In 2008 and 2009, Matthew Curran and Egan O’Keefe formed a partnership in the field of plant cultivation. They gained extensive experience in indoor, outdoor, and greenhouse cultivation and worked with some of the largest multistate operators, giving them exposure to top fertility programs and nutrients.

Recognizing the need for a high-quality, simplified water-soluble fertilizer, Matthew formulated Front Row Ag to improve solubility and provide optimal availability of micronutrients. Through thorough research into various environments, cultivars, and cultivation methods, the ideal formulation was created using the best technology and proprietary ingredients, such as chelates, emulsifiers, and solutionizing acids. Front Row Ag’s fertilizer is simple, cost-effective, and can be used in injection systems or added directly to reservoirs.

Great for injection systems by mixing stock concentrate or direct from the bag into reservoirs.

In 2016, the company was formed to bring its products to market and has since become the leading water-soluble fertility program, serving commercial and hobbyist cultivators globally. With a commitment to progress, innovation, and value, Front Row Ag believes that simplicity and high-quality inputs are key to improving plant yields, aroma, terpenes, and cannabinoids.

Solstice Agriculture, under Patrick Kanzler and Zack Vondrak, is the exclusive distributor of Front Row Ag’s offerings and works closely with the company and customers to provide outstanding service and performance.

When making a decision to work with the Front Row Ag Team our commercial customers will get access to:

• Fertilizer Onboarding Services

• Continuous Technical Support

• Access to Best Practices Wiki

Each Commercial Customer will get access to a

DEDICATED COMMERCIAL REP as well as the Technical Support team at Front Row Ag. Our goal is to be your fertilizer partner and support network.

Fertilizer Usage Estimation

Fertilizer Mixing Demo

Irrigation Equipment Review

Substrate/EC Consideration

Feed Chart Selection

Product Interaction Analysis

Tech/Validation Tools Review

Lab Testing Analysis (Optional Service)

• Water

• Tissue

• Soil

• Mineral

Additional Consulting Services

Available Beyond Fertilizer Onboarding

Delivers a complete blend of required micronutrients with unprecedented solubility utilizing the highest quality chelates. Part A provides the perfect volume of calcium and nitrogen to amplify flowering and vegetative growth.

Complements Part A by delivering the essential concentrations of magnesium and sulfur as well as ideal volumes of potassium and phosphorus to ensure optimized photosynthesis. Within Part B, a blend of surfactants evenly distributes fertilizer ions and water while conditioning the medium to hold more oxygen. Finally, our proprietary solutionizing agent drives cation uptake ensuring unparalleled solubility.

Front Row Bloom is a potassium and phosphorus booster. Enhanced with magnesium and sulfur, Bloom is engineered to optimize yield and quality via increased aromatic attributes and terpenes.

PhosZyme is a concentrated enzyme product with biostimulant effects targeted towards increasing yield and quality. It’s a soluble powder containing high concentrations of mannanase and phosphatase, enzymes that enhance water availability, nutrient uptake, and microbial activity.

The activity of these enzymes have a number of positive effects on plants including:

• Increased water and nutrients absorption

• Greater fertilizer efficiency

• Enhanced microbial activity in rootzone

These effects contribute to improved stress and drought tolerance that ultimately leads to greater rates of photosynthesis and increased production of flowers and secondary metabolic products including cannabinoids and terpenes.

• Mannanase works by breaking down starches around the root exudate. This process draws water and nutrients towards the plant roots and yields plant available sugars for absorption at the roots. These sugars are used later for metabolism, protein creation, tissue building, and generating terpenes.

• Phosphatase enzyme catalyzes the conversion of phosphorus into forms that are readily available for absorption, without requiring additional microbial action in the root zone.

• PhosZyme can be used in one of three ways:

• Direct to reservoir (Direct to Res) at 0.4 g/gal

• With a dedicated injector at 0.25% with stock concentrate mixed at 160 g/gal

• Added to the Part B stock solution at 80 g/gal (assuming B is injected at about 0.5%)

• PhosZyme should be used starting with mothers and clones up through week 7 of flower.

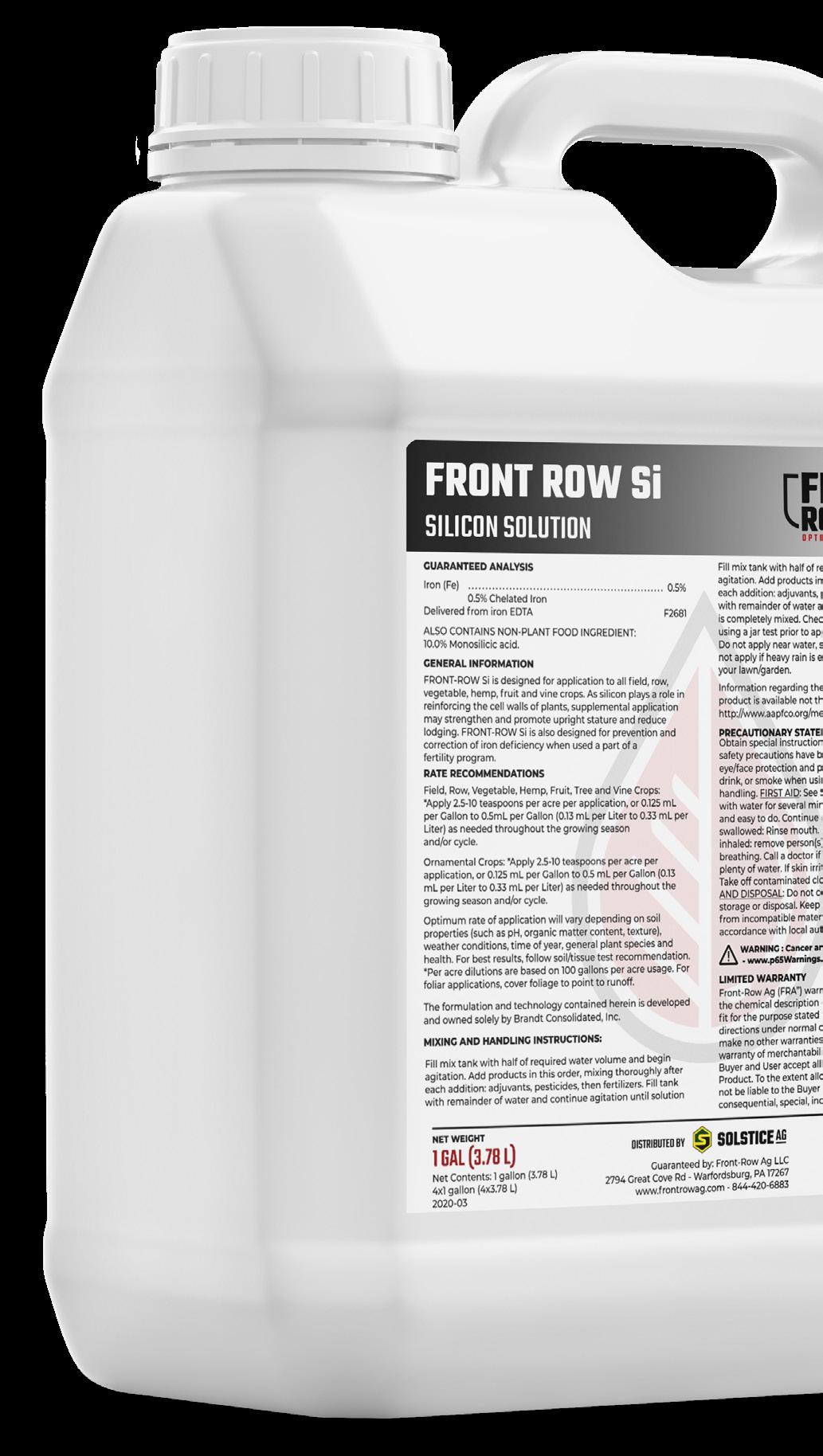

Front Row Si is a concentrated form of liquid silica containing 10% monosilicic acid, the only form of Plant Available Silica (PAS). It uses a new sugar alcohol (polyol) stabilizing technology that contains no polyethylene glycol (PEG) and allows for higher solubility while reducing risk of precipitation.

Silica contributes to several desirable outcomes in plants.

• Increased yield and quality

• Enhanced pest and pathogen resistance

• Improved resistance to abiotic stress (drought, light, temperature, salinity)

• Protection against heavy metal toxicity

These beneficial outcomes are mediated through a number of pathways.

• Mechanical effects: As it’s incorporated into plant tissues it increases the weight and strength of cell walls, creating a physical barrier to insects and fungal pathogens. The increased strength also leads to improved plant posture and resistance to drought, temperature, and wind.

• Nutrient absorption: Silica improves the uptake of beneficial elements and interferes with the absorption of harmful ones such as heavy metals.

• Water balance: By modulating the leaf transpiration rate and enhancing root water uptake, silica alleviates drought stress.

• Regulation of plant hormones and genetic expression under abiotic stress conditions.

• Enhanced activation of plant immune and antioxidant systems.

Enhance nutrient uptake, nutrient efficacy, tolerance to abiotic stress, and overall crop quality.

• Si in batch tanks or reservoirs must be fully used within 48 hours - if this isn’t possible, foliar application is preferred.

• Si usage rate must be reduced with higher EC - refer to Feed EC vs Usage Rate table

TABLE

Warning about High EC – DO NOT USE Si above 3.5 EC You must decrease dilution as feed EC/ppm increases to avoid precipitates.

Front Row Ag Clean Up is a wettable, dry soluble water conditioner that increases Oxidation Reduction Potential (ORP) and alkalinity, raising pH in a variety of irrigation systems.

• The potassium carbonate adds alkalinity, safely and consistently raising pH of the feed solution.

• The calcium hypochlorite dissociates into hypochlorous acid and hypochlorite to increase ORP of the feed solution.

Clean Up’s primary function is as a “pH up”, raising feed pH and increasing the stability of the feed solution. It’s a perfect pH up adjuster for RO tap water up to 120 ppm carbonate/ bicarbonate.

• The secondary function is to increase the ORP of the feed solution. Research at UC Davis Ag Extension Dept. performed by Dr. Trevor Suslow has shown that maintaining proper water chemistry is essential for nutrient and irrigation efficiency.

• The carbonates in Clean Up combine with acid (H+) ions in the fertilizer solution to form CO2 and H2O, raising pH and increasing the buffering capacity of the solution.

• The hypochlorite and hypochlorous acid function to raise the ORP of the solution, increasing water potential, nutrient uptake, and nutrient availability.

• We recommend using a 0.2-2% injector and making stock concentrate at 23 g/gal.

• Stronger stock concentrates are possible but require much longer mixing times

• Use a corded drill or impeller style mixer for best solubility.

• For Direct to Res, add in steps of 0.05 g/gal, mixing for 5-15 minutes between additions until target pH is achieved.

• Addition of more Clean Up than required to achieve target pH can results in fallout, filter build up, and clogged emitters. Use the minimum amount required.

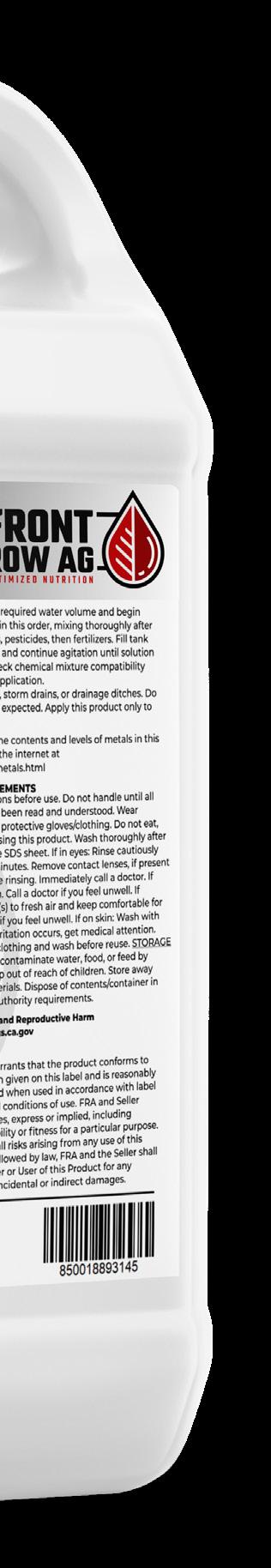

Triologic is a microbial root inoculant containing high concentrations of plant growth-promoting rhizobacteria (PGPR) including Azotobacter vinelandii that promote the uptake of essential minerals.

The highly concentrated bacteria in Triologic work within the substrate to increase yield, improve fertility, and enhance resistance to pests and disease. Applying these bacteria to the rootzone early in a plant’s development can reduce the effects of abiotic stresses while making more efficient use of fertilizers.

Plant growth promoting rhizobacteria colonies in the substrate are able to fix nitrogen and cycle other essential nutrients, including Phosphorus and Potassium into forms easily available to the plant roots. Additionally, these beneficial bacteria can help supply nutrition to the mycorrhizae that are protecting the plants roots, aiding the formation of beneficial fungal colonies.

Usage:

• 1-2 ml/gal, 1x per week.

• Best used as a hand water drench.

Stimulate root growth

Optimize your nutrient uptake for enhanced growth during veg and bloom phases.

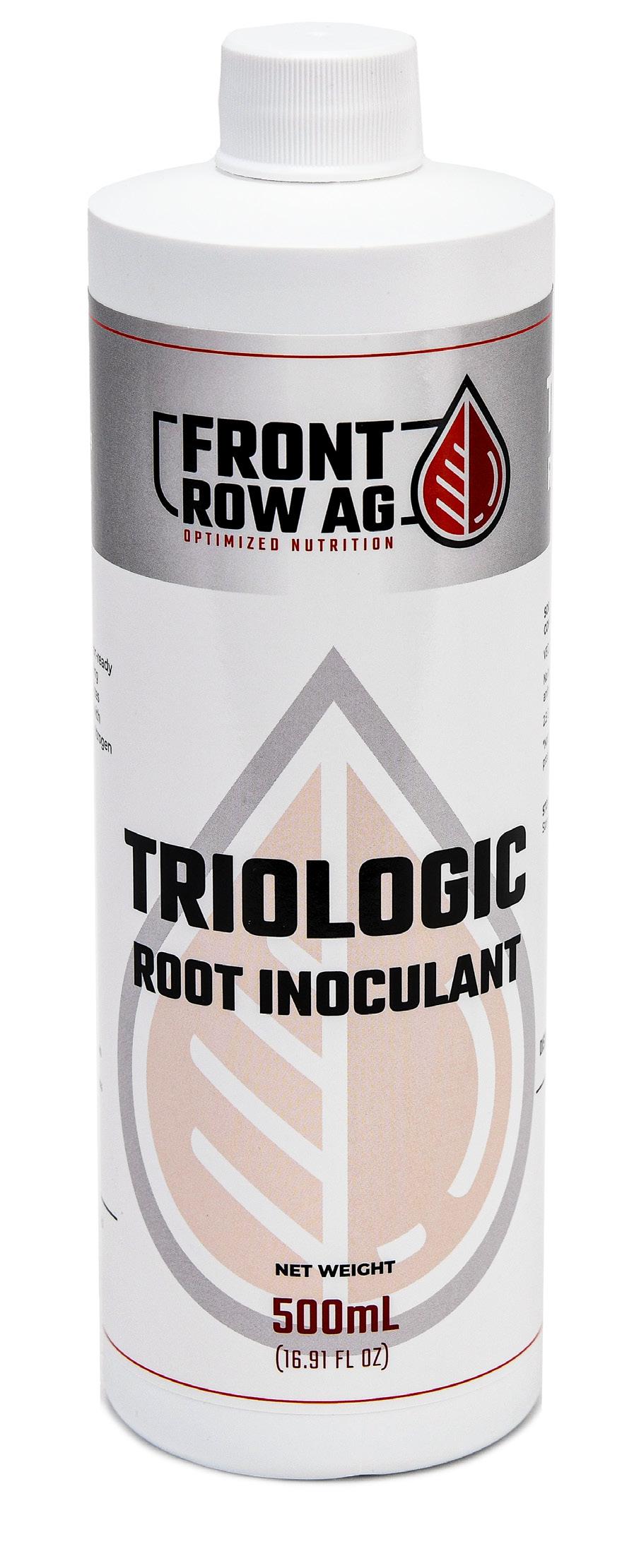

If your reservoir or irrigation system is accumulating biofilm or mineral buildup that’s causing clogged emitters, BioFlo is your solution.

BioFlo cleans pipes, filters, and emitters of biofilm and mineral buildup using natural bioactivity instead of harsh chemicals.

BioFlo comes in a liquid concentrate form so you can easily clean your lines, emitters and equipment without harming plants or beneficial microbes downstream.

Simply mix enough BioFlo to fill and soak your irrigation lines and allow your lines to soak for a few hours.

30 mL/Gallon

• Mix only enough to fill irrigation lines.

• Let lines soak for 8-12 hours.

• Flush System.

*See label for specific instructions.

Keep lines flowing

Clean your lines, emitters, & equipment without harming your plants or beneficial microbes downstream.

1. Fill reservoir to target volume; begin agitation.

2. Add Front Row Si*; agitate 3-5 minutes.

3. Add Part A; agitate 3-5 minutes.

4. Add Part B; agitate 3-5 minutes.

5. Add Bloom; agitate 3-5 minutes.

6. Add Clean Up in 0.05 g/gal steps until target pH is achieved.

7. Validate ph/EC and adjust as necessary.

* Only use Front Row Si if reservoir will be fully used within 48 hours.

• When using Front Row Si, reservoirs should be fully used within 48 hours.

• Without Front Row Si, reservoirs should be used within 5-7 days.

• Avoid mixing strong oxidizers, especially peroxides into reservoirs. If running a sterile reservoir, use calcium hypochlorite at 1-3g / 100 gallons.

• All feed charts are based on using RO water. If your starting water has any EC, be sure to account for that in the total EC.

• If using PhosZyme, add with Part B.

FRONT ROW while agitating. Wait 3-5 minutes between each component addition.

Continue agitation, adjust pH and check solution after 510 minutes

* “Stack” recipe can be used from start to finish of the flower cycle.

These feed charts are not a prescription, but an example of the general ranges and relationship of EC and recipes that can be used. Each facility and cultivation methodology will require customization of EC values. See the “EC Considerations” section on the Supplemental Information page.

1. Start with clean stock tanks marked at target volume.

2. Add RO water to 50% of target volume; begin agitating the tank.

3. Add fertilizer over 5 minutes, while continuing to agitate the tank.

4. Add RO water to target volume; mix for 10 more minutes.

5. Validate and adjust stock tank as necessary.

FRONT ROW & MIX

method allows each fertilizer part to be injected equally. This method is best for most situations as it allows the use of whole bags and creates equal volumes of stock concentrates which are used at the same rate.

VALIDATION INSTRUCTIONS:

• Remove exactly 50 ml of well-mixed stock concentrate and add to 1 gallon of RO water.

• Mix and check EC against validation chart. Adjust stock concentrate strength as necessary to match validation EC

• Repeat for each stock concentrate, validating against EC.

4-3-3 Stock Concentrate refers to the number of 25 lb bags of each product that are added to a stock concentrate drum - Part A with four 25 lb bags per 53.5 gal, Part B with three 25 lb bags per 60 gal, and Bloom with three25 lb bags per 60 gal. Mixing with the 4-3-3 method allows each fertilizer part to be injected equally. This method is best for situations where the injection equipment requires higher concentrations of stock concentrate and/or lower injection ranges.

BEST PRACTICES:

• Stock concentrates should be used within 2-4 weeks of mixing.

• Only mix stock concentrates with RO water.

• Store in covered, opaque containers in a climate controlled area.

* “Stack” recipe can be used from start to finish of

FEED CHART NOTES:

These feed charts are not a prescription, but an example of the general ranges and relationship of EC and recipes that can be used. Each facility and cultivation methodology will require customization of EC values. See the “EC Considerations” section on the Supplemental Information page.

* “Stack” recipe can be used from start to finish of the flower cycle.

FEED CHART NOTES:

These feed charts are not a prescription, but an example of the general ranges and relationship of EC and recipes that can be used. Each facility and cultivation methodology will require customization of EC values. See the “EC Considerations” section on the Supplemental Information page.

HERE’S OUR RECOMMENDED ORDER FOR INJECTORS:

1. FRONT ROW SI (*optional)

a. Silica should always be first in line if it’s being injected.

b. A 0.03-0.3% or 0.2-2% injector both work fine, refer to Si instructions on making a stock dilution for each range.

c. Follow with a mixing chamber.

PART A

a. Use a 0.2-2% injector or similar. b. Follow with a mixing chamber.

3. PART B (AND PHOSZYME)

a. Use a 0.2-2% injector or similar.

b. Optional: PhosZyme can be mixed directly into the Part B stock tank, refer to PhosZyme instructions for details.

4. BLOOM

a. Use a 0.2-2% injector or similar.

b. Follow with a mixing chamber.

5.CLEAN UP (pH adjustment)

a. Should be last in line.

b. Use a 0.2-2% injector if possible, which allows a stock concentration at 23g/gal.

c. If facility requires pH lowering, do not use Clean Up, use a pH down product.

d. Follow with the final mixing chamber prior to pH/EC meter. FRONT ROW

Crop Steering is the strategic manipulation of climate and rootzone environment to influence how a plant partitions resources during different phases of growth. At any given time, growth will be somewhere on a spectrum between “vegetative” and “generative”.

By manipulating parameters like feed EC, substrate EC, water content, irrigation frequency, and net dryback, we can change how a crop partitions resources and ultimately improve yield, quality, and efficiency.

These resource-partitioning effects are accomplished through the use of vegetative and generative cues; changes to specific parameters that signal the plant to shift resources towards vegetative growth (stems, leaves, shoots, roots) or generative growth (fruits and flowers).

is the difference in water pressure between the inside of a leaf (100% RH) and the air surrounding the leaf. This difference is one of the primary drivers of the “pull” side of transpiration from the leaves and is dependent on leaf temperature, air temp and air RH. It is generally measured in kilopascals (kpa). Keep VPD within these ranges for optimal plant performance. Generally night time VPD should be higher (dryer) to reduce the likelihood of fungal pathogens.

This table summarizes a number of vegetative and generative cues. Contact your Front Row Rep for more information on the specifics of irrigation and EC.

What EC should I feed at?

Given the variance in facility infrastructure, cultivation methods, and cultivars, it’s impossible to give a specific EC prescription that applies to all scenarios. Most facilities feed at 2.0-3.0 EC with Front Row Ag, and our “Standard” and “High Strength” Feed Charts reflect effective feeding strategies in this range. The following table shows some considerations that affect EC choice:

Smaller pots

Larger pots

Frequent irrigation Infrequent irrigation

Consistent runoff

Less runoff

Substrate monitoring No substrate monitoring

Higher PPFD

Lower PPFD

Heavy feeding strains Lower feeding strains

Higher CO2 Lower CO2

Tight environmental control Less environmental control

Why feed at higher EC early in the cycle?

Plant nutrition requirements are highest during the stages at which plants are growing most quickly, veg and during the first three weeks of flower. At this stage the crop will have a smaller root mass and drybacks will take much longer. As the plant finishes stretch, mineral requirements will be reduced and substrate EC should also be reduced via lower feed EC and/or increased runoff.

How is Front Row Ag different from other mineral fertilizers?

Front-Row Ag uses the highest purity agricultural inputs containing precise blends of micronutrients, chelates, complexing agents and surfactants.

Do I need to use Cal Mag with Front Row Ag?

No, our formula contains ideal ratios of calcium and magnesium based on years of testing and plant tissue analysis. If deficiencies are observed, raise EC by increasing all parts equally to maintain ideal mineral ratios.

Do I need a bloom booster with Front Row Ag?

No. you will not need an additional bloom booster - Front Row Ag Bloom contains all the required micronutrients with ideal quantities of phosphorus and potassium to maximize density, yield, and quality.

What is the cost per gallon for Front Row Ag using Part A, Part B, and Bloom?

$0.10 per gallon at 2.6 EC with commercial pricing.

What is the proper injection order for Front Row Ag?

1. Front Row Si

2. Part A

3. Part B

4. Part Bloom

5. Clean Up (or pH down if necessary)

What is the easiest way to use Front Row Ag?

Using dosatrons or an injection system with our 3-2-2 Stock Concentrate Mixing is the easiest method. This allows use of whole 25lb bags in 50 gal stock barrels that can be injected at equal injection ratios.

How do I use Front Row Ag for clones or seedlings?

How long can Front Row Ag be stored for?

Solutions should be stored in opaque containers in climate controlled areas.

For Direct to Reservoir mixing what is the required mixing time between adding each part?

• 3-5 minutes between Si, A, B, Bloom.

• 5-15 minutes between additions of Clean Up, to allow for full pH adjustment effect.

What causes color change or cloudiness of fertilizer solution in a reservoir?

Turbidity or “haziness” of the feed solution can be caused when bacteria or oxidizing chemicals react with certain metal micronutrients, forming suspended particles and changing the solution color. While this does not cause any functional problems with the fertilizer, it can be an aesthetic or cleaning issue. Turbidity can be avoided by following a few key practices in water quality and sanitation. Most often it is caused by strong oxidizing agents, especially hydrogen peroxide compounds, reacting with the high concentration of micronutrients in Front Row Ag. It can be avoided by removing these from the feed solution and triple-rinsing tanks prior to cleaning with these solutions.

How often should I clean my batch tanks?

As needed, depending on each facility’s inputs and water quality. Generally every 10-14 days is recommended, although facilities running a sterile irrigation system will require cleaning less frequently and facilities running microbial additives may require more frequent cleaning.

How do I spray Front Row Si?

0.5-2 ml/gal, sprayed weekly up to day 21 of flower.

Can Front Row Si be injected?

Yes, at 0.1 - 0.5 ml/gal. There are two important considerations with injecting Si:

• Higher feed EC requires lower usage rate of Si.

• If the injection system is filling batch tanks, they must be fully used within 48 hours.

Why does Front Row Ag improve quality, aroma, and yield?

Our formula’s high quality soluble minerals and full spectrum of micronutrients has been engineered specifically for the plant’s needs.

Do Front Row Ag users test for heavy metals?

Yes, we have hundreds of customers in markets with stringent heavy metal limits that use Front Row Ag to ensure finished products have low levels of heavy metals.

How often should my irrigation components be replaced?

Generally everything downstream from hard plumbing (primarily poly line and drip emitters) should be replaced annually.

How often should I clean my fertigation skid?

1-2 times per month is an ideal cleaning frequency to ensure cleanliness and consistent functioning of fertigation equipment.

How much does each FRA part raise the EC per gram per gallon?