4 minute read

BID GROUP

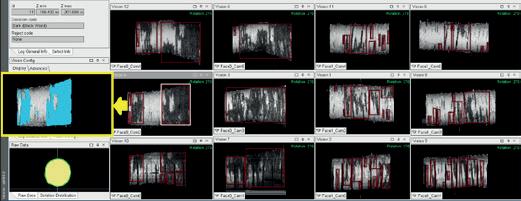

Examples of water pocket detection displayed in the optimization software

Using AI makes sense

Advertisement

Integration of artificial intelligence technology can be easily achieved to boost sawmill performance

BID Group’s Artificial Intelligence (AI) can be integrated with existing scanners and across most existing sawmill equipment in the market today. That is certainly the case for bark detection, split detection on logs, wood species detection, and wood defect detection. “AI is here to stay,” BID Group stated. “We’ve made it easily accessible so you can take advantage of the accuracy, speed and high-performance AI offers.” AI bark detection with lineal scanners

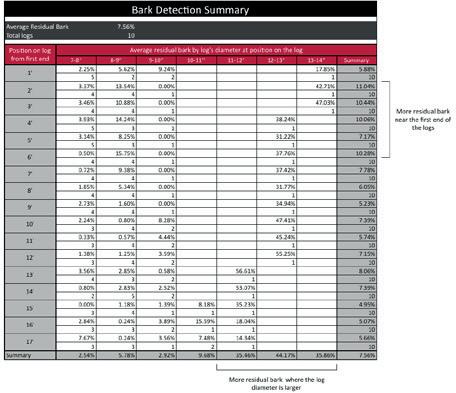

Traditionally, bark detection required someone to observe stems and logs, or analyze wood chips. This time-consuming task can now be replaced with a bark detector. BID Group’s Bark Detection with AI identifies the percentage of residual bark on a stem or a log. This information can be used to determine the performance of the debarker.

The Bark Detection software can be integrated either to the scanner used for the bucking optimizer or the primary breakdown scanner. The existing 3DPro laser heads capture images that are analyzed for bark and this information is displayed in the software interface to show the areas of wood and bark on the log.

In this example, several images display the residual bark detected by AI on one log. In the yellow frame on the left, the blue areas identify the bark detected by AI

The information is also sent to the Bucking optimizer database. The bark detection data is then organized and displayed in the debarker report (by diameter and position) and in the primary breakdown dashboard. This information is always available and can be accessed from a computer or any mobile device.

Split detection with bucking or OLI scanner

The split detection on logs was recently improved with AI. This functionality can also be integrated either to the scanner used for the Bucking optimizer or the OLI. The split detection data is used to find the best optimization solution for your products. This is a valuable feature when processing very dry wood.

Wood species detection with AI

The SpecPro can be integrated to an existing Comact transverse EdgExpert or TrimExpert in the sawmill, a GradExpert in the planer mill, or installed independently. It is also possible to add it to another manufacturer’s scanner. The upgrade and commissioning are simple to execute, and excellent results are obtained quickly.

The SpecPro offers the most accurate wood species detection in the industry. Its efficiency is not affected by any level of moisture content in the wood and it also works very well with frozen wood.

This system is based on Deep Learning (artificial intelligence). It was designed to optimize wood drying but it can also detect species once the wood is dry. The SpecPro uses color vision then analyzes boards of different widths/thickness. There are no maximum board dimensions.

The SpecPro is low maintenance and the system can detect multiple species simultaneously with consistent results over 98%.

Note that the SpecPro can also detect and process crayon marks (grade marks, trim marks, cut-intwo marks, etc.) on boards.

Integrate wood defect detection with AI on a TrimExpert

Wood defect detection with AI was developed extensively for the Comact GradExpert and all detections are available on the TrimExpert and transverse EdgExpert, namely the detection of wood species, knots, rot, water pockets, and crayon marks.

Note that it is also possible to integrate rot detection on a Comact Trimmer without vision, using the SpecPro.

WeighPro scale

The WeighPro scale can be installed before or after a transverse trimmer scanner. It is used to determine the weight of a board that allows to calculate the wood density. With this data, it is possible to categorize the wood by density to optimize the drying.

The WeighPro can handle any board width, length, or thickness. This scale is compatible with dry, humid, or frozen wood and all wood species. The weight precision is around 5% from 0-200 kg (may vary depending on the chain noise and vibration).

Determine optimal wood drying solutions

BID Group created a winning combination to determine optimal wood drying solutions. When using the wood species and water pocket detection with AI, combined with the WeighPro scale, data is obtained for specific and optimal wood drying solutions.

Based on this information, wood pieces can be grouped according to drying requirements to ensure uniform bundle drying. This saves energy and avoids loss of wood quality (splits, shakes, and warp when the wood is too dry or downgrading when it is too wet, and eventually mold development).

These examples demonstrate how our AI platform can be integrated easily in a mill. In the short and medium term, our complete range of machines will benefit from developments in applications that go beyond optimization.

BID Group’s objective is to meet the client’s current and future needs in an outstanding manner with its brand portfolio and offer a return on investment unparalleled by competition. All of this is supported by BID Group’s renowned 24/7 service.