10 minute read

FELLER BUNCHERS

803M Tracked Feller Buncher

From the L-Series wheeled machines to the 959ML and M-Series Tracked models, the John Deere feller bunchers deliver productive, reliable machine solutions built with loggers’ needs top of mind. 959ML Shovel Logger

Advertisement

The 959ML Shovel Logger tackles steep slope applications with ease. Equipped with industry-leading leveling technology, the 959ML provides exceptional stability in challenging terrain. “Our 959ML has been a game-changer for us. It is very maneuverable in the extreme conditions we work in, and its ability to reach down into a deep ravine and grab timber amazes me. Operators love the spacious cab and impressive visibility. And it delivers the same uptime, reliability, and dealer support I’ve come to expect from John Deere machines,” said Andrew Johnson, owner of Wolf Lake Logging Ltd. This smooth-functioning machine features standard walkways that provide access to all areas of the enclosure without climbing down. The 959ML offers convenient access to service components, allowing for quick and frequent maintenance checks. Additionally, the machine comes with several optional features such as a weldon, tether-ready hitch field kit, slope monitoring system, and four-point seat harness. When paired with the FL100 Felling Head, the 959ML delivers outstanding grapple strength, arm durability, and rotate and tilt power.

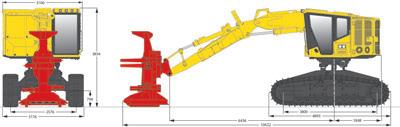

803M Tracked Feller Buncher

M-Series Tracked Feller Bunchers

Ongoing input from customers has helped to make the 800M- and 900M- Series Feller Bunchers more productive and user-friendly. The spacious operator station was designed by loggers for loggers and includes ergonomically designed controls. Other features include fully adjustable armrests with mounted keypads, a sealed touchpad allowing longer switch life, and floor-to-ceiling front windows to improve visibility. “The guys in the cab, they can see so much better off of the visibility. And that visibility should equate to better productivity… if the guy can see better, he can do a better job,” said Cory Isley of D&J Isley and Sons.

The 800M- and 900M- Series are equipped with a Final Tier 4 engine, increasing overall performance and reliability by minimizing fluid consumption. This latest Final Tier 4 engine meets EPA regulations in emissions without sacrificing power or torque. The optional Rapid Cycle System (RCS) allows for faster, low-effort joystick control of all boom functions. This helps operators of 800M- and 800MH-Series machines to be more productive by combining automated felling head arm cycling with simple boom controls. RCS significantly reduces operator fatigue while increasing efficiency and productivity.

843L-II Wheeled Feller Buncher

L-Series II Wheeled Feller Bunchers

The L-Series II Wheeled Feller Bunchers were designed based on extensive customer input, resulting in a lineup of machines that improve operation, maintenance, and reliability.

The simplified L-Series II models incorporate several part changes to reduce complexity. Changes to the electrical and hydraulic systems and improvements to component placements enhance the logger experience when servicing the machines. “The two-piece wiring harness makes it easier to work on the machines,” said Wayne Sugg of Sugg Logging. “Wiring is rerouted, so it is not bunched up in the machine, which reduces rubbing wear. The cylinder guards protect the hoses from falling limbs. These changes help make the machine more reliable, which saves time and money on maintenance.”

The heavy-duty axles on the 643L-II and 843L-II Wheeled Feller Bunchers provide the operator with the stability and hill-climbing power they need to navigate challenging forest conditions. The higher-ply tire options are available from the factory, increasing tire strength for carrying heavier loads and powering through rugged wood conditions.

New steering sensors enable operators to control articulation speed for frameto-frame contact, cushioning impact during full articulation, and improving operator comfort. Further enhancing operation, the electrohydraulic controls can be configured to personal preferences for the operator. The optional joystick and foot controls deliver smooth, low-effort control to decrease operator fatigue over long shifts.

The TimberMatic™ Maps and TimberManager™ map-based production planning and tracking systems are available for the M-Series Tracked Feller Bunchers and the L-Series II Wheeled Feller Bunchers. Optimizing productivity and efficiency, TimberMatic Maps helps eliminate guesswork for operators related to routes and the location of the timber. TimberManager provides complete visibility to the operation from the land harvested to the machines at work, allowing operators to streamline communication and increase efficiency.

643L-II Wheeled Feller Buncher

643L-II Wheeled Feller Buncher

REVERSIBLE FANS FOR AUTOMATIC RADIATOR CLEANING | www.cleanfix.org

more Cooling more Power

more Productivity

less Downtime

A Tigercat 2000 shear bunching eucalyptus in Australia

Tigercat builds a full line of innovative felling attachments designed to match the high performance and productivity of Tigercat carriers.

The product range includes disc saw and shear felling heads, fixed wrist and directional bar saw felling heads, and a growing line of harvesting heads. Tigercat felling attachments are used around the world and can be matched to virtually any type of mechanized felling application from small diameter pulpwood and biomass clear fell applications to selective felling of oversized, high-value hardwood.

2000 bunching shear

The original Tigercat bunching shears were designed in the mid-1990s for North American pine thinning operations. Over the years, the evolution of the 2000 series shear has made into what is considered the premium plantation eucalyptus felling head for the blue gum applications in highly abrasive soil conditions and rocky terrain. With fast shear cycles, the 2000 has proven to be highly productive, and extremely reliable. Compared with a disc saw, maintenance requirements are less and bushfire risk is minimized.

The shear arm pivot bearing design is extremely strong and reliable. The chassis is constructed with hardened steel, with bronze alloy bushings installed in the grab and accumulator arms. The shear blades are the toughest on the market and replaceable hardened steel wear strips are available for very sandy soil conditions.

The massive 0.62 m2 accumulation pocket allows for larger bunches, subsequently boosting skidder production and reducing fuel consumption as the skidder can more quickly accumulate a load. The shear improves the flow of the entire harvesting system.

5300 Bunching saw

The Tigercat 5300 bunching saw boosts feller buncher productivity in smaller diameter plantation wood under 405 mm (16 in). It has greater accumulating capacity than the 5000 bunching saw but the added weight of the additional trees and extra steel in the structure means that the 5300 is only suited to the full-sized Tigercat 870 series track carriers. Feller buncher productivity and efficiency improves because more trees are cut per cycle, reducing unnecessary machine travel.

Skidder productivity and efficiency improves because the bunches are large, well aligned and easy to pick up.

The Tigercat 5195 for performance when cutting and shoveling

5702-26 felling saw

Tigercat’s 5702 felling saw has been a highly successful workhorse on Tigercat tracked and wheeled feller bunchers for almost two decades and now Tigercat has introduced an important evolution – the 5702-26 for tracked bunchers. The 5702-26 shares the same arms, horn, wrist and asymmetric geometry of the 5702 with a larger saw housing and blade to increase single-cut capacity, throat width and accumulation area.

The 5702-26 features a 1,625 mm (64 in) diameter blade with 20 teeth spun at up to 1,050 rpm (max rated speed) delivering up to 30% more blade energy than the regular 5702. The single-cut capacity is 660 mm (26 in) for the 5702-26 compared to 580 mm (23 in) for the 5702.

As with all Tigercat felling heads, the 5702-26 is designed for durability, long life and easy maintenance. It features durable, well-guarded, cushioned cylinders and strength-to-weight optimized frames. Hardened wear plates and replaceable liners are installed in critical areas.

Heavy duty spindle and bearings in saw drive system can take the punishment from harsh forestry conditions.

The 5702-26 is best matched to Tigercat 870 series feller bunchers.

5185 fixed felling saw and 5195 directional felling saw

Tigercat’s 5185 and 5195 felling saws are steadily increasing in popularity globally in large timber and steep slope operations.

Contractors in native hardwood and other oversize timber applications are seeing benefits from the 5195 coupled with the LS855E shovel logger due to the excellent shovelling performance on steep slopes. This significantly decreases the amount of side cut skidder trails required to access the timber which is a big advantage in forests with strict regulations and stringent oversight.

The 5195 can efficiently top the trees within the cut block. With continuous rotation, the head is quickly and easily repositioned and double cuts on steep slopes are performed quickly without moving the carrier. This makes the head versatile for oversized timber over 1 m in diameter.

The 5195 has full 360° rotate with through-the-link central hosing for enhanced hose protection and extended hose life. Oversized twin grapple cylinders deliver high performance and control when felling cutting and shovelling. The fully fabricated chassis and grapple arms design provide strength and added longevity.

The 5185 shares the saw performance and strength and longevity characteristics of the 5195. Where the 5185 excels is in its ability to control fell and place high value trees, avoiding breakage. In timber stands with

The new XT465L-5 sets high industry standards of excellence for Track Feller Bunchers

Improved service access, reliability and durability means increased productivity for the Komatsu XT465L-5 feller buncher.

Built for ease of serviceability, a gull-wing style engine hood folds down, providing an elevated service work platform. Four additional service doors provide easy access. The innovative hydraulic tank design features two tanks, requiring 55% less total hydraulic oil.

Operator comfort and convenience are premium with a state-of-the-art cab, which has been relocated to the left of the boom. The design changes provide superior lines of sight to each track. The intuitive IQAN-MD4 digital control system puts machine control at the operator’s fingertips.

The rugged undercarriage significantly increases service life, including rugged, stronger track chain links that resist twist and longer-wear track roller and idler bushings. The new triple labyrinth floating seal housings protect the final drive seals against mud packing.

Fuel consumption is up to 5% lower due to advanced engine and hydraulic system control designs with the 331 peak hp (247 kW) Cummins QSL9 9-liter engine.

Lift capacity at full reach has been significantly increased and the XT465L-5 now readily operates the Quadco 24-inch (610 mm) cutting capacity disc saw heads. Features

Gull-Style Engine Hood

Gull-wing engine hood folds down providing an elevated service platform. Hydraulically-actuated with backup manual hand pump. Robust design provides a secure footing with 500 lbs (227 kg) load capacity. Offers excellent visibility and access to all engine-related components. Provides full access to engine oil filter, air filter, fuel filters, coolant, DEF fluid and hydraulic filters.

Relocated Operator’s Cab - Increased Track Visibility

State-of-the-art cab relocated to the left side. Tracks are now highly visible through the side door and boom side windows • Larger Door window has an

“L-shaped” flat bottom • Engine/pump compartment is set-back; top 2/3 portion is indented rearward

Rugged New Undercarriage

Rugged new Komatsu undercarriage provides longer service life due to: • Heavier 8.5“ track chain links have a thicker bushing strap which is stronger at resisting

“twist” • Track rollers & idler bushings are made of high-density material

• New track sliders have a reduced angle providing 30% lower contact • Final drives use a new triple labyrinth seal to protect from mud-packing • Crawler Box improvements include: • Removeable track guards have larger roller side openings to reduce mud packing

• Additional set of steps has been added to each crawler box

16% Greater Lift Capacity

Increased lift capacity at full reach vs. XT-3 due to improved boom & arm geometry and larger cylinders. Provides better balance between boom lift & arm holding capacity. Broad line of Quadco high speed disc saws available.

Built for ease of serviceability, a gull-wing style engine hood folds down, providing an elevated service work platform