2 minute read

HAFFNER BRINGS TWO NEW MACHINING CENTRES TO MARKET

There’s more support on offer from AluK for installers of its window, door and façade systems, with the launch of a dedicated online portal which allows them to access and download everything from product datasheets to sales brochures direct from the AluK website.

Installers just have to register their details at https://www.alukgb.com/portal/home, confirm which fabricator they are buying from, and then they can set up their own password protected account.

The downloadable options are tailored specifically to the needs of installers so there are datasheets, wallcharts, product cards and brochures available, rather than the technical files and CAD details which are within the separate AluK fabricator and specifier portals.

Antoniya Stoycheva, AluK’s Digital Marketing and Communications Manager explained the benefits: “This is a quick and easy 24/7 way for Installers to get the info they need on any of our products – and it also includes access to our Part L portal which includes our valuable ‘Installers’ Guide to Part L’.

“It’s not intended to replace what they already get from their fabricators, or the sales and technical advice that AluK provides– but it is a useful addition to our package of support and is another example of our commitment to strengthening our partnerships with our installers.”

More info at: www.aluk.co.uk

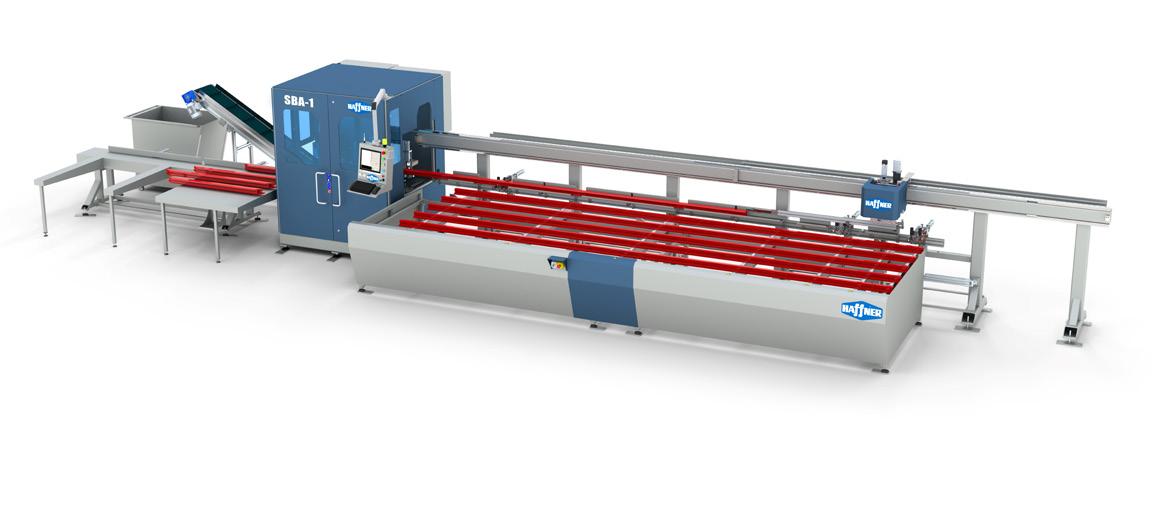

Haffner Ltd, the multi-award-winning machinery specialists, has just unveiled two new PVC-U automated machining centres, which are due for market release over the next few months.

Dave Thomas, Chief Executive Officer at Haffner, said: “As a business committed to delivering the machines our customers need, we have extended our SBA machining centre portfolio with the addition of two new machining centres. Like all our machines, they have been designed to deliver high levels of automation throughout the fabrication process, speeding up production, improving product accuracy and turbo-charging efficiency.”

The new SBA-1 Machining Centre has been designed and built by Haffner to assist the smaller fabricator who wants to compete in a market where labour prices are high and skilled workers are also hard to find. This sensibly priced machining centre will allow fabricators to cut and route between 300-400 windows per week with just one operator.

Similarly, the new SBA-5 Machining Centre is a machine powerhouse. It has all the attributes of the highly popular SBA-4 including additional servos to further increase routing times on both door profiles and night vents.

Dave commented: “The benefits of automating window and door fabrication have always been clear when boosting efficiency and productivity on the factory floor. The two new machines are suitable for fabricators at all levels looking to scale production output as fluctuating demand dictates with minimal resources.”

As you would expect from a Haffner machine, innovation and technical excellence is evident at every level.

The machines are easy to programme, control and adjust which gives them maximum flexibility and useability. And with minimal operational manpower needed, they also help lessen the impact of the current workforce shortage too.

Dave said: “Automated machines speed up the manufacturing process and can amplify the workforce by achieving more output with less skilled manpower. This allows fabricators to adapt to the current workforce shortage, help create more efficient processes and relieve existing workforce pressures too.”

The new machines look set to be popular with the company already receiving its first pre-launch order for the new SBA-5 Machining Centre from a largescale fabricator. Proof, if any were needed, that the combination of innovative machine technology, highquality engineering and the proactive Haffner support, is extremely attractive.

Tel: 01785 222421 www.haffnerltd.com

Does your secondary glazing supplier leave you in the dark? Switch.

Secondary glazing is simplicity itself.

It’s simple to sell, survey and install. It offers great acoustic and thermal performance. It has great profit margins. And it gets you into projects you couldn’t normally get into.

So why make it more complicated? Call Roseview today and ask about adding Incarnation secondary glazing to your range.