IMPROVED FLEET OPERATIONS POSITIVELY IMPACT OPERATOR RETENTION PAGE 48

IMPROVED FLEET OPERATIONS POSITIVELY IMPACT OPERATOR RETENTION PAGE 48

P-TIER COMPACT TRACK LOADERS

You never know what the work will throw at you. So you need a machine that can catch any of it. Our newest compact machines support over 100 different attachments and have the power to put them to work. Because it’s not enough to be on the jobsite, you have to run it.

Election

What’s next for construction under the

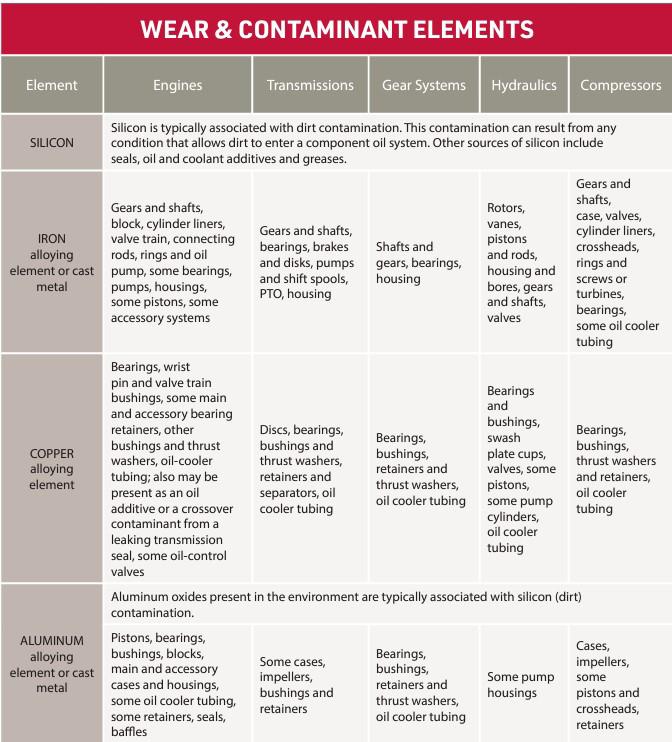

The impact of oil analysis for mixed fleets and ways to measure the success of this

As demand increases and labor options diminish, remote operation and automation technologies pave the way for innovative contractors to grow, compete and

How a commitment to safety demonstrates respect for your teams and creates a beneficial work environment

Strategies for keeping an eye on costs and planning ahead

Construction

entrance into the compact track loader market and what makes this move a

Understanding the latest

for

and how contractors can take advantage of these offerings to boost their

Kathy Wells Editor-in-Chief Equipment Today kwells@iron.markets

With another election cycle in the books, Donald J. Trump has regained presidential power in the White House and is set to begin his second term Jan. 20, 2025.

The businessman and media personality turned politician served his first term as the 45th U.S. president from 2017 to 2021.

Looking ahead to his upcoming administration, President-Elect Trump promises sweeping action on policy, including taxes, tariffs, climate and energy, and workers’ rights, although, in his first days as president, top agenda items may broadly center on securing the border and improving the economy.

Many in the construction industry view Trump’s second term as an opportunity for growth and progress.

“This is an exciting day for our industry,” said Associated Builders and Contractors (ABC) President and CEO Michael Bellaman. “ABC is optimistic about the future of America’s construction industry and the opportunities to advance policies that protect free enterprise, reduce regulatory burdens and expand workforce development. With leaders and lawmakers committed to promoting economic growth and supporting the principles of fair and open competition, we are confident that the construction industry will

thrive, and all workers will be given the opportunity to build America with fewer obstacles.”

ABC endorsed Trump in July 2024, supporting the potential for overcoming several key industry challenges.

According to Bellaman, “ABC looks forward to working with the Trump administration and Congress to advance policies that solve the issues that the construction industry faces, including the skilled labor shortage of more than half a million, widespread regulatory burdens and inflation and tax challenges.”

Under the new Trump administration, tax policy change is a major topic of discussion. PresidentElect Trump has proposed several targeted tax breaks on the horizon, including the elimination of federal taxes on tips, Social Security benefits and overtime pay.

Among other key areas important to the construction industry, materials demand and supply chains will be areas to watch moving forward. Trump’s first administration placed tariffs on imported materials, including steel and aluminum, and goods from China — many of which are critical to production in the construction environment.

President Biden elected to maintain many of these Trump-era tariffs, and in some instances, even increased tariffs

on many items, including batteries, semiconductors, solar panels and electric vehicles.

On the campaign trail, Trump promised to impose tariffs of up to 60% on all goods imported to the U.S. from China and 20% on other U.S. imports.

According to ABC Chief Economist Anirban Basu, Trump’s incoming trade policies increase uncertainty regarding construction materials costs.

“Beyond the implications of potential tariffs, input prices may rise in the short term if purchasers rush to import materials prior to the implementation of those policies. As of October, contractors expected their profit margins to expand through the first quarter of 2025, according to ABC’s Construction Confidence Index. That portion of the index will bear close watching as trade policy shifts in the coming months.”

For more on how incoming policy changes may affect the construction industry, Equipment Today will be highlighting even more expert insights in our annual State of the Industry coverage, available in our February 2025 print issue and online at forconstructionpros.com.

Take care,

Need

If you’re looking for timely, valuable industry-related updates and information, be sure to subscribe to our weekly e-newsletter, Breaking Ground. Brought to you by Equipment Today, Breaking Ground features information on the latest equipment, as well as business and fleet management tips that can help commercial construction contractors improve efficiency, productivity and profitability on their jobsites.

Quality heating, cooling and power solutions are critical for your business. Whether it’s a planned event or unexpected outage, count on our experts to proactively prepare engineered solutions and deliver rapid emergency response, no matter the size of your project or facility. From a sensitive single room to a warehouse stocked with perishables or an entire medical center, count on United Rentals for your tailored, rental-ready emergency response solutions.

Call 877.767.6797 or visit UnitedRentals.com/PHVAC

These pages

The DX17Z-7 weighs approximately 4,200 lbs. and is the smallest member of the DEVELON mini excavator fleet. The DX17Z-7 takes on a compact size and a retractable undercarriage with a collapsible dozer blade. This enables the mini excavator to squeeze into small spaces when needed and provides steady operation when working on slopes. The 16-hp DX17Z-7 offers a 48-in. track width, allowing for travel between homes on tight lot lines or flush against existing structures in developed areas. The machine’s zero tail swing design also makes navigating in urban areas and around confined worksites or obstacles possible. Operators can maneuver with next to structures without sacrificing turning, digging or lifting performance. The new mini excavator features an open canopy cab for operator visibility. A selectable control pattern switch gives operators the ability to change between ISO and “backhoe” patterns depending on their preference. The change valve is located beneath the floor cover and is accessible without the need for any tools.

Powered by a 105.8-hp Yanmar engine, the 333 P-Tier delivers a bucket breakout force of 13,750 lbs. The 333 P-Tier can be equipped with SmartGrade Ready including 2D grade control or 3D SmartGrade with Topcon. On Board Diagnostics enable access information on machine settings and codes. New monitor option offers active diagnostic trouble codes containing detailed descriptions about the issue. The machine also includes a new hydraulic system.

HD Hyundai Construction Equipment North America expands into crawler dozers with its first new dozer model, the 115-net-hp (86 kW) Hyundai HD100. The undercarriage system includes dual-flange rollers outside the chain of the track and single-flange rollers inside the chain of the track to help the track stay on the undercarriage. The 10-ton-class machine features a standard blade capacity of 2.9-yd3 and a digging depth of 1 ft., 6 in. The four-cylinder Hyundai G2 DM03 engine meets Tier 4 Final emissions standards. Standard operating weight is 23,589 lbs., and track length on the ground is 108 in. A hydrostatic transmission provides control of speed and torque. Offers visibility to the standard six-way angle blade. The electronic cooling system at the back of the machine offers an unobstructed view of the blade. Furthering visibility are the narrow front hood, placement of the inline pre-cleaner under the hood, minimized cab pillars and maximized glass areas including all-glass doors. Rearview camera, high-illumination LED lights and four wiper blades are all standard. Standard six-way variable-anglepitch dozer blade, with a maximum angle of 25 degrees, delivers precision when grading or moving materials. The standard blade float function is for fine finishing or back grading.

ASV’s RT-65 Posi-Track loader is a radiallift machine with components to maximize power from the compact track loader’s 67.1hp Tier 4 Final Yanmar diesel engine and optional 26.7 gpm high flow. The hydraulic system and direct drive pumps transfer more flow and pressure directly to the attachment, resulting in a 2,000-lb. rated operating capacity and 5,714-lb. tipping load. The 7,385-lb. RT-65 achieves maximum traction due to ASV’s flagship Posi-Track rubber track undercarriage. The suspension system, made up of two independent torsion axles per undercarriage, allows for traveling speeds up to 9.1 mph. The torsion axles allow the flexible track to maximize contact with the ground, increasing pushing power and lowering ground pressure as low as 4.2 psi.

The 9,610-lb. TL80VS is a construction-grade, durable machine. A 2,900-lb. rated operating capacity and 74-hp Yanmar Tier 4 Final diesel engine offers performance on the jobsite. A 10-ft., 6.5-in. max bucket pin height supports the TL80VS’ ability to load dirt into trucks and conduct at-height tasks. Users can navigate the jobsite with a top travel speed of 8 mph. A torsion axle suspended undercarriage features a pivot link system at the rear axle. The linkage technology uses a spring load that reduces oscillation and stabilizes the machine. The TL80VS can be optioned with a 34.3-gpm high flow with performance maximized by large line sizes, hydraulic coolers and direct-drive pumps. In the cab, operators can access a standard mechanical suspended seat and 7-in. touchscreen display. 360-degree visibility enables jobsite awareness and safety, supported by a removable roof hatch escape.

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

The Dingo TX 1000 TURBO, for a limited time only, will be available in an exclusive, textured matte black finish. The release of the Dingo TX 1000 TURBO Limited Edition coincides with the 10th anniversary of the Dingo TX 1000, the compact utility loader with a rated operating capacity of 1,000 lbs. The Dingo TX 1000 TURBO is the next stage, offering a turbocharged Yanmar diesel engine and the new patentpending Smart Power feature to maximize engine, auxiliary and traction torque. The Dingo TX 1000 TURBO’s new turbo diesel engine delivers increased torque, boosting productivity when using attachments such as the trencher and auger.

Available in four models ranging from an open (ROPS) station to a deluxe cab, the new SVL50x is powered by a 49.6 hp (SAE J1995 gross) Kubota diesel engine and features a working range that includes a rated operating capacity of 1,176 lbs. at 35% of the tipping load, 4,900 lbs. of bucket breakout force, and a hinge pin height of 101.6 in. Built for jobsites that require a tracked machine that can easily fit through narrow passageways and operate in confined spaces, the SVL50x is 48 in. wide, and measures 76.5 in. in height and 92.8 in. in length, with an operating weight of 5,620 lbs. The SVL50x is available with a one-piece sealed cab that helps prevent dirt, dust, rain and debris from entering the operator space while providing a quiet operating environment. The SVL50x also includes technologies featured in Kubota’s compact track loader lineup for the first time, including an anti-stall system, and an auto-idling system that helps save fuel by reducing engine rpm when high engine speed isn’t needed and the control levers are in neutral for more than 4 seconds; a creep mode that slows the machine to a crawl when operating a trencher, snowplow, and other similar attachments; and an undercarriage suspension with the midrollers suspended by torsion axles.

The Cat 995 Wheel Loader is designed for large-scale material transfer and loading operations on jobsites. This machine is built to the same size as the 994K it replaces. It features a higher rated payload and 6% increase in hydraulic force with equal cycle time. The higher payload rating enables a one-pass reduction when loading Cat 785, 789 and 793 Mining Trucks, equaling up to a 33% increase in production when loading the 785, up to a 25% increase with the 789 and up to a 20% increase with the 793. Features include: ˜ Up to 11% lower hourly fuel consumption when operating in Enhanced Eco Mode compared to throttle lock mode on the 994K

˜ Redesigned, pressurized next generation cab offers 50% more legroom, reduced vibration feedback, lower sound levels and automatic temperature control

˜ Taller windshield provides a 25% increase in glass surface area and a 64% increase in wiper sweep area improves visibility to the bucket

Designed for all-terrain and off-road use, the battery-powered electric telehandler E313 offers zero-emission and low-noise operation for moving materials around indoor construction, urban, residential and municipal projects. With a 3,500-lb. (1,587.57-kg) maximum lift capacity, a 13-ft., 1-in. (3.99-m) maximum lift height, 5-ft., 8-in. (1.73-m) forward reach and 9.3-mph (14.97-km/h) travel speed, this JLG electric telehandler serves as a compact, electric-powered machine for loading and unloading trucks and flatbeds, moving materials around or accessing work at height in single-story buildings. Features include:

˜ 18.6-kW/h electrical system with six maintenance-free 48V lithium-ion batteries for environmentally friendly operation with no emissions

˜ Up to four hours of continuous operation or extended intermittent use

˜ Dual on-board battery chargers with 110V and 220V charging adapters for charging

˜ Electric drive motors eliminate the need for fuel or oil

The JCB 370X heavy-duty excavator in the 35- to 40-ton sector has the ability to move 18 tons more material per gallon of fuel than competitive models and includes a Tier 4 Final 322 hp Cummins diesel engine. The 370X has a new JCB UX user interface, with 10-in. color touchscreen display and controls and increased hydraulic pressures. The Cummins L9 diesel engine is a 8.9-L, 6-cyl. with 322 hp available at 1,700 rpm, delivering power within a reduced operating rev range to increase fuel economy and reduce overall noise levels. The Kawasaki tandem hydraulic pump operates with an increased 5,076 psi pressure, rising to 5,511 psi during power boost cycles. Operation gets a boost from the valve block and a hydraulically operated cooling fan with reversing function. A heavier counterweight contributes to added stability, while larger structures cope with the additional forces. Increased service pipework diameters and raised hydraulic pressures result in more power at the dig end, which has been redesigned with cast boom foot and hydraulic ram pivot points for additional strength and longevity. The 370X is supplied with a 21 ft.-monoboom, with a choice of three arms up to 13 ft.

These pages feature some of the latest equipment available. For more information on these products, scan the QR code shown.

The 370 X4S has advanced technology, including Digital Level, Dynamic Stability Assist, Height and Depth Alarm, and Payload. The 83,776-lb. 370 X4S includes an electronically controlled hydraulic pump system and Tier 4 Final engine with 268 hp. Maximum dig depth is 24 ft., 2 in. and reach at ground level is 36 ft., 1 in. Bucket digging force is 56,160 lbf. Bucket capacity is 1.26-2.93 yd3. Maximum travel speed is 3.5 mph. The heart of these machines lies in their electronically controlled hydraulic pump system and the Spool Stroke Control (SSC) system. This innovative combination enhances efficiency and control, while the Isuzu AQ-6HK1X Final Tier 4 engine, known for its fuel economy, powers the machine. Notably, the 370 X4S achieves up to 7% improved fuel consumption without requiring a Diesel Particulate Filter (DPF), eliminating the need for maintenance or replacement. Operators can select four power modes (Speed Priority, Power, Eco, and Lift), allowing them to optimize power, precision and fuel savings for each task, resulting in enhanced cost-effectiveness.

Read More eqtoday.co/x99nf3uw

The L120 Electric wheel loader is a 22-ton machine with 6-ton lifting capacity and a recommended rehandling bucket capacity of 5 yd³, giving it nearly identical performance capabilities as its conventional counterpart. Its 282-kWh lithium-ion battery system can run for five to nine hours on a single charge, depending on the application. Charging options include a 50-kW DC mobile charger that will charge the L120 Electric from empty to full in about six hours or a 150-kW DC fast charger that can charge it from empty to full in two hours. It is equipped with separate electric motors for propulsion and hydraulics. The system recoups deceleration energy to extend battery runtime, reduce brake wear and minimize the need for axle oil cooling. Features active cooling and heating of the high-voltage batteries and passive cooling for the electric motors, transmission and hydraulic oil. Features include: on-board weighing with the Volvo Load Assist system, torque parallel linkage, electro-hydraulic lever controls and auto bucket-leveling functions.

Read More eqtoday.co/ctl86at6

Vermeer’s model features a 25-ft (7.6-m) pile driving capability, allowing solar contractors to install longer piles for larger solar arrays and on varied terrain. The PD25R’s extended reach enables contractors to adapt to changing project requirements and site conditions for productivity in solar field construction. Powered by a 74-hp (55.2-kW) Tier 4 Final/ Stage IV engine, the Vermeer PD25R delivers impressive performance in the field. It achieves transport speeds of up to 2.5 mph (4.0 km/hr) and generates substantial hydraulic power for improved hammer downforce. This power combination enables the machine to operate effectively across a wide range of ground conditions, including challenging terrains. As a result, contractors can tackle diverse project sites, expanding their business opportunities and improving project efficiency.

The TL623 offers the extended reach and lift capacity of a heavy-duty telescoping boom combined with Bobcat’s multi-attachment versatility enabling operators to tackle a wide range of jobs with one machine. The TL623 has a lift capacity of 6,000 lbs. and a lift height of 23 ft. The advanced Tier 4, turbo-charged engine delivers emissions compliance without the use of a diesel particulate filter (DPF) or selective catalyst reduction (SCR). Operators will also appreciate the engine’s reliable cold weather starting, along with a variety of features that make maintenance and service more convenient. Features include:

˜ Four steering modes for application-matched maneuverability

˜ The Bobcat Smart Handling System for tailored boom movements via controls on the joystick

˜ Powered by a 73-hp engine

˜ 4-cyl., 300-in. displacement engine

˜ Hydraulic system delivers 42 gpm flow

˜ Dump height and dig depth of almost 7 ft.

˜ Bucket breakout force of 13,000 lbs.

˜ Operating weight of 20,305 lbs.

˜ Comes standard with one-way and two-way auxiliary hydraulics, and a second set of two-way auxiliary hydraulics for attachments

˜ Dedicated constant flow provision for mulchers, allowing them to run efficiently without sacrificing hydraulic flow for other attachments

THE ROAD FROM A TO B ISN’T JUST MADE FROM CONCRETE.

the powertrain options and tech trends making today’s trucks essential to your fleet

As contractors look to replace vehicles in their fleet, innovation and decarbonization are driving many of the recent offerings in today’s pickup market. For a look at some of the latest offerings, Equipment Today spoke with both Ford Pro’s Kevin Lieberum and Ram Brand’s David Sowers for more information on recent developments and insights on future pickup product lines.

Lieberum, Ford Pro F-150 and Lightning brand manager, is not only well acquainted with trucks, but also the construction environment and the concerns of today’s fleet owners. “The trends driving today’s demand for pickups

are the same as they always have been — capability, cost of ownership, and technology,” said Lieberum. “We are a nation that works hard and, for those in the trades and running businesses, we’ve developed the most powerful and capable pickups that exist, but we have also created new ways of making business more efficient.”

Today, Ford Pro offers end users heightened features such as Pro Power Onboard, allowing customers to use their truck as a mobile generator. Lieberum also notes that tech features like Ford Pro Software can streamline operations, make daily routines more efficient, and help end users reduce downtime.

Sowers, director of Ram Professional Operations at Stellantis, Ram Brand, who has more than 30 years of truck-centric automotive experience, says customers steadily demand more innovation, technology and safety components in their fleets, noting that the primary concerns of today’s fleet owners are capability and efficiency.

When it comes to general demand, Lieberum says the economic environment greatly influences demand, and the company tends to see truck demand move in sync

with GDP, housing starts and other macroeconomic factors. But when it comes to the type of trucks most in demand for construction fleets, heavy-duty seem to top the list. However, every fleet owner’s needs are different and many are looking for versatility in their fleet.

For instance, according to Ford, volumes are high for the Super Duty, since the models span across a wide variety of trims, pickups and chassis cabs to fit different construction use cases and duty cycles. Ford’s range of pickups can be used for industry needs at various levels of work, says Lieberum. “Maverick, Ranger and F-150 are all light duty pickups, Super Duty F-250-450 are Heavy Duty pickups, F-550 is a Class 5 Heavy Duty chassis cab, and F-600 is classified as a Class 6 Medium Duty chassis cab. We also offer larger Medium Duty trucks in the F-650/F-750.”

Ram continues to grow alongside industry demand, says Sowers. “The 2025 Ram 1500 has come a long way as far as capability. The past decade has turned what was once a ‘halfton’ pickup into a one-ton pickup, with payload capability up to 2,300 pounds. That level of engineering has cascaded through the entire truck with greater efficiency and technology. The same can be said for the Ram Heavy Duty lineup

to a greater extent in capability with payload numbers up to 7,680 pounds.” Sowers notes there are a number of use cases throughout the construction environment, which is why many operators have both light duty and heavy-duty versions. “In many cases, the Ram 1500 serves two jobs: as a work truck [during the week] and family hauler on the weekends,” said Sowers.

Contractors adding to their fleet face the task of specifying a pickup that fits a variety of needs and, according to Lieberum, they must be able to tailor the truck as a tool to fit those needs.

“Ford offers a variety of configurations when it comes to cab size for worker accommodations and secure tool storage, bed length for payload volume and ease of access, maximum tow rating, axle ratios for towing power versus fuel efficiency, engine, transmission and driveline options for the balance of power and efficiency, and towing technology to make it easier for more employees to hitch up and comfortably tow the trailers they need.”

While there is no shortage of specs or factors to consider, most selections are driven by usage and budget. Lieberum says everything — from cab size, box length, 4x4

Ford Pro’s F-150 Lightning offers an electric fleet solution with overnight charging that allows you to start the day at a full charge and Pro Power Onboard which turns the truck into a fully-functioning generator.

needs, axle ratio, payload, towing capacity, and powertrain attributes — need to fit the job at hand. “There is no one-size-fits-all [solution], but we often see customers buying bigger trucks to make sure they have every possible need covered,” said Lieberum. “Sometimes, customers who use telematics are surprised when they look at actual usage data — using tools, like our EV Switch Assist — and find they are able to replace their aging work trucks with new F-150 Lightnings or XL Hybrid powertrains that will not only do the job, but also save them money.”

Sowers stresses the importance of working closely with your dealer to identify the specific needs of your fleet and working to “job rate” your vehicles. “By providing [your dealer] specific usage requirements, they can help spec the right vehicle in terms of gross vehicle weight, payload and trailer towing capability,” said Sowers. When it comes to trailering needs, says Lieberum, the first thing to consider is the tow rating and other relevant weight ratings, but also towing frequency. “If the truck is towing something very heavy nearly every day, then, typically, that leads to consideration of diesel or higher capability gas powertrains” said Lieberum. “However, if that tow usage is only occasional, then it might be more cost effective to buy a powertrain that is optimal for day-to-day usage but still has the capability to tow that load even if its performance while towing is less than what a larger, more expensive powertrain would have provided.”

Ford offers trailer tow enabling features on all of its trucks, which range from basic equipment — like tow mirrors and trailer brake controllers — to high-tech features like 360-degree cameras with trailer and Pro Trailer Hitch Assist.

Ford’s top-performing heavyduty truck is the F-450, featuring a 6.7-liter Power Stroke Diesel High Output producing 500 horsepower and 1,200 lb-ft of torque, rear wheel drive configuration, with a single cab and dual rear wheels. “With the proper trailering options, like the Max Tow Package, this pickup is capable of towing 40,000 pounds using a gooseneck hitch” said Lieberum.

“This truck is designed for extreme work, towing the largest flatbed or lowboy trailers to move equipment like excavators, telehandlers and bulldozers.”

Lieberum also notes that when it comes to chassis cabs, Ford’s F-600, a Class 6 truck, can be customized with a variety of second unit bodies, including dump bodies or stake beds more in line with pickup usage — though it offers the same cab and interior features as the F-250 through F-450 pickups, despite having a gross vehicle weight rating of 22,000 lbs.

Ram’s most powerful, most capable pickup in the segment, The Ram Heavy Duty, offers a towing capacity of up to 37,090 pounds and a payload capacity of 7,680 pounds. “Ram was the first to achieve the 1,000 lb.-ft. of torque milestone with the Cummins I-6 Turbo Diesel, now rated at 1,075 lb.-ft. of torque,” said Sowers. Along with these capabilities, Sowers says operator comforts are also a priority. “Class-leading ride and handling is accomplished via a class-exclusive link-coil rear (2500) suspension system with optional rear air suspension (2500 and 3500),” said Sowers.

Looking ahead in this segment, Sowers says Ram will be launching its new 25MY 2500 and 3500 pickup trucks in Q1 2025, noting the 25 model will include significant updates in capability, technology and safety.

As manufacturers deliver more diverse powertrain options, the optimal powertrain for any one construction fleet is unique to that fleet and should be based on the contractor’s specific needs. Lieberum says key considerations include cost of ownership, regulatory compliance and convenient access to service centers. “Generally,” said Lieberum, “fleet customers tend to buy the standard powertrain unless their needs dictate otherwise in order to optimize their budget.”

“For heavy-duty towing applications, [Ford’s] PowerStroke diesel engine remains highly soughtafter,” said Lieberum. “Contractors seeking a balance of payload, towing capacity and cost often opt for the

3.5-liter EcoBoost V6 or 7.3-liter gas V8 engines.”

According to Sowers, “We see traditional gas and diesel powertrains continuing to be the mainstream uses through the end of the decade, but there will be increasing mixes of electrification and ZEVs.”

Lieberum says Ford’s alternative options, PowerBoost Hybrid system and F-150 Lightning Pro, offer unique advantages for jobsites lacking power infrastructure. “These vehicles enable contractors to recharge cordless tools, power corded equipment, and serve as central power sources for entire work areas while minimizing idle fuel consumption,” said Lieberum.

“Most fleets are taking a pragmatic approach to introducing electrification as part of a smaller mix and growing over time,” said Sowers. He also notes that most fleets will mix their powertrains for their specific needs, and electrification is applied where the functional needs can be met.

“For those requiring heavy-duty towing capabilities, diesel engines are the ideal choice,” said Lieberum. “Customers prioritizing a balance of payload, towing capacity, fuel efficiency and affordability often opt for gas-powered models. In terms of specific vehicles, those seeking optimal fuel economy and utility usually gravitate toward the Maverick Hybrid while those looking for significant electrical power for jobsite applications might prefer the F-150 Lightning Pro. In 2024, we switched the base engine on F-150 to the 2.7L Ecoboost and have seen many happy customers appreciate that power and capability.” He also notes the construction industry tends to demand V8 gas F-150s for towing smaller trailers, while the Super Duty pickups come standard with the 6.8L V8 gas engine or optional 7.3L V8 gas engine, which customers tend to prefer when ultimate towing capability is not required.

Lieberum notes that recently, many customers have begun to gravitate toward hybrid or electric vehicles to capitalize on fuel savings and government incentives. Ford Pro now offers E-Switch Assist, a tool that helps businesses assess the suitability of their current Ford vehicles for transitioning to electric options.

On the sustainability front, Ford aims to achieve carbon neutrality by 2050 globally, and 2035 in Europe, focusing on its vehicles, operations and supply chain. Today, the company offers a range of gas, hybrid and electric vehicles to support this goal, giving end users the opportunity to make informed choices on their own path to carbon-neutral transportation.

Ram is aiming for carbon neutrality on a tighter timeline, with a plan to reduce carbon emissions by 50% by 2030 and be entirely carbon neutral by 2038, including the Ram Truck line.

Within the last decade, technology adoption has boomed as contractors began to see gains in efficiency and productivity driven by data. According to Sowers, “Data usage will be a significant part of improving business efficiency going forward. Today, it amounts to using telematics to improve vehicle efficiency, but the future will integrate the vehicles with the tools and equipment to make an efficient workplace.”

Ford Pro’s Telematics offering delivers key information to end users, including fuel consumption, EV range, idling time, fleet tracking and vehicle health monitoring. Further enhancing these fleet management capabilities, the Ford Pro Telematics Drive app allows remote monitoring, trip detail exports, vehicle checks and remote locking/unlocking.

Ram’s Sowers notes that new technology not only helps to improve vehicle and fleet efficiency, but also steps up resale value, maintenance and reliability. Telematics especially optimizes operations and provides an added layer of protection to fleets.

As Lieberum notes, the integration of Lytx dashcams with Ford Pro Intelligence and Ford commercial vehicles is another layer of technology designed to promote safer driving practices. “Construction customers are recognizing the value of active modems in their vehicles,” said Lieberum, “which enable a range of digital capabilities such as remote security, advanced telematics and remote video. Ford Pro offers complimentary services like Ford Pro Telematics Essentials and E-Telematics to enhance fleet efficiency and security. “

As we look to the future of truck technologies, Lieberum says even more features and benefits will come to market and continue to improve pickup offerings. For example, one of Ford’s new features, Smart Acceleration Truncation on the F-150 Lightning, provides enough power to drive normally, and intelligently adjusts for the load on the truck while not delivering all of the available 775 lb-ft of torque when not needed, to help optimize efficiency and wear and tear on things like tires.

“With our engineers and employees constantly innovating, the potential is limitless to bring future innovations that provide a better product to our customers,” said Lieberum.

According to Sowers, “All future trucks will likely [include] connected platforms to allow telematics, predictive maintenance and repair via over-the-air updates.” And today, the future is appearing much closer than anyone might expect.

Read More eqtoday.co/pickupprogress

Stellar 990DLX Deluxe Fuel Trailer

Fully DOT-compliant, 990DLX Deluxe Fuel Trailers feature fuel tanks that are independently mounted on the frame with spring-loaded bolts for maximum vibration control. An adjustable hitch makes it easy to connect the trailer for towing to and from your worksite.

Standard Features:

• 54-in. weatherproof lockable cabinet with gull wing doors

• Dual 6,000-lb. spring axles with electric brakes

• 7,000-lb. manual jack

• Safety chains

• Adjustable height hitch

• Aluminum wheels

• DOT-compliant LED lighting

• Two LED floodlights

Two-part primer powder/powder coating process

• Rock guard coating on fenders and frame

• Spring-mounted internal tub-baffled tank

• Reinforced tread plate fenders with access steps

• 5-in. x 2-in. tubular steel frame Fuel Pump Options:

• Gas-powered 5.5 hp motor with 2-in. pump. Capable of 40 gpm. Dual-filter system with high-flow auto nozzle.

• 12V pump capable of 25 gpm. Single-filter system with auto nozzle.

• 12V DEF pump capable of 8 gpm, DEF filter and on-board battery. Optional Upgrades:

• Air compressor or combination air compressor/generator

• 1/2-in. x 50-ft. air reel

• Spare tire carrier and tire

• Full drawer set with four 3-in., two 5-in. and one 7-in. drawers

• Solar battery charger

12V electric jack

• Rear cabinet

• V-nose cabinet

Western Global MultiCube NonHazmat Diesel Fuel Trailer

Western Global has introduced its first non-hazmat, multitank diesel fuel trailer solution: MultiCube. This transportable 630gal. multi-tank diesel fuel trailer is for fuel distributors, rental companies, general contractors and others looking for a simple option that allows them to haul diesel fuel without needing hazmat drivers. Designed to safely transport diesel fuel when and where it’s needed, the rugged MultiCube features six independently isolated 105-gal. fuel tanks housed within an outer tank, providing built-in, double-walled containment.

Air-tow Trailers offers the 3D-12 Dump Flat Trailer, which facilitates material and equipment transfer on jobsites.

This heavy-duty trailer features a 12-ft. deck made of diamond steel plate for durability. The 3D-12 can serve as both a drop-deck and dump trailer, offering versatile applications for businesses. This trailer features an equipment capacity of 10,000 lbs. and a dump capacity of 8,000 lbs. Capable of reaching a full dump angle of 45 degrees, ground-level loading makes operation safe in work areas. This tandem axle trailer is equipped with rubber suspension, a 2 5/16-in. ball coupler, four D-rings, remote control and adjustable chain. It has a powder coat finish (royal blue) for protection against water, debris and mild corrosion. Optional accessories include the following: 16-in. spare tire, 6-amp battery charger or solar charger, roll-up canvas cover, extended sideboard bracket kit and wireless hydraulic pump control.

FuelPro Skid Mount Fuel Trailer FuelPro Trailers has introduced skid mounted fuel trailers that facilitate onsite refueling with an emphasis on longterm construction projects. Single tank or multitank versions are available from 475 to 990 gal. FuelPro skid mounted fuel trailers can be customized with additional compartments for DEF, grease, hydraulic fluid, engine oil, reclaim oil, water, anti-freeze and gear oil, as well as components such as a custom six-drawer tool box, ARC N AIR compressor/ generator with welder and battery charger, tool/parts storage compartment and more. The 700-gal. multi-tank model features a 25-gpm 12-volt DC industrial grade pump, a 40-gpm electric start gas engine, 35- or 50-ft. auto-retracting 1-in. hose reel, 18 ft. of 1-in. hose (30- and 50-ft. lengths optional), auto-trip nozzle, FuelPro 20-micron fuel filter, lockable vented fuel caps, tank pressure relief vent and at-a-glance fuel gauge. Optional accessories include air compressor/generator, custom six-drawer tool box, custom paint and more. It is also coated with PPG Delfleet Essential polyurethane epoxy primer for protection against the elements.

Charger

Utility Trailer has released its new Cargobull Liftgate Battery Charger as an integrated option with Cargobull 625 and 655MT Hybrid TRUs (transport refrigeration units). The Cargobull Liftgate Battery Charger is available on Utility’s 3000R refrigerated trailers with Cargobull’s ultra-low-emission TRUs. The Cargobull Liftgate Battery Charger helps keep trailers’ liftgate batteries topped off and in optimum charge condition. The device takes 480 volts of electrical energy from the Cargobull 625 or 655MT Hybrid TRU to provide liftgate batteries low-voltage charging with a maximum output of 40 amps or 480 watts of power. The new liftgate battery charging system is separate from the charger that maintains the Cargobull 625 and 655MT Hybrid TRUs’ starting battery. Located close to the liftgate battery pack, the Cargobull Liftgate Battery Charger routes 480 volts through a conduit to protect the cable from normal wear and tear.

Take the guess work out of buying online with bidadoo.

Trained experts inspect the equipment from its chassis down to its sprockets, create a detailed Verified Conditions report, and upload photos and video to every listing.

Our five-star rating system confirms the quality of the equipment you’re purchasing. A quality and condition rating is given to product specifics like chassis, undercarriage, engine, hydraulic system, and more.

Your purchase is protected through eBay’s Business Equipment Purchase Protection.

All inspections are completed by bidadoo experts, a trusted eBay partner with over 20 years of industry experience.

Get end-to-end support at every step through bidadoo experts for questions about the product, shipping, financing, or liens and warranty.

Chassis

Sheet Metal/Body

Paint/Decals

Frame

C-Frame/Push Arms

Blade Linkage Pins/Bushings

Belly Pans

Undercarriage

Track/Show&Link Condition

Track Tensioners

Front Idlers

Sprockets

Rating Key

Based on age and use

Talbert Custom 70SA-RC-RA Trailer

This trailer incorporates multiple axle configurations based on customer requirements for versatility. The trailer’s design features a flip extension to accommodate a tri-axle jeep dolly, allowing for maximum load configurations.

Talbert’s E3Nitro self-tracking axle extension accommodates a 3+3+3 configuration for proper weight distribution and weight transfer. The trailer maintains a 70-ton rating at half the deck length and offers 6 in. loaded road clearance. The 70SA-RC-RA features a wide center bolster for axles one and two and two and three, as well as a rear half bolster with a lightweight design of axle three for even weight distribution from the truck to the rear of the trailer. The specialized trailer can run with three, four or five axles in a row and offers a 120-in. swing radius with a gooseneck extension for up to a 222-in. swing radius.

The 10SSA, 10SSE, 12SSA and 12SSE equipment trailers offer 10- to 12-ton capacity, and models with electric or air brakes are available based on operating preferences. These trailers feature adjustable Hutch 9700 three-leaf suspension, as well as Sumitomo tires and hub piloted wheels for reliable transport. Stability is facilitated by double-acting springs and an accessible lightweight ramp for loading and unloading equipment. LED wiring harnesses are sealed for protection from rugged elements on the jobsite. The heavy-duty trailers have a 33-in. deck height, as well as a 19-ft. flat deck with a 6-in. beavertail.

Felling Trailers Adds Larson Cable Trailers to Offerings

Felling Trailers has added Larson Cable Trailers to its product offering with the LCT-7500, LCT-5620 and LCT-5700. A division of Felling Trailers, acquired in May 2021, Larson Cable Trailers specializes in fiber-optic cable-handling trailer products. The Felling Trailers sales team now offers the LCT models as part of its expansive product line.

The C550 55-ton hydraulic removable gooseneck construction trailer delivers more load versatility and faster turnaround times to ensure you get more out of every minute on the road or on-site. Premium QT100 steel construction and the largest deck well in the industry enable you to haul a variety of equipment with ease. These trailers are reliable, designed with long-lasting components that eliminate costly repairs and reduce the total cost of ownership. They are also backed by unmatched customer service and support. Through its collaborative product design process, Brandt has consulted extensively with customers to create heavy haul trailers that set the standard for the industry, providing versatility and reliability in a premium product offering.

Curry Supply’s new Utility Truck and Trailer product line is an expansion into the utility vehicle market made possible through partnerships with Dur-A-Lift, Stellar Industries, Posi+, Axion and Dakota Bodies. With these partnerships, Curry Supply has curated a selection of trucks and trailers that can be customized to fit specific customer requirements. The line includes products ranging from insulated and non-insulated aerial lifts to crane service trucks, digger derricks and utility trailers, the new line offers solutions for a variety of tasks, from electrical work to heavy lifting, as well as sign and signal maintenance to roadside repairs. The trucks and trailers are designed to withstand demanding jobsites and weather conditions with safety as a priority. Each product can be tailored for various needs, offering a range of configurations, body styles and equipment options.

Faster when it Matters Most

Set to Deliver a Bigger and Better Event in Chattanooga

January 28 - 30, 2025

Chattanooga Convention Center

Chattanooga, Tennessee

NOTEWORTHY FEATURES:

Over 120 industry-leading Manufacturers & Suppliers from the Paving & Pavement Industry

Robust Educational Program Featuring Tracks on Paving, Striping, Sweeping, Sealcoating, & Business Management & More!

Fast-Paced Demonstration Showcase with Enhanced Hands-On Opportunities

Unlimited Networking Opportunities Including the Pre- and Post-Show Parties!

The backhoe market is strong in response to demand and the versatility that the construction equipment offers on the jobsite. Meanwhile, cleaner and highly efficient models are continuously being added to company’s lineups.

A Global Market Insights (GMI) report on the backhoe market indicated the market was valued at $48.8 billion in 2023 and will grow at a CAGR of more than 5% from 2024 to 2032, driven by rising environmental regulations and a growing focus on sustainability in the construction industry.

The report pointed out manufacturers are responding to strict emissions and air quality regulations by developing cleaner and highly efficient backhoe models. There is mounting pressure on the construction sector to adopt sustainable practices and the significance of eco-friendly backhoes has increased in the last few years, GMI noted.

Various governments offer incentives and subsidies to encourage the adoption of environmentally friendly equipment, further driving contractors to opt for cleaner backhoes.

The demand for backhoes is associated with construction and infrastructure projects, according to the report. With the growing urban areas and government investments in roads, bridges and buildings, the need for versatile earthmoving equipment such as backhoes remains high in the current landscape. Additionally, the increasing trend of renting construction equipment also supports market growth, according to the GMI report.

The construction industry is focused on prioritizing sustainability and emission reduction.

This shift is set to drive the development and adoption of hybrid and fully electric backhoes, GMI points out.

The construction and mining segment accounted for around 55% market share in 2023, according to the report. The adoption of backhoes in construction and mining applications is driven by their versatility, costeffectiveness and ability to perform various tasks, GMI noted.

Backhoes can efficiently handle excavation, trenching, material handling and loading, making them essential for a wide range of tasks on jobsites, the report pointed out.

Additionally, backhoes excel in foundation work and utility installation in the construction industry. Their adaptability to different environments and tasks makes them a preferred choice for contractors seeking efficient and multifunctional equipment, GMI noted.

Based on propulsion type, the diesel segment held around 91% of the market share in 2023. Factors cited include high torque output and large payload capacity.

NORTH AMERICAN BACKHOE MARKET DOMINATES

The North American backhoe market leads with a share of more than 33% in 2023, driven by increased infrastructure investments, urbanization and technological advancements, according to the GMI report.

GMI noted the American Jobs Plan has significantly funded infrastructure projects across the geography, thus increasing the demand for versatile equipment such as backhoes.

The ongoing development of cities and their utilities are a driving factor

in the need for backhoes. The GMI report cited Caterpillar and John Deere as being focused on the development of innovative models to meet the market’s changing needs.

The United States is the largest market for backhoes, driven by significant construction, infrastructure development, and agricultural activity, the report noted.

Significant expenditures on roads, bridges, and public utilities drive up demand for backhoes in construction and excavation operations, noted GMI, adding backhoes are required for a variety of applications across the vast agricultural terrain, including land clearing, trenching\ and material handling in the country.

The U.S. market is open to technology advancements in backhoes, including telematics, automation, and fuel-efficient engines, thus creating lucrative opportunities for the market, according to GMI.

John Deere, CNH Industrial N.V. and Kubota Corporation held a significant market share of more than 18% in 2023, the report pointed out.

The companies are noted for actively investing in cutting-edge technologies such as IoT, AI and machine learning to develop intelligent backhoes. Their machines feature predictive maintenance, automated controls and heightened operational efficiency, according to the report.

In the past couple of years, CASE Construction Equipment has introduced several new backhoe loaders to meet modern jobsite needs, noted George MacIntyre, product manager, backhoe loaders and tractor loaders, CASE Construction Equipment.

“The 580EV electric backhoe is our latest innovation — and the industry’s very first of its kind — that offers an overall more sustainable option for municipal crews, utility teams and other contractors, with zero emissions, low-noise operation and biodegradable hydraulic fluid,” he said.

CASE also recently launched the 580SV Construction King side shift

backhoe and larger 695SV side shift and center pivot models.

“This was in response to jobsites becoming tighter and tighter as well as labor shortages, as these machines excel in versatility and maneuverability, letting operators use the side shift backhoe to move the boom left or right to work more efficiently parallel to walls or in confined spaces, and bring real muscle to the job, too,” MacIntyre said.

The CASE 580EV, 580SV, and 695SV backhoes ultimately serve different jobsite needs, MacIntyre pointed out, adding that the biggest differentiator between them is that the new 580EV is electric.

“That makes it ideal for public works departments, urban, utility or other work in areas with strict emissions and noise regulations, like parks, schools and residential areas,” he noted.

“The 580EV carries over the same dimensional loading and digging specifications and delivers the same breakout forces as our popular fourwheel-drive, 97-horsepower CASE 580SN diesel model. It is designed to deliver up to eight hours of operational run time on a single charge, depending on the application. “

Electrification also provides performance features like torque response and peak torque at any RPM so operators do not need to wait for an internal combustion engine to ramp up to meet load demands.

The 580EV is powered by a 400-volt, 71-kWh lithium-ion battery platform that is charged with the same type of Level 2 J1772 adapter found in automotive EVs.

The four-wheel-drive 580EV uses two independent electric motors for the PowerDrive transmission and hydraulic pumps feeding the loader, backhoe, and steering systems for performance in loading applications.

The 580EV includes an Extendahoe

to boost reach, while features like ProControl swing dampening, PowerLift/PowerBoost and electrohydraulic controls are designed to improve precision and ease of use on the jobsite.

Electrification also provides performance advantages like instantaneous torque response and peak torque at any RPM, so operators do not need to wait for an internal combustion engine to ramp up to meet load demands.

The diesel-powered 580SV side shift and 695SV Construction King models — available in side shift and center pivot configurations — deliver power and maneuverability for heavy-duty construction, MacIntyre pointed out.

The side shift models excel in tight spaces and let operators dig rectangular trenches without the need to reposition, while the center pivot models are ideal for general construction applications, he added.

The 580SV side shift features a tool carrier design that improves stability and material retention, while its sideshift configuration and narrow width make for more productive work in confined spaces, MacIntyre noted.

CASE also included new features, like an 8-inch color display, air conditioning, a front-dash display and adjustable four-corner, multicolored LED strobe lights.

The battery platform also uses a thermal management system with system-specific cooling circuits to regulate temperatures and help maintain performance in hot or cold conditions.

The cab features heating and air conditioning, an 8-inch touchscreen display, customizable work mode/ sensitivity settings, push-button start and operator security codes. Multicolored, four-corner strobe lights are designed to enable operators to work safely and meet regulatory requirements, with adjustable colors,

strobe patterns and an “always-on” feature for low-light conditions when strobes are not needed.

For bigger, tougher jobs, the CASE 695SV side shift and center-pivot models feature a tool carrier loader arm, allowing them to do double duty as a wheel loader, meaning one less machine to bring to the jobsite, noted MacIntyre.

Both 695SV models are equipped with four-wheel drive, four-wheel steer (with front wheel, crab, and circle steering modes) and four equalsized tires and include a PowerShift transmission, he added.

The expanded CASE backhoe offering is also compatible with numerous attachments, giving crews a big toolkit for improving productivity, speed and accuracy on highly varied jobs, MacIntyre said.

David Young, Caterpillar product application specialist, pointed out, “While the standard backhoe remains a workhorse of the construction jobsite, new electric models are now also contributing to sustainability gains on-site.”

New Caterpillar models now available include the Side-Shift BHLs (428, 432 and 434) and Center-Pivot (415 IL, 416, 420, 420 XE, 430, 440, 450).

“For the side-shift models, it’s all about a small footprint and being able to work in tighter locations,” Young notes of their benefits. “Side-shifts also have advantages in terms of roading as well, for both roading length and ride quality. Also, because the hoe can shift from side to side the operator does not have to reposition the machine as often for certain applications.”

Bobcat Company recently expanded its product line with the Bobcat B760 backhoe loader, designed to offer the most digging depth in its size class. The B760 backhoe loader will

be available at Bobcat dealership throughout North America in late 2024 into early 2025.

The Bobcat B760 features a lift capacity of more than 2,200 pounds at full reach, a digging depth of 18 feet, 5 inches, and nearly 180 degrees of backhoe swing for less repositioning and fast cycle times.

The backhoe loader comes with a standard-equipped extendable arm that provides up to 8 inches of additional dig depth compared to other machines of the same size. The frontend loader provides a lift capacity of 7,985 pounds with its standard, general purpose bucket.

“The new B760 helps operators accomplish more on the jobsite with its dig, load and carry versatility,” says Jamison Wood, Bobcat product development specialist. “The backhoe loader is designed for durability, easy operation, simple maintenance and incredible performance. Its size keeps it accessible on sites with limited space, while its impressive travel

speeds keep operators productive across large jobsites.”

Powered by a turbocharged 3.4-liter, 96-horsepower Bobcat engine, the B760 is designed to deliver powerful, high-torque performance and efficiency and achieves emissions compliance without the use of a diesel particulate filter for no regeneration, less downtime and easy maintenance.

The backhoe and loader breakout forces are designed to enable operators to dig in some of the most challenging jobsite tasks such as excavation, site preparation, material handling, trenching and snow removal, among others.

The power shift transmission provides quick direction changes while the backhoe loader’s swift travel speeds allow operators to minimize the need for a trailer.

The B760 controls have been designed to be laid out and easy to use so new operators can reach maximum productivity in less time.

The 5-inch color display panel provides full-featured machine interaction and monitoring capabilities for efficient and productive operation. The operator station and optional cab are designed for all-day comfort, with controls designed for easy use and minimal operator fatigue.

Additional standard features that enhance operator productivity include:

˜ Ride control for reduced bucket spillage and enhanced operator comfort.

˜ Automatic return-to-dig positioning to maximize cycle time efficiency.

˜ Eight work lights for long days of loader and backhoe operations.

˜ A 1.4-cubic-yard general purpose loader bucket for greater jobsite versatility.

˜ Pilot controls for smooth, fast and precise backhoe workgroup operations.

˜ Auxiliary hydraulics to power attachments from the front and rear.

The Bobcat B760 is designed for digging, trenching, and attachment work. Operators can load and carry in the front and dig in the back.

Operators can drive down the road at 22.6 mph with the Bobcat B760, enabling quick transport across large jobsites or to entirely different jobsites without having to always use a trailer.

The four-wheel drive power shift transmission is designed to provide simple, on-the-fly operation and quick direction changes for easy loader work and machine positioning.

John Deere also offers an option in the market with the 310 X-Tier backhoe. The backhoe — tested and showcased in 2021 — is one of the company’s E-Drive (hybrid-electric) models. The E-Power technology is designed to provide lower daily operating costs, lower jobsite noise and zero tailpipe emissions. In 2023, the 310 X-Tier E-Power backhoe model entered the next phase of development.

Read More eqtoday.co/backhoemkt

The Caterpillar 432 side shift backhoe loader is designed for moving materials, digging and filling on construction sites. This 92-hp machine is powered by a C3.6 electronic turbo Intercooled engine and is equipped with an all-wheel drive configuration, enabling stable performance on rugged terrain. Under the hood, flow-sharing valves help manage oil flow across various functions of the backhoe loader. A four-speed powershift transmission comes as standard on the 432. Operation is facilitated by the directional control lever, rather than floor mounted lever, to shift gears. The six-speed automatic shift transmission is available as an option. Heavy-duty axles and a 100% locking rear differential come as standard on Cat backhoe loaders. The axles provide durability whilst providing traction on uneven surfaces. No daily greasing is required on the front axle.

JCB 3CX Backhoe Loader

The entry-level 3CX full-size backhoe loader is now available with optional pilot controls, allowing operators to easily adapt from operating an excavator to a backhoe. 74-hp Ecomax diesel engine delivers 295 ft.-lbs. of torque and meets Tier 4 Final emissions standards without the need for a diesel particulate filter

• Standard backhoe dig depth of 14 ft. with 13,942 lbs. of breakout force

• 13,603-lb. maximum loader breakout force and 6,354-lbf. loader lift capacity to its full height

• 38-gpm hydraulic flow

• Stress relieved and reinforced excavator end

• Features standard limited-slip differential, parallel lift loader geometry, return-to-dig setting, loader arm float, daily fluid auto-checks and JCB LiveLink telematics

• Reversible stabilizer feet allow use on asphalt/concrete and in the dirt

• Low, narrow hood line and four-ram geometry loader arm design provide enhanced visibility to the work area Rear-opening, one-piece hood provides easy engine access

• Optional climate-controlled cab, hammer pipework, an extending dipper and loader pipework

Kubota L47 and M62 Tractor Loader Backhoes

The 47.1-hp L47 and 63-hp M62 fourwheel-drive loader and landscaper utility tractors incorporate the HST Plus transmission, which automatically controls the hydrostatic pump and drive motor to provide optimal control.

• Feature Tier 4 Final engines and come in tractor-loader or tractor-loader-backhoe configurations

• Transmission includes standard Stall Guard Plus and Backhoe Crawling Mode

• Boast digging depths of 10 ft. and 14 ft. 2.4 in. and bucket digging force of 5,825 lbs. and 6,572 lbs.

• IntelliPanel provides vital machine information and relays key messages to the operator

• Feature an independent PTO, throttle-up switch and low-effort electronic throttle lever and PTO switch

The L-Series includes engine upgrades, pressurecompensated load-sensing (PCLS) hydraulics on the 310SL and machine control improvements.

• 310L, 310SL, 315SL, 310SL HL and 410L now feature a 4.5L

John Deere PowerTech EWL Tier 4 Final engine that boosts horsepower across the models Lift mode added to the 310SL, providing up to a 10% to 15% increase in backhoe lift capacity

• AutoShift technology available as a base offering on the 310SL, 315SL, 310SL HL, 410L and 710L

• Optional Auto Ride Control

• 310L EP includes a simpler front-axle design and a four-speed manual synchromesh transmission

The new CASE 580EV electric backhoe loader carries over the same dimensional loading and digging specifications and delivers the same breakout forces as the four-wheel-drive, 97-hp CASE 580SN diesel model. With this new production unit, CASE has made several updates from thermal management to operator controls to electrify a machine with comparable specs to the 580SN. CASE also included new features, like an 8-in. color display, air conditioning, a front-dash display and adjustable fourcorner, multicolored LED strobe lights. Powered by a 400V, 71-kwh lithium-ion battery platform that’s charged with the same type of Level 2 J1772 adapter found in automotive EVs, the new electric backhoe loader is designed to deliver up to eight hours of operational runtime on a single charge, depending on the application. The battery platform also uses a thermal management system with system-specific cooling circuits to regulate temperatures and help maintain performance in hot or cold conditions. The four-wheel-drive 580EV uses two independent electric motors for the PowerDrive transmission and hydraulic pumps feeding the loader, backhoe and steering systems for performance in loading applications. The 14-ft. backhoe also includes an Extendahoe to boost reach, while features like ProControl swing dampening, PowerLift/PowerBoost and electrohydraulic controls support use on the jobsite. Electrification also provides performance features like torque response and peak torque at any rpm, so operators don’t need to wait for an internal combustion engine to ramp up to meet load demands. The cab has features like heating and air conditioning, an 8-in. touchscreen display, customizable work mode/ sensitivity settings, push-button start and operator security codes. Multicolored, four-corner strobe lights also let operators work safely and meet regulatory requirements, with adjustable colors, strobe patterns and an “always-on” feature for low-light conditions when strobes are not needed.

The B760 backhoe loader features a lift capacity of more than 2,200 lbs. at full reach, digging depth of 18 ft., 5 in. and nearly 180 degrees of backhoe swing for less repositioning. The backhoe loader comes with a standard-equipped extendable arm that provides up to 8 in. of additional dig depth. The B760’s performance and versatility extend throughout the machine, with the front-end loader providing a lift capacity of 7,985 lbs. with its standard, general purpose bucket. Powered by a turbocharged 3.4L Bobcat engine, the B760 delivers powerful, high-torque performance. It achieves emissions compliance without the use of a diesel particulate filter (DPF). Features include:

• Ride control for reduced bucket spillage

• Automatic return-to-dig positioning

• Eight work lights for long days of loader and backhoe operations

• A 1.4-cu.-yd. general purpose loader bucket for jobsite versatility

• Pilot controls for backhoe workgroup operations

• Auxiliary hydraulics to power attachments from the front and rear

the launch of its ST230V,

At Trimble Dimensions 2024, held Nov. 11-13 in Las Vegas, Nevada, SANY America Inc. announced its formal entrance into the compact track loader (CTL) manufacturing scene with the launch of the SANY ST230V. The move not only expands the company’s existing product portfolio, but also propels SANY America to a new tier within the equipment market.

SANY America’s parent company, Sany Group, started in 1989 and has grown and evolved into a global brand with a presence in 140 countries around the world. Since 2006, SANY America has been investing in growth across the United States. Its 272-acre facility in Peachtree City, Georgia, employs more than 300 employees, and its expanding dealer partner network stretches from Maine to Washington.

Alongside the launch of the ST230V, Equipment Today (ET) sat down with SANY America’s Nichole Greco (NG), director of marketing, to discuss the new release, as well as the company’s current priorities and plans for future.

ET: LET’S TALK ABOUT THE NEED FOR THE ST230V. WHY A COMPACT TRACK LOADER AND WHY NOW?

NG: We have a large, global parent company behind us, SANY Group, which is No. 1 in excavators in the world. But we definitely want to have a presence in America and in Canada as well, and part of that presence is building out a full product line. The

CTL is a new product line for us — we know it will be fantastic in this market, plus, we’re the value player. This the perfect machine for us, because this is the perfect place to put value.

ET: WHAT DOES THE ST230V LAUNCH OFFER END USERS?

NG: We always want to be honest and upfront with our customers. We want them to understand what we offer: easy-to-own, easy-to-operate machines.

We back all our machines — from our ship-to-shore cranes to regular cranes, from drill rigs to excavators, and now the CTL — with the industry’s strongest standard warranties, which means we either meet or exceed whatever best warranty is out there today.

Part of our value proposition is bringing in components by trusted brands — for instance, the ST230V features a Yanmar engine. We are offering Virnig Manufacturing attachments —15 to start — and we’re excited to have that collaboration with them, bringing equipment operators high-quality products that deliver value.

We’ve made some smart moves in design and accessibility, making everything easy to get to. The fuel tank is on the side of the machine, so it’s easy to fuel. The cab is spacious, and the AC is cranking — you’re never going to be hot in this machine. I love the door — it can be easily closed from the outside, so operators don’t have to engage it from the inside and then close it and then hop out. There’s a great backup camera and work light package, as well. End users are getting a great value and reliable OEM support from SANY America in the launch of the ST230V.

Our dealer network across the U.S. will be growing exponentially in 2025.

In the compact equipment market, features can make or break an operator’s success in getting the job done well. Below, Lance Taylor, product manager of the CTL and skid steer at SANY America Inc., shares the ST230V’s key differentiators and what sets it apart from the competition.

➊ Fully loaded — The fully loaded model is the initial offering in this category.

➋ High-flow hydraulics — 36.2 gpm high-flow hydraulic systems provide more power to attachments.

➌ Auto-reversing radiator fan — Allows operators to set the time either as needed or manually.

➍ Air-ride seat — Limits shocks and vibrations for the operator.

➎ Flip-down door — Offers operators easy access in areas with limited clearance.

We’re building a couple of company stores that you’ll see pop up soon, and we’re looking at expanding our sales channels and increasing brand awareness. We want end users to get to know us and know who we are, what we can deliver and where we stand in the marketplace. We’re committed to being here. We’re definitely going to be here for the long haul. We have our dealers across the country, and we’re building out that full product line and something that’s different about us compared to other OEMs.

PRODUCT IN DEVELOPMENT?

NG: We’ve wanted this machine, and we’ve been going down the right path for it for about three and a half years. In truth, that’s how long it takes to get it right, reviewing all considerations of what it should be. It went through all the design integration and engineering conversations and the process of selecting the right components to put into it. Following those conversations, then we get down to the nitty gritty of operational concerns: Does it have

the visibility it needs? Does it have the safety features it needs? What features are we offering on our other machines that end users have come to expect? It’s a challenge to find the fit and the specs to build what we want to deliver and get it to the right price point, as well as ensuring it’s a top-of-line, reliable machine that we can easily sell without any problems. And it will be that’s exactly what it’s become, and soon, we’ll scale up production and get this into the hands of our dealers and end users.

ET: HOW DID SANY AMERICA COME TO THE DECISION TO LAUNCH THE ST230V?

NG: A group of people, including myself, sit on the product steering committee. Our decision to launch had to do with how many units are in the marketplace, where our dealers are located and what our dealers are asking for. We knew that there needed to be another solution out there, and SANY America, being the value player, wanted to offer contractors that solution. Lance Taylor, product manager of the CTL and skid steer at

Operating on a Yanmar 4TNV98CT engine and offering a 2,430-pound rated operating capacity with a max breakout force of 5,733 lbf, the ST230V made its debut in November at Trimble Dimensions 2024.

SANY America, did a fantastic job with this machine. It would have taken so much longer to get it to the finish line if he wouldn’t have been involved. He came on-board, and he’s the one that really took this to the finish line for SANY America.

ET: WHAT KIND OF RESPONSE ARE YOU GETTING FROM DEALERS?

NG: They are very excited. We brought the ST230V – this is the first machine we’ve done this for – to SANY America’s demo site at our Peachtree City facility. It’s a great place for dealers to bring their customers. It was everyone’s first chance to see the machine, and every one of the dealers and their customer said the same thing: “This is great!” They were so surprised and happy about it. We wanted it to be right before it reaches the market, so we gathered and applied their feedback, did

additional testing of the machines by putting them through a lot of hardcore work with skilled operators and owners. Then we filtered through any additional adjustments and set a course for the launch.

If they could write orders right now, they definitely would. We showed it at a recent dealer meeting and their response was, “How many can I buy? When can I buy this? What is the price?” Availability will fall somewhere in the midyear 2025 timeline, and there’s more to come soon regarding pricing and the warranty. However, as the value player, we’re committed to making sure the price is favorable and we’re offering a great warranty. We know we have a great product to bring to the construction jobsite.

We’re confident about that, and dealers are confident about it too.

Read More eqtoday.co/st230vlaunch

When it comes to production and availability for the ST230V, SANY America is aiming for a midyear 2025, but says this is just the beginning for its path forward in the American market. The company has several other announcements, integrations and equipment developments in the works following this release, including:

• TRIMBLE PRODUCT INTEGRATIONS SANY America is in the process of finalizing Trimble integration offerings for the ST230V, as well as its excavators, graders and other equipment.

• WHEELED SKID STEER Following the ST230V, next, SANY America will offer a new wheeled skid steer, along with different size classes for both it and the CTL product lines.

• CRANE — While information is limited at this time, in 2025, SANY America also anticipates the launch of a new crane for the construction market.

The 9,205-lb. TL75VS is a durable, construction-grade machine. A 74-hp Yanmar Tier 4 Final diesel engine and 2,555-lb. rated operating capacity enables performance on the jobsite. The 10-ft., 6.5-in. max bucket pin height supports the ability to load dirt into trucks and complete other at-height tasks. Operators can navigate the jobsite, reaching travel speeds up to 7.5 mph. The vertical-lift unit supports at-height work and truck loading applications, featuring a high lift height and rated operating capacity. The new machine features a torsion axle suspended undercarriage with a pivot link system at the rear axle. The linkage technology uses a spring load that reduces oscillation and stabilizes the machine for material retention. Furthermore, the TL75VS can be optioned with a 26-gpm high flow maximized by large line sizes, hydraulic coolers and direct-drive pumps for reduced power loss and increased flow and pressure directly to the attachment.

The TL10V2 has a tipping load of 7,205 lbs., bucket breakout force of 6,520 lbs. and lift arm breakout force of 5,400 lbs. Vertical lift design enables a maximum hinge pin height of 10 ft. 4.8 in. and dump height fully raised of 7 ft. 11.9 in. Kubota 3.3-liter, Tier 4 Final diesel engine produces 74.3 hp and 195 ft.-lbs. of torque. Standard Active Power Control automatically maintains engine power and keeps engine within its optimal range. Fully redesigned operator’s station with 5.7-in. color multi-informational display and precision pilot controls. Updated undercarriage with wide block quiet ride track system provides better flotation and ride quality and reduced noise and vibration.

March 4–7

The SANY ST230V compact track loader operates on a Yanmar 4TNV98CT engine and offers a 2,430-lb. rated operating capacity with a max breakout force of 5,733 lbf. The multifunctional control panel features one-click startup and one-click unlock, alongside a 7-inch LCD display. The spacious cab features autotemp HVAC, and air-suspension seat and pilot controls. Standout features of the ST230V include: 36.2 high-flow hydraulic system; hydraulic quick-coupler-ready design; auto-reversing radiator fan; air-ride seat; flip-down door. Available mid-2025.

The CL35 has a rated operating capacity of 2,458.2 lbs. (50% tipping load).

• 62-hp Kubota V2403 engine

• Offers a 6,475-lb. breakout force, 7-ft. 9-in. dump height and 38° dump angle

• 5.6-psi minimum ground pressure

• Comes in open canopy or fully enclosed cabin with heat and air conditioning

• Comfortable interior with adjustable seat and easy to operate pilot controls

Rubber inner running surface of tracks reduces roller wear from contact with core metal while minimizing vibration and noise

The John Deere 331 P-Tier compact track loader features a new one-piece cab design, technology features and operating power. This compact track loader is powered by a 98-hp Yanmar four-cylinder engine with a 29.5-gal. fuel tank. During use, the 331 P-Tier offers 11,000 lbs. of bucket breakout force. Two speed settings are available on the machine with a maximum travel speed of 8.5 mph. Rubber tracks with steel inserts enable movement over rugged terrain. Attachment Manager is available as an upgrade on the 331 P-Tier. This solution takes the guesswork out of determining attachment performance parameters by enabling preprogrammed flow and pressure for John Deere attachments. Standard lighting equipment includes two halogen lamps at the front and one at the rear.

The Bobcat T770 compact track loader delivers more digging force, pushing power and lifting capacity to keep moving in bad weather and less than ideal ground conditions. With a 92-hp engine, 3,475-lb. rated operating capacity (ROC), strong lifting power (up to 11 ft. of vertical lift) and added reach, you can place cargo, dig deeper and tackle the most demanding tasks with less ground pressure. Like all M-Series models, the T770 was engineered to meet customer needs with a cab design that offers improved comfort, visibility and operator-friendly features. The optional pressurized cab provides a cleaner and 60% quieter work environment. Other available options include Selectable Joystick Controls (SJC) that move up and down in conjunction with the seat and a deluxe instrumentation panel to monitor key loader functions.

Built to perform in tight spaces, our compact excavators are designed to keep your projects moving seamlessly. With a reduced tail swing and fuel-efficient engine, you’ll be equipped to work all day, every day.

4 ways propane-powered equipment can offer jobsites more performance, portability, safety and savings

Data from the Propane Education & Research Council (PERC) shows that propane-powered small-engine job site applications can reduce greenhouse gas emissions by up to 17% and sulfur oxide (SOx) emissions by up to 16% compared with gasoline-fueled models.

Propane engines also provide consistent and steady power output, which is ideal for construction equipment that requires a reliable energy source to maintain productivity. Compared with its counterparts, propane engines also start reliably in cold weather, minimizing delays year-round.”

The fuel chosen to power jobsite equipment can be a game changer, impacting everything from operational costs and environmental impact to performance and reliability — and propane comes with a strong, strategic business proposition.

As construction professionals weigh their options and look for the best fit for their operation, they should consider what key perks propane has to offer. A growing number of professionals across various industries, including construction, are finding propane helps check all the important boxes as an energy source.

Notably, propane can provide reliable and versatile power for construction mainstays like jobsite heaters, light towers, forklifts, concrete trowels, backup generators and towable generators.

While operating propane, your crews will notice the following:

Construction professionals know the best jobsite equipment and energy sources are the ones that help maximize productivity. Propane is a highly portable energy source, allowing contractors to complete work without bringing in an alternative power source for electrical equipment.

Because propane can be stored on site, it’s always accessible regardless of severe weather or other interruptions.

Propane’s grid independence allows teams to get mobilized and start work immediately — and is especially beneficial for jobsites that aren’t yet connected to utilities or are located off the grid entirely.