® Helping you optimize ROI on your construction equipment DECEMBER 2022 #1 Market Leaders Send a CTL ASAP: Today's Compact Track Loaders Are More Precise, Faster HARDER, BETTER, FASTER, STRONGER Backhoe-Loader Tech Evolves CLEAN-UP TIME Contractors Rally to Remove Natural Disaster Debris BACKHOE-LOADER SPEC GUIDE 2022

™ MADE FOR AMERICA | SERVICE THAT’S LOCAL EASY TO OWN, EASY TO OPERATE | BUILT TO ENDURE FULLY LOADED IS THE NEW STANDARD * Warranty applies to 2022 Excavator models only. sanyamerica.com

PROFIT MATTERS

RUNNING THE BUSINESS

For

THE

PRODUCT ROUNDUPS

EARTHMOVING

FLEET MANAGEMENT

EARTHMOVING TRENDS

Prepare for the Future of Backhoe-loader Technologies Backhoe-loader technologies are advancing fast, and operators must be ready for changes.

BACKHOE-LOADER SPEC GUIDE

The 2022 Backhoe-Loader Spec Guide

Explore the latest backhoe-loader features and specs from various equipment manufacturers.

FLEET MANAGEMENT

Construction Equipment and Contractors Aid in Hurricane Ian Disaster Cleanup

Disasters during the past 20 years have caused more than $1 trillion in damages.

FLEET MANAGEMENT

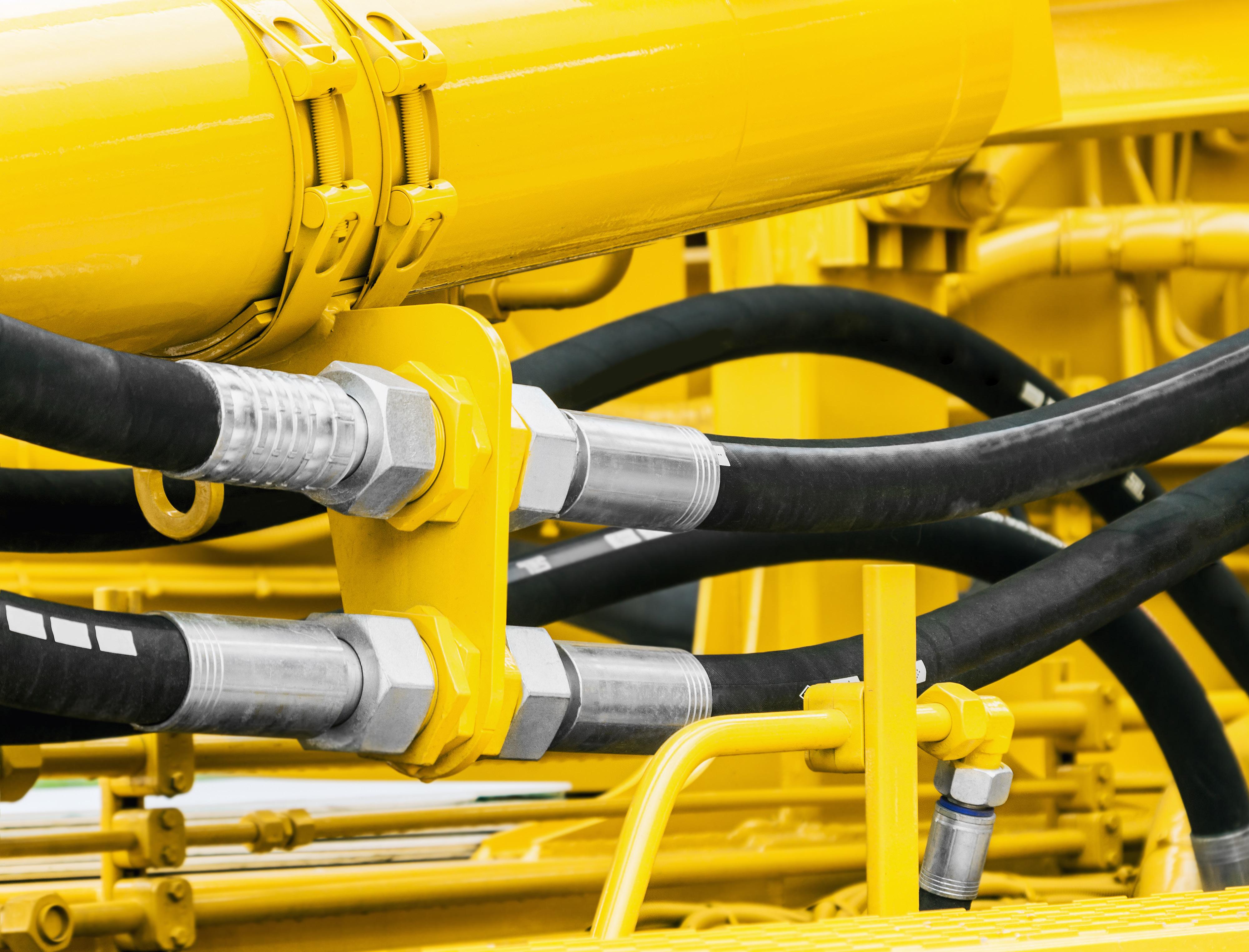

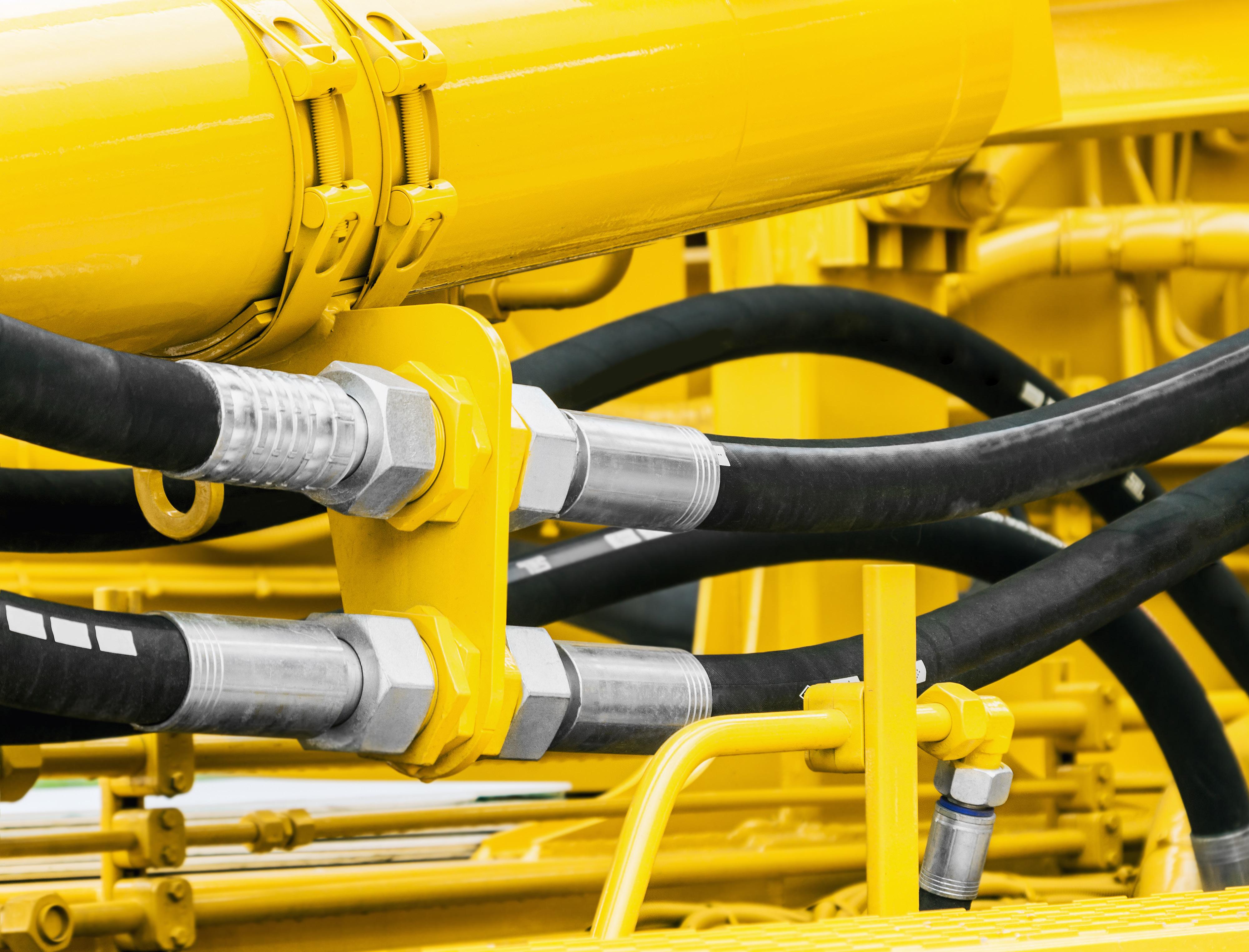

How Long Should a Hose Last?

Knowing what can kill your hose is half the battle. Prevention plus proactive care will maximize life and improve bottom line.

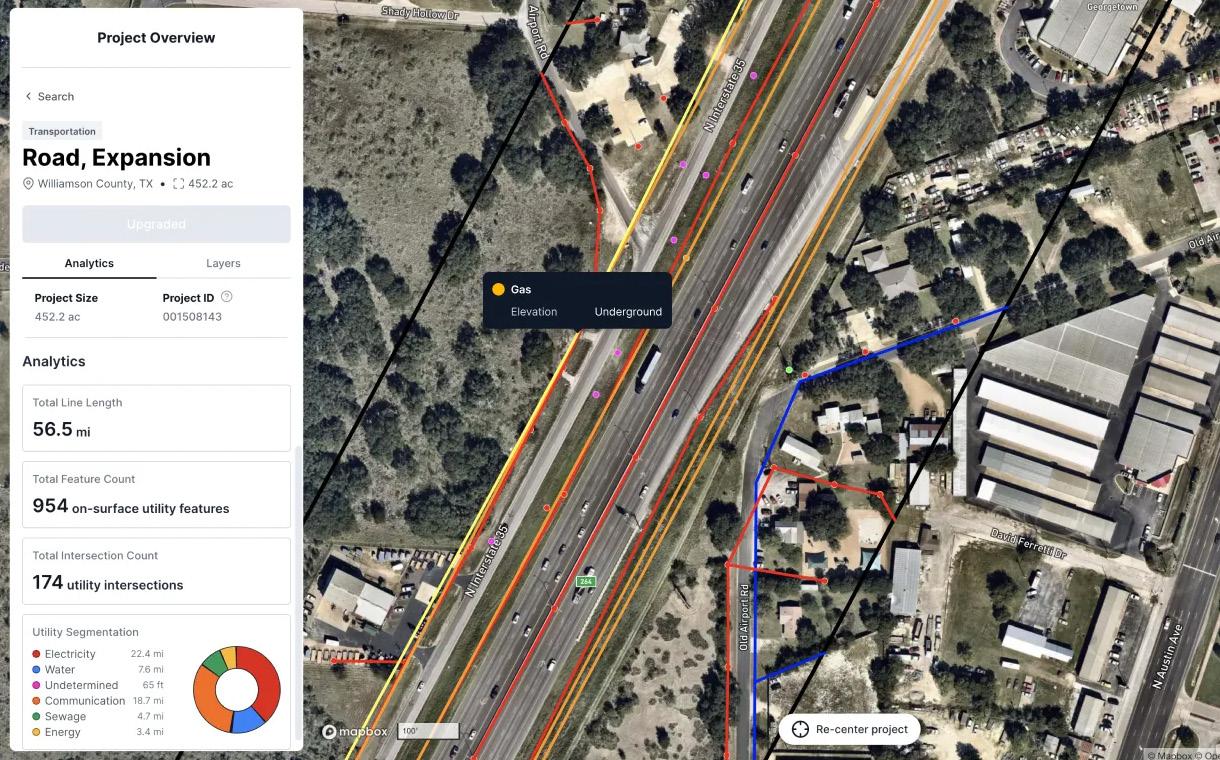

FLEET MANAGEMENT Telematics-based Fleet Management Is the New Normal for Aerial Equipment By fine tuning data into workable amounts, aerial equipment fleet managers can use telematics to improve daily operations.

FLEET MANAGEMENT

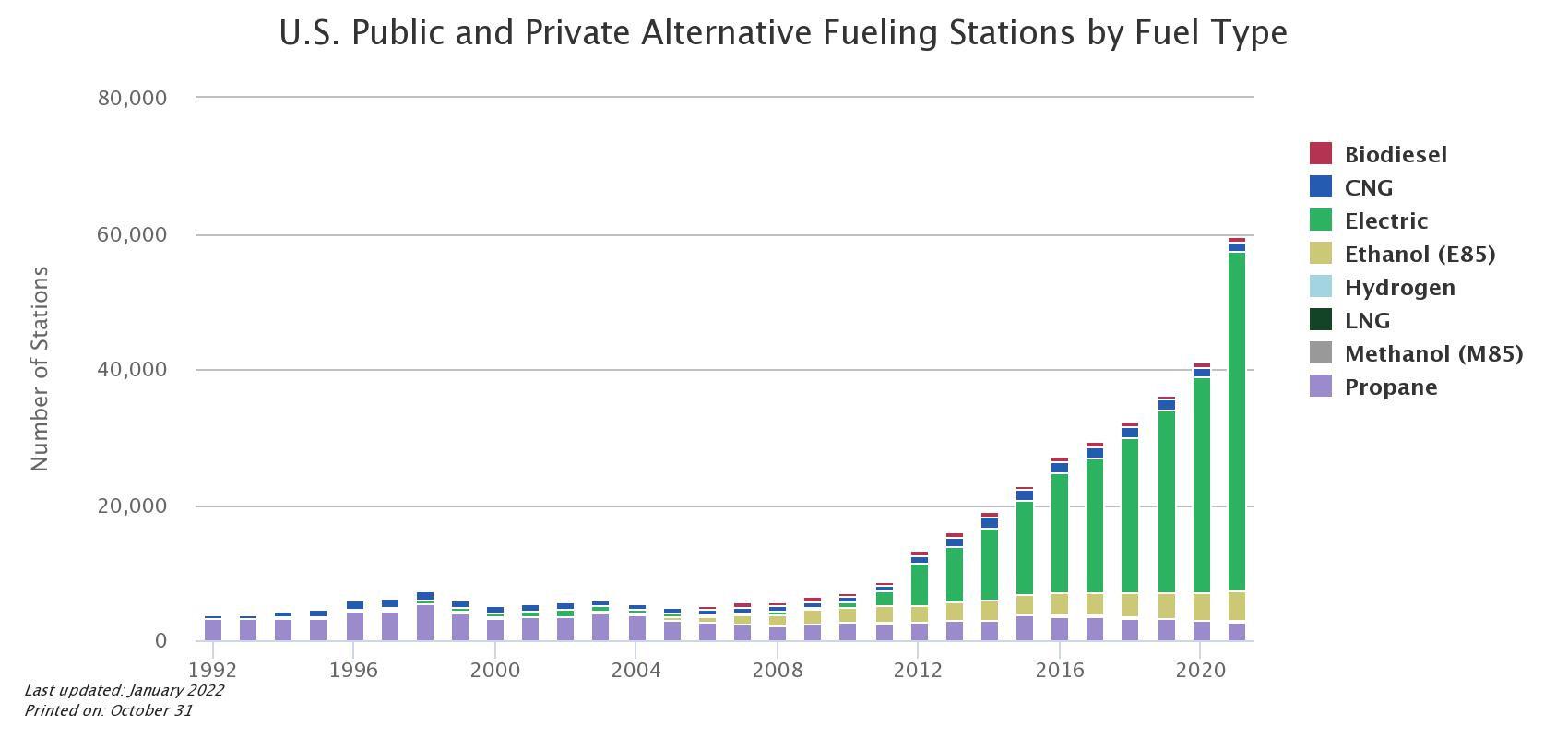

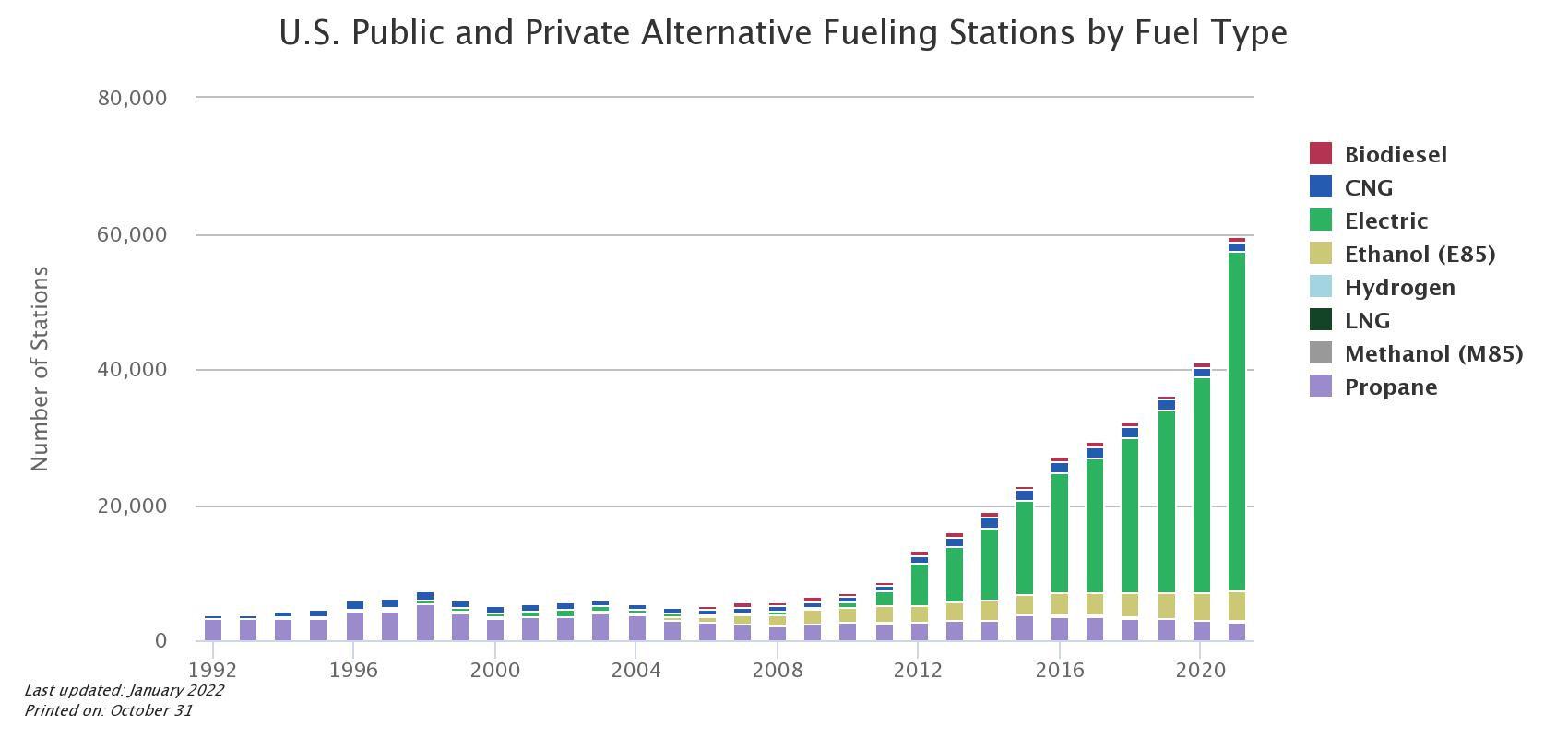

The Future is Now: Examining Construction’s Power Alternatives It is up to construction industry manufacturers to find ways to lessen diesel’s carbon impact.

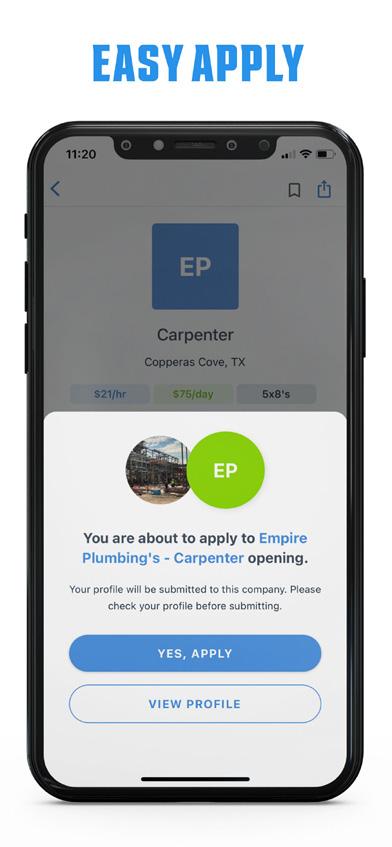

TECHNOLOGY How A Kentucky Contractor Punches Their E-Ticket To Success Eliminating trucks waiting at the paver or plant by sending those trucks to another project allows contractors to lay more asphalt. TECHNOLOGY Why Redundancy of Connectivity is Essential on the Jobsite Repetition is key when determining safeguards to keep IoT connections working. TECHNOLOGY How Technology is Increasing Productivity on Jobsites Technology in the form of accounting software, project management software and AI has changed construction processes.

Published and copyrighted 2022 by AC Business Media Equipment Today makes every effort to report manufacturers’ product news accurately, but is not responsible for validity of news claims.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. and Canada to management, engineering, supervisory, equipment maintenance and other personnel who have buying influence in the construction equipment industry. Subscribe online at www.ForConstructionPros. com. Publisher reserves the right to reject non-qualified subscribers.

One year subscription to non-qualified individuals: U.S. $50; Canada/Mexico $70; all other countries $100 (payable in U.S. funds, drawn on U.S. bank).

Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). For change of address or subscription information call (847) 559-7598 or fax (847) 291-4816. Equipment Today (USPS 369-290, ISSN 0891-141X) is published is published 12x with issues of January, February, March, April, May, June, July, August, September, October, November and December by AC Business Media, 201 N. Main Street, 5th Fl., Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Please send change of address to Equipment Today, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA. Canada Post PM40612608. Return Undeliverable Canadian Addresses to: Equipment Today, PO Box 25542, London, ON N6C 6B2.

4 EQUIPMENT TODAY | December 2022 Contents December 2022 | Vol. 58 No. 10www.forconstructionpros.com/equipment Contents www.forconstructionpros.com/equipment

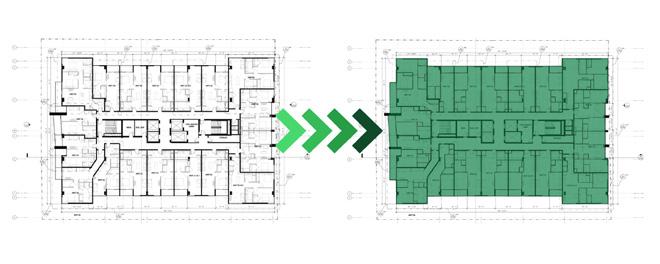

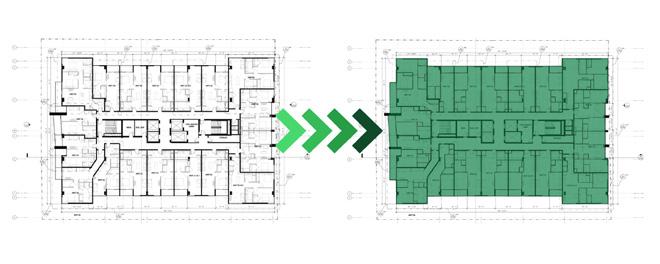

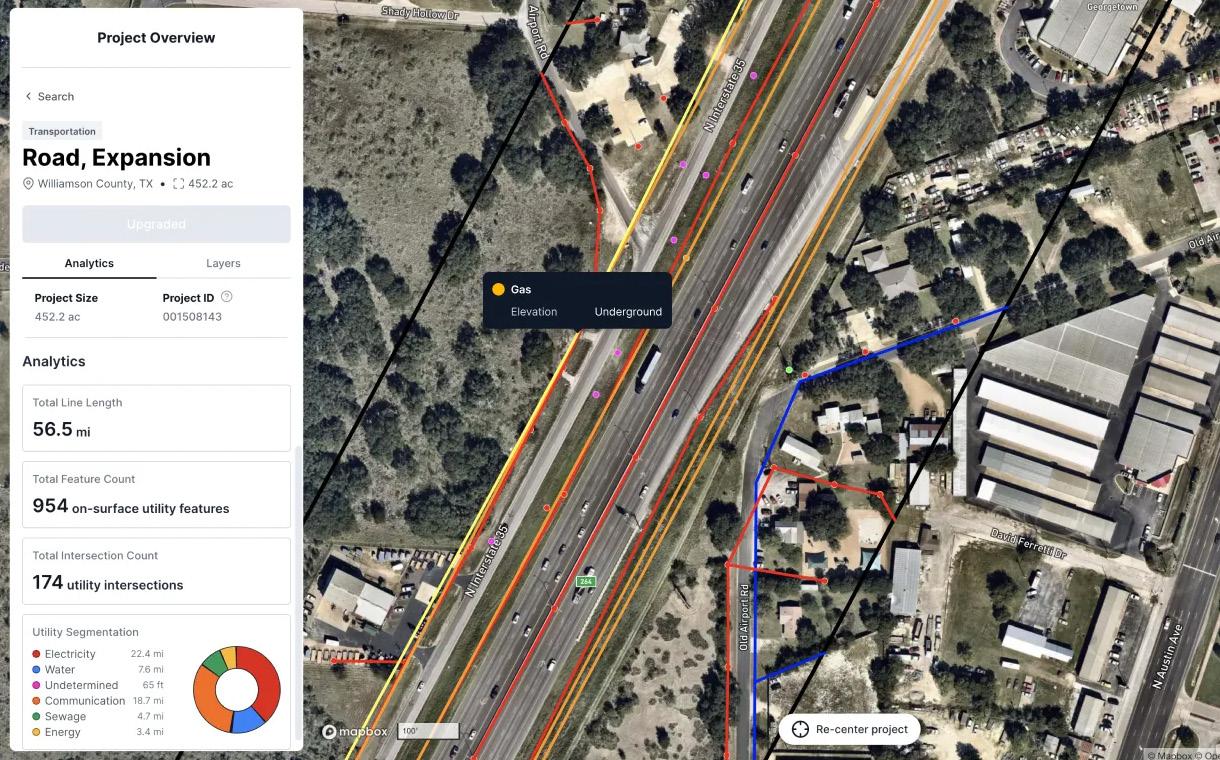

Unlock

Data to Improve Construction Fleet

Telematics

20 23 26 30 32 34 36 38 40 42 December 2022 | Vol. 58 No. 12 PREMIUM CONTENT https://eqtoday.co/9pd73s DIGGING DEEPER PODCAST https://eqtoday.co/s7sfkm VIDEO NETWORK https://eqtoday.co/k2p285 WEB EXCLUSIVES COVER STORY How Compact Track Loaders Get the Job Done Quickly and Precisely Today’s compact track loaders range from supersized to ultra-small, offering new versatility and tech on jobsites. BREAKING GROUND Cat Operator Challenge Offers Fun, Glory for Competitors Operators from Cat dealerships around the country competed at the national challenge in Clayton, N.C. EQUIPMENT

New Product Launches from bauma and more

latest telehandlers, wheel loaders, dozers and

TECHNOLOGY

Hidden

Efficiency with

The construction fleet industry has advanced in ways previously unimagined.

INTRODUCTIONS

The

more.

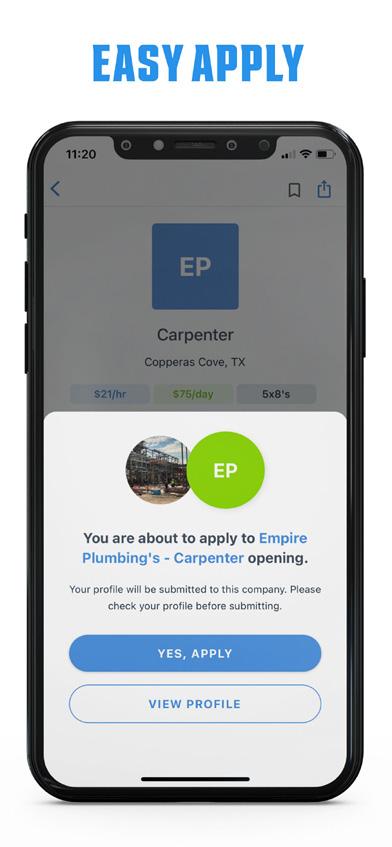

Proves Enterprise Tech Can Transform Smaller Contractors

Little Dixie

and

Commercial contractor leans on Trimble Viewpoint Spectrum, EquipmentShare, Procore to adopt new project delivery systems

exceed owner expectations.

Prepare

Next Year No matter what size your company is, you have to assume competitors are looking for ways to improve productivity and leave you in the dust.

Training Translate

Real-World Results?

6 8 44 48 49

BRIDGING

GAP Does Simulation

to

Safer, more efficient and cost effective: the ROI for simulation training shows broad benefits to both workers and employers who need skilled people on the job quickly.

New backhoe, compact track, skid steer loaders for the jobsite.

16 25 35 FEATURES 10 DEPARTMENTS Cover photo courtesy Mack Trucks

Tires, batteries, chargers and more to keep a fleet functional. TECHNOLOGY Maps, apps, kits and other tools to supercharge an operation.

Caterpillar Global Operator Challenge

Offers Both FUN AND GLORY for Competitors and Onlookers Alike

Afew days before I left for Munich, Germany to attend bauma 2022, I had the fortunate experience of attending the Caterpillar Global Operator Challenge Regionals in Clayton, N.C. As a fun drone preview video depicted beforehand, the competition featured the widest representation of all the major Cat equipment types: excavators, wheel loaders and backhoe-loaders.

The drone loops overhead and circles around operators, dodges between the spaces between worksites and flits in and out of open equipment cabs, foreshadowing the finesse and precision the competing operators would need to possess at the challenge. The drone buzzes by a woman in an office room, eliciting a particularly humorous tossup of papers and a, “Hey! I’m rehearsing in here!” shout. Watching the preview video left me enthused to attend and witness these best-in-class operators in real time.

Finally, 36 operators descended on the Raleigh area on Oct. 18 and Oct. 20, with intentions of demonstrating their best possible skills. A rainstorm the night before did not dampen the competitive spirit, due to the Edward J. Rapp Customer & Training Center facility team, led by Matt Smith, a Caterpillar marketing leader, laying down gigantic tarps across the competition sandboxes, which the team then weighed down with the competition equipment to prevent the tarps from blowing away. Thus, the demonstration dirt was clean, dry, and ready for digging, compacting and moving on the first day of the competition.

I enjoyed interviewing several of the leaderboard competitors, all of whom said the excavator is their favorite piece of construction equipment to operate. The excavator portion of the challenge was highly technical and specific, requiring exact digging and avoidance of a strategically buried “utility” pipe during operation. The wheel loader challenge proved more flashy, requiring the competitors to cart around a Cat yellow 1980s-era Chevrolet Blazer.

Fittingly, this issue of Equipment Today has a special focus on backhoe-loaders, which were a highlight of the Caterpillar Global Operator Challenge Regionals, as well. Specifically, the competitor needed to cross a deep, pre-dug trench with care and without holding the loader bucket too high. Then, the competing operator had to pluck three sports balls off the top

of orange safety cones—a tennis ball, a basketball and a soccer ball—and deposit them from the loader bucket into a barrel.

One competitor stood out during this challenge, operating with gentle nudges and careful but confident maneuvering –John Schiedeck of Texas, who ended up winning the entire North American eastern regional challenge on Oct. 18.

“The backhoe seemed like 30 minutes,” Schiedeck said, who completed the challenge in well under 15 minutes. “I had to tell myself, ‘Slow down, slow down,’ because I didn’t want to rush it and then mess up.”

Schiedeck owns his own contracting company, Schiedeck Construction, and purchases equipment from Caterpillar dealer Holt Cat in San Antonio, Texas.

“It makes me feel accomplished in my career and it kind of reaffirms what I feel like I can do, you know?” Schiedeck said, expressing gratitude that his wife, children and in-laws could be there to cheer him on throughout the several-day trip to North Carolina.

Schiedeck, along with Matt Ferris of Kinkaid Civil Construction (Empire Cat), the winner of the North American western regional challenge, will compete for the world title at the Caterpillar Global Operator Challenge Finals at CONEXPO in Las Vegas in March 2023. Keep an eye on ForConstructionPros.com/Equipment and our Equipment Today social media accounts for live coverage of the Caterpillar Global Operator Challenge world championships final at CONEXPO! ET

Erica Floyd Editor-in-Chief Equipment Today efloyd@ACBusinessmedia.com

Charles Rathmann crathmann@acbusinessmedia.com

6 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

Read more at: https://eqtoday.co/BGDec22

BREAKING GROUND | By Erica Floyd, Editor-in-Chief Equipment Today E @EquipmentToday D @EquipmentToday C @equipment-today-magazine-official Q @equipmenttoday EDITORIAL Editor-in-Chief

Managing Editor

Editor

AUDIENCE Audience Development Manager Angela Franks PRODUCTION Senior Production Manger Cindy Rusch

Art Director April Van Etten ADVERTISING/SALES Brand Director Sean

Sales Representative Nikki

Sales Representative Kris

Sales Representative Tadashi

Sales Representative Kristin

AC BUSINESS MEDIA Chief Executive Officer Ron Spink Chief Financial Officer JoAnn Breuchel Chief Revenue Officer Amy Schwandt Chief Digital Officer Kris Heineman VP, Audience Development Ronda Hughes VP, Operations & IT Nick Raether Content Director Marina Mayer GM, Online & Marketing Services Bethany Chambers Content Director, Marketing Services Jess Lombardo Director, Demand Generation & Education Jim Bagan Director, Enterprise Sales Kay Ross-Baker CIRCULATION & SUBSCRIPTIONS PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax:

circ.EquipmentToday@omeda.com LIST RENTAL Sr. Account Manager

Data

LICENSING

® Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 www.ACBusinessMedia.com www.ForConstructionPros.com/equipment

A Caterpillar Global Operator Challenge operator demonstrates skills during the eastern regional competition in Clayton, N.C. Erica Floyd

Erica Floyd efloyd@acbusinessmedia.com

Gigi Wood gwood@acbusinessmedia.com Technology

crusch@acbusinessmedia.com

Dunphy sdunphy@acbusinessmedia.com

Lawson nlawson@acbusinessmedia.com

Flitcroft kflitcroft@acbusinessmedia.com

Soma tsoma@acbusinessmedia.com

Pride kpride@acbusinessmedia.com

(847)-291-4816

Bart Piccirillo,

Axle 402-836-2768 | bart.piccirillo@data-axle.com REPRINTS &

Sales Representative Greg Schulz 920-542-1239 gschulz@ACBusinessMedia.com

www.IronPros.com

Cramped, high-traffic jobsites create major challenges. All-new -7 Series mini excavators run circles around obstacles to dig, lift and push productivity to the max.

SCAN THE CODE Learn more about new -7 Series mini excavators.

FEARLESS MOBILITY. POWERED BY INNOVATION.

©2022 Hyundai Doosan

Hyundai

The

Infracore. All rights reserved.

Doosan Infracore is an affiliate of Hyundai Heavy Industries Group.

Doosan trademark, , is used under license from Doosan Corporation.

Doosan DD100 Dozer

The 10-metric-ton DD100 dozers are now available in North America. This machine features a six-way variable angle pitch blade. Customers can choose from two blade options: a standard 2.9 cu. yd. blade or an optional 3.4 cu. yd. capacity blade. Specifications include:

˜ Horsepower (gross): 122 hp (91 kW)

˜ Operating weight: 22,300-24,900 lbs. (10.1-11.3 metric tons)

˜ Blade capacity: 2.9-3.4 cu. yd. (2.2-2.6 m3)

˜ Blade height: 3-ft. 7-in. (1.1 m)

˜ Blade width: 8-ft. 11-in. to 10-ft. 6-in. (2.7–3.2 m)

˜ Blade angle: 23°

˜ Drawbar pull: 35,300 lbf. (16 ton-force)

˜ Tumbler distance: 7-ft. 7-in. (2.3 m)

˜ Travel speed, max: 5.6 mph (9 km/hr)

˜ Dozer cabin is ROPS/FOPS certified

Read more at: https://eqtoday.co/ubm5ld

Takeuchi TB335R

Takeuchi has added the new generation TB335R short tail swing compact excavator to its TB300 Series. This excavator fea tures a rugged interior and exterior design, as well as functions that provide performance on the job site. The TB335R’s short tail swing design results in a rear overhang of only 3.1 in. over the tracks, for working in tight or con fined spaces. The cab model TB335R has an operating weight of 8,310 lbs. (3,770 kgs), a maximum bucket breakout force of 9,127 lbs. (40.6 kN) and a maximum arm digging force of 4,290 lbs. (19.1 kN). The excavator is powered by an EPA Tier 4, EU Stage V emission-compliant engine delivering 24.4 hp (18.2 kW) and a maximum torque of 70.6-ft. lbs. (95.8 Nm). The TB335R offers two working modes – Standard and ECO – allowing operators to match the mode to the task at hand, choosing more power or fuel savings as desired.

Read more at: https://eqtoday.co/wo9els

Caterpillar Lithium-ion Batteries

Caterpillar has announced the development of 48V, 300V and 600V batteries for the off-highway industry. The battery range uses lithium-ion technology and features a modular design for performance and packaging. The development program also encompasses inverters, motors, electronic controls, digital services and other critical technologies to deliver the performance, reliability, durability, maintainability and value needed for equipment buyers working in harsh operating environments.

Read more at: https://eqtoday.co/xqwwlc

Caterpillar D1-D3 Dozers with Operator Assist

Cat D1, D2 and D3 Next Generation Small Dozers now feature a suite of operator assist technologies focusing on machine performance and efficiency in the field. The technologies offered include Stable Blade Lift and Tilt, Blade Load Monitor, Slow Slip Traction Control and AutoCarry. Today’s D1-D3 dozers also offer a Cat Command for dozing Remote Control (RC) ready option plus include added mounting features and wire harness routing paths for installation of third-party grade control systems. Simplifying training and operator transition from small to medium machines, small dozers now provide a common technology solution with Cat Command on medium dozer models.

Read more at: https://eqtoday.co/ui7hbm

Bobcat Light Compaction Equipment

The full range of Bobcat light compaction products includes rammers, forward plates compactors, reversible plates compactors and trench rollers. The light compaction line can be used in a variety of settings and is designed to meet compaction requirements on jobsites.

˜ Bobcat rammers (models R60P and R68P)

˜ Three Bobcat forward plate compactors (models FP10.33, FP15.40 and FP15.50)

˜ Three Bobcat reversible plate compactors (models RP22.40, RP30.50 and RP49.20D)

˜ Bobcat TR75 trench roller

Each machine within the line possesses different strengths, including maneuverability, power, fuelefficiency and much more. The versatility of this line was thoughtfully crafted with operators in mind.

Read more at:

https://eqtoday.co/9myrx5

Moog Electric Compact Wheel Loader

Moog has partnered with Komatsu to build a fully electric compact wheel loader. The companies are demonstrating the connected and automation-ready, zero-emission, battery-powered machine at bauma 2022. Moog’s machine electrification system includes an electric traction motor, lift, tilt and steering elec tric cylinders, power electronics, system control computer, battery and battery management system. The integrated software acts as the system’s brain to connect and coordinate actions across the machine while the all-electric actuators and motors provide the muscle. Komatsu will provide the vehicle-level design and assembly, including struc tural configurations that utilize Moog’s machine electrification system. The companies plan to jointly test the all-electric loader after bauma 2022 to further prove the concept. Moog’s machine electrifica tion system will help Komatsu control not only the loader’s motion but also its energy use.

Read more at: https://eqtoday.co/da9lal

EQUIPMENT INTRODUCTIONS 8 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Toyota Material Handling 3-wheel Electric Forklift

Toyota Material Handling has launched an updated version of the Toyota 3-wheel electric forklift. The updates consist of new features and technology, including ergonomics, operator assist, as well as onboard programming and diagnostics. Automatic Mast Control (AMC) promotes stability of loads and the mast cushioning feature reduces wear and tear on the mast. Base features include 3,000 to 4,000-lb. capacity, an AC drive motor and extended travel times. An optional Toyota lithium-ion battery minimizes maintenance costs and downtime.

Read more at: https://eqtoday.co/aqf8eu

Bosch GTB18V-45 and GCU18V-30

Bosch Power Tools, a manufacturer of power tools and power tool accessories, has announced the launch of a new tool category for Bosch, drywall, with the GTB18V-45 18V Brushless 1/4-in. Hex Screwgun and GCU18V-30 18V Brushless Cut-Out Tool. The cordless tools include the technology for performance in an ergo nomic design for construction sites. The GTB18V-45 18V includes variable speed for controlled operating speed and the GCU18V30 18V includes soft-start technology to reduce startup torque. Both include brushless motor technology to provide the power required when working with and cutting through drywall.

Read more at: https://eqtoday.co/rb52k5

DEWALT Cordless Drill and Hammers

Designed for heavy-duty demolition, concrete and masonry work, the DEWALT 60V MAX 22-lbs. Cordless SDS MAX Chipping Hammer breaks down dense concrete with up to 19.4 joules of impact energy. The midweight 60V MAX 15-lbs. Cordless SDS Max Chipping Hammer delivers up to 10.5 joules of impact energy and is maneuverable for horizontal chipping in upper or lower walls and concrete surface preparation applications. DEWALT heavy-duty Critical Connection Undercut (CCU+) Anchors are designed for critical mechanical anchor connections. The 3/8-in., 1/2-in., 5/8-in. and 3/4-in. CCU+ anchor range combines with Hollow Stop and Undercutting Bits, 60V MAX rotary hammers and dust extractors for an OSHA Table 1-compliant cordless system.

Read more at: https://eqtoday.co/1wposc

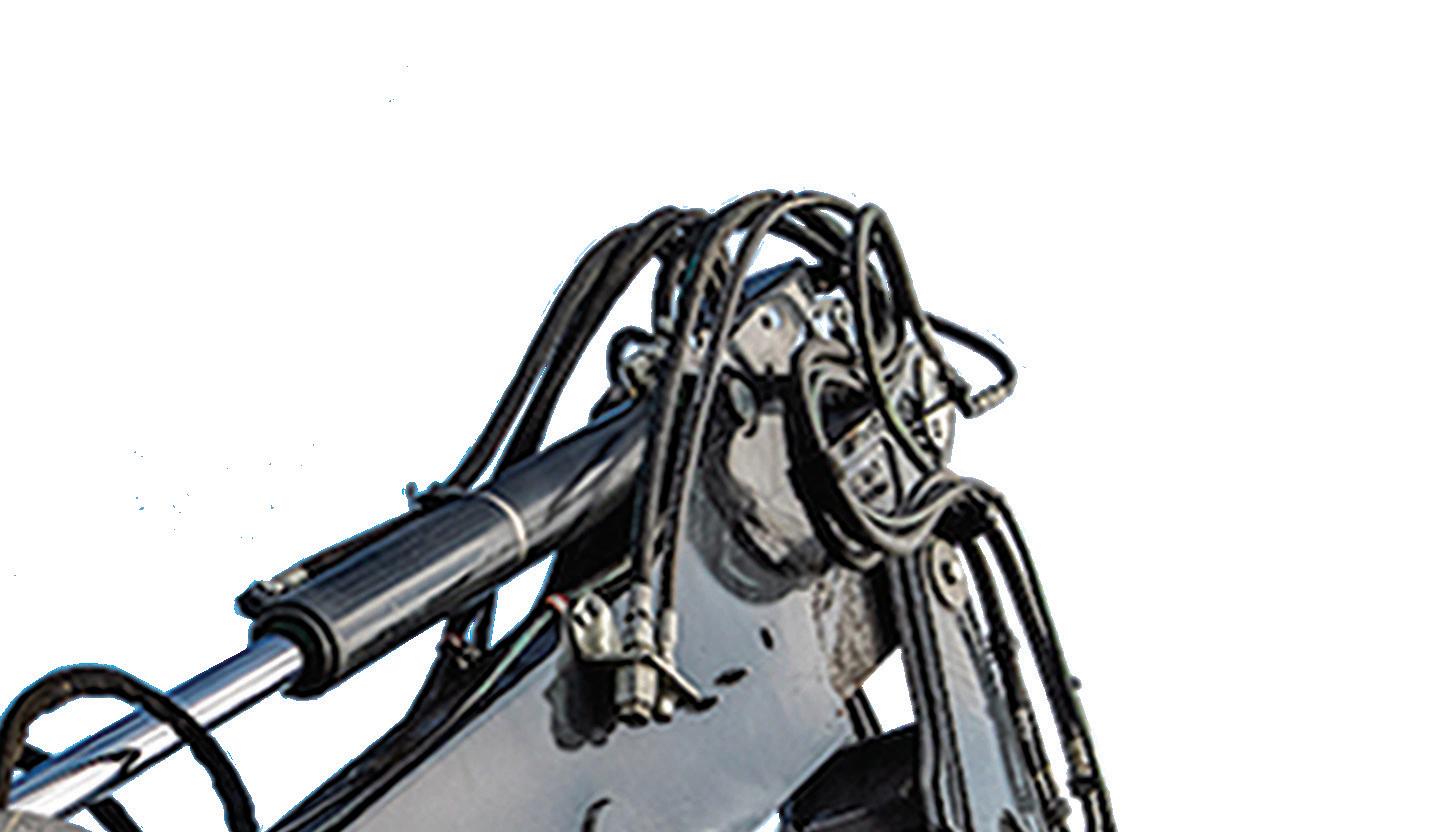

Werk-Brau NOX Tiltrotators

Werk-Brau's Nox tiltrotators for excavators attachment provides 360° of endless rotation with a tilt angle of 2 x 50°, allowing versatility with a wide range of attachments. These tools transform excavators into multi-functional carriers that work in deep trenches, under or between existing pipes and tubes and in other confined space applications. Designed for use with fork tines, grabs, grippers, buckets and more, this technology allows operators to complete projects without repositioning the carrier. A range of Werk-Brau NOX tiltrotators are available for excavators in various classes and categories, from 3-25 tons. With integrated hydraulics and no components protruding from the compact design, the risk of damaging hydraulic cylinders, hoses or other components is reduced on the jobsite. An elliptical rotary actuator provides a low overall height and a narrow width with no cylinders. A low-maintenance worm drive is designed for rugged tasks. For safety, the D-Lock coupler locks the front and rear pins and does not require a safety pin.

Read more at: https://eqtoday.co/1jd3x7

Manitou Construction Machines

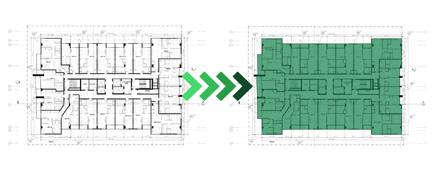

Manitou Group displayed four new aerial work platforms, rotating telehandlers and a fixed telehandler at bauma. The 200 ATJe roughterrain platform (20m working height) is available with four-wheel steer for maneuverability and a basket that can now take 250 kgs of load, 30 kgs more than on the two-wheel drive version. The range of rough-terrain electric telehandlers also welcomes the160 ATJe and 180 ATJe, with a working height of 16m and 18m respectively; these platforms also see their capacity increased by 50 kgs for a basket that can take a total weight of 250 kgs. There is also a second version named 160 ATJ+ e, with capacity increased to 400 kgs. A range extender solution is also available. The MT 625e electric compact telehandler has a capacity of 2.5 tons and a height of 6m, offers performance similar with the internal combustion version and is the same size. Manitou also presented an electric rotating telehandler models MRT 2260e and MRT 2660e with a loading capacity of 6 tons for a lifting height of 22m and 26m respectively. Manitou launched new modeling tech, as well. Available in French and English in the BIM library via the manitou.com website, BIM architects, modelers and designers can introduce Manitou machines into their work environments during construction projects.

Read more at: https://eqtoday.co/c1z8wg

Merlo TF65.9 Telehandler

Merlo's TF65.9 telehandler is designed for heavy handling, where lifting capacity, combined with engine power, is required. Its maximum lift of 29 ft. handles 9,900-lbs. Its 5 ft. reach can carry 4,400-lbs. without flex. The telehandler, with its maximum operating capacity of 14,300-lbs., maintains a compact dimension (17-ft., 3-in. x 7-ft., 10-in. x 8-ft., 2-in.) during use. The TF65.9 has 4WD with three steering modes, 170 hp engine and the Merlo CVtronic continuous transmission. Merlo's new generation safety system, the ASCS (Adaptive Stability Control System), checks the operating parameters of the telescopic handler in real time and allows the operator to work safely. The exclusive Eco Power Drive (EPD) reduces fuel consumption up to 18% with technology that automatically controls and adjusts the engine revolutions based on operating conditions.

Read more at: https://eqtoday.co/89avxy

EQUIPMENT INTRODUCTIONS December 2022 | EQUIPMENT TODAY 9 ForConstructionPros.com/Equipment

Send a CTL ASAP: How Compact Track Loaders Get the Job Done Quickly and Precisely

COMPACT TRACK LOADERS EXCEL AT BIG SHOW DEMONSTRATIONS AND EVENTS

I recently watched a Caterpillar operator nimbly zip around a signature construction yellowhued Cat compact track loader to scoop demonstration dirt, deposit it into excavated trenches and circle around the outdoor demo area to hop into a compactor. The compactor then tamped down the soil for the next competitor round at the Edward J. Rapp Customer & Training Center during the recent Caterpillar Global Operator Challenge Regionals in Clayton, N.C. The result was a demonstration area with freshly-compacted earth that appeared to not have been touched by a previous operator.

In yet another controlled environment, a Bobcat operator in Munich, Germany at bauma remote-controlled a Bobcat compact track loader in reverse to set up a new demonstration of the company’s recently launched E19e electric compact excavator.

Both scenarios left me with my jaw on the ground; I was in awe witnessing these compact track loaders transform a ripped up, disheveled demonstration area to a precise, smooth one in seconds.

COVER STORY | By Erica

Editor-in-Chief, Equipment Today

Floyd,

Compact track loaders range from supersized to ultra-small, offering versatility on jobsites on the road to zero emissions.

10 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

The CASE TV620B tackles a mulching task on soft ground in a heavilywooded area.

The CASE TV620B tackles a mulching task on soft ground in a heavilywooded area.

December 2022 | EQUIPMENT TODAY 11 ForConstructionPros.com/Equipment

CASE Construction Equipment

Joel Honeyman, Doosan Bobcat vice president of global innovation, highlighted the features of the new Bobcat T7X all-electric compact track loader at a bauma FORUM presentation in Munich, Germany, on Oct. 28. Bobcat

“The increased flotation pro vided by [Bobcat compact track loader] track systems makes them ideal on a wide range of jobsites with soft ground sur faces such as sand, mud and clay,” said Michael Fitzgerald, marketing manager for Doosan Bobcat. “With their weight dis tributed throughout the track and ground contact area, CTLs can travel across uneven ground more efficiently and are better at maneuvering through softer ground conditions. Additionally, their long ground contact and light footprint make compact track loaders a good fit for level ing work and finish grading.”

legroom and new joysticks were added with the intent to add to operator ease and efficiency.

The SVL75-3 includes a sealed, pressurized, tilt-up onepiece cab design that is new for the Dash-3 generation. The Dash-2 model — the Kubota SVL75-2 compact track loader line — also had a sealed, pressurized, tilt-up design, but it was not strictly a one-piece design, because the floor pan did not tilt up with the rest of the cab.

With the new one-piece design, the whole cab — includ ing the floor pan — now tilts up and out of the way, leav ing an operator with wide open access to maintenance controls and needs. The move to this one-piece design should help by keeping dirt, dust and noise out of the operator’s working environment.

Kubota has also improved heating and cooling performance of its climate control system.

One further benefit of the new design is increased foot room. There are roughly 2 inch es more in the new Dash-3 cab compared to the Dash-2 model.

Plus, Kubota has overhauled its switches and control layout for this new machine. At the head of the armrests are a pair of updated joysticks. Kubota has implemented fingertip control of all major functions and attachment operations for the SVL75-3 into these sticks, which also feature backlit switches for easier identification of functions.

One note on the new joy sticks: while they are standard on the high-flow models of the SVL75-3, they are an upgraded option for standard-flow models.

Along the right side of the cab is the new 7-inch color touchscreen, jog dial and switch layout. The new display can be controlled by touch or via the jog dial near the switch layout and keeps alerts and machine operation statuses like fuel level, hydraulic oil temperature and auxiliary modes at a glance.

The rated operating capac ity at 35% of tipping is up 8% over the Dash-2 model to 2,490 pounds. Rated operating capac ity at 50% on the SVL75-3 is 3,557 pounds.

package and vents hot air out of the side of the machine. It is a smarter variable speed fan than past models. Kubota has designed the fan to turn more slowly in colder weather, allowing for the engine to warm up faster. Additionally, an autoreversing fan is available.

Other new compact track loaders introduced to the market recently include the Bobcat T7X all-electric compact track load er, launched in early 2022, the platinum edition of Bobcat’s T76 compact track loader, launched in fall 2022 and CASE's TV620B compact track load er, launched in late September 2021. The Bobcat T7X was one of the highlights of bauma for our Equipment Today and IRONPROS crews, given that the machine features a heretofore unexplored innovation — the complete removal of hydraulic power.

As someone who is new to the construction equipment industry, I have studied up on terminology, new product launches and equipment func tionalities and features in the past six months. However, noth ing beats the experience of seeing the equipment in action or, bet ter yet, getting in the cab and operating a new machine.

While I did not operate a compact track loader at bauma or the recent Caterpillar Global Operator Challenge Regionals, I did recently get to jump into the cab of the CASE Minotaur DL550 compact dozer load er, a scaled-down dozer with compact track loader features and benefits. Even better, our IRONPROS team got an upclose look at the new Kubota SVL75-3 compact track load er, the next generation of the OEM’s flagship CTL, at Kubota’s latest event in Grapevine, Texas.

THE

NEW KUBOTA SVL75-3

COMPACT TRACK LOADER BOASTS INCREASED CAB COMFORT

The new SVL75-3 is a compact track loader that Kubota declares will impress long-time customers of this popular machine. Updated cab comfort, increased

Access to the cab is improved, thanks to Kubota’s wide entrance and sliding front door design. Beyond entry and exit, the door can be left open during oper ation, and it can be opened regardless of the position of the bucket or loader arms.

This feature is a popular design choice by Kubota, but even so it’s one that much of the rest of the construction equipment industry has not implemented, because a sliding door currently forces manufacturers to place buttons and other controls along armrests. However, Kubota said the company feels that the entry, exit and visibility conveniences afforded by the door outweigh any ergonomic issues that may arise.

Upon entering the cab, it is hard to argue with that logic. The controls are not buried beneath the operator’s arms. In fact, all the needed controls are inches away from the operator during operation.

Bucket breakout force and lift arm breakout force are essentially the same as the previous model at 6,191 pounds and 4,723 pounds, respectively.

At the heart of this machine is a new engine, an updated ver sion of the turbocharged V3307 that can reach higher maximum torque than the version found in the SVL75-2.

Kubota has also made improvements to the cooling sys tem on the SVL75-3. During high-load work, the SVL753 doesn’t require as much fan power to keep the engine cool, allowing that saved power to be used for larger tasks.

The hydraulically-driven fan on the SVL75-3 pulls fresh air in from the top of the cooling

BOBCAT T7X ALL-ELECTRIC COMPACT TRACK LOADER FEATURES NO HYDRAULICS, FOURHOUR BATTERY USE TIME Bobcat’s T7X stands out from the compact track loader crowd because it produces zero emis sions, said Joel Honeyman, Doosan Bobcat vice president of global innovation.

“The additional benefits that operators may not immediately realize is the machine is built for power and ultra-quiet comfort,” he said.

At a bauma presentation in Munich, Honeyman shared that the T7X will provide up to 80kW of power – the equivalent of 107 horsepower – to the drive, lift and tilt functions of the electric compact track loader. The resulting operating costs of the T7X platform are one-tenth of its diesel hydraulic equivalent machine, according to Bobcat.

The Bobcat T86 platinum edition compact track loader excels on grassy sites.

COVER STORY 12 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

Company

Bobcat Company

LOADS OF OPTIONS. ZERO COMPROMISE.

You can’t always choose the deadline. But you can choose how you get the job done. That’s why we offer distinct levels of innovation, comfort, and performance to help you get done faster, more efficiently, and on budget.

DEERE.COM/TAKEYOURPICK

Doosan Bobcat partnered with Moog Construction recently to entirely remove all of the hydraulic fluid power systems in the T7X compact track loader prototype development process. Moog replaced hydraulic systems with linear, electromechanical actuators in the Bobcat T7X compact track loader and collaborated with multiple third-battery providers to make batteries for the T7X.

“It doesn’t require much main tenance, maybe every seven years or eight years,” said Aditya Karan Sharma, business development manager for Moog Construction. “If you’re running really hard, then you might need a little bit of components to be replaced.”

Depending on the applica tion, the battery can provide up to four hours of continuous operation or longer during inter mittent use, Honeyman said, allowing recharge with a com mon 220V outlet.

HVAC, 7-inch touch display screen, Bluetooth radio, a heated cloth air ride suspension seat, premium LED lights, a rearview camera installed, the Power BobTach system, 7-pin attachment control, high-flow hydraulics, two-speed travel, dual-direction bucket positioning, automatic ride control and a reversing fan.

“The Bobcat platinum pack age machines were designed for the customer who appreciates the latest and greatest features, along with unique styling to stand out amongst the crowd,” said Rob Otterson, Bobcat vice president of product management.

CASE TV620B COMPACT TRACK LOADER LARGEST EVER BUILT

Launched in late September 2021, the CASE TV620B compact track loader is a 114-horsepower, 6,200-pound rated operating capacity (at 50% tipping weight) machine, and it comes with a 1.25 cubic-yard

that make it extremely versatile,” said Jeff Jacobsmeyer, product manager for CASE Construction Equipment.

CASE will be releasing additional heavy-duty attach ments designed for use with the TV620B and has engineered the hydraulic cooling capacity of the machine to support use of highcapacity attachments.

“The combination of strength, performance and stabil ity of the TV620B is unmatched by any other machine and pro vides a robust platform for working with larger buckets and high-capacity attachments,” MacIntyre said. “Heavy pallets, loading larger trucks, and run ning attachments that require enhanced-high-flow hydrau lics are all handled with ease by this machine. The combination of track-on-ground, hinge pin height and reach at maximum dump height specs really make this a machine designed for load ing trucks of all sizes.”

COMPACT TRACK LOADERS A GOOD FIT FOR A VARIETY OF PROJECTS

Aside from zipping around dem onstration rings and arenas, compact track loaders also per form serious work. From loading yards with potentially soft under foot conditions to a residential site that needs grading, versatility is the name of the game when it comes to compact track loaders.

agricultural, a compact track loader comes in handy on softer ground where pallets need to be loaded and unloaded.

BACKYARD DREAMING: CTLS MAKE WORK ON SLOPED LAWNS SIMPLY A CINCH

In my quest to understand the full range of possibilities of com pact track loaders, I interviewed at least three OEMs, all of which said that CTLs make landscaping projects much easier, particularly on sloped ground and turf.

Because CTLs have low ground pressure, they are better at traveling over lawns and other improved surface areas with minimal ground disturbance, according to Fitzgerald. This can be a significant advantage when projects require travers ing established lawns or other landscaping.

“When working on a “back yard” project, a compact track loader can move materials across the front and side yards with minimal damage to turf and other landscapes, minimiz ing damage and repair costs,” Fitzgerald said.

The T7X is up to 90% more efficient than a simi lar, diesel-powered compact track loader, according to Moog Construction.

“These are highly efficient,” Sharma said. “If you go with a conventional hydraulic pump unit, they are about 30% effi cient. From 30% to 90% efficient is a huge jump, efficiency wise.”

PLATINUM EDITION OF BOBCAT T76 COMPACT TRACK LOADER FEATURES EXTENDED COMFORT AND PERFORMANCE

The Bobcat T76 platinum compact track loader package includes Bobcat MaxControl remote operation, auto throttle, a five-year subscription for Machine IQ, engine block heater, LED side lights, clearsided enclosed cab with auto

heavy-duty bucket designed spe cifically for the TV620B.

“The TV620B is built to simplify heavy work such as cold planing, mulching, heavy material handling and loading high-sided trucks,” said George MacIntyre, product manager for CASE Construction Equipment.

The TV620B offers a selec tion of buckets, including a heavy-duty 84-inch, 1.25 cubicyard bucket with SmartFit teeth, and is designed for use with other heavy-duty attach ments such as mulching heads, cold planers, and the new CASE grading blade.

“The rubber tracks, lower ground pressure and the over all stability it provides are really the core operating advantages of this machine category – matched with hundreds of attachments

“Compact track loaders real ly excel in environments where achieving a lower ground pres sure with your machine is desired. This could be on fin ished turf surfaces so as not to disturb the grass and the ground underneath it, or it could be on jobsites with softer under ground conditions that could bog down a machine with tires,” Jacobsmeyer said. “That’s the beauty of a compact track load er – the tracks help disperse the pressure of the machine to create minimal disturbance.”

Compact track loaders can be doing any number of jobs on a site, the most obvious of which are loading, grading and moving materials, said Jacobsmeyer.

“But these machines are also compatible with hundreds of attachments that allow them to do so much more on site,” Jacobsmeyer added. “A set of forks allow them to unload and move palletized materials.”

From building materials to

“It’s as much about improving performance as it is about mini mizing rework at the end of the day,” Jacobsmeyer added. “The wide tracks and lower ground pressure helps the machine move easily across any number of surfac es, and to do so with stability and confidence — especially on slopes or grades. But that low ground pressure also minimizes the amount of ground disturbance, avoiding the rutting that can sometimes happen when working with a true skid steer on turf or softer surfaces.”

Eliminating rutting is a big plus. “That rutting always has to be cleaned up and returned to the way it was found at the end of the job, which takes up additional time and resources,” he added.

What’s more, according to Jacobsmeyer, landscape attach ments for compact track loaders like lawn preparators help achieve final grade and a great seed bed. Healthy plants, landscaping and spring flowers are all satisfying ways to see the fruits of the operator’s labor.

From muddy sloped ditches to yards that simply need a finetuning, compact track loaders shine. ET

Read More at https://eqtoday.co/Dec22CTLs

COVER STORY 14 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

The Kubota SVL75-3 is the company's latest compact track loader. Wayne Grayson

Takeuchi TL6R Compact Track Loader

Takeuchi's TL6R compact track loader is easy to transport and is powered by a Kubota 2.4 L, 65.2 hp engine. The CTL features a radial lift loader design with a maximum lift height of 9 ft., 6.4 in. with a rated operating capacity of 1,841 lbs. The model has a width of 5 ft., height of 6 ft., 5.8 in. and weighs 7,480 lbs. Its canopy is 7,780 lbs. when equipped with a cab. The TL6R features a newly-designed cabin with an overhead 5.7-in. color display and backlit rocker switches, and includes a swing-out door, heat, and air conditioner for greater operator comfort. The TFM telematics system is available during the machine’s warranty period of two years at no additional cost, and it is able to provide a variety of data points including machine health and condition, run time and machine location.

Caterpillar 415 to 430 Backhoe-loaders

The 415, 416, 420, 420 XE and 430 are powered by 70 to 07-net-hp Cat C3.6 Tier 4 Final emission engines.

• Operating weights from 15,246 to 22,355 lbs. with loader lift capacities from 6,730 to 7,230 lbs. and max dig depths from 14 ft. to 15 ft. 2 in.

• 420 XE offers up to 15% more boom lift capacity as well as seat controls that enable Dual mode capability for more efficient machine repositioning

• Electronic loader controls on 420 XE enable selectable parallel lift, programmable loader kickout and return-to-dig on an LCD touchscreen display

• Selectable power management modes on 420, 420 XE and 430 offer the choice of Standard Mode or Standard Plus Mode to maximize backhoe implement speeds

ASV Turf Tracks

ASV offers smooth turf tracks for minimized damage to soft, delicate surfaces. With a combination of greater ground surface area and the performance of ASV’s Posi-Track undercarriage, the turf tracks can achieve equal or better traction than treaded tracks on dry surfaces. This product minimizes damage to topsoil and root systems, allowing for faster job completion in landscape, hardscape and golf course applications. ASV’s green turf tracks have a smooth design and are manufactured from a specialized blend that resists cracking, provides traction and maximizes overall life. The rubber tracks eliminate rusting and corrosion because they contain no steel cords.

Sany SLB95 Backhoe-loader

New Holland B75D Backhoe-loader

The economy class B75D has an 18,298-lb. operating weight and provides over 18 ft. of maximum digging depth.

• Standard four-wheel drive and a power shuttle synchromesh transmission with four forward and four reverse gears

• 74-gross-hp FPT 3.4-liter FPT engine features a diesel oxidation catalyst (DOC) with no fluids or diesel particulate filter required

• ROPS/FOPS-certified canopy or optional enclosed cab

• Comes with four front and two rear halogen work lights

• Includes a heavy-duty hydraulic oil cooler and 7-micron, spin-on oil filter

The SLB95 backhoe-loader has a 17,637-lb. operating weight, a 14-ft. 3-in. maximum digging depth and 12,354 lbf. of backhoe bucket breakout force.

• Low-maintenance Deutz TCD3.6-L4 Tier 4 Final engine rated at 95 net hp at 2,200 rpm

• Four-wheel-drive powershift transmission with limited-slip differential for traction

• 41.2-gpm load-sensing hydraulic system with pilot controls and ISO/SAE pattern changer

• Loader includes full float function and return-to-dig

• Auxiliary circuit on backhoe for breakers and other attachments

EARTHMOVING Products 16 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

JCB 1CXT Compact

Backhoe-loader

The 1CXT delivers the material-handling and excavating capability of a backhoeloader with the maneuverability and transportability of a compact track loader.

• Measures less than 6 ft. wide and 12 ft. long with a transport weight under 9,600 lbs.

• Delivers a loader bucket breakout force up to 5,180 lbf. and maximum dig depth of 10 ft.

• Tracks enable enhanced climbing capability, pushing power, stability and soft ground performance

• 49-hp Perkins engine with 122 lbs.-ft. of torque requires no diesel exhaust fluid or replaceable diesel particulate filter

• Hydraulic system includes a 24.6-gpm auxiliary circuit capable of powering high-flow attachments

Bobcat T86 and S86 Loaders

Bobcat has launched the T86 compact track loader and S86 skid-steer loader for tough jobs and construction work. Setting the T86 and S86 apart is Bobcat’s Premium Power Performance, a power management system that distributes power on loaders equipped with high-flow and super-flow hydraulics. Each component in the T86 and S86 loaders – including the engine, pumps and hydraulic system – has been engineered to deliver hydraulic performance. Bobcat attachments are engineered to be fully integrated with the carrier’s electronics, hydraulics and geometry. The T86 and S86 can power a wide variety of attachments including those specifically designed for super-flow hydraulics such as super-flow snowblowers, cold planers and forestry drum mulchers.

MB Crusher MB-HDS220

The coupling system promotes freedom of movement of the operating machine. Operators can view the materials during use, as well. As with other HDS models, the MB-HDS-220 allows the rotors to be changed directly onsite by the operator. The bucket facilitates work on construction sites where there is a need to aerate packed topsoil. This includes when a green area, a garden or a flowerbed needs to be landscaped; or when there is a need to reclaim and clean soil from various demolition debris, stones or roots. The padding bucket can also be used to select material for covering pipes or trenches and making the bedding.

Better? It’s something we all strive for. But to be better you must be efficient. Be productive. Be versatile. Be dependable. And you need equipment that supports you every step of the way, no matter how big or small the task. Because good enough is never good enough.

Check out our full line of JCB products at your local dealer or visit JCB.com today.

December 2022 | EQUIPMENT TODAY 17 ForConstructionPros.com/Equipment

C

JC BN

M E RIC A JC BN A

JCBNA @J

BN A

ORTHA

www.jcb.com

SHERRY BARKER - CE BARKER

“The best feature of our JCB equipment is less downtime.”

Read More at https://myfc.pro/bthlz0

Bobcat 60 Frame-size R-Series Compact Track Loaders

The 8,727-lb. 68-hp T64 offers a 2,300-lb. rated operating capacity, while the 8,927-lb., 74-hp T66 has a 2,450-lb. rated operating capacity.

• Redesigned lift arms with cast steel segments and optimized lift arm linkage provide increased strength and 120-in. lift height to hinge pin

• 17.6-gpm auxiliary hydraulic flow with a 26.9-gpm high-flow option

• Feature a redesigned, no-DPF Bobcat 2.4-liter Tier 4 inline engine design and direct-drive system

• One-piece, sealed and pressurized, roomier cab with standard 5-in. display or optional 7-in. display with Bluetooth, eye-level push-button controls and keyless start and theft protection

• Cast-steel Bob-Tach attachment mounting system

CASE Project Zeus 580 EV Electric Backhoe Loader

John Deere Upgraded L-Series Backhoe-loaders

The L-Series includes engine upgrades, pressure-compensated load-sensing (PCLS) hydraulics on the 310SL and machine control improvements.

• 310L, 310SL, 315SL, 310SL HL and 410L now feature a 4.5L John Deere PowerTech EWL Tier 4 Final engine that boosts horsepower across the models

• Lift mode added to the 310SL, providing up to a 10% to 15% increase in backhoe lift capacity

• AutoShift technology available as a base offering on the 310SL, 315SL, 310SL HL, 410L and 710L

• Optional Auto Ride Control

• 310L EP includes a simpler front-axle design and a four-speed manual synchromesh transmission

The 580 EV (Electric Vehicle) from CASE Construction Equipment is the construction industry’s first fully electric backhoe loader.

• The power and performance of the 580 EV is equivalent to other diesel-powered backhoes in the CASE product line and provides considerably lower daily operating costs while also producing zero emissions

• Powered by a 480-volt, 90-kilowatt-hour lithium-ion battery pack that can be charged by any 220V/three-phase connection

• Each charge will support most common eight-hour workdays depending on the application

• The battery separately powers the drivetrain and hydraulic motors, resulting in hydraulic breakout forces equal to dieselpowered machines and improved performance during simultaneous loader and drivetrain operation

Ranko VF Venieri Backhoe-loaders

VF Venieri articulated multifunctional backhoe-loaders combine an articulated front loader with Z-bar kinematics and a power excavator on the back with the carry-on system (four wheels equal-size drive).

• Four models range from 8,800- to 21,900-lb. operating weights and offer 52 hp (VF 1.33B) or 106 hp

• Backhoe dig depths from 9 ft. to 19 ft. 8 in. with breakout force from 5,730 to 13,450 lbs.

• Loader bucket capacities from .5 to 1.7 cu. yds. with breakout force from 5,600 to 23,800 lbs.

• Hydrostatic transmission enables speeds up to 25 mph

Maximize productivity by not biting off too much, or too little, material at one time. The new Battle Ax rotor has unique depth gauges that optimize the material feed rate for top efficiency.

Thoroughly process material with the exclusive two-stage cutting chamber featuring an adjustable primary shear bar.

18 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment DON’T BITE OFF MORE THAN YOU CAN CHEW …OR LESS LOFTNESS.COM Mulching Heads Flail Mowers Mechanical Trimmer LOW AND HIGH FLOW SKID STEERS & EXCAVATORS 10,000 LBS - 88,000 LBS BATTLE

AX TWO-STAGE CUTTING CHAMBER

EXCLUSIVE DEPTH GAUGE DESIGN

EARTHMOVING Products

Prepare for the Future of BACKHOE-LOADER TECHNOLOGIES

Backhoe-loader technologies are advancing fast, and operators must be ready for changes.

As jobsites continue to become smaller and small er, and advancements in hydraulic and engine sys tems occur at an exceedingly fast pace, operators are demanding compact, powerful machines that enable them to complete their tasks as accurately, consistently and quickly as possible.

In response, the construction industry is integrating perfor mance and power into smaller machines that have been creat ed to accept several attachments, thereby enhancing operators’ productivity even on the most demanding jobsites.

One such machine is JCB’s purpose-built 1CXT backhoeloader, which offers operators high efficiency, as it can perform in any type of application, while providing them comfort and ease of use, too. Highly maneuver able as well, the 1CXT also has a universal quick hitch that’s com patible with a majority of skid steer attachments. And it is easy for operators to trailer and tow it, often without a commercial driver's license (CDL), as a result of its compact size and weight.

“Due to its compactness, the 1CXT can also be easily trans ported and operated in confined workspaces,” said Ethan Clowes, product manager, skid steer/ compact track loaders and back hoe-loaders at JCB. “With a standard skid steer hitch, it has a unique front loader design as well, which ensures a 25% great er dump angle and 15% more breakout. Furthermore, for highsided trucks, it has a load over height that’s 8 feet, 8 inches, resulting in smooth loading.”

He added, “With a fully-inte grated side-shift backhoe, the 1CXT can dig close to walls for

Deere's backhoes are focused on providing operators a straightforward way for them to operate their backhoe-loaders in a manner that ensures consistently high performance.

John Deere

ease, too — digging up to 10 feet, 1 inch, with the extend ing dipper option. By offering 12 feet, 10 inches of groundlevel reach, the backhoe-loader allows operators to improve pro ductivity by also enables users to maximize their productivity by minimizing their need to reposi tion it.”

Despite its compactness, the 1CXT has a spacious cab that ensures operators are comfortable. It also has ergo nomically-designed controls that reduce operators’ fatigue. And it requires less downtime than other backhoe-loaders, as its engine has a 500-hour service interval.

Of equal importance, it offers operators a wide, one-piece engine cover, too, as well as removable side panels that provide them fast, ground-level access to daily check points and routine service items.

Featuring a side-mounted, 11.9gal. fuel tank, the 1CXT can be used for long working stints and easily refueled, as it has a long filler neck that decreases the likeli hood of spillage.

“In addition, the 1CXT has an innovative side-door entry and all-round visibil ity — through the cab’s large, laminated front window and toughened glass,” Clowes said.

There are a number of updat ed technologies on backhoe loaders that are improving opera tions for contractors.

TECHNOLOGY OFFERINGS POSITIVELY IMPACT BACKHOELOADERS

Aside from the 1CXT, a variety of other backhoe-loader tech nology offerings also stand out, including those that improve precision and stability during loader applications (like selfleveling and ride control) and those that enhance power deliv ery whenever necessary (such as power lift and power boost). Pilot controls and loader arms, along with the designs of loaders’ backhoes themselves, are present ly standing out, too.

According to Ryan Anderson, product marketing manager for backhoe-loaders, New Holland

Construction, pilot controls, par ticularly on backhoe-loaders like the company’s D Series, utilize a variable displacement pump, lead ing to more controllability for operators. Since they’re consid ered a “hydraulic over hydraulic” design, pilot controls also provide operators more functionality for precision digging.

“An example of this would be precision swing control, which prevents backhoe arm movement and shaking when operators dig and unload the bucket to a pile,” he said. “This stops unwanted material from spilling back into the excavated hole, or adds an extra level of precision when oper ators place loads like wall blocks.”

Moreover, pilot controls offer operators features like return to dig and ride control — features that, according to Anderson, are critical for ensuring back hoe-loaders are as productive as possible throughout the materials handling process. In the mean time, current backhoe-loaders have straight or curved loader arms, too, each of which per forms differently for different reasons. For instance, straight loader arms provide operators two main advantages: improved lift capacity and higher visibil ity to the loader bucket. Curved loader arms, on the other hand, offer an enhanced bucket break out force, along with a more

20 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

EARTHMOVING TRENDS

precise placement of loads as operators utilize them since curved loader arms are closer to backhoe-loaders than straight loader arms are.

“Concerning backhoe design, operators can utilize internal and external slide hydraulical ly-extendable dippers (HEDs),” Anderson said. “Internal slide HEDs like New Holland Construction’s offer high lift capacity with the dipper, as well as less wear and tear on the HED itself since debris, dirt and rocks aren’t able to fall into the sliding mechanism. To compare, exter nal slide HEDs provide more versatility for hydraulic thumb placement on the dipper though.”

Electro-hydraulic seat-mount ed control systems also stand out presently, particularly those that are provided with Caterpillar’s 420 XE, 440 and 450 backhoeloaders. Rather than providing operators two sets of controls — one for the loader and one for the hoe — the electro-hydrau lic seat-mounted control system ensures one pair of joysticks is mounted to each backhoeloader’s seat instead. This pair of joysticks will also travel with operators as they turn from the front to the back and from the back to the front.

“The technology behind the control offering provides a feature known as ‘Dual Mode’, which allows operators to manipulate or control the implement he or she is not facing,” said David Young, product application specialist, Caterpillar. “For example, if an operator is facing the hoe, they

Caterpillar is focused on continuing to build upon its electro-hydraulic platform, regarding the 420 XE, 440 and 450 backhoe-loaders that presently utilize the electro-hydraulic seat-mounted control system.

can use the feature to change the RH joystick so that it becomes the loader control, thereby enabling the operator to reposi tion much more efficiently while running the hoe.”

He continued, “Likewise, operators can be faced forward and use the ‘Dual Mode’ fea ture to control all functions of the hoe. Lastly, the feature also allows operators to dig with the hoe anywhere in the swing arc of the loader’s seat. So, at any point between being latched forward or rearward, operators can use both implements.”

John Deere Construction Equipment, in the meantime, also has various current back hoe-loader technologies that particularly stand out. After all, according to Justin Steger, solu tions marketing manager at John Deere, the company’s back hoes are especially focused on providing operators a reliable, straightforward way for them to operate their backhoe-loaders in a manner that ensures consis tently high performance.

To do so, the company offers operators the John Deere PowerTech EWL engine, which eliminates any necessity for a

diesel particulate filter (DPF) and exhaust gas recirculation (EGR) system. Utilized for four models of John Deere backhoe-loaders — the 310L, 310SL, 410L and 710L — the engine has more reliability than previously released engines, as well as enhanced torque and a 3% to 7% increase in net horsepower, improvements that underground utility opera tors will especially notice.

Additionally, the 310SL, 410L and 710L models of backhoe-loaders utilize pres sure-compensated, load sensing (PCLS) hydraulics, which pro vide improved multifunctioning, smoother machine control and up to 15% higher craning capac ity, via Lift Mode, than other hydraulics released by the com pany in the past.

“Collectively, the John Deere PowerTech EWL engine and the PCLS hydraulics offer operators distinct customer experiences, along with high machine reli ability,” Steger said.

Stressing that “John Deere is committed to developing innovative, robustly tested and reliable equipment” for its cus tomers, the company is, in turn, focused on “unlocking

ops products that meet those needs,” he said. “To do so, at this moment, John Deere is focused on its electric backhoe proto type, too, and is continuing its product testing and development process.”

BACKHOE-LOADER MANUFACTURERS FOCUS ON THE FUTURE

In preparation for the future, JCB is focused primarily on sus tainability, first and foremost.

“It’s no surprise to any in the industry that the next progression of backhoe-loader technology is tied directly to sustainability efforts,” Clowes said. “How can we look after the planet, while providing the same performance, safety and efficiency for which we are known? In short, how can we find a better way of getting the job done as a manufacturer, as well as machine operators?”

For answers to these two questions, JCB has introduced innovations that are focused on hydrogen engines. In par ticular, the company’s hydrogen combustion engine — the con struction industry’s first-ever hydrogen engine — enables its advanced engine technology to be utilized for decades to come. Yet, at the same time, due to the potential of completely renew able hydrogen fuel, the engine may possibly have zero-carbon emissions one day, too.

“The hydrogen combustion engine is an example of JCB accepting today’s challenge for tomorrow,” Clowes said. “When

December 2022 | EQUIPMENT TODAY 21 ForConstructionPros.com/Equipment

Caterpillar

JCB’s 1CXT backhoe-loader, which offers operators efficiency, can perform in any type of application, while providing them comfort and ease of use. JCB

AdobeStock/WinaiTepsuttinun

New Holland Construction's pilot controls, particularly on backhoe-loaders like the company’s D Series, utilize a variable displacement pump, leading to more controllability for operators. New Holland Construction

we consider replacing fossil fuels with a zero-carbon alternative that still allows heavy machines to do heavy work for up to 12 hours each and every day, it’s obvious that batteries aren’t practical for machines with high power demands and remote jobsites.”

He added, “Additionally, the weight, cost and charging time are prohibitive to the uptime and performance that operators expect out of a backhoe-loader.”

Thus far, JCB has produced a prototype backhoe-loader that utilizes the hydrogen combustion engine. According to Clowes, “it can do everything that its dieselpowered equivalent can do.” One key difference has been observed though: the hydrogen-powered backhoe-loader doesn’t emit any carbon dioxide at the point of use, as only steam is emitted from its tailpipe.

Alongside sustainability, there are four other driving factors for future technological enhancements, according to Anderson — a decline in risk, higher precision, more comfort and increased safety.

A John Deere-developed, batterypowered and electric vehicle design, the concept, known as E-Power, will mainly target the company’s diesel-powered, 100 HP 310L Backhoe’s ease of operation and performance level.

various suppliers, in order to acquire highly-advanced lasers and receivers, including 2D selfleveling lasers and magnetized receivers. Providing highly accurate results, they can also be effortlessly installed and used in a straightforward fashion.

For safety, the company may eventually offer enhanced camera visibility around each of its backhoe-loaders, too. Much like customers in the automotive industry, customers within the equipment industry desire to have bird’s eye, 360° views around their machines. As a result of this potentially improved visibility, customers will be able to operate their backhoe-loaders more safely than before. Furthermore, they’ll be able to minimize the risk of damage to their machines and property, while also decreasing the injuries of people who utilize them or are near them.

“The same comfort, visibility and safety features that operators have grown comfortable with in today’s cars, trucks and other motor vehicles will soon be available in New Holland Construction’s construction equipment,” Anderson said. “Operators’ abilities to confidently maneuver their backhoe-loaders around their jobsites without having to worry about damaging their equipment or jobsites — while also keeping their team members safe — will pay dividends in the form of less fatigue, less expenditures for their employers and better overall productivity.”

ELECTRIFICATION IS THE NAME OF THE GAME

— Ryan Anderson, product marketing manager for backhoeloaders, New Holland Construction

“For advancements in precision, 2D laser tools are becoming a staple in the backhoe-loader market,” Anderson said. “The usage of lasers and receivers in precision excavation and grading are proving to be the next level of profitability and productivity for backhoe-loader operators.”

With this in mind, New Holland Construction utilizes

Meanwhile, Caterpillar is focused on continuing to build upon its electro-hydraulic platform, regarding the 420 XE, 440 and 450 backhoe-loaders that presently utilize the electrohydraulic seat-mounted control system. To achieve this goal, it is primarily interested in developing features that are generally found on excavators and loaders.

“On the hoe side, this would mean features like e-fence,

e-ceiling and swing limits,” Young said. “On the loader side, Caterpillar is looking at payload measuring, as well. In addition, the incorporation of grade control is on the table.”

As Caterpillar prepares for these future technology advances, the company is especially focused on efficiency and performance.

“These types of advanced fea tures are being implemented with the following goals in mind — ensuring your backhoe-loader works faster, safer and at a higher level of quality than in the past,” he added.

John Deere, on the other hand, is preparing for the future by working with National Grid, an electricity, natural gas and clean-energy delivery company. By doing so, it will joint test an electric backhoe concept. A John Deere-developed, battery-pow ered and electric vehicle design, the concept, known as E-Power, will mainly target the company’s diesel-powered, 100 HP 310L Backhoe’s ease of operation and performance level.

“The design is intended to provide substantially lower daily operating costs, along with enhanced machine reliability, lower jobsite noise and zero tailpipe emissions,” Steger said. “Currently, the electric backhoe concept is only being field tested, as it is not yet available to purchase.”

The E-Power backhoe has been created to perform the same operations and run the same attachments as a conventional diesel engine-powered backhoe — without sacrificing any of its versatility.

“Increased versatility comes in the form of customer and job site requirements, which, in the future, may drive the need for an E-Power backhoe,” he said. “Companies and jobsites are striving to improve sustainabil ity, too. The decarbonization of their fleets’ equipment could be a large component of their sus tainability efforts.”

He added, “By testing the backhoe during Phase 1 now, John Deere will be positioned to develop it in the future and, consequently, meet customers’ needs, concerning lower daily operating costs and jobsite noise, as well as enhanced machine reliability and a considerable decline in tailpipe emissions.”

Along with testing the E-Power backhoe, John Deere is also preparing to showcase new

performance-tiering models of backhoe-loaders at CONEXPOCON/AGG next year. For example, the 310L EP is transi tioning to the rugged 310 G-tier, while the 310SL and 310SL HL are transitioning to the 320 P-tier and the 320 P-tier with a heavy-lift option, respectively. In preparation for these transitions, the 320 P-tier’s engine horse power is set to increase, as well.

While looking ahead to the future, Clowes predicts a back hoe with zero emissions at its point of use will eventually be released. After all, a majority of backhoes are used in cities and towns, many of which have committed to becoming carbon neutral in the future, according to Clowes.

Anderson, meanwhile, adds that alternative fuels are at the forefront of product development for virtually every manufacturer at this time. For example, electric power is the most popular manufacturing trend in the construction industry — even more popular than liquid propane, methane and natural gas, according to Anderson. As a result, more equipment and vehicle manufacturers are responding to this trend, offering more electric vehicle options than ever before.

“Electric vehicle options will continue to expand as battery technology evolves,” he said. “Alternative fuels are impacting operators directly, too, as battery technology is going to be the most important factor in the growth of electric equipment and vehicles.”

Two key considerations stand out, in regards to alternative fuels: performance and run time, as batteries must work harder and longer than they ever have.

“With this in mind, the con struction industry will continue to notice more electric vehicle options start popping up in the future, especially as battery tech nology improves,” Anderson said. “There is no question about it. Construction operators must prepare for a future of electrifi cation, as the current movement will likely become a reality one day — across the construction industry.” ET

Chris Lewis is a freelance writer for Equipment Today.

Read more at: https://myfc.pro/l5rv9o

EARTHMOVING TRENDS 22 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment

Deere

John

advancements in precision, 2D laser tools are becoming a staple in the backhoeloader market.”

“For

CASE CONSTRUCTION EQUIPMENT

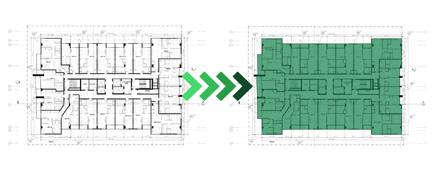

Backhoe-loaders are multi-taskers that combine the capabilities of two machines into one attachment-friendly piece of equipment. Here’s an

look at models available in North America from leading suppliers. To learn more about a particular backhoe-loader,

the

code with your smartphone camera to visit the specific model on ForConstructionPros.com.

CASE N Series backhoes feature ProControl, a swing dampening system that eliminates rebound on the backhoe, providing faster cycle times, less wear on components, greater operator precision and less fatigue. Engine ECO Mode encompasses a number of features that include ECO settings in both loader and backhoe functions to provide up to 10% fuel savings with minimal loss in productivity, as well as auto engine idle and auto shutdown.

Read More at https://eqtoday.co/casenseries

58580 Super N 97 17,269 14' 4" 14,452 0.85 - 1.29 10,947 580 Super N WT 110 20,077 14' 5" 15,070 1.00 - 1.50 10,873 580N 90 16,589 14' 8" 11,517 0.85 - 1.29 10,622 580N EP 74 15,795 14' 11" 11,517 0.85 - 1.29 9,607 590 Super N 110 20,532 15' 5" 15,853 1.00 - 1.50 12,776

JOHN DEERE

Boasting significantly more lifting capability than previous models, along with pressure compen sated load-sensing (PCLS) hydraulics available on select models, the John Deere backhoe loader line-up provides increased productivity and performance on the job. On the 310SL, 310SL HL, 410L and 710L models, PCLS provides increased productivity and smooth multifunction control at any engine speed. PCLS also allows for trenching operation to be conducted at a lower engine rpm, reducing fuel consumption and jobsite noise. Auto idle automatically slows engine speed when the backhoe pilot controls are released, with the preset engine speed resuming when levers are reactivated. Auto shutdown turns off the engine after an operator-selected period of inactivity. Read More at https://eqtoday.co/DeereBHLs

KUBOTA

The Kubota L47 and M62 incorporate the HST Plus transmission, which automatically con trols the hydrostatic pump and drive motor to provide optimal control. The transmission also boosts efficiency through features like the standard Stall Guard Plus and Backhoe Crawling Mode. The IntelliPanel provides vital machine information and relays key messages to the operator, including machine working status, engine conditions, fuel and oil warning signals, plus an array of maintenance indicators to help keep the machine in peak working condition.

Read More at https://eqtoday.co/KubotaBHLs

NEW HOLLAND CONSTRUCTION

Read More at https://eqtoday.co/NewHollandDSeries

December 2022 | EQUIPMENT TODAY 23 ForConstructionPros.com/Equipment

Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.)

Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) 310L EP 69 13,822 13'

310L 100 14,669 14'

310SL 103 15,872 14'

310SL HL 113 16,571 15' 1" 15,723/17,349* 1.12-1.31

315SL 103 17,554 13' 5" 12,361 1.00-1.31

410L 116 17,786 15' 11" 15,723/17,350*

710L 148 25,588 17' 3"

*Lift mode Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) B26TLB 24.3 4,001 8' 3.5" 4,210 0.34 2,343 L47TLB 47.1 7,205 10' 5,825 0.57 4531 M62TLB 63 8,925 14' 2.4" 6,572 0.87 5,992

8" 10,844 1.00-1.25 9,564

1" 10,844 1.00-1.25 9,512

3" 12,356/13,634* 1.12-1.31 10,541

10,598

10,608

1.31-1.50 10,361

17,622/18,959* 1.31-1.87 16,539

New Holland D Series tractor loader backhoes offer a model to match your needs. These backhoes feature a straight loader arm design that improves visibility

Their high-performing lift capacity, comfortable operator’s platforms and

depth will help you increase your productivity

work.

Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) B75D 68 18,298 18' 4" 12,598 1.3 13,778 B95D 95 18,805 18' 4" 12,933 1.3 13,977 B95D TC 95 18,695 18' 4" 12,933 1.3 14,711 B110D 108 20,084 19' 3" 13,418 1.3 14,253

to the bucket top edge.

outstanding dig ging

in a wide range of

updated

scan

QR

VF-VENIERI

VF Venieri (Ranko Equipment) has one of the only articulated multifunctional backhoe loaders available. It is more than a backhoe-loader, it is two machines in one. It combines an articulated front loader with Z-bar kinematics and a power excavator on the back with the carry-on system (four wheels equal size drive). All models are powered by a hydrostatic trans mission that enables a 25-mph platform that can complete a wide variety of tasks by utilizing various attachments on the front and rear.

Read More at https://eqtoday.co/RankoBHLs

JCB

JCB Backhoe loaders can be equipped with several automated fea tures. These features simplify repetitive tasks, lowering operator fatigue and ultimately improve productivity. AutoSTABILIZERUP is an example of one of eight automate features, it will raise the stabilizer legs with a full stroke of the stabilizer lever. This allows the operator to get on with their next task instead of waiting for the legs to fully raise. The time savings may seem small, but adds up over the days, months and years result in a big time saving and productivity improvement.

Read More at https://eqtoday.co/JCB

CATERPILLAR

The latest Caterpillar backhoe-loaders run on the CAT C3.6 engine, which is EU Stage V compliant. The C3.6 engine, along with updated hydraulic valves, offers 10-15% fuel effi ciency improvement on the latest generation models. All Cat backhoe-loaders are now avail able with a front IT loader coupler. This interface works with a large portfolio of front work tools. The new seat mounted joystick control system increases floor space in the machine and provides a more comfortable running position compared to a pilot or mechanical control set up. A Dual Mode feature allows an operator to operate the implement they are not facing and offers full hoe control anywhere in the swing zone of the seat.

Read More at https://eqtoday.co/CatBHLs

24 EQUIPMENT TODAY | December 2022 ForConstructionPros.com/Equipment Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) VF 1.33B 52 8,800 9'-10' 7" 5,730 0.5 5,600 VF 10.33C 106 20,700 15' 8"-17' 8" 12,120 1.7 20,060 VF 8.23F 106 18,700 15' 1"-17' 8" 10,050 1.4 15,200 VF 10.23D 106 21,900 16' 4"-19' 8" 13,450 1.7 23,800

Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) 415 70 16,279 14' 0" 12,207 1 12,207 416 86 16,532 14' 0" 12,207 1 12,207 420 92 17,271 14' 0" 11,216 1.25 11,216 420 XE 92 17,271 14' 0" 11,216 1.3

430 107 18,051 15' 2" 11,216 1.25

440 104 21,544 15' 6" 13,560 2.0

450 131 24,039 17' 0" 13,560 2.0

11,216

11,216

13,560

13,560

Gross Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) 1CXT 49 9,572 10' 1" 5,291 0.47 5,180 3CX Compact 74 13,514 14' 2" 7,363 0.92

3CX 74 17,196 18' 6" 13,730 1.30 13,600 3CX-14 74 17,704 18' 6" 13,730 1.40 13,603 3CX-14 Super 91/109 18,614 18' 6" 13,730 1.60 13,603 3CX-15 Super 109 19,090 20' 1" 13,730 1.60 13,603 4CX-14 Super 109 19,172 18' 6" 13,730 1.60 13,728 4CX-15 Super 109 19,648 20' 1" 13,730 2.00 13,728

Mecalac’s backhoe-loaders are specially designed to provide immediate ROI without sacrificing performance or quality. Pairing a powerful Tier IV final 4-cylinder Deutz electronic fuel injection diesel engine and robust hydraulic system, the TLB840R excels at digging, reaching, lifting and loading tasks. The curved boom design and up to 13-ft., 5-in. loading height provides excellent clearance to reach up and over obstacles, as well as the ability to load closer into trucks for greater productivity. Read More at https://eqtoday.co/TLB840R Net Operating Backhoe Dig Backhoe Breakout Loader Bucket Loader Breakout Model HP Weight (lbs.) Depth (ft. in.) Force (lbs.) Cap. (cu. yds.) Force (lbs.) TLB840R 74 16,138 17' 10" 12,139 1.32 9,442 TLB890 110 19,842 18' 7" 15,444 1.7 12,454

8,285

MECALAC

Zivan CT3.3

Zivan has announced the launch of CT3.3, a new onboard battery charging solution. The CT3.3 serves as a rugged battery charger for onboard installations, in electrically-powered machines and vehicles. Designed for non-road mobile machinery, aerial work platform, e-mobility, AGV-AMR and others, Zivan began the CT3.3 development to complement SG3. New features will be introduced with the CT3.3, such as water cooling, increased power density, optional integrated DC-DC converter and input over-voltage protection. The CT3.3 and the SG3 can be installed in a stackable configuration to scale up charging power.

JCB Mobile Hydrogen Refueler

JCB has unveiled a mobile hydrogen refueler. The mobile hydrogen refueler provides a way for customers to refuel their machines on site. Around 97% of construction machines have fuel delivered to them while working on site. This means customers are already accustomed to a transportable fuel, allowing refueling to take place in a matter of minutes. The first hydrogen-powered machine to be unveiled was a JCB backhoe loader, followed a year ago by a Loadall telescopic handler.

Michelin 26X11N14 TWEEL UTV Tire

The 26X11N14 TWEEL UTV Tire is 2.8-in. wider and has an increased carrying capacity of 608-lbs., 85% more than the 26X9N14 current model. This increase allows customers to fully load their UTVs without exceeding the load capacity of the TWEEL. Available in 5 SKUs, the new wide-based rear fitment model is offered in five different bolt patterns to allow fitting for a wide variety of UTVs. It also features additional load capacity from the current TWEEL (26X9N14) up from 715 lbs. per tire to 1,323 lbs. per tire with a speed rating compatible with the current 26X9N14 model of 62 mph.

BKT EM 933 SUPER