CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vol. 52

July

2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S. Kathy Sternenberg

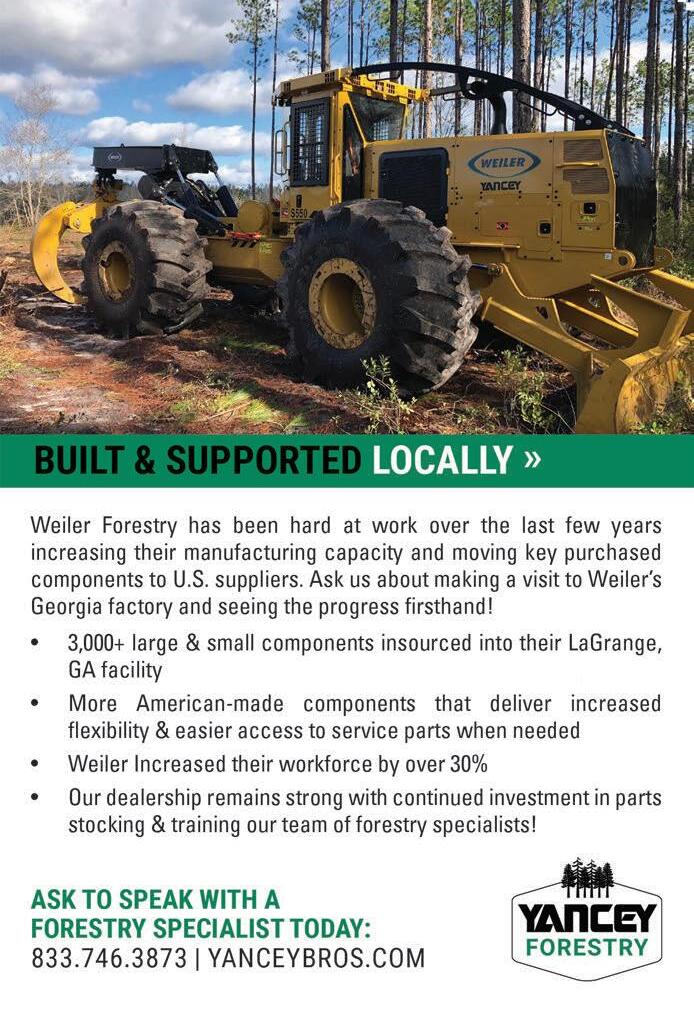

JWB Logging owner John Brockner didn’t grow up in Texas or in logging, but he got to both as fast as he could! In business for himself for the last six years, the young log-

ger likes to keep it simple, not straying too far from what works, maintaining a registry of mostly late-model John Deere and Weiler/Cat machines. Story begins on Page 8. (Photo by Jessica Johnson)

Tel: 251-928-4962 • Fax: 334-834-4525 219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons Tel: 905-666-0258

29 Bugelli Dr. Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA Tim Shaddick

Tel: 604-910-1826 • Fax: 604-264-1367 4056 West 10th Ave. Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett Tel: +34 96 640 4165 +34 96 640 4048

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.southernloggintimes.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Southern Loggin’ Times magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA.

POSTMASTER: Send address changes to: Southern Loggin’ Times,

No.7

(Founded in 1972—Our 610th Consecutive Issue)

4 ● JULY 2023 ● Southern Loggin’ Times Other

publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy 14

P.O. Box 2419, Montgomery, AL 36102-2419

Hatton-Brown

Southern Stumpin’..............................6 Bulletin Board...................................24 From The Backwoods Pew..............26 Industry News Roundup..................30 Safety Focus......................................36 Machines-Supplies-Technology......38 IronWorks..........................................41 Coming

W.D. Abercrombie Logging

Events/Ad Index.................46

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SOUTHERN STUMPIN’

By David

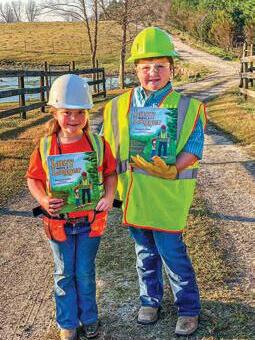

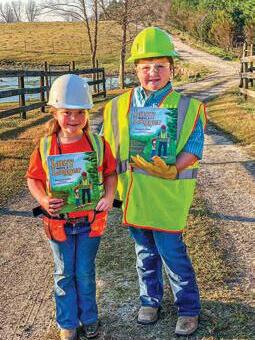

Kids’ Stuff

and hopefully to have an interest in this industry.

As it happened, Stephanie’s oldest sister had recently published her own children’s book about their hometown called Searching for Santa in Chambers . That gave Stephanie an epiphany: ForestryWorks® could produce children’s books about logging. She pointed out kids already have other books that offer a more environmentalist per-

never get a Penguin House to even look at us,” Stephanie admits. Her sister had been working on her book with a company in Virginia called Amplify Publishing, and recommended Stephanie to the editor. Turned out they were interested.

Three years later they have published two completed books (Lucy Meets a Logger officially released in 2021, and Travis Visits a Tree Farm in 2022), with a third (Sam Visits a Sawmill) on the way later this year. Amplify will continue to publish the rest of this “Tiny Timber Crew” series, planned for one book a year, as it explores the entire supply chain, from “woods to goods.”

based in Chambers County, Ala. “It is a family legacy,” Stephanie says. “I grew up in a family of five girls; daddy had no sons, so we knew the legacy would have to continue through a son-in-law.” The sisters knew at least one of them had to marry a logger! As it happens, Stephanie has one brotherin-law who is a logger and another is a forester.

Though she says she was “homeschooled” in forestry by way of her upbringing, Stephanie actually got her degree in agricultural economics from Auburn University. She knew she wanted to do something with economic, workforce, and business development and political advocacy for agriculture and forestry in rural communities, but she wasn’t sure just how to do that.

She found the answer when she happened to meet Chris Isaacson, President of the Forest Workforce Training Institute, at Alabama Governor Kay Ivey’s inauguration in 2019. “He was behind me in line for a reception and overheard me talking about my dad being a logger, and he asked who he was,” she recalls. “In a former life Chris was a timber buyer that my daddy cut for years ago.” This chance encounter led to an opportunity for her at the Forest Workforce Training Institute, which also goes under the promotion brand name ForestryWorks®. “It was a perfect fit.”

During her first year in the job, Stephanie began to notice a trend in the organization’s efforts to interest young people in a logging career. When they would visit middle school career events, students often expressed a negative view of forestry based on common misconceptions. “We realized we spent more time educating them about sustainable forestry than talking to them about career opportunities,” she says. She wondered how to educate younger students, elementary school age, about sustainability, so that when they get to 14 or 15 and start thinking about what they want to be when they grow up, a foundation has been laid for them to understand

The Lorax, who “speaks FernGully: The Last Rainforest, both of which have been adapted into animated isn’t necessarily anti-forestry, but it doesn’t tell the complete story of reforestation,” Stephanie says.

She continues, “We wanted to give our industry members a tool that they can take into the schools in their communities to tell the students what they do every day through a fun, interactive children’s book. What we have found is that through these book readings, it not only educates the students, but also the teachers, public officials who read it to the kids, and if there is a media outlet there, it educates that person who is writing for that newspaper. It’s a way to advocate for the forest industry through early childhood education. Sometimes our teachers and parents are spreading misinformation about the forest industry, not maliciously, but because they are repeating all they have ever heard. If we don’t tell our story, someone else is going to tell it for us.”

Stephanie doesn’t have kids of her own, but she has nieces and nephews under age six who proved to be a good test audience as she developed her concept. Still, writing a children’s book seemed outside her wheelhouse. “I have an economics degree; I have never claimed to have any sort of creative ability,” she says. “It felt like a massive undertaking when I took the project on. I had no idea how I was going to do this.” But she grew up in the industry and has fond memories of visiting the logging woods, so she tried to channel that inner child and relate what it felt like to see everything so big and so loud. She started writing from that perspective, and soon the words came to her.

Getting published as a first time author of a very niche book is no easy task. “We knew we would

Stephanie writes her story in a Microsoft Word document and sends it to her editor. The publishing house has an illustrator bank who work on contract; from their art samples, Stephanie eventually chose artist Agus Prajogo from Indonesia to illustrate the books. “He makes the vision come to life,” she says. “It’s a really cool process to see how well he represents an industry he has never seen.”

The books are available on Amazon and anywhere books are sold: Barnes & Noble, Books-A-Million, Target, Wal-Mart and so on. The publisher handles distribution, shipping nationwide from warehouses in Virginia and Texas.

ForestryWorks® in Alabama maintains stock in their offices from which they donate copies to classrooms and public libraries.

ForestryWorks® owns the copyright and proceeds from sales go back to the Institute to order more books or reinvest into future publications. “This is a unique part of my job,” the young author considers. “I never thought I’d be doing this, but we believe that forestry education is forestry workforce development. If you don’t have those conversations early you’re never going to be able to have those conversations later on.” SLT

6 l JULY 2023 l Southern Loggin’ Times

• Ph. 334-834-1170 • Fax: 334-834-4525 • E-mail: david@hattonbrown.com

Abbott • Managing Editor

Author Stephanie Fuller withAlabama Governor Kay Ivey

The book series helps kids learn about logging.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Fuller introducing a class to Lucy MeetsA Logger

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Something Important

■ For John Brockner logging isn’t just a profession, it’s a passion and a calling.

By Jessica Johnson LIVINGSTON, Tex.

By Jessica Johnson LIVINGSTON, Tex.

John Brockner, 31, didn’t get into the woods by exactly a straight line, but that’s okay with him. All that matters is that he’s here now. Having been exposed to an incredibly strong work ethic from a young age, Brockner values doing things with his hands. After heading from his native Louisiana to Houston for auto body training in 2010, he says he needed some extra gas money. Luckily for him, his aunt and uncle ran a logging crew in east Texas and they took him on washing trucks and doing some mechanic work. Over Christmas, he decided he needed a little more gas money, so he wanted to go out into the woods to run a saw.

That decision changed his life. But first, his uncle asked him the critical question: had he ever run a saw before? Brockner had a quick answer: “No, but I don’t think anyone knows how to do something until they do it.” So, he went out there and tried it. And he loved it. After cutting logs with a saw for a few years, he migrated to running equipment. Though he knew he loved it, he admits he tried out oilfield work to chase “bigger and better,” but came right back to the woods after a year. He hasn’t left again since.

After the passing of his uncle, Brockner made the choice to strike out on his own, when his aunt decided she didn’t want to continue the business. He purchased a fellerbuncher, skidder and loader from her to start JWB Logging in 2017. Brockner soon secured a contract with Steely Lumber Co., where his

uncle was contracted, and he still logs for that mill to this day. “We have a great relationship with Steely,” the logger asserts. “When I started on my own, they said they would take me on a probationary period to see how I’d do. I guess I did pretty well,” he laughs.

Operations

The crew averages 15-18 loads per day; it varies, depending on, as Brockner says, “literally everything.” Saw logs and chip-n-saw go to Steely Lumber. Pulpwood is marketed to WestRock in Evadale and RoyOMartin OSB in Corrigan. Recently, in an effort to find another destination for wood Steely can’t use, Brockner has also been sorting

out some products for Georgia-Pacific. By using a mix of JWB trucks and contractors, Brockner does his very best to keep trucks rolling on a constant basis, making sure that they get as much as they can.

The single JWB Logging crew operates rather simply, with one fellerbuncher, two skidders, two loaders and four trucks. Brockner believes keeping it simple has allowed them to be successful. They might change up where the feller-buncher cuts first, or skid trail placement, but he admits even when they do change something up, the crew goes right back to what they know. He says, “Every minute affects the day. So I don’t try to get too crazy with ideas. If it works, we keep on doing it.”

★

The 748L-II skidder,a 2023 model,is the newest piece on Brockner's job.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

John Brockner

One thing he is a stickler about is where the loaders are set up. He doesn’t like having one loader throwing to another. The landing is set up so the delimbing loader is away from the trucks, not having to swing wood around. He believes this is the safest method. “Safety is the biggest thing out here,” he believes.

Brockner may be young and determined, but he doesn’t fall into the glitzy, ritzy trap of the brightest and shiniest iron. Instead, he keeps an assortment of used pieces and only slightly used pieces (with 1,000 hours or less), and recently he added one completely brandnew skidder.

Equipment

JWB’s set up works well, Brockner says, because he doesn’t have anyone in a bind throughout the day—as long as the buncher is working ahead. In the woods, the crew uses a 2023 John Deere 748LII skidder and 2018 Deere 748L skidder; 2021 Deere 843L-II fellerbuncher; 2020 Weiler K560 loader; 2015 Caterpillar 559C loader; and a 2000 John Deere 650H LGP dozer. They also have access to a backup feller-buncher, a 2016 Deere 843L. Brockner has 2020 and 2021 Peterbilt trucks with an assortment of pole and other trailers.

For dealer support, Brockner relies on Gaar Equipment in Dodson, La., and Doggett Machinery and Texas Timberjack, both in

used equipment can be risky, but he feels like using dealers that are straight shooters means their offerings have a unique value. It’s not just a piece at a good price. “You might have a full-fledged warranty, but they will stand by their machines. Gaar Equipment is like that—I can call and say, ‘Hey this machine is broken down,’ and within reason Spencer will work to make it right,” he emphasizes.

This focus on building a relationship with dealers like Gaar is one of the principles by which Brockner runs his business. He strongly believes his logging operation is successful because Steely Lumber is successful. The two companies need one another and both of them have to be in good

doing well. “It’s a constant change out here—the mills, the equipment, the weather. You have to adapt and overcome. That’s just

to have a good relationship with the mill, your equipment dealers, your parts houses and your insurance man.”

Brockner likes to keep the loaders set up separately,with the newerWeiler keeping trucks rolling (15 or more loads a day)...

➤ 10 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

...while the older Cat knuckleboom sorts and delimbs.

Maintenance

While Brockner has both a shop at his own home and in nearby Cleveland, Tex., mainly, operators tackle maintenance in the woods, typically on the weekends. Like many loggers, Brockner works on as much as he can himself to control costs. “You might not get to play as much but you don’t have to

pay as much either,” he says. Machines are greased twice a week, usually on Tuesday and Thursday to set a schedule so no one forgets. Newer pieces get oil changes every 400-450 hours. Once a piece hits 8,000 hours, Brockner ups the schedule to every 300 hours. “When it has more hours on it, you’ve got to take better care of it,” he believes.

Likely a holdover from his days working on cars, Brockner is a stickler for Lucas Oil products. He believes using it gets more life out of the motor, and helps cut down on how often he changes injectors, especially important with a used fleet. Same with the Shell Rotella grease—it

10 ● JULY 2023 ● Southern Loggin’ Times

Fromleft,JohnBrockner,RandyValderez,VirgilProctor,JodyCurrie,GuillermoMejiaandJamesCarter

Brockner cuts for Steely Lumber and hauls to a variety of mills.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Clayton Coaliron

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

patience and things settled into the groove. Parts of the crew have been together for nearly 20 years. With that comes the knowledge of how a person is, when to give them a minute and when to push.

For Brockner, the bottom line is: this is fun. Yes, it’s work, but it’s still fun, too. Turning up the music as loud as you want, getting into the machine and doing your thing without talking to many people if you don’t want to has an appeal that other jobs don’t offer. “That’s what’s nice,” he thinks. But with an older crew, the worry of “what might happen if…” still creeps into his thoughts.

Logging is how he makes a living, but it is also how Brockner feeds his family, the single most important thing in his life. His wife Bridgette, their daughter Haddox and son Walter Wayne to be born in October, are his true pride. Bridgette runs parts, keeps all paperwork straight and handles office work from their home. The soon-to-be father of two says he likes knowing he’s contributing to the world by doing what he loves.

He explains, “I like coming out here, taking a truck, putting it in the woods, hauling the raw product and then you leave. And you have people building houses; that’s a product of what us loggers do out here. I take pride in that. I built a wooden fence at my house recently; and I looked for the Steely Lumber stamp. I might have cut that tree; one of the other contractors might have, but I say I did! Any operation that produces a raw material has a certain level of headache that goes with it. But still, we do something important.”

SLT 12 ● JULY 2023 ● Southern Loggin’ Times It's hard work,but at the end of the day,Brockner enjoys it and believes it's important. 10 ➤ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Simple Man

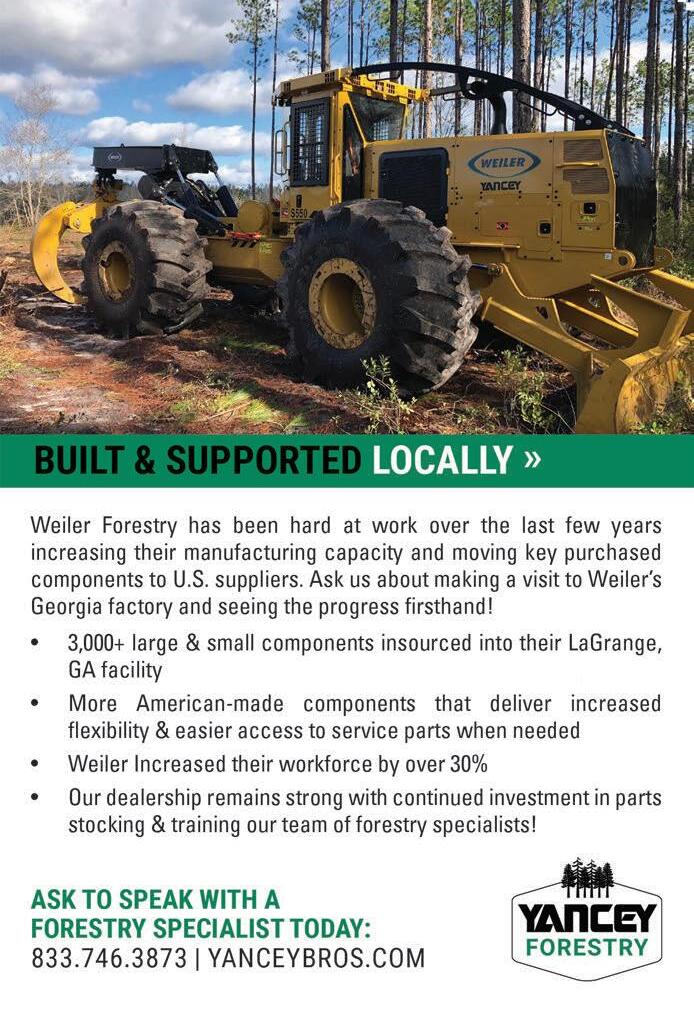

■ Look up “logger” in the dictionary and

By David Abbott LAURENS, SC

If an author, an artist or a Hollywood moviemaker tried to create a fictional character designed to represent the archetypical classic southern logger, what they came up with probably wouldn’t look so different from Mark Abercrombie, 62. The owner of W.D. Abercrombie Logging, LLC, is a fourth generation logger who’s never done anything else; he grew up in the business passed down to him from his dad, granddad and great granddad.

When did he know he wanted to be a logger? “Always,” he says emphatically. “From a real young age, I knew. I have probably been out here since I was old enough to walk.” What does he like about it? “You’re outdoors, you’re never in the same location. It’s just something different all the time, not the same old job every day in and day out.”

Also not unlike a lot of loggers, Abercrombie is a man of few

All The Hats

Abercrombie started his career working with and for his dad, William D. (Bill) Abercrombie—

together. In 2015, Mark turned the company into an LLC and Bill fully retired. He died just over a year later, in December 2016.

W.D. Abercrombie Logging, LLC

★

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

you’ll find Mark Abercrombie’s picture.

her own contract log truck for her brother, and his son-in-law, Ethan Landrith, mans the loader. Two employees, cutter man Willie E. James and skidder driver Willie J. Anderson, have both been with Abercrombie for about 35 years, since the late 1980s. Now that’s what you call long-term loyalty, so they might as well be like family at this point. Will Sumerel, the only full-time company truck driver, is also a cousin in the family.

Abercrombie also hauls loads part-time, and fills in on machines if an operator is out. Logging company owners frequently have to be comfortable wearing many different hats, and this one is no exception. He says he has too many jobs to run a machine full-time, with overseeing the operation and taking care of whatever needs to be handled.

“Sometimes there’s not enough of me to go around,” he chuckles.

Equipment

This lifelong logger runs almost all Tigercat machines, half of it very new. Just in the last two years he’s added a 2022 model Tigercat 720G feller-buncher, a 2023 model 610E skidder and a 2022 Tigercat TCi 920 forestry dozer. His roster also includes a 2015 Tigercat 234B loader, and he still keeps in reserve a 2013 model Tigercat 610C, the first new machine he ever bought. A 2006 D5 Cat dozer is the only nonTigercat branded piece of equipment in the lineup.

To haul production, Abercrombie has two trucks manufactured about 20 years apart: a 1997 Peterbilt and a 2018 Mack, pulling two Pitts log trailers. He also has a Pitts lowboy for moving equipment from tract to tract.

Abercrombie bought his first Tigercat machine, a used fellerbuncher, in 2003. He used to run Cat skidders and Prentice loaders, but in 2013 he bought his first new piece, the aforementioned 610 skidder. He’s been buying all Tigercat ever since. “I think they’re well made,

better than Tidewater in service, and in parts and sales. They are real good people to get along with.”

Tidewater Equipment in Newberry has been Abercrombie’s supplier for all that Tigercat iron as well as the Pitts trailers. His newer truck he bought from Mack dealer Shealy Truck Center in Columbia.

One of the hats most loggers have to wear is a mechanic’s. This one says he used to do a lot of major repairs for himself. These days, though,

under warranty, he now does minor repairs and routine maintenance on the job site or at his shop, but leaves major repairs for Tidewater. Since he trades skidders and cutters on a regular three-year rotation, he doesn’t have to worry about breakdowns too much, freeing him up to focus on production instead.

Operations

The logger contracts through timber buyer Foothills Forest Products

in Whitmire. He is mostly content to leave that aspect to them, so he can concentrate his time and attention squarely on logging operations instead of worrying about cruising and scheduling tracts. They communicate and keep him in the loop if there is anything unusual he should know about the next job site.

When Southern Loggin’ Times visited at the end of the first week in April, the Abercrombie crew was working on a property that belongs to Michelin Tire, which has a plant nearby on Highway 39. The crew had already been working this site for two months total, off and on; weather conditions had them leave it once before and come back later. This section was a 165-acre block of planted pine, excluding some hardwood hollows. It was a firstthinning job, even though the timber was 24 years old. “It should have been thinned six or seven years ago,” Abercrombie believes.

The prescription here was for fourth row thinning, though Abercrombie normally cuts every fifth row on first thinnings. Most first thinning jobs call for around 70-80 basal area, the logger says. His crew specializes in first thinnings, but does a little of everything, including

Southern Loggin’ Times l JULY 2023 l 15

He's been buying allTigercat for the last 10 years.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Left to right,long-time employeesWillie James andWillieAnderson; owner MarkAbercrombie,his son-in-law Ethan Landrith and sister Brenda Rogers; truck driverWill Sumerel

some clear-cut jobs.

Production goal for Abercrombie Logging is 50 loads a week. “But we have been shy of that a lot, between rain and quotas, this year so far,” he says. “Pretty much overall everything has been on quota.”

The crew hauls to a variety of mills: Norbord in Kinards, Enviva in Greenwood, International Paper in Silverstreet, Georgia-Pacific in Prosperity, West Fraser Newberry, Boise Cascade-Chester Plywood in Chester, and New Indy Container Board (the former Bowater pulp mill) in Catawba. In April, Abercrombie says, the crew could only haul four days a week. “We’ve been scrounging around to get what loads we can at different mills, a load here and a load there,” he says. “Pulp logs, saw timber, chip-n-saw, you name it, mills are full, I guess.”

Though he’s blessed with a crew of family members and longterm employees, the logger admits truck drivers are the hardest position to fill these days. The number one hindrance is driving records that meet insurance standards.

Cypress Risk Management Ltd. Co. in Ridgeville covers his trucking insurance and some of his paid-for equipment.

“The economy worries me right now,” Abercrombie acknowledges. “Years ago when fuel went to $5 a gallon, basically that’s all that happened. Nothing else went up; pretty much everything stayed the same. But now everything has gone up. There’s just not enough compensation, I guess you could say, to cover the increase of everything. And it’s not just for logging; it’s for everybody. You go to the grocery store and you can’t walk in there for less than $100, and you walk out with nothing.”

So how can loggers cope with all this inflation? “All I can do is run as efficient as I can and make it up with production,” he says. “My hands are tied. All of agriculture’s hands are tied, period. You are at the mercy of what you get for your product. It’s all commodity products. I don’t know of a way to control it.”

When he’s not working, Abercrombie still likes to spend a lot of whatever leisure time he can find outdoors. He enjoys fishing and hunting deer when he can. He and his wife Janet have two daughters and three granddaughters. Older daughter Samantha and her husband Michael Gilstrap have two girls, Addy and Savannah (who goes by Anna), while younger daughter Jeny, who's married to loader man Ethan Landrith, has one baby, Zoey. SLT

16 l JULY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

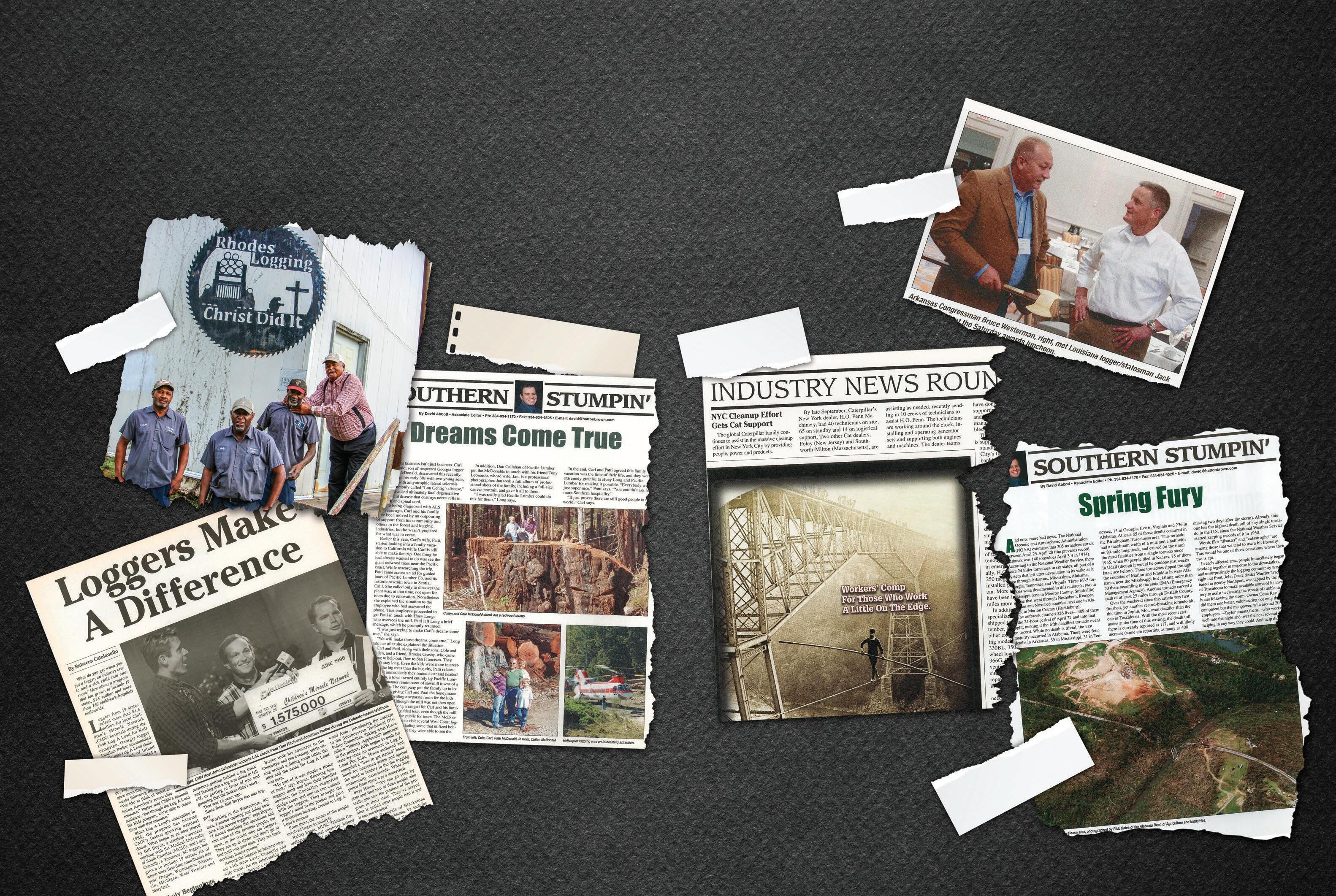

Looking back over the years. April2019 August 2007 August 1996 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SLT Scrapbook ■

June2011 Oct 2001 Nov 2016 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Spotlight On: Felling, Processing, Etc.

Editor’s Note: SLT invited manufacturers of feller-buncher/harvester saw heads, processor heads and all related components to submit material describing their products. The submissions of those that participated are presented here, edited only for editorial style consistency and space constraints as necessary.

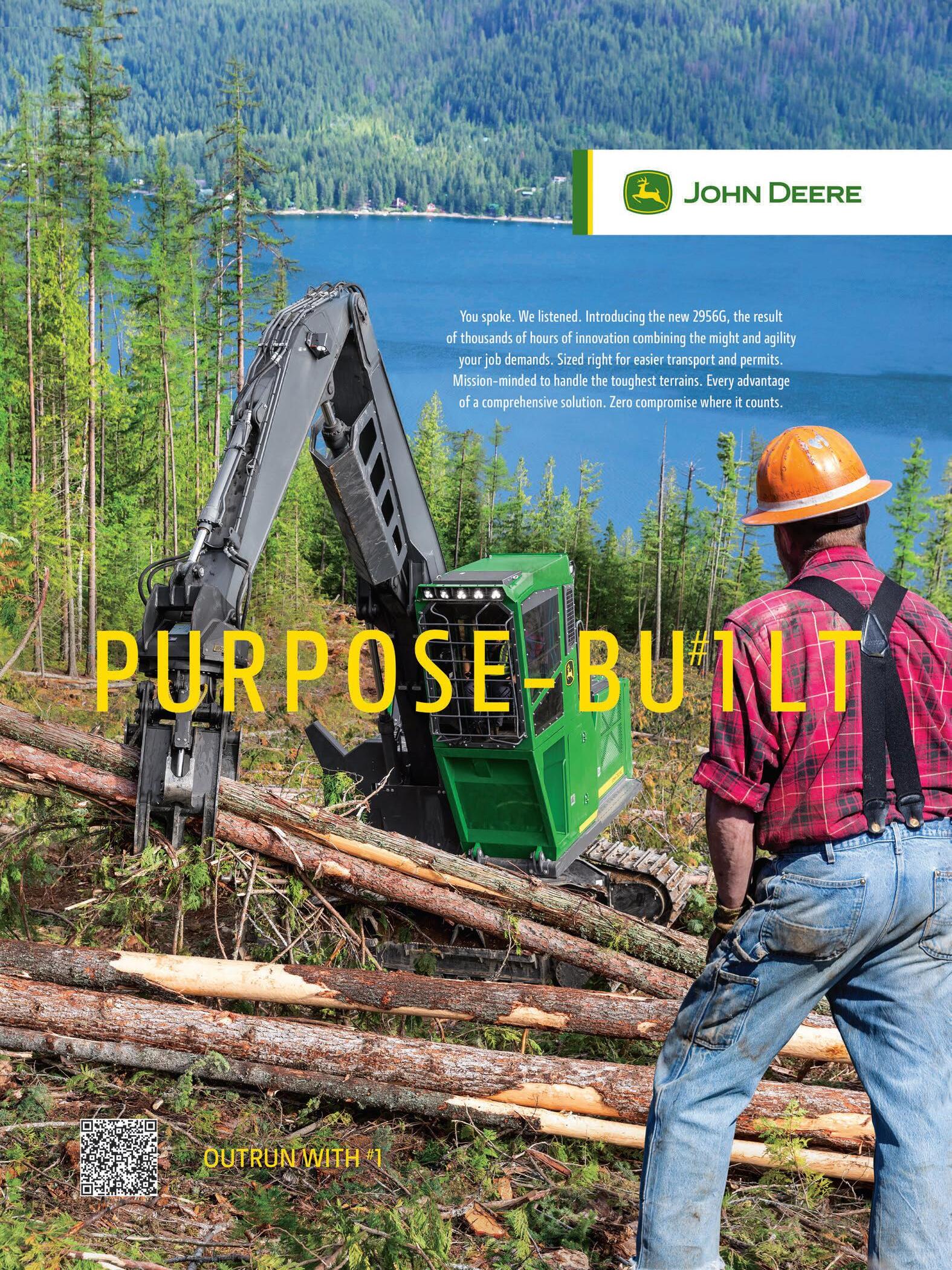

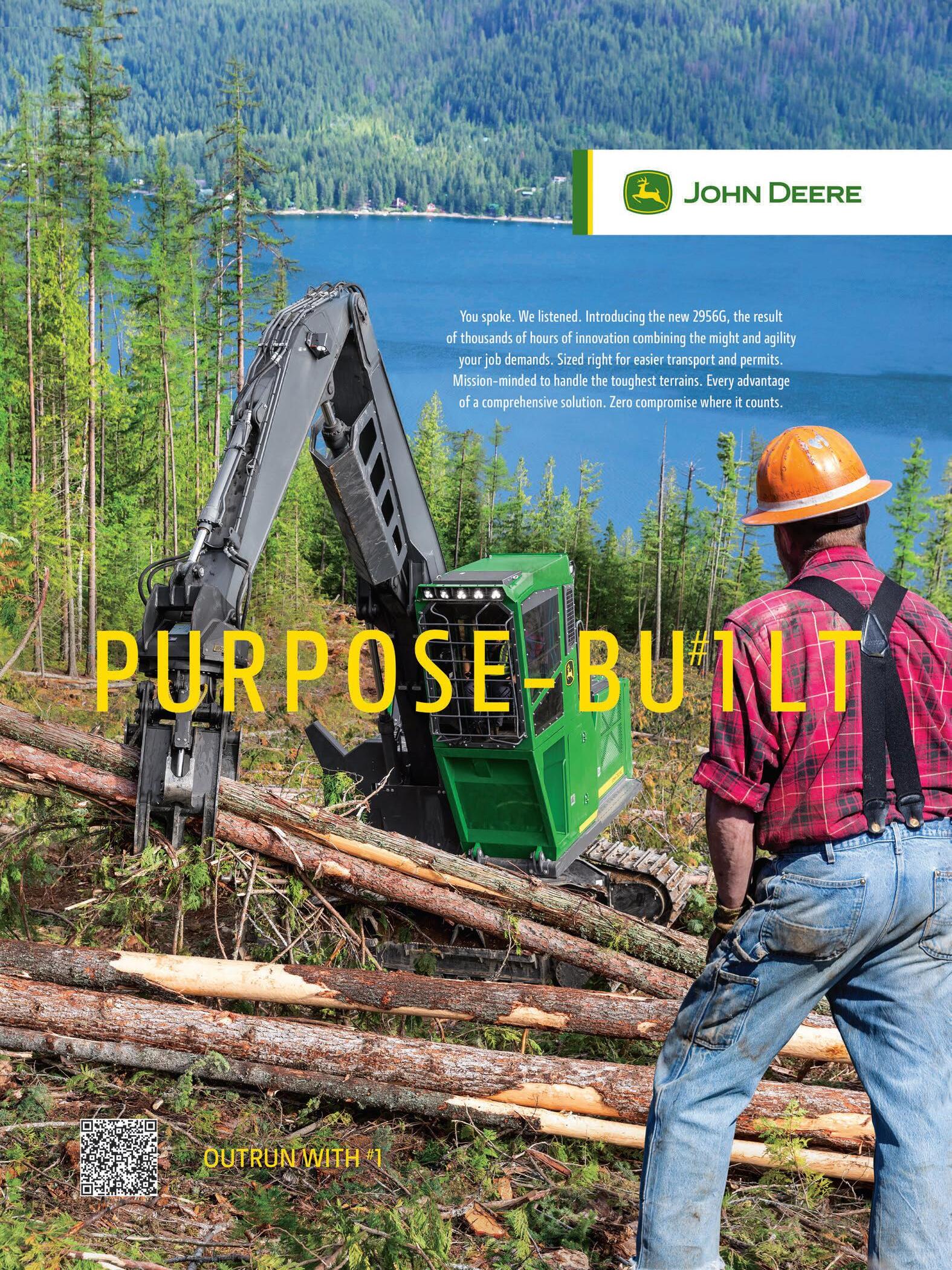

John Deere

John Deere forestry technology is revolutionizing logging operations around the world, offering increased efficiency, improved safety, and reduced environmental impact through innovative solutions and equipment. The FR27 Disc Saw Felling Head boasts a design that combines the advantages of a traditional chain saw with the power and efficiency of a disc saw. (It is) standard on the John Deere 953M and 959M feller-buncher models, and available as an upgrade on the 853M, 859M and 903M feller-bunchers. Building upon the success of the FR24B, John Deere has designed the durable FR27 as a solution aimed to increase productivity on the job.

The FR27 is designed for large single stem cutting to mid-sized accumulation, and boasts an all-new design and overall rebranding from previous John Deere felling head models. The felling head is adaptable to various terrain and tree sizes, ensuring operators can navigate challenging environments and efficiently handle diverse logging tasks. The FR27 features an impressive cutting capacity of up to 27.2 in. and an accumulation capacity of up to 7.5 ft., improving capability in the woods. By introducin to the John Deere line-up, customers are provided with a larger, more durable attachment to help increase their bottom line.

In terms of safety, the John Deere FR27 eliminates the risks associated with chain saw kickback, a common hazard faced by operators. The use of this technology significantly reduces the potential for accidents, making logging operations safer for workers. The design of the FR27 enables operators of all experience levels to tackle even the most ambitious jobs with confidence knowing their machines are built to excel in a variety of forestry applications.

In addition to the FR27 safety features, this disc saw felling head has incorporated sustainable practices that have become increasingly important in the forestry industry. The John Deere FR27 aligns with this global trend by minimizing environmental impact. The precise cutting technique of the disc saw reduces damage to surrounding trees, promoting sustainable forest management. Furthermore, the efficient felling process reduces fuel consumption and emissions, contributing to a greener approach to logging. With a superior lineup of machines, technology, support, and financing, John Deere can help move your forestry operation forward. Visit deere.com for more.

Ponsse

The newest member of the Scorpion family seamlessly complements the entire Ponsse harvester range. Developed according to the requests from our customers, Ponsse Scorpion Giant conveniently fulfills the gap between Scorpion King and Bear in the Ponsse harvester lineup comparison. Ponsse Scorpion Giant can be equipped with the H8 harvester head. Smaller heads are available for customers who mainly require more lifting power. With the new C50+ crane offering more lifting power and more tractive force, Ponsse Scorpion Giant is right at home in working with larger trees, in snow, slopes, and soft grounds.

Ponsse Scorpion Giant is a beast of a harvester with more modern and stylish features and increased comfort. The best properties are still there – just upgraded from the feedback of operators. The entirely new cabin is full of features that improve visibility, safety, ergonomics and usability. All of these increase the operator’s comfort, while the completely new air conditioning system, larger storage spaces and dozens of other small details add their finishing touches. When you step into the spacious and quiet new cabin, you can experience a new kind of comfort never seen in work machines before. The new stylish design, high quality upholstery and increased spaces make the operator feel like everything is in the right place.

The new Ponsse H8 harvester head enables faster, more efficient, and comprehensively economical harvesting even when there are plenty of large-diameter trees to handle. Thanks to the robust structure, great sawing power, excellent gripping geometry and uncontested agility, the new H8 allows smooth proceeding without unnecessary interruptions. Steady progress makes work profitable and the new H8 one of the most essential tools for a successful logging business. The new H8 encompasses –especially in relation to its compact size – exceptional power and ability to perform. Even though the head’s agility enables operations in all types of forests, the new H8 maintains its stability well. This results for example in efficient feeding and fast, yet flowing tilt function. The new H8 provides uncontested durability, excellent reliability, and lower lifecycle cost – also to the saw blade and chain. The more challenging the conditions, the better the new H8 stands out: the renewed saw box prevents snow from packing, and the completely new active speed function enables changing th ally on the fly. The new H8 utilizes sophisticated automation that adjusts sawing according to the tree diameter and saw bar position. This speeds up cutting, helps avoid damages and enables the saw bar and the chain to last longer. At the end of the day, this turns into a more efficient and economical sawing, resulting in quicker project completion and better productivity. Trees are always fed at the correct length, at the best possible speed. Controlled feed acceleration and deceleration provide smaller pressure peaks, fewer feed damages, and improved efficiency. The grip pressure of delimbing knives and feed rollers adjusts continuously according to the trunk size. Feed rollers support trunks from below, ensuring low friction and a firm grip during feeding. The advanced capabilities of the new H8 enable complete delimbing of trunks with diameter down to 50 mm (roughly 2 inches). Plane-like knife profile lowers friction, saves fuel and maintains its sharpness for a lot longer than harvester heads that feature flat knife bottom. The new H8’s smooth, fast and strong tilt has its own proportional directional valve, which enables separate movement speed adjustments for lifting and lowering in the Opti system. Advanced high-quality geometry provides optimal tilt power and speed, allowing the tilt to go near the stem surface. This helps minimize the lift-up torque, further extending the head’s productive lifetime. The new H8 harvester head is also ideal for multi-stemming. The geometry of the rollers and delimbing knives is also excellent for collecting and cutting larger diameter trees. Visit ponsse.com to learn more.

20 ● JULY 2023 ● Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

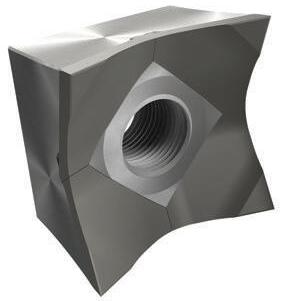

Quadco

All our high-speed disc saws now come standard from the factory with QPS teeth. QPS, which stands for Quadco Performance Series, is the most significant development in cutting tools in recent years. Available in both steel and carbide, this “Next Generation” tooth not only generates better cutting performance and efficiency but also more tooth at the same cost, resulting in lower cost per operating hour and lower cost per ton. Thanks to its larger kerf, the QPS tooth provides more clearance to the butt plate and saw disc. The patented “Flare” design of the tooth reduces drag, meaning better saw RPM control and better recovery and fuel efficiency. More material also means increased wear life and more time between turns.

The QPS Steel-type and Carbide both feature a new distinctive tip design. It is inspired by our “Concave” tooth, recognized for its cutting efficiency, except that here only the tip is concave, not the whole cutter. The incurved/concave tip has the following advantage: it provides better chip flow and improves wear patterns.

The QPS Carbide version has carbide inserts that are substantially beefier than previous generations, up to 25% thicker. Combine that with an improved patented tip overlap, and you get a much superior tooth. The QPS Carbide comes with a choice of “Sharp” or “Beaver” tips to match customer preference. A new optional carbide grade is now offered to match your ground conditions. If you operate in abrasive soil while at the same time faced with small gravel or stone, a new “D” grade carbide can be ordered that is more resistant against cracking, flaking or chipping in lightly contaminated soil. Visit quadco.com for more information.

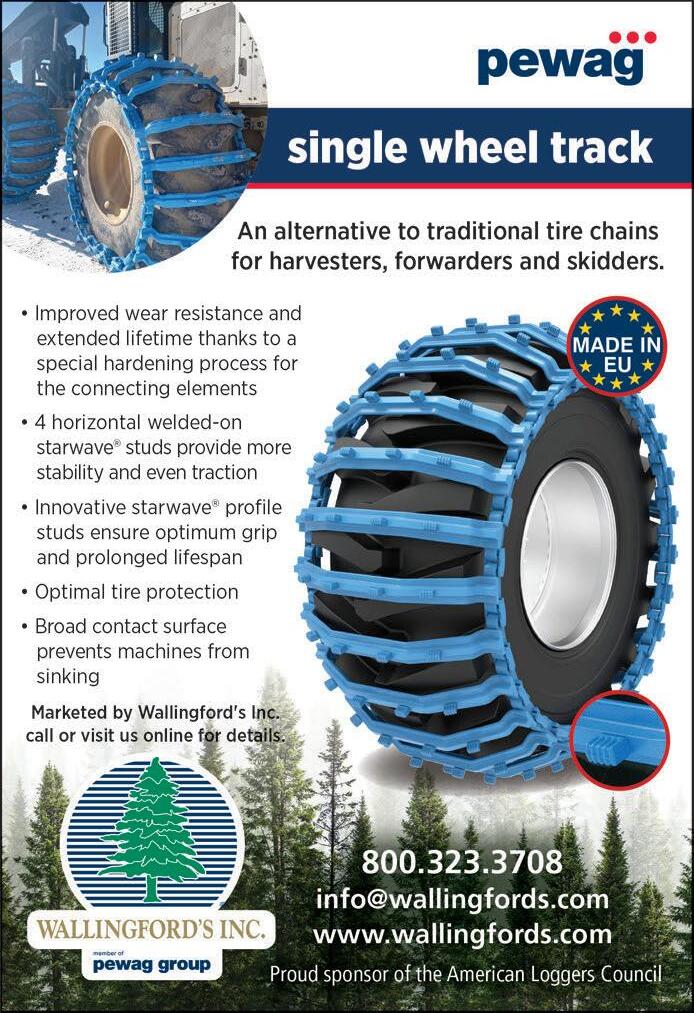

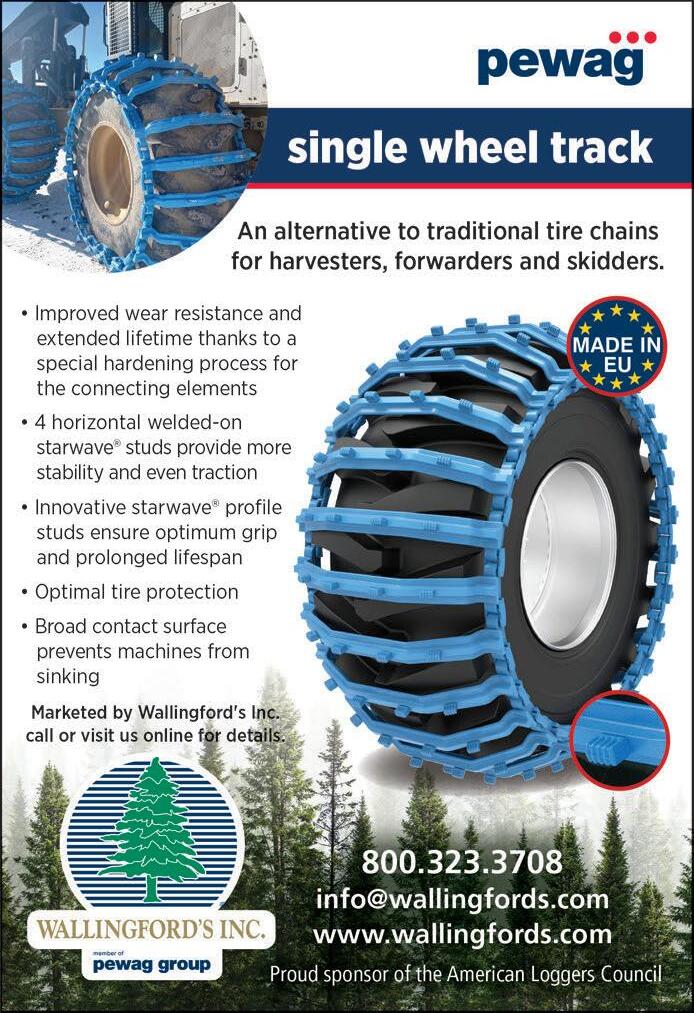

Wallingford’s Inc.

Since 1959, GB has built a solid reputation by manufacturing products that set new industry standards, playing an active role in the development in the forestry equipment industry. A unique blend of titanium and alloy steel yields the ultra-high strength material with uniform metal hardness throughout the bar. Since the rail is non-tempered, this reduces rail flexing and cracking. This alloy steel is extremely durable, resulting in fewer bends and better “memory” allowing it to return to original shape, which increases run time for operators.

GB Professional Harvester Bars are available in both .404" and ¾" pitch and are designed with mounting configurations to fit most mechanical harvesting processor heads. The .404" XV line has a patented 15-tooth sprocket, which reduces RPMs, resulting in less friction and wear. This, combined with the patented “Lube Direct” channels to directly feed the bearings’ lubrication, improves overall performance and life. The ¾" BC tip has the “Lube Direct” system and a machined edge to control chipping to improve overall longevity.

GB also offers slasher bars for many mount configurations. For any questions on cross-over from another manufacturer’s part number, please give us a call during normal business hours and we can

22 ● JULY 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

help you find the right GB part number for your machine.

We also have GB sprockets for .404 and ¾ set-ups, as well as GB chain repair tools. GB also offers an excellent line of ProTOP professional chain saw bars.

Orbit harvester saw chain is manufactured with high quality alloy steel and offers professionals the best balance of quality and value in the industry. Both Orbit ¾" and .404 pitch saw chain have micro radius semi-chisel cutters and increased kerf width. Both Orbit lines of harvester chain are engineered for maximum performance and fast cutting speed. All Orbit saw chain is manufactured with enhanced multi-layered chrome plating providing excellent durability and wear resistance. We also carry Orbit Titanium non-safety saw chain for the professional chainsaw operator.

Please email any questions at wallingfords.com, which contains additional information regarding GB and Orbit products, or you can call 1-800-3233708 during normal business hours.

Waratah

For 50 years, loggers across the globe have relied on Waratah Forestry Equipment for their operations. Waratah’s full line of harvesting, processing and felling heads are used for a variety of logging applications – from cut-to-length hardwood harvesting at the stump, to processing on a landing, felling on steep slopes or debarking on plantations.

Each head is built to work and proven to stand the test of time. And using Waratah genuine parts makes all the difference when it comes to performance and uptime. They are designed to outperform imitator parts and are the perfect fit for your machine.

For maximum peace of mind, each Waratah part is covered with a Genuine Parts Warranty: six months for customer-installed or 12 months for dealer-installed. And you can always count on Waratah’s unparalleled customer support, whether it’s through the WaratahPlus app, a phone call or boots on the ground. The Waratah product support team has your back – from helping you get the right parts to assisting with installation or set-up questions.

For quick and easy access, search for the Waratah genuine parts you need using the online Parts Catalog at PartsCatalog.Waratah.com. The online catalog features parts for current and select older model Waratah products including 200/400/600 Series heads, felling heads and control

systems. The easy-to-use search bar helps customers quickly find any part they need that’s on the head.

With the online Parts Catalog, parts distribution centers, an extensive dealer network and dedicated support across the globe, Waratah will make sure you get the right genuine parts when and where you need them. Visit Waratah.com/parts for more information.

Southern Loggin’ Times ● JULY 2023 ● 23 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Experience Counts, Costs

An old engineer retired. A year or so later, the firm called on him to troubleshoot a technical issue with a machine he had designed. No one else in the company could figure out was wrong with one of his signature machines.

He walked to the machine, opened a panel and stared into the workings. After a while, he pulled a piece of chalk from his pocket and scribed an “X” on a component. He said, “There’s your problem,” and left. Sure enough, the firm replaced the component and everything was working fine.

A few days later, the firm received a bill from the retired engineer for $10,000. The manager called him, asking why the bill was so outrageous. The engineer calmly replied, itemizing the bill: “That’s $1 for the chalk and $9,999 for knowing where to put it.”

Working Together

There was once a man who lived with his three sons. His sons were hard workers, but they constantly fought with each other. Even though the man continuously tried to help his sons make peace with each other, he was never successful. In fact, their fighting got to a point where their neighbors would make fun of them.

50 Years Ago…

I replied, “Well you better get back to it, before the farmer notices you’re missing.”

Messages On Church Signs

Be Kind Whenever Possible. Pro Tip: It’s Always Possible.

Do You Spend Your Time With God’s Book Or Facebook?

Store The Bible In Your Heart, Not On A Shelf.

Acting Perfect In Church Is Like Dressing Up For An XRay.

Tweet Others As You Want To Be Tweeted.

Our Sign Broke. Come Inside For The Message. No SPF Needed To Spend Time With The Son. God Recycles—He Made You From Dust.

Jesus Is God’s Selfie.

Always Remember That Hell Is Really Un-cool. Need A Lifeguard? He Walks On Water.

The Best Vitamin For A Believer is B1.

When You Throw Mud At Someone You Lose Ground. Call 911—Our Pastor Is On Fire!

If You Are More Fortunate Than Others, Build A Longer Table, Not A Taller Fence.

Lord, Help Us Be The People Our Dogs Think We Are.

Eventually, the father became ill. He begged his sons to learn how to work together because of his impending death, but they didn’t listen. The father then decided to teach his sons a practical lesson to help his sons forget their differences and become a united team.

He called his sons and said, “I’ll give you each an equal collection of sticks to break in half. Whoever breaks the sticks the fastest will be rewarded.” After agreeing to the task, the father gave each of his sons 10 sticks and instructed them to break each stick in half.

This task took the sons mere minutes to complete, but once they were finished, they started to fight about who finished first.

The father said, “The task isn’t finished. Now I’ll give each of you 10 more sticks, however, you must break the sticks in half as a bundle rather than snapping each one separately.” His sons agreed and attempted to do what he had asked. They each tried their best, but none could break the bundles in half.

In response, their father said, “See, it was easy to break the sticks in half individually, but you couldn’t break all of them at the same time. Similarly, if the three of you stay united as a team, nobody will be able to harm you. However, if you fight all the time, anyone will be able to defeat you. Please come together as a united team.”

This lesson helped the man’s sons understand the power of being a team and they promised their father that, moving forward, they would work together as a team, no matter what the situation might be.

The Moral: Being an effective member of a team helps contribute to the overall morale and motivation of the team. Strong teams are naturally aligned to work harder, support each other, and cooperate in working toward a mutual goal. Individuals each have diverse talents, strengths, and weaknesses to contribute to teamwork, so staying focused on the task at hand rather than allowing personal disputes to get in the way will help achieve desired results.

Turned Down, Turned Around

Sally visited a local bar one Saturday night, and later told me what happened when a strange, ugly guy approached her:

“The wierdo actually pinched my butt. Then he demanded, ‘Give me your number, sexy.’”

I replied, “Have you got a pen?”

He smiled and said, “Yes.”

Is Prayer Your Steering Wheel Or Your Spare Tire? The Struggle Is Real, But So Is God.

Looking For The Perfect Gift? Find Him Here.

You Have A New Friend Request: From Jesus.

When Gratitude Becomes Your Default Setting, Life Changes. Trust In God, But Lock Your Car.

Church Parking Only. Violators Will Be Baptized.

I was Going To Waste, But Jesus Recycled Me.

God Loves You Whether You Like It Or Not.

Prevent Truth Decay. Brush Up On Your Bible.

I Am Also Making A List & Checking It Twice—God.

Exercise Daily: Walk With The Lord.

God Is Our Wireless Provider.

This Heat Wave Is Temporary. You Do Not Want To Face An Eternal One!

Body Piercing Saved Our Souls.

If God Had A Fridge, Your Picture Would Be On It.

I Hate This Church: Satan.

Under The Same Management For More Than 2,000 Years. Prophecy Class Cancelled Due To Unforeseen Circumstances. Does Your Spiritual House Need Spring Cleaning?

Keep Using My Name In Vain & I’ll Make Rush Hour Longer: God.

If Your Life Stinks, We Have A Pew For You. IPod? IPad? Try IPray. God Is Listening.

Practice Thanking God For More Than Elastic Waistbands. The Manger Was The First King-Sized Bed.

We Have A Prophet Sharing Plan.

Jesus Said “I’ll Be Back” Way Before Arnold Did.

Gossip Is The Devil’s Radio. Are You His DJ?

Eternity Is A Long Time To Think About Where You Went Wrong. This Is Your Sign To Come To Worship.

Easter Comes Once A Year. How Often Do You?

Feeling Warm? This Place Is Prayer Conditioned.

Download Your Worries & Get Online With God.

Jesus Is Coming. Get Busy!

ATM Inside: Atonement, Truth, Mercy

Give Satan An Inch & He’ll Become Your Ruler.

God Wants Full Custody, Not Just Weekend Visits. Sinners Wanted. Apply Within.

Wrinkled With Problems? Come To The Lord’s House For A Faith Lift. Life Changes. Growth Optional. Choose Wisely.

24 l JULY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Numerous companies,most of them small,privately owned outfits, offered felling and skidding attachments in the early 1970s.Two of the most popular products were Roanoke tree shears and skidder grapples made by Lewiston,NC-based Harrington Mfg.Co.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FROM THE BACKWOODS PEW Culverts

Certainly, this is a topic that is near the forefront of every seminary’s curriculum. What is a culvert, and how can it be used to further God’s Kingdom? Of course, we all know what a culvert is, and have driven over them daily for as long as we have been rid-

ing in the horseless carriage. The culvert is simply a pipe placed under a road; or in one old woods path I found, a hollow cypress log. For an example of your own, try looking at your driveway the next time you are outside. Usually there will be a culvert at the roadside ditch. That culvert allows water to pass under your driveway instead of over it. Remember that definition, it might show up

on a test at the end of the book. When it comes time to access a block of timber, either for logging it or for the sake of managing it, the first step is laying out a road. How else are we going to get there? As we lay out our proposed road, often we find that there are one or more streams or ditches that must be crossed if we are to get from Point A to Point B.

If you want to break any drought, follow these steps. The forester looks at the tract of timber and decides he can lay out a temporary road. He ignores the need for a culvert because the summer has been dry and there is no water in the stream. He has the logger move in, and cutting begins. After the first few days, the logger has valuable timber cut and lying on the ground, waiting to be loaded. It is then, that in nine out of ten cases, the drought will break. Rain, unseen since the days of Noah, will descend from the clouds. The dry, little stream is now rejoicing in renewal. And as it rejoices, it grows in volume, rising against the side of the road, until it reaches the surface of the road, and begins to once again carve out its original channel. When the forester returns days later, he usually finds that the little access road is no more. For the lack of a culvert, the stream has destroyed his road. Now he must start over, regroup, and spend more money. All the time, the “money clock” is ticking. The logger can’t get to his equipment; he can’t make loads; which means he can’t make his payments, and the mill can’t get wood—all because of the lack of a culvert.

Culverts allow water to go about its business, flowing along happily; and the road above can do its job, which is to provide a foundation for transportation. Without a reliable culvert, water flow can be blocked until it reaches critical mass, and it will then seek some means to follow gravity. Watch any news report of major floods, and you will see that when water decides to follow gravity, not much will stand in its path.

Let’s keep the culverts. Let’s make sure they are large enough to handle the expected water flow, and let’s keep them from being clogged. I had a tract with a cantankerous culvert. It always seemed to find logs, sticks, mud, and leaves and anything else lying around; and it would somehow stuff itself with these items to the point that no water could pass through it. I soon found out that the culvert was having help, and the helpers belonged to a rowdy, local beaver colony. It seemed to be their favorite pastime. They would hide quietly while I raked out the debris; and with disdain they would watch my satisfied smile as the water again flushed under the road instead of over it. They would stay hidden even while I would call for more rocks and sand to be delivered to make the road drivable again. Then that night, they would get their gang together and stuff every log and

26 l JULY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

limb they could find into the mouth of that culvert; laughing hysterically no doubt, as the water quickly rose up and washed away my road. To be true culverts, water had to pass through them, and this group was

making sure I had no culverts.

Culverts and what they are used for, can give us a picture of prayer. How are we supposed to pray? Christ gave instructions to His disciples concerning prayer, of how to talk to

God, to communicate with Him. In Matthew 6:9-13, Jesus offers us an example of prayer. Look closely at verse 12:

“And forgive us our debts, as we forgive our debtors.”

Now that’s pretty basic. It’s a plea for forgiveness. How often do we pray that portion of verse 12, “forgive us our debts?” But seldom do we pray the rest of the verse, the part about us forgiving someone else. Jesus goes further in verse 14, and what He says is very sobering. If we do not forgive others, then God cannot forgive us. Let that sink in for a minute. Ever hold a grudge? Ever refuse to talk to someone because they offended you in some way?

Life, events, and circumstances all keep coming at us. Many things are out of our control. We cannot control how others may act, but we can control our response. And the Bible tells us we have to forgive if we want God’s forgiveness. When someone does us wrong, we have to forgive them, whether—sit down for this— they say they are sorry or not. You see, it’s like a culvert. We have to let those instances of hurt and anger flow on past. We cannot allow them to build up against us and inside us

until they reach a critical mass and then explode. Explosions are not good. Valuable time and effort is wasted, progress is set back, often abandoned all together.

Forgiveness: it is an open culvert, allowing those instances of hurt and anger to flow on past us. Let them go. Why destroy the road? Have you ever heard the saying, “Don’t burn your bridges”? Bridges make it possible to use the road, for you and for others. My adaptation of that saying is: “Use the right culvert, and keep it open.” Perhaps the best example of showing forgiveness would be Jesus Himself. While hanging on a cross, beaten, dying, and suffering for my sins and yours, He looked at those people, the very people who were cursing and taunting Him, and forgave them

(Luke 23:34). What an example!

What a challenge! Keeping the culvert open will often be a chore. Emotions will seek to clog it. Anger will push mud into it. But keep working at it. Take the rake out yet again, and forgive. Let the water flow. Save the road for you and others.

Excerpted from Bibles, Beavers, and Big Timber, Bradley Antill author, see this and more at www.onatreeforestry.com

28 l JULY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

As We See It: Loggers, Truckers Provide Critical Connections

By Scott Dane

By Scott Dane

All aspects of the timber industry supply chain are vital. None can exist without the other. But the weakest link is the logging and trucking sector. Logging and trucking have become very

capital-intensive elements of the forest products industry, with the most labor challenges and the tightest returns on investment.

Trucking is getting increasingly more difficult with regulations, driver

shortages, inflationary expenses and insurance and maintenance becoming cost prohibitive. The price of a new truck is nearly $200,000. A review of publicly traded forest products manufacturers and landowners reveals strong, if not record, returns on investment over the past few

years. Although forest product prices have fallen dramatically compared to the record prices, large forest products companies have posted strong stock value increases over the past couple of years. Two of the largest companies have reported stock price increases of two to five times 2022 prices. These companies have also reported annual net earnings of more than $1 billion.

Landowners, including Real Estate Investment Trusts (REITs) and industrial landowners (mills), have initial investment costs, but minimal annual costs. The return on investment for landowners, particularly REITs and industrial landowners, has been consistently positive, with an annual percentage increase in value of 25% over the past three years. Large industrial landowners have experienced similar increases in the value of their timberlands.

In contrast, it is obvious at times that the large manufacturer or landowner is unconcerned about paying a service contractor (logger) to harvest raw materials at rates that keep the contractor sustainable and their crews making a sustainable family wage. Too often, the large company succeeds in leveraging the smaller logging service contractor to harvest at unsustainably low margins. Why have the smaller service contractor loggers and truckers not experienced the same gains as the larger companies in the forest industry?

According to Forisk Timber REIT (FTR) Weekly, timber REITs as a sector realized a value increase/return of 25.09% based on appreciation and 30.12% on a total returns basis in 2021. These “snapshots” of timberland investment returns demonstrate an attractive return on investment for REITs and industrial landowners. However, many smaller private landowners have not seen comparable returns on their timberland investments.

There is nothing wrong with segments in the supply chain being profitable. In fact, they all should be profitable. It is the only way that the timber and forest products industry will be sustainable. However, there is a major discrepancy between the return on investment of the landowner and mill compared to the logging and trucking sector. The logging sector invests millions of dollars in equipment that does not increase in value but instead continually depreciates in value. It is similar for the timber trucking industry.

Employment within the logging industry has steadily declined on

30 l JULY 2023 l Southern Loggin’ Times INDUSTRY NEWS ROUNDUP

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Dane

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

average 2% per year. The infrastructure is eroding. A prior survey found that half of the logging companies in the U.S. operated at a break-even or loss, while the greatest percentage of profitable logging companies operated at a 1%-3% profit margin. In most instances, the price paid for delivered wood has not kept pace with inflation over the past 10 years, while all costs (fuel, labor, equipment, insurance) have increased more rapidly than the Consumer Price Index (CPI) inflation rate.

Many forest landowners and mills subscribe to forest certification programs that require specific training and practices of the logger. Much of the implementation and expense of achieving these initiatives is primarily borne by the logger in the name of sustainability, without any tangible benefit offsetting their cost, realizing any market gain, or stability. Sustainability is important for the future of the forests and the timber industry, with certification programs emphasizing “Sustainable Supply Chains.”

We do not see the same landowner or mill focus on the sustainability of the logging and trucking suppliers.

32 l JULY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

A discrepancy in the “certification criteria” is the requirement to “use written agreements for the purchase of raw material.” While this may be practiced between landowners and procurement entities, it is only figuratively practiced between loggers and facilities. The latter “agreements” volume and price can, and is, changed at the discretion of the facility. There are few if any “binding” agreements between loggers and end users. This limits longterm investment security and business practices.

Current standards have demonstrated a failure to ensure that sufficient attention to supply chain sustainability exists and is maintained across all sectors of the timber and forest products industry.

Certification programs must include logging sector sustainability requirements if they are legitimately concerned about the long-term sustainability of healthy forests. Incorporating “fair trade” verifiable requirements for the service contractors in the certification process will fill a gap in the current sustainability criteria of forest and product certification programs.

Without the logger and trucker, the landowners cannot harvest their

timber and realize the return on their investment. Without wood, the forest products industry cannot produce the products that generate income and profit. The logging and trucking industry values its key role in the timber and forest products supply chain. But, as has been demonstrated, the chain must be strengthened to ensure this link does not continue to weaken and eventually break. Without the logging and trucking sector, there would be no supply-chain connection between the forests and forest products mills.

Certification programs are the thread that stitches these sectors together. Certification programs need to ensure that all sectors of the timber and forest industry supply-chain are considered essential components to meet sustainability and certification objectives. Otherwise, forest sustainability will fail across all sectors, and “certification” programs will have proven ineffective in ensuring healthy, sustainable forest management.

Originally written for the Louisiana Loggers Council & Louisiana Forestry Assn. Scott Dane is Executive Director of the American Loggers Council. ALC is a 501(c)(6) trade association representing the interests of timber

harvesting and timber hauling businesses across the United States. For more information visit www.amloggers.com.

Paper Markets Going Through Big Changes

Pulp, paper and containerboard producers are undergoing a shift in infrastructure and product focus that’s resulting in big impacts to fiber demand and currently hitting loggers hard in the procurement areas surrounding such wood consuming facilities.

The pulp and paper segment is continuing to adjust to declines in demand for publishing paper and other print media as more people work from home. There’s also been a drop in demand for shipping and packaging paper products, reversing the skyrocketing demand for packaging at the height of the COVID pandemic when traditional retailers were closed, leading to a boom in online shopping.

A comprehensive report in Fastmarkets RISI’s early June North American Woodfiber & Biomass Markets by Chris Lyddan notes that across 30 pulp-paper industry sites

since 2020, outright closures and displacement through expansion that’s utilizing mostly recycled fiber have had a huge impact:

“Altogether, an estimated six million tons of finished product, perhaps 20 million tons of chips, has so far shut either permanently or indefinitely across nearly 30 mill sites, large and small, recycled and virgin,” he says.

Closures just announced this year include WestRock at North Charleston, SC; Pactiv Evergreen at Canton, NC; Cascades in Niagra Falls, NY; and Graphic Packaging in Tama, Ia. And those closures don’t count the unscheduled downtime, reduced operations and indefinite closures.

Huber Landing Next OSB Mill In Southeast

Huber Engineered Woods LLC (HEW), a subsidiary of J.M. Huber Corp., plans to build a new oriented strandboard (OSB) facility in Shuqualak, Noxubee County, Miss. The plant will increase the company’s production of its ZIP System and AdvanTech structural panels, while providing more than 150 direct new jobs.

Southern Loggin’ Times l JULY 2023 l 33

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

“After considering multiple locations for what will be our most efficient and sustainable facility, we have decided to invest in and partner with Shuqualak, Mississippi, and the broader Noxubee County region,” HEW President Brian Carlson comments. “We will build a world-class workforce by leveraging the diverse talent in the surrounding communities. In line with our commitment to sustainability and environmental stewardship, we have already started our permitting process in Mississippi.”

The Shuqualak location will be HEW’s sixth OSB mill in the U.S.

“Huber Engineered Woods is committed to meeting demand for customers, and we are excited to do so in a state with a rich history of sustainable forestry and wood products manufacturing,” Carlson adds. “Our mill will create a market for the abundant supply of smaller diameter timber, creating environmentally focused efficiencies.”

The new facility, reportedly a $418 million investment, will be located on 551 acres and will feature some of the most advanced processes and technologies available for manufacturing operations. Initiation of project construction is pending various federal, state and local permits as well as economic development incentive approvals and/or processes.

Mississippi Development Authority is providing assistance for infrastructure needs. MDA also certified the company for the Advantage Jobs Rebate Program, which is designated for eligible businesses that create new jobs exceeding the average annual wage of the state or county in which the company locates or expands.

Conway CLT Plant Is Back On Track

Mercer International Inc. and its subsidiary Mercer Mass Timber, a manufacturer of timber building materials, completed the acquisition of Structurlam Mass Timber Corp. and its subsidiaries in mid-June.

Mercer Mass Timber immediately takes possession and continues the operation of Structurlam’s manufacturing facilities, which will now operate under the Mercer Mass Timber brand, including a new production facility in Conway, Ark. and in Penticton, British Columbia, Can.

At the end of May, Mercer International received Bankruptcy Court approval of the acquisition for $81.1 million. Structurlam had filed for bankruptcy earlier this year.

The Conway facility is a modern, state-of-the-art manufacturing facility that was built in 2021 and has an annual capacity of approximately 75,000 m3; can produce both glued laminated timber (glulam) and cross-laminated timber (CLT); includes more than 280,000 sq. ft. of manufacturing space; and is strategically located in the Southern U.S. in proximity to growing construction markets and with access to a large and high-quality regional wood basket.

The purchase also includes three facilities located in British Columbia with a combined annual capacity of 40,000 m3 of glulam and CLT.

These assets complement Mercer’s existing Mercer Mass Timber facility in Spokane Valley, Wash.

A local paper in mid-June reported that the Conway facility had resumed production and will

increase its pace as the order file heats up.

Mercer International Inc. is a global forest products company with operations in Germany, U.S. and Canada with consolidated annual production capacity of 2.3 million tonnes of pulp, 960MMBF of lumber, 210,000 thousand m3 of cross-laminated timber, 45,000 m3 of glulam, 17 million pallets and 150,000 metric tons of wood pellets.

Caribou Purchases StumpGeek Software

Caribou Software, a forestry software company that services more than 300 timber companies across North America, announced its acquisition of the StumpGeek forestry software system to extend its product offering to smaller logging contractors and sawmills.

“Over the years, we’ve spoken to many, many logging contractors and small sawmills who move 10 to 30 loads a week and need a simple way to pay trucking subs and ensure they are receiving payment for all their loads, but they don’t need the full capabilities of our Logger’s Edge and Cutting Edge systems,” says Teresa Hannah, President and Co-Founder of Caribou. “StumpGeek allows us to assist those smaller, simpler companies at a price point that works for their budget.”

The StumpGeek product was designed by Wesley Bushor, a logging contractor in Wisconsin, who wanted a better system than the interlinked spreadsheet he had developed over his 30 years of harvesting timber to keep up with his own log-

ging business. He partnered with a professional software developer, and the two of them first launched StumpGeek into the market in 2015. StumpGeek’s existing client base is mostly centered in the Midwest, but it also encompasses companies in Arkansas, Maine, New Hampshire, Oregon, West Virginia and Mississippi.

In addition to tracking production volumes, revenue and payments associated with load tickets, StumpGeek also has a “Work Log” for tracking things like truck mileage, fuel costs, road-building hours, and other types of non-load-based work. It even has a “Money Log” that serves as an electronic checkbook.

International Names Waters Top Dealer

International Truck announced Mississippi-based Waters Group as the 2022 North American Truck Dealer of the Year. The award recognizes the top International Truck dealer for commitment to provide industry-leading uptime and unparalleled performance in customer satisfaction, annual sales, service and community involvement.

David Waters and Vaughan Waters were in attendance to accept the award. “Waters Group has a customer-first mindset that Navistar values in our dealers and they have forged phenomenal relationships with local fleets, resulting in notable sales numbers,” says Jeff Felix, group vice president, Dealer Sales and Operations. “Because of their rich legacy, community involvement and family-oriented business model, we are proud to have them as one of the many successful dealerships in our vast dealer network.”

Waters Group operates seven locations and employs more than 300. The Waters family acquired the International franchise in 1938 when Ray Waters Sr. founded the company in Columbus, Miss. Now 85 years later, the company is family owned by third and fourth generation family members: Mike, ML, and David Waters and their sons Michael, Josh, and Vaughan Waters, respectively.

“A core goal of our company and a stated Waters family value is to achieve B.O.B. Excellence (best of the best) in all we do,” says David Waters. “This is a goal we set for each and every team member throughout our company. This was a tremendous team effort by all our employees and vendor partners that has allowed the Waters Group to be recognized. Most importantly, we appreciate our customers having faith and trust in us to serve their transportation needs.”

34 l JULY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

In 2022, Waters Group delivered more than 500 units to customers, sold nearly $21 million in parts, and all dealer locations received “Prestige Standards” certification for customer service.

Adamres Plans Housing Factory In Georgia

ADMARES, which specializes in industrialized manufacturing of buildings and homes, plans to construct its first U.S. manufacturing facility in Waycross, Ga. The company expects to create more than 1,400 jobs and invest $750 million in Ware County.

ADMARES originates from Turku, Finland and specializes in the mass production of buildings using proprietary technology. Currently, the organization is in the process of relocating its headquarters to the U.S. while continuing to leverage its innovative technology. The company’s buildings have been used in both the residential and hospitality sectors.

Mikael Hedberg, Founder and CEO of ADMARES, comments, “With the rise of modern industrialization practices, we have combined our expertise to create a revolutionary robotic-driven manufacturing process that allows entire buildings to be manufactured at a factory rather than on a traditional construction site. With our advanced technology, we are adopting successful practices that are common in other advanced industries.”

Hedberg adds that Waycross is an ideal location for a transportation hub with easy access to major highways and extensive rail connections. Its proximity to the Port of

Brunswick, one of the busiest ports on the Eastern seaboard, offers a competitive advantage for global trade.

ADMARES has selected a greenfield site to construct a 2.5 million sq. ft. build-to-suit facility located along Highway 23. The manufacturing facility will specialize in producing buildings for the housing sector and is expected to begin production in late 2025.

Ponsee Looks Ahead To Fossil-Free Steel

SSAB and Ponsse Plc have joined forces in a partnership in which SSAB will deliver fossil-free steel to Ponsse gradually beginning in 2026. This partnership will further solidify Ponsse’s position as a provider of sustainable forest machines and bring SSAB closer to its goal of establishing a fossil-free value chain.

“Our products and services will play a crucial role in assisting our customers in achieving their climate objectives during the transition to a low-carbon economy. Our Ponsse EV1 forwarder concept with completely electric drive and our partnership with SSAB regarding fossilfree steels will lead our development towards carbon neutral forestry,” says Juha Inberg, Chief R&D and Technology Officer, Ponsse Plc.

SSAB aims to deliver fossil-free steel to the market at a commercial scale during 2026 and to largely eliminate carbon dioxide emissions from its operations in around 2030. SSAB works with iron ore producer LKAB and energy company Vattenfall as part of the HYBRIT initiative

to develop a value chain for fossilfree iron- and steelmaking, replacing the coking coal traditionally used for iron ore-based steelmaking

with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxide-emissions in steel production.

Southern Loggin’ Times l JULY 2023 l 35

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

High Risk While Securing A Load

BACKGROUND: On a clear spring day in the Appalachians, a timber harvesting operation was actively working. The loader operator was engaged in loading a tractor-trailer with two bunks of 20' pulpwood. The first bunk was loaded, and the loader operator began to load the second bunk.

PERSONAL CHARACTERISTICS: The loader operator was in his early 50s and had been working in the logging industry for over 30 years. The contracted truck driver was also in his 50s and had been hauling wood for several years. It is unknown what formal safety training either of the workers had.

UNSAFE ACT: The front bunk had been loaded, and the truck driver approached the truck on the far

side of the trailer and began to unroll his tie-down straps. The loader operator could not see the driver and wasn't aware that he had walked close to the trailer. The driv-

er wasn't wearing a hardhat or other safety equipment.

CLOSE CALL: The company forester, arriving on to the job,

observed the situation. He saw the grapple, full of wood, carried high over the trailer while the driver was busy working on the opposite side. The forester moved quickly to get the loader operator's attention and stopped the loading process. No accident occurred, but the situation presented a high risk. If the wood had slipped or a hydraulic line broke, there could have been a serious injury or fatality.

INJURY: None. The owner of the crew was grateful that the forester intervened.

RECOMMENDATIONS FOR CORRECTION:

l Always wear the proper PPE in the landing area and the woods.

l Never assume an operator knows where you are.

l Always make eye contact with the operator and communicate that it is safe to approach the area.

l Establish universal hand signals between crew members when voice commands can't be heard.

l Always move the truck away from the loader and in a safe place before securing the load.

36 ● JULY 2023 ● Southern Loggin’ Times

Supplied by Forest Resources Assn.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Air Burner’s CharBoss

things, such as material and stock management, procurement, sales, deliveries, field work control and maintenance, invoicing. It will also be used for aftersales processes, such as spare parts sales and maintenance.

CharBoss, the world’s first mobile onsite biochar production system, has arrived. Air Burners partnered with the USDA Forest Service to boost the environmentally-friendly technology while adding power and speed to the new selfcontained CharBoss. The fully assembled above-ground air curtain burner system is an advanced pollution-control device scientifically proven to eliminate wood waste 40x faster than open burning and significantly reduces particulate matter, like black carbon smoke, to help mitigate climate change.

CharBoss accepts whole trees, logs, root balls, slash piles, invasive shrubs, and other unwanted biomass debris. It burns 1 ton per hour, leaving behind 20% biochar, a valuable carbon-rich residual to sell or return to the soil. The towable CharBoss is ideal for hard-to-reach remote areas, like forest thinning, land clearing, and disaster cleanup (recovery). Orchard growers and farmers turn to the CharBoss to maneuver in and out of tight spaces without damaging crops or equipment.

After a successful debut at the University of Idaho Experimental Forest in January 2023 and a biochar production demonstration in Harrisonburg, Va., the world’s first mobile onsite biochar production system is ready to tackle even the most challenging, most demanding jobs with no grinding, hauling, or permanent facilities. Visit airburners.com.

Ponsse Global ERP

Ponsse continues to utilize technology to develop its operations and has invested in a new, global ERP solution. Customers will receive even better service than before and in a more efficient way when the solution streamlines and automates processes.

The new ERP solution has already been successfully implemented in Ponsse’s Swedish and Norwegian subsidiaries. Particular attention has been paid to the user experience, and all functions can be used anywhere in the world, with any device.

ERP is being used for a number of

Following a thorough selection process, Ponsse chose the Microsoft Dynamics 365 complemented by the Annata 365 designed for the manufacturing and distribution industry of vehicles and heavy machinery. The solution will be delivered to Ponsse by Fellowmind, which has plenty of experience in ERP solutions for the manufacturing industry. Visit ponsse.com.

Rottne E-Cabin

The new E-Cabin from Rottne is a testament to innovative engineering, where an outstanding cabin has become even better, with a focus on enhanced ergonomics and functionality. Integrated screens on the control panels and additional buttons on the joysticks make the work environment more flexible and efficient. Beneath the panels lies a completely new control system that complies with all laws, standards, and regulations.

“We have devoted a lot of time to optimizing driver comfort, button placements, and functionality. All the buttons required to operate and work with the machine are now on the palettes, creating an optimal work environment for you as the driver,” explains David Selstam from Rottne's development department.