MAKING THE CUT

The Worldwide Leader in Concrete Paving Technology

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/ cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

A focus on safety

From a runaway

BY TREENA HEIN

Tsaw blade to exploring best practices when sawing.

his spring in downtown Eugene, Oregon, a four-foot circular saw blade somehow came spiralling away from a concrete slab saw being used to cut a sidewalk for access to a gas main. In the blink of an eye, it spun across a nearby parking and very nearly killed a man.

It was travelling at such high speed that upon striking a nearby convenience store it shook the building and embedded itself two feet deep into the front wall, a few centimetres from the door.

A customer named Shane Reimche had entered the store a moment before, recalling later that as he did, he’d heard a nearby banging sound and a yell. Over his shoulder, he’d also glimpsed a puff of smoke and a worker tumbling into a ditch. Reimche was understandably shaken. “Obviously, it wasn’t my time,” he said to reporters, “but probably the closest I’ve ever experienced.”

The event went viral on social media (scan the QR Code to check it out).

Thankfully, nobody was injured or killed, but

the event serves as an outstanding reminder to adhere to every single safety practice with regard to cutting concrete.

DON’T SKIP THE INSPECTION

The saw in Oregon was a slab model used on a sidewalk, but regardless of the saw type or application, inspection before each use by an experienced person is critical. While details of the incident report are not public, it may well have been that the blade of this slab saw might have been damaged, possibly going unnoted.

Sometimes inspections do not occur, or may not be completely thorough or, at times, damage may occur while using the equipment. Similarly, guards may always get checked to see if they are securely fastened, or perhaps a guard had just come loose.

David Ohashi, and engineer and general manager at Ontario Cutting & Coring, also advises that workers should verify “that all controls are functioning properly, including the throttle, emergency stop button and blade guard” before each use.

When sawing a wall, the mounting housing must be inspected

CONCRETE CUTTING

to ensure it is secure, as should blade alignment to minimize the risk of kickback. Gas-powered saws need their fuel, oil and coolant levels checked, and should also be inspected for fuel leaks. With electric-powered saws, Ohashi says the condition of all connections should be inspected, and they should always be properly grounded using a Ground Fault Circuit Interrupter (GFCI).

When using wire saws, the operator should inspect the wire, pulleys, all other moving parts, the motor, and guards.

“In addition, check and maintain proper wire tension as per the manufacturer’s specifications to prevent breakage or snapping,” says Ohashi. “Never exceed recommended tension levels, and use a wire specifically rated for the job.”

If coring rather than sawing, the bit should be similarly inspected for signs of wear or damage, as should the stand or rig for stability. Ohashi stresses that if drilling overhead, make sure the anchor system is strong enough to support both the drill’s weight and the torque.

NAVIGATING SAFE OPERATION

Working from a stable stance beside the saw and not directly behind it is a best practice that helps avoid injury from sudden saw movement or kickback, and consistent, moderate pressure will allow the blade to cut the concrete efficiently without forcing it. Sudden changes in pressure with a saw or bit can increase the risk of injury from binding or kickback.

One possibility with the accident is that the saw blade could have met with a foreign object or material harder than concrete, causing it to escape its housing.

The Ontario Ministry of Labour, Immigration, Training and Skills Development has a website that shares advice about the use of quick-cut saws. As the site explains, “Saw blades build up tremendous kinetic energy during cutting.” When their speed is suddenly reduced, “the energy must go somewhere.” When they instantly start moving again, they can do so in dangerous ways.

established around a saw in use. The immediate work zone, adds Ohashi, should be marked with safety cones, caution tape or barriers to clearly indicate restricted access. In addition, operators should “carefully mark cutting lines and set up guide rails,” he says, “to ensure precise cuts and reduce the need for on-the-fly adjustments.”

Each concrete saw should have an emergency shutdown mechanism, and all operators should be trained in its use.

“Identify and communicate emergency stops and protocols to all team members working around the equipment,” says Ohashi. “Use radios or hand signals to maintain clear communication with team members, especially when working in areas with high noise levels or restricted visibility.”

Of course, there should also be a Class A/B fire extinguisher nearby and a wellstocked first aid kit on-site, and all personnel should know the locations of these and how to carry out first aid procedures.

When shutting down the saw, Ohashi explains that the blade should be allowed

OUT: January 21-23, 2025

to come to a complete stop before moving or adjusting it. After use, clean the saw to remove dust and debris, inspect for damage and wear, and store it in a dry location with the blade protected.

HANDLING THE DUST

WorksafeBC notes that cutting concrete without proper dust controls can generate high levels of silica-containing dust.

“Breathing in this fine dust can cause a serious lung disease called silicosis, which is characterized by scarring and thickening of the lungs, and can result in death,” states the organization.

Ohashi advises the use of an N95 or P100 respirator, especially when cutting without water. Using a continuous water supply minimizes dust generation, however, which not only protects the lungs but keeps visibility high and reduces friction and prevent overheating.

“Check the water system for any blockages, and make sure it’s operational before starting,” Ohashi says. “If working indoors, ensure the area is well-ventilated to prevent dust buildup, and consider using additional dust control systems.”

SILICA CONTROL TOOLS

Working with scientists at University of British Columbia, WorksafeBC and industry, the British Columbia Construction Safety Alliance (BCCSA) released its online silica control tool in 2017. BCCSA health and exposure scientist Melanie Gorman says the tool took about three years of development, and that it receives ongoing updates.

Users navigate a series of drop-down menus used to estimate the level of dust from grinding, cutting, drilling, hammering, rock crushing, and other scenarios involving silica dust, to then suggest mitigation options. The tool will also indicate how much each option will reduce dust levels.

An Ontario-compliant version, and one for New Brunswick, were introduced to construction employers in those provinces about a year ago.

PERSONAL PROTECTIVE EQUIPMENT

As with any equipment, it’s crucial to use the right personal protective equipment (PPE). Beyond dust mitigation, we need

to minimize risks associated with flying debris, noise, vibration and potential equipment malfunctions.

Ohashi advises that workers should limit exposure to vibration from the saw by taking frequent breaks and alternating with other tasks if possible.

“Use anti-vibration gloves and maintain good posture to minimize vibration impacts on hands and arms,” he says.

Safety goggles or glasses will protect the

eyes from dust and debris, but a face shield over goggles is recommended to protect the face against flying debris. Hearing protection is a must, for the operator of the saw and for those in close proximity, as well as those in confined spaces with the operator. Cut-resistant gloves with a good grip are recommended, as handling a slab or wall saw can expose hands to sharp edges and abrasive surfaces. Durable, long-sleeve clothing is also a must.

POWERFUL TRENCH COMPACTOR

The Husqvarna LP 9505 is a powerful, easy-to-operate trench compactor essential for demanding compaction jobs. Maintenance is quick and easy with all service points clearly marked under the easy-to-access protective hoods. Featuring smartly designed solutions, the LP 9505 can be used on a wide range of applications. Visit our website to learn more.

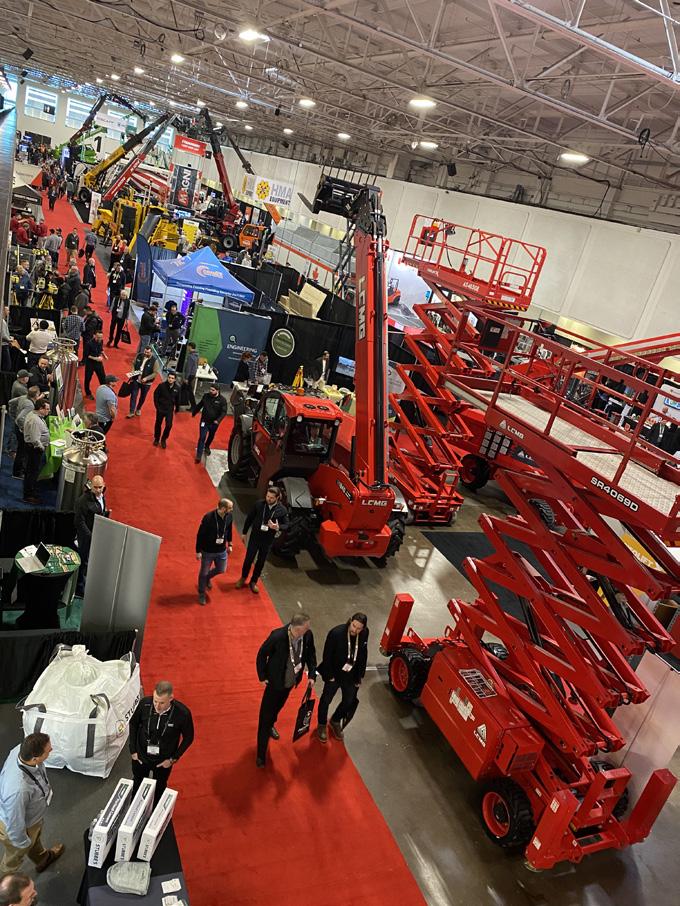

CANADIAN CONCRETE EXPO expands its offerings

This year’s CCE is stepping up its game with more exhibitors, specialized pavilions, live demonstrations and more industry educational sessions than ever before.

CANADIAN CONCRETE EXPO

February 12-13, 2025

International Centre

6900 Airport Road, Mississauga, Ont.

Canada’s national trade show dedicated to the concrete, construction and aggregates industries, the Canadian Concrete Expo (CCE) returns to the International Centre in Mississauga, Ont., on February 12 and 13. Building on a highly successful 2024 show, the 2025 event will bring more of almost everything, along with a few new twists that will put attendees in the driver’s seat, or at least at the controls.

In addition to the more than 360 exhibitors across the 300,000-square-foot exhibition floor, the event is ramping up its product demonstrations game, adding a new area with ongoing live equipment and tool demos.

“Attendees can test drive telehandlers, for example, and can operate tools and equipment used in concrete construction,” says CCE president Stuart Galloway, who is looking forward to seeing how the live demonstrations will augment the more traditional equipment displays usually found at an industry show. “This is something new, just to add a little bit more variety, and to give a better user experience for those that are attending.”

In addition to the equipment in the demonstration area, Milwaukee Tool has secured a 10,000-square-foot space to introduce its full line of cordless concrete tools, something the company is calling MX Fuel the Future.

Another new addition is the CCE forming, shoring and scaffolding pavilion.

“We’ve put all the major suppliers and

manufacturers in those sectors all in one area, and everybody’s come together and supported it,” says Galloway. “There’s a lot of new things happening this year. We just want to keep evolving and provide value.”

That commitment to value is a big reason for the event’s continued growth.

“We’re probably going to grow by about 15 per cent again for the 2025 show over the 2024 show,” he adds. “The feedback we get is that there are high-quality, targeted attendees that are attending CCE... We’re trying to stay focused in our approach for attendees, and trying to stay focused on concrete construction.”

That sector focus has generated interest from the concrete segment, but the number indicate that the event is also garnering strong interest from general contractors interested in some of the new developments happening in concrete construction as well.

From sourcing new suppliers, reconnecting with industry contacts, or getting hands-on with the latest equipment, the

annual CCE show offers lots of opportunity for professionals looking to expand their industry knowledge and skills, including through the 30 educational sessions that are on this year’s agenda.

“We have more sessions than we’ve ever had, and we’ve got a lot of new lot of new speakers,” says Galloway. “We put quite a bit of effort into getting high-quality presentations, and hopefully that pays off.”

Highlights for this year on the education side include new sessions on the concrete pumping industry, as well as a certification program for concrete pump operators.

Set to take place in February, the 2025 edition of CCE will be located at the International Centre in Mississauga, only five minutes from Toronto’s Pearson International Airport. Registration is now open, and pre-registration fees are half of the at-the-door costs.

Visit canadianconcreteexpo.com for more show information, and to register for the event, and for conference sessions.

PHOTOS

CONCRETE PRODUCT SHOWCASE

CONCRETE REPAIR MORTAR

Designed for horizontal and formed vertical repairs as well as overhead structural repairs, Versaspeed RMC from Euclid Chemical is a fast-setting, one-component, cementitious repair mortar that is shrinkage compensated, pozzolan and microfibre modified, and contains an integral corrosion inhibitor. The product is appropriate for applications where a fast return to service is required. Pre-mixed with pea gravel, the product is ready-to-use, designed to minimize cracking, and offers low permeability with excellent freezethaw resistance.

VIBRATORY SCREED BAR ADAPTER

Milwaukee Tool has expanded its screed accessory offerings with the addition of a Screed Bar Adapter. The adapter allows the MX Fuel Vibratory Screed to accept L-shaped bars, using a clamp-on design for quick attachment and removal, providing concrete professionals greater flexibility and versatility. The adapter accepts four- to 16-foot L-shaped bars.

SMART SENSOR FOR CONCRETE

Real-time data from Doka’s wireless DokaXact sensors helps to ensure that concrete is poured as fast as possible while providing the best possible concrete quality. The sensors, which can be used with traditional concrete mixes as well as more climate-friendly CO2-reduced concrete mixes, are designed to be tough, waterproof, dustproof, and easily connected to the user’s smartphone via Bluetooth.

REBAR TYING TOOL

MAX USA has introduced the RB443T, the newest addition to its TwinTier rebar tying tools platform. The tool is designed to streamline operations and maximize productivity with such features as an integrated autoload assist mechanism, to accelerate wire loading and minimize downtime, as well as an easy-pull trigger that requires half the effort compared to its predecessor, the RB441T.

BACKUP SAFETY SYSTEM

Freightliner Trucks, a division of Daimler Truck North America LLC (DTNA), has introduced the Backup Alert System for its Plus series of trucks. Available as a factory-installed safety option, the passive system includes a seven-inch integrated touchscreen display, backup camera, and reverse proximity sensor to meet the needs of drivers across a multitude of applications, including the construction and utility segments.

TRAILER-MOUNTED PUMP SYSTEM

The X-40D trailer-mounted concrete pump system from Blastcrete Equipment is engineered to provide high-volume pumping in a compact design for a variety of applications. The versatile pump is capable of handling aggregate mixes up to 1.5 inches, and can be used on projects ranging from residential concrete jobs to highway infrastructure improvements. The system boasts 1,000 psi of piston face pressure, with a five-inch discharge and the ability to put out 40 cubic yards of concrete per hour.

CLIMATE-CONTROLLED CURB AND GUTTER MACHINE

Power Curbers has launched a climate-controlled cabin as an option for the company’s Power Curber 5700-D slipform machine for pouring curb and gutter, sidewalk, barrier, ditches, paving, tunnels, agricultural and specialized applications. The new feature includes a fully enclosed operator’s platform with air conditioning, heating systems, and a unique glass floor insert that is strategically positioned to offer direct visibility of the mould and the finished concrete.

3D CONSTRUCTION PRINTER

Equipped with an extendable ground-based track system, the BOD3 3D Construction Printer from COBOD International is engineered for 3D printing of real concrete. Designed to be an advanced solution for high-volume low-rise construction, the machine eliminates printer downtime between the printing of multiple buildings on the same site for continuous, linear printing of multiple buildings.

Limitless extension along the Y-axis expands the printable area to cover two or three buildings, reducing setup time to a single installation for multi-building projects.

CONCRETE PAVING TRAIN

Wirtgen has a number of machines that can be organized to form a complete concrete paving train. One such example is comprised of a WPS 102i placer/spreader, an SP 124i slipform paver, and a TCM 180i texture curing machine. The company’s SP 15i and SP 25i machines enable flexible positioning of the slipform paving mould, while the SP 15i is equipped with a telescoping extension for a better overview of the paving results, the concrete feeding system, the transfer hopper, and of the inside of the consolidation compartment of the mould.

VOCATIONAL WORK TRUCKS

International Truck’s redesigned HV Series equipped with the S13 Integrated Powertrain combines toughness with an advanced integrated powertrain, says the manufacturer. With the S13, workers no longer need to stop work to perform active regens, and the company has simplified maintenance by eliminating components like the exhaust gas recirculation (EGR) cooler and diesel oxidation catalyst. The trucks feature a sloped hood, panoramic windshield, and two smooth and steady crawler gears.

Anticipation building for World of Concrete 2025 in Las Vegas

Returning for its 51st edition, World of Concrete, Informa Markets’ exhibition serving the construction and masonry construction industries, will take place from January 21 to the 23rd at the Las Vegas Convention Center (LVCC). Event organizers are looking forward to building on last year’s 50th Anniversary event, which attracted nearly 60,000 registered professionals from various industry sectors for three days of exhibition and four days of education.

World of Concrete 2025 will have all the newest products, leading-industry suppliers, resources, and educational sessions that concrete and masonry professionals are looking for. This year’s event is expected to have over 1,300 exhibitors putting their newest offerings on display across more than 750,000 square feet of indoor and outdoor exhibit and event space. The show is so large that it will take up the North, Central and South Halls of the LVCC, and will also use the venue’s Silver and Bronze parking lots for outdoor exhibits and events.

“If you’re involved in the commercial concrete or masonry sectors, the World of Concrete is the must-attend international event of the year,” stated the show’s senior marketing manager Steven Pomerantz. “Whether you’re a first-time visitor or a returning attendee, the impressive range of technology, equipment, and new product launches showcased at WOC will inspire you and offer essential insights for success, no matter the size of your business.”

In addition to the ever-popular Spec Mix Bricklayer 500 World Championship and the Mason Contractors Association of America’s Fastest Trowel on the Block, this

WORLD OF CONCRETE 2025

January 21-23, 2025

Las Vegas Convention Center

year’s special events include the Western Star Trucks Get Tough Challenge, which is open to attendees with a CDL, the Decorative Concrete Experience that features peer-to-peer presentations from industry experts, as well as Work Truck Live, an experiential area designed to showcase the innovations in trucks.

This year’s education program, which gets a one-day head start with first sessions being held the day before exhibits open, will offer more than 180 sessions of in-depth learning options for concrete and masonry professionals, including seminars

exploring technical applications, business best practices, project management, and safety-relevant topics for every skill level and job title from beginner to experienced, and even company owners.

“At World of Concrete 2025, we’re excited to unveil over 40 per cent of brand new educational offerings, featuring more than 180 sessions designed for concrete and masonry professionals at every skill level,” stated Maddie MacLellan, WOC’s senior education manager. “From technical applications to business best practices, our program has something for everyone in the industry.”

The World of Concrete show runs from January 21 to 23, with education sessions available from the 20th to the 23rd. For more information about the show, and to register, visit www.worldofconcrete.com.

SMOOTH

Join the power players of concrete and masonry. OPERATOR

There’s only one place you’ll find the heavy hitters of concrete and masonry this January: Vegas, baby — at World of Concrete 2025, the largest and only annual international event dedicated to your business. Be here to mix with industry giants. Get your hands on the latest technologies revolutionizing safety, performance and speed. And learn what it takes to not only claim a piece of our industry’s massive projected growth but dominate the field.

Learn more about WOC

EXHIBITS: JANUARY 21-23, 2025

EDUCATION: JANUARY 20-23

LAS VEGAS CONVENTION CENTER