› › › www.ForConstructionPros.com/Pavement MAINTENANCE & RECONSTRUCTION MARCH 2024 THE OFFICIAL MAGAZINE OF PAVE/X FUTURE FUEL THE REAL REASON EVS WILL DISPLACE DIESEL

You Buy An ASPHALT PLANT? ★1st Was a HIT

Should

NEAL’s innovative Pavement Preservation Package provides game-changing efficiency on both detail and high-volume sealcoating. Our versatile DA 350’s blower and cut-in attachments complete detail work up to 7 times faster. While our High-Volume Road Maintenance Vehicle’s high material output makes short work of large surface areas. EASY AS Blow Cut-in Apply TALK TO OUR EXPERTS: 770-830-1282 // WWW.NEALEQUIP.COM High-Volume Productivity You Can Count On WORLD OF ASPHALT // MARCH 25-27, NASHVILLE, TN // BOOTH 2818

TABLE OF CONTENTS

FEATURES

12 Intelligent Compaction 101: How It Works and How You Benefit

It’s time to transform compaction from an art to a science. Find out how intelligent compaction technology helps you achieve compaction specs in fewer passes — and how that translates into money saved.

18

Entering The Big Leagues

Are you an asphalt paving contractor working on blacktop, parking lots, commercial, and/ or residential? Have you’ve ever considered owning your own asphalt production facility? Depending on your size and scope, it might be time to take the plunge!

COVER STORY

24 Electric Power Will Displace Diesel Machines

Why will EVs eventually dominate the market? Whether it comes from gas, diesel, liquid hydrogen or solid state batteries you are buying energy. And pound for pound, ounce for ounce, dollar for dollar – electric means more bang for your buck. Eventually, they are going to save you money.

ON THE COVER Introduced during CONEXPO 2023, the Schwarze M6 Avalanche EV is seeing early adoption in areas where municipalities are looking to transform their fleets green.

DEPARTMENTS

6 Editorial PAVE/X Express A.K.A The Chattanooga Choo-Choo

8 Hot Mix

The latest news in the industry

10 The Product Lane

Select new products and upgrades

14 PAVE/X Pulse

The inaugural, premier event for pavement maintenance professionals launched in downtown San Antonio and the well-attended event exceeded the highest estimates.

28 Your Business Matters

Your Balance Sheet: A Critical Financial Tool

30

31 NAPSA

NAPSA partnered with the inaugural event in San Antonio to bring industry-specific content to attendees

31 WSA

In the fast-paced world of pavement maintenance, staying ahead means more than just attending a trade show or a handful of seminars.

32 Contractor Snapshot

Sealtite Asphalt Maintenance

34

March 2024 | Issue 3, Volume 37 www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 3

The Owner’s Desk

Fast and Cheap... You (and

Can Pick Only Two

Good,

Your Clients)

Education

Tailgate Talk Ignorance Costs More Than

IN EVERY ISSUE 21 Pavement Profit Center 33 Classifieds

[FREE WEBINAR] Top 5 Tips to Maintain Your Construction Equipment Tires

Size and tread design are among many factors to consider when selecting and maintaining tires.

Formoreinformationvisit

https://pavemg.com/hb6ru1nu

[VIDEO] 2024 Contractor of the Year Sees Massive Benefits to Attending PAVE/X

Tom Eosso with Eosso Brother Paving chats with PAVE/X co-founder Jessica Lombardo about the business benefits of attending industry events and taking educational courses to help your company grow.

Formoreinformationvisit

https://pavemg.com/f0fj6r6k

What Your Construction Business Numbers Mean in 2024

Prices are up, inflation is up -- how are you planning for your construction business in 2024?

Formoreinformationvisit

https://pavemg.com/s61i353o

ADVISORY BOARD

PAVEMENT

or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros.com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March, April/May, June/July, August/September, October/ November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

Agua Trucks Inc Wickenburg, AZ, Scott Duscher

Asphalt Contractors Inc., Union Grove, WI Robert Kordus

Asphalt Restoration Technology Systems, Orlando, FL Connie Lorenz

Brahney Paving, Hillsborough, NJ .............................................................. Steven Brahney

Eosso Brothers Paving; Hazlet, NJ ...................................................................... Tom Eosso

Maul Paving/Concrete/Sealcoating, PLainfield, IL Chris Maul

Parking Lot Maintenance, Lake St. Louis, MO Todd Bruening

Petra Paving, Hampstead, NH Chris Tammany

Pioneer Paving, Albuquerque, NM

Don Rooney

Roberts Traffic, Hollywood, FL Lisa Birchfield

Show Striping Inc. (SSI), Wisconsin Dells, WI Amber Showalter

T&N Asphalt Services, Salt Lake City, UT Nick Howell

Young Sealcoating Inc, Lynchburg, VA Steve Young

The Paving Lady............................................................................................... Mauro Comuzzi

Please send change of address to , PO Box 3605, Northbrook, IL 60065-3605.

Printed in the USA.

PAVEMENT MAINTENANCE & RECONSTRUCTION is proudly supported by these associations:

JMP Excelsior Services ............................................................................... Jim Panzenhagen

Sweeping Industry Veteran Gabe Vitale

Flat Nickel Management Michael Nawa

Wis-Coat Asphalt Maintenance

Marvin Joles

Clear Choice Sealing Warren Johnson

Jacketta Sweeping Services Debbie Jacketta

Royal Pavement Solutions Kenneth Roy III

ASSOCIATION REPRESENTATIVES:

Pavement Coatings Technology Council Brian Riggs, Executive Director

68 WHAT’S ONLINE 4 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Vol. 37, No. 3 March 2024 Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment

PAVE/X Express: The Chattanooga

Choo-Choo

What was my biggest takeaway from the week I spent in San Antonio, Texas, for the first-ever PAVE/X: The Pavement Experience? Every downtown needs a cool riverwalk! In all seriousness, I wish that Cleveland would do something unique with its rivers, which are most famous for catching on fire multiple times because they were so polluted. If you’re ever in Ohio and someone offers you a “Burning River” IPA from Great Lakes Brewery, now you know where that comes from.

Brandon Noel, Editor bNoel@iron.markets 234-600-8983

Brandon Noel, Editor bNoel@iron.markets 234-600-8983

But enough joking-around, PAVE/X was so much more than any of us on the team could have possibly anticipated. I wish I could convey to all of you reading the magazine, just how much of a success it was, because despite all the planning you do, all the meetings you have, there’s no way to know what is really going to happen until you get there. On the surface, when you see members of the team out at the shows, at an after-hours event, or in an educational session, it might seem like we are all cool, calm, and collected. However, the truth is that it took so much work to make it all come together, and then the payoff was the overwhelming response from all of you.

Every single person I talked to was buzzing with energy while we were there. This thing had the rizz, and what you should all know about PAVE/X 2025 is that the team behind this year’s event has essentially transitioned immediately into planning for it. Everything that was good, we want to make even better. The things that you wanted more of, we are finding ways to expand. A year from now, Chattanooga won’t know what hit it when the blacktop nation descends upon it. Whatever you do, don’t miss out on what’s going to happen in 2025.

DIESEL VS EV: THE BATTLE THAT ISN’T

This month’s cover story was inspired by a conversation I’ve had so many times that I decided I had to write about it. Talking EV is the most confounding thing I hear guys talk about, and I heard a lot of talk about it at PAVE/X, too. When Matt Stanley was out in the live demo area using an electric paver (LeeBoy’s 8520c) there were guys over in the line for beer voicing their negative opinions on EVs loudly. This has never made any sense to me.

Don’t skip over the article, where I go into a much deeper explanation, but here’s a little preview. Whether you’re powering your machines with gasoline, diesel, batteries, coal, or even steam-power, there are all delivering the same thing: energy. They may be different fuels, but what you’re buying is ENERGY. There’s a reason we don’t travel the Atlantic Ocean by sail power anymore. The transition to EVs and battery power ISN’T yet at the place where it’s widely economical, but there was also a time that you didn’t have 50-inch flat screen TVs in your house.

The displacement of diesel will happen just like the end of tube televisions, wired telephones, and the VHS. Not because of a “woke” agenda or some invisible governmental body forcing it upon you. It will eventually happen because it will save you $$$ on energy costs. I explain it in detail on page 24.

See you on the road! ■

EDITORIAL

Noel bnoel@iron.markets

Contributing Editor Jessica Lombardo jlombardo@iron.markets

Managing Editor Gigi Wood gwood@iron.markets

Senior Editor, Equipment &

IRONPROS Michael Cheng mcheng@iron.markets

Junior Editor Merina Shriver mshriver@iron.markets

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager ..................................................... Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer ............................................. Amy Schwandt

Corporate Director of Sales Jason DeSarle

Brand Director, Construction, OEM & IRONPROS ......................................................Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director ....................................................... Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605

(877) 201-3915 | Fax: (847)-291-4816

circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

6 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t EDITORIAL

PAVEMENT @PAVEMENTMAGAZINE WWW.FORCONSTRUCTIONPROS.COM/PAVEMENT Published by IRONMARKETS 201 N. Main St. Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 • IRON.MARKETS.COM

Editor ............................................................................. Brandon

Workwear,

@PAVEMENTMAGAZINE @PAVEMENTMAGAZINE @PAVEMENTMAINTENANCE

FULL PERFORMANCE WITH BATTERY-POWERED CONVENIENCE

INTRODUCING THE NEW LINELAZER ® ES 500

HIGH-PRESSURE, BATTERY-POWERED LINE STRIPER

Battery-powered simplicity combined with Graco's industry leading LineLazer capabilities.

� NO ENGINE NOISE

� NO ENGINE FUMES

�NO ENGINE VIBRATION

Delivered complete with two DEWALT® FLEXVOLT® batteries and fast charger for continuous striping.

MADE IN THE USA WITH GLOBAL COMPONENTS © 2022 Graco Inc. 3J0322B 12/22 Printed in the U.S.A. DEWALT® and the DEWALT Logo are trademarks of DEWALT Industrial Tool Co. and are used under license. All trademarks are the property of their respective owners. Product covered by issued and pending patents, see graco.com/patents.

LEARN MORE ABOUT LAZERLAZER AT GRACO.COM/LINELAZERES500

Coalition Aims to Advance ZeroEmission Vehicle Infrastructure

Recently, Powering America’s Commercial Transportation was started to try to connect commercial electric vehicles with more charging infrastructure. This initiative is meant to bridge the gap between sustainable vehicle power and the accessibility to electric power.

Powering America’s Commercial Transportation (PACT), a coalition focused on education and advocacy for accelerating the construction of nationwide infrastructure for mediumand heavy-duty (M/HD) zero-emission vehicles (ZEVs), launched with the express purpose of overcoming the many barriers delaying access to ZEV infrastructure and enhancing national climate policies to address the infrastructure needs of M/HD ZEVs.

PACT was established by Daimler Truck North America, Navistar, and Volvo Group North America, who collectively represent 70% of all new M/ HD truck sales in the U.S., and are committed to ambitious electrification

goals. Each original equipment manufacturer (OEM) has battery-electric vehicles in the marketplace, but access to charging infrastructure is a bottleneck to the widespread adoption of these technologies. Coalition membership is open to stakeholders with an interest in accelerating the deployment of zero-emission commercial vehicles and the requisite infrastructure, including other OEMs, and others. Other founding members include ABB E-mobility, Burns & McDonnell, BC Hydro, Greenlane, Prologis, and Voltera.

So far in the United States, transportation electrification has largely focused on the needs of light-duty passenger vehicles, a far different market segment that does not require the same unique considerations as M/HDs. Quickly deploying reliable and accessible ZEV infrastructure to power the nation’s commercial transportation fleet requires distinct considerations for capital investment, electrical grid upgrades, and dedicated charging equipment. According to the International Council on Clean Transportation, nearly 700,000 chargers will be needed nationwide to accommodate the 1 million Class 4-8 M/HD ZEVs anticipated to be deployed

A roundup of recent news, moves and events impacting the pavement maintenance industry

For more information visit

https://pavemg.com/mz1q1r

by 2030, which will consume 140,000 MW of electricity every day, equivalent to the monthly energy needs of over 100 million American homes.

“The transition to zero-emission vehicles is stalling without the deployment of the needed charging infrastructure,” said John O’Leary, president and CEO of Daimler Truck North America. “Through PACT, we aim to accelerate this infrastructure buildout so that fleets can adopt ZEVs at scale and we can all benefit from impactful emissions reductions as quickly as possible.”

While supporting the deployment of commercial ZEV infrastructure, PACT will not advocate for specific vehicle, power generation, or utility distribution technologies. PACT exists to educate stakeholders about infrastructure challenges that hamper M/HD ZEV adoption in the marketplace and work with stakeholders to find solutions for the benefit of all interested parties. The coalition also champions practical and efficient infrastructure solutions capable of supporting increasing M/HD ZEV deployments.

AEM WELCOMES NEW PUBLIC RELATIONS MANAGER

The Association of Equipment Manufacturers (AEM) recently revealed that it has a new member joining its PR team. According to the organization: AEM announced a new addition to the Association of Equipment Manufacturers Communications and Public Relations Team - Mary Stratton. AEM

Straton joined AEM at the end of January as the public relations manager and will work with the PR team on many things including serving as the point of contact for media registration for tradeshows, working with internal staff to schedule and plan media interviews, drafting press releases for distribution, and she will be on-site at World of Asphalt 2024.

Stratton has a degree in journalism from Loyola University and has earned several awards and recognition for her reporting in the Chicago and Midwest region. Stratton comes to AEM from WOI-TV in Des Moines, Iowa, where she served as an investigative and political reporter. Those in the Des Moines-Ames DMA might know her by Mary Sugden. “We are confident she will bring fresh perspectives and expertise to our outreach. As we continue to grow and innovate, Mary’s contributions will undoubtedly play a significant role in our success,” said Public Relations Director Sandra Mason.

8 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Booth #2731

Booth #2731

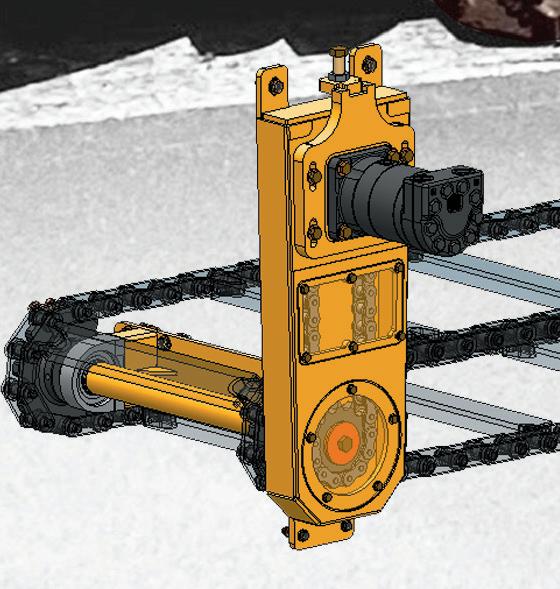

KIOTI TL750 and SL750

Kioti Tractor Division, Daedong-USA Inc.

KIOTI Tractor has unveiled its latest innovation with the launch of the TL750 Compact Track Loader and SL750 Skid Steer Loader. Both machines feature a wide cabin, available with the standard open station design or an optional enclosed cab with HVAC. The compact models include a high-back suspension seat and LCD digital display. The standard rollup style door allows for entrance and exit, regardless of the position of the bucket or attachment. The overhead door design increases flexibility on the job as operators can work with the door open or closed. Both models utilize a 74-hp KIOTI diesel engine. Field-tested across various applications, the engine delivers consistent power and reliability. Designed to lift, push and power through rigorous demands, the machines have up to a 10.8-ft. height to hinge pin and vertical lift path. Operators can dump materials into trucks and high-sided hoppers.

Komatsu GD955-7

Motor Grader

Komatsu America Corp.

Komatsu has introduced the new GD955-7 motor grader to the North American market. The GD955-7 provides operators with the ability to build and maintain haul roads for truck fleets of 100 tons and up. This new machine generates blade downforce pressure for grading performance. With faster working travel speeds compared to the previous model, Komatsu engineered the GD955-7 to increase grading performance while helping reduce maintenance requirements. Horsepower is 426 hp @ 1,900 rpm (313 kW @ 1,900 rpm), operating weight: 104,323 lbs. (47,320 kg), moldboard: 18-ft. (5.5 m) standard, 20-ft. (6.1 m) moldboard optional. Despite its large size, the GD955-7 offers maneuverability on the jobsite. It can execute tight U-turns on a standard 100-ton class haul road without the need to fully cut the wheel or course.

E

Indicator

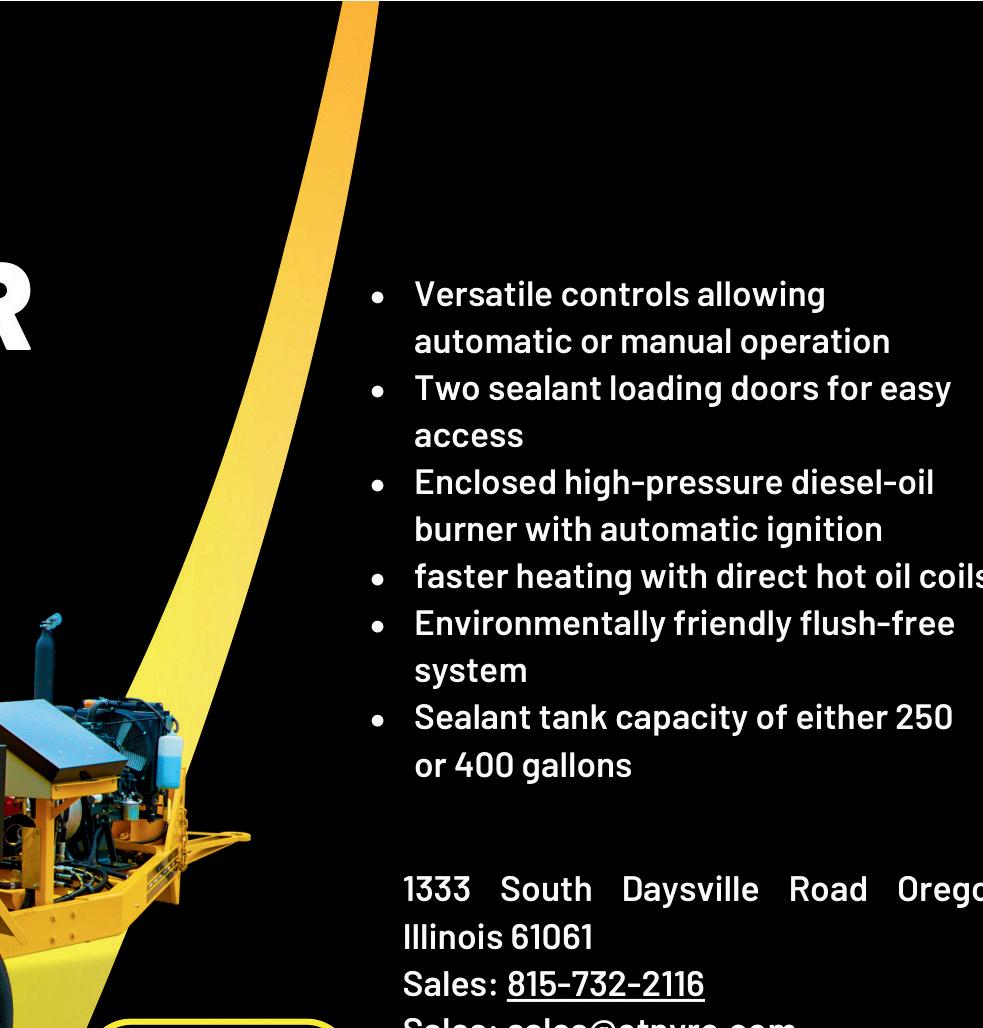

Only towable VRAM applicator without needing a CDL

Fastest melt rate in class

Lowest load height and quietest operation

Average daily production of 5-7 lane miles or less

Get fast, relevant product information in the Buyers Guide at ForConstructionPros.com

1 2

Gallon Crack Sealer

Gallon Material Capacity M2TM Crack Sealer Machine

Longitudinal Joint Sealer

230

410

MA4TM

Experience the Future of Pavement Maintenance with Cimline at World of Asphalt! BOOTH #2517 INNOVATION IN PRESERVATION Permanent pavement maintenance solutions at the lowest operating costs available in the industry. Contract # 080521-CME

ortless setup

operation with Cimline controls

and

lights show active system and proper speed range

10 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

3 4 For

more information visit

Hilltip SnowStriker VTR Snowplow

HillTip

Hilltip’s new SnowStriker VTR snowplows are designed for compact tractors and loaders weighing 2.5 to 5 tons. These v-plows feature heavy-duty box construction to withstand harsh winter conditions. Available in six models ranging from 5.5 to 8.6 ft wide, VTR snowplows have a curved, powdercoated snow blade to create a snow-rolling effect. The blades are made of high-strength steel, helping to make the plows light, yet durable. An adjustable, two-segment cutting edge with trip springs offers plow protection. Additionally, the plow provides superior coverage because the segments compress independently when obstacles are hit. The cutting edges are available in polyurethane or high-strength steel.

Wirtgen Hamm HD+ 120i Series Wirtgen America

While the HD+ 120i V-VIO 12 t tandem roller features a vibrating roller drum (50 Hz or 3,000 vpm) at the front and a VIO drum at the rear, the HD+ 120i VIO-2 HF provides additional application options with two VIO drums. An automatic control feature on the HD+ 120i VIO-2 HF keeps the front drum (in relation to the direction of travel) always working in vibration mode, while oscillation or static compaction is used on the rear drum. The HD+ 120i VIO-2 HF has also been designed as a high-frequency machine (HF), offering a vibration frequency of 67 Hz or 4,020 vpm (front and rear). Both models are powered by a 115 kW (154 hp) Deutz engine. The tandem rollers also have the ability to switch between vibration and oscillation or, in the case of the HD+ 120i VIO-2 HF, combine two vibration and oscillation drums together, removing the need to switch machines or deploy an additional machine and another operator on the construction site. https://pavemg.com/2a6kgs www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 11

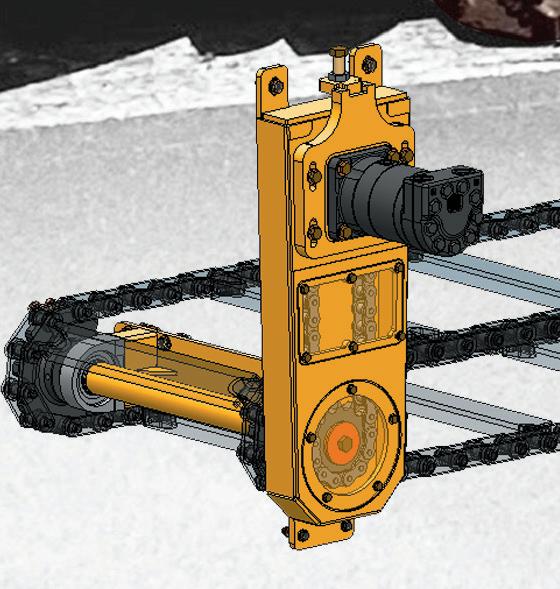

INTELLIGENT COMPACTION 101: How It Works and How You Benefit

Are you grading sites or paving roads the “traditional” way — relying on operator intuition and human measurement to ensure you’re meeting specs? If so, you’re not just risking over- or under-compacting. You’re also missing out on compaction technology’s many money-making, money-saving benefits. Here’s what you need to know about intelligent compaction and what it can do for your business.

FIRST OF ALL, WHAT IS INTELLIGENT COMPACTION?

This onboard technology helps ensure the compaction process gets done right the first time. GNSS mapping, integrated measurement, accelerometers,

infrared thermometers and onboard reporting systems work together to help operators achieve uniform density and optimal control and coverage. So rather than hoping you hit specs — or overcompacting in an attempt to make sure — you know exactly.

HOW DOES INTELLIGENT COMPACTION WORK?

Not all systems function the exact same way. However, here is an overview of some available features you might find on equipped pneumatic tire rollers and soil, aggregate, asphalt and landfill compactors.

• Intelligent Compaction technology assesses each pass providing a relative reading of material stiffness.

“Less fuel burned reduces your operating costs.”

• Instant feedback informs operators in the cab about which areas are compacted and which areas they still need additional passes.

• Navigation technology makes it quick and easy for operators to monitor compaction progress and coverage.

• Compaction and coverage reports give project managers the data to confirm

TECHNOLOGY UPDATE 12 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

It’s time to transform compaction from an art to a science. Find out how intelligent compaction technology helps you achieve compaction specs in fewer passes — and how that translates into money saved.

Caterpillar

a job is done correctly and meets specifications. Depending on your application — soil versus hot mix asphalt, for example — you can select from options like compaction meter value, machine drive power, auto adjustable compaction and more. Use the QR code at the bottom to see more information on how each works in more detail for specific application purposes.

WHAT ARE THE ADVANTAGES OF INTELLIGENT COMPACTION?

The ability to achieve compaction specs in as few passes as possible can lead to all kinds of benefits:

• Less fuel burned reduces your operating costs.

• Fewer machine hours lessens wear and tear.

• Reduced rework lowers your material costs.

• Speedier job completion lets you meet tight deadlines.

• Simpler operation helps novice operators work more accurately and confidently.

• Less need for ground personnel to check compaction enhances site safety.

Making the transition takes training, execution, and the right tools on the job. In the end, the benefits in efficiency and costs mean you can’t afford not to learn more. ■

Lonnie Fritz is a senior market professional at Caterpillar.

For more information visit https://pavemg.com/15u54etx

www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 13

Brandon Noel, Editor

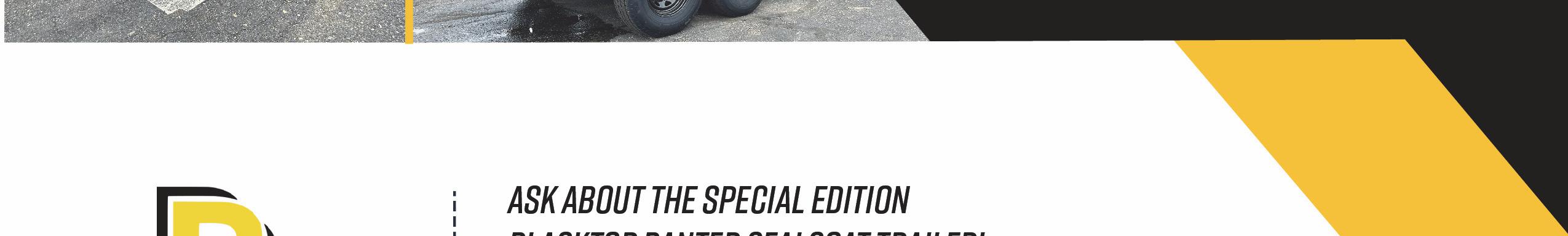

TThe First PAVE/X SMASHED Expectations

The inaugural, premier event for pavement maintenance professionals launched in downtown San Antonio, Texas, and the well-attended event exceeded the highest expectations.

he lead-up to the first-ever PAVE/X: The Pavement Experience trade show was like a fresh mat of asphalt: hot and compressed. Announced fewer than 12 months ago by IRONMARKETS, the show had to fight to gain name recognition in a well established industry, as well as to entice potential attendees to spend their money and time during the traditional off-season.

There’s only so many weeks of downtime pavement pros have, and to do something like this, it has to be worth their while. The biggest question mark for this event was first, “Would people show up,” and secondly, “Would the experience deliver?” Now, after three solid days of quality educational sessions, jam packed trade show flow space, and phenomenal live equipment demonstrations, it’s safe to say PAVE/X blew past what anyone could have expected.

Attendees from all over the United States came to Texas to see live outdoor demonstrations, learn about the latest equipment and innovations for their businesses on a sold out trade show floor, and learn from industry experts during 60+ hours of educational conference programming.

Many of the classes were jam packed, with the industry panels and roundtables being some of the most indemand sessions. Conference attendees were engaged and energized, even when they were a bit sluggish from a full night of activities in San Antonio’s beautiful downtown riverwalk area.

The inaugural PAVE/X event in San Antonio saw nearly 1,700 industry attendees and featured exhibits from over 70 manufacturers. But the highlight of the event was the 9+ hours of live outdoor equipment demonstrations.

HIGHLIGHTS AND EVENTS

PAVE/X really started off with the Pavement Award Ceremony where the event celebrated the hard work and dedication of paving and pavement maintenance professionals with awards in 10 categories. Attendees could also visit the Innovation Theatre to hear presentations on the latest technology and other advancements the industry has to offer.

And innovations were evident from the over 70 manufacturer partners that were on hand to showcase what they had to offer to help attendees gain a competitive edge in their business. As a group of contractors were about to enter the convention center, I stopped to get a sense of what drew them to come to PAVE/X, a brand new show.

“Just all the contractors that were going to be here, and all the actual equipment suppliers,” said Cisco Barren, with AB Sealers. “You know it’s the first, inaugural show and we wanted to be a part of it. We loved the live demonstration.”

Throughout the course of the three days, attendees also had plenty to see inside on the trade show floor. Several brand new products were launched

at the Tuesday night preview, seen by contractors in-person for the very first time. LeeBoy unveiled the HB4T Hotbox, which featured:

• Trailer Mounted 4 Ton Hopper

• Thermostatically Controlled Diesel Burner

• 110 VAC Overnight Heater

• Single Material Unloading Door

• Full Width Shoveling Platform with Integrated Material Shutes

• Hydraulic Dump Hopper

• Curb Side Operation

• Cantilever Side-to-Side material loading doors

• Integrated Compactor Storage Compartment

“Our dealers and customers have been asking for something like this from us, for years,” said Bryan Thornton, Leeboy’s governmental sales manager.

“The engineering team has had this product in production now, or in planning now for a little over a year. The finishing touches just went on prior to PAVE/X.”

Crafco also brought something new to the floor with their new “EZ Patcher” which is so new that the red paint was quite literally still drying when it arrived at the PAVE/X show floor.

Not many details are publicly available yet concerning the EZ Patcher, however, Crafco said that in the very near future there will be more to come. What was revealed about its mastic magic included:

PAVE/X PULSE | By

14 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Day 1 of educational sessions were packed!

Brandon Noel

• 65-gallon heated mastic applicator attachment for skid steer loaders

• Integrated skid steer hydraulics and power

• Hydraulic operated material gate with adjustable speed

• Hydraulic bi-directional auger/mixer with auto-reversing mix-melt mode

• Machine is symmetrical/reversible for dispensing on either side of the loader

• Floating drag box with quick release slide latches

However, it was JCB that brought the most exclusive and new hardware to San Antonio with them. Re-entering the North American paving market with two high efficiency rollers, the CT160 and the CT260.

“The models have been available in markets outside of North America for some time. They have proven to be a great success, and the durability has been truly tried and tested,” said James Gill, Product Manager at JCB North America.

Speaking to a few contractors at the event, the sentiment seemed to be unanimous: more. Everyone loved what they saw, and they just wanted more of it.

“It’s better than I expected,” said David from Bright-Stripe Services, based locally out of San Antonio. He drove down to see what the fuss was about, and was glad that he did. “I know you’re [probably] sold out for space, you know, and I know you have probably a waiting list for next year, but all I could say is to add even more.”

There were two asphalt plant companies who also had booths. Both Asphalt Drum Mixers (ADM) and ALmix were out there trying to educate contractors who might be considering taking that next leap into the industry.

“It’s a little different, you know? We’re not a direct product that a lot of these guys use,” said Ryder Harman, sales manager, ALmix. “We’re here to

kind of educate everyone on the benefits of stepping up to using our product and how it can give them tighter control of their business, cost savings and the potential ROI. Even if you’re a year out, two years out, or three years out, it’s good to start thinking it through. So you understand what the plant will look like, what equipment you’ll need, and get kind of a game plan for moving forward, when you do get to that point.”

I followed up, and asked what are some of the key indicators that signal a contractor is ready or nearly ready to take this kind of a plunge.

“What we hear a lot of is that most are people who are having trouble getting the asphalt that they need when they need it. They’re at the mercy of their competitors,” Harman said.

THE PAVEMENT AWARDS

The awards ceremony was a surprisingly emotional event this year, with the return of the former editor of Pavement Maintenance & Reconstruction magazine, Allan Heydorn, who was inducted into the Hall of Fame by his successor and protege, Jessica Lombardo. Heydorn graciously relented to calls for a speech when he reached the stage, and spoke humbly about his beginnings, but, also, about where he still sees his legacy all these years later.

“I started out in this job not knowing anything about pavement or asphalt,” said Heydorn. “But thankfully, I met people who were open to me asking a lot of questions along the way. When we created the Hall of Fame, I never imagined I’d someday be in it, because it was meant for people who’d shaped or impacted the industry in significant ways.”

In addition to all the awards that were given away this year, the next Pavement Awards will feature a BRAND NEW award category. Currently, there are two awards for sealcoating and striping, for either large or small jobs. Striping has always been included in the sealcoating awards due to the fact it goes hand-in-hand with

it. However, the skill, profession, and technology surrounding the striping arm of the pavement industry has grown by leaps and bounds. We felt that it was time to specifically honor that.

For the 2025 Pavement Awards, there will be a striping specific award: The Superior Striping Award. This new recognition will be graded and judged on three main components:

• Scale: the overall size of the job submitted, in terms of amount of materials utilized and the physical space in square feet

• Design: how was the job laid out? How complex was the job? How many colors and what types of materials were used?

• Execution: what was the plan of attack? How long did it take to complete? What challenges were presented and overcome? What innovative techniques or technology were incorporated?

Ultimately, this is only a fraction of all the amazing events, parties, sessions, and personal interactions that transpired in San Antonio. It truly was an experience, and if you happened to miss out on it this year, be sure to sign up ASAP when registration opens in June.

PAVE/X 2025 |JAN 29-30 AT THE CHATTANOOGA CONVENTION CENTER

“We will take what we learned in 2024, along with attendee feedback, and apply that to the PAVE/X 2025,” Lombardo said. “We have a great space reserved and have plans to expand the tradeshow floor. The demonstration experience in the demo lot will be close to the convention center in the parking lot of Naked River Brewing. Attendees will love the city of Chattanooga and we can’t wait to keep the momentum for 2024 going into 2025.”

Registration for PAVE/X 2025 will open in June 2024 at pavexshow.com. ■

For more information visit https://pavemg.com/pavex

16 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t PAVE/X PULSE

Because Being the Gold Standard isn’t Enough

Learn More at Crafco.com.

most

Visit us at Booth #1501 March 25-27 Nashville, Tennessee Connect with us

Being #1 just means you have to work harder to stay there. But Crafco has a better reason to keep making our materials and equipment better: You. We provide the

powerful, efficient and safe tools possible so you can get more done. From cracks and potholes to sealcoating and bridge decks, Crafco has the solution to help your hard work last.

THE BIG LEAGUES

Tips for buying your first plant, or upgrading your current operation.

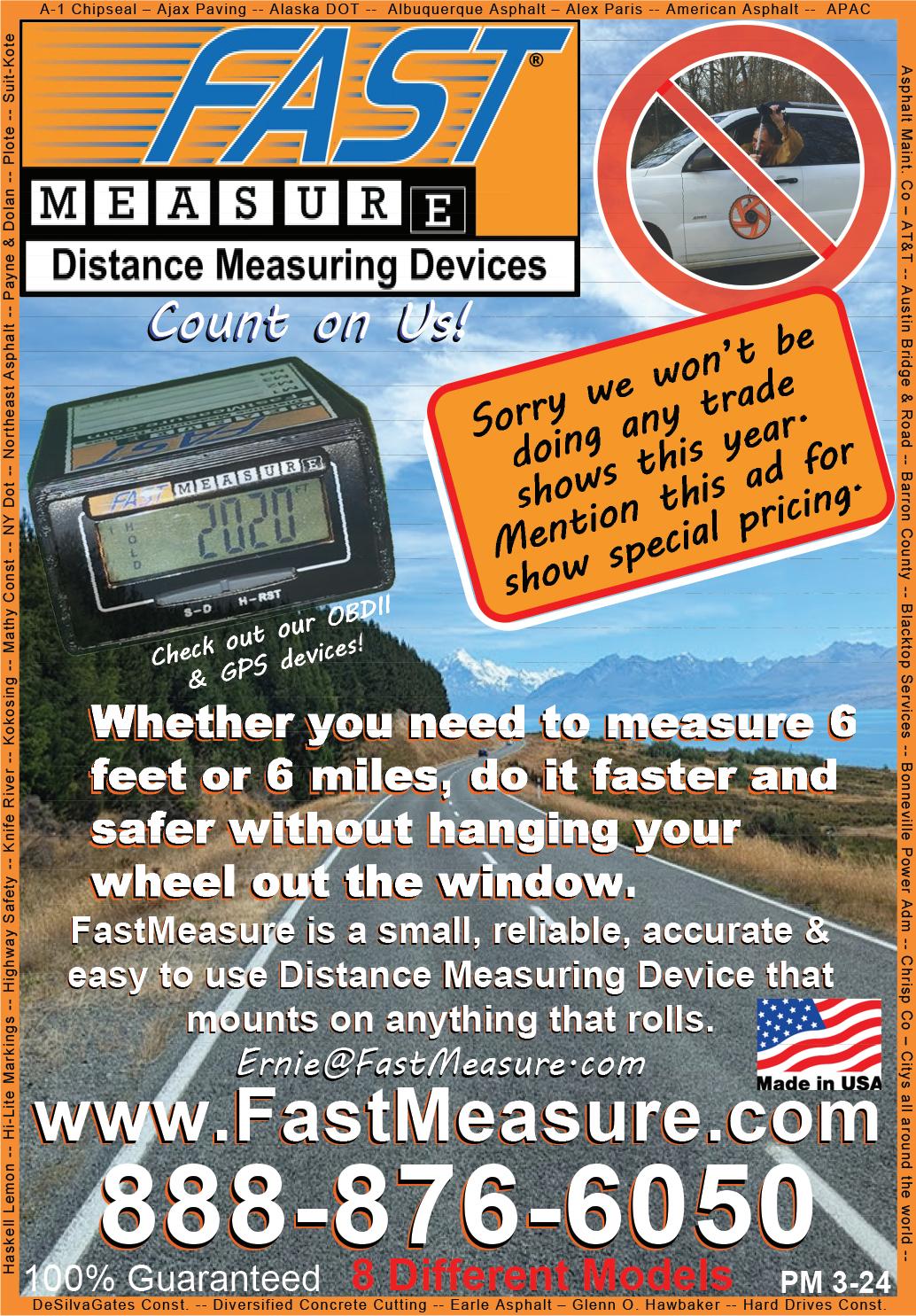

Returning from PAVE/X and considering whether it makes sense for your paving business to begin producing your own asphalt?

This is a common scenario for many paving companies that do not currently produce for themselves, and there are numerous considerations before deciding to make the investment.

Trent Nielsen, president and owneroperator, Nielsen Blacktopping & Concrete in Kasota, Minn. asserts, “As an asphalt and concrete paving company, owning your own asphalt plant is a real game-changer.” A third-generation, medium-size business, the company was started by Trent’s grandfather, Carl Nielsen, in 1969, and passed to Trent’s father, Craig Nielsen, and ultimately to Trent and his brother, Chad Larson, in 2006. The company operates within a 60-mile radius in southern Minnesota.

As a third-generation contractor, Nielsen Blacktopping and Concrete provides expert service in asphalt paving and concrete, excavation and preparation, and maintenance and restoration. Trent

stated, “Purchasing our own asphalt plant enabled our business to expand from a mostly residential and commercial paving company to a major player in municipal/public projects by completely changing the bidding process.”

He continued, “Pretty much all of our competitors in the area produce their own asphalt. Now that we produce ours, our pricing is more efficient and competitive to begin winning bids. Buying our product outside at higher prices and iffy availability was previously a big issue when it came to winning bids over our competition.”

Trent further remarked, “Producing our own asphalt even helped our residential and commercial projects because we’re easily able to get the different mixes we need for paving and patching driveways and parking lots. Not being in the metro area, it’s really important to be able to supply your own asphalt. Otherwise you don’t have control of your market.”

After completing their research and getting a number of pre-prep items in place, Nielsen Blacktopping & Concrete purchased an ADM EX 7636 counterflow asphalt plant. Asphalt production started in June 2022 with two silos. By Spring 2023, Nielsen added a third silo to supply asphalt to other businesses, and in June of that same year, the company had its own lab operational.

With the lab, Nielsen was able to test the mix and show customers the results. Trent said, “So far, this has been a big plus. Showing test results really gets the decision made for customers to go with the project. Our local cities do testing as well, and being able to offer companion testing has given us a real competitive advantage. Our plant operator, Troy Borwege, has his Bituminous Mix Designer Certification (BMDC) and is able to make quick adjustments for

quality control of the mix.”

In making the purchase decision to buy a plant, Trent stated, “Setting up your own asphalt plant is not for the weak of heart.”

Many considerations come into play to help determine whether the purchase of an asphalt plant is right for a particular asphalt paving business. Some of those key considerations in making that decision to purchase a plant includes:

• A paving company’s market size

• Location

• Start-up expense

• Plant features

• Return on investment (ROI)

• Understanding when to upsize Assessing your market size is the first place to start to determine whether buying an asphalt plant is advantageous to a paving company. Trent remarked, “One of the first factors in making our purchase decision was knowing we would have a reliable aggregate source for making our asphalt. We developed a relationship with an aggregate producer who was expanding his gravel business. Having an aggregate source was as key to deciding to buy a plant as being able to control our own mix.”

Market size also includes such factors as your company’s annual asphalt usage and cost to your business, estimating the number of additional jobs your business could accommodate annually without the wait time, and the potential for selling the asphalt you produce to outside businesses.

Trent completed a cost-per-ton analysis, and because he knew pavers go to the closest plant to get product, he would be able to draw cities and counties to buy Nielsen’s asphalt, in addition to making the company’s own.

The location of where a company plans to put its asphalt plant impacts

ON THE JOB 18 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Nielsen Blacktopping & Concrete in Kasota, Minn.

Provided by ADM

permitting for the plant, transport of the plant, plant size, and even the appropriate plant type. Permitting rules and fees vary greatly from one locality to another and are different state-by-state, as well.

Trent said, “Once we knew market size was viable, we pulled off application and permitting before making our plant purchase. We checked compliancy with Minnesota Pollution Control Agency (MPCA) regulations, a big factor for us since hot-mix asphalt facilities in our locale, including portable plants, must have a permit for stormwater and wastewater activities.”

Location also factored in for Nielsen Blacktopping & Paving. The company made sure that the planned plant location was strategic in being able to sell asphalt in the western counties and the southwest edge of Mankako, Minn.

It’s important to determine factors such as the additional labor your

business will need and cost of mix components, both of which will help you to determine how much you will need to charge per ton to turn a profit, if you are selling to competitive pavers, and how much you will save on your own material costs.

Obviously, a major factor in start-up expense is the price of the plant. A plant may cost less initially, but if it isn’t fuelefficient or doesn’t produce enough tons per hour for efficient operation, it will cost more over the course of its lifetime.

A fourth consideration comes down to plant features. Plants with counterflow technology, like the plant which Nielsen purchased, will maximize fuel efficiency while minimizing hydrocarbon pollution. Clean-burning plants will also extend the life of the baghouse, and the efficiency of counterflow technology will result in increased production.

Easy calibration of a plant is another important feature. This lowers the risk of drifting out of spec, which in turn gives producers confidence in the product they produce while helping to guarantee customer satisfaction. Easy calibration is especially important when producing mix for Superpave jobs as Nielsen does for its municipal customers.

A paving business needs to take into account its ROI expectations and project its potential bottom line improvements to help make an informed decision to purchase. Trent explained, “It’s a numbers game. We looked at how much our labor efficiency would be improved.

20 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t ON THE JOB QUALITY Widener ELIMINATE ROLLOVERS REDUCE LABOR MAXIMIZE EFFICIENCY PLACE PRECISELY 844-494-3363 www.roadwidenerllc.com Visit us at booth 2755 SEE HOW WITH

We understood we wouldn’t have an outside asphalt bill. We knew we would have better cash flow because we could produce as we went, rather than making up-front product purchases. Our outside costs were going up due to inflation with fuel and aggregate.”

Trent continued, “In the end, making our own asphalt in the first-year cost as much as going outside for asphalt the previous year, but product availability was king. We weren’t cut off by the oil contractors which was a real concern before we made our own asphalt. When it comes to ROI, it was also important to look at how fast we could pay the plant off. Again, it’s a numbers game.”

For paving companies that already have an asphalt plant, it is important to know when and if the time is right to upsize. If you’re already in the asphalt production business, you may be considering a newer, larger capacity plant.

Just as you did before buying your first plant, consider your market size, location, long-term expenses, and plant features when examining the costs and potential savings of buying a new plant.

Recycle systems allow cost-efficient RAP to be used at higher percentages. Better quality storage tanks in modern plants offer a more economical way to store and monitor pricey liquid asphalt cement, while newer storage silos provide a way to keep freshly mixed asphalt at an ideal, constant temperature until it is ready to be discharged.

A big part of Trent’s initial homework in deciding to make the asphalt plant purchase for Nielsen was a visit

to an asphalt plant that already had the brand and model he was considering..

“I was comfortable with their operation and equipment. They basically operate similar to how Nielsen operates,” Trent said. “We liked what we saw, so the trip was helpful in making our decision. Now that we produce our own asphalt, our trucks are no longer waiting in line for asphalt supply or unable to work on projects because we’re cut off at 5:30 p.m. With our own asphalt, we can work through the weekend like we did recently for a local hospital parking lot, producing 2,400 tons in a two-day period to get the job done.” ■

Cindy Carvour is director of client services at 300M.

For more information visit https://pavemg.com/fdbyom

www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 21

Provided by ADM

22 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t PAVEMENT PROFIT CENTER 800.543.7077 | neyra.com customerservice@neyra.com PAVEMENT SEALERS | ADDITIVES & PRIMERS | CRACK SEALANTS & PATCHING SPORTS SURFACING | MARKING PAINT | TOOLS, SUPPLIES & EQUIPMENT Family-owned and operated since 1975. Trust our industry experts to help you grow your business and optimize your time and efforts. “CUSTOMER FIRST” FOCUS INDUSTRY LEADING INNOVATION EXCEPTIONAL CUSTOMER SERVICE PREMIUM PRODUCT QUALITY Quality you need. Service you deserve.

www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 23 Proven, Reliable, Cost-Effective Rugged, Road-Tested, Purpose-Built sales@ezlinerarrow.com ezlinerarrow.com EZ Liner and Arrow are affiliates of VTS. 4 Kettle Thermoplastic Striper Rumble Strip Truck 6 Box Grinder 4 Box Grinder CustomLiner Teton 500 Gallon Capacity Arapahoe 230 Gallon Capacity Windrunner Stencil Truck Cascade 110 Gallon Capacity Plural-Epoxy Latex Paint Truck Contact us today! (800) 373-4016 Contract #080521-EZL

By Brandon Noel, Editor

Electric Power Will Displace Diesel Machines

EVs will eventually dominate the market.

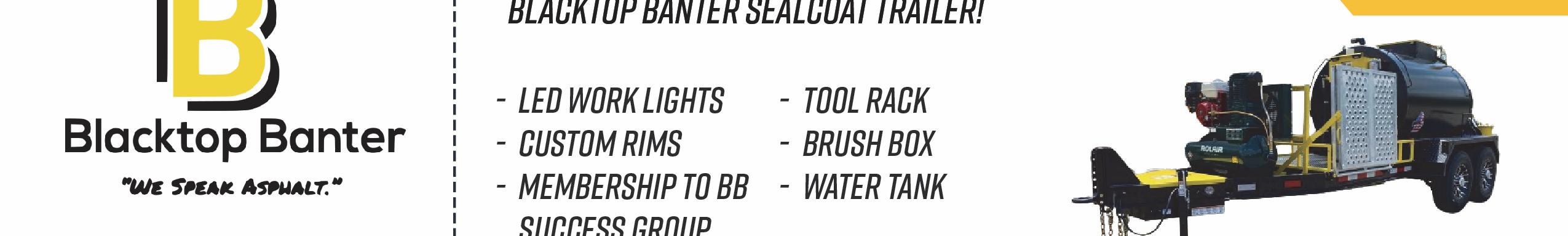

Electric vehicles (EV) and construction equipment may not be what you really need to buy right now, but in the not too distant future, you’ll be hard pressed to find a reason not to. Electrification is a hot button issue, not just in the world of manufacturing and construction, but operators and contractors feel a deep sense of connection to the machines they’ve known, used, and relied on for decades.

That’s even more true for the asphalt pavement industry, where pavers are entwined with the identity of their machines similar to the way professional athletes are with their shoe brands. With that in mind, when I heard in early 2023 that LeeBoy, one of the most popular producers of commercial pavers was bringing a prototype fully electric model – I was intensely curious to see more.

For one of the leading manufacturers to jump feet first by launching an electric version of the central machine of our industry is pretty exciting, but also risky. So, after seeing it on the show room floor, live demoed at PAVE/X, and then eventually getting to operate it for myself at the LeeBoy proving grounds in North Carolina; I spoke with the team who developed and manufactured it.

“Every new machine or solution from LeeBoy starts its life right here,” said Chris Broome, senior product manager, as he walked me to the physical and metaphoric heart of their plant in Lincolnton, N.C. From where we stood, I could see a group of employees, including two of the founding Lees, working on a hulking frame of steel. It was explained to me that they were building a large template to simplify the manufacturing process.

“This is our Seal Team Six, these are our problem solvers,” said Broome. “One of the most important things about the electric project was the lessons we learned in its development. Some of those lessons have actually turned around and provided benefits to our diesel machines. Obviously, it’s nice to be the first to do something, but the process itself has had immeasurable benefits that will carry on to the next innovation, and the next, and so-on.”

On the sweeper side of the industry, there are a number of electric and hybrid models already on the market, where the efficiency gains by going electric are changing the game. “With our fully electric model [M6 Avalanche EV] we didn’t just replace the diesel side, we also replaced all the hydraulics with electric motors,” said Jim Adair, director of product management at Schwarze. “We haven’t been able to stall out the brushes, and, whereas, over time your hydraulics will start out at about 80% efficiency and gradually become less efficient over time, the electric system doesn’t really experience that.”

These first-generation electric

iterations are just a starting point, and they are important steps for our industry as it moves into the future.

“Advancements in things like battery materials and density are happening so fast,” Adair said. “They’re only going to get more cost effective, safer, and more energy dense.”

STATE OF ELECTRIFICATION

While construction manufacturers have slowly introduced many alternative fuel options into the market place in the form of rollers (Dynapac, BOMAG, Volvo CE, HAMM), street sweepers/ brooms (Elgin, Nighthawk, Schwarze, LeeBoy), line stripers (Graco) and excavators (Volvo CE, CAT) it is important to note that these investments aren’t made based on political whims or public opinion. These companies are built to generate profits, and part of that strategy is to be ahead of the curve on the future of technology and innovation in their markets. Behind closed doors, there’s a sea-change happening and what

24 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t CONTRACTOR’S CHOICE |

Matt Stanley demoing the 8520c at PAVE/X.

Brandon Noel

is driving it is an energy revolution.

Part of the power of this moment in the industry is seeing the various ways the approach to the transition is happening. At the very first Celebration of Construction on the National Mall in Washington, D.C., organized and put on by AEM in May of 2023, Volvo proudly displayed their, “carbon free zone,” which boasted the large excavator EC230, as well as a hydrogenpowered truck. Talking to their head of electromobility Lars Arnold, whenever I asked about “charging” the various machines, he never corrected me directly, but he would reframe it back to me subtly as, “fueling,” the machines.

This felt like a small but significant forward thinking about EV. The machines are still doing the same job, they just run on a different fuel. It forced me to stop thinking about EV and traditional machines as two different things. They are the same thing, doing the same work.

Investing in the conversion of internal combustion engine (ICE) construction equipment isn’t about satisfying a “woke” agenda. Imagine the construction machine industry today is at the same point the cell phone market was between 2005-2007. With the hindsight of nearly 20 years, everyone wants to be Apple iPhone, and nobody wants to be the LG Chocolate. Whoever figures “it” out first might dominate their respective market the way Apple has for the past 20 years.

WATCHING THE MONEY

On Nov. 15, 2023, the Biden administration announced via the Department of Energy (DOE) a $3.5 billion investment in the battery and supply chain industry to strengthen domestic production, as well as to protect the country from scenarios where imports might be hindered due to unforeseen circumstances. According to the press release from the DOE:

“Batteries are a critical to national competitiveness – for grid storage,

for the resilience of homes and businesses, and for electrification of the transportation sector. With the demand for electric vehicles (EVs) and stationary storage alone projected to increase the size of the lithium battery market by five- to ten-fold by the end of the decade, it is essential that the United States invests in the capacity to accelerate the development of a resilient supply chain for high-capacity batteries, including non-lithium batteries.”1

In an article from September 2023, Joanna Glasner, a business and technology columnist, wrote about global and domestic battery investments coming from the private sector. She remarked that the projects were likely to be the highest on record.

Glasner said, “Looking at recently funded rounds, it appears investors pursuing this goal have coalesced around three primary themes: more sustainable battery production, scaledup EV battery manufacturing, and improved grid storage.”3

Adam Levy, a journalist covering tech companies and investments opportunities, wrote, “Major battery producers are investing heavily to meet rising EV battery demand. Meanwhile, battery technology start-ups are developing new energy storage systems.”4

In November of 2023, Toyota revealed a battery breakthrough. James O’Neil, writing about technology for TopSpeed.com said, “Solid-state batteries (SSB) will allow EVs to get up to 745 miles per charge. This is a longer range than most ICE vehicles. Perhaps more impressive than the long driving range is the short charging time. Toyota’s SSB can charge in 10 minutes or less.”8

Toyota plans to have it’s first SSB vehicle roll off the assembly line in 2027.

According to a report by GlobalData on EV, over the last three years there have been over 1.7 million patents filed and granted in the automotive industry.9

These are just small windows into where major money moves have been

taking place in the energy sector. One thing seems apparent: people are betting on the energy solution of the future, and that future belongs to batteries.

FUTURE PROOF

Every technology has a predictable lifecycle, but it isn’t measured in years, it’s measured in phases.5

• Innovation: Here, you invest time, money and resources into a technology that may not work out.

• Growth: The technology begins to gain wider acceptance and adoption.

• Maturity: It becomes more standardized and widely adopted, and growth begins to slow down. The market becomes more saturated, and companies focus on reducing costs and increasing efficiency, rather than investing in new innovations.

• Decline: Demand begins to decline. Companies may continue to sell the technology but profits are low, and eventually the technology becomes obsolete.

If you were to place ICEs on this timeline, where would it fall?

COST OF DOING BUSINESS

No matter what you choose to power your machines, what everyone is buying is energy. Just like you see on your month electric bills, every fuel can be expressed in Kilowatt Hours (KwH). The utility company usually expresses it as cost per KwH. A single gallon of diesel contains ~38/KhW, which is really good, except there’s a problem. An ICE can’t convert 100% of that potential energy into working energy. It can vary between 30% to 45% efficiency, depending on age, model, and usage. When you hear companies talk about their machines being, “more

www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 25

Schwarze

efficient,” that’s what they mean. More of the potential energy per gallon is getting turned into power for you paver, excavator, or roller, etc.

Let’s break down what this means:

• 1 gallon of diesel = 38KwH (potential energy) • .40 (ICE conversion efficiency) = ~15KwH of mechanical energy per gallon

• The average cost for that gallon in 2023 was ~$4.50 / 15KwH = ~$.30 per/KwH of working energy

At this point you can see how much you are paying per KwH. How many KwH are you buying a day? Let’s analyze the daily fuel needs for an average commercial paver.

unexpected fuel hikes, because of how unstable the price can be.

Lastly, every jobsite that I’ve visited has one thing in common. All the machines spend a great deal of time every day idling. While they are idling, they are still burning fuel. It’s a small amount, but it is still working against your cost-of-energy. You are literally burning money, but getting no mechanical power for it.

TIME IS MONEY IS TIME

• 1,200 KwH (daily required energy) • $.15 = $180 daily energy cost

• $360 (ICE) - $180 (EV) = ~$180 daily fuel savings

• $180 • 150 (working days a year) = ~$27,000 annual fuel savings

Yes, currently, the initial investment costs for these new machines are sometimes two or three times that of a traditional one. But how long before the ROI tips the other way?

BUT WHAT ABOUT...

I hear a few objections every single time the conversation around EV comes up. Some arguments have real merit, and they are important to discuss.

When talking about electric motors using these exact same terms, it becomes a little clearer why all these companies are racing to compete in this market. Electric motors have an energy conversion rate of ~85% of stored potential energy (battery) into mechanical power. This is nearly double the efficiency of even the most efficient diesel motors on the market.

Swap out your number of gallons a day for mine, your average work hours, and so on, to reach your answer.

• Smaller asphalt pavers can require between 5 to 8 gallons of diesel an hour, depending on use7

• An average workday consists of approx. 10 hours

• 50-80 gallons a day, conservatively, are needed just to run the paver

• 80 gallons of diesel • 15KwH = 1,200 KwH • $.30 = $360 daily paving energy cost

It’s vital to note that this is not a daily operating cost. This is purely trying to distill what you are spending on energy to run one paver.

Additionally, diesel costs can be extremely volatile, jumping upwards of $5 -$6 a gallon without warning. I’m sure that many of you experienced how this impacts job costing, threw off profit margins, and forced you to have to go back to customers and seek adjustments. Many contractors have added clauses in their contracts with clients to include

“The 8520c paver battery is 48 KWh. So, basically, I can pave 200to-300 tons of material with the same energy that is normally contained in 1-1/4; gallons of diesel fuel,” said Chris Broome. “If you only had 1-1/4; gallons of diesel fuel, how much would you be comfortable paving? You would never order the first truck. That’s the difference in efficiency.”

Also, the national average for commercial utility electricity is $.13 per/ KwH. Let’s plug these numbers into the same cost formula we used above for diesel, and we will use 38KwH as the base unit, since that would equal 1 gallon’s potential energy:

• 1 until of electricity = 38KwH • .85 (EV conversion efficiency) = ~32KwH of mechanical energy per equivalent unit

• The average commercial cost for that 1 unit of electricity would be (38KwH • $.13) $4.94 / 32KwH = ~$.15 per/KwH of working energy

That’s half of the cost of extracting energy from diesel. Let’s carry that through all the way down using the same 1,200 KwH as a benchmark for how much energy the paver requires in a day to operate:

The most common complaints people levy against the idea of EVs are about charging times, daily battery life, mobile on-site energy solutions, or the fact that you might charge an electric machine with a diesel generator. While using a generator would mean you’re paying the higher per KwH price for energy, the energy conversion of the electric motor still means a net savings/ gain in energy utilized.

However, let’s be honest. No one is pointing out the diesel-generator scenario because they are concerned about emissions or the environment. The same goes for those who point out that asphalt itself is a petroleum-based product, as if that somehow negates the potential technological and economic benefits of an EV.

While the inevitable transition to EV will hopefully have some positive environmental impacts, that isn’t really the driving force. The driving forces behind this change are essentially the same economic factors that transitioned the world away from whale oil and lumber as the dominant sources of fuelenergy in their times. One day, those contractors who transition to the more efficient non-ICE machines will have a competitive advantage against the contractors who don’t. ■

For more information visit

http://asphalt.com/kk3fi1

26 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t CONTRACTOR’S CHOICE

Brandon Noel

RAISING THE STANDARD

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

weilerproducts.com

YOUR BALANCE SHEET: A Critical Financial Tool

The balance sheet is one of the most underutilized financial tools in business, and it shouldn’t be. It can provide valuable information about the health of your business, and also help you ensure the accuracy of your financial statements.

Your balance sheet is the financial statement that tells you what you own and what you owe. The balance sheet lists out your assets – cash, receivables, inventory, equipment; your liabilities – payables, credit cards, loans; and your equity – owner contributions, distributions, and retained earnings. Your balance sheet tells you the “net worth” of your business. While this net worth is not the market value of your business, it does help you to see how healthy your business is. A balance sheet is a point-in-time report. This means that your balance sheet represents the various balances you own and owe as of a specific date. Typically, you run a balance sheet on the last day of the month to use as a part of your monthly financial analysis.

WHAT’S ON THE BALANCE SHEET?

Assets

The assets section of your balance sheet lists out the various assets that your business owns, including your cash, receivables due from customers and others, inventory, and fixed assets.

Liabilities

The liabilities section of your balance sheet lists out what you owe to others, whether it be to your suppliers, your bankers, government agencies, related entities, etc.

Equity

The equity section of the balance sheet represents the owner’s value in the business. This section will show money contributed to the business by the owner, money taken out of the business by the owner, and retained earnings. Retained earnings are those earnings from prior periods.

Current vs. Long-Term

Further breakdowns in your balance sheet will separate your current assets and liabilities from your long-term assets and liabilities. Current assets are those assets that can be converted into cash within one year. Examples of current assets are cash, accounts receivable, inventory, and other shortterm assets. Long-term assets are those assets that will take longer to convert to cash. These are items like buildings,

equipment, and vehicles – assets that you can’t sell easily or wouldn’t get the full value if you were to sell quickly.

YOUR BALANCE SHEET AND THE HEALTH OF YOUR BUSINESS

Your balance sheet can help you to evaluate the health of your business. A healthy balance sheet will have more assets than liabilities. If your total assets equal more than your liabilities, then you can have some level of comfort, knowing that you have enough cash, or things that can easily be turned into cash, to pay off your liabilities. If your total assets balance is less than your total liabilities balance, your business doesn’t have enough assets to cover its liabilities. You’re highly leveraged. If you had a slowdown in the business, you would struggle to meet your payment obligations because you don’t have enough reserves.

Bankers, investors, and potential acquirers use the balance sheet to evaluate the health of the business. You may have a strong-looking P&L, but if you are managing your cash and

YOUR BUSINESS MATTERS 28 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Adobe Stock/Pormezz

FROM THE OWNER’S DESK

BY NICK HOWELL

BY NICK HOWELL

Good, fast or cheap — you can’t have it all.

WGood, Fast and Cheap... You (and Your Clients) Can Pick Only Two

hat drives you? Are you driven by price or by quality? Could you be driven by both? With ever more intense competition from both legit and non-legit contractors, this is a battle we face daily.

We chose many, many years ago to be a quality-driven company. Unfortunately this comes with the fact that we will lose jobs, as many property managers are all about price. For the ones who are willing to pay, we feel we can offer them better service and better quality.

Recently, I was faced with a call from a big client whom we had previously done work for, calling and wanting a bid on what sounded like a big project. But there were red flags right from the start: They had no scope of work, and they were quick to point out that multiple bidders were coming over the next few days to also price it out.

My problem sits at the fact that I know we won’t be competitive on the “low bid” model; that’s just not us. But I also know that’s what this client now wants. This client was not this way initially, but the client has changed. It’s what this client has turned into wanting.

So I was faced with do I bid or not? Sure, it doesn’t hurt to bid. However, these folks require bidders to meet with them to walk the parking lot, which always turns into a several hour ordeal. As I thought about this, I don’t ever want to get complacent or “fat and happy,” however, I know our style of

estimating and our style of work. I also know our style of clients, which are the ones who appreciate the way we estimate, the way we approach our jobs and the quality of work we provide. This client used to be a client who appreciated that, but it wasn’t one of those types of clients anymore.

with the driven-by-quality model will pay off in the long run, even if that does mean fewer jobs. We don’t want to “turn dollars” or, worse, lose money just to work. But all too often that’s what some contractors do.

I’ve tried to spread the hashtags #saynotolowbid and stop the #racetothebottom in hopes that our industry would change. Contractors should charge more fairly for their services, and clients should pick middle bidders rather than the lowest. It’s all in fun – I doubt it would ever be a movement – but hey, maybe it will catch on!

So what did we decide to do?

I ended up responding that if the client would provide a scope of work that we would love to bid. But I also reminded them that we are a lowervolume, higher-quality operation and likely couldn’t compete on the price level that they seemed to want. I don’t know if it was the best solution, but where do you start and stop with these?

To further back up my thoughts, there is a saying, “Good, fast, cheap –pick only two.” If you want it “good and fast,” it won’t be cheap. If you want “cheap and fast,” it won’t be good. If you want it “cheap and good,” it won’t be fast.

I like that approach, but I’m not sure every customer does. I feel that sticking

As an owner, I know we live and die by our reputation. So even though next season a client may not remember we were high priced, they would surely remember if we got the job, but failed at sealing, paving, or striping their lot.

I would encourage everyone to remain quality-focused. It’s something that will never hurt and it surely won’t hurt in the way that being the #lowbid guy who cuts corners can. ■

For more information visit

https://pavemg.com/9zys7k

Nick Howell, president of T & N Asphalt Services, Salt Lake City, UT, has been a regular presenter at National Pavement Expo since 2008 and a member of the Pavement Advisory Board since 2007. Let him know your thoughts on “From the Owner’s Desk,” and if you have a question or topic you’d like covered – let him know that too! You can reach Nick at nick@tnasphaltservices.com.

30 PAVEMENT MAINTENANCE & RECONSTRUCTION | March 2024 | www.ForConstructionPros.com/Pavemen t

Adobe Stock/kittima

SWEEPING ASSOCIATIONS

First-ever PAVE/X Featured Sweeping Education + LIVE Equipment Demos

NAPSA partnered with the inaugural event in San Antonio to bring industryspecific content.

by Nancy Terry

For many years, NAPSA has been looking for a way to bring the sweeping industry together. While we attend many events each year to bring valuable education to our members, there have been few times where we’ve been able to experience the excitement and energy behind what we were doing.

At PAVE/X last month, nearly 1,700 professionals in the paving, pavement, and sweeping industries gathered in San Antonio and found what we were looking for from a national event: passion, pride and enthusiasm.

NAPSA partnered with PAVE/X in

early 2023 to help them craft education that was tailored for the sweeping industry and execute on the event the way we know our members would enjoy.

“It was an incredible honor to help bring sweeping education back to the forefront of a national event like PAVE/X,” Jessica Lombardo, conference manager said. “We are taking everything we learned from an epic Year One and applying it to Year Two.”

After a successful Year One, PAVE/X 2025 will head to Chattanooga with even more space, revamped hours and outdoor equipment demonstrations.

“We always have had the best interests of the industry at heart,” Lombardo said. “Attendees and exhibitors can take full advantage of their time, as the conference programs are positioned right outside of the tradeshow floor and the outdoor

demos will be located in the parking lot of Naked River Brewing and Barbeque.”

PAVE/X has secured nearly double the size of space at the Chattanooga Convention Center. PAVE/X is already booked for next year’s event at 140% percent of the 2024 opening show floor.

NAPSA continues to work with the team at PAVE/X to ensure a better tradeshow floor experience. Reach out to info@powersweep.org if you have any questions or suggestions. ■

The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership, please visit www.powersweeping.org or call (888) 757-0130.

Navigating the Sweeping Industry’s Educational Landscape for Lasting Success

Staying ahead means more than just attending a trade show or a handful of seminars.

by Ranger Kidwell-Ross

Staying on the cutting edge requires a commitment to continuous learning and adaptation to the ever-evolving trends within the sweeping industry. The recent PAVE/X trade show by the PAVEMENT organization sought to equip attendees with tools for future success, but true prosperity demands a year-round dedication to education.

I started working with Schwarze Industries in 1987, when the Schwarze family owned it. The strategy for growth I brought to the table was an emphasis on providing education to their customers and prospects.

Recognizing this, initiatives like the “Supervac Quarterly” newsletter, the Schwarze.com website, and sponsorship of my American Sweeper magazine in the 1990s were instrumental in catalyzing the company’s expansion. These platforms not only disseminated information but also fostered a community of knowledge sharing among contractors.

As technology advanced, so did the means of education. The inception of the World Sweeping Association (WSA) more than a decade ago marked a new chapter in providing ongoing education. Through regular bulletins, interviews with successful contractors, and the educational articles and more on the WSA website, members are empowered to stay abreast of legacy info along with the latest developments and best practices.

The remarkable renewal rate of WSA memberships underscores the

recognition among industry leaders that continuous learning is not just beneficial — but essential — for sustained success. In today’s fiercely competitive landscape, complacency is not an option. Those who prioritize ongoing education position themselves to thrive.

Whether through avenues like the WSA or other educational resources, the message is clear: invest in learning yearround. The dividends of knowledge are invaluable. ■

www.ForConstructionPros.com/Pavemen t | March 2024 | PAVEMENT MAINTENANCE & RECONSTRUCTION 31 NAPSA WSA

WSA contributor Ranger Kidwell-Ross has been providing information to the power sweeping industry since 1988. He is editor of WorldSweeper.com, an information resource for power sweeping, as well as founder and executive director of the World Sweeping Association. For more information about WSA visit www.WorldSweepingPros.org or contact Kidwell-Ross at director@worldsweepingpros.org.

By Brandon Noel, Editor

Increasing the Value of Your Business

Sealtite knows there are lots of ways to make your business valuation grow over time.

Austin Watt, CEO of Sealtite Asphalt Maintenance saw the incredible potential in this industry, and decided to go all-in. However, it wasn’t where he started out in business or where he thought he would be, even just a few years ago. Despite that, when he walked up to me at PAVE/X in San Antonio, between educational sessions, he made it abundantly clear that this is where he wants to be for the foreseeable future.

“I had an automotive dealership, but that wasn’t really where my passion was at. I’ve just always been an entrepreneur, and that’s how I ended up there,” said Watt. “That’s where I met Jim Dochterman.”

Jim was the owner and founder of Sealtite Asphalt Maintenance, and would come in, drink coffee, and shootthe-breeze with Watt a couple of times a week. He built Sealtite into what it was, and, over the years, he’d serviced his clients well and made a fair living.

Overtime, Dochterman’s visits developed their friendship and that would eventually lead Watt to where he is today.

“We would talk about everything,” Watt remembered. “Politics, the economy, and it just felt like we really understood each other.”

Then things took a serious turn during 2020 when the COVID-19 pandemic hit, and, as was the case for so many businesses during that time, things took a downturn. Watt’s dealership was on hard times, and some even harder decisions were still ahead of him.

“Jim reached out to me, and told me that he was already thinking of retiring, and that he didn’t have anyone in line to take it over from him,” Watt said. “I decided to close the lot, liquidate all my inventory, and buy Sealtite from him in 2021.”

In just three short years since Watt took the baton from Dochterman, Sealtite has seen the value of its business grow by whole new leaps and bounds. On average, they’ve seen growth of around 150% annually, and it shows no signs of stopping. With no background in the asphalt industry, to what does Watt attribute the robustness of the company’s growth?

“I think for me, having sales experience from the car world and integrating parts of that into selling asphalt and commercial maintenance, it gives me a big edge,” he explained. “I’m an older millennial, I grew up with computers, technology, and the internet -- smart everything, right? Jim already laid a solid foundation, I just added those things to the process.”

While those factors are important, Watt confessed that they aren’t everything. This was exactly why we ran into each other at PAVE/X, because he was there to expand his knowledge and learn from other successful owners in the industry who are willing to share

their knowledge and expertise.

“That’s exactly why I attended events like PAVE/X and the IGNITE Construction Summit. The networking, meeting of industry peers, and getting feedback advice from those who’ve done it was just awesome. It’s so important to keep control of your growth, bring on the right people, and implement the right policies and procedures. Last year, we ended at like just over $1 million in business, and that was the first year that’s happened in Sealtite’s history.”

If things stay on this kind of pace, and conditions prove to be favorable, Watt has even bigger plans.

“I’m a numbers guy,” said Watt. “Over the next decade, South Carolina Department of Transportation is repaving 85% of all roads in the state. They don’t have the infrastructure to support it. So, over the next five years, if I can get close to the number I’ve got mapped out, then I want to go in on an asphalt plant.”