3 minute read

The 2023 attachment guide has 50-plus products to maximize fleet performance. Couplers

Caterpillar Tiltrotators (TRS) The TRS10, TRS14, TRS18 and TRS23 models for tracked excavators seamlessly integrate to the machine, contribute up to 13% more productivity and offer easy operation. • Available for machines from 11 to 30 metric tons (24,250 to 66,140 lbs.) • 360° bidirectional rotation and 40° left and right tilt allow work from many different angles with less machine repositioning • Machine controls allow for simultaneous tilt, rotation and machine movement • Pin-on or S-type coupler top interfaces or S-type coupler bottom interfaces • Optional grapple module allows operator to move materials out of the way, such as large rocks, without switching attachments Steer Quick Attach Frame The Mini Skid-Steer Quick Attach Frame for Mini Track Loaders by Artillian Tractors includes a common industry interface loader quick attach, enabling use with a variety of manufacturers' mini loaders. Highlights include: • Designed for a maximum load of 3,000 lbs. at an 18-in. load center, depending on fork tine capacity • Frames can be used with the company's pallet forks, grapples, stump buckets, hydraulic plow and more • Built using high-strength steel with MIGwelded construction • Baked-on powder coat augmented by a proprietary graphite coating on the fork rails for easier sliding of forks • Includes a built-in 2-in. receiver

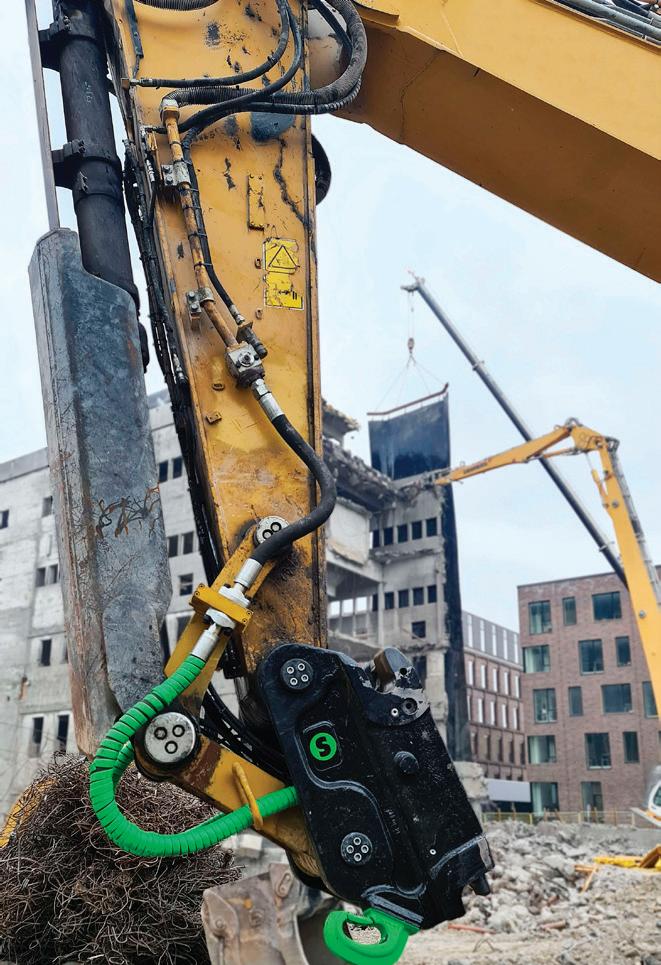

Steelwrist SQ90 Fully Automatic Quick Couplers The SQ90 fully automatic coupler system is targeted toward excavators up to 70 tons in the demolition industry. • Provides increased safety and the ability to change hydraulic powered work tools in seconds without leaving the cab • Compliant with the Open-S standard • Upgraded Front Pin Lock safety solution offers mechanical lock of the front shaft to limit the risk of an unintended drop of heavy demolition tools • Hydraulic couplings with Qplus technology enable higher hydraulic flows with less pressure drops Werk-Brau Hydra-clamp Bucket The Hydra-clamp bucket features a builtin rotary actuated thumb that maintains consistent clamping force on the load through the entire rotation for improved flexibility and precision. • Helical actuator provides up to 54,000 ft.-lbs of torque at 3,000 psi • Provides consistent clamping force throughout the 120° range of motion • Serrated side plates help secure debris while moving and are available in various sizes to match machines capacities • Tapered side plates reduce wear on bucket sides and allow easier dumping • Various tooth options or bolt-on cutting edge available

Kubota Productivity Package The compact productivity package includes a Heavy-Duty Excavator Bucket, a Main Pin Hydraulic Thumb and D-Lock Coupler, providing added versatility and production for excavators from 5,000 to 25,000 lbs. • Combination allows users to dig into virgin soil, move rocks, logs, debris and other materials, demolish structures, and more • Standard buckets range from 10 to 42 in. and feature T-1 steel in all critical or high wear components, heavy-duty horizontal wear straps and tapered side plates and a dual taper radius • Thumb comes in two-, three- and four-tine versions, offers roughly 120° of thumb rotation and can be left on the machine during normal excavation • D-Lock Coupler includes an automatic front lock, multi-pin centers and multi-pin diameters and only two hydraulic lines required for installation

DEMOLITION

Komatsu V-Series Hydraulic Breakers

• Completely enclosed sound-dampening housings The 100% hydraulic-fired V-series breakers modulate their impact force and frequency with up to 16 working positions to match to most applications. Compatible with the PC210 up to the PC490 excavators. Energy-saving recovery valve recuperates energy to drive efficiency. Automatically select best piston stroke length and speed based on material hardness. Shock-dampening upper and lower suspensions help reduce risk of cracking booms and breaker housings. Brokk Drum Cutters These drum cutter attachments are suited for detailed excavation applications such as contouring and trenching. • BDC 40 and RT 15-40 offer 15.2- and 4.7-in. cutting widths and are suited for the Brokk 70 demolition machine • BDC 50 pairs with the Brokk 110, 120DII and 170 to provide a cutting depth of up to 1.2 in. at a width of 18.9 in. • BDC 100 for the company's larger demolition machines (200, 300, 500, 520D and 900R) is 24 in. wide with a cutting depth of up to 2.6 in. • BDC 250 pairs with the Brokk 500, 520D and 900, is 26.8 in. wide and offers up to a 3.1-in. cutting depth