FLOORS & FLATWORK

HOW PHAZE CONCRETE USED AN INNOVATIVE TOOL TO ‘BURN

THE EDGE’

LEVEL FLOORS STEP 1: RECOGNIZE THE SKILL March/April 2024

SUPER FLAT &

THE

INDUSTRY’S FIRST VARIABLE-RATIO MIXING SYSTEM FOR 2-COMPONENT FLOOR COATINGS

MEET YOUR NEW MIX STATION

FREES UP LABOR FROM MIXING

ELIMINATES MIX ERRORS

MIXES UP TO 120 GALLONS PER HOUR

SUPPORTS FULL RANGE OF RATIOS FROM 1:1 TO 6:1

REDUCES MATERIAL WASTE

MAXIMIZES MATERIAL WORKING TIME

REMOTELY MIX UP TO 250 GALLONS PER CHARGE WITH ON-BOARD, HIGH-CAPACITY LITHIUM BATTERY –OR–

IT TO THE FLOOR! USE IT AS A STATIONARY MIX STATION

TAKE

SEE TRUMIX XT IN ACTION graco.com/TruMixXT MADE IN THE USA WITH GLOBAL COMPONENTS

©2024 Graco Inc. Form No. 3J0612 Rev. A 1/24 Printed in U.S.A. All brand names or marks are trademarks of their respective owners.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 3 FEATURE 14 ‘Concrete Is Cool’ How skateboarders turned concrete craftsmen accomplished award-winning concrete work in a Washington state skatepark. HOW TO 22 Getting Started with Super Flat & Level Floors The first step in super-flat floor work is recognizing the skill required. Let’s go over the elements involved. SPOTLIGHT 18 World Of Concrete Wrap-Up A collection of news and annoucements from the show. DEPARTMENTS 4 Editor’s Letter 6 New Products 12 Product Focus Concrete Saws 28 Product Focus Vacuums & Dust Collection Systems 42 The Last Placement FORM YOUR BUSINESS 38 Monolithic Concrete Placements Drive Efficiency If completed with the right equipment and considerations, contractors can reap the benefits without sacrificing quality. WHAT’S INSIDE MARCH/APRIL 2024 | Issue 2, Volume 26

photo courtesy of Operative Plasterers’ & Cement Masons’ International Association

Cover

above provided by Phaze Concrete Image provided by Grindline Skateparks Inc. 8 Floors & Flatwork: Burn The Edge How an innovative tool allowed the concrete professionals at Phaze Concrete to producte high quality edge results. Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Concrete Contractor (USPS 021-799, ISSN 1935-1887 (print); ISSN 2471-2302 (online) is published six times a year:January/February, March/April, May/June, July/August, September/October and November/December by IRONMARKETS, 201 N. Main Street, Ste 350, Fort Atkinson, WI 53538. Printed in the U.S.A. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Send address changes to Concrete Contractor, PO Box 3605 Northbrook, IL 60065-3605 March/April 2024, Issue 2, Volume 26 One year subscription to non-qualified individuals: U.S. 1 year: $35, 2 years: $70. Canada & Mexico 1 year: $60, 2 years: $105. All other countries 1 year: $85, 2 years: $160 (payable in U.S. funds drawn on U.S. banks). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International) Printed in the U.S.A. Published by: IRONMARKETS 201 N. Main Street Ste 350 Fort Atkinson, WI 53538 (800) 538-5544 • WWW.IRON.MARKETS WHAT’S ONLINE Thalle Industries Mixing it Up for Charity Ready-mix supplier, Thalle Industries decided to display its support for local non-profits on its two new concrete mixer trucks.. https://CONC.me/mz22unry COVER STORY

Photo

Productivity & Battery Power Reigned at World of Concrete

They can increase efficiency. They can integrate some of the most innovative ideas this side of green concrete. They can redesign systems to be safer, more userfriendly, decrease the working noise, etc. For me, all I saw when walking the halls of World of Concrete was productivity. Productivity not only for the contractor but from the work the manufacturers and exhibitors put in throughout the year(s).

True, one would have been able to find new tools and equipment to help the construction professional be more productive at every show, but the industry has been slowly pulling away from the pandemic years. Allow me a bit to walk through my week and attempt to explain why I think a “productive” World of Concrete is important for the construction industry.

This year’s show marked the its 50-year anniversary. Join us in celebrating year 51, World of Concrete 2025 is scheduled for January 21-23 in the Las Vegas Convention Center with educational sessions starting on January 20.

This year hosted nearly 60,000 registered construction professionals. According to the show runners, that’s a 23% increase in attendance from the year prior. Anecdotally, people were saying that the numbers felt like “pre-COVID.” Economically, this points to a good sign. I sat down with Dodge Construction Network, chief economist Richard Branch. On top of their forecast, it seems to allude that not only are contractors like yourself out there eager to reconnect with fellow pros, but very interested in looking at more products and equipment to increase efficiency—or be as productive as they can.

A team from Wisconsin won the SPEC MIX BRICKLAYER 500 Championship for the second year in a row. Michael Schlund and tender Aaron Kowalski laid 752 bricks in one hour. They took home a trophy, cash, and a brand-new Chevrolet Truck.

The ever-increasingly successful Concrete Industry Management auction raised $1.8 million for their program providing funding for concrete industry management programs in Chico State, Middle Tennessee, New Jersey’s Science and Technology, Texas State, and South Dakota State. Donated auction items included a concrete mixer truck from Mack Trucks Inc. and Revolution Concrete Mixers, a Peterbilt & ConTech mixer truck, a concrete pumper donated by Alliance concrete Pumps & Pape Kenworth, and many others.

If lucky enough to walk by during the ceremony, attendees were even able to see a marriage in front of the WOC logo installation in the grand entrance of the Center. A celebrity minister from Las Vegas officiated the wedding of Patricia and James Estrada on January 24 at noon. Quoted in the official announcement, James says, “I’ve been married to concrete for 30 years, so it was finally time I married Patricia. It felt like the right moment and right place to share the blessings my career has provided.” If you’re readers or not, congrats you two.

Read more on some World of Concrete happenings on page 18 in this issue.

That’s enough from me. Until next time, stay safe out there.

ADVISORY BOARD

Kim Basham

KB Engineering Cheyenne, Wyo.

James Baty II

Concrete Foundations Association

Mt. Vernon, Iowa

Dennis Purinton

Purinton Builders, Inc. East Granby, Conn.

Jim Cuviello

Cuviello Concrete Polished | Stained | Crafted Stevensville, Md.

Chris Klemaske

T.B. Penick & Sons, Inc. San Diego, Calif.

EDITORIAL Editor.......................................................

Managing Editor

Junior Editor Merina Shriver mshriver@iron.markets

AUDIENCE............................................................................

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director Marcy Murphy

ADVERTISING/SALES

Brand Manager, OEM & Construction Nikki Lawson nlawson@iron.markets

Sales Representative Patty Maroder pmaroder@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer .................................. Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP Audience & Marketing Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

GM, Online & Marketing Services Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services .......... Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816

circ.ConcreteContractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager, OEM & Construction ........... Nikki Lawson nlawson@iron.markets

EDITOR’S LETTER

4 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete WWW.FORCONSTRUCTIONPROS.COM/CONCRETE Published by IRONMARKETS 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.iron.markets

Jonathan

Kozlowski jkozlowski@iron.markets

Gigi Wood gwood@iron.markets

and copyrighted 2024 by IronMarkets.

rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

Published

All

JONATHAN KOZLOWSKI, EDITOR JKOZLOWSKI@IRON. MARKETS

As a small business owner, you can’t escape your to-do list. That’s why Progressive makes it easy to save with a commercial auto quote, so you can take on all your other to-dos. Get a quote in as little as 6 minutes at ProgressiveCommercial.com

Progressive Casualty Ins. Co. Coverage provided and serviced by affi liated and third-party insurers.

DICA Ground Protection Products

• SlatTrax is a linear roadway system that provides vehicle access to worksites while protecting the ground. Approximately 100 ft. of pallet-based DIY Trax with ratchet straps can be deployed or retrieved manually in 15 minutes or less. The compact, self-contained systems require less space for transport and storage. Steel Grapple Pallets are an option that allows the crew to use their grapples to move the system when forks are not available.

• AlturnaMATS and VersaMATS are ground protection mats are also made of HDPE plastics, they are durable and resistant to breaking, cracking, splintering, delaminating and absorbing moisture. These mats can be used to create stable work platforms, access roads or temporary parking areas in construction sites.

https://CONC.me/gfx3605q

Western Global FuelCube

Western Global has announced upgrades to its FuelCube onsite fuel tank. The FuelCube now offers four-way forklift pockets that allow it to be moved around the work area with a forklift when empty. The new design uses less metal than the previous model, making the 250- and 500-gal. versions light enough to be relocated with a pallet jack. The upgraded FuelCube comes in 250-, 500-, 1,000- and 1,800-gallon sizes. Its 110% double-walled containment eliminates the need for a secondary basin. The FuelCube also offers a removable inner tank for cleaning and inspection. It features corner brackets that allow users to save space on the jobsite by stacking it up to two-high when empty. Additionally, a lockable equipment cabinet increases security for the fuel supply.

https://CONC.me/c4n15ds7

Komplet K-IC 70 Impact Crusher

The Komplet K-IC 70 impact crusher enables contractors to recycle waste materials on jobsites. The K-IC 70 can be used for crushing and stockpiling in diverse recycling applications including construction and demolition waste, asphalt paving, clay and concrete bricks and blocks, porcelain, ceramics, glass and other solid waste. This machine is powered by a 100-hp Doosan Tier 4 final engine. A 25- x 20-in. jaw allows the crusher to handle different types of materials during use.

The K-IC 70 is equipped with a vibrating feeder with chamber level sensor and rubber pads bolted on metal track chains for safe transportation. The compact size and intuitive operation make each of these machines applicable for contract crushers, independent rental houses and small-scale operators.

https://CONC.me/cht4i4yf

Allmand Bros Hybrid LT-Series

Allmand Bros’ new Hybrid LT-Series a concept hybrid light tower is equipped with a Vanguard lithium-ion battery, allowing for all-night operation without noise pollution. Powered by smart technology, an electronic controller gives users immediate runtime feedback, allowing them to reduce their carbon footprint through light-level settings. Allmand also offers Maxi-Power generators, making power accessible in remote work areas. The entire generator line, which includes the MP8XR, MP15XR, MP25 and MP45, is manufactured in Nebraska. The generators are used in oil fields, drilling rigs, special events and music festivals because they are designed to provide reliable, quiet and clean power.

https://CONC.me/nfj71ms2

Blastcrete X-40D Swing Tube Piston Pump

Blastcrete Equipment’s X-40D trailer-mounted concrete pump system provides high-volume pumping in a compact design for a variety of applications and rounds out the Blastcrete product line with a low-maintenance, versatile pump capable of handling a range of rock sizes. Capable of handling aggregate mixes up to 1.5 in., the X-40D incorporates a PULSAR piston pump from Mecbo to deliver high volume in a compact design. The 6-in. x 39-in. (150 mm x 1,000 mm) swing tube piston pump is supported by a rugged receiving agitator to keep the concrete mixed and ready for pumping. The X-40D pump features 1,000 psi of piston face pressure, with a 5-in. discharge and the ability to put out 40 cu. yd. of concrete per hour. The 7,080-lb. pump and integrated trailer can be hauled to jobs that range from creating piers for overpasses to backyard projects such as installing in-ground swimming pools.

https://CONC.me/zk8pal25

6 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

NEW PRODUCTS

ACI Resource Centers — Southern California, Chicago/Midwest, and Mid-Atlantic

Helping meet the increasing need for ACI knowledge through hands-on training, educational offerings, and on-demand access to ACI Certification programs. Designed for the trades, contractors, inspectors, designers, and engineers, ACI Resource Centers are a great fit for new-hire onboarding, employee education, and customer or member training.

Learn more at ACIResourceCenters.org

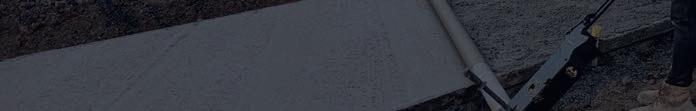

Floors & Flatwork: Burn The Edge

How an innovative tool allowed the concrete professionals at Phaze Concrete to produce high quality edge results.

@bannafarsai - stock.adobe.com COVER STORY » BY JONATHAN KOZLOWSKI, EDITOR 8 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

One of the more challenging aspects of working on a larger slab project like a grocery store is matching the edging of a new placement to the existing slabs. A ride-on machine can weigh upwards around 2,600 lbs. which limits how close an operator can get to the edge. While there may be 50 ways to finish edges, a keen eye brought a non-traditional method to the job—without going manual.

John Beagley founded John Beagley & Sons roughly 30 years ago along with a handful of 8 people including his 16-year-old nephew, Leroy Johnson—who now sits as vice president of operations. Much like many contractors do when they start, they began with residential projects. In the early 2000 they became certified as a Walmart finisher for new stores. From there-on, they grew.

After changing the company name to Phaze Concrete in 2009, that small company has grown to over 400 employees. The company covers a massive territory—everything west of the Mississippi, with offices in Montana, Denver, and headquarters in Cedar City, Utah.

“What stands us apart is we’re always cutting edge,” says Johnson. Their niche is working on the larger slabs, buildings over 1 million sq. ft., parking structures, tilt-up construction, and more. The company has a significant presence in the ACI community, Johnson himself sits on a couple of ACI boards (360 and 380), the owner sits on a handful of committees like 317, 304, 303.60 as well as a number of ASTM groups. Over the years, they’ve won several awards from SSI.

What can only be a testament to the quality of their work, they’ve also never advertised. Impressively, their growth has been mainly from word of mouth.

Another unique feature of the company, Phaze also uses a fully accredited four-year mentorship program providing students education on basic CAD designs, estimating skills, managerial skills, and more. The program has been a powerful tool. “One of the things we do is make sure [the students] graduate with a GED…and an on-site work ethic that most people don’t have,” adds Johnson. On average, they take on 12 to 20 students a year. They had 8 in 2023. According to Johnson, roughly half go on to start their own businesses or work elsewhere. In fact, Johnson’s son and daughter went through the Phaze student program. His son is now a superintendent running a team. His daughter draws CAD and conducts estimates.

In a way, the mentorship addresses the skilled labor shortage. Many of the students continue afterward and work for other companies. The goal is improvement. Johnson explains that the owner’s goal is that if someone has a better offer or a way of bettering their life, he feels like he’s been successful. Adding that, “he encourages every person to better their circumstances as they can.”

AN OPEN SLAB

Phaze was hired for a new build project for CostCo—a client with high standards for their concrete. This standard required them to burn the edge of the concrete placed to match the rest of the slab with FF / FL specs at 40/35 using 4,000 psi concrete supplied by Knife River.

“It’s always a challenge,” says Johson.

While you can finish most of the slab with a 2,600 lb. ride-on machine–except for the edges. Roughly about 6-8 in. from the joint gets black from the weight of the machine. The trick here at the edge

is ensure the edge is blended to the rest of the concrete and the neighboring slab, which makes the joints stand out.

Offering it up as some friendly advice, Johnson explains, “When your lights are on, and you see a nice slab right up to the cold joint and you have 8 in. on one side that’s not black, that’s the challenge. They all hate it…all the grocery stores that we pour that have finished slabs—that is one of their biggest pet peeves.” While Phaze was successful for years using walk-behind; it takes time and a skilled finisher.

For the CostCo job, Phaze had 26 workers on the project with 13 each on the finishing and laying out teams. Work started at 2 a.m. in the morning with each pour working a 20,000 sq.ft. (roughly) 6-in. deck. The schedule was placement from 2 to 7 a.m., finish until noon, and then saw cutting from noon to 6 or 7 p.m.

As packed as the schedule may have been, timing is (and will forever be) everything.

As an open-air slab, a portion of the building was constructed which placed some of the concrete exposed to the sun—creating yet one more challenge to finishing process. As Johnson explains, sun and/ or shadows on a slab can slow down the hydration of the concrete and pushing different set times. Shadowed areas can leave a dark streak in the concrete. “It can make it hard to burn off (also known as ‘blackening’) because you don’t get a consistent burn on the top of the surface,” explains Johnson.

They followed their standard process. After screeding, taking a straight edge, then float it twice until the initial set starts. After, they finish 12 in. away because the ride-on pans can finish that close. While this process is going on, they’ll run pans, clean up machines, and burners alongside a 3 ft. walk-behind to blend.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 9

Photo by Phaze Concrete

It’s this last step where they opted to change tools. Having experimented with the tool on smaller pours previously, this was first large project Johnson brought a Kipper 11.5 to help blend the edge. As Johnson explains it, they were able to use the tool for that 12-in. area and worked right up to the edge with half the work. “It was easy to control with little bit of water and finish it right up to the edge,” he says.

He adds that with the tool, “You have quite a bit of a window to finish, but with a 2-ft. machine if you get on it too wet, it leaves trowel marks. With this little Kipper you just lift up on it a little bit, feather it in and come back when it’s a little more ready.”

Blackening the concrete happens when a metal blade darkens the surface. If the process isn’t done just right, the surface will remain a lighter tan and end up spotty. The variation between black and dark gray will cause your edging to look un-uniformed.

Before blending on the CostCo project, Johnson experimented with the Kipper 11.5 elsewhere. One for some trench drains where he gave the tool to his son to work around the drains of a 200,000 sq.ft. building, creating a ton of piping and a pain to finish. While not necessary to burn the edges at that time, they wanted to put the tool to the test. Knowing the need to burn the edge and proper blending will be vital to the customer, the results convinced him to bring it to other jobs.

Ultimately, there’s a sense of optimistic productivity with the tool as it helps nearly anyone to produce proficient work. “The bright spot of it is there is a way to get those edges to look a little nicer,” Johnson says. “To give your client a better product without having to have as high a skill set as you normally would have to do to get that perfect. I can take a guy that’s a pretty good finisher, [but] that I would never put on those edges, give them 20 minutes of education, let them go and make those edges look like a professional.”

10 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete COVER STORY CONTINUED

Images courtesy of Phaze Concrete

AD

CONCRETE SAWS

The Norton Clipper

C914P Compact Push Saw

With extreme reliability, portability, and strong performance, the new full featured Norton Clipper C914P walk-behind saw is redefining the compact concrete saw class.

The powerful Honda 9HP engine, 14 in. maximum blade capacity, and the strongest chassis in class make for the fastest and straightest cuts every time. Designed for easy transportation, simple operation, and low maintenance, the C914P is the right choice for contractors and rental.

The C914P is equally at home cutting concrete, sidewalks, asphalt, or decorative concrete making it the perfect saw for any job.

https://CONC.me/r17wisy6

U.S. Saws FSB-150H Hydraulic Walk-behind Saw

The FSB 150H hydraulic walk-behind saw is suited for concrete and asphalt cutting applications such as street repair and utility work.

• Heavy-duty frame design reduces vibration for a fast, accurate cutting

• Compact size makes transportation easy

• No exhaust fumes suited for use with interior applications, trench cutting and restoration

https://CONC.me/p4vxox

The 80V Max XGT Brushless 14-in. Power Cutter by Makita

Makita U.S.A. Inc.’s 80V max (40V max X2) XGT Brushless 14-in. Power Cutter (model GEC01) is powered by two 40V max XGT batteries and delivers a performance comparable to a 75.6cc gas power cutter, giving users a true gas replacement for cutting concrete, masonry, and metal.

The 14-in. wheel diameter allows for single pass cuts up to 5 in. deep in various masonry and metal materials, and the integrated allaluminum wheels are ideal for floor cutting applications. Additional features include Active Feedback-Sensing Technology, an electronic feature that turns the motor off if wheel rotation is suddenly forced to stop. And it’s equipped with an electric brake, which allows the tool to be repositioned faster for maximum productivity.

Cutting concrete requires OSHA Table 1 Dust Management and the 14-in. Power Cutter is able to meet those requirements with an integrated water delivery system with an easily adjustable flow knob that continuously feeds water to the cutting surface. The integrated water delivery system can be easily connected to a Makita 2.6 Gallon Pressurized Water Tank (988-394-610, sold separately) to allow for a longer cutting duration.

https://CONC.me/c05fq6

Hilti DSH 700-22 Cut-off Saw

Hilti offers the DSH 700-22 rear handle, cordless cut-off saw for concrete, metal and masonry projects. This battery-powered saw is compatible with the Nuron battery platform. Unlike gaspowered saws prone to fuel mix issues, the DSH 700-22 does not generate fumes during use. A cordless design promotes mobility around congested worksites.

• Dimensions: 29.1-in L x 11.4-in W x 13.8-in H

• IEC battery operated

• Arbor size: Option 1:1-in; Option 2:20 mm

• A-weighted emission sound power level: 108 dBA (according to EN 60745)

https://CONC.me/si2dhx

Milwaukee Tool’s MX FUEL 6-in. Green Concrete Saw

The MX FUEL 6-in. Green Concrete Saw will join the system providing easier, more accurate cutting of control joints. This solution allows users to cut 1 1/2-in. depth on a 6-in. blade, maximizing users’ productivity. This solution delivers instant starts with no gas headaches, no regular maintenance, and zero emissions providing a safer workspace indoors and outdoors. Milwaukee is excited to continue revolutionizing the light equipment market with their groundbreaking cordless system and provide concrete contractors with solutions that increase performance and productivity, removing the frustrations and limitations of gasoline and power cords.

https://CONC.me/h08spg

12 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

Minnich Flex Shaft Vibrators: The Experts Choice for Solid Results

Minnich Flex Shaft Vibrators

Built to exceed your expectations and outperform the competition. With results in mind, our vibrators are engineered for control and durability, ensuring a smooth and flawless pour every time. With more control over your results and a longer lifespan than other options on the market, our flex shaft concrete vibrators are the perfect choice for the professional looking to take their work to the next level.

‘Concrete Is Cool’

How skateboarders turned concrete craftsmen accomplished award-winning concrete work in a Washington state skatepark.

As the first-place winner in the American Concrete Institute’s (ACI) 2023 Excellence in Concrete Construction Awards/ Decorative Concrete Category, the Torguson Park skatepark demonstrates concrete’s potential for visual appeal and much more. Opened in 2021 in North Bend, Washington, the cast-in-place concrete facility meets high standards for safety, requires little maintenance and provides a fun and challenging environment for its users. The old 6,000 sq.-ft., single-bowl-style facility was replaced with one nearly 13,000 sq.ft.

GRINDLINE

The park was built by Grindline Skateparks Inc., a Seattle-based skatepark construction company. The Grindline team is comprised of former professional skateboarders turned concrete craftsmen, which puts them in touch with the needs of their parks’ users. Grindline worked with the community to gather input for the new design and began construction in 2020, staying on schedule even during the COVID-19 pandemic.

Ready-mixed concrete allowed the team to design and build any shapes

they desired. The earthy color palette of the concrete, achieved using integral color, was inspired by nearby Mt. Si, which can be seen from the facility. The skatepark was constructed using the shotcrete method, which helped achieve the smooth-flowing transitions and curves of the design.

“The complexities associated with building a skatepark don’t have to do with its structural system, as people sometimes assume,” says James Klinedinst, the senior project manager for Grindline. “Skateparks are non-structural slabs-on-grade—a

14 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

Grindline Skateparks Inc.

Bio-based PoreShield makes concrete invincible against damaging salts and moisture for 10+ years, without the drawbacks of expensive toxic sealers.

Learn how PoreShield protects from the inside by visiting PoreShield.com.

very familiar type of construction. We use earthwork to provide the shape and support of the concrete skating surface. The complexities have to do with making the surface smoother than what is required by many other types of concrete construction.”

When constructing a new skatepark, earth is shaped and then formwork is installed. “The formwork used for skateparks is unique compared to other types of concrete construction,” says Matt Fluegge, chief executive officer for Grindline. “We don’t use panels, since every part of a skatepark is geometrically unique. We custom fabricate radii out of plywood and board lumber.”

After formwork is in place, concrete is installed, 6-in. thick in areas requiring the shotcrete method, and 5-in. thick in the conventionally placed slab areas.

As with all concrete construction, crews must make sure they are using installation methods that will prevent

cracking. Since wide expansion joints containing joint filler would create too much roughness on the skating surface, the team ensures smoothness first by sequencing pours in such a way as to create seams in locations that might be prone to cracking, and second by saw-cutting 1/4 in. control joints in the remaining critical locations.

Finishing methods are also important. “We hand trowel an airentrained mix, which is not standard,” says Klinedinst. “Typically, air-entrained mixtures are broomed or textured. It requires a technique learned over years to hand-trowel in a way that releases the trapped air and prevents delamination.”

Having consistency in the concrete mix is also critical. “We’ve used a tried and true, off-the-shelf shotcrete mix from Heidelberg Materials for years. And while we have that single, preferred mix, because we build parks all over the country, we also have to

take into consideration variations due to regionally available aggregates and other local materials,” says Klinedinst. “We address this by sending our suppliers a cut sheet that breaks down aggregates and other mix contents.” The concrete mix included Heidelberg Materials’ EcoCemPLC portland limestone cement, which lowers the carbon footprint by about 10%.

CONNECTING SKATERS WITH CONCRETE JOBS

The Grindline team is not the only organization to discover that skateboarders and concrete are a natural fit. A program called Skate4Concrete points passionate skateboarders who are looking to build their careers toward industry opportunities.“Whether an individual is college-bound or not, there’s a way to make a mark on the skateboarding community and play a bigger role in the sport. Skate4Concrete

FLATWORK/SLAB CONTINUED 16 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

shares information on concrete construction and supply jobs, along with information on certification. It even connects skaters with details on degree programs,” says Crystal Howard, founder of Project Cornerstone and Skate4Concrete.

Corey Rosson, senior sales representative, Pacific Northwest Heidelberg Materials, works in the building materials industry but has been a skateboarder since he was 10 years old. Rosson became aware of Skate4Concrete when Heidelberg Materials North America mentioned the program on social media channels. “It’s exciting to see Skate4Concrete offering a different approach to career development. Often, three main routes come to mind for young people coming out of high school: college, trade school or the military. Having an additional pathway that connects people to work—work that’s built around something they already love—is a real benefit,” says Rosson.

A major initiative of Skate4Concrete is an internship program that had its first student

intern in the summer of 2023. Interns spend three months being part of a building team for a skatepark and, one day a week, gain exposure to various aspects of the concrete industry by touring facilities such as concrete and/or cement plants and quarries. They also spend time with city officials who are managing the skatepark construction project. As a joint effort between Skate4Concrete, California State University Chico and skatepark designers, it is currently available only to Concrete Industry Management program students.

“Nominated from our Washington Excellence in Concrete Construction awards program, Torguson Park competed and won at the highest level of concrete competition: ACI’s International Excellence in Concrete Construction awards program. This recognition has opened doors for our industry locally as we conduct tours and meet with officials to present them with their awards. Over the course of only one year, concrete skateboard parks have achieved fantastic

Team Members:

• Owner: Si View

awareness of our industry, our product, and our connection with community, and Skate4Concrete has placed a highly regarded concrete curriculum in our high schools and community colleges to attract the next generation of workforce that will lead our industry. Torguson isn’t just another skateboard park; it’s now an ambassador for our industry and clearly says, ‘concrete is cool!” says Bruce Chattin, Executive Director, Washington Aggregates & Concrete Association and Washington ACI Chapter.

Metropolitan Park District

• Architectural Firm: Grindline Skateparks Inc.

• Engineering Firm: Mackay Sposito

• General Contractor: Grindline Skateparks Inc.

• Concrete Contractor: Grindline Skateparks Inc.

• Concrete Supplier: Heidelberg Materials (formerly Cadman Inc.)

Lori Tiefenthaler is the senior director of marketing for Heidelberg Materials North America.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 17 POWER AND BRAINS. JUST UNSTOPPABLE. Expertly engineered to redefine industry standards, one Brokk robot at a time. Brokk Inc. | Monroe, WA | 1-360-794-1277 | info@brokkinc.com | www.brokk.com

World of Concrete Wrap-Up

DEWALT POWERSHIFT

DEWALT launched its POWERSHIFT electrified equipment system for concrete jobsites. Designed to meet the needs of concrete professionals, the electrified line will allow users to transition away from gas-powered equipment. The system, made up of six concrete tools, uses the same DEWALT POWERSHIFT 554 WH battery and high-speed charger across all tools. It is backed by DEWALT’s portfolio of complimentary tools, accessories and technology.

https://CONC.me/f5gwv522

THE MAKINEX MS-150 MIXING STATION AND MIXER

The MS-150 Mixing Station and Mixer from Makinex for self-leveling cements, compounds, and epoxies is capable of blending up to six bags in seven minutes, all while ensuring precise pouring and reduced waste.

The MS-150 Mixing Station and Mixer from Makinex for self-leveling cements, compounds, and epoxies is capable of blending up to six bags in seven minutes, all while ensuring precise pouring and reduced waste. The tool saves time and labor on flooring projects, and curbs operator fatigue and injury thanks to its ergonomic lightweight design. Meticulous mixing and pouring within the single unit is practically guaranteed.

It features a removable vacuum attachment for spills and dust suppression, helping to reduce ‘construction dust’ - airborne particles - from construction activities.

https://CONC.me/4msgjgxi

ACPA’S PUSH FOR SUSTAINABLE INFRASTRUCTURE

The American Concrete Pavement Association announced its new responsibility to help make roads and buildings more sustainable, including:

• Release of a report titled, “How Agencies can Reduce Costs by Improving the Competitiveness of their Bid Environments.” The report details industry research, including research performed by the MIT Concrete Sustainability Hub (CSHub) that examines how the split of Department of Transportation (DOT) paving expenditures between industries impacts paving unit costs. Findings include the fact that, as inter-industry competition increases, unit costs of both concrete and asphalt paving materials fall significantly—particularly those of concrete. For example, if a state with a low concrete market share (e.g., 1%) were to increase its concrete market share to 25%, it would lower concrete and asphalt paving material unit costs by around 29% and 8%, respectively. The ACPA report also includes recommendations on how to start a competitive paving program.

• ACPA’s participation in the Reduced-Carbon Concrete Consortium (RC3). The RC3 will disseminate funding information, facilitate application submission, provide technical assistance, and enhance contractor preparedness with critical next steps like Environmental Product Declarations (EPDs).

• A growing library of long-life pavement case studies. .

The press conference also covered the International Grooving & Grinding Association’s white paper titled “Diamond Grinding: A Safe, Sustainable, Quiet and Cost-Effective Solution to Better Roadways.” The IGGA is affiliated with the ACPA in a partnership known as the IGGA/ACPA Concrete Pavement Preservation Partnership.

https://CONC.me/hy8dhnmk

18 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete SPECIAL REPORT » COLLECTED BY JONATHAN KOZLOWSKI, EDITOR

NEW FOR 2024...

Ligchine’s ScreedSaver® PRO PLUS

LIGCHINE has over 15 years of experience building laser guided screeds right here in the USA. The PRO PLUS has SCREEDSHIFT™ technology that allows the operator to move the screed head around obstacles and penetrations without rotating the head. With an increased auger size, longer boom reach and wider head, the PRO PLUS is highly productive in all applications from warehouse floors to exterior multiple slope pavements. Achieving FF/FL specifications is not only possible but repeatable on a daily basis.

LIGCHINE.COM

812-903-4500

• 18 ft boom with an 11’ High Performance screed head

• Powered by a 24 hp Yanmar diesel engine

• SCREEDSHIFT™ Pivoting Frame up to 12˚

• Controlled by wireless remote

• 200 sq ft coverage per screed pass

• 20 gallon water tank/sprayer

• Transport with a ¾ ton truck and trailer

• Rotating undercarriage for versatility and speed in smaller or congested areas

TRENDS & CONVERSATIONS

By Lori Ditoro, editor of EquipmentToday

Our team’s booth visits and the equipment and technology at the show cover these trends and many more.

• A move to electric power, particularly for equipment used indoors or other areas where exhaust might be a safety risk

• Swappable batteries to extend equipment usage

• Cordless tools (specifically featured by Milwaukee Tool)

• Using technology to improve and simplify tasks for operators

• A desire to provide an entry point for small concrete contractors

• Our team’s booth visits and the equipment and technology at the show cover these trends and many more.

Editors Note: Read Lori’s account of the show including updates on Liebherr, Toro, KUBOTA, Ignite Attachments, Bobcat, FleetWatcher, Command Alkon, Trimble, DEVELON, B2W Software, Topcon Positioning Systems, Vanguard Commerical Power, and FARO.

https://CONC.me/3cv121i2

PCA’S CONCRETE & CONSTRUCTION ECONOMY OUTLOOK FOR 2024

In his presentation during the show, Ed Sullivan, the Portland Cement Association’s (PCA) Chief Economist and Senior Vice President of Market Intelligence, predicted that the U.S. economy may “gradually weaken” during the first half. Yet recover, slowly, in the second. Despite the slowdown, he says that the chance of a recession is unlikely. Some of the factors, he explains included the end of COVID-19 relief programs, the lagged impacts of monetary policy, and credit tightening.

https://CONC.me/uhju6aq1

WHO RECEIVED A 2023 GOLDEN TROWEL AWARD?

By Jeff Rogers, director of engineering at

The Face Companies

The Golden Trowel has been presented for 35 years to contractors who produce the world’s flattest and most level floors. They are awarded in several different categories, based on how the floor was initially struck off, how wide the floor castings are, how much shakeon hardener or steel fibers were used, and other factors that influence flatness and levelness. Golden Trowel Gold Plates are awarded to the winner in each category, while Golden Trowel Silver Plates recognize truly outstanding entries that achieved exceptional results but did not dominate the category.

BOSCH RELEASES NEW CORDLESS TOOLS & ACCESSORIES

Bosch Power Tools will debut more than 30 new cordless products in 2024, ranging from impact wrenches and inspection cameras to Bulldog Tough SDS-plus drill bits, many aimed at concrete applications.

https://CONC.me/szqfdeph

The best floor in the world back in 1990 wouldn’t even be considered for a Golden Trowel today. Of the 12 Gold and Silver Trowels awarded during this year’s World of Concrete, 10 were from Brazil, China, and Thailand, and only 2 were from the USA.

https://CONC.me/54tnegjm

20 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete WORLD OF CONCRETE CONTINUED

No matter how hard the job gets, JLG® is built to help you stand tough through it all. High-capacity telehandlers are engineered to weather the worst while delivering state-of-the-art tech including Smart Load technology that keeps focus up and downtime down. Never settle. Leave your mark. LEAVEYOURMARKWITHJLG.COM YOUR WORK STANDS THE TEST OF TIME. YOUR EQUIPMENT SHOULD TOO.

Getting Started with Super Flat & Level Floors

The first step in super-flat floor work is recognizing the skill required. Let’s go over the elements involved.

Be in guidelines or requirements, all details of what a job requires should be found within the scope of work. When there’s a specification on the floor flatness (FF) and floor levelness (FL), Concrete Contractor spoke with Nick Demonte, ITF cement mason coordinator from the OPCMIA to find out how one begin working toward achieving those higher numbers.

To start, the biggest criteria is understanding the concepts involved. OPCMIA trainings start with a demonstration of determining the tolerance of a slab by using 10 ft. straight edge. While

this straight edge does not correlate to the FF numbers, it provides a visual effect of the tolerances of the end goal. Demonte explains. “If you put a 10 ft. straight edge on the floor, if it teeter-totters in the middle, you know that obviously you have a bump in the middle. That tolerance could be an eighth of an inch, it could be a quarter of an inch, it could be a half of an inch. That’s how the gauge the floor flatness.” While there may be some nuances, put simply the higher the FF, the flatter the floor. If attempting to achieve an FF 25 (a quarter of an inch depth over 10 ft.)

one should be able achieve that by a regular straight edge methods with a bull float. Higher numbers like FF 50 would allow an eighth of an inch over 10 ft., and FF 100 would be a 16th of an inch over 10 ft.

At least that’s how it was once done. Today, contractors have some more modern types of measuring devices to use. For one, the Dipstick Profiler from Face Companies developed by Allen Face. Contractors can also use an inclinometer to measure the floor and produce a profiler graph, or utilize a 3D scanner.

22 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete HOW TO BY JONATHAN KOZLOWSKI,EDITOR

All

images provided by Operative Plasterers’ & Cement Masons’ International Association

FINISH TOUGH SURFACE PREP JOBS FAST

Tackle the most demanding removal jobs with SMITH FS351 DCS Heavy-Duty Scarifiers.

SMITH FS351 DCS heavy-duty scarifiers are ideal for challenging removal applications such as leveling floors, grooving, and removing thick epoxy coatings.

PRODUCT FEATURES:

¡ Remove path up to 15 inches wide

¡ Precisely control cut depth with SMITH’s electronic DCS Depth Control System

¡ Self-propelled with variable speed drive for precise speed control

¡ Wide variety of cutters available, including PCD shaving drums

¡ Propane, Gasoline, and Electric models

AVAILABLE MODELS: © 2024 Graco Inc. 3J0220B 2/24 Printed in the U.S.A. Product covered by issued and pending patents, see graco.com/patents Gasoline 38 HP Kohler® EFI Propane 25 HP Kohler EFI Electric 20 HP 380/480v 3ph A GRACO COMPANY ®

MADE IN THE USA WITH GLOBAL COMPONENTS LEARN MORE AT SMITHMFG.COM/FS351DCS QuikCut PCD Shaving Drum DEPTH CONTROL SYSTEM

HOW TO CONTINUED

The introduction to the 3D scanner to this process helps contractors respond more proactively to the situation. “Prior to the 3D scanner, the only way you could measure the floor was after you had poured it,” says Demonte. “After you poured it, and you finished it, you got 72 hours to measure the floor within that timeframe. But using a 3D scanner and how technology has improved, we can hook the 3D scanner up and get a scan of that slab within seconds of all different types of points.”

With this technology, contractors would be able to recognize if an area was too high and correct it on-site as they’re pouring as opposed to later and grinding the areas down or filling them.

“That’s going to help production if we don’t have to come back and treat the slab in any kind of way…because these tolerances are hard to achieve it takes a special skill set to do that. It starts from the formwork and so on down the road – there are a lot of variables that move in there. Training is the biggest key to putting down super flat floors—training your eye to the finer details.”

One of the biggest keys here is recognizing the skill needed to ride a ride-on trowel machine: how and when to get it on the floor, when and why to use pans instead of floats, as well as gauging the angle of the blades.

CRITICAL DETAILS

• Forming

• How you pour the concrete

• The equipment used to finish; consider the setup and finetuning of the laser-guided screed; the patterns from the ride-on trowel machine and how they’re going to cross; the direction used with a vibrating screed vs bump cutter Polishing is another matter completely. If the floor will need to be polished, it’s important to consider the relationship between the finish and FF value. For example, depending on the finish some polish classes may need a certain tolerance. Demonte explains that many of the seminars they produce goes through the importance of trying to achieve those FF numbers when delivering a polished finish.

Timing and know-how is essential. Plan and keep track of the order of pours while noting shady vs areas more exposed to the sun. “There are a lot of moving parts about super flat floors. It’s not something that a contractor just takes on to try and see if they can get into this work,” says Demonte. “The best way to start—the easiest way to start is…reach out to your local [union].”

He recommends contractors is to do a little homework. The finishing industry has been working to make the language more universal so that the classification and levels of gloss are more coordinated. Part of that homework is also communication and being involved. If you’re the polisher for a job, attend the pre-conference meeting so you know what mix is used, how the floor will be finished—all the important details to achieve a quality floor.

24 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

Monolithic Concrete Pours Drive Efficiency For Concrete Contractors

How monolithic concrete placements can drive efficiency for today’s contractors.

Throughout history, many new processes have come along to improve how people achieve end results. These innovations— even those that eliminate just one step—often lead to dramatic increases in productivity and efficiency. In an ever-evolving industry, contractors innovate through the equipment they purchase and processes they adopt. When it comes to concrete, monolithic pours are one process that contractors can use to drive efficiency.

Monolithic pours streamline concrete work by pouring curb and gutter simultaneously with flatwork, instead of completing these pours one at a time. If completed with the right equipment and considerations, contractors can reap the benefits without sacrificing quality.

SAVINGS

A traditional pour most often requires curb and gutter work to be poured, finished and cured to outline the pavement area. Then, the crew returns at another time to pour and complete the flatwork.

A monolithic pour, or an all-in-one pour, improves efficiency by completing curb and gutter at the same time as flatwork. This process saves a considerable amount of time by completing the entire job with one pour instead of two, boosting productivity and the bottom line.

Driven to continually seek new ways

to keep up with ever-growing demand, more contractors are seeing the benefits of monolithic pours, especially for parking lots and streets. Contractors who streamline the most time-consuming aspects, such as hand-shaping curb and gutter, experience the most significant spike in efficiency and often double production. Just as the digital camera created a more productive photo development process, monolithic pours drive up efficiency for contractors.

PROGRESS

With a good crew, walk-behind curbing machines are capable to maintain the production pace found with a laser screed while eliminating the extreme physical labor and the need for large machinery for curbs. These machines consist of a handle attached to a metal drum that is connected to a hydraulic power source. The single-operator machine reduces the intensive manual labor of shaping curb and gutter while producing a consistent, high-quality result, even for operators with minimal experience. While these machines were originally developed for completing curb and gutter work on traditional pours, most can be modified to adapt them for use during monolithic pours.

Newer entries to this class of equipment incorporate battery power and a

The monolithic pour process allows contractors to improve efficiency by completing flatwork and shaping the curb and gutter at the same time.

All images provided by Curb Roller Manufacturing

design specifically created for monolithic pours. These machines combine the benefits of traditional walk-behind curbing equipment with lightweight portability to quickly move throughout the jobsite. Battery-powered walk-behind curbing machines offer easy maneuverability and transport due to their relatively small size and lack of cords and hoses.

Consider a contractor who was hired to install a large parking lot for a private company. The crew used a laser screed due to the sheer size of the project. They worked during the night to limit traffic interference and were able to pour about 2,000 yards of concrete pavement per night. However, they were only able to shape about 300-400 feet per night by hand. Investment in a battery-powered walk-behind curbing machine doubled that productivity to 700 linear feet per shift.

RESULTS

Laser screeds and walk-behind curbing machines are ideal for projects such as parking lots with large amounts of flatwork and multiple areas of curb throughout. However, a machine that can shape curb and gutter simultaneously with flatwork can be ideal for certain

26 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete FORM YOUR BUSINESS

Walk-behind curbing machines with monolithic kits and batteryoperated walk-behind curbing machines are two options that contractors may consider for a more streamlined process of handshaping curbs.

monolithic pour applications like street construction or replacement. Slipform machines are one of the more efficient solutions if and when the project matches the machine design parameters and there’s enough volume of concrete to justify their operation and overhead costs.

Some manufacturers offer custom drum options for hydraulic screeds. These drums can reach up to 16-ft. long and can be designed to match a specific shape, like half of a street, including the curb and gutter. Custom drums replace the pipe on a hydraulic roller screed and use a spinning motion to shape the concrete.

This monolithic pour method is ideal for streets due to the long stretches of pavement that are the same shape. It is especially convenient for replacing existing streets because it allows one lane of traffic to remain open. After the crew completes one side of the street and it’s ready for use, they change the traffic flow to complete the second side. In the past, this was only possible with large, expensive slipform pavers or through manual labor, but a custom drum with a hydraulic screed provides a method to complete the work for a fraction of the cost or time.

QUALITY

A common misconception is that monolithic pours produce lowquality curb work. This may be true if a crew that is primarily focused on flatwork is hand shaping the curb. They may have little experience in curb and gutter work, and they have to apply most of their focus to the flatwork, which is the larger portion of the job.

However, the proper equipment can provide a key advantage and increase-all around quality to a monolithic pour. Replacing manual curb work with one of these mechanized systems makes it easy to achieve consistent, spec matching results, even with an inexperienced crew. The equipment is user friendly and enables contractors to accomplish more with less labor, a key advantage in a difficult employment environment.

WEATHER

A key consideration when determining whether a monolithic pour is the right solution is the weather. Monolithic pours really shine in tough weather conditions. As seasoned concrete workers know, the weather dictates when and how efficiently they can pour. Dealing with a small pour window becomes less of an issue with a smaller number of pours.

For some monolithic concrete pours, contractors may benefit from using one machine to shape the curb and gutter as well as the flatwork simultaneously. This capability comes in the form of a custom drum with a hydraulic screed.

With the right equipment, monolithic pours can double or even triple production and help crews maximize the work they can complete before that window closes.

Despite all the advantages, there are some cases where a monolithic pour is not the best solution. These situations will come into play in colder climates. If a job uses asphalt for the pavement, the concrete curb and gutter must be poured separately. Additionally, the monolithic pour method is not ideal if the curb and gutter or flatwork may need to be replaced separately. In colder regions where brine regularly collects in the gutter, the freeze and thaw breaks down the concrete and leads to a shorter life for the curb and gutter than the pavement.

DEMANDS

Contractors can maximize their investment in concrete equipment by purchasing machines that increase productivity for a variety of applications. Beyond custom drums for monolithic pours, hydraulic screeds also pair with standard pipes to screed flatwork for jobs such as streets and sidewalks. Walk-behind curbing machines have multiple drum options and can also complete curb and gutter for traditional pours. Additionally, battery-powered walk-behind curbing machines effectively complete patch and repair work and complement slipform machines to complete corners and tight radii.

The demands of the construction industry are shifting rapidly. There is a high demand for work, and contractors can capitalize on these opportunities by finding innovative solutions that improve their processes and increase their capacity.

Monolithic pours are not the answer for every concrete project, just as instant cameras and rakes are still used instead of digital cameras and mowers with baggers. But with the right equipment and the right application, a monolithic pour may be what drives an operation to peak efficiency.

This article originally published May 2023, by On-Site magazine.

Seth Ulmer is the sales manager at Curb Roller Manufacturing, joining the company after spending over a decade in the concrete and construction industries.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 27

VACUUMS & DUST COLLECTION SYSTEMS

Dust Hog Pro LLC’s Dust Hog Vacuum Attachment Tool

Dust Hog Pro LLC helps keep construction jobsites much cleaner, and in compliance with OSHA respirable silica dust safety regulations. This solution was invented by a professional contractor and thoroughly field-tested and refined to ensure durability and performance—fitting most mixing containers including 1, 5, 30 and 50 gallon pails and drums.

The Dust Hog is ideal when mixing cement, mortar, joint compound, stucco and other powdered materials on commercial and residential jobsites.

Simply insert the vacuum hose of most shop vacuums into the Dust Hog, hang the unit on the rim of the mixing container, turn on the vacuum and begin mixing. It uses Vortex Suction Technology to create a high-velocity, circular air current throughout the mixing container.

The company offers complete test data from an independent laboratory, backing up all impressive claims (which is available on its website). Also available is a 3-part, architectural specification for jobsites that require more thorough documentation.

https://CONC.me/teiisr3q

Ruwac Slurry Pro Jr. Vacuum and Pump

The Ruwac Slurry Pro Jr. industrial vacuum and pump serves as a slurry management solution for contractors focusing on smaller projects. The little brother to the original Slurry Pro, the goal was to design a vacuum system that simplifies slurry maintenance to support production rates using a smaller and more portable platform. This machine is powered by a 1,200-watt motor deliving 1.6 hp during use. The Slurry Pro Jr. has a 20-gallon liquid capacity with a 2-in. bottom discharge for cleanout and maintenance. Portability around jobsites is facilitated by 10-in. solid rear tires and front locking swivel casters.

https://CONC.me/tajzcb

The Lavina Elite V32 Dust Extractor

The Lavina Elite V32 Dust Extractor takes dust collection to a new level of performance and productivity. Lavina Elite dust extractors feature important upgrades for efficient dust management on the jobsite and are OSHA compliant.

• Four-stage dust collection for a dramatic increase in cleaning efficiency: Integrated pre-separator captures the large particles and extends filter life; Second cyclone around the conical filter captures the mid-sized particles; Conical M class filter with high air permeability and large filter area for better suction and longer working time between cleaning intervals with a large filter area; and a Hepa filter H13 as the last filtration point captures 99.95% of particles 0.15-0.23 μm.

• An integrated emergency lamp reminds the operator to clean the filter.

• Option to upgrade to automatic cleaning

• Lighter and more compact body design.

• Offered in propane (V32GE - 470 cfm) and electric models (V32E - 490 cfm, 220V or 480V). https://CONC.me/9400v9

The iQ1550 Dry-Cut Masonry Saw from iQ Power Tools

iQ Power Tools’ iQ1550 masonry saw is a huge leap forward in cutting technology. This is not your grandfather’s masonry saw. Whether materials to-becut are small or large, this tool is designed to save cutting time and increase productivity.

The iQ1550 can tackle any jobsite, dry cutting and eliminating the dust cloud, allowing workers to increase their efficiency and productivity while maintaining a safe work environment.

Equipped with a 230v Super Duty 3 HP saw motor and 3HP vac motor, it can handle cutting through 8-in. wall blocks and capture the dust. It’s integrated dust collection chamber holds 75 pounds of dust and with the automatic filter cleaning system maintenance is simple. Highly portable, the iQ1550 is equipped with highfloatation tires, forklift pockets, and a center lift point to make transportation easy.

The iQ1550 features the following industry firsts:

• 21.5 in. Q-Drive blade with a 8 in. depth and a full 16 in. length of cut

• Saw Dimensions: 32-in. wide by 67-in. high by 51-in. length

• Unmatched cutting speed

Designed with soft start technology, the iQ Power Management System controls the power ramp up without the spike and the automatic filter cleaning system. Easily transported around the jobsite, the cutting performance and speed of the iQ1550 along with integrated dust collection makes it the ultimate saw for serious masonry and hardscape professionals.

https://CONC.me/f3upco

BossTek DB-10 Atomized Mist Cannon

BossTek has introduced the DustBoss DB-10 atomized mist cannon, which can be used to suppress indoor particulate emissions during demolition and raw material handling. Engineered for enclosed working environments, the maneuverable unit provides suppression in a compact, portable design. The outcome is airborne particle control with minimized emissions and less standing water. The compact mist cannon is mounted on two wheels with a tall handle. A 3/4-hp fan delivers 3,335 CFM of airflow, powered by 120-volt current. Mounted on the front of the cannon is a circular manifold with 12 atomizing nozzles that fracture pressurized water into a fine mist. About as loud as a hand-held hair dryer, the fan forces air through the barrel then pushes millions of tiny droplets in a cone-shaped pattern up to 30-ft.

https://CONC.me/k1u8s6

28 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

Unearth outstanding deals Great savings on all skid steers. www.ebay.com/heavyequipment

NEW OZTEC BP-45 BACKPACK AND RUBBERHEAD® WITH OPTIONAL EXTENSION PIECE

Oztec is proud to introduce the newest edition to its industry leading backpack vibrators. The New BP-45 adds a powerful 2HP option, capable of running vibrator heads up to 2” in diameter, in a lightweight configuration. This backpack maintains Oztec’s Job-Proven Rugged design. Built to withstand the demands of concrete construction sites with a sturdy steel frame, dependable Honda engines, fully adjustable padding system and the highest quality components, all designed for easy maintenance and long life.

The BP-45 is an option between Oztec’s lightest weight model, the BP-35, and Oztec’s most powerful option, the BP-50a. As with all of Oztec’s power units, the BP-45 includes our patented Quick Disconnect for easy interchangeability with Oztec flexible shafts and vibrator heads.

New RubberHeads® with Optional Extension Piece

In December of 2019 Oztec Industries, Inc. reintroduced its 1-1/8” & 1-1/2” RubberHeads®. Both of these heads are available with an optional rubber coated extension piece. With Oztec extension pieces, you can greatly reduce the chance of the vibrator head becoming entangled in the rebar. These heads were originally designed to meet the needs of the construction of the Hood Canal Floating Bridge in Washington State, where over 30,000 cubic yards of concrete were poured in heavily congested rebar without a single head getting entangled in the rebar.

Oztec RubberHeads®, ranging in size from 1-1/8” to 2-3/4”, not only protect epoxy coated rebar and delicate form faces, but also produce better consolidated concrete and are job proven to be more efficient and effective than any other vibrator head on the market!

Oztec Industries, Inc.

65 Channel Drive · Port Washington, NY 11050

1-800-533-9055 - 516-883-8857 - Fax 516-883-7857

www.oztec.com

30 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete Idea

Idea File

File

Packed with demolition power, the BROKK 70 is the perfect solution for safe and efficient demolition in very confined spaces. Brokk Inc. | 1-360-794-1277 info@brokkinc.com | www.brokk.com

MEET BROKK 70 THE MINI SUPER HERO

Blend In, Stand Out

When you need a fast repair in concrete or oxidized asphalt, you don’t want it to show. Crafco’s High Performance Concrete Cold Patch offers a long-lasting, gray-colored repair that doesn’t stick out. Effective for potholes, spalls and more, HP Concrete requires no heating or mixing. Just pour, tamp and open up for traffic immediately. The patch permanently adheres and won’t release, even in hot, cold or wet weather. Available in 50lb. bags, HP Concrete can be stored for up to a year. Get HP Concrete Cold Patch for fast repairs that last and say goodbye to ugly patches.

Idea File www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 31

Visit us at crafco.com for more information.

UNSURE ABOUT YOUR NEXT BIG PURCHASE?

IRONPROS has what you need:

NEW PRODUCT PAGES

Bringing you through a funnel of research, insight and comparison.

HOW IT WORKS? Provides the Right Questions to Ask

Description of the Product & Use Cases

Pros and Cons of Renting vs. Buying Applicable Add-Ons

Scan Here!

ACI CERTIFICATION

The American Concrete Institute has been certifying concrete craftsmen, technicians, and inspectors for more than four decades. With more than 30 certification programs available across concrete testing, inspection, construction/specialist, and designer roles, the industry has seen considerable growth over the years in the number of projects requiring ACI-certified individuals.

Having ACI-certified concrete professionals on your project team is a great value proposition that can help you win more work. Project owners can award jobs to certified contractors with confidence, knowing the work will be performed to the highest quality. Contractors can also build a reputation with clients and project owners by advertising team certifications. Through proof of certification, you are guaranteeing that your team will perform concrete construction, testing and/or inspection up to codes and standards for safe building.

Idea File 32 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete

Brought to You By:

Minnich Manufacturing, the leading manufacturer of concrete dowel pin drills, concrete vibrators and vibrator monitoring systems, is dedicated to helping concrete contractors maximize efficiency.

Minnich’s Stinger and Controlled Speed Vibrator (CSV) are just two examples of how the company’s concrete innovations serve customers.

The light yet rugged Stinger electric flex shaft concrete vibrator is a 14.5-pound double-insulated universal motor that can drive the full line of Minnich vibrator shafts and heads from ¾ inch to 2 ½ inches.

The CSV enables contractors to communicate using their cell phone’s Bluetooth to select set speeds of vibrations per minute (VPM) in coordination with the concrete slump being poured. Minnich will continue to bring products to the industry that support the findings of concrete research facilities across the country.

For more information, visit www.minnich-mfg.com

Idea File www.ForConstructionPros.com/Concrete MARCH/APRIL 2024 CONCRETE CONTRACTOR 33

MINNICH’S VERSATILE INNOVATIONS HELP MEET TODAY’S CONCRETE PLACEMENT CHALLENGES Offer Versatile Solutions Reduce Physical Strain Increase Crew Ability Anyone Can Operate Produce Uniform Results Require Minimal Maintenance INFO@CURBROLLER.COM // 785-467-3132 // WWW.CURBROLLER.COM Prepare to elevate your concrete game with machines that:

HELP SHAPE

CONCRETE SHAPING SOLUTIONS

THAT

YOUR SUCCESS

Risk Management: Safety First

Aprime aspect of “risk management” is the effort to limit, reduce, or eliminate any construction effort that would pose a safety risk. It’s more than a list of do’s and don’ts, it’s a culture, it’s part of the DNA of your company about how they perform work and commited to sending their workers home safe.

The legality and science of risk management is quite well known among most contractors and is growing in need to be embraced, understood, and practiced by all specialty contractors. It is wise to take safety seriously, having not only documents that are required but more, have a commitment to see that every worker is educated on, trained on how, and understanding the “why” behind doing things right the first time in the most safe manner possible.

Safety must be everywhere possible in your company. It is in the actions and behavior of our most senior of leaders, including the owner, that sells safety first. A few suggestions on what you can do to demonstrate in action and behavior that safety is first:

• Personally invest in safety education.

• Lead safety training workshops personally.

• Make safety related questions part of your daily discussions with field leaders, office workers, field workers, etc.

• Personally investigate when there’s been a safety failure.

• Publicize safety first via signage, posters, proposals, contracts, “grafitti” on company trucks, business cards, and all marketing pieces and internet outlets.

RESOURCES

Consider all literature, tools, and equipment that should be reviewed, updated, and replaced as needed as it relates to safety. Commit a budget amount each year for this.

• Inventory your hand tools and consider what needs “sharpening,” fixed, and replaced.

• Are your educational materials clear in

their intent to teach safe practices?

• Do you have clear and visible signage in your shop, yard, and especially on each jobsite?

• Do you have informative “5-S Maps” that indicate where everything is kept on trucks, trailers, your shop, and yard?

• Keep ample supply of barricades, flare tape, emergency kits, safety vests, tie-offs, and just about every other “safety tool” that can help prevent any issues.

EDUCATE

Education most certainly includes actual training workshops and live demonstrations of safe working processes and techniques, but it also affects your company in a few other areas. Consider:

• The purchase of hats and shirts that have a clear reference to safety.

• Commit 5-7 minutes of stretching for all workers and leaders…office and field employees.

• Require part of your “pre-con” for the new project to address every safety “risk” potential on the new job.

• Take a brief “safety debrief” after each project from the hourly workers involved with job. If you perform more than one project in a short time span, review multiple projects once a week with your hourly workers.

• Incorporate one positive safety story a week in meetings or share a learning lesson from another company who may have had a safety problem.

RECOGNIZE & REWARD

• Recognize all new milestones of “incident free” goals and the people who are making it happen.

• Engage rewards to include company logo giveaways such as shirts, hats, gloves, etc.

• For exceptional safety performance and results look at some “cash” rewards or tickets, coupons, dinner cards, etc. Be

careful here due to the taxing of such items but provide some form of “hard” proof that safety is saving you money.

• Engage proven workers to conduct the safety training for newly hired employees.

• Consider appointing a “Safety Coordinator” for each work crew and your office. The SC isn’t the safety czar but instead, another outlet for employees to go to with questions, resource needs, etc. They can also assist foremen on scouting out potentially unsafe work areas, inspect equipment and tools needing repair, and assist in placing orders for new safety equipment.

All the previous suggestions and examples are for naught if we do not practice what we preach and hold people and processes accountable.

• Hold leaders accountable to invoke safety discussions before every project and at the beginning of each new day.

• When leaders do not practice the previous, coach, counsel, and discipline as needed.

• Clearly educate your workers on safe practices and when they do not comply with such practice, coach, counsel, and discipline as needed.

• When “repeat offenders” continue to be non-compliant about following safety rules and practices…counsel, document, and fire!

• Make Safety First mandatory for every employee.

Prevention is the key word here. Prevention in the form of education, reminding, and having needed safety resources and safe working equipment and tools can reduce your risk ten-fold. But we need to clearly communicate safety and be consistent in practicing what we are preaching about safety.

34 CONCRETE CONTRACTOR MARCH/APRIL 2024 www.ForConstructionPros.com/Concrete THE LAST PLACEMENT

Read the full article at https://CONC.me/rksol5tw

Be recognized as a BEST contractor To be considered, eligible contractors are required to have a minimum of 15 full-time or part-time employees in the U.S. and a primary business of: General Building Construction, Earthmoving, Paving, Concrete or Specialty and trades (Underground, Utility, Electrical, HVAC, Demolition, etc.) Apply today at BestContractorsToWorkFor.com APPLICATION DEADLINE JULY 12, 2024 SCAN HERE Apply for a chance to be acknowledged as an exceptional employer that demonstrates people are their most important asset. Completing the application process online is FREE and gaining the distinction of being a best contractor provides the advantage of attracting the hardworking and skilled workforce your company deserves.

GET THE EDGE GO THE DISTANCE

There’s no time waiting for the Ulti-Grit blade to open up. It cuts smooth and fast - with no chatter - right out of the box.”

- Jacob Parker, Equipment Operator at B&D Concrete Cutting -

ULTI-GRIT FLAT SAW BLADES

Rip through the toughest of concrete with Ulti-Grit, a series of powerhouse blades engineered to squeeze every ounce of performance from your flat saw. Go further and faster* with exceptional flat saw performance – from the first cut to the last. We’ve done the hard work – now go the distance. Schedule a demo with your Husqvarna Representative or visit our website.

www.husqvarnaconstruction.com

*20% faster cutting speed (according to internal test vs. previous F1500 & F900 blade series)

ULTI-GRIT™ SERIES