12 SMART Furniture & Joinery Production

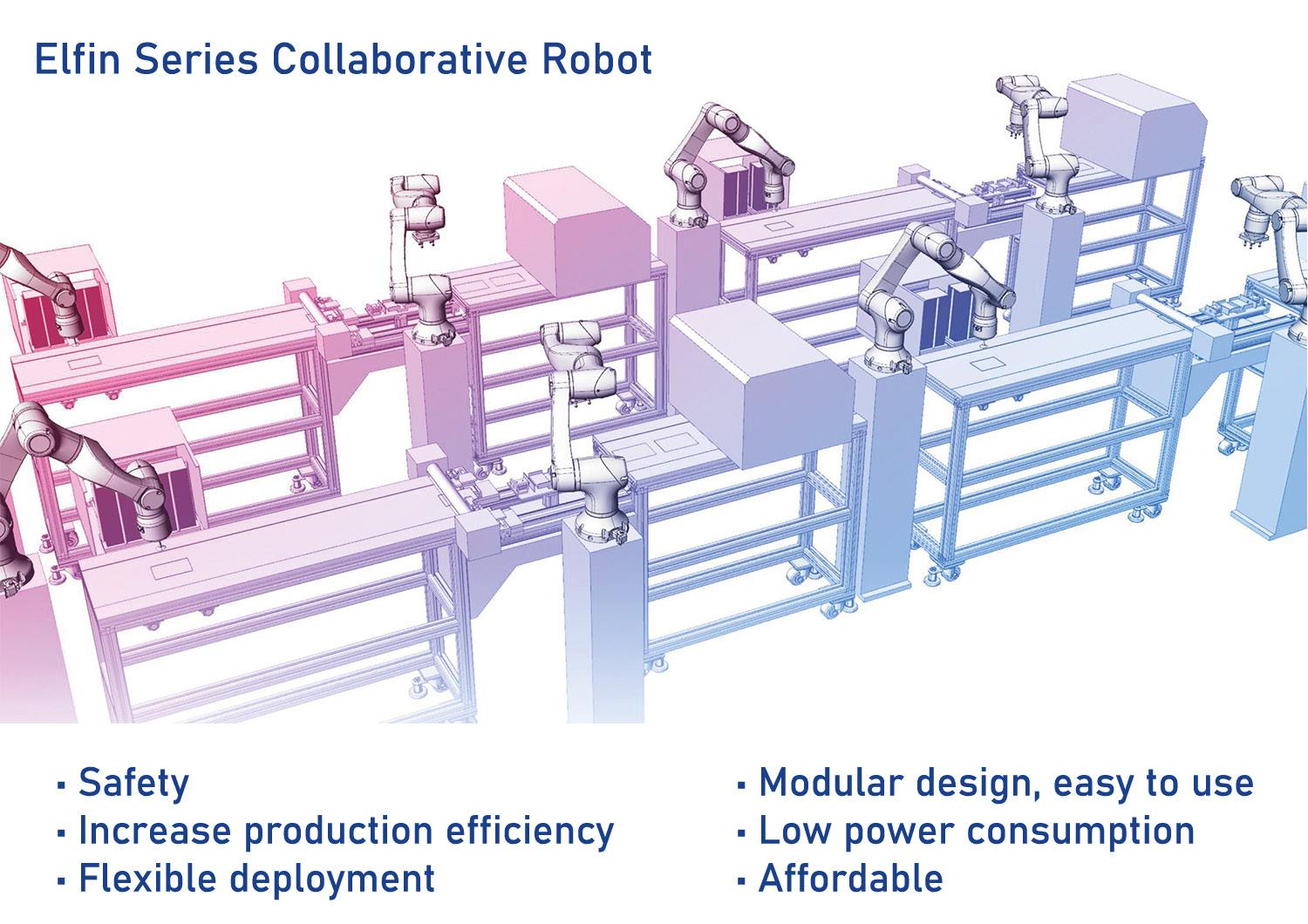

Biesse’s SmartAction concept provides a complete Smart Factory solution to companies of any size Compact, connected, and accessible, Biesse’s SmartAction concept offers companies looking to increase efficiency a straightforward route to transform their operations into a real ‘Smart Factory’. To enable this, machines are connected in real time to deliver optimised production, making manufacturers more efficient, and therefore more competitive – and it is software that leads the way to enable integrated production management. With the complete digitalisation of processes, products can be produced quickly and flexibly, with scope for customisation. Smart Factories are not only in the domain of large-scale production sites – smaller factories

can equally benefit by exploiting all the power and effectiveness of highly integrated solutions, including: • Reduced space with reduced labour • Integrated and optimised production management • Easy management and learning, even for less-experienced operators • Reduced resource consumption • Minimal investment Interconnected machines with B_Cabinet The key to unlocking a Smart Factory is to connect machines, and Biesse enables this via its B_Cabinet software suite, which provides

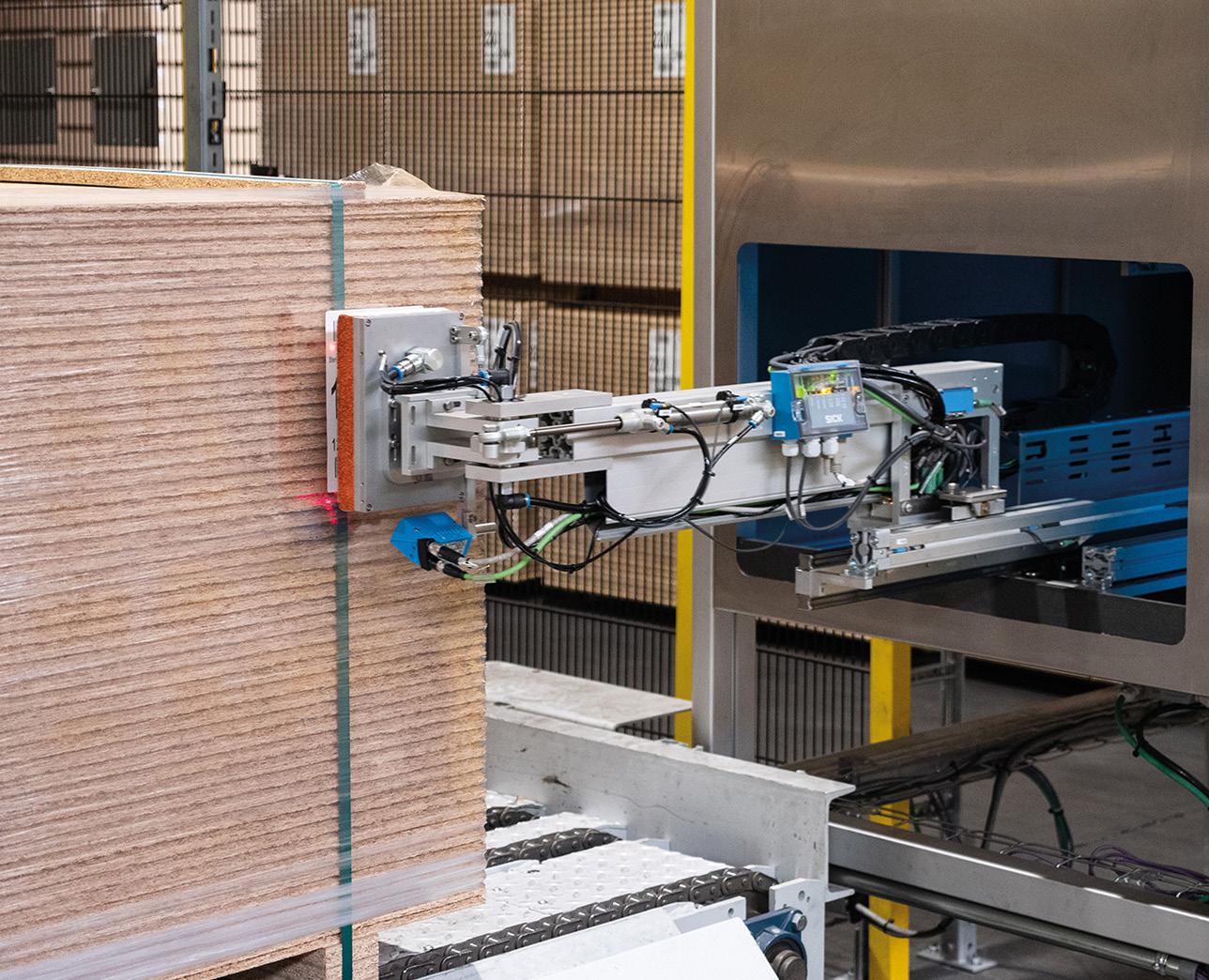

real-time communication with all machines, from machining centres and panel saws to edgebanding machines, drilling and sanding machines. This allows the software to deliver integrated production management and enable data exchange to send job orders, monitor machines and produce production reports. Compact, financially accessible solutions While the idea of a Smart Factory may seem out of reach to many manufacturers that think it can only be achieved by utilising robots and/ or automated handling systems, as can be seen from the two factory plan layouts, a Smart Factory can operate in limited production