tensioning system, the 7110C ensures smooth and consistent paving power on any terrain.

With over 90 years of proven Blaw-Knox paving technology, the PF-7110C delivers all the power you need and more.

What do you do if you weren’t “Raised On Blacktop” and you’re also the editor for Asphalt Contractor magazine? You go to school! The soon to launch second season of No Edge Lines is headed to more than twice as many jobsites as season one!

Watch the video at: https://asph.link/tyulfoqd

Russell Standard Acquires Asphalt Terminal in Delaware, Expands Northeastern Reach

Exclusive comments from the company’s CEO, Matt Johnson, about their latest moves, as well as, where they intend to take things in the near future.

Read more at: https://asph.link/ bwnjsbhi

In the wake of the Francis Scott Key Bridge collapse, and the blockage of the United State’s ninth largest port, TRIP highlights the increasing backlog of infrastructure deterioration and the need for more domestic funding.

Read more at: https://asph. link/er23f9d4

With the release of Command Cloud the ready mix, aggregates, and asphalt systems are all unified under a single platform, bringing artificial intelligence and predictive analytics to material suppliers.

Read more at: https://asph.link/ eih4r4qm

social with us!

Bio-Process Oils are biodegradable, renewable and fire resistant, as well as EPA and ISO 1400 compliant.

Read more at: https://asph.link/ yjpsatzz

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

Brandon Noel, Editor

Brandon Noel, Editor

bNoel@iron.markets

234-600-8983

There are always people under you with something great to offer; they’re just waiting for someone to invest in them.

My whole life I’ve been an ideas-man, but in every place I was before IRONMARKETS, I never seemed to have the support to help me succeed in the way that I’ve experienced in my current role. And I’ve been through some interesting phases in the road that led me here. Anytime I sit down with a new contractor, asphalt worker, or industry executive, and we talk for any amount of time, I get asked, “What did you do before?”

It’s only appropriate, on the two-year anniversary issue of when I became editor of Asphalt Contractor, that I get a little bit into it while also sharing what I’ve learned about leadership. Because I believe that it’s applicable across all types of business, industries, and organizations. It’s something universal, and, I also believe, important.

I bet if you stopped and thought about it, you could conjure up your own list of dead ends and opportunity cul-de-sacs where things did not go the way you hoped or imagined. It can make you feel like a failure, and I felt that way for a long time, but I no longer do. I have come to see that those weren’t necessarily failures of my ideas or, especially, my efforts; but failures of support and leadership. I wanted to invest IN myself at a new level, but no one knew what to do with me.

Without knowing it, I was always looking for a leader who would say, “All right, let’s go. What do you need from me?” Even when I was working in a steel factory, as the operator of a repetitive stamping machine, I would stand there and have ideas on how we could change things. Anytime I tried to share them, there was no interest. I experienced that in many parts of my life, in various ways, and either by

choice or by lack of time and energy, things never came together.

At your company, right now, there is somebody, and maybe more than one, who is an idea-person. They can’t help but want to put themselves fully into the work they do, no matter how small. You might have recognized their hard work, or, at the very least, their weird enthusiastic ways of approaching the job. They stick out a bit, right? They can’t help but want to rethink how to get things done, even if “the way it’s been done” has worked for many years. Any time you put them on something new, they’re quickly wanting to discuss changes or new methods. They just might be looking for someone to believe in them, invest in them, and support them.

What helped me come to this realization was finally finding myself under the type of leadership that listened to my hair-brained ideas and responded with enthusiasm in-turn, and really gave me the support to make them happen.

I don’t want to give the impression that I was always the perfect employee, however, at past jobs, whenever I tried to invest myself into my work in a greater way, it was met with either indifference or outright resistance, rather than with leadership.

Look around at your group of employees, the people you’re charged to lead, and find the ones who are wanting more. I charge you to tell them, “What do you need from me?” and see what might blossom from that seed.

See you on the road!

EDITORIAL

Editor Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Gigi Wood gwood@iron.markets

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@iron.markets

Junior Editor .............................................................. Merina Shriver mshriver@iron.markets

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative ..................................................... Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Audience Development Ronda Hughes VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan

Corporate Director of Sales Jason DeSarle

Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.asphaltcontractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

The future is connected. That’s why we’ve designed the ALmix Insignia Control System (ICS) around the power of high-speed Ethernet communication. An ethernetconnected facility means our team of programmers have complete visibility into your plant equipment and motor control center for diagnostics and remote troubleshooting. View and control data from your asphalt plants like never before. The Insignia Cloud Platform provides access while you are at the plant, in the office, or on the go. Critical, real-time, plant information is at your fingertips when you need it.

DON’T LET YOUR EXISTING ASPHALT PLANT CONTROLS KEEP YOU GUESSING:

The Insignia Control System is available on all new ALmix Asphalt Plants and is also available for existing plant control upgrades.

SCAN HERE TO LEARN MORE OR TO SCHEDULE A DEMO

Kleemann has added the Tool Management feature to the SPECTIVE CONNECT mobile app. Tool Management permits documentation of plant crushing tools and service life. It’s first used to make the manual selection of the tool. These are the TRON rotor ledges, the BITE crusher jaws and the CONE bowl liner and crusher cone. The current tool, operating hours and the crushed tons during the current usage period are displayed in the dashboard. Furthermore, other optional tools can be displayed and assigned by project.

Inspected has launched Permit Hub, an all-in-one permit management platform for builders and construction professionals. Serving as the gateway for permit management, Permit Hub enables permit tracking, notarization, plan reviews and inspection results. With the help of remote accessibility, Permit Hub provides team collaboration for inspectors, engineers and architects to work with their teams in one integrated system. Permits, applications and all required documents are available for online submission in PDF format. Permit Hub allows contractors to connect to a notary service to get permitting documents generated in the field, auto-generating documents for local municipalities.

Caterpillar has announced the availability of VisionLink Productivity for cold planers. An online web platform, VisionLink Productivity delivers near real-time machine and jobsite data. Available for Cat PM620, PM622, PM820, PM822 and PM825 Cold Planers, VisionLink Productivity gathers, analyzes and summarizes detailed data such as time spent waiting for trucks, cutting and travel at the jobsite as well as distance cut, fuel burn, location and cycle mapping. This gives contractors insights into equipment utilization. VisionLink Productivity segments data into dashboards, providing multiple ways to view more detailed data and key product indicators (KPIs). Contractors can track the hours and distance milled each day and visualize excess travel, slow milling speeds and stoppage. Eliminating manual data gathering, detailed reports are available in PDF, Excel and CVS formats and can be scheduled for email inbox delivery.

Autodesk has released several new features in Autodesk Construction Cloud (ACC) aimed at helping project leaders and teams make decisions, track progress and view data. The Specifications tool adds new machine learning (ML) capabilities to ACC, building upon current AI enabled workflows across Autodesk’s Design and Make Platform. Specifications automates the manual process of preparing specifications by using ML to extract and section project requirements into relevant specification divisions within Autodesk Build and Autodesk Docs. Users can auto-generate specification divisions and sections for navigation, as well as upload and publish specification documents from the Files tool and perform detailed search and filter workflows.

i.safe MOBILE and RealWear have launched the RealWear Navigator Z1 for construction professionals. The product is designed to be an intrinsically safe and ATEX/IECEx certified head-mounted wearable. The Navigator Z1 is designed for use in hazardous areas for troubleshooting equipment via remote expert guidance, virtual training and for e-workers using Field Services Management (FSM) or inspection data management systems (IDMS). The Navigator Z1 is powered by a chipset with a built-in AI engine. The platform lays the foundation for RealWear’s broader AI Core vision for frontline workers. Navigator Z1 has voice recognition for hands-free use up to 100dBA, a feature for noisy oil and gas work environments. The Navigator Z1’s modular design enables customization for various add-ons like an IS-certified thermal camera and a swappable battery. Connectivity with Wi-Fi 6 and an optional 5G solution for private and secure enterprise connectivity.

Trimble has announced two of its cloud software solutions that support asset lifecycle management have received Level 2 Certification based on the security requirements of the Texas Risk and Authorization Management Program (TX-RAMP).

The two Trimble solutions are e-Builder Enterprise - Commercial, a digital project delivery software for owners of capital improvement programs, and certain capabilities within AgileAssets, an enterprise asset management software for organizations that manage and maintain complex infrastructure networks. The two specific capabilities within AgileAssets that earned TX-RAMP certification are pavement management and maintenance management.

As part of the Texas Department of Information Resources (DIR), the TX-RAMP program addresses the security of commercial cloud computing products and services that process data for Texas state agencies. Identifying and deploying TX-RAMPcompliant technologies helps state government officials manage risk in a cloud-based environment.

TX-RAMP Level 2 Certification is the higher of two designated levels of compliance with Texas-state cybersecurity standards for cloud technologies that process, store or transmit data that is deemed confidential and a source of moderate or high impact information.

FuelPro Trailers has introduced the FuelPro 990 for refueling and service on worksites. With a 990-gal. capacity, as well as additional compartments for tools, DEF, grease and more, these DOT compliant fuel trailers allow construction contractors to refuel and service equipment. The rugged chassis is constructed from 6-in. C-channel for durability. The tank features 7-gauge steel double seam welded for strength. Each tank is equipped with internal fuel surge baffles and cross bracing, a fuel shutoff valve, a lockable vented fill cap, a tank pressure relief vent and an at-a-glance fuel gauge. A self-priming industrial grade pump rated at up to 25 gpm is standard and runs on a deep cycle 12-V marine battery. The fuel delivery system includes a 1-in. hose with auto-trip nozzle, available in 18-, 30- or 50-ft. lengths.

Provides customers with extensive fleet management capabilities for Weiler material transfer vehicles. Weiler Watch is currently available for Weiler material transfer vehicles and offered with a one, three or five year initial subscription.

• Access from a computer, tablet or phone with real-time location, hours, status and fluid levels.

• Analyze fleet utilization with runtime performance including working hours, idle hours and fuel burn rates.

• Machine specific wear life calculations.

• View machine fault codes with status, source, description and type.

• Receive notification of next scheduled maintenance.

• Customize to your needs.

ROCKEAT is First Green’s newest line of electric, cabinless skid steer loaders, designed with a low clearance, 360degree camera and remote operability. ROCKEAT produces zero carbon emissions, uses minimum operating fluids and offers near-silent operation. Remote control technology allows for more accurate and refined movements, increasing precision, especially in tasks like excavation or material handling. Remote control operation is compatible with First Green electric attachments and standard hydraulic. ROCKEAT machines are charged using a standard 110V or 220V outlet. The 700 and 1200 models are 67 in. and 71 in. wide, respectively. The machines offer a maximum power of 3x36.2 hp, maximum torque of 3x89 ft.-lbs., and load capacity of 1,500 to 3,300 lbs.

CM Labs’ virtual Walkaround Inspection is an additional exercise included with CM Labs simulated earthmoving equipment training packs. It addresses the need for training operators on safety protocols and daily pre-use inspections. The exercise includes hints and detailed information at each inspection checkpoint during the evaluation. Walkaround Inspection is included on the Backhoe, Dozer, Tracked Excavator and Wheel Loader Training Packs. As with all exercises, scores from Walkaround Inspection are managed in CM Labs training management Intellia Instructor.

By Brandon Noel, Editor

By Brandon Noel, Editor

The machines that we use to pave, mill, and compact are getting smarter at an increasingly fast pace.

Iwent to World of Asphalt 2024 knowing there would be a lot of new technology on display, but what I found was a surprising reality of just how advanced the tools of our trade have become. Data capture and telematics give us all the pieces of the jobsite

puzzle. How long before a system can put them all together better than human operators? With the power of new algorithms and, not to mention, the creeping presence of artificial intelligence, the answer might be, “Sooner than you think.”

THE EVER PRESENT NOW: PAVING

The rate of technological change and advancement is mind bending, even in just the two years since I came into this industry, I’ve seen rapid evolutions in precision and power. Before exploring

what the future might hold, there are plenty of exciting and useful products that are helping contractors today get the job done.

“We have for quite some time, been trying to figure out how we can help reduce some of the mental fatigue of the job while at the same time improving the pavement,” said Tom Travers, director of technical sales, talking about Astec’s newly revealed SmartEdge joint matching screed.

“That’s what drove the development of this sensor. If we just think of conventional paving, the work of

information, but, also, educational items that can be learned from.

“That is a big piece of what the construction market wants today,” said Mark Larranaga, director of intelligent paving business development at Topcon. “This is particularly true in the payment. Not only do they want to have the data from what they were going to construct, they also want to have the data from what actually is constructed. Then they can compare those bits and pieces of information, and make sure that they got the job done correctly.

The new Topcon MC-X3 is a more compact and powerful “brain” than its predecessors and it comes with features beyond just data capture. Like the Trimble Roadworks, it can allow for 3D milling procedures to take out imperfections in a surface, by getting down beneath years of old mill-and-fills. It can also implement what Larranaga called the, “virtual ski.”

“It’s doing variable depth milling so that you get down to a flat surface instead of leaving bumps and dips,” Larranage explained. “If I’m not using 3D, and I’m running skis on a mill, I have to have a physical ski out there with sensors actually feeling it, and that’s what’s given us our smoothness. In some cases and conditions like bridges, or curves, that ski might not actually be useful. Now, we can use a virtual-ski, using a digital file instead of a physical ski.”

There’s also no shortage of technological advantages in the realm of compaction, both for dirt and asphalt. BOMAG has BOMAP Connect, a subscriptionbased cloud solution that interfaces with an Android tablet or smartphone, which can track number of passes, soil compaction, material stiffness, and any other set jobsite parameters. While some other companies like Dynapac have launched new technological advances built into the roller drum itself.

a strong push for the technology’s applicability on asphalt surfaces.

“There’s a natural resonance frequency of every surface that you’re compacting,” said Eric Booth, Dynapac’s compaction production manager. “What you’re doing is matching that frequency with the drum to get a more optimal compaction. Traditionally, what double drum rollers do is turn to a low amplitude, and a high vibration. That hits the asphalt hard. If you ever see a chalk-like color on your mat, it’s shattering the rock. That reduces how dense your road is going to be.”

The SEISMIC system uses special sensors combined with a smart computer system to find the best frequency to set the vibration and oscillation, in order to, not only prevent over compaction, but to reduce wear-and-tear, improve operator ride experience, and get the best possible density. That’s especially good news for those jobs where measured density is a payable item.

Caterpillar has similarly gone all-in on putting more technology in its lineup of rollers, the CB-10, 8, and 7, greatly expanding their versatility and features.

The SEISMIC technology was first rolled out for Dynapac’s soil division, but at WOA 2024 they were making

“One of the new features is a split drum,” said Cary Bryant, senior service engineer at Caterpillar. “The front and rear drums are both split in the middle. It works like the differential in a car. When you make a tight turn, the outside of the drum can turn a little faster than the inside of the drum. That allows the drum to go around a tight turning radius and not tear the asphalt mat.”

However, there are some cases where tearing or cutting the mat is what you need to do. On certain density critical jobs, like airports, the required density must go all the way edge-to-edge. In those situations where there are unconfined edges, the material has a tendency to be squeezed outwards as you reach those zones. To correct for this, it usually requires a cutter, and Caterpillar now has those as options for these split drum rollers.

“The edge cutter is a more economical way to remove that material than to have an individual saw cut a mile and a half,” said Bryant, but there are other options, too. “Instead of cutting or moving you can compact and constrain. If you think about that same unconfined edge, instead of a cutting wheel, when we’re first compacting that mat, it uses a wheel with a 45 degree bevel to it. It prevents the material from smashing out, and it puts a nice, clean angle on the edge of the mat.”

The amount of technology coming standard on new machinery is impressive, and so are the after-market modules that can be fitted to almost any machine on the jobsite. Where is all the headed? This leads back to the first question we asked in this article. Speaking strictly off-the-record at World of Asphalt, more than one person told me that true machine automation is a lot closer than it may currently seem. This included talk about automated mills and pavers, operating on pre-built models.

The leap from “operator assist” to “assisting operator” aren’t that far apart, and would flip the current script where the technology guides our human workers, to a jobsite that has the human element present to guide and aid automated machinery. As has been said many times before, the human element will never be fully removed, but a change in roles is definitely on the horizon.

Could asphalt plants eventually run themselves?

Over the last few years, as artificial intelligence, machine learning, and other algorithmic tools have risen to greater use and prominence, the biggest question to me has been how these types of tools might be put to use in the production, mix design, and quality control of asphalt production. Large-scale data capture was already seeing adoption, and the rollout of

Environmental Product Declarations (EPDs) has only spurned the need for high fidelity production data and analytics.

While there’s certainly a present consensus that the human element should never be fully eliminated, it doesn’t seem that far fetched or that far off into the future where highfunctioning AI asphalt mix assistants could be trained on a plant’s own

internal data sets,

making. Certain experts in the industry agree with that sentiment.

“AI asphalt production assistants that use a plant’s own data sets could be developed within the next 18 months, as technology and data handling capabilities continue to improve,” said Gary Bisel, product owner. “The evolution depends significantly on advancements in AI algorithms tailored for specific operational processes within the asphalt industry.” Command Alkon recently released a unified, AI-powered platform called Command Cloud.

In some ways it’s alarming to think of such powerful tools being available, in potentially less than two years, but, as is the case with technological advancements in any space, there are barriers and developmental hurdles that must be overcome. But what would those look like in our industry?

a threshold of viability required. What that threshold is, who can say? What we do know is that the more, the better. Thankfully, the industry is gathering large quantities of high-fidelity data in larger numbers than ever before. Some are doing so because of the requirements for filing EPDs. They use tools like the National Asphalt Pavement Associations’ Emerald Eco EPD tool (https:// asphaltepd.org), where producers enter their captured plant data.

The demand for this data has only increased the use of newer, digital tools, which have the added benefit of being more efficient and cost effective. What we are hypothesizing here is that, beyond the use of EPDs, all that captured data could also become useful to producers in added ways with the incorporation of AI.

“The main barriers to developing AI tools for asphalt production include the need for large, high-quality datasets, significant investment in technology infrastructure, and working that learning into a simple user experience that empowers plant personnel to produce the best asphalt possible,” Bisel said.

Let’s break down these barriers and what they mean:

• Large, high quality datasets

• Technology infrastructure investments

• User interface and workability

The first barrier is likely the easiest to overcome, or, at the very least, the one to be overcome first. AI’s thirst for data is never-ending. There will never be “enough” data, but, rather, there is

As far as technological infrastructure investments, some of these are out of the hands of the industry directly. They rely on federal contributions and interest, which can change based on the given administration and its political focus. However, the public sector isn’t the only source, and when it comes to private investment in artificial intelligence, the United States ranks first in 2024 with an estimated $249 billion in private funding, followed by China ($95 billion), and then the United Kingdom ($21 billion).

The hardest step, seemingly, would be how to take things down to the user level, and deliver a product that is functional, helpful, and profitable. That trio of factors is the potential stumbling block for many AI related tools. The nuance required to create something of this complexity is a lot deeper than just throwing a sufficient amount of money at it. But there’s another question at-hand. Many might wonder if all this trouble is even worth it? Humans have been doing it, and will keep doing it, so is there any real benefit here to be gained?

benefits,” said Bisel. “There are other areas where AI can play a critical role such as logistics optimization and more dynamic pricing that account for operational constraints and customer behaviors. Its success will depend on how easily it integrates into existing systems.”

It’s a long walk with a lot of “ifs” but should all these barriers be overcome, and with the next two years we have AI asphalt tools in the hands of producers, where might the most impact be felt in the process? What aspects of production could see the biggest benefit and optimization? What AI models do best is crunch numbers, analyze, and give predictive measures.

“The aspects of asphalt production that would benefit most from AI include mix design optimization, where AI can analyze data to produce more consistent and higher-quality asphalt, and predictive maintenance, which can minimize downtime by forecasting equipment failures before they occur,” said Bisel.

But they are quick to point out that their aspects of the production process that wouldn’t really benefit much from AI and automation. Those types of tasks include ones that require high levels of human judgment and adaptation, such as on-site adjustments during asphalt laying.

“These elements often depend on real-time decisions and adjustments that AI infrastructure will need to push towards the edge where man and machine are interacting,” concluded Bisel.

“An AI tool for asphalt production would likely benefit the industry by enhancing precision in mix designs, improving quality control, and optimizing resource use, which can lead to cost savings and environmental

For more information visit https://asph.link/wmjikv

SOURCES: 1. https://www.techopedia. com/top-10-countriesleading-in-ai-researchtechnology#:~:text=The%20 US%20leads%20the%20 way,and%20private%20 and%20public%20funding.

With so many software options now available, it can be difficult to select one that works best for you. We invited four asphalt technology platforms to sit down and answer our questions, in order to provide you with some starting points in the process.

This roundtable discussion, including some of the answers below, has been edited for length. To download and read the unedited, full-length discussion, visit Forconstructionpros.com/constructiontechnology or use the QR code at the end of this article.

What’s your current assessment of the climate for new software adoption?

OneCrew: It’s an exciting time to be building software in the paving industry. A variety of trends are driving further adoption including increased trickle-down demand driven by the IIJA, a more tech savvy generation moving into management, and private equity driving increased competition requiring software adoption. After many years of discussion around widespread software adoption, the tides seem to be strongly turning and will continue to over the next several years as the trends above persist.

Bitumio: Overall, there is definitely a growing appetite for integrating software across both new and existing asphalt generations. Customers want simplicity through digital documents, easier ways to sign proposals, and better communication about their jobs. Customer demand is driving the increased need to adopt software solutions.

Pavewise: It seems like the asphalt market is realizing the benefits of new software in terms of streamlining work, increasing efficiency, and staying competitive in the industry. This has also become important in attracting the younger generation to join the workforce. The asphalt industry faces significant challenges when it comes to adopting new technology.

It can be a daunting task to convince new clients to trust the technology and to provide them with the necessary training for a smooth transition. Changing behaviors can be a significant hurdle to overcome in order to ensure the success of any technological change in daily routines.

EDGEVANTA: I find that many asphalt contractors are receptive to new ideas and software if the ROI and time savings are clear. The credibility and reputation of the team delivering and implementing the software matters a great deal. As a 4th generation contractor myself, and someone who worked in the industry much of my life, I was always interested in technology, such as: GPS modeling, 3D paving, automation, and digitization.

Adoption takes time and involves a lot of interaction with your users to

figure out what they really want. What is the most common hurdle contractors express and how does technology address them?

Pavewise: As a construction business owner, I have faced two major challenges: weather and communication. Weather is something we cannot control, and communication in this industry can be difficult due to the many variables involved in paving, and it can change rapidly.

We try to address these issues by providing a comprehensive solution through building predicted schedule impacts for project-specific locations and provide text notifications for inclement weather with best practices in operational changes to combat the environment changes. We address communication issues by providing a centralized platform that allows all team members to see project requirements, goals, productions, plans, and anything else needed to complete the work successfully.

EDGEVANTA: Lack of standardization in their bidding process and backlog tracking. We often hear that clients are bidding millions of dollars of work each year, but lack a repeatable, scalable process for figuring out the right profit margin to bid on their jobs. Estimating is figuring out the costs, whereas bidding is figuring out the pricing strategy.

Bidding is both an art and science. Spreadsheets and legacy systems are often being used to track bid results and bid spreads. People acknowledge that spreadsheets are not a scalable solution. We see similar trends with

with a passion for harnessing the power of technology to inform business decisions and streamline complex processes. With a wealth of experience in crafting user-centered solutions, Jared is dedicated to creating software that empowers organizations, fosters innovation, and drives efficiency in today’s ever-evolving asphalt landscape.

We want to enhances user’s existing

backlog tracking and forecasting. We want to enhances user’s existing processes through a centralized platform and single source of truth designed to save folks money and time. At the end of the day, we want to make sure we are getting the right data in the right person’s hands at the right time to help them make the right decision. When that happens, it’s magic.

OneCrew: We consistently hear about two key issues: estimating and organization within the many moving pieces of a paving operation. For estimating, we’ve heard contractors, time-and-again, express struggles with accurate, consistent, and quick estimating. Typically, contractors can

Ari Bleemer, Co-founder & CEO, OneCrew

time, travel time, and formulating an electronic or PDF proposal that can be instantly sent to clients for signature.

What role do you envision AI playing in the next generation of software technology and development?

OneCrew: Any software company these days has to have at least an idea for an AI strategy, but at OneCrew, we are also seeing a ton of overuse or forced use of AI in a variety of software products. We see AI as a tool rather than an ultimate solution to any problem.

working on a solution to improve the price prediction process many contractors are using today. We must remember that the most effective AI applications are augmented, meaning they just make the human’s job easier, but do not replace the human altogether.

How do most of your clients engage with your product, and what have you learned from how your customers use it?

available to contractors. In 2022,

Prior to OneCrew, Ari worked in the management consulting and private equity practices of Bain & Company, where he spent time working across industries but found a passion for critical infrastructure. Experiences across multiple industries demonstrated the lack of effective software and data collection and analysis available to contractors. In 2022, Ari teamed up with his cofounder Max to launch OneCrew to build a new generation of business management software for paving contractors. Since then, OneCrew has supported over $1B of paving projects across the US and Canada.

accomplish some of those three. However, getting all of them together is the big challenge, which OneCrew works to solve for them. The second piece is taking the estimate and using it to drive the many other aspects of the business, from scheduling to work orders to job costing. OneCrew connects operations from lead to invoice, and it can be a gamechanger for contractors, entirely changing the way they do business and the productivity of their teams.

Bitumio: The slow process and all the repetitive steps and calculations required to create estimates. Estimating is foundational for companies to grow and scale. However, if an owner/operator is spending all day running a paver, it is difficult to then spend all night putting together estimates. Our platform aims to simplify this process and pull all the steps of creating an estimate into a single platform including calculating material needs, trucking needs, job

There is certainly potential for AI in auto-generated estimates, mapping measurements, and scheduling recommendations. However, we don’t see as much value in things like AI-driven proposals that introduce more risk and uncertainty into the process rather than anchoring on consistency. We’re excited to lead the way in bringing AI to the management side of the paving industry.

Bitumio: AI will undoubtedly advance further, with some platforms like Attentive.ai already showcasing innovative applications in the industry. I foresee AI continuing to push boundaries not only in measuring and counting for contractors, but also in aiding business decisions. Software platforms collect vast amounts of data, which, when coupled with AI and Machine Learning, can provide valuable insights and recommendations for companies to enhance their operations.

Pavewise: I strongly believe that AI is going to play a significant role in managing collected data and the development of a universal, “construction language,” that the industry can use to reduce project risks and build better quality products, while also increasing profits. In a highly competitive industry, profits will always be the key driver. If you haven’t already integrated AI into your software, you are likely lagging behind your competitors.

EDGEVANTA: AI is the application of math and code to teach computers how to process things the same way that humans do. I believe AI will be huge in the next generation of software development. We see potential with AI and bid pricing optimization. We are currently

EDGEVANTA: Desktop mostly with some mobile capability. One of our clients ran a single report the day before a big letting. It showed that they could add 4% to all their bids over the past 12 months and still win almost every meaningful job. The executive who ran this report shared it with his team. Armed with this insight, they felt confident in their decision to capture $1 million in additional profit on the letting the next day that they wouldn’t have otherwise added.

One of the unexpected requests we’ve heard from customers is their desire to physically print reports and analytics from the platform. They like to bring them to meetings and write on them. Who knew?

Bitumio: Computers and tablets work well for all aspects of the platform. Many estimators prefer to use tablets in the field for generating estimates and sending customers proposals. Our mobile app for Apple and Android really simplifies the communication between office and field and allows notes and information to be passed between the field and the office without constant text message threads.

We’ve learned there is no “standard” way of estimating or tracking jobs. Somedays, it seems like every contractor uses a different formula to figure their cost estimates. As a result, we’ve really had to design our platform to be flexible and adaptable to support these varying methods.

OneCrew: Typically, office staff including admin, estimators, project managers, finance, etc. are engaging with OneCrew on desktop and/or tablets while foremen and crew out in the field are using mobile devices. One

Weiler Material Transfer Vehicles lead the way with proven innovations to provide the lowest cost per ton of operation.

Innovative and reliable operator friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

Clam shell doors and full width drop down floors provide unmatched access for cleanout and maintenance.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

The multiple, incremental improvements to the 4th generation of chains, sprockets and augers are retrofittable to all machines and provide increased wear life.

Bryce Wuori,

Co-founder & CEO of PavewiseAn expert in Asphalt Paving who believes technology is the future key to success within the Infrastructure Industry. Bryce has been recognized nationally as an asphalt expert who is currently generating large amounts of success by integrating project variables within Asphalt Paving quality procedures to increase project revenues. variables within Asphalt Paving

surprise was how much we’ve enabled remote work for estimators. We have many customers who’s estimators are now only in the office once or twice a week for some meetings, but otherwise spend all of their time in the field assessing new jobs, creating estimates, and sending proposals.

Pavewise: Ninety percent of our users are utilizing our product on mobile devices. We designed our software to cater to the needs of the front-line workers who use it in the field. We discovered that our users require access to data, but they do not want to spend time managing or organizing it. To address this issue, we created an AI tool called PAT (Pavewise Assistant Tool) to automate file location and document management tasks. Our aim was to reduce the burden of tedious work for our users.

How does your platform impact and/or streamline people management solutions, i.e. hiring, onboarding, development, etc.?

EDGEVANTA: Our platform helps get new estimators and project managers up to speed on the company’s process for bidding work, competitive intelligence, and using data to make better decisions.

Pavewise: It offers management solutions to assist users in assigning crew members to active projects. The platform provides GPS pin locations and mapping to support locating project sites, plant sites or any other location that is critical to the project. Pavewise also offers recommendations through text automation based on patent-pending engines that utilize a custom-built library developed from over 20 years of experience. The platform provides users with guidance on operational and quality procedures in the field with up-to-date information presented or coming to impact the project. The main goal of Pavewise is to empower individuals with the necessary data to identify risks and provide recommendations to mitigate these impacts.

Bitumio: Some of the best feedback we’ve received relates to supporting new hires, particularly estimators. Our platform automates many repetitive calculations for materials, job time, equipment, and more directly in the proposal. This feature has made it significantly easier for companies to onboard new estimators and be confident that their estimate amounts are accurate and in line with expectations.

OneCrew: On the onboarding side, we’ve seen our customers cut their onboarding time for new estimators from many months to just a few weeks, allowing those estimators to start earning commission more quickly which keeps them around. Additionally, many customers use our job costing and analytics to calculate commission for their salespeople and evaluate their project managers, foremen, and crews to reward those that excel.

How do you manage the expansion of usability and integration with other software/hardware, while protecting contractors digital security?

EDGEVANTA: We’ve worked hard to integrate with estimating software and ERP systems. This helps eliminate manual entry for our users, which is critical. Authentication and data security are paramount given the sensitivity of all this information.

Bitumio: We treat our customers’ data with the utmost sensitivity and protection. In nerd terms, all data is encrypted, meaning it is unreadable by humans and computers, as data moves through our platform and when it is stored. We ensure that no customer data is mixed with other customers’ data, enhancing data protection measures. This approach simplifies the management of access to sensitive pricing data and regulates the sharing of data with third-party platforms. We never sell data to third-parties and are very explicit when integrating with a platform to vet them and only share enough information for the integration to work.

Pavewise: We have not yet integrated with any other software platforms. However, we have been in talks with a few companies about potential integrations in the future. Our main focus currently is on integrating existing hardware in the industry into our platform. The data related to hardware integration is managed through our secure and encrypted platform, ensuring the digital security of our users. As we work towards integrating our software into other platforms, we will ensure that our customer’s data is protected with advanced security measures.

OneCrew: Digital security is a top priority at OneCrew. We use modern authentication protocols for both our platform as well as our integrations to ensure end-to-end digital security for our customers. While we are constantly expanding the capabilities of OneCrew, we never sacrifice information security for a new feature.

What can asphalt contractors expect in terms of a return on investment (ROI)?

Bitumio: We see contractors who have never used software before more than pay for the platform in the first deal they close. Customers love the simplicity of receiving and signing their proposals electronically. How much more work can you win if the customer did not have to print, physically sign with a pen, scan the document and email or fax (what is a fax machine) it back to you. As a result, many first-time

Tristan Wilson, CEO & Co-Founder of EDGEVANTA

Tristan Wilson, CEO & Co-Founder of EDGEVANTA

From a legacy of a family’s business, Barriere Construction, based in South Louisiana. He spent most of his career bidding and managing highway construction projects, realizing that the key to winning contracts lies not just in calculating one’s own costs, but in considering many other important factors like historical bidding data and intelligence about competitors.

Tristan experienced firsthand the pain and difficulty of trying to be the lowest bidder while also avoiding leaving significant money on the table.

As an estimator on his first major asphalt bid, he left an embarrassing 33% on the table on a $2.1 million job.

The process was marred by a lack of robust tools, reliance on intuition, and cumbersome spreadsheets. Meanwhile, there were numerous contractors out there striving to improve their bid hit rates and margins, wanting to understand themselves and their competitors better but lacking the means to do so. understand themselves and their competitors better but lacking

software users are experiencing significant returns on investment.

EDGEVANTA: Industry average dollars left on the table (dollars between first and second place bidder) on DOT work is 8%. So, a paving contractor doing $100 million of work is likely giving $8 million back to the market every year. When you reduce your dollars left on the table down a bit from 8% to 5% without sacrificing market share by using a proven bidding methodology and process, your return on investment is $3 million.

Pavewise: Asphalt contractors who utilize Pavewise software can expect a fast return on investment. Although each company, user, and crew may have different experiences, we have found that in many cases, our software pays for itself on the first significant project or within the first 30 to 40 days of full implementation use with crews. In some cases, we have even helped contractors save up to $10,000 to $50,000 on a single project. One of the most significant benefits of our platform is the time it saves. When combined with our GroundTruth hardware solution, our software can save an operational manager up to 1-3 hours a day by automating data organization and physical busy work such as monitoring rain gauges and completing daily weather logs. Our goal is to automate these tasks so that users can concentrate on managing their crews, ensuring safety, and building relationships with people.

OneCrew: It doesn’t take long for contractors to see significant ROI from investing in OneCrew. We see a variety of sources of ROI. Increased estimate / proposal output can double the productivity of a contractor’s salesforce. In today’s labor market, maximizing productivity and efficiency of the people you have is as important as ever. With OneCrew, contractors are also able to deliver best-in-class customer experiences, driving additional repeat business. And a third driver of ROI for our customers is eliminating dropped projects or crews showing up to the wrong site or with the wrong equipment. OneCrew’s end-to-end system empowers our customers’ operations to efficiently complete every job they sell.

What is one thing you wish contractors knew before they started shopping for a new software platform to help with their business?

Pavewise: As a previous business owner looking for software, I faced a problem that was costing me a lot of money but couldn’t find any solutions that could solve it specifically. So, I researched the available software

options and contacted the companies for demos to check if they could meet my company’s needs. My advice to anyone who is planning to buy a new software platform for their business is to first make a list of the top five things that are costing their company the most money, and then prioritize them. This will help you identify the key features you need the software to have, so you can make an informed decision.

EDGEVANTA: I advocate for having a buying process and/or committee that sets you up to not miss out on the next great wave of innovation. Who knows what you’ll learn by answering that email or phone call? You may meet some neat folks working on hard problems that matter to you.

OneCrew: We’ve seen that contractors that do the following are the most successful: be ready to pull the trigger, be ready to invest, and have a champion. At OneCrew, we fully

encourage customers we’re working with to look at other solutions. It’s a big decision for your business and one that hopefully you only have to make once. When you’re going into the software buying process, you’re going to be able to make the right decision if you enter the process ready to buy. Along those lines, like many things, software is a product where you’ll get what you pay for. Premium solutions are going to cost a premium. Software migrations are incredibly expensive in time and can also be expensive in money, so selecting a solution that can grow with you and your business is worth the initial investment. And lastly, the most successful contractors that we’ve seen typically have a champion leading the buying and onboarding process. It’s important to involve a variety of stakeholders in the evaluation process, but having a designated leader can help keep the buying process to a timeline and expedite a decision.

Bitumio: Software is not going to be a magic elixir and upon signing up, all of your administrative work goes away. Platforms like Bitumio are dedicated to simplifying the entire end-to-end operation of businesses. However, regardless of which platform they choose, there are going to be changes in their current process to adapt to the software. The software also needs to adapt to their processes. But it will take work and effort to get things set up properly so the software can support your business. If contractors go into software with the mindset that the upfront work will be worth it on the backend, then the onboarding of the software into their company will go much more smoothly.

For more information visit https://asph.link/ lsdxqdgs

From the field to the construction site, effective leadership makes the difference.

I’m passionate about people development. I think business and the growth of business is accomplished through people. It is shortsighted to believe that we can develop and grow without the interaction and

development of people. My greatest accomplishments are when I see someone that I’ve worked with achieve their goal. Witnessing their growth, promotion or accomplishing things in their life -- that’s the enrichment portion of it, and where I derive the greatest thrill. I’ve been blessed and have accomplished many things in my life but other people have helped me develop my talent. It is fulfilling to pay it forward, and help others develop, as well.

When I was young, my mother worked a lot of hours and so did my older brothers. If it wasn’t for a coach who was a family friend, I wouldn’t have gotten involved in football. He was willing to pick me up, take me to practice, and look after me. When I was young, my coaches would fill the gaps that my family couldn’t. Then this became a pattern, because in the business world, I had amazing managers, coaches, leaders, and other mentors. I noticed that the

great managers were different, they were like coaches. They weren’t just the manager that could help you, “with your job.” These leaders helped enrich my life and helped me become a better man. I’ve been blessed to have great mentors and leaders in my life.

I’ve been involved in sports my entire life – first as a player, then as a coach and leader.

Sales and sports are very similar. You work very hard and practice very hard for those opportunities to be able to use your skill to accomplish your end goal.

When I came to FleetWatcher, I realized that sports and contracting, specifically heavy civil contracting, were also very similar. Each person on the team has a vital part in the success of the endeavor. It’s the team aspect

that sports really drives home for me when in contracting. It starts with leadership. Team leaders must make sure everybody’s in the right place, they have to make sure everybody’s aligned with the mission, and then hold everyone accountable in that to get things done.

Also, being in sports, the competitive nature of business has always been a positive thing for me, and I see the grit in companies getting work done on timelines. I see the cooperation with government entities like DOTs and being able to perform at a high level under strict regulations. Games have rules that you have to abide by and things of that nature. When you talk about sports and you talk about my field, which is sales and sales leadership, and then you couple that with this construction space, this isn’t an individual contractor painting the side of a building. These are teams. These

are hundreds of men and women. That is really the thread pulling everything together for me.

I’ve always been in business leadership. We’re a construction technology company, helping companies work more efficiently by providing complete transparency so that all of the assets in their fleet can be productively employed. I’ve worked for Verizon and Hewlett Package on their mobile services, so I understand the mobile aspect of the business. And I worked on the marketing and advertising with contractors, so I understood their concerns. But it was people and process development that brought me into FleetWatcher.

I’ve been in the cell phone business, then I sold marketing to contractors. How I got my name out there has been in people development. I’ve either

“These Leaders helped enrich my life and helped me become a better man.”

managed teams or managed leaders. They call me the coach because I enjoy coaching teams, growing teams, coaching culture, and developing folks to be the best that they could be. How I got into FleetWatcher is through those avenues.

Larry Baker, the owner of FleetWatcher, was a mentor of mine. We have a lot in common – we’re both alumni from Ball State University, and

sales leaders in the city of Indianapolis. He and I always were on the same page about growing people, growing industries, and helping folks achieve to the highest level that they can achieve. Now my involvement with FleetWatcher made a ton of sense because I was already working with general contractors: Roofing, painting, and smaller electrical contractors. I understood the problems, the people, and I understood the language.

Even though I understood the mobile technology aspect and the value proposition that we bring to contractors, it wasn’t always smooth sailing. What I didn’t know about this space, but that I realized very early, is that the construction space was underserved by the technology world. There are a lot of fields that adopted technology at a higher rate, at a faster speed, and construction still hung on to some of the old-school ways.

It wasn’t in a negative way. The success formula that contractors used to reach the top, and be there for a hundred years, had just not quite changed much to meet the times and the demand.

When I joined FleetWatcher, we were right at the cusp of a breakthrough, which was going to change the way contractors were going to do business. It was just good timing. While timing was important, so was the leadership component - giving people the tools that they need to get the job done but also holding them accountable FleetWatcher technology brings order to the chaos. I felt like not only were we filling the gap in serving the construction space with technology, but we’re also bridging the gap to allow leaders to be able to lead and hold their teams accountable at a high level.

A new operator can get onboard equipment with machine control and nail a plan to spec in a minimum number of passes.

These technologies provide precision and finesse, even for novice operators.

The lack of young talent entering the construction industry and an exodus of veteran operators retiring or moving to a different career have created a shortage of experienced, skilled labor. Quality and productivity must be maintained, shifting the focus toward technology to close the skills gap.

Contractors who have not updated their machines or fleets with autonomous controls may have struggled to compete because basic, traditional equipment requires dead reckoning and an escort of grade checkers and surveyors to minimize the multiple passes required to get a surface prepped to spec. Lost time, wasted material, inability to adjust to changing conditions on

the fly and added rework are forcing old-guard operators to modernize.

Meanwhile, machine and grade control technology only gets more sophisticated, cheaper and easier to install. It’s not unusual for owners of older equipment to install a simple 2D control unit on a machine and suddenly inject new life into an aging investment.

“It’s easier than ever to get into the game,” said Cameron Clark, earthmoving industry director for Trimble. “Tiered solutions exist that can take you from entry-level technology add-ons for basic bucket and blade control up to laser, global positioning system (GPS), onboard diagnostics and full 3D control, all installed on an existing piece of equipment.”

Original equipment manufacturers (OEMs) have been designing different levels of machine and grade control automation into their earthmoving equipment since the late 1990s, when

research and development teams began experimenting with smart technology for construction applications. Early solutions evolved from basic hydraulic valve controllers and lasers to onboard hardware sensors and software that automatically read a machine’s position in relation to a surface and adjust to match the design—a science that has gotten more precise with every passing year. These days, you’ll find diggers that automatically grade, machines that automatically detect nearby objects, and trucks that automatically drive featured at every industry event. Most of the new equipment comes with special harnesses and brackets built in that make it easy to upgrade an earth mover to the latest technology on demand.

As Oscar Cantu, construction content manager at Topcon Positioning Systems, puts it, “There’s no sacrifice involved in putting control technology on an existing machine. You simply bring the vehicle

An automation upgrade is similar to adding an app on a smartphone once the technology is installed on the asset.

into the shop for a day; the sensors get mounted, calibrated, and tied to the electronics; and the surgery is complete. [It is] ready to roll and start producing at a higher degree of accuracy immediately.”

Machine control is widely viewed as the first step in the automation trajectory, leading from 2D grading and earth moving to 3D trenching, sloping, digging, and other complex project applications. At its core, machine control relies on the GPS and global navigation satellite system to position a tractor extension to cut a stretch of earth to a prescribed height and level according to a triangulated digital map. Often, an external base station is used to read the satellite signals, then relay the reference points to receivers on the machine that automatically control the equipment in relation to the earth, guiding the tractor along the correct path and plane.

Where 2D control tells the operator the position of his equipment relative to the desired plan—high, low, or on a slope—3D control is better for more complex designs, adding depth and angles to the modeling data and grading scheme.

“While OEMs are working hard to bring next-generation machines to the market, it’s difficult to foresee changing needs in the field that may require different functionalities not already designed into the equipment,” said Joe

Baldi, director of new business ventures at Moog Inc. “Fortunately, it’s easy enough to equip these machines with controls that manage grade, payload weight, material conditions and other variable factors just by adjusting the onboard software.”

Mark Colvin, senior product manager for grade management at John Deere, agrees. “You can get a lot of productivity out of a tractor equipped with advanced sensors and GFSS heads alone,” he said. “A new operator can get onboard one of these machines and nail a plan to spec in a minimum number of passes, eliminating rework, saving material and finishing the job in less time.”

A basic system will read a 2D site plan and control grade to within onetenth of a foot. Add-ons can include:

• External base stations for more precise digital mapping

• Rover components that pick up signals and collect data

• Inertial measurement units to finesse position changes

• Other technology to enhance safety, improve accuracy and minimize waste 3D control offers more precision and accuracy, reading terrain variations through a combination of GPS data, sensors and modeling software that account for X, Y, and Z axes. With 3D machine control, operators can excavate, grade and pave to within millimeters of any given site plan.

If 2D control is considered entry-level technology for machine automation, 3D grade control would be a significant step up. Concerned most often with excavating equipment used in trenching and digging operations, applications may include digging ponds, waterways, drainage features or other complex surfaces where control over a blade, bucket or auger is required to satisfy a plan. Even rock drills and rock saws can be precisely controlled using the technology.

In most cases, an operator will be in the cab. However, in some cases, such as in mining operations where human safety is a concern, remote joystick controls

may be used to achieve the design without an operator in the cab.

“Some projects call for added flexibility in tight spaces, where a tilt bucket, rotator or boom needs to perform some complex excavation,” said Sean Mairet, group product manager for grade management for John Deere. “Trenching for utility infrastructure, curbing and certain landscaping projects come to mind. This is where 3D machine control can really pay off.”

The very nature of 3D grading involves multi-axis control, calling for an added dimension of automation and visibility. For instance, 3D software onboard a backhoe enabled with GPS capabilities will display a site plan in 3D, showing the exact dozer blade position as it carves or moves the required surface material to spec. The result is a more accurate pass on the first attempt.

2D technology can also perform some level of 3D work using GPSenabled sonic tracers or lasers with the right software but without the same level of precision. Projects may include rough cutting a trench to a specified depth or grading areas in tight spaces using a compact track loader equipped with the technology.

Joe Baldi likens the “automation upgrade concept” to adding an app on a smartphone. His company offers the all-electric TerraTech ecosystem for intelligent vehicle control, among other integrated technologies. “Once the central control system is set up on a vehicle, it’s as easy as downloading a new program to gain new capabilities without adding new hardware.”

Selectable settings on most control systems allow different users to save their configurations, so the same machine can quickly accommodate a new operator. Likewise, different applications set for different seasons of the year can be saved for future reference, allowing contractors to build a custom library of settings, for example, coldweather paving or heavy payloads.

It’s time to unleash your team’s productivity because…

Astec Digital is the leader in plant automation, telematics, and data management from Rock to Road and beyond. We are creating a platform to connect every piece of your operation and tear down the silos so that you can have the visibility and insights to improve efficiencies and reduce costs. Real-time data, increased control, and higher profits start here. The future is connected: AstecDigital.com

“You’re … looking at a two-step connection, either way,” said Cantu, whose company designs, manufactures and distributes precision measurement and workflow solutions. “The solution connects the operator to the machine so that in turn, the machine can connect to the surface and design [that] it’s targeted to prep.”

Whether equipped with 2D or 3D technology, automated machine and grade control can achieve project results. Clark’s company provides field solutions, from semi-autonomous machine control to virtual reality. With more than 20 years in the business, he’s seen grade control used on simple residential

“Trenching for utility infrastructure, curbing and certain landscaping projects come to mind. This is where 3D machine control can really pay off.”

driveways and car parks to large-scale projects, such as airports and golf courses.

“There’s nothing cookie-cutter about it,” says Clark. “You can program a machine to grade a golf course fairway exactly to spec, causing a ball to roll to an exact spot, just as the course architect intended.”

Rail construction; solar pad preparation; oil and gas platforms; mining operations; and more common applications, such as building pads and road construction can all be prepared artfully and accurately using autonomous equipment.

In addition, different materials can be manipulated accurately by adding sensors to detect stiffness, helping determine the exact level of compactness required for a job. Or sensors can be added to read the temperature of asphalt, for instance, ensuring that the grade is paved at the right setting, without having to remove it and start again.

John Deere’s Mairet assures that even a 2D system without a base station or rover can produce some amazing results.

“Cutting a ditch around a house so that water slopes away from the structure is a good example,” he says. “Add a laser app to the system and you can accurately grade areas in wooded areas, working around tree cover, or finesse a surface inside a building before the concrete gets poured.”

The benefits are clear. Autonomous machine and grade control can eliminate the need for bulky survey staking

and other manual grade-checking tasks, saving time and money, while also reducing errors and rework. Without a traditional ground crew escorting the machine, not only is labor reduced, but safety is improved.

Last-minute adjustments can be made on the fly using onboard software, without re-staking the job, easily accommodating unplanned changes. The fact that rookie operators can perform all this work with minimal training is an advantage, especially in a tight labor market. Most important, the design plan is met precisely, often on the first pass, creating customer satisfaction and boosting contractor reputation in the process.

Most technology can be used in diverse ways, so learn what the options are and plan accordingly. Avoid buying more technology than you need.

It’s a good idea to make a list of questions to ask in advance. Dealers and machine and grade control technology companies know their capabilities and are adept at explaining them. Once you feel comfortable with a purchase, request a demo, and try the equipment for yourself before you buy.

Lastly, make sure that your chosen supplier offers adequate support and training on the technology.

A good, dedicated, tech support team is critical to ensuring that you get the most out of your investment. If something isn’t working right, a quick call to the support desk can be all it takes to remedy the situation.

by Joe Zagorsk, a freelance writer.For more information visit https://asph.link/InvInf2

Adding control technology on an existing machine is simple. You simply bring the vehicle into the shop for a day. The sensors get mounted, calibrated. and tied to the electronics. Then the process is complete.

Supporting EV adoption and the bolstering of the EV charging infrastructure creates ample opportunities in several job sectors, including construction.

On Jan. 11, 2024, President Joe Biden’s administration announced that it was earmarking $623 million in grants to fund the buildout of electric vehicle (EV) charging stations nationwide, all to reach its goal of 500,000 new charging stations by 2030. Since Biden took office, EV sales have skyrocketed, exceeding 10 million vehicles sold in 2022 alone. However, with this exponential growth has come some growing pains, namely with unavailable or unreliable EV charging stations.

As the federal government’s interest in growing the EV market has increased, the need for an expanded and more supported EV charging station infrastructure has become apparent. With the ambitious initiatives put forth by the Biden administration, all eyes

are on the current EV charging network to see where the problems lie and what solutions can be brought to the table.

As any EV driver could tell you, there was a time when driving an EV meant harboring a certain level of “range anxiety.” Since 2013, when the average EV battery range was around 136 miles, their range has greatly improved. The 2024 Tesla Model S, for example, can go up to 405 miles on a full battery charge. Now, with reliability issues of the EV charging network, “range anxiety” has shifted to “charging anxiety” with EV drivers concerned that when they do need a charge, the charging station will either be unavailable or inoperable.

Facing these challenges has been a centerpiece of the federal plan to encourage EV adoption nationwide. The significance

of improving and sustaining the EV charging network cannot be overlooked if current and future administrations hope to reach lofty EV adoption goals.

The unreliability of the current EV charging station network is likely the most significant hurdle in the way of widespread EV adoption. The issues affecting the network vary and will require a multifaceted and strategic plan to solve. Some of the largest concerns of EV drivers and proponents of EV adoption concerning the charging network include:

• Lack of availability: While some states such as California have vast amounts of public charging stations available, other states like North Dakota have only a little over 200

available statewide, making the prospect of broader EV adoption in the states with few charging stations less likely. It is this sporadic availability that has prompted the Biden administration to pledge to build 500,000 new stations nationwide by 2030.

• Unreliability: The unreliability of the existing EV network is welldocumented, with one study finding that upwards of 20% of all current charging network infrastructure is inoperable at any given time. With the amount of new EV drivers hitting the open road every year, a 20% inoperability percentage is untenable. Although the National Electric Vehicle Infrastructure (NEVI) program has approached this issue with funding for a large-scale deployment of EV charging stations nationwide, their goal of a 97% operational uptime for these charging stations seems out of reach under the current support approach. There simply are not enough trained and certified, EV-specific technicians available to support a 97% uptime aspiration.

• Lack of support: The lack of technicians specifically trained in supporting the complex needs of the EV charging infrastructure presents a significant issue for the network’s planned expansion across the US. To resolve this, there must be educational outreach initiatives to electricians, IT engineers, and automotive technicians to imbue them with the necessary knowledge and skills to make widespread and reliable EV charging infrastructure a reality. Additionally, a comprehensive database of these skilled and credentialed professionals must be created so that those in charge of building and maintaining new EV charging stations know where to turn when they require maintenance.

The initiatives brought forth to fund and support new EV charging stations are part of the larger push for a greener

future for the United States. Wider EV adoption is not only a critical component of the country’s transition to clean energy but also a cornerstone of the Biden administration’s campaign that has remained a core focus of its time in office.

For instance, the Bipartisan Infrastructure Law has set aside $2.5 billion for the Charging and Fueling Discretionary Grant Program to provide funding for strategic EV charging infrastructure plans through two distinct avenues. The first, Corridor Charging, will provide EV or alternative fueling infrastructure along designated alternative fuel corridors. The second, Community Charging, seeks to install needed EV charging and alternative fuel infrastructure near public roads, schools, parks, and public parking spaces while also targeting rural areas that have, until now, been deemed “charging deserts.”

The current administration is aware that for the United States to be a leader in the EV revolution, it will need to have a keen eye tuned to the charging infrastructure. The federal government is also aware that by investing in clean energy initiatives, a robust EV charging infrastructure, and EV adoption, they are helping to build economic growth and a new job market.

Supporting EV adoption and the bolstering of the EV charging infrastructure creates ample opportunities in several job sectors, including engineering, construction, IT, cybersecurity, and networking. Plans to expand the infrastructure also aim to help unlock new opportunities for the manufacturing sector, as new parts, electrical components, and skilled installers will be required to meet the administration’s goals. Moreover, a greater number of ancillary jobs and entrepreneurial ventures will also be necessary to support an expanded EV charging infrastructure, from those who create new EV-adjacent software programs to fleet management companies.