52 minute read

Site Prep and Land Clearing

Wishek Y2000 Offset Disk The Y2000 offset disk has a large tubular frame (6 in. x 12 in. x 3/8 in.), strong 36-in. blades and a low bearing-to-blade ratio to ensure durability when performing site prep, land clearing, soil drying and other construction applications. The unit is available with a 10-ft. working width and 18-in. blade spacing. It exerts 1,273 lbs. per foot to help the notched blades cut through the most difficult ground and asphalt. A manual leveling system offers easy depth and pitch adjustment. The gang angle can also be adjusted. Other features include heavy-duty 385/65R 22.5 truck tires on 10-bolt hubs, a hitch jack, bearing guards and washers, a gang bolt wrench, solid mount double scrapers and transport warning light package.

Fecon RK6015 Standard-flow Mulcher Head The RK6015 wider, standard flow mulcher head is suited for use with most skid-steer loaders and other carriers up to 75 hp that are able to provide 17 to 27 gpm of hydraulic flow. • Bite-limiting split ring rotor holds 26 knife or carbide-type cutting tools and has a 60-in. working width • Operates at 2,400 rpm and can easily shred brush and small trees up to 5 in. in diameter • Variable-displacement, 45cc hydraulic motor standard • Includes an adjustable bolt-on push bar with serrated ears for directing material • Weighs 1,490 lbs. with mounting plate and push bar Caterpillar HM3013 and HM5515 Mulchers The HM3013 and HM5515 mulchers can be used on frontreach machines from 11 to 36 tons and long-reach front machines from 40 to 52 tons. • HM3013 offers a dedicated bite limiter drum and the HM5515 has a standard drum • Variable torque hydraulic piston motor shifts between high speed, low torque and low speed, high torque to deliver speed and power when it’s needed • Hardened counter blades mounted inside housing help break down finished material • Ability to adjust hydraulic mulching door allows operator to control material throw for increased operating safety • Bolt-on replaceable skids

Werk-Brau Skeleton Rock Bucket Werk-Brau Skeleton Buckets are specifically designed to separate large rock and other debris from smaller loose materials. All Werk-Brau buckets are made in the U.S. and are available through equipment dealers and distributors worldwide. • Available in various widths and sizes for either loaders or excavators. • Manufactured with high-strength T-1 steel in all critical wear points • Abrasion-resistant wear straps to reinforce the bucket bottom • Tapered side plates reduce wear on the bucket and allow for easier dumping Loftness H Series Battle Ax Mulching Attachment The H Series Battle Ax mulching attachment is designed for high-flow skid steers and compact track loaders with 33 to 62.9 gpm and 50 to 150 hydraulic hp. • V-Drive variable-displacement piston motor automatically shifts rotor rpm from highest speed to a lower range for increased torque • Unique rotor with built-in depth gauges that function similar to raker teeth on chain saws to prevent attachment from engaging too much material at one time • Two-stage cutting chamber design • Can be used with reversible planer knives, hardsurfaced planer knives or double carbide teeth

Frustrated with long lead times?

VMAC air compressors ship in 10 days.

UNDERHOODTM 40 Van & Truck Series

30-40 CFM*

UNDERHOODTM 70

60-70 CFM*

UNDERHOODTM 150

90-110 CFM*

DTM70

60-70 CFM*

DTM70-H

25-65 CFM/2.5-8.0 GPM*

Supply chain shortages are causing significant deck mounted air compressor delays. We have a vehicle integrated solution for your entire fleet, shipping in 10 days. Available for Ford, Ram, GMC/Chevrolet, International, and Mercedes/Freightliner.

*Maximum CFM/GPM output varies by vehicle application, engine RPM, and/or hydraulic pump size and operating mode.

Find Your Solution at: VMACAIR.com/10days

Fecon FDX36 Disc Mulcher The 2,965-lb. FDX36 Disc Mulcher pairs with 15-ton excavators and features a 36-in. cutting width. • Designed to enable top-down or bottom-up feeding into the disc • Hinged right-side door allows operators to snip treetops with either left- or rightside sweeping motions • Closing cutting chamber by hinging right-side door closed creates a smaller product size and limits debris dispersion • Integrated pusher pad with rake-style teeth allows moving of felled materials or brush piles for maximum productivity

Loftness Battle Ax Extreme Mulching Attachment The Battle Ax Extreme horizontal drum mulcher is designed for prime movers up to 375 hp. • Rotor features built-in depth gauges to prevent the attachment from engaging too much material at one time • Two-stage cutting chamber processes material more thoroughly by cutting material twice • Equipped with twin hydraulic motors • Uses triple carbide teeth for reliable performance in even the toughest operating conditions

John Deere Mulcher and Brush Cutter Excavator Attachments The ME36 and ME50 Mulchers and the RE40 and RE50 Rotary Brush Cutters are equipped with knife-style cutting teeth on a split ring rotor. The spiral, double helix tool pattern and tool shape allow for efficient cutting for mulch up to 5-inch material. A controlled and metered cutting depth allows the operator to maintain high rotor revolutions per minute (rpm) and a productive mulching rate. The teeth may be sharpened and flipped for a fresh cutting edge, extending the tool's life. The mulcher attachments are designed for right-of-way maintenance and fire/fuel reduction, clearing standing or felled trees and brush along fencerows, roadsides, waterways and other hard-toreach places. The RE40 and RE50 brush cutters are designed for embankment and ditch management, over-fence brush management, rail right-of-way maintenance, and otherwise difficult to reach areas. Three swinging blades mounted to a blade carrier can fell and cut material up to 6 inches in diameter. A heavy-duty hinged debris shield retracts when the head is engaged with trees and brush, exposing the blades, and allowing for aggressive cuts. Fecon BLACKHAWK BK6218 Forestry Mulcher The BK6218 includes the features of the BLACKHAWK mulcher frame but in a narrower frame that facilitates precision mulching. • Features 24 knife tools and has a 62-in. cutting width • Cutting chamber designed to process material going forward or back dragging without leaving unprocessed material • 18-in.-diameter rotor spools up quickly and minimizes wait times • Rugged construction with 5/16-in.-thick HS steel cutting chamber with AR steel replaceable wear parts • Suited for skid steer and compact track loaders with hydraulic flows of 30 to 45 gpm

Jess Tools Bell Auger The Jess Tools Bell Auger is a skid steer attachment for belling pier holes. The belling auger reshapes a straight augured hole into a bell shape and cleans out the dirt, leaving the surrounding soil undisturbed, all in one process. It will save you money in labor, and increase the quality of your concrete piers. The Bell Auger is designed to survive the harshest conditions. It includes 1-in. solid steel control arms, a robust central shaft, hardened bushings and bolts and a width gauge that indicates how wide your bell is, so users can cut to the size they need. The attachments is available in four sizes: • 9-in. hole, 18-in. bell • 12-in. hole, 24-in. bell • 18-in. hole, 36-in. bell • 24-in. hole, 48-in. bell

Werk-Brau Grubber The Grubber slices roots and extracts brush in one easy motion and is available in models to fit most excavator sizes and classes including minis. • Constructed with a heavy-duty upper channel, AR400 steel cutting edges and triple pass welds on the high-stress areas • Available with a replaceable bolt-on edge V-edge or straight edge • Suited for select extraction of brush and nuisance vegetation • Minimize ground disturbance, reduce erosion and promote grass growth

Terex Compact Equipment Drilling and Auger Tools This line of hydraulic auger drives, augers and accessories is suited for use with skid steers and other compact construction equipment. • Includes dirt or rock augers with 4 1/2- up to 36-in. diameters • Come standard with replaceable teeth and a 2-in. hex coupling • Optional round coupling in 2 or 2.5 in. • Suited for equipment operating at a 3,500- to 5,500-ft.-lb. torque range and stem length of 48 in. or less MB Crusher MB-HDS220 The attachment features 1-ton weight and load capacity of .6 m-cubed. This padding bucket can be used on loaders and skid steers from 4.5 to 11 tons. The size of the inlet mouth opening is 2.20 m, which facilitates loading by keeping the tracks or wheels of the carrier machine clean. The inlet is designed to convey material to the rotors. Greasing is centralized and done onsite. The coupling system promotes freedom of movement of the operating machine. Operators can view the materials during use, as well. The MB-HDS-220 allows the rotors to be changed directly onsite by the operator. The bucket facilitates work on construction sites where there is a need to aerate packed topsoil. This includes when a green area, a garden or a flowerbed needs to be landscaped; or when there is a need to reclaim and clean soil from various demolition debris, stones or roots. The padding bucket can also be used to select material for covering pipes or trenches and making the bedding.

Diamond Mowers Excavator Drum Mulcher DC Pro X and Boom Drum Mulcher Made for heavy-duty mulching applications, Diamond Mowers’ SK Drum Mulcher OD Pro X is a hybrid design that combines the versatility of an open drum with depth control precision. Ideal for users requiring both power and flexibility, this easy-to-operate attachment efficiently processes material up to 9 inches in diameter and is strategically engineered to allow heavy ground engagement for maximum productivity. Differentiated in the marketplace by its optimized infeed system, shredding performed in the drum chamber reduces the need for back-dragging and produces a uniform mulch with a smaller particle size than conventional open drum models.

John Deere ME36 and ME50 Mulchers The ME36 and ME50 are suited for right-of-way maintenance and fire/ fuel reduction as well as clearing standing or felled trees and brush along fence rows, roadsides, waterways and other hard to reach places. • Knife-style cutting teeth on a split ring rotor • Spiral double helix tool pattern and tool shape allow for efficient cutting of up to 5-in. material • Controlled and metered cutting depth allows the operator to maintain high rpms and a productive mulching rate • Teeth may be sharpened and flipped • Tested and optimized to work with the company's excavators and compatible with many competitive 5- to 10-ton models

THE CLEAR ADVANTAGE.

Spend less time in the cold switching multiple blades with Brandt’s purpose-built 4-in-1 snow blade:

More Versatile

Adjustable side wings rotate 180° for maximum versatility in all conditions.

Safer Operation

Two trippable edge configurations means added safety & longevity to the loader and attachment.

Low Maintenance

Blade hydraulics remain protected with cover plates, reducing repair costs.

WHAT HAPPENS AT CONEXPO STAYS AT CONEXPO.

BRANDT HOPES TO SEE YOU SOON IN VEGAS!

Find your solution at

brandt.ca

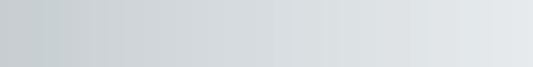

Felling Trailers Pan Tilt Trailer

Felling Trailers has unveiled an upgraded version of the drop-deck Pan Tilt model to increase operator ease of use and safety. The Pan Tilt is a gravity tilt trailer, using gravity and a center pivot point for tilting the trailer bed. Modifications have been made to the Pan Tilt's locking mechanism, lighting, license plate mount position and location. The tilt locking mechanism is a modification designed to support the production process, flexibility to function with optional features and operator ease of use. The previous locking mechanism was a purchased part that required modification and multiple latches dependent upon a trailer build's selected features, power up and down or a toolbox, as it was mounted on the front of the trailer.

PALFINGER FHS Series Forklifts

PALFINGER has unveiled the new FHS Series truckmounted forklifts for industrial and construction sites. The full range of forklifts in the 5,500-lb. capacity class is available in four configurations: STANDARD, STANDARD REACH, 4-WAY AND 4-WAY REACH, as well as with 10-ft. or 12-ft. masts. During use, the patented reach system extends the forks to the centerline of the trailer, while the mast remains firmly against the side of the truck or trailer. This allows the operator to lift full capacity loads at maximum reach while retaining the ability to tilt and side shift at all times. The FHS 55 4-Way Reach is a solution for complex, same side loading and unloading situations. The reach system allows the operator to lift full capacity loads from across the truck or trailer, while the steering can be switched to the front wheels to allow sideways driving.

BKT RIDEMAX FL 615

BKT has developed the RIDEMAX FL 615 radial flotation tire is designed for free rolling wheels of trailers, tankers and spreaders. RIDEMAX FL 615 has a steel-belted structure that provides high puncture resistance along with durability and high load capacity. The rounded shoulder and large footprint area ensure reduced soil compaction making the tire an ideal partner for operations on grassland. In addition, low rolling resistance and top selfcleaning properties round up its distinguishing features making the tire particularly suitable for transport applications with heavy loads and weights. RIDEMAX FL 615 is presently available in size 800/65 R 32.

Dynamic Tool Organizers

The Dynamic tool brand has introduced a new line of tool organizers. The line includes several solutions for storing sockets, wrenches, screwdrivers and other small tools. The magnetic socket organizer stores sockets in an upright position. Complete with magnetic base, the organizers are available in red for SAE and blue for metric sockets, and they have sizes printed on them for identification and selection. The next product is a socket organizer tray, which features a slim profile design for placement within shallow toolbox drawers. It uses magnets to hold sockets in place and comes with stickers for size labeling sockets. The third product is an aluminum socket organizer rail, which includes clips with spring-loaded bearings to hold up to 20 sockets in place. All three socket organizers are compatible with most regular and deep chrome sockets, as well as impact sockets. Options are available to accommodate 1/4-in., 3/8-in. and 1/2-in. drives in both SAE and metric sizes.

BATTLE AX

LOW AND HIGH FLOW SKID STEERS & EXCAVATORS 10,000 LBS - 88,000 LBS

DON’T BITE OFF MORE THAN YOU CAN CHEW …OR LESS

EXCLUSIVE DEPTH GAUGE DESIGN

Maximize productivity by not biting off too much, or too little, material at one time. The new Battle Ax rotor has unique depth gauges that optimize the material feed rate for top efficiency.

TWO-STAGE CUTTING CHAMBER

Thoroughly process material with the exclusive two-stage cutting chamber featuring an adjustable primary shear bar.

Mulching Heads Flail Mowers Mechanical Trimmer LOFTNESS.COM

Perkins Lithium-ion Batteries

Perkins engineers are currently developing and field testing 48-volt, 300-volt and 600-volt battery configurations that can be leveraged by OEMs in the construction, industrial, materials handling and agricultural industries. The lithium-ion batteries are a modular design and feature factory-installed telematics to optimize performance and packaging in off-highway applications. They are also being designed for recycling and reuse at the end of life to incorporate sustainability across their entire life cycle. Perkins continues to invest in new engine technologies, including dual label certification for EU Stage V and U.S. EPA Tier 4 Final. By optimizing the entire engine system from the air intake to the end of the exhaust pipe, Perkins has developed a full range of engines from 0.5 to 18 liters and 8.2 to 597 kW (11-800 HP) with an integrated suite of advanced technologies that not only reduce GHG emissions, but also deliver improvements in power density, performance and operation.

JCB Mobile Hydrogen Refueler

JCB has unveiled a mobile hydrogen refueler. The mobile hydrogen refueler provides a way for customers to refuel their machines on site, allowing hydrogen to be taken from on-site tube trailers and distributed to machines via the JCB refueler as they work on the jobsite. Around 97% of construction machines have fuel delivered to them while working on site, according to JCB. This means customers are already accustomed to a transportable fuel, allowing refueling to take place in a matter of minutes. The first hydrogen-powered machine to be unveiled was a JCB backhoe loader, followed a year ago by a Loadall telescopic handler.

BKT AGRIMAXFACTOR

BKT has launched AGRIMAXFACTOR, the company’s brand-new 70 series for tractors that suits both transport and soil tillage operations. AGRIMAXFACTOR is a new name for a new tire identity. The product is the company’s response to requests for a bigger tire. The tread design features increased lug length and updated lug orientation and angle for the purpose of providing handling and roadability. Stability plus steering response – even at high speeds and under heavy-duty service – are supported by a strong carcass made of polyester, a material that replaces nylon. In particular, there are six polyester belts and four strong polyester plies providing stability at various speeds.

Rotary Mobile ADAS

Rotary has unveiled a new mobile Advanced Driver Assistance System (ADAS) solution. The new calibration system is powered by TEXA, a company specializing in the design, development and production of multi-brand diagnostic tools, exhaust gas analyzers, air conditioning recharge stations and tele-diagnostic devices. The mobile ADAS solution offers repair service professionals a way to recalibrate cameras, radars, LiDARs and sensors when replacement is required, and additional measures are necessary that affect them. This solution is applicable to replacing the windshield and bumper, repairing suspensions, aligning wheels, changing tires and replacing the engine control unit.

Zivan CT3.3

Zivan has announced the launch of CT3.3, a new onboard battery charging solution. The CT3.3 serves as a rugged battery charger for onboard installations, in electrically powered machines and vehicles. Designed for non-road mobile machinery, aerial work platform, e-mobility, AGV-AMR and others, Zivan began the CT3.3 development to complement SG3. New features will be introduced with the CT3.3, such as water cooling, increased power density, optional integrated DC-DC converter and input over-voltage protection. The CT3.3 and the SG3 can be installed in a stackable configuration to scale up charging power (3.3 kW, 6.6 kW, 9.9 kW and more) depending on application or specific needs.

Caterpillar XQP115 Generator

Caterpillar has launched the 115 kVA Cat XQP115 generator set, a new mobile power solution that extends the company’s lineup of mobile power solutions that meet European Union (EU) Stage V emission standards. Caterpillar’s range of small mobile power solutions meeting EU Stage V emission standards are equipped with the XQCP digital control panel, which provides all generator set controls and system indicators in a single interface. They are designed with a dual-wall fuel tank with an open bund that helps to protect the environment by containing spills, while coastal insulation protection (CIP) enables operation in harsh conditions. Impact-absorbing base frames, customer connections isolated from circuit breakers and optional CEE sockets are designed to facilitate transportation, set-up and use. Forklift pockets, dragging points and a lifting arch helps loading, unloading and placement around the worksite. Cat mobile generator sets meeting EU Stage V emission standards can use up to 100% hydrotreated vegetable oil (HVO), a renewable diesel fuel meeting EN15940.

Telehandlers Offer 3-in-1 Capabilities for Construction Sites that Need Multitasking Heroes

The market for 360-degree rotating telehandlers has grown exponentially in North America. Here are some of telehandlers' best features and uses.

Ben Morton, a contractor and owner of Ben Morton Builder who performs residential construction along Maine’s coast, notes that material management and handling is the most expensive factor in residential construction.

To that end, he’s a big fan of the diverse functions of rotating telehandlers. He has two Manitou rotating telehandlers and one traditional telehandler in his fleet.

“Anything I can do to make materials management more efficient is a big win for me,” Morton said. “Getting into a rotating telehandler has the benefit of being three machines in one. Not only does it move materials with forks like a regular telehandler, but it works equally as a crane and also as a man basket.”

That enables the operator to secure and offload the materials while maintaining control of the machine, he added.

The ability to position the machine in a static spot and rotate 360 degrees, easily switch out attachments and operate with a wide variety of attachments makes the machines versatile for jobsites of all shapes and sizes, said Steve Kiskunas, Manitou Group product manager.

“When compared to a traditional telescopic handler, it can take the driving aspect out of the equation when moving material. Minimized movements around jobsites helps reduce the number of moving vehicles and machines around workers. This is a major product advantage on tight urban jobsites, where space to maneuver the machine is limited,” he added.

Addressing the user-friendliness of his fleet’s rotating telehandlers, Morton said he started off with an older one that took quite a bit to figure out how to use it.

“When I got the new one, I understood the platform,” he said. “The new one was a breeze. When one is set up on outriggers, I can teach one of my guys to use the remote in a matter of minutes. In getting them familiar with the entire machine, it definitely takes a few days to a week in in terms of understanding how to set it up.

“You have to know to use it properly. It's not like a regular forklift. You would not want to rent one just for the day. It has a longer learning curve than a normal forklift.”

Morton said he chose Manitou equipment for the interchangeable attachments. “It’s a huge benefit,” he said.

For example, the forks go on all three machines.

“You need to make sure the plate on the attachment mast is in the system for the machine,” he said. “The machine has to be technically rated for the attachments, which they all aren't.”

While Morton is saving costs by investing in one piece of equipment that performs multiple functions, he’s also saving on labor costs, he said.

“I’m not going to say it replaces people, because my company has actually gotten bigger since I've gotten the machines,” he said. “But it allows the people that I have to be optimized. Instead of just burying materials around, their focus is on cutting and installing materials properly.

“They’re not tired in our store at the end of the day. They're able to focus all their energy into creating instead of carrying stuff. Since I’ve gotten the machines, it’s been nothing but great. To determine the value, you’d have to set up a stopwatch and time how long it takes a guy to carry 50 sheets up to the second floor versus the machine doing it in a minute and then multiply that by how much you're paying the guy per hour.”

JLG

LOOKING FOR A SOLUTION TO BOOST YOUR REPAIR SERVICES IN EVERY PIECE OF EQUIPMENT?

DIAGNOSE, REPAIR AND REDUCE THE DOWNTIME OF YOUR FLEET WITH JALTEST OHW

ConAg Tech / Applied Machinery

Morton said he avails himself of training offered by the National Commission for the Certification of Crane Operators (NCCCO) specific to telehandlers.

“That is phenomenal because for me, I had to get trained in all three: a forklift certification, a Mobile Elevating Work Platform certification and crane certified. The NCCCO, which does the crane certification, just came out with a three-in-one course.

“The crane course was almost prohibitively expensive, long and difficult for a carpenter. I’m not a dedicated crane operator — I’m just a guy who operates the machine of the crane occasionally. But the new course combines all three, simplifies them and is making it easier to get certified on these.”

Manitou offers a full line of rotating telehandlers with varying sizes, operating ranges and engine types, including two electric models that run with zero emissions, low noise and reduced total cost of ownership.

Maximum capacities reach as high as 15,432 pounds with height reaches up to 113 feet and 10 inches, and a reach of 91 feet and 10 inches.

Manitou MRT Vision Plus telehandlers are designed to be powerful, safe, precise and versatile handling solutions offering visibility through a panoramic cab with machine accessibility from four sides.

The machines feature a large, ultraintuitive touch screen that works even while wearing gloves. The pressurized cab is designed for a healthy working environment and additional sound insulation.

Each rotating telehandler functions as a telescopic material handler, suspended load handler, and an aerial work platform with a number of compatible attachments, including forks, man baskets, and jib and winch systems.

“With complete 360-degree rotation of the turret, most of the required operations can be executed easily without needing to move the machine,” Kiskunas said.

The MRT Vision Plus also is

The multi award-winning Snorkel S3019E self-propelled electric scissor lift features a revolutionary sunken scissor stack that stows entirely inside the chassis for a low step-in height. A low stowed height can pass through doorways without the need for folding guardrails. This zero-emission lift stacks the deck with all-electric drive and electric steering that eliminate hydraulic hoses.

ELECTRIC STEERING

STACKING THE DECK

FOR MORE INFORMATION CALL Snorkel™ at +1 (785) 989-3000 or visit www.snorkellifts.com

FIT TO BE compa t c

WORLD OF CONCRETE BOOTH #O30099

JANUARY 17-19, 2023 LAS VEGAS, NV

equipped with a new radio remote control with integrated display.

“We’re seeing this as extremely beneficial with operators who prefer to work at or near the place where a load is being picked or placed versus viewing it from the cab,” said Kiskunas. “This also makes it even easier for the operator to communicate with their co-workers on the ground.”

Each rotating telehandler is equipped with audible and visual indicators informing the operator in case of overloading or excessive tilt.

“There’s also the ability to set restrictive zones to prevent swinging a certain way if the machine is positioned in a consistent place on a jobsite and there are obstacles to avoid,” said Kiskunas. “You can similarly set height restrictions to avoid overhead obstacles.”

Each Manitou MRT Vision Plus rotating telehandler is able to identify the type of attachment that is equipped, as well as the outrigger position, to provide the operator with proper load charts installed directly into the machine’s load management system.

While rotating telehandlers are suitable for work on all jobsites, they excel in a few areas: more confined urban jobsites, jobsites with varying terrain and obstacles and jobsites where materials need to be lifted to heights that may exceed what is possible with a traditional telescopic telehandler, noted Kiskunas.

“We’ve seen some applications, such as with large-scale homebuilders, where a rotating telehandler can be set in a central position on the jobsite and used to place building materials to all sides of the project,” he said.

Ben Morton Builder

Daliborka Ribeiro, JLG director of product management for telehandlers, said that while all telehandlers are versatile, rotating telehandlers can significantly increase productivity and reduce the time it takes to pick and place loads.

“With a rotating telehandler, the machine generally remains stationary, and the operator simply rotates the upper frame to pick-and-place materials, like setting HVAC units into place on rooftops or lifting drywall panels into a high-rise renovation project eight stories up,” she said.

JLG rotating telehandlers are purpose-built for masonry, roofing, demolition, cladding, renovation and tunneling applications and are wellsuited to handle loading and unloading tasks on these types of jobsites, said Ribeiro.

They also are designed to transport and distribute heavy suspended loads on flat, firm surfaces and uneven terrain, she added.

Speaking to their benefits, “along with their rotational capabilities, rotating telehandlers generally provide very high lift height, with most models able to work at heights well above 60 feet,” said Ribeiro.

JLG has three models in its initial rotating telehandler offering: the R11100 has a maximum reach height of 97 feet, while the R1385 can reach 84.5 ft and the R1370 can reach 67 feet.

JLG rotating telehandlers come standard with a mechanical coupler and auxiliary electrics and hydraulics. A hydraulic coupler and dual auxiliary hydraulics are optional, said Ribeiro.

Addressing the user-friendliness of the equipment, Ribeiro said precision lifting and placing features include an inching feature enabling the operator to run the boom at optimal speed without shifting the transmission into neutral.

Finely-tuned boom controls and soft stop slows the boom as it approaches the end of its stroke for precise lifting and placement of materials, she added.

“A remote boom control feature allows the operator to maneuver the boom from outside the cab when obstructions prevent clear visibility of the work area,” Ribeiro said.

JLG

All models also come with an intuitive operator interface and dual joystick proportional controls. The right joystick operates boom lift and lower and attachment tilt. The left joystick controls boom extension and retraction, as well as turntable rotation.

Key features of the JLG rotary telehandlers include continuous rotation of the upper frame, to allow both horizontal and vertical lift and place capabilities and multi-section booms to support higher reach and greater lift capacities.

“Advanced technology and features like LMI to prevent overloading the machine, attachment recognition that automatically loads the appropriate load chart and keeps the operator within the limits of the machine and ClearSky telematics” are another benefit, Ribeiro said.

Ribeiro said rotating telehandlers can reduce a user’s costs of operations, making them a more affordable and attractive solution.

“Rotating telehandlers come at a much lower acquisition cost for the equipment owners compared to the cost of mobile cranes,” she added. “This makes these machines available at an attractive, affordable price point for companies looking to add these machines to their fleet.”

Applied Machinery Sales, which imports and distributes the Merlo telehandler line, offers six rotating telehandler models with lift capacities up to 15,400 pounds and as high as 115 feet.

Merlo designs its outriggers with independent jacking and to be compact to the machine.

“An operator can set the Roto up on

its stabilizers no matter how tight the jobsite is,” said Susan L. Doyle, company spokesperson.

Additionally, “with today’s jobsite demands and hiring needs, contractors want a machine versatile enough to be able to do many different things and simple enough to not have to rely on one or two designated operators.”

Its versatility through the ability to use different attachments, coupled with high maximum lift heights enables a single Roto telehandler to potentially replace three different machines, said Doyle.

Roto telehandlers are used in a number of different applications, such as carpentry, masonry, oil and gas, steel erection and with arborists.

Speaking to the telehandler’s user-friendliness, Doyle points out all Merlo Roto telehandlers are equipped with multiple technological systems and safety features.

“Merlo designed a very ergonomic cab with numerous decals that very clearly explain what each button does,” she added. “If you attempt to perform a function that the machine decides is unsafe, a prompt will display on the dash with a short but concise message explaining what the operator should do to proceed safely. Most operators can sit in the Merlo cab for the first time, get acclimated quickly and make their first lift within a few short moments.”

Addressing how to best derive an ROI from a telehandler, Doyle suggested considering what equipment is designated for a job and then decide if using a Roto telehandler with a number of attachments could free up those pieces of equipment to be used somewhere else.

“If that is possible — and it usually is — a company now has one machine perform the same tasks that maybe three other pieces of equipment were doing,” she added. “Having a Roto in place then reduces equipment costs for that particular job, thus increasing ROI.”

Magni offers 16 rotating telehandler models with lift heights from 57 feet to 167 feet and lifting capacities from 11,000 to 28,600 pounds. The equipment’s load-limiting technology — when paired with a full LMI system — is designed to ensure the highest level of safety possible.

Magni machines are manufactured with Liebherr Slewing drives, designed to offer smooth and controlled rotation.

The company offers dozens of attachments to allow the machines to perform the work of a telescopic forklift, rough terrain crane, and aerial work platform, among other functions.

“Rotating Telehandlers benefit anyone with a need to lift and set materials, including concrete contractors, framing contractors, steel erectors, masons, and tree removal companies,” said Joseph Leinwol, chief sales officer, Magni North America.

“A Magni rotating telehandler allows the operator to set the machine and remain in place while picking and delivering materials,” he said. “Testing shows that versus traditional methods requiring machines to be constantly moving and repositioning, productivity increases by up to 100 percent.”

By having the machine remain stationary, the site environment is much safer with the opportunity for ‘struck by’ incidents greatly reduced, Leinwol said, adding fuel consumption also decreases by reduced machine movement.

“All Magnis are equipped with a proprietary system that recognizes the specific attachment being used, displays the appropriate load chart digitally, includes a full LMI system, and ensures safety by limiting the load movement to only safe areas,” he said. “This unique system serves to take operator error off the table.”

Leinwol said Magnis are “highly intuitive and super easy to learn and use. Any operator who has operated a traditional telehandler or crane can quickly pick up how to operate a Magni. With more than 300 messages displayed on the high visibility touch screen, the machine helps to guide the operator on exactly what to do.”

An ROI is derived by having a Magni on a project to replace several machines with one, thus offering rental, fuel, transportation and insurance savings, Leinwol said.

“With rotation, you get up to 100 percent increased productivity,” he said. “Framing contractors report the nail guns never stop.”

JLG

The remote control makes it possible for one person to do the job of multiple people, greatly reducing human labor hours on the project, he said.

“By having the ability to lift higher, heavier, faster and safer, Magni allows you to drive greater profits,” said Leinwol.

Roto telehandlers are quickly gaining popularity in North America and are widely accepted in various U.S. markets, Doyle said.

Roto telehandlers can fit in spaces where other types of machinery may not and in high density urban markets tend to be a “perfect fit,” she said.

Leinwol noted the increased adaptation of rotating telehandlers, such as that offered by Magni in the U.S. underscores that in a general sense, contractors are always looking for ways to perform their jobs safer and more efficiently.

An established dealer network offering end users service, parts and training also is key to that adaptation.

Kiskunas said when one considers what rotating telehandlers offer holistically, they are essentially three machines in one: a telescopic material handler, suspended load handler and a work platform.

“Between labor shortages and smarter fleet management practices where business owners are adding equipment to their fleet that serves multiple functions for optimal utilization, the North American market is responding very favorably to these machines,” he added. Read more at: https://eqtoday.co/telehandlerpopularity

Carol Brzozowski is a freelance writer for Equipment Today.

BUILDING A SOLID FOUNDATION

9,000lbscapacity 44ftliftheight 74hp

BOOTH #O30099

JANUARY 17-19, 2023 LAS VEGAS, NV

Manufactured in the land of the free and home of the brave, the Xtreme XR944 is made with long-lasting all-steel roller booms that can lift loads up to 9,000 lbs. Designed with safety, reliability and serviceability in mind, Xtreme proudly manufactures in the U.S.A.

to help you build your American dream.

For more information on Xtreme telehandlers visit

Trimble/Ajax Paving

Adopting 3D CONTROL for Concrete and Asphalt Paving for No Strings Attached Results

Ajax Paving relies exclusively on 3D paving for concrete and mission-critical asphalt projects. concrete and mission-critical asphalt projects.

Flint, Mich.-based Ajax Paving handles both government highway and demanding private asphalt and concrete paving duties from its headquarters and asphalt jobs from a subsidiary in Fort Myers, Fla.

The company employs 500, and operates aggregates and aggregate, concrete and asphalt mixes in Michigan and aggregates and asphalt plants in Florida. Ajax Paving has been involved in marquee projects, ranging from the repair of the Sanibel Causeway following Hurricane Ian, reconstruction of North Port, Fla. roads to pass the coffee cup challenge, the I-275 near Detroit and the Florida I-75 Mega Project. Ajax Paving has been named a 2021 Best Contractor to Work For by ForConstructionPros. com. The company has taken a leadership position on environmental stewardship, partnering with Road Forward, the National Asphalt Pavement Association (NAPA) net zero carbon emission asphalt initiative.

But the company also leads as an early adopter of 3D paving technology, and has since built a program deploying it strategically over a period of what had been, at the time of our December 2022 debriefing with Ajax Paving 3D Paving Manager Jeff Robinson, more than nine years. 3D paving differs from 2D screed control in that it does not just control the elevation of the screed, but can accomplish variable depth paving, quickly changing the depth of the pavement and even the cross slope if needed, as is the case in a superelevated curve. In this environment, an array of total stations locks onto receivers on pavers, rollers and milling machines through a prism mounted on each machine. 3D paving controls on each machine contain a digital model of the job, enabling the equipment to deliver on the model automatically including slope, crossfall and even compaction density.

This enables a paving contractor to increase quality and increase margin while shrinking the budget, timeline and employee hours.

Some of the benefits come from automating the interaction between the flow of materials to the site, the paver and the compactor. By getting all of these steps to dovetail, the paving crew can achieve a consistent rate of production which in turn results in smoother pavement with less rework and grinding.

“You want to avoid stops as much as possible and changing speeds is nearly always better than stopping,” Trimble General Manager of Civil and Specialty Solutions Kevin Garcia told ForConstructionPros, describing the process for asphalt paving. “The Ajax Paving relies exclusively on 3D paving for concrete and for mission critical asphalt projects.

screed floats but a stop lets it sink, driving out the air voids with the weight of the screed. Every time you stop, there is a discernable bump in the road. Oftentimes, you will have to come back and grind that bump—bring out the diamond grinder and grind a high spot, particularly if it is next to a low spot. These are incurred costs that you may not have budgeted for and may cause you to exceed your buffer.”

The asphalt compactor’s job would seem simpler than that of the paver, but also benefits from 3D technology to monitor the number of passes, degree of compaction and temperature of the asphalt. Too little compaction and the asphalt will contain air pockets, which lead to premature erosion. Too much

DRIVING THE INDUSTRY FORWARD THROUGH

Education • Best Practices • Construction Insights • Industry Trends • & More!

FORCONSTRUCTIONPROS.COM

©Kossmoss – stock.adobe.com

compaction, as can happen when an operator loses track of the number of passes they have completed and completes more than is necessary in order to be thorough, and they can crush and break down the aggregate in the asphalt. According to Garcia, overcompaction of asphalt also can have a knock-on effect, where the paver pulls further and further ahead of the compactor, which must do its job when asphalt is at the correct temperature. This causes the paver to stop, which again results in uneven spots that must be milled out.

In concrete, 3D paving leaves very little finishing work to be done. 3D concrete technology can typically control the pan of the machine to a certain elevation and steer the machine to align with the model. This engineers out the string, which is a barrier to operating equipment on the site, and yields results that can help meet conditions required for a smoothness bonus. It is still important for contractors to maintain a uniform delivery schedule for materials with consistent properties from one batch to the next to ensure continuous flow and results. Consistent batch to batch properties is important. State department of transportation (DOT) guidance says paver vibrators should be operated between 5,000-8,000 rpm and should run without stops.

3D paving controls on machines contain digital models of jobs, enabling equipment to deliver on the model automatically, including slope, crossfall and compaction density. 3D paving differs from 2D screed control in that it does not just control the elevation of the screed, but can accomplish variable depth paving, quickly changing the depth of the pavement and even the cross slope if needed, as is the case in a super-elevated curve.

ADOPTING 3D PAVING TECHNOLOGY

“Nine years ago, maybe even 10 years ago, we started out in the machine control and paving world,” Robinson said. “We weren’t sure which way we were going to go between Trimble, Topcon or Leica. We did a demo between the systems, and at the time, concrete paving was not even something we were doing yet. We weren’t even thinking about it. We were doing asphalt. But then Trimble came to us and asked what we would think about doing some concrete paving—they were doing a beta test. I talked everybody into it at our company and told them we would learn a lot.”

Trimble came on site with Ajax Paving for base testing of the concrete paving and according to Robinson, “Day One, we put stringline up with engineers. On the second day, I didn’t put the stringline up and just told them if it worked on Day One, it better work on Day Two. From that day on, we have not put stringline up for a concrete paver. The next year, we went from one machine to 14 machines.

Ajax Paving does not use 3D asphalt paving much on highway projects where they are paid by the ton. On these projects, the asphalt is trimmed to grade.

“Most of it is airports, test tracks, NASCAR and things like that,” Robinson said. “It is more specialty things we do with 3D asphalt.”

The process for these demanding projects has changed radically thanks to 3D technology.

“Back in the day, even before me, when you did an airport runway job, we would put stringline up and trim to fine grade,” Robinson said. "Asphalt would come in and paint it black. Concrete would come in and put their own stringline in and there would be conflicts because the grade was too high or too low. Now we don’t have that. Everybody just kind of comes together in harmony.”

FLOW OF DATA TO BACK OFFICE

Data flow should be a two-way street in construction, and just as project requirements go from the field to the back office, data on project and equipment performance can return from the field to drive functions like work in

Trimble/Ajax Paving

progress reporting, application for payment, quality management, corporate performance management and more.

Ajax Paving relies on the Trimble SCS900 Site Controller software. Using this application, an engineer in the field can quantify progress and manage machine operations. Performance data and as-built data are stored on the device and can be extracted as a .TXT or .DXF file.

“We are starting, with the 3D paving equipment, to get some of the quantities and other data off of it,” Robinson said. “The concrete paving equipment lets you download the as-built data, and it tells you the elevations and smoothness so you can calculate international roughness index (IRI). We use that quite a bit. We are starting to do a lot more mapping with this data, mapping for quantities. And we are trying to figure out with Trimble how to drive value for this for paving. It is a great tool for the earthworks and the dirt guys. We are still working on it to make it better for the paving world. The mapping part of it works—you can see where you paved and get some rough quantities. I am going to be seeing if we can correlate the paving with the earthworks data to correlate our trimming with our paving together.”

Trimble technology can also operate a multiple-machine production line including pavers and compactors, for optimal results.

“We know the Trimble technology will correlate machines together,” Robinson said. “I have not thought about machines talking, there may be some value to it. We have tried tracking technologies on our trucks, but because our batch plants are on site, we don’t have very far to move the material.”

FINDING ROI

The Ajax Paving 3D program has taken some capital and effort, and it has been up to Robinson to ensure the juice is worth the squeeze.

“It has been profitable,” Robinson said. “Jobs are built faster and quicker with less people. I started off with this from nothing, and now, we are one of the best in the nation with 3D concrete paving and asphalt paving. It has been challenging at moments, but we realize a profit because jobs are built faster, quicker, with fewer people. I started out from this with nothing—and it made Ajax Paving what it is—one of the best with 3D concrete and asphalt paving.”

This efficiency can help Ajax Paving win business, as can the simple fact that they are using 3D paving.

“The market is competitive, but material prices are the same for everyone,” Robinson said. “Controlling your yield and getting off the job quicker do help you win business. We are seeing 3D paving required in some RFPs from the big automotive OEMs like Ford, GM, Chrysler and Toyota. We do a lot of the test facilities for the major manufacturers—skid tests, straightaways. There are flatness specifications each manufacturer wants to achieve.”

THE AJAX 3D ARSENAL

Across its two locations, Ajax Paving runs an armada of 3D printers to meet owner requirements.

The company runs a fleet of 24 Gomaco concrete pavers in various sizes, and one Gunner paver.

All of Ajax Paving’s asphalt pavers are CAT AP1055s, which are integrated with Cat Accugrade GPS. Asphalt paving machines are replaced or traded every three years, according to Robinson.

Using this complement of equipment, Ajax Paving can achieve accuracy within a hundredth of an inch for airport projects and has achieved accuracy of about 1 millimeter to meet one test track project specification.

But success is not purchased from the dealer—there are still some skills and good decision making required to achieve optimal results.

DUPLICATING AJAX’S RESULTS

“You have to make sure on an asphalt job that you are using a high-density screed to make sure pavement is 92 percent compacted,” Robinson said. “If it is less compacted, you have rollers trying to achieve accuracy. With concrete we easily achieve that tolerance because it is a one lift application. But it goes both ways. With an airport project, most runways are concrete and asphalt under that. For automotive pavement, it is most often asphalt. But for concrete, we have done alternative bids internally to determine what is the best strategy to get to the desired outcome.

But success has not come overnight for Ajax Paving, and Robinson advises being in 3D paving for the long haul.

“You want to be dedicated, Robinson said. “Have an individual to champion it. Build a staff. Having great owners that believe technology has also been a success factor for us. We started this endeavor and spent millions and millions of dollars, and they never told us no.”

Read more at: https://eqtoday.co/PMAjaxTrimble

©Yasin – stock.adobe.com

Buying a unit and financing it works if you have used units to trade-in or sell off to apply the proceeds to the purchase. It also helps if business is strong and generating taxable profits that you would like to avoid.

Consider the Construction Equipment Financing Options Available

The past three years have really upset the equipment market. Supply chain issues basically stalled the delivery of the new equipment you ordered and needed in 2021 and 2022. Some may have showed up, and then again, probably many did not. And I have to bet many of you suffered sticker shock when the final price tag was created.

What happened next was no surprise. The used equipment market came on the scene with skyrocketing prices for just about any used equipment in running condition. Not a bad situation if you had excess units in your fleet that you could covert to more cash than expected.

But no matter how you look at it, there are contractors and rental companies needing to upgrade their fleets with either new or late model used equipment. Many of you reading this are probably in this situation; figuring out what you may need, what you can sell off or trade-in, deciding if you can “pay the price” for the utility value of the equipment needed to complete your project. Kind of a sticky situation to be in.

Let’s look at the financing options you have available. Hopefully, you can find a couple that will not cripple your cash flow or the ability to take on new work.

Financing today is a big deal because we have not had to deal with the interest rates we are now facing. Me, I like to base financing decisions on the importance of the units being

©spoilergen – stock.adobe.com

In the end, what is required is a careful analysis of cash ow and tax position.”

-Garry Bartecki

purchased and the availability of the equipment I need in the markets I work in. I really hate to take on a fixed debt payment that lasts 60-72 months if I can avoid it. I also hate to take on long-term leases, which are basically the same as a note purchase agreement with perhaps less benefits than buying a unit and financing it. In the end, what is required is a careful analysis of your cash flow, free cash flow, tax position (do you expect taxable income or not) and your relationship with your bank in terms of your bank covenants. Depending on your financial condition, there may be financing options that better match up with what you can handle.

What options do we have? Here are some potential choices: We can buy it and finance it over 60-72 months. You can lease it with a residual value option at the end of the lease. You can rent it and avoid all the costs of ownership and operation. You can enter a rent-to-buy program that allows you to demo the machine and then buy, by having some rent payments applied to cost of the unit. With interest rates in the 7% + range these days, it pays to try to get the seller to buy down your rate and reduce the impact on cash flow. Because you do not want to overdo it by purchasing too much equipment in a short period of time, you may want to refurb used units in house, or look for used units for sale that you can refurb.

Each option has an impact on cash flow, collateral value, tax expense, gross margins and your covenant calculations. As I said, in this environment, you have to carefully think this through in terms of how many ACTUAL HOURS the machine will be used on jobsites; not sitting on the jobsite, but actually working on the jobsite. If you cannot tell me what that number is expected to be for the next three years, maybe you should not be considering a five- or six-year commitment to finance.

Buying a unit and financing it works if you have used units to tradein or sell off to apply the proceeds to the purchase. It also helps if business is strong and generating taxable profits that you would like to avoid. For example: If I sold a lot of used units and have tax recapture to consider, I may want to purchase and take advantage of bonus depreciation and

Section 179 deductions. If I have a history of producing taxable profits using a purchase to have Uncle Sam help pay for the unit and deferring the tax. If I have no bank issues, where adding to my fixed payments or increasing my debt will cause a problem. Purchase for $100,000. Tax writeoff of $80,000 reducing taxes by $28,000 give or take. I am comfortable that I will have at least 75% time utilization in the field with this unit. That $100,000 unit will have an annual debt service of approximately $24,000 a year. Add on your cost to operate the unit and that 24% of the unit cost increases to 30%. To stay on track, you need to measure both the time and dollar utilization of the unit (like rental companies do). You need to bill $30,000 a year for that $100,000 unit to cover debt service and maintenance.

That’s a lot to think about.

Leasing is somewhat similar to the purchase because you have a long-term commitment, usually an up-front payment and a residual option of at least $25,000 for a $100,000 purchase: It is another fixed payment. I used $100,000 again as the purchase price. The residual is a positive because if you don’t like the machine, you can return it and not pay the remaining $25,000. If you have a capital lease (pay off basically 100% of the purchase price), you may be eligible for the bonus and 179.

The lease will be considered a longterm commitment going forward. So, if you have bank issues, you may want to reconsider the lease if you think the lease payments are not considered long-term obligations. There are many ways to structure a lease transaction and thus manipulate your payment plan.

Rent-To-Own

I like it. You get to try out the unit and then decide if you want to buy it. And if you buy it, you get the “purchase benefits” outlined above. The rental rates will be somewhat higher than a pure rental transaction but are 100% expensed for tax purposes. In most cases, these rates are offered by equipment dealers representing the major brands.

On the downside, the material costs to operate the unit remain with the seller. But if you damage it, you will have to pay the repair bill.

Renting

The cost of ownership and the cost to operate mainly remain with the lessor. You can use it a day, a week, a month or any extended period. Work out an annual rate sheet at beginning of year. If it breaks, they fix it or replace it. You need to provide a certificate of insurance covering the value of the unit (same for rent-to-own). When you need it, they may not have it. You have to have contact with multiple suppliers. The least risk to cash flow and bank covenants. If you damage it, you will pay. Less staff required to move or repair equipment.

Other Options

Those are not the only options available to you and your business. For example, you could share equipment with other contractors, or you could sub out work where expensive machines are required.

If I use a unit valued at $100,000, the total amounts paid for principal and interest are not materially different, unless you buy down the interest rate or push out payments into the residual payment. This is because residual payment leases allow you to keep your cash until the final payment is made or not made, if you turn in the unit.

In my mind, you do not want to put yourself into financial hardship to do your work when you have other options available.

Read more at: https://eqtoday.co/RtBJan

Garry Bartecki is managing member of GB Financial Services LLP and a consultant to the Independent Equipment Dealers Association.