Magna Parens Materia

Hybrid Stone and Timber Mid-Rise Building

Magna Parens Materia

Hybrid Stone and Timber Mid-Rise Building

Magna Parens Materia

Over the last century, architects have been driven by market conditions to build with the highest possible combination of CO2-heavy materials, including steel and reinforced concrete frames filled with glass, aluminum, and fired clay bricks. This studio speculates on the potential of turning the construction industry from one that emits a significant amount of CO2 to one that sequesters it. By designing in stone (a partial substitute for reinforced concrete and steel) and timber (a heavy carbon sequestrator), we explore the feasibility of lowering the carbon footprint of new mid-rise buildings. At the same time, while our studio followed a hybrid approach employing stone and timber, we recognize the necessity of designs that may include other mixes of (potentially carbon-intensive) materials.

The studio begins with a crash course in stone’s material properties—structural, tactile, textual, financial, and carbon cost—and, thanks to “source to product” suppliers and specialists, we continue by touring quarries, stonemasons’ workshops across Belgium and the UK, and buildings in London (where student projects are set, in the Earl’s Court development of the London framework plan). This studio aims to recalibrate practice for real-world applicability, engage with building technology, sustainability, and codes, and establish a reciprocity between technical and conceptual aspects.

Studio Instructors

Hanif Kara, OBE, and Amin Taha

Teaching Assistant

Austin Sun

Engineering Support

David Watson

Students

Robin Albrecht, Michael Chang, Baiting Chen, Xinyi Chen, Ihwa Choi, Elliott Friedman, Hamees Gabr, Yvonne Gu, Madison Kim, Jackie Pan, Susu Pan, Gustavo Ramirez

Midterm Review Critics

Nelson Byun, Michelle Chang, Olayinka Dosenkun-Adjei, Yun Fu, Eric Höweler, Ian Miley, Cristina Parreño Alonso, Edgar Rodriguez, David Saladik, Carl Fredrik Svenstedt

Final Review Critics

Jennifer Bonner, Meriem Chabani, Brandon Clifford, Lucio Frigo, Eric Höweler, Caroline Johns, Chris Lee, Rahul Mehrotra, Mohsen Mostafavi

The class stands on a posttensioned stone beam during a visit to the stone yard and workshops of the Stonemasonry Company.

Preface

8 Powerlessness: A Precise and Prescriptive Approach to Design Research

Hanif Kara, OBE, and Amin Taha

Stone and Timber Hybrid Structures

46 Stone: The Uninhibited Material

Carrières du Hainaut team

48 Quarry to Site: Reorganizing Structural Stone in Construction

Gökhan Karakuş

52 The Raw and the Cooked: A Mythology of Stone and Concrete

Justin McGuirk

58 Mid-Rise Building at Earl’s Court

Sharon Giffen Calculation in Design

226 EN15978 as a Design Tool

Amin Taha

230 Get Your Calculators Out!

Jennifer Bonner

234 A New Architectural Vocabulary

Amin Taha

High-Tech Stone Curtain

Michael Chang

Rotundas of Modern Stone

Baiting Chen

Arch, Vault, Tower

Xinyi Chen

Drawing the Curtain

Ihwa Choi

Pile of Piles

Elliott Friedman

Stone Harmony: Mining the Future

Hamees Gabr

Yvonne Gu

Sheer

Madison Kim

Jackie Pan

Susu Pan

Gustavo Ramirez

Powerlessness: A Precise and Prescriptive Approach to Design Research

Hanif Kara, OBE, and Amin Taha

Hanif Kara, OBE

Rather than pretending we have all the answers and know how it ends, this studio continues to rely on and explore the things that we know could work: nurturing and building on the culture of “design research” over the short period of a semester. The starting point of the brief for this studio connects explicitly to the February 2022 report of the United Nations’ Intergovernmental Panel on Climate Change (IPCC).1 Some might argue that the report implies we are doomed to climate chaos, but I believe it speaks to a climate-resilient future. For the built environment, the IPCC report offers clear pathways toward a transformation in which pedagogy (at the early stages of education) can play a role by rethinking what we teach and how we approach climate change mitigation, climate change adaptation, and achieving sustainable development. The report also tells us that transformation is now inevitable. The question for our study was to test if we can make material choices that drive such transformation through design, beyond those forced upon us by the climate we have altered.

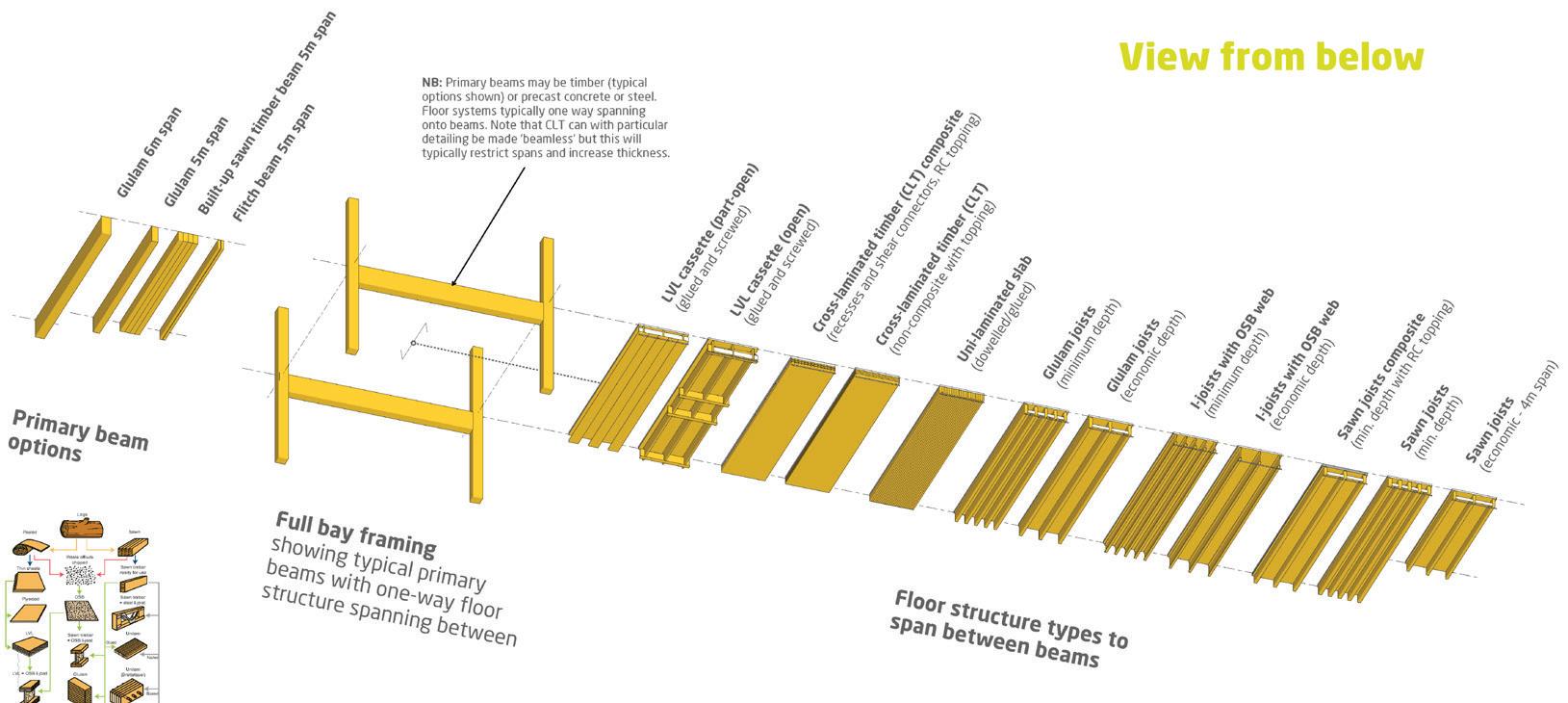

We chose to focus on a “mid-rise” building, defined as a structure typically between five and twenty stories tall. These buildings are less ubiquitous than low-level housing and less specialized than high-rises, yet they represent a widespread building type. Prescribing a real site constrains the students to be specific in their projects. Simultaneously, it tests the outcome of each project over a very short period of 14 weeks, considering the broader factors students must account for in their proposals. We also decided to jump-start the studio with a primer that gave students basic information on construction systems, particularly horizontal structural systems, and a fundamental

The Structural Primer provides basic guidelines and rules that are intended to help students begin their project with confidence. These rules serve as a foundational framework that students will reference throughout the semester as they develop their designs. Courtesy © AKT II.

Powerlessness:

common grounding of knowledge across the students. Design untangles and deciphers complex accumulated knowledge across many disciplines, scales, and geographies to put it to use for the benefit of all species that inhabit the natural world.

The corollary is also significant: what design is matters as much as what design does. My own interest lies in the boundary between science and art, engineer and architect. I have learned that a common definition of architectural design research does not exist, nor is it essential for productive transactions in that territory. I follow a long tradition of scholars who rely on drawings, models, and intellectual curiosity to present insightful texts, designs, and references as part of architectural discourse. In my mind, design research is neither intuitive nor based on rule-of-thumb processes. Instead, it takes a different starting point, as we hope the brief and output of the studio show.

At a time when the role of architecture in education and practice is once again under scrutiny, are the architectural profession, educators, and education fit for purpose, given the socioecological and socioeconomic challenges we face? Over a number of years at the GSD, I have been able to trace a productive aura of learning and teaching born out of a deep respect for the history of architecture and design research. This is through a combination of my own work, the experimental work of a co-taught studio, and the choices students make, with the opportunity to offer compelling outcomes and possibilities of interaction for academics and practitioners alike, even those seeking progress through a less prescriptive studio.

The studio does not claim anything is new; on the contrary, there is a hidden assertion that our speculations are rooted in the history of architecture, engineering, and art over time. It is thus daunting to summarize and write about the work the critics have positioned as models to debate over many years of their journey in practice, offering it as a resource for others to incorporate and integrate into their practice and study. This studio provided an opportunity to explore again, through various collaborations and intersections with our students, what we have taught and built together and separately. Perhaps the common ground lies in our sincere pursuit of speaking to audiences

Hanif

across disciplines of design and many generations. The studio’s output is also shaped by many colleagues who supported the studio, by visits to London and to the Stonemasonry Company, the quarry in Belgium, and the site at Earl’s Court. I cannot deny that to focus the reader on what lies beyond this text, they must also read between the lines wherever possible to spot slippages into many years of conversations with students and colleagues. This report offers a good view of the role played by these particular conditions, allowing us and the students to build several bridges between design and research through conversations about sustainable technology that expand and resist oversimplification and are sometimes driven by narrowing the work to the use of “stone and timber” today.

The distinction I make is that the work presented doesn’t merely emphasize quantitative techniques, optimal solutions, or experiments in the two materials. Instead, it presents experiments that test and extend many material aspects through the interplay of making, drawing, practice, and academia. This enriches the work and is particularly accented by the experience of two different practitioners with different positions on design research, both striving to resist formal “newness,” “uniqueness,” or “originality.” This is pertinent, as the timing of the studio coincides with promising signs of change in architectural practice and education. Many parts of the world now accept and embrace design research as a legitimate research area in its own right. This was not always the case, as we critics have faced some resistance to our position globally. One goal is to seek the potential to sharpen what we already know, enabling us to speculate with our students and “cross new bridges of clarity” without ignoring or relying solely on systematic knowledge for the ultimate design integration in practice. The range of the output of the work and its analysis reveals and retrieves an opportunity to continue this work on mid-rise types. In some student projects, one recognizes a disorderly aesthetic that shows signs of collective intelligence within the context of this report. In my opinion, this sense of encompassing outcomes, processes, and investigations that are personal and cross many origins and places allows us to make a broader contribution to

Powerlessness:

design research through testing, writing, and disseminating our work. In addition, it offers us the opportunity to speculate openly on what the authors consider acceptable and powerful. I want to thank Dean and Josep Lluís Sert Professor of Architecture Sarah M. Whiting for encouraging this studio and Chair of the Department of Architecture Grace La for inviting us. I am also grateful to all our students and Amin Taha for indulging in this inquiry.

Amin Taha

The making of an architect’s ideas has consequences, we hope, with positive outcomes sympathetic to the immediate needs of those who hire us; and those ideas and intentions should continue to contribute more broadly long after the developer hands over the keys to the building’s next owner.

And by what criteria do we judge whether we have succeeded? As Richard Sennett might have it, to what outcome do we architects put our skills without ethical purpose?2 For those commissioning buildings, it’s clearly existential if the program has been met and improved, if they are still within budget, or if a bank will finance the project. The building must meet structural, thermal, and fire building code; warranties, insurance, and sustainability requirements. After all, the construction sector is responsible for 40% of global CO2 emissions—58% in materials and construction, the remainder in operation. Clearly, ethical criteria should be used to judge success before the unarguably subjective questions of beauty, appearance, and style.

Where is the architect’s agency in these? In the areas of cost control, structure, thermal performance, fire safety, and sustainability, it has diminished, with the architect at best acting as a “team leader” to specialist consultants. For example, the cost consultants who will dictate whether steel or reinforced concrete, gas or electric heating systems, etc., are specified, will choose the cheaper approach. The structural, mechanical, and electrical engineers will then locate their grid of columns, beams, and services as conveniently as possible behind whatever external and internal elevations the architect has composed. By that process, the architect’s role is inexorably

defined as that of an overqualified and highly indebted wallpaper artist, hanging the facade du jour onto that structure. Nevertheless, and all being well, the building stands, doesn’t burst into flames, and likely receives outstanding or platinum LEED certificates. Yet, on inspection, it uses the same amount of concrete, steel, and aluminum as it would have three or four

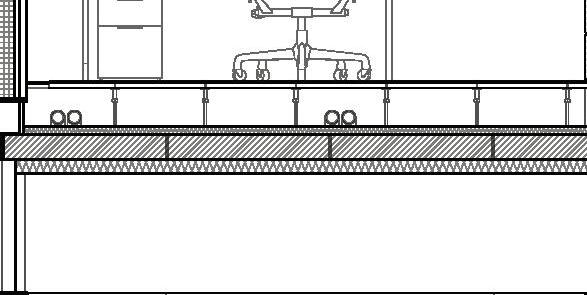

(1) 150 mm galvanized steel

(2) 20 mm mortar

(3) 533 x 210 x 109 mm UB

(4) 600 mm-thick stone lintel

(5) bolts fixed through MS plate and UB

(6) bolts fixed through MS plate and UB

(7) 20 mm mortar

(8) MS plate

(9) 800 x 500 mm stone column

(10) 150 mm air cavity

(11) inner glazing

(12) 300 x 800 mm glulam beam

(13) 200 mm CLT slab

(14) 200 mm raised floor system.

Timber floor slab to stone exoskeleton connection detail. Courtesy © Groupwork.

decades before sustainability became a legislated concern. There is no reduction to the 40% contribution in CO2 emissions under the architect’s watch—the architect is a team leader in name with little agency to effect change.3

Yet such a reduction is completely within the architect’s reach. The course of thirty years of practice has led me to real-

ize that carbon assessment through sustainability engineers’ BREEAM, LEED, and so on software prioritizes operational carbon. While operational carbon could be reduced in past decades through such incentives, the same high-embodied-carbon materials that were employed fifty years ago are still used today. Ironically, within this framework (and despite using high-embodied-carbon building materials) one can still achieve the highest levels of green building standards. The over-emphasis on operational carbon hinders the architect from choosing low-embodied-carbon materials in the first place.

This studio introduced EN15978, the globally agreed-upon measure for embodied carbon across a building’s lifespan, and the BSRIA/University of Bath Inventory of Carbon + Energy into the design process. With the help of Buro Happold, Eight Versa, Webb Yates, and Groupwork, it combined these into an Excel sheet for material and operational carbon. Set out as a traffic-light schedule, with red for the highest and green for the lowest embodied carbon, it is an iteration tool enabling the user to input and then substitute material volumes and expected levels of renewable energy. Materials range from aluminum at +36mtCO2/m3, through mild steel at +12mtCO2/m3, fired clay bricks at 1.2mtCO2/m3, stone at +0.032mtCO2/m3, and eventually carbon-sequestrating timber and biomass materials with sawn hardwoods at -1.2mtCO2/m3.4

The studio focused on stone, with its weathering and environmental robustness, as a substitute for these superstructures; stone boasts a carbon footprint 99.7% lower than that of mild steel and 97.8% lower than reinforced concrete. Simultaneously, stone can also act as an external and internal finish, depending on thermal lines. Going on to combine stone with internal timber, glulams, cross-laminated timber (CLT), dowel-laminated timber (DLT) floor and wall plates, and internal partitions defined as “Category A” fit-out elements (high-end interior finishes suitable for offices) allows office floors to be let out as ready-to-use commercial premises. Through these findings, lower embodied carbon is achievable, ultimately demonstrating that all designs can achieve negative carbon outcomes.

Across the twelve students in the studio, a variety of stone hybrid structural typologies were investigated, including those stacked in brick and block form, with trabeated post and lintel pretensioned frames, as well as those triangulated or with ribbed arches or vaults.

Sometimes, in combination, the design process requires a series of iterations through the EN15978 software to test these comparative efficiencies against the current conventions for steel and reinforced concrete. We might substitute those materials with stone and timber, and thus we might also decrease or increase the volume of the new materials substituted for high-embodied-carbon ones, with the end goal of reducing the project’s embodied carbon.

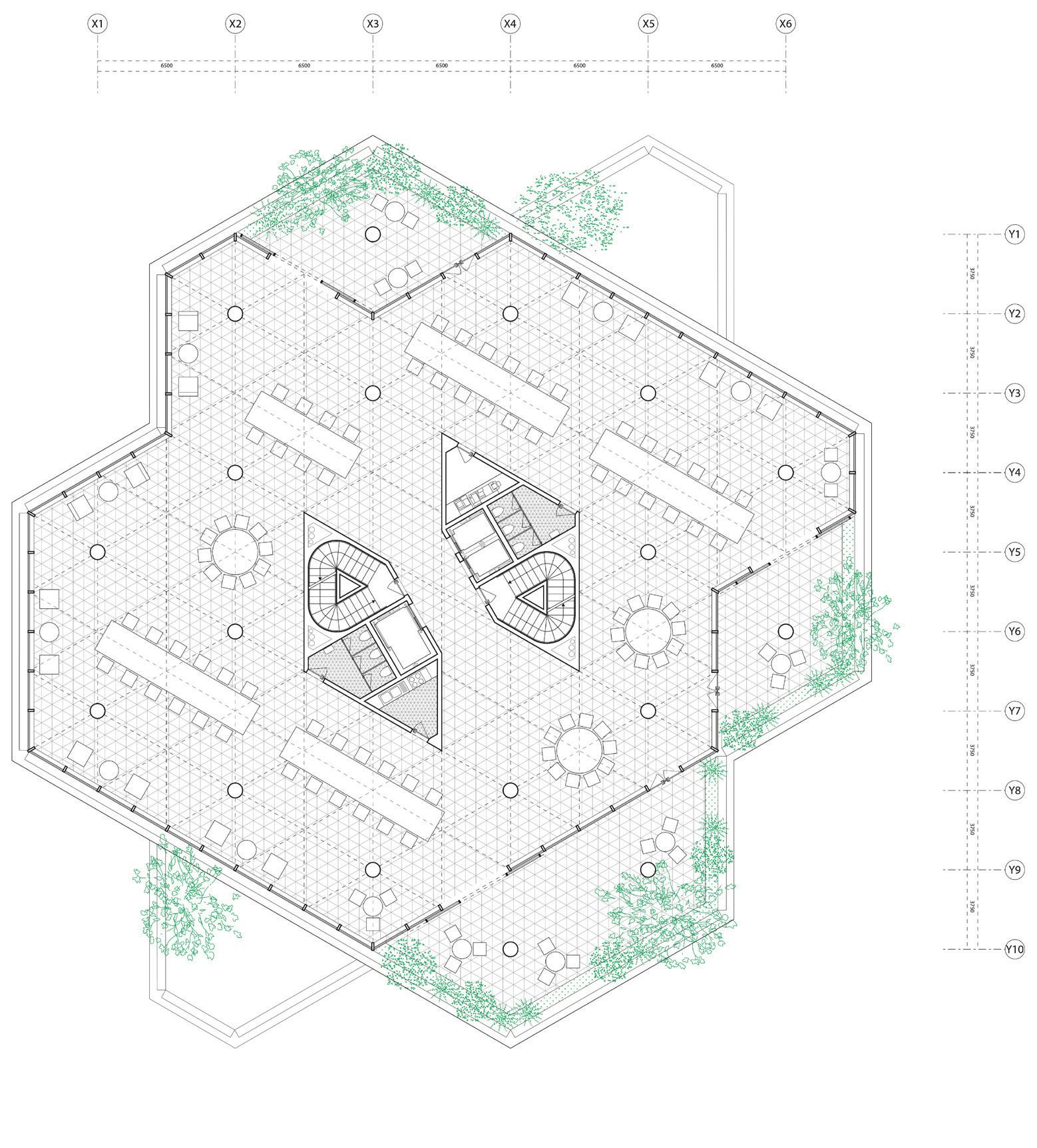

The Earls Court Development Company provided the studio with their $12 billion, fifteen-year framework plan, set to accommodate 4,000 homes and 2.5 million square feet of office space. Students were allocated plots and expected to propose office mid-rise buildings from ten to twenty floors to challenge the expectations for generic speculative office space. To freeassociate with Semper’s words, how would stone, timber, brass, or steel be joined with post-COVID working/social programs?5 What architecture could result?

1 The February 2022 IPCC report highlights the widespread impacts of climate change while emphasizing the need for immediate action to address vulnerabilities and adapt to worsening environmental conditions; see the United Nations Intergovernmental Panel on Climate Change, Climate Change 2022: Impacts, Adaptation, and Vulnerability, February 2022, https://www.ipcc.ch/report/ ar6/wg2/.

2 I’ve paraphrased a line from Richard Sennett, The Craftsman (Yale University Press, 2008).

3 The building industry contributes 40% of manmade greenhouse gas emissions annually. See The Climate Group’s “Built Environment” at https://www. theclimategroup.org/built-environment#:~:text=Overview,set%20to%20double%20 by%202050.

4 +36mtCO2/m3 refers to “36 metric tons of CO2 per cubic meter,” and so on. These are figures published by the University of Bath and British Services Research and Information Association (BSRIA) in their Inventory of Carbon and Energy (ICE) at https://greenbuildingencyclopaedia.uk/ wp-content/uploads/2014/07/Full-BSRIAICE-guide.pdf.

5 Gottfried Semper, Die vier Elemente der Baukunst: Ein Beitrag zur vergleichenden Baukunde [The four elements of architecture] (Friedrich Vieweg und Sohn, 1851).

At Carrières du Hainaut, stone is carefully extracted using techniques that ensure the preservation of its quality. This durable limestone is valued for its distinctive blue-gray color and is used in various construction and design projects.

Engineers at Carrières

demonstrate the bluestone extraction process to students, highlighting the techniques used to quarry this durable limestone and its significance in construction and design.

du Hainaut

Stones quarried are the size of building elements and can be four meters long.

date back 350 million years,

The origins of Hainaut blue limestone

when the region that comprises today’s Belgium was submerged in a tropical sea. Over millennia, aquatic fauna and flora were layered in sediment, forming a homogeneous and very compact limestone.

Blue limestone can only be found in one specific carbonated geological vein. This particular vein runs from east to west across Belgium and comes close to the surface in the region of Soignies, in Hainaut.

Due to its fossil content, unprocessed Hainaut blue limestone displays a range of textures and nuances.

Chain saws are used for cutting softer types of stone, such as limestone. These specialized chain saws are designed to allow them to efficiently cut through large blocks of stone with precision.

Belgian blue limestone results from the accumulation of innumerable fossilized crinoids cemented into a mass of microcrystalline calcite. The stone, which takes on a light gray patina upon exposure, also contains other fossils, such as shells, corals, and bryozoans.

The Stonemasonry Company in Rutland in England’s

Midlands region specializes in stonework, from manufacturing to installation and completion. They create pretensioned and posttensioned load-bearing structural stone elements and self-supporting stone floors.

East

We learned about picking the right stone for load-bearing purposes, the quarries for supply and finishes, and the most efficient methods for cutting, transportation, installation, and developing connection details for stone columns and floors.

The Black & White Building in central London employs a hybrid structure comprising a beech LVL frame with CLT slabs and core that has been designed to create open workspaces. The design is expressed through the constituent parts, avoiding excess or unnecessary architectural flourishes. The beauty of the completed building stems from the inherent qualities of each layer and each material without decoration. Courtesy © TOG/FORA/Waugh Thistleton Architects.

Designed to offer flexible, shared workspaces to companies, this modest yet significant building with a powerful sustainable agenda is the tallest engineered timber office building in central London. With no structural internal partition walls and the MEP carefully coordinated to minimize visual intrusion, the layout can be easily adapted as future demands change.

Courtesy © Ed Reeve/Waugh Thistleton Architects.

The timber structure is framed by the glazed curtain wall, with solar shading provided by a second skin of vertical timber louvers.

The Vortex sits in the main reception of the Bloomberg European Headquarters in London. The space is defined by three large curved walls of timber, respectively rotated 120 degrees and reciprocally connected at the top. The structure consists of a double wall, constructed as a stressed skin in a series of pre-assembled cassettes, where the main joists have been oriented to generate the curvature of the surface, but keeping the timber elements straight. Following the concept of a developable surface, this rationalization removes the need for complex CNC cutting of structural elements.

Stone: The Uninhibited Material

Carrières du Hainaut team

At the initiative of SigmaRoc, Carrières du Hainaut has recently begun a close collaboration with institutions of architecture and design education. For SigmaRoc and Carrières du Hainaut, interacting directly with architecture students has been a foundational experience. Through introducing students to our product, Hainaut blue limestone, we have also witnessed the first steps that architects and designers take toward conceiving of and developing projects. We’ve been proud to see them discovering stone, from its extraction from the quarry to its transformation into a finished product, and to see them understand and appreciate light-, space-, and structure-enhancing design solutions.

As a material well known from the age of cathedrals, those grandiose, ambitious constructions reaching toward the sky, hard stone promises to be present for future generations to appreciate. Hainaut blue limestone, like other hard stones, bears the mark of time: it is composed of layers of fossils turned to minerals, a material that contains history.

As with wood, the honesty of this material and its intrinsic qualities ensure its appeal both now and in the future. Like the use of wood, another natural resource used for millennia, stone in mid-rise structures has largely been reduced to purely decorative applications offering the image of a reassuringly rustic material. The saying “as old as the hills” applied well, with available products marketed as “classic” and intended only for finishes. In fact, until recently, the stone sector wasn’t considered one where advanced research and development took place.

However, certain qualities intrinsic to stone have recently brought it to the attention of future professionals (in this case, students of architecture and urban planning) over the course of their design educations. First, and recently better understood, is the fact that stone is a low-embodied-carbon material; and secondly are

those tactile and aesthetic qualities that render it a pleasure to employ.

In order to best utilize these material qualities and take advantage of stone’s structural and mechanical potential, an investigation into technological advancements in the potential uses of stone, such as pre- and posttensioning techniques, was called for. Under the guidance of Hanif Kara and Amin Taha, these GSD students have had the opportunity to explore the essential architectural properties that make stone a promising element for contemporary architectural applications. As a coda to this collaboration, SigmaRoc and its subsidiary Carrières du Hainaut are now working on a demonstration research project that will set out a universal engineering design code for building with stacked, arched, vaulted, pre- or posttensioned stone. In addition, we began a life cycle of analysis of Belgium’s stone sector in late 2023 in order to provide more sustainability criteria to forward-thinking industry professionals in their selection of materials.1

This project brings together reflections on questions of technology and design within the context of historical, economic, social, architectural, and environmental challenges. In the current environment, geo- and bio-sourced materials like stone, with its low embodied CO2, are gaining ground after the long popularity of concrete (with its very high embodied CO2), and the debates arising from this change stimulate the industry positively. SigmaRoc looks forward to turning possibilities into reality in partnership with the architects and urban planners of tomorrow, building in harmony with nature, and respecting the energy considerations of today and tomorrow.

1 For more info, see the resources for professionals offered by Carrières du Hainaut, “Support,” at https://www.carrieresduhainaut.com/en/professionals/support.

Quarry to Site: Reorganizing Structural Stone in Construction

Gökhan Karakuş

Integrating structural stone into modern architecture utilizes ancient building practices and proposes sustainable design and construction methods. This approach revitalizes stone, a historically central material, by leveraging modern digital technology for enhanced application and efficiency.

Historically, stone’s durability and beauty made it fundamental to building, as evidenced since Neolithic times in structures such as the Göbeklitepe site in Turkey, in which the beginnings of architecture can be seen.1 However, the contemporary role of stone has diminished from a structural role to cladding and decorative uses. Today, we can consider alternative approaches such as using stone in hybrid stone and timber structures; this paradigm is based upon understanding how the natural stone industry extracts and quarries the material, is grounded in sustainable architecture, emphasizes responsible resource use, aligns with ecological principles by specifically repurposing the massive amounts of stone quarry debris, and minimizes waste. When looking holistically at the process of stone quarrying to design and construction with an eye to ancient stone architecture, these are all key factors in reassessing stone as a structural and expressive material for construction.

Practically speaking, a realignment of the process of natural stone extraction and the required knock-on effect (that is: if we quarry and use more stone, we will also need to (re)train people in how to build with it) is needed. Here, we need to be aware of the poignancy of the roughly 10,000 years of architecture and structural stone construction. Specifically, looking back to the ancients, we can see that the quarry and the building site were directly related. Based on the archaeological record that has recently become more accessible for the Neolithic and Chal-

The Denizli travertine quarry illustrates the connection between stone extraction techniques and the dimensions of structural stone elements used in modern construction. The quarry, operational since 1970, produces 40,000 cubic meters of cut dimension product stone annually from a 24-hectare licensed area, with active mining on 11 hectares as of 2024. Courtesy © Burak Alimoğlu.

colithic periods, we can see that the quarry was also a site of design, where stones were sized and quarried on-site based on project needs.

Today, we propose a similar process that begins with the methods of natural stone quarrying and extraction methods. This “archaeotectural” assessment seeks to reinvigorate the quarry as a site of design by selecting and preparing suitable quarry stone for use as design and construction elements. The extraction of natural stones such as marble, travertine, and limestone results in a plethora of variously sized stones appropriate for use with this method. We propose innovative techniques to transform this irregularly sized stone into a practical construction material. Digital tools like 3D scanning and modeling optimize structural performance and aesthetics, while CNC milling and robotic cutting ensure precision and reduce waste. By using a mix of digital and handcrafting techniques, irregular non-standard stones can be transformed into standardized elements. When combined with materials like timber as joinery, this enhances construction speed and accuracy, resulting in adaptable, resilient structures.2

In conclusion, rethinking structural stone building based on the examples of the ancients, focusing on the journey from quarry to construction site with the application of contemporary technology and the use of complementary materials like timber, offers a broad approach to sustainable architecture. This method combines ancient practices with modern means, resulting in resilient, aesthetically pleasing, and environmentally responsible stone construction and an integrated approach to sustainable architecture.

1 For Göbeklitepe archaeological excavations, see Jens Notroff, Oliver Dietrich, Klaus Schmidt, “Building Monuments, Creating Communities. Early Monumental Architecture at Pre-Pottery Neolithic Göbekli Tepe,” in Approaching Monumentality in the Archaeological Record, ed. James Osborne (SUNY Press, 2014), 83–105.

2 This research is being undertaken in the travertine quarries of Denizli, Turkiye. Travertine is one of the leading natural

stone products globally. See M. Özkul, A. Gül, T. Koralay et al., “Denizli Travertine: A Global Heritage Stone Resource Nominee from Western Türkiye,” Geoheritage 16 (2024): 67, https://doi.org/10.1007/s12371024-00970-w. The travertine quarry in Denizli produces 40,000 cubic meters of cut dimensioned product stone annually from a 24-hectare licensed area, with active mining on 11 hectares as of 2024. From this, only 15% of the mined area are usable, while the remaining 85% is waste.

Quarry

Gökhan

This page: Stone CNC wire-cutting machine at the Stonemasonry Company in Rutland, UK, used for precise curved stone cutting. This technique can be seen in Jackie Pan’s “Urban Mangrove” (p. 184).

Courtesy © Pierre Bidaud/Stonemasonry Company.

The Raw and the Cooked: A Mythology of Stone and Concrete

Justin McGuirk

There is a tendency, in the West at least, to think of the history of technology as a universal story. We might forget that both the etymology and our origin myth of technology are rooted in ancient Greece, and that they carry a particular cultural inflection. In the myth, Prometheus steals fire from the gods and passes it on to us, sparking a revolution of human inventiveness. The transition from stone tools to metallurgy is born in the heat of the forge, and thus, the origins of craftsmanship, science, and civilization are linked to fire—to energy. The myth appears to establish an unbreakable correlation between culture and energy, each rising in tandem.

This is certainly not the only origin myth linking culture to fire, but it may be the only one that comes with such a heavy dose of technological determinism. In his study of the myths of the Indigenous peoples of the Amazon, The Raw and the Cooked, the anthropologist Claude Lévi-Strauss also found fire to be the critical link in the development of culture, but here, culture is associated with cooking rather than the forge.1 In the myths of the Tupi, Guarani, and Ge peoples, for instance, fire is acquired from an animal, often a jaguar or a vulture. Where food was once eaten raw (or predigested through sun-drying or rotting), it could now be cooked. Cooking becomes the means of socializing nature.

What, we might ask ourselves, is the difference between these origin myths? Do they not both equate culture with energy? To a certain degree, they clearly do. But raw/cooked is only one of the binary oppositions Lévi-Strauss finds in Amazonian myth structures, including fresh/decayed and terrestrial/celestial. These are complex cosmologies in which there is a place for the raw and the rotten, just as there is for the

cooked. Fire is kept in balance, unlike the Promethean flame, which gave humans a god-like sense of destiny. Amazonian peoples, as we know intuitively, live in harmony with their habitats rather than seeing energy as a tool to dominate or separate themselves from nature.

The cooking metaphor is useful when thinking about the materials with which we build the modern world. We speak of “raw materials” and, in doing so, often fail to appreciate the ways in which they have been cooked. To speak of “cooked materials” binds in their energy consumption. However, that is not to imply that they are more cultured. Indeed, the purpose of this essay will be to gently challenge the notion that, when it comes to architecture, more energy equals more culture. The raw has a vital role to play if we are to make it to our high-tech future.

There is no better illustration of the difference between raw and cooked materials than stone and concrete. Where stone is raw, needing only to be cut to size and shape, concrete is highly processed. To produce the equivalent weight of concrete, limestone must first be extracted, then crushed into rubble, crushed again with clay, and ground into kiln feed. This is heated in a kiln the length of a jumbo jet at 1,400 degrees Celsius to produce clinker, which is then ground into the ultra-fine powder we call cement. To make concrete, that powder must then be mixed with sand and gravel, which also need extracting. For every kilogram of concrete, one kilogram of CO2 is released into the atmosphere. And given that concrete is the second most consumed material after water, its production alone accounts for between 4 and 8 percent of global CO2 emissions. Concrete is not just cooked; it is the ultra-processed food of our material

diet. It is the bleached flour and the refined sugar of our buildings.

This is before we even get to reinforced concrete, which is given structural strength through the use of steel rebar. To make rebar, carbon steel needs to be melted at 1,500 degrees Celsius and extruded into thin—let’s just say it’s cooked.

The fact that concrete is enormously energy-intensive to produce is inscribed in its history. Even though the Romans used it, concrete was such a luxurious material in its energy consumption that it was not revived until the nineteenth century with the arrival of plentiful, cheap coal. Indeed, there is a direct correlation between the popularity of concrete and the price of fossil fuels. The elevation of concrete to its own language of architectural expression in the mid-twentieth century coincides with the oil booms of the postwar period. And its apotheosis in the high style of Brutalism in the 1960s and ‘70s is deeply associated with the optimism of the welfare state. In Britain, Labour swept to power led by a Promethean, Harold Wilson, exalting “the white heat” of technology. The combination of paternalistic spending and cheap fossil fuels provided exceptional conditions for the utilitarian aesthetics of concrete. Brutalism’s energy-rich mannerism was guilt-free in those halcyon days before we knew what global warming was. Equally, it is no coincidence that its decline began after the oil crisis of 1973.

If the “cookedness” of concrete is well established, do we need to dwell a little on the rawness of stone? Is it like sashimi, to be sliced into cool slabs and arranged in neat rows? Or is it like carpaccio, shaved into decorously marbled surfaces? We could debate the rawness of stone, given that it is the product of millions of years of heat and pressure, but let’s agree that it was not cooked by human hands. Whatever energy it takes to extract it with our diesel-powered cutting machines, it is a tiny fraction of what it takes to produce concrete. And thus, in the strange language of the climate crisis, we have started referring to it as “carbon sequestering.” As with meat, rawness retains the carbon lifeblood, while cooking releases it. Like a filet mignon served bleu, the mineral essence of stone remains cool to the touch, its proteins not allowed to be denatured by heat. Is it to some

The Raw and the Cooked: A Mythology of Stone and Concrete

degree alive? The comedian Denis Leary had a joke about the way he liked his steak: “Bring me a live cow over to the table. I’ll carve off what I want and ride the rest home.” Interestingly, the anthropologist Tim Ingold has imagined being a piece of stone. Far from inanimate, it is highly conscious of having been extracted from its context. It observes us as our civilizations wax and wane, resenting its displacement from the Earth’s crust. Its surfaces—its skin, if you like—are “the scars of separation” exposed by the hammer and chisel.2

Ruskin saw things differently. In its raw, earthbound state, stone was “dead and cold.” Only through human hands could it be brought to life. According to Ruskin, stone’s structural integrity may remain intact, but its surfaces have to be worked into a state of aliveness—turned into the veil of art—through the craftsman’s skill. This raises a different form of energy: human labor. And here, too, stone and concrete come with their own politics. Since its rise to ubiquity in the late nineteenth century, concrete has been the material of choice for de-skilling and disempowering construction workers. Until then, stonemasons and carpenters were the aristocrats of the construction industry, the highly skilled workers without whom significant buildings were not possible. They were also a political force—unionized and with the bargaining power to command decent wages. Concrete changed all that.

No one has narrated the politics of concrete more provocatively than the Brazilian architect Sérgio Ferro. Offended by the death toll of workers in the construction of Oscar Niemeyer’s Brasilia, Ferro was unusual for an architect in making the construction worker’s well-being central to his own architecture. But his writing is the more trenchant. In his essay “Concrete as Weapon,” he paints a convincing picture of concrete as a tool of regressive politics. In Ferro’s historical account, the low skill levels required to build with concrete offered a way to bypass the traditional trades and “break their monopoly over construction.” In other words, it was not the liquid plasticity of concrete that was its greatest appeal, but its ability to undercut and dispense with the uppity stonemasons. Furthermore, with the arrival of reinforced concrete in the early

Justin McGuirk

1900s, the technical skills required for building passed from the masons and carpenters to the engineers, with the quality control falling to the site supervisors. This is what Ferro finds most galling: the fact that concrete facilitated the separation of manual and mental labor into blue-collar and white-collar roles. “No other means of construction,” he writes, “allowed such a satisfactory separation of the mental from the manual elements of labor.”3 In that view, he is like a latter-day Ruskin extolling the medieval stonemason’s right to express himself somewhere up in the cathedral’s fan-vaulting.

There are other ways stonemasons have been politically inconvenient. The Zionists who built Tel Aviv in the 1930s may have admired the region’s traditional stone architecture, but the White City was to be a modernist paradise of smooth concrete. While that was partly an ideological aesthetic, it was also a discriminatory one because all of the skilled stonemasons were Palestinians, and the only way to bypass Arab labor and protect Jewish wages was by using low-skill concrete construction.4

What Ferro sets up for us is a model whereby raw materials are equated with know-how and technique, while cooked materials are synonymous with de-skilling. Stone masons and carpenters are both masters of the “raw,” since stone and wood are largely unprocessed, unbaked, and unreconstituted materials. Whereas concrete, which is the opposite of all those things, is so plastic and easy-pour that it not only de-skilled workers, it de-skilled architects, who could more or less design what they wanted and charge the engineers with making the designs stand up by calculating where to apply the most steel reinforcement. Given that, it is perhaps surprising that a highly plastic concrete architecture—the kind practiced by Niemeyer or Saarinen or even Le Corbusier at Ronchamp—remains the exception, with most concrete being poured into rigidly rectilinear forms. Either way, concrete is like any other modern technology that “democratizes” access by lowering the barriers to its use.

To return to Lévi-Strauss’s cooking metaphor, you might say that the heat in cooked materials reduces the need for labor energy, just as cooked food requires less energy from the stomach to digest it. Cooked food, as we know, is a quicker-release

The Raw and the Cooked: A Mythology of Stone and Concrete

Justin McGuirk

form of energy. This suggests, in the Amazonian mythologies at least, a correlation between culture and bioavailability or ease of digestion. In the Promethean version, it’s more about ease of use (except that no so-called labor-saving devices have ever genuinely saved labor; they have only increased productivity). The more nonhuman energy is applied, the less human energy is required. The question is, how far does one take that logic, especially when the energy required to cook our materials is now cooking our planet? When does our calorific intake become too much? Is our consumption of materials much like the Western consumption of food in a society where people are more likely to die of overeating than starvation? Is it not time to rediscover the raw? And if that were to require a re-skilling of the workforce, would that be a bad thing?

1 Claude Lévi-Strauss, The Raw and the Cooked (Harper & Row, 1969).

2 Tim Ingold, Correspondences (Polity Press, 2021), 137.

3 I take this quote from page 19 of the version of “Concrete as Weapon” published as a special insert in Harvard Design Magazine 46 (2018). It has more recently become available in Sérgio Ferro’s Architecture from Below: An Anthology, eds. Silke Kapp and Mariana Moura and trans. Ellen Hayward and Ana Naomi de Sousa (MACK BOOKS, 2024).

4 This history is well told in the second chapter of Andrew Ross’s Stone Men: The Palestinians Who Built Israel (Verso, 2019).

The Earl’s Court framework plan includes 4,000 new homes; 2.5 million square feet of workspace delivering around 12,000 new jobs; 300,000 square feet of space for retail, dining, leisure, and culture; and plans to include a generous network of exhibition gardens, open spaces, and three large new cultural and performance venues. The framework plan was developed by Hawkins\Brown Architects and Studio Egret West for the Earls Court Development Company. Courtesy © Earls Court Development Company.

Mid-Rise Building at Earl’s Court

The Earls Court Development Company (ECDC) is an Earl’s Court-based business, responsible for driving the transformation of the forty-acre former Earl’s Court Exhibition Centre site. ECDC has a vision “to bring the wonder back to Earl’s Court” with a framework plan that opens up the site to the local community, celebrates the legacy of world-class ingenuity, creates a better piece of city, and responds to the climate emergency. We are committed to working with communities and stakeholders from day one, ensuring the operation of ECDC and the framework plan support the generation of social value and economic inclusion across the local community throughout the lifetime of the project.

As a part of our long-term commitment to sustainable development, we welcomed GSD students to tour the Earl’s Court development site and to base their 2024 spring semester studio projects here as they explored new possibilities in hybrid stone and timber mid-rise construction.

As these GSD students have learned, the site of today’s Earl’s Court development has a curious history, and it has long been at the forefront of historic, economic and societal change. Until the mid-nineteenth century, the area was still farmland providing London with dairy products and agricultural produce. With the arrival of railways, housing and industry began to take root in Earl’s Court; at the same time, multiple railway lines had also formed a triangular eighteen-hectare site that was essentially locked in. This parcel initially attracted itinerants looking for shelter, and soon it became a site for entertainment in the form of circuses and “shows of spectacle.” In 1886, John Robinson Whitley booked “Buffalo Bill and the Roughriders and Redskins” there, forever defining the area as one for “entertainment and wonder.” Since then, the area’s exhibition space has featured boat shows, horse jumping competitions, dog and cat shows, and ideal home shows; the former Earl’s Court

Sharon Giffen on behalf of the Earls Court Development Company

concert venue hosted concerts by Bob Dylan, David Bowie, and Pink Floyd, and Earl’s Court has twice welcomed Olympic Games events.

Over the same period of time, communities— housing and the retail establishments that served them—became established around that triangular site, and the train lines that created it joined the broader London network, allowing for easier commuting. More recently, far more extensive and more convenient entertainment venues opened in redundant East End docklands. With London now exceeding its pre-WW2 population and housing demand exceeding supply, the 18 hectares of Earl’s Court were flagged for redevelopment. The demolition of the exhibition centers in 2015 created a rare opportunity to develop a new part of the city in central London.

It has been exciting to have twelve GSD students tackle the dilemmas of building in a time of post-COVID workspace change, housing needs, and, not least, the challenges of climate change. Seeing each student spend their semester investigating and delivering convincing concepts for viable stone-timber hybrid structure office buildings from ten to twenty stories is inspiring. Tackling how we might work—that is, how developers can benefit from flexible workspaces, and how inter-floor relationships can socially enliven and offer opportunities for smaller and larger organizations—is insightful for us. Combining, in principle, stone and timber with ground source and photovoltaic renewable energy strategies for fully carbon-negative outcomes in material, construction, and operation is important. These are strategies that we hope to follow up on with the architects and engineers engaged to see through the first phase of development of the new Earl’s Court. Ultimately, through our framework plan, we will reimagine the very fabric of living, working, and urban well-being for London.

Students learned about the proposed framework plan through a visit to the Earls Court Development Company. The site model shows the different parts of the development.

Several rail and tube lines cross through the site. At the center sits an existing deck over the West London Line (known as “The Table”) that will be repurposed into a central green in the current framework plan for the site.

The facades of existing buildings facing Empress Place will be retained. New buildings developed behind retained facades will be set back and will step up in scale toward the center of the site. Under the new framework plan, Empress Place will be extended into the Earl’s Court development.

Lillie Bridge Depot is situated within our site. It is a maintenance depot on the London Underground Piccadilly and District lines, situated between the West Brompton and West Kensington stations.

The Depot is scheduled to be decommissioned by 2024 as part of the Earl’s Court redevelopment scheme.

p. 102

p. 162

Partition Building

Robin Albrecht

The Partition Building is a low embodied carbon stone-timber hybrid 15-story mid-rise office building. The building reimagines the column grid open-floor-plan office through parallel shear wall structure. Parallel shear walls partially eliminate the need for partitioning with furniture. Partitions provide opportunities for openness and enclosure, publicness and privateness, and offer users the possibility of modifying their workplace.

The project explores the innovative use of stone, detailed into a contemporary prefabricated assembly. The building features double-layered stone panels and wood-stone composite floors, all prefabricated and assembled on-site in a sophisticated integration of traditional materials and modern construction techniques. The inventive prefabricated stone panels offer a low embodied carbon modularized alternative to concrete or steel. They integrate various functions, comprising the structure, internal partitioning, and external and internal finishes, thereby eliminating the need for additional layers of construction.

Opposite page: Site axonometric. The site strategy is informed by the building’s position as a gateway to Earl’s Court, situated at the entrance to the site and complemented by a plaza in front of the building. The location and orientation of walls vs. curtain walls relate to solar gain. The solid facade corresponds to the highest solar gain on the south. Large balconies are provided that break through the solid walls, creating openings. The east and west facades are curtain walls.

This page: Model (MDF, sandblasting, plywood, mounting board), 1:75. In the second half of the twentieth century, the open floor plan office was invented to “free” workers. It was a space void of hierarchy. Action Office 2, a semi-private enclosure (or a cubicle) launched by Herman Miller in 1968, was imagined to be a flexible system to encourage spontaneous encounters. However, it turned into the monotony of the cubicle office culture.

Robin Albrecht

Ground floor plan. The project’s ground floor provides an entryway into Earl’s Court. Stepped terraces lead from the entry to the site at the West Brompton tube station to the raised section.

Spaces in-between walls are built-in meeting spaces or private offices

Floor Plan for one user

Can be converted into housing

Plan subdivided into several units

Opposite page: Section. Typical office floor plans are interrupted by a series of multi-story spaces on the ground floor, mid-height, and at the top of the building. Terraces provide outdoor spaces on various floors.

This page: Subdivision diagram. Office floor subdivision and partitioning diagram. The floor plan can be occupied by one, two, or up to eight clients. The partitions also embody the capacity to allow the transformation of the office tower into housing should it be needed in the future.

Office

Robin Albrecht

Floor

Opposite page: Perspective. The partition becomes an information technology device that reconfigures space organization.

This page: Typical floor plan. The partitions provide malleable spaces to focus, collaborate, socialize, and hold smaller private conference rooms, coffee bars, and the like.

Robin Albrecht

Opposite page: Floor assembly plan. The assembly consists of five layers: The first layer is a 450 mm glulam beam that physically interlocks with the wall assembly with a rod, providing lateral stability. Sawn lumber joists provide a secondary structure, followed by stone floor slabs that can radiate heat. The following two layers of the assembly are a raised timber structure to meet office wiring demands (and diminish the need for ceiling wiring) and the floor finish.

This page: Prefabrication construction diagram. The prefabricated system consists of sandwich stone wall panels and glulam-stone floor panels, assembled through a physical interlock on site. The prefabricated construction consists of three major elements: sandwich stone wall panels, glulam-stone floor panels, and an east-west curtain wall system. A crane will lift prefabricated 3 x 10.5 m floor panels and 1.5 x 4 m wall panels into place.

Robin Albrecht

Robin Albrecht

High-Tech Stone Curtain

Michael Chang

This 20-story mid-rise office building proposal offers a compelling alternative to “high-tech” architecture by employing stone to achieve an equally inspiring and gravity-defying design. This design uses bifurcated prestressed stone struts to support each floor plate, creating remarkable open spans. This project also features a curtain with a prestressed substructure and clad with marble tiles that effectively deflects wind upward and away from the structure. The tiles diffuse light into the interior and can be opened to provide stunning city views with minimal visual impact.

This project advances a “neo-high-tech” architecture, one that addresses sustainability and carbon footprint concerns and sets a new standard for material efficiency and environmental responsibility, one that surpasses the limitations of the steeland-glass twentieth-century model. The carbon footprint of those older “hi-tech” structures, with their multiple layers of waterproofing, insulation, and fireproofing, and their high costs for labor, materials, and transportation for construction and maintenance, implies that they may not be the pinnacle of hightech architecture. A neo-high-tech architecture challenges the notion that stone is a material confined to conventional systems and reimagines its application to achieve extraordinary structural and aesthetic effects.

Opposite page: Model (MDF), 1:100. The stone curtain facade comprises marble tiles supported by a prestressed stone frame. From a distance, the structure dissolves, presenting the facade as a vast, floating surface. The project redefines the use of stone in architecture, evolving Mies van der Rohe’s exploration of glass toward a neo-hightech future for stone construction.

This page: Elevation. Light diffuses through the marble curtain, casting even, ambient illumination throughout the interior. Select tiles pivot open to reveal views of the London skyline.

Michael Chang

page:

This page: Ground floor plan. The overhead stone strut system liberates the ground plan from structural interruptions, creating a true open-plan layout.

Opposite

Reflected ceiling plan. Bifurcated stone struts support the upper floors, transferring loads through the building’s six structural cores. A two-way prestressed stone grid holds CLT flooring.

Michael Chang

Opposite page: Section perspective. The structural system offers flexibility in form, accommodating mezzanines, single and double-height spaces, atriums, and courtyards.

diffuse lighting permeates the office spaces through the marble facade, moderating the internal climate. At certain points, the facade peels away, offering framed views of the city.

This page: Interior perspective. Generous

Michael Chang

Opposite page: Detail of structural module. The system integrates CLT floors supported by prestressed stone struts, enveloped by continuous glazing. The stone curtain features marble tiles tensioned by a steel cable mesh, backed by a prestressed stone space frame.

This page: Diagram of building skeleton. The building’s skeleton features a two-way stone floor system, supported by bifurcated stone struts that transfer loads through six primary structural cores.

Michael Chang

Rotundas of Modern Stone

Baiting Chen

The building and construction sector is responsible for approximately 40% of global carbon emissions annually. Traditionally, architects remain rudderless, deferring to engineers and consultants to address this challenge. However, it is becoming increasingly clear that architects, armed with a thorough understanding of building materials’ structural properties and embodied carbon, can play a crucial role in reducing carbon footprints and improving our built environment. This intersection of ecological ethics and spatial aesthetics opens the door to innovative architectural paradigms.

This 10-story project exemplifies such an approach by employing natural limestone and timber as primary structural materials to construct a carbon-negative office building. The choice of primitive geometric forms and primitive natural materials extends beyond evoking nostalgia or poetic sentiment. Instead, it aims to establish a workplace prototype where people feel comfortable and happy working together again in the digital age. Central to the design is the “rotunda” unit, a round column-free space 21 meters in diameter, which saves on material, structure, embodied carbon, and cost, and is optimized for group work and promoting the seamless and effective exchange of ideas. This spatial ideal is achieved by combining pretensioned stone exoskeleton and stressed-skin CLT floors.

Rotundas of Modern Stone

Opposite page: Model (cork), 1:100. The structure system of stone exoskeleton and CLT floor slab allows for a column-free space of 300 square meters.

This page: Evolution of prototype diagram. The building forms a continuous stone screen.

(1) Floor slabs are stacked together to form a single tower.

(2) Spatial dynamics are added through the shearing, displacement, and narrowing of columns floor to floor.

(3) Two types of envelope addition: diagonal bracings + photovoltaic brisesoleils.

Ground floor plan. Adjacent rotundas share two columns and are connected. The ground floor belongs to the public. Gardens of different sizes create outdoor working scenes. Double-heighted interior space hosts public events.

1/F

Program: Public

Rentable Area: N/A

2/F

Program: Office

Rentable Area: 2,700 m2

5/F

Program: Office

Rentable Area: 1,800 m2

6/F

Program: Office

Rentable Area: 1,500 m2

9/F

Program: Office

Rentable Area: 600 m2

Opposite page: Interior perspective. Stressed skin CLT floor slabs could be partially removed to connect lower and higher levels.

10/F

Program: Office

Rentable Area: 300 m2

This page: Floor plan diagrams. Each floor is connected to the roof garden. They vary in rentable areas and could be separated or joined together.

Opposite page: Model (cork), 1:100. Continuous roof garden.

This page: Diverse floor layouts.

Baiting Chen

Opposite page: Exterior rendering. From the campus side, the sequence of roof gardens expands in front, inviting people to enter and work.

This page: Elevations. As a response to different conditions in the north and in the south, the building takes on two completely different appearances.

Baiting Chen

Rotundas of Modern Stone

Steel Plate t = 24mm

Opposite page: Rendering of detail. A simple post-andbeam tectonic system is adopted to enclose and support the space.

This page: Detail. Posttensioned stone beams and posts are connected with CLT floor beams, using the standard joint detail applied throughout the building.

Steel bracing d = 200mm

Structural basalt column

Column top plate

Structural basalt beam

M24 threaded bar

Steel L plate

210x210x24mm

Beam T plate t = 24mm

M16 bolt

M24 bolt

L shaped steel plate t = 20mm

Motar t = 4mm

Steel T beam t = 50mm

M12 bolt

Wood finish t = 5mm

CLT ring beam

Stressed skin panel beam

Rotundas of Modern Stone

Baiting Chen

Arch, Vault, Tower

Xinyi Chen

This project confronts the challenge of rediscovering stone’s potential by proposing a 20-story building of vaults and arches, merging traditional compression-based design with the demands of contemporary architecture. Stone, a natural material, has been a cornerstone of building construction for thousands of years. Due to its low tensile strength and high compressive capacity, stone is particularly suited to structures such as arches that capitalize on compression principles. This method is present in the Roman aqueducts that stretch for miles using local stones as well as in the segmented arches and pillars of the Chapel of King’s College London that support its lofty architecture. However, industrial materials with higher embodied carbon have overshadowed stone’s historical significance. By innovating with vaults and arches, this work seeks to push the structural boundaries of stone, aiming for a high-rise structure with low embodied carbon.

Opposite page: Model (foam), 1:100. Illustrates a stacked system, innovating and iterating upon traditional methods of vaulting stone construction with contemporary designs. The building has potential for becoming an iconic piece of architecture within the

This page: Sectional perspective through the cores. Illustrates the juxtaposition between the vertical cores and the double-height space.

Earl’s Court site.

Xinyi Chen

(2)

(3)

(4)

Arch, Vault, Tower

(1)

Opposite page: Sectional perspective. Illustrates vertical circulation and environmental design, featuring centralized cores, thickened floor slabs for HVAC ducts, a dropped perimeter ceiling for shading, and a double-height space with a mezzanine. (1) Glazing line, (2) mechanical floor, (3) raised floor with mechanical services, (4) mezzanine floor.

This page: Paired axonometrics and sections of floor plate modules. With four balanced cores designed to be stacked and iterated, the module offers flexibility and uniformity across multiple levels.

Opposite page: Paired floor and ceiling plans. Structural ribs accentuate the glazing locations, suggesting diverse programmatic space usages.

This page: Typical floor plan. Potential test fit of the plan layouts, where ceiling lines define the vault structures, with glazing options either between the cores or aligned with the ceiling lines, suggesting a variety of programmatic uses of the space.

Xinyi Chen

Arch, Vault, Tower

(1) Pretensioned stone beam

(2) CLT floor

(3) floor joist

(4) glazing

(5) CLT mullion

(6) CLT floor mezzanine

Xinyi Chen

Drawing the Curtain

Ihwa Choi

This 15-story project investigates stone as a soft, plastic, and translucent material. A new exhibition and event center that takes the form of a billowing and rippling curtain in the middle of the city, it lends a spirit of wonder and spectacle to its site. What appears to be a monolithic carved rock is, in fact, a porous stone wall acting as a robust superstructure. Created by tools used in the typical core-sampling process in quarries, a composition of punctures allows the outer walls to become transparent and blurs movement and objects inside the building. On the exterior, the center appears enigmatic and shroud-like. The thinness of the volume is revealed by entering the structure and passing through the double wall. The entrance peels out toward the street and is supported by a tall, gleaming, massive bronze curtain pole that acts as an “autonomous detail” to signal the entryway while carrying the load from above. Pretensioned stone beams seem to push and pull at the stone faces, reminiscent of the relationship between the fabric and structure of tents and stages. Acting as an “articulated detail,” the bronze caps at the ends of the beam catch and reflect sunlight to render the curtain a decorative fabric. In Gottfried Semper’s words, they are “completing the tectonic assembly as culturally emblematic ornamentation.” The interior experience is diaphanous and sheer. The stone becomes a light filter; the east face absorbs the morning sun; and the west face receives the afternoon and setting sun with apertures sized according to the light levels of the internal program.

Opposite page: Model (watercolor paper, granulating paint, brass, foamcore, MDF), 1:75.

This page: Cross section.

Opposite page: Street perspective.

This page: Longitudinal section. The section shows the central spaces of the building.

Opposite page: Street perspective. The entrance into the building through its stone curtain is visible at the center.

This page: Ground floor plan. View of the building lobby.

Drawing

Opposite page: Perspective inside a terrace.

This page: Floor plan of exhibition space.

Ihwa Choi

Opposite page: Conceptual night collage.

Ihwa Choi

This page: West elevation.

Opposite page: Model (watercolor paper, granulating paint, brass, foamcore, MDF), 1:75.

Ihwa Choi

This page: Detail axonometric.

(1) limestone pretensioned stone beam

(2) timber joist

(3) limestone tile with flamme finish

(4) timber raised floor

(5) limestone tile with piquete fin finish

(6) 200 mm perforated limestone panel

(7) 400 mm limestone column

(8) limestone floor with flamme finish

(9) timber joist

(10) glazed inner facade

(11) carved arch connector

(12) brass endcap.

Pile of Piles

Elliott Friedman

Stone is equivalent to the ground. While we usually perceive and engage with stone as an object, we forget that all pieces of stone begin as part of the ground. Most architecture has a fraught relationship with the ground at every scale, particularly large urban office buildings. While conversations around embodied carbon remind us of macro networks of ecological harm at sites near and far, we can’t forget the micro-scale of the the Earl’s Court site itself. In this project, stone is returned to the earth as part of an effort to remediate architecture’s relationship with the ground.

This 12-story office building takes these piles as its starting point. The demolition of existing Victorian-era buildings on the site is minimized; posttensioned stone piles are placed in the ground and held together by a porous web of triangulated ground beams, allowing flora to grow in between and creating a public park on the ground floor. Twenty-two of the piles rise directly out of the ground, becoming columns and supporting the structure of the building above in partnership with lattices of triangulated glue-laminated beams. The piles terminate at different levels, resulting in generous outdoor garden terraces for each level of leasable office space.

The project aspires to propose a less harmful form of speculative development while also considering every scale. The ecological crisis and embodied carbon demand that we do not lose the forest for the trees, but we can’t completely forget about the trees either.

Opposite page: Section showing where piles become columns.

Elliott Friedman

This page: Axonometric diagram.

This page: Typical office floor plan. View of office layout with terraces. Elliott Friedman

Opposite page: Ground floor plan. The existing facades, shown as projections, are preserved and can be occupied.

Opposite page: Interior perspective. View of office area and balconies.

This page: Typical office floor plan.

Elliott Friedman

Pile

STORK Stone/Cork Flooring Tile 20mm

Raised Floor Mechanical Zone 250mm

Cellulose Fibre Board 40mm

Pre-Tensioned Limestone Slab 120mm

Cellulose Insulation Panel 60mm

Glue-Laminated Timber Beam 600mm Steel ‘Catherine Wheel’ Bolted Connection

Pre-Tensioned Granite Column 700mm diam. Floor Construction

Stone Harmony: Mining the Future

Hamees Gabr

Drawing inspiration from the rich architectural heritage of Earl’s Court and beyond, this 20-story mid-rise office building employs the structural and aesthetic motif of corbel arches. These arches not only lend strength and stability to the building but also infuse it with a sense of timelessness and grandeur, echoing the spirit of the past while embracing the future.

The Earl’s Court redevelopment strategy emphasizes the past while stimulating the future. Similarly, this studio focuses on how we can envision architectural strategies that focus on the future of our profession and planet while using the timeless material of stone. My project merges tradition with innovation, looking to the past to maintain our future.

Sustainability has shifted from being trendy to being essential. Architects now see it as a must-do, not just to lessen environmental harm but also to ensure the durability and relevance of our buildings in the face of climate change. It’s become a core principle guiding our profession and shaping how we design and construct for a better, greener future. Understanding a material and its innate qualities makes the design opportunities endless. This project capitalizes on stone’s strength, insulating properties, and finishes to create a 20-story building that will transform the Earl’s Court skyline.

Opposite page: Section. Twenty-story tower, blending corbel arches with sustainable design and utilizing Belgian blue limestone. The civic center features a public rooftop lounge overlooking the Earl’s Court site. The louvers on the office building provide shade and cooling to the building; they are attached to the corbel arches.

This page: Detail axonometric. The structural strategy consists of stacking bluestone blocks to create tiered corbel arches that function as apertures for windows and balconies. CLT flooring allows for a modular design that is easily modified to create balconies and double-height spaces.

Stone Harmony: Mining the Future

Opposite page: Ground floor plan. The view showcases the entrance to the civic center (bottom left) that is enclosed by two public gardens. The civic center is open to the public and allows for light and air to flow through the structure. The mezzanine overlooking the first floor is an active corridor between the civic center and the office building, leading up to the rooftop terrace through an internal stairwell.

This page: Typical floor plan. The larger office space (top right) is broken up into four parts. The columns uniformly decrease in thickness as the structure progresses up the building. Acting as a more private end of the site, the office spaces offer communal spaces for employees as well as kitchenettes.

Hamees

Fissures

Yvonne Gu

“Fissures” is used here in a broad way for this 10-story office building. A “fissure” is a noun indicating a long, narrow opening or a line of breakage made by cracking or splitting, especially in rock or earth. Ground fissures can naturally form from tectonic faulting, earthquakes, or human activity such as oil mining and groundwater pumping. On the other hand, the drilling traces on cut limestone blocks resemble the natural fissures on rocks, forming this project’s concept.

First, fissures are used as a visual device. Peek into the rain garden courtyard: the stones are stacked according to the rule that the upper stone must overlap with the lower stone for at least two-thirds of the lower piece. On the other hand, the narrow fissure entrance provides a subtle yet mysteriously welcoming gesture to the people from outside.

Second, fissures are used as apertures. Even though each fissure is very narrow, these openings provide abundant views and air-exchange opportunities. The large openings of the massing provide much larger and across-floor views and climatic mechanisms.

Third, fissures are circulation spaces. These narrow, linear strips of circulation that slash the spatial fissure of the building leads to questions: “how can architecture offer comfort for people who live and work inside?” and “how can architecture organize structural work, lighting, equipment of air conditioning, ventilation, and management of thermal flows through fissures over different time frames?”

Opposite page: Model (particle board), 1:100. The building is located adjacent to the main road on the northern edge of the neighborhood. This page: View of main entrance.

Yvonne Gu

Opposite page: West facade.

This page: Circulation diagram. Green blocks indicate social gathering spaces.

Yvonne Gu

This page: Ground floor plan.

Opposite page: Section with climatic analysis.

Yvonne

This page: Typical floor plan.

Opposite page: Interior perspective. Inhabitable corridor along the southern side of the building.

Yvonne Gu

(1) limestone

(2) L-shaped 50 x 43 x 3 mm galvanized steel bracket

(3) galvanized steel support bracket

(4) aluminum sliding door

(5) clear double glazing

(6) circulation and maintenance corridor

(7) T-shaped 3 mm galvanized steel sheet joint

(8) pressed mesh grating

(9) window vertical profile in natural anodized aluminum finish

Yvonne Gu

(1)

(2)

(3)

(4)

(5)

(6)

(9)

(8)

(7)

Shear, Sheer

Out of reverence for stone’s infinite diversity, this proposal for a 15-story office building asks what it means for a whole to split into parts and for parts to become whole again. This project celebrates stone’s unique properties and its distinct extraction process. Unlike concrete, which forms a continuous mass based on an additive process, stone is first quarried out of a larger body and then broken into pieces for use. Each fragment possesses a distinct aggregation, striation, and color, even compared to other pieces of the same type of stone quarried from the same location.

The “parts” of the building consist of blocks sized to utilize the offcuts produced in stone extraction. Instead of relying on larger pieces of stone for a monolithic expression, the building breaks these neglected pieces into smaller blocks to emphasize their heterogeneity. In enhancing the potential of these offcuts, this strategy minimizes waste and allows the building to showcase a broader palette of stone from around the country. The stone blocks are then reassembled with varying levels of porosity. While the structure’s core is tightly stacked, the facade is loosely stacked to allow light and views into the office floors. The blocks are also arranged at different angles to create texture and depth, further articulating the sense of parts.

Located at one of the main entries into Earl’s Court, the building responds to its context along a strong axis formed by the existing railway. The structure splits into two buildings with a facade that disintegrates, welcoming the public into the park.

Shear, Sheer

Opposite page: Model (foamcore), 1:100. Light shines through the slit between the two buildings.

Madison Kim

This page: Axonometric. From top to bottom: Stone slab/floor finish; stone and timber beams; and facade and shear walls.

Opposite page: Ground floor perspective. The ground floor of the building is partially open to allow the public to engage.

This page: Ground floor plan. Stone blocks are positioned to create texture and porosity in the facade.

Madison Kim

Opposite page: Interior perspective. View inside the open lounge.

This page: Typical office floor plan.

Madison Kim

Shear, Sheer

Opposite page: Exterior rendering. The facade is composed of offcuts of various locally sourced stone, exhibiting the country’s material landscape. Stone pieces stack to pattern the facade.

This page: Drawing of detail. The structure meets the facade with custom connections.

Madison Kim

Urban Mangrove

Jackie Pan

This proposal for a 10-story office building begins with a ground plane of reintroduced biodiversity and urban social ecology. This invites pedestrian crossover and entry, yet pathways are limited via the placement of water channels, wetland reedbeds, and shade-tolerant plantings. These are set within meandering turning pathways defined by walls and columns curved for structural stability and material efficiency.

The design is derived from a matrix of stone wall columns placed following an orthogonal structural grid. These pillars rest on the bases of C-shaped walls. As the structure ascends through 10 floors, the walls taper gradually, ultimately transitioning into thin columns. Using stone wire-cutting technology, the design features curved stone plates directly sliced from the raw stone cubes quarried with maximum use and relatively low embodied carbon.

On the lower floors, the curved walls form a series of enclosures and corridors, fluidifying conventional rigid circulation paths and creating unexpected moments. The lower floors aim to blur people’s directionality, allowing people to be willingly lost and spend their time within the forest of columns. The walls, arranged like the flow of a magnetic field, gently guide people along diagonal paths, fostering dynamic crowd movement. The plan layout eventually transitions to a typical free plan on the upper floors, offering great flexibility for multiple uses.

Opposite page: Model (rockite, chipboard, PLA), 1:50. Image shows ground floor. Brackets hold the composite timber floor plates.

This page: Ground floor plan. Indicates the spatial integration of biodiversity and social ecology. The largest C-shaped walls in the building are deployed on the ground floor, constituting the stone jungle that blurs people’s directionality.

Jackie Pan

Opposite page: Plan of the second and third floors. The dense forest of stone columns forms a semi-public space fostering both privacy and spatial fluidity, ideal for uses like libraries, galleries, or restaurants.

This page: Plan of the ninth and tenth floors. The columns are shaved down to minimum sectional dimensions, to incorporate with the open plan that allows for miscellaneous programs.

Opposite page: Conceptual photograph of the “quarry.”

Piles of casted column pieces for the structural model, which resemble a quarry. This page: Interior perspective.

Jackie Pan