CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Hatton-Brown Publishers, Inc.

Street Address: 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address: P.O. Box 2268

Montgomery, AL 36102-2268

Telephone: 334.834.1170

FAX: 334.834.4525

Publisher: David H. Ramsey

Chief Operating Officer: Dianne C. Sullivan

Editor-in-Chief: Rich Donnell

Senior Editor: Dan Shell

Senior Editor: David Abbott

Senior Editor: Jessica Johnson

Publisher/Editor Emeritus: David (DK) Knight

Art Director/Prod. Manager: Cindy Segrest

Ad Production Coordinator: Patti Campbell

Circulation Director: Rhonda Thomas

Online Content/Marketing: Jacqlyn Kirkland

Classified Advertising:

Bridget DeVane • 334.699.7837

800.669.5613 • bdevane7@hotmail.com

Advertising Sales Representatives:

Southern USA

Randy Reagor

P.O. Box 2268

Montgomery, AL 36102-2268

904.393.7968 • FAX: 334.834.4525

E-mail: reagor@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

29 Bugelli Drive

Whitby, Ontario, Canada L1R 3B7

905.666.0258

E-mail: jsimmons@idirect.com

Western USA, Western Canada

Tim Shaddick

4056 West 10th Avenue

Vancouver BC Canada V6L 1Z1

604.910.1826 • FAX: 604.264.1367

E-mail: twshaddick@gmail.com

Kevin Cook

604.619.1777

E-mail: lordkevincook@gmail.com

International Murray Brett

58 Aldea de las Cuevas, Buzon 60

03759 Benidoleig (Alicante), Spain

Tel: +34 96 640 4165 • + 34 96 640 4048

E-mail: murray.brett@abasol.net

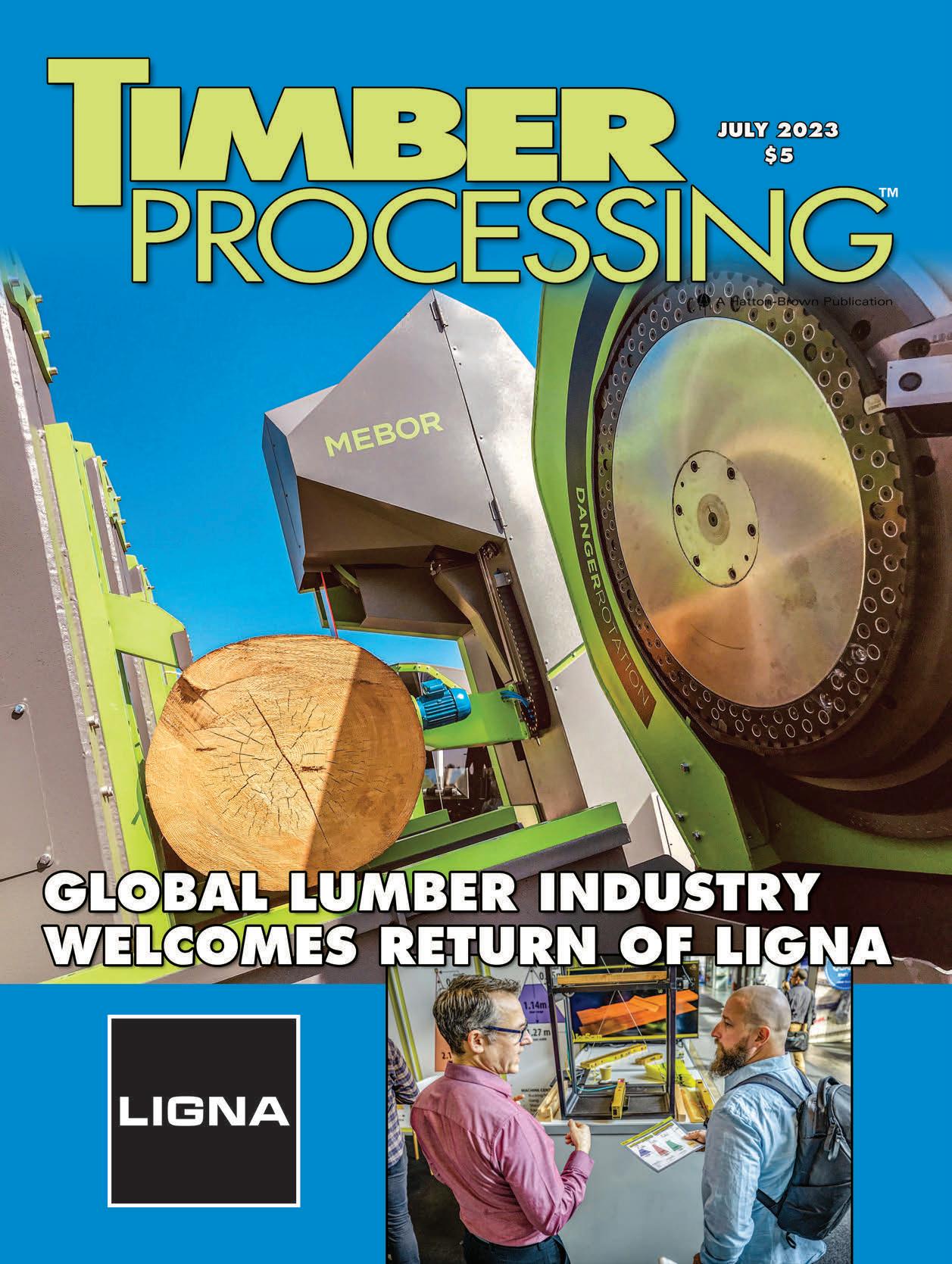

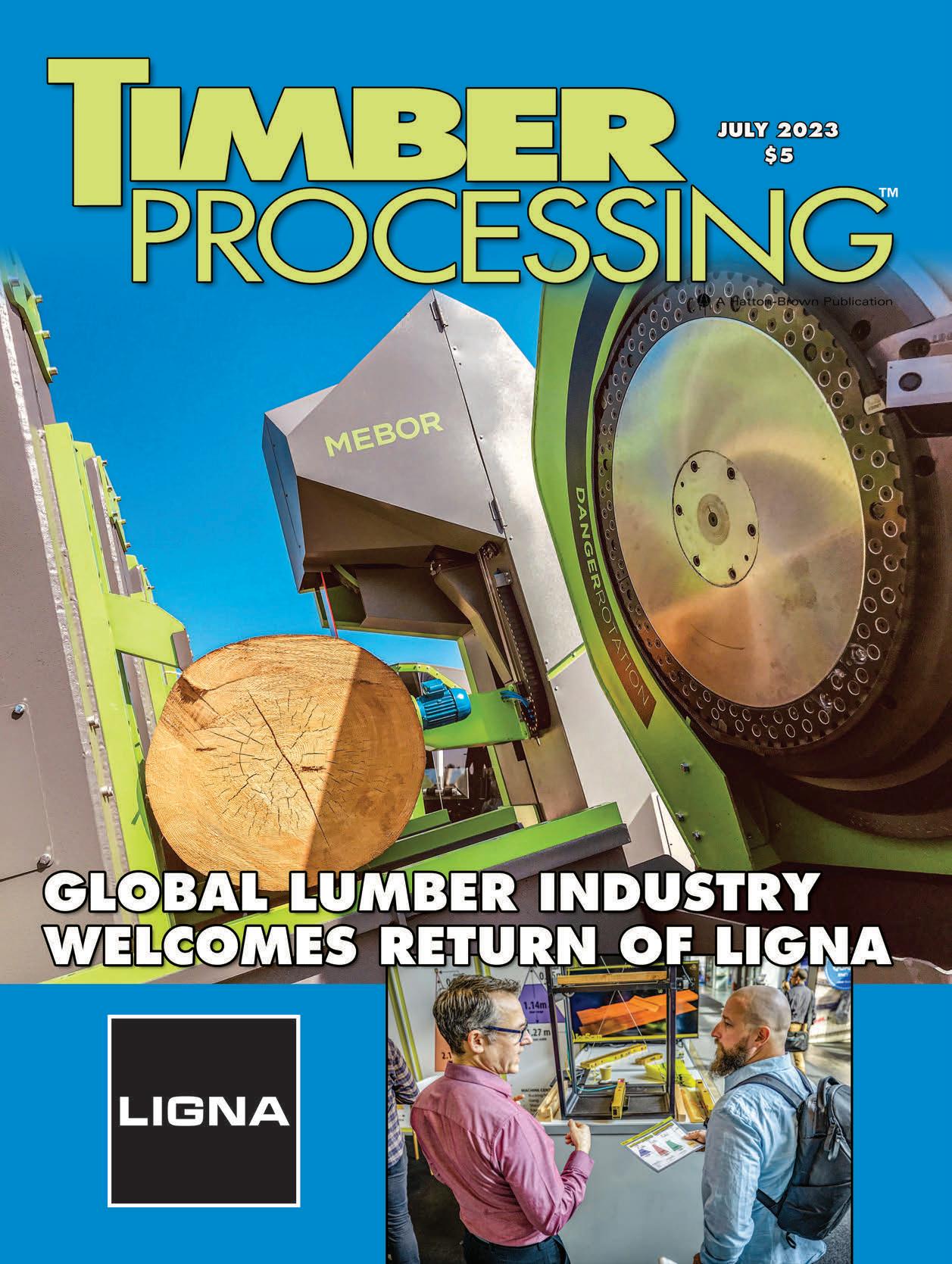

COVER: The Ligna trade show in Hannover, Germany was back to its� normal self following a brief pause due to the pandemic. PAGE 20. (Rich Donnell photo of Mebor outside exhibit; inset photo of JoeScan booth, Koval Digital)

VISIT

Timber Processing (ISSN 0885-906X, USPS 395-850) is published 11 times annually (monthly except Jan./Feb.) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—TP is free to qualified owners, operators, managers, purchasing agents, supervisors, foremen and other key personnel at sawmills, pallet plants, chip mills, treating plants, specialty plants, lumber finishing operations, corporate industrial woodlands officials and machinery manufacturers and distributors in the U.S. All non-qualified U.S. Subscriptions are $55 annually: $65 in Canada; $95 (Airmail) in all other countries (U.S. Funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries— TOLL-FREE: 800-6695613; Fax 888-611-4525. Go to www.timberprocessing.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Timber Processing magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorse nor makes any representation or guarantee as to the quality of goods and services advertised in Timber Processing. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed in U.S.A.

Postmaster: Please send address changes to Timber Processing, P.O. Box 2419, Montgomery, Alabama 36102-2419

Other Hatton-Brown publications: Timber Harvesting • Southern Loggin’ Times Wood Bioenergy • Panel World • Power Equipment Trade

Volume 48 • Number 6 • July 2023 Founded in 1976 • Our 497th Consecutive Issue NEWSFEED Robbins Lumber Expands Sawmill Operations

6 LIGNA 2023 New Sawmill Technology Was Everywhere 20 LOGGERS’ MINDSET Challenges Aplenty In The Woods 34 BYPRODUCTS Waste Not Want Not 30 MACHINERY ROW J.D. Irving’s New Investment 38 AT LARGE Hancock Lumber Turns A Mere 175 44 MAIN EVENTS SFPA Expo Is Up Next 54 Renew or subscribe on the web: www.timberprocessing.com A Hatton-Brown Publication

OUR WEBSITE: www.timberprocessing.com

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Dan Shell Senior Editor

THE LOGGER SUPPLY CHAIN STRAIN

During the Southern Forest Products Assn.’s educational sessions at the 2021 event, longtime sawmiller and consultant Huey Long noted that early in his career, one of his mentors said that to help maintain perspective, it’s important to always keep a basic line chart graph showing 20 years of lumber prices on your office wall.

These days, that advice may be as important as ever as lumber prices have fallen from all-time 2021-2022 highs to what looks like relatively “normal” (whatever that might be) prices coming on the heels of interest rate increases that have cooled housing markets, at least until housing surged again May.

The big zig-zags in the lumber price chart the past four years come more than a decade after the “Great Recession” and the lowest lumber prices since the Great Depression.

And just as lumber producers have adjusted operations to changing markets, so have timber harvesting companies, as noted in the report on the 2023 Timber Harvesting Logger Survey on page 34. Our affiliate magazine, Timber Harvesting, has conducted an annual loggers’ survey for years, and we thought it would be of interest to show of those results in Timber Processing

We made a point of comparing the ’23 survey results to those of 2019, before the pandemic and how operations are faring now. One of the interesting data points was a slide toward less profitability for loggers in the past four years, as the percentages of loggers reporting pre-tax margins in several categories dropped significantly.

As a result, the percentage of loggers who rated their business health as “very good” was cut in half from 2019 to 2023, and the percentage of loggers who rated business health as “poor” or “very poor” more than doubled.

This has led to a downsizing in number of crews as a result of lower profitability and labor issues.

It’s important to remember that while loggers have sacrificed and worked through the pandemic, as did sawmill operations, those logging businesses experienced nothing even remotely like what sawmillers did with forest products price run-ups that enabled key investments and built up cash reserves.

And those hot building products markets have now been followed by inflation that’s affected every nook and cranny of business. Unable to recoup rising costs, for a logging company there’s little way to react outside of pulling back, changing direction or finding something else to do.

Labor is also a huge concern for loggers, and is a key to sustaining a healthy supply chain. Only 25% of those who responded say they are able to offer health care, which is huge if you want to build a stable payroll.

As one logger says: “If the industry wants to attract new people, we have to be able to offer health care, and the money has to come from somewhere.”

This isn‘t to point fingers: Loggers’ health care and profitability issues aren’t the absolute responsibility of wood-consuming organizations, though much to their credit some manufacturers don’t shy away from it. But if certain supply chain viability issues aren’t resolved, such problems have a way of spreading.

Contact Dan Shell,

20 30 34 44 THEISSUES

TP

ph: 334-834-1170; fax 334-834-4525; e-mail: dan@hattonbrown.com TIMBER PROCESSING ■ JULY 2023 ■ 5 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ROBBINS ACQUIRES MAINE SAWMILLS

Robbins Lumber, Inc., based in Searsmont, Maine, has acquired two sawmills from Pleasant River Lumber Co., expanding the company’s footprint from two locations to four locations. The sawmills in Hancock and Sanford, Maine will retain all 74 employees between the two locations. The company says the acquisition will allow it to build upon its eastern white pine production, which the company already produces at existing locations in Searsmont and East Baldwin.

“Robbins Lumber is recognized for its quality products, safety and great employees,” says co-owner Catherine Robbins-Halsted. “The addition of these two sawmills along with more than 70 new members of the Robbins Lumber team will not only grow this company’s ability to produce, but it will also grow this company’s reputation throughout the region.”

Robbins Lumber is coowned by Catherine and her siblings Jim and Alden Robbins. They are the fifth generation of the family to own and manage the operation, which has been in business for more than 140 years.

“This acquisition is a game changer,” Jim Robbins says. “We are now a four sawmill/ planer mill, biomass power plant, and coatings facility company with an expanded customer base. Our geographic footprint now covers a larger area of our state, and we have a strategic plan to continue investing and growing this business.”

The two acquired sawmills have been renamed to reflect the purchase. The Hancock location will now be known as Robbins Lumber Downeast, LLC, and the Sanford location will be known as Robbins Lumber Sanford, LLC.

“These two locations will

help to make Robbins Lumber even better, and even stronger,” Alden Robbins adds. “We are very proud of our existing workforce, and adding the new members of our Robbins Lumber family to the mix will only add to the company’s exceptional reputation, customer service, and work ethic. To put it simply, this is an exciting time for Robbins Lumber.”

Frank and Otis Robbins opened the first Robbins Lumber stave mill in 1881 on the St. George River. Today, Robbins Lumber, Inc. owns and manages 30,000 acres of its own forests and buys logs from more than 150 independent loggers. Headquartered in Searsmont with a milling operation on a 40 acre site, Robbins Lumber’s main location includes a 8.5 MW cogeneration plant, a computerized sawmill, planing mills, and 70,000 sq. ft. of warehouse space.

With the addition of the Hancock and Sanford locations, Robbins Lumber now employs 250 throughout its four locations.

Having divested these two sawmills and its Moose River Lumber mill in Jackman, Maine, Pleasant River Lumber now owns and operates two sawmills—at Dover-Foxcroft and Enfield—multiple log purchasing yards, two saw filing shops, and a trucking company spread out across Maine. The SPF mills’ current capacity is 300MMBF annually.

CONWAY CLT PLANT IS BACK ON TRACK

Mercer International Inc. and its subsidiary Mercer Mass Timber, a manufacturer of timber building materials, completed the acquisition of Structurlam Mass Timber Corp. and its subsidiaries in mid-June. Mercer Mass Timber immediately takes possession and continues the operation of Structurlam’s manufacturing facilities, which will now operate

under the Mercer Mass Timber brand, including a new production facility in Conway, Ark. and facilities in Penticton, British Columbia, Can.

At the end of May, Mercer International received Bankruptcy Court approval of the acquisition for $81.1 million. Structurlam had filed for bankruptcy earlier this year.

The Conway facility is a modern, state-of-the-art manufacturing facility that was built in 2021 and has an annual capacity of approximately 75,000 m3; can produce both glued laminated timber (glulam) and cross-laminated timber (CLT); includes more than 280,000 sq. ft. of manufacturing space; and is strategically located in the Southern U.S. in proximity to growing construction markets and with access to a large and high-quality regional wood basket.

The purchase also includes three facilities located in British Columbia with a combined annual capacity of 40,000 m3 of glulam and CLT.

These assets complement Mercer’s existing Mercer Mass Timber facility in Spokane Valley, Wash.

“We are thrilled to welcome Structurlam into the Mercer Mass Timber fold,” says Brian Merwin, Senior Vice President of Mercer Mass Timber. “This acquisition will allow us to offer our customers a wider range of mass timber products, and to better support their projects with the addition of more cross laminated timber (CLT) capacity and glulam production capabilities. Our goal is to become a one-stop shop for all mass timber needs. The additional manufacturing facilities that the Structurlam acquisition brings will enable us to create greater efficiencies.”

A local paper in mid-June reported that the Conway facility had resumed production and will increase its pace as the order file heats up.

Mercer International Inc. is a global forest products com-

pany with operations in Germany, U.S. and Canada with consolidated annual production capacity of 2.3 million tonnes of pulp, 960MMBF of lumber, 210,000 thousand m3 of cross-laminated timber, 45,000 m3 of glulam, 17 million pallets and 150,000 metric tons of wood pellets.

SCHILLINGER IS NEW HAMPTON CEO

Hampton Lumber named Randy Schillinger as CEO, following the retirement of Steve Zika, who had served as CEO at Hampton since 2003. Zika assumes a position as Vice Chairman of the Hampton Board.

Schillinger has more than 25 years of experience in the Pacific Northwest wood products industry. He began his career with Weyerhaeuser in 1998 where he provided strategic planning and analysis before moving to their Trus Joist Engineered Wood Products division, where he worked on sales and operations planning and manufacturing. He joins Hampton from Pacific Woodtech Corp., where he most recently served as Chief Operating Officer. Pacific Woodtech manufactures engineered wood products such as beams, headers and studs.

Schillinger grew up in the forest sector and was raised in Washington’s Cowlitz Valley, where Hampton has operated mills since 1999. He received his undergraduate degree from Washington State University and holds an MS in Forest Economics from Oregon State University and an MS in Agricultural Economics from the University of Illinois.

“Randy has demonstrated experience in the Pacific Northwest wood product industry and is well equipped to guide Hampton into the future,” says Board Chairman Eric Schooler. “He shares the Hampton family’s commit-

NEWS

6 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ment to continuous improvement, innovation, employee health and well-being, and community.”

Zika is assisting with the transition in the coming months. “Over the past two decades, Steve has fostered a culture of continuous improvement at Hampton,” Schooler says. “He shepherded the company through the challenges of a Great Recession and a global pandemic and cemented Hampton’s reputation as a highly respected and community-minded member of the forest sector.

“On behalf of the Board and the Hampton family, I want to express our profound thanks to Steve for his leadership over the past 20 years. We are thrilled to welcome Randy to the executive team and look forward to this exciting new chapter for the company.”

Hampton Lumber is a

fourth-generation, familyowned company headquartered in Portland, Ore. Hampton operates 10 sawmills in Oregon, Washington and British Columbia. Hampton also manages a wholesale and export division and numerous reload and remanufacturing facilities throughout the U.S.

TIMBERLAB OPENS GLULAM FACILITY

Timberlab, a nationwide provider of mass timber systems, is opening its second glued laminated timber fabrication facility in Greenville, SC. Timberlab’s goal is to provide the Eastern U.S. with a more regional platform for a sustainable, low-carbon building material and accelerate the mainstream adoption of mass timber construction to benefit the planet and its people.

The newly renovated 75,000 sq. ft. East Coast facility began operations in April and expects to be at full capacity by the second quarter of 2024. Staffed by 30 manufacturing and timber professionals, the Timberlab facility is the largest of its kind planned in the region, according to the company. The facility is equipped to produce an estimated 1MMSF annually once at full capacity.

“Greenville was selected due to its close proximity to an abundance of southern yellow pine that is durable, renewable, and fast-growing and—mainly because of that—has emerged as the species of choice for producers east of the Mississippi River,” says Manufacturing Director Jared Revay. “There are a significant number of glulam producers throughout the Southeast who need a valueadd partner, like Timberlab, in order to fully participate in the

commercial, prefabricated mass timber industry. As we saw in the Pacific Northwest, our Eastern U.S. manufacturing center is expected to positively impact the Southeast with an expanded supply chain.”

The company notes that in the past five years, the number of projects incorporating mass timber has doubled every two years, and this trend is expected to continue for the next 15 years. Timberlab expects the adoption rate in key areas along the Eastern seaboard to outpace this projection. Glulam columns and beams for the University of Arkansas’ Institute for Integrative and Innovative building in Fayetteville, Ark. will be the first components fabricated in the East Coast facility.

“There is an existing network of timber suppliers and glulam manufacturers in the

NEWS

8 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

Southeast that have been operating for decades with limited opportunities to deploy their product,” says Timberlab President Chris Evans. “The CNC fabrication is currently the significant pinch point in the mass timber supply chain and where Timberlab will make a tremendous impact not only for suppliers but also in the adoption of this sustainable building system.”

Timberlab opened its first location in Portland, Ore. in 2020 where it produces annually to build an estimated 800,000 sq. ft. of fabricated glulam components. By replicating its successful West Coast business model, the East Coast facility will support the Southeast’s trajectory as a new regional powerhouse for mass timber construction. “Our intention is to expand the supply chain and, thereby, reduce the

cost of mass timber structures, ultimately promoting the deployment of timber for commercial buildings along the Eastern seaboard, particularly in the office, multi-family, civic, and higher education sectors,” Evans says.

In addition to its custom fabrication services, Timberlab also dedicates a team to pursue mass timber innovation and research. The firm partners with Clemson University and other universities as well as the U.S. Forest Service to advance the adoption of mass timber construction. Areas of focus have included fire testing, vibration testing, and seismic load testing for tall timber buildings.

Timberlab expects to tap local trade schools, community colleges, and universities to fulfill job opportunities, offering new career paths in engineering and fabrication. The company will employ up to 30

prefabrication and shop technicians, CNC machinists and programmers, and operations positions. In addition to engineers and fabricators, Timberlab’s robust construction crews travel nationally to install the firm’s mass timber structures. “A key to our success in this industry is that our team is vertically integrated,” Revay adds.

Timberlab evolved from Swinerton, a leading general contractor with offices across the country and early adopters and innovators of mass timber construction.

STORA ENSO PLANS BIG RESTRUCTURING

Stora Enso is planning restructuring actions to strengthen the Group’s long-term competitiveness, improve profitability and focus capital allocation in strategic growth mar-

kets. Stora Enso is also taking the next step in driving a decentralized operating model targeting increased customer centricity, business focus and cost reductions. The planned restructuring actions, combined with previously initiated negotiations in the Packaging Materials division, would result in total reductions of 1,150 employees.

Stora Enso plans to permanently close down its Sunila pulp production unit in Finland, the De Hoop containerboard site in the Netherlands, one containerboard line at its Ostrołeka site in Poland, and the Näpi sawmill in Estonia.

“These measures are of course very difficult and would not be proposed unless it was absolutely necessary for our long-term competitiveness,” says Annica Bresky, Stora Enso President & CEO. “We are at a critical juncture

10 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

in our strategy advancement, and to further our market position an increased focus on capital allocation and decentralized empowerment is needed. This sadly means that assets suffering from challenged profitability would need to be closed, in combination with a more streamlined headquarter organization. Through these actions we would be able to continue to deliver strategic growth from a more resilient and cost-efficient business platform, better equipped to support the long-term growing demand for Stora Enso’s renewable products.”

Stora Enso will start negotiations with employees at its Sunila pulp production unit to permanently cease pulp production and lignin extraction. The Finnish wood market has been structurally impacted by increased competition for pulp wood and stopped wood im-

ports from Russia. Under these new conditions, resulting in significantly higher wood costs, the Sunila site is no longer cost-competitive.

The site has an annual capacity of 375,000 tonnes of long-fiber pulp, employing approximately 270. The planned closure would take place during the second half of 2023 and affect an estimated 250 employees, decreasing Stora Enso’s annual market pulp capacity by 13%.

The Group’s strategy for developing biomaterial innovations remains unchanged. The pilot facility for hard carbon-based battery material continues to operate at the Sunila site. A feasibility study for lignin extraction has been initiated at Stora Enso’s Skutskär pulp production site in Sweden. The Group also continues to develop other sourcing alternatives, including

partnering, for long-term lignin supply, and to investigate competitive locations for commercial scale up of hard carbon, Lignode, production.

As a consequence of the overcapacity in the European containerboard market, Stora Enso is proposing to permanently close down both production lines at the De Hoop site in the Netherlands and one of the four production lines at its Ostrołeka site in Poland. These planned closures would enable an improved market balance for containerboard volumes, thus benefiting Stora Enso’s supply from larger and more cost-efficient production sites.

Stora Enso plans to close down its Näpi sawmill in Estonia due to reduced long-term raw material availability, increased wood costs and low profitability. Stora Enso plans to improve the competitiveness

of its total wood products business by focusing on the sawmills with strategic growth opportunities.

The Näpi sawmill has an annual capacity of 50,000 m3 of sawn timber, 180,000 m3 of further processed wood products and 25,000 tonnes of pellets. The planned closure would take place during the fourth quarter of 2023 and directly impact 100 employees in Estonia.

HUBER TAKES ANOTHER SWING

Huber Engineered Woods LLC (HEW), a subsidiary of J.M. Huber Corp., plans to build a new oriented strandboard (OSB) facility in Shuqualak, Noxubee County, Miss. The plant will increase the company’s production of its ZIP System and Advan-

NEWSFEED TIMBER PROCESSING ■ JULY 2023 ■ 11 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Tech structural panels, while providing more than 150 direct new jobs.

“After considering multiple locations for what will be our most efficient and sustainable facility, we have decided to invest in and partner with Shuqualak, Mississippi, and the broader Noxubee County region,” HEW President Brian Carlson comments. “We will build a world-class workforce by leveraging the diverse talent in the surrounding communities. In line with our commitment to sustainability and environmental stewardship, we have already started our permitting process in Mississippi.”

The Shuqualak location will be HEW’s sixth OSB mill in the U.S.

“Huber Engineered Woods is committed to meeting demand for customers, and we are excited to do so in a state with a rich history of sustain-

able forestry and wood products manufacturing,” Carlson adds. “Our mill will create a market for the abundant supply of smaller diameter timber, creating environmentally focused efficiencies.”

The new facility, reportedly a $418 million investment, will be located on 551 acres and will feature some of the most advanced processes and technologies available for manufacturing operations. Initiation of project construction is pending various federal, state and local permits as well as economic development incentive approvals and/or processes.

Mississippi Development Authority is providing assistance for infrastructure needs.

MDA also certified the company for the Advantage Jobs Rebate Program, which is designated for eligible businesses that create new jobs exceeding

the average annual wage of the state or county in which the company locates or expands.

In March, the U.S. Army Corps of Engineers and the Mississippi Dept. of Environmental Quality released a joint public notice for Huber’s application for a permit pursuant to the Clean Water Act, and in May MDEQ released a Large Construction Notice of Intent under the Large Construction General Permit applied for by Huber at Shuqualak.

Huber had planned to build its sixth OSB plant in Cohasset, Minn., but after experiencing constant entanglements in the process from governing authorities, including a Minnesota Court of Appeals decision that would have caused further delay in the construction of the $440 million plant, Huber opted to pull out of the project and begin looking elsewhere.

CANADA FIRES AFFECT MARKETS

What’s being called Canada’s worst-ever spring fire season has torched 9.9 million acres as mills and loggers across the country take extensive downtime as thousands have been evacuated and drifting smoke has blanketed the Northeast U.S.

Blazes have affected forest operations in British Columbia, Alberta and Quebec and forced downtime at dozens of facilities and restricted timber harvesting activities, say officials with the Forest Products Assn. of Canada (FPAC). For example, Resolute Forest Products closed four Quebec sawmills temporarily, and Chantiers Chibougamau was forced to temporarily shut its Nordic Kraft pulp mill in Lebel-sur-Quevillon, Quebec.

NEWSFEED 12 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SAWMILLERS CONV

By Rich Donnell

HANNOVER, Germany

Sawmill machinery and technology companies from around the world turned out in force at the Ligna trade show held May 15-19. They were part of an event that covered the entire range of forest products production, from harvesting and in-woods chipping machinery to primary and secondary wood products manufacturing, as 1,300 companies from 50 countries exhibited, attracting 80,000 visitors from 160 countries, with everyone excited to be there following the missed 2021 event due to the virus.

Dave Purinton, VP Marketing at Burton Solutions, an affiliate of USNR, said Ligna once again proved itself to be a key event for global contacts. Burton Mill Solutions and USNR had adjacent booths.

“It was a wonderful opportunity to connect and re-connect with customers from, literally, across the planet,” Purin-

20 ■ JULY 2023 ■ TIMBER PROCESSING

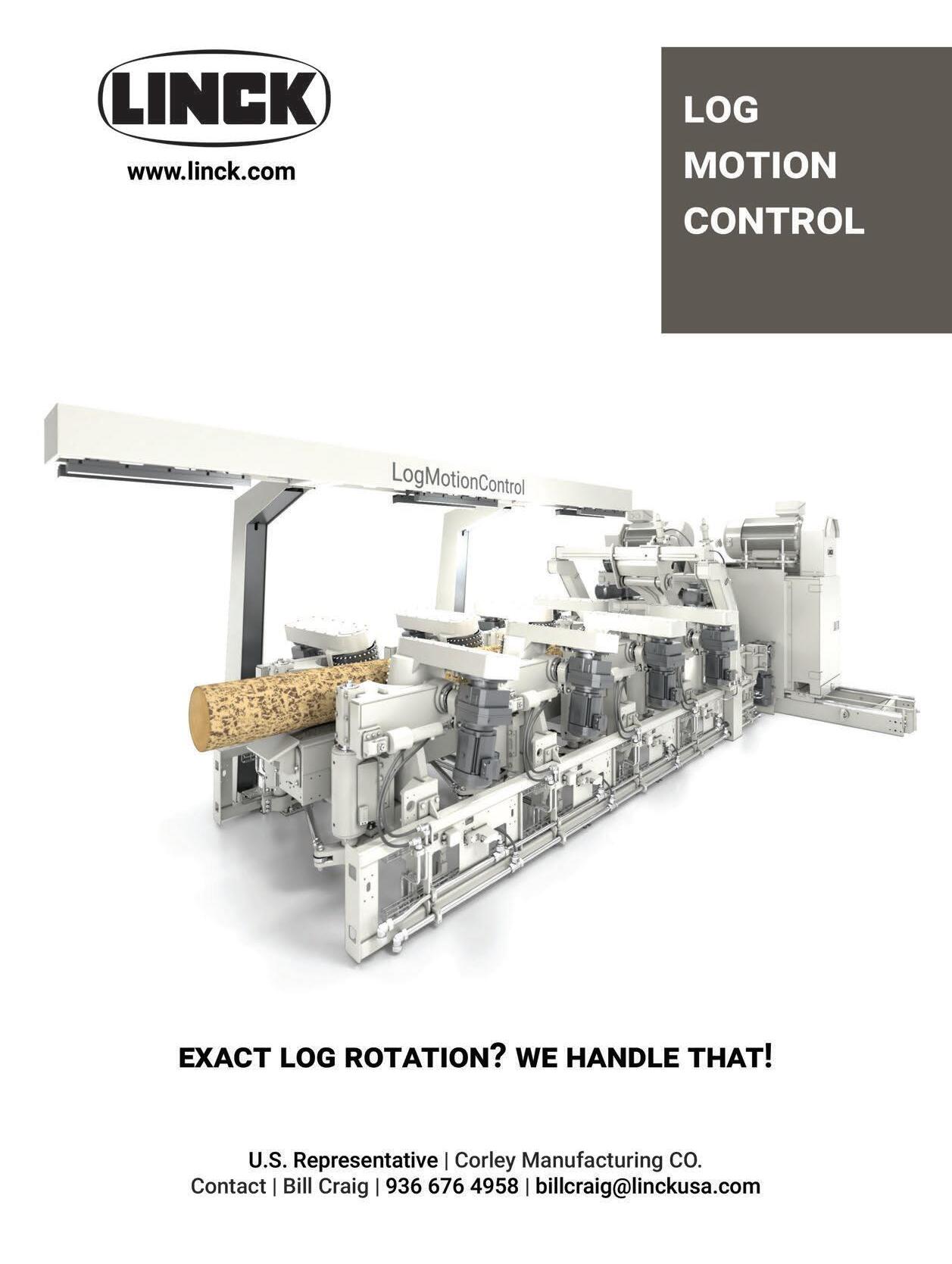

Linck’s exhibit had a modular theme.

USNR put plenty of perspective into its exhibit.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Ligna served to put the pandemic in the rear-view mirror.

NVERGE ON LIGNA

TIMBER PROCESSING ■ JULY 2023 ■ 21

Barton had a colorful log carriage presentation.

Ledinek Stratoplan planer received attention.

EWD bandmill stood tall.

MiCROTEC Goldeneye was front and center.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

They noted that after navigating through several challenging years due to the COVID-19 pandemic, “It was a joyous occasion to experience a ‘normal’ Ligna show once again. The event provided a platform for industry professionals to come together, share valuable experiences and information, and collectively showcase their offerings together. The event has left us energized and inspired as we embark on the next chapter of Springers’ journey.”

The Williams & White Group of Companies exhibited its saw grinding and sharpening machinery adjacent partner German manufacturer, Kohlbacher, with its line of band saw grinding and tipping machines. Riley Kufta, sales and market-

ton said. “We had a wonderful opportunity to introduce customers of each of our businesses to the appropriate contacts within our brother business. Given all that is going on in the world, the sentiment was encouragingly positive and upbeat. Wood fiber processors across the globe are similar to farmers, in that they have an innate optimism in the future and in better times ahead.”

USNR’s two-story Ligna stand included the Bioluma trimmer scanner and VAB scanner, as well as the super fast

Austria-based Springer was extremely busy at its booth and also off-site, as the company hosted an impressive celebration party for its 70th anniversary at Expowal near the show grounds.

Timo and Gero Springer commented, “Ligna proved to be the perfect venue for this milestone, bringing together our partners from around the world. It was a

cess. Customers from all over the world flew in. It was a fantastic show that left us feeling very confident and bullish for the coming years!”

Tris Young, Group Business Development Manager for John King Chains, said visitor interest was high on the company’s press chains, and several praised JK’s British manufacturing capabilities, along with its uprated materials and heat treatments to provide extended service life.

John King’s recent acquisition of DAB Valves and development of bulk/mill master conveyor solutions were well received. “Clients are 100% seeing us as more than just a quality chain manufacturer,” Young said. “They like the fact that they can come to us for holistic solutions, not just products but solutions to improve efficiency of their plants.”

Ledinek was riding high off an order from Rigidply Rafter of Richland, Pa., which is upgrading its existing glulam production capabilities with a new automated glulam manufacturing plant for curved, cambered and straight beams.

The new plant has been developed around the advanced Ledinek cold pressing technology and some of the key com-

Wood-Mizer had the logs coming through.

22 ■ JULY 2023 ■ TIMBER PROCESSING

Sennebogen stood out under blue skies.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Williams & White teamed with Kohlbacher.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ponents include the infeed system for loading into the line, fingerjointing machine Kontizink H 5000, Stratoplan high speed planer, Rotopress glulam press, Hyperpress for curved beams, Flexipress for special beams and columns, XXLCut for customized length cutting, Superles beam planers for L and XXL beam and X-Lam Manager production control software.

Ledinek said the international visitors demonstrated the popularity of its products worldwide. “Our stand was very lively throughout the day, and we would

like to thank all the business partners, students, other exhibitors and guests who visited us, saw our machines on display and spent a pleasant hour with us.”

Mebor, one of the biggest European sawmilling machinery manufacturers, participated with a large stand and presented a wide range of sawmilling machinery from horizontal and vertical band saws to combined board edgers, continuous circular saws, debarking machines and chipper canters. Ten machines were displayed including the premier of the redesigned and upgraded hor-

izontal band saws, HTZ 1300 PLUS and HTZ 1100 PRO. The HTZ 1300 PLUS was presented with an entirely new band saw bed with improved structure and log handling solutions.

Visitors were also able to see Mebor’s new BM chipper canters for applications either in continuous sawing lines or in combination with the VTZ PLUS log carriage.

Mebor’s stand outside welcomed visitors from all over the world who were able to watch over 120 live demonstrations. Mebor reports the number of inquiries ex-

24 ■ JULY 2023 ■ TIMBER PROCESSING

Combilift sold its CSS container loader to Robinson Lumber in the Southern U.S.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Prinz showed how to make the cut.

ceeded the previous Ligna show.

Drying technology specialist Hildebrand-Brunner didn’t have far to travel from its home base in Hannover (the company also has a U.S. office in Nashville, Tenn.). It presented new developments for continuous kilns and introduced the current project of four HCK continuous kilns in Latvia.

The new generation of HCK continuous kilns combine great flexibility and energysaving potential. Versions with several tracks and intermediate heating offer a higher degree of flexibility. Hildebrand Turbo Technology makes use of the alternating climate effect in combination with the specially developed B-Vector control system. For uniform drying, it can be useful to expose the wood alternately to a stress situation and a relaxation phase. This

TIMBER PROCESSING ■ JULY 2023 ■ 25

Springer spared no expense to celebrate its 70th year.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Valutec had all hands on deck.

with interesting visitors and discussions,” commented Christopher Brunner, managing director. “We had high-calibre visitors who are involved with major projects. You could tell that people missed the trade show.”

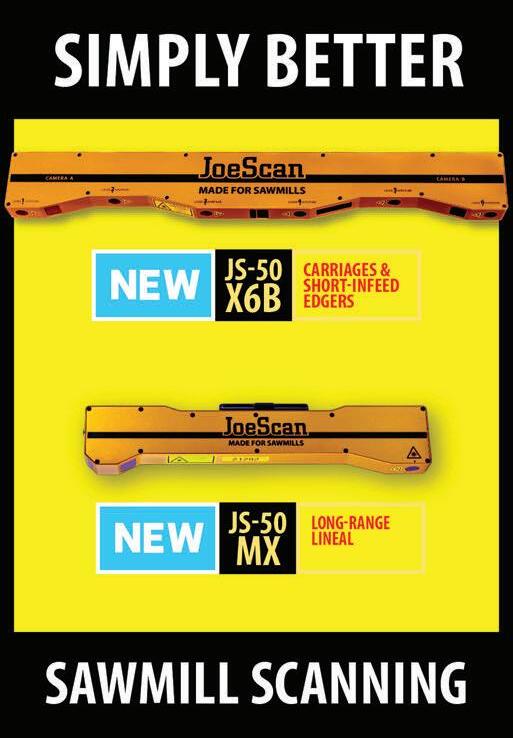

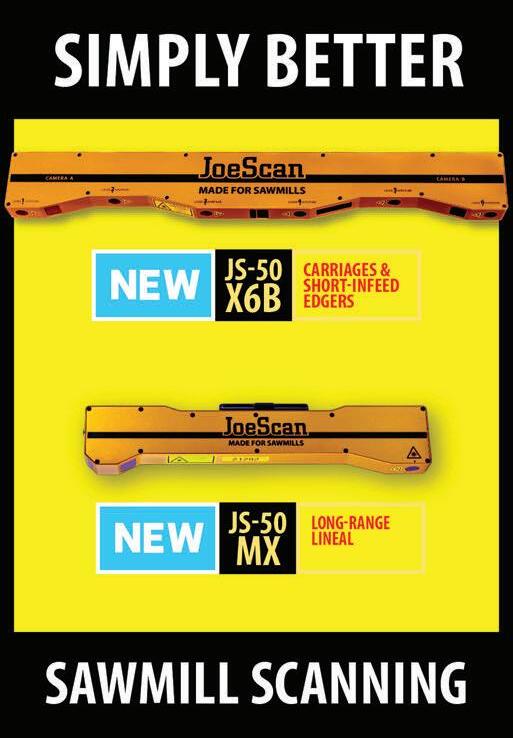

JoeScan President Joey Nelson said this was the biggest and busiest Ligna the com-

the world. We had customers and other visitors at our booth from six different continents.”

JoeScan showcased a new lineup of JS50 scan heads, including the newest, JS-50 MX extended range scanner. It is an upgraded version of the JS-25 MX scan head, and was designed for lineal applications

that require a little extra stand-off distance, such as bucking lines or sharp chains.

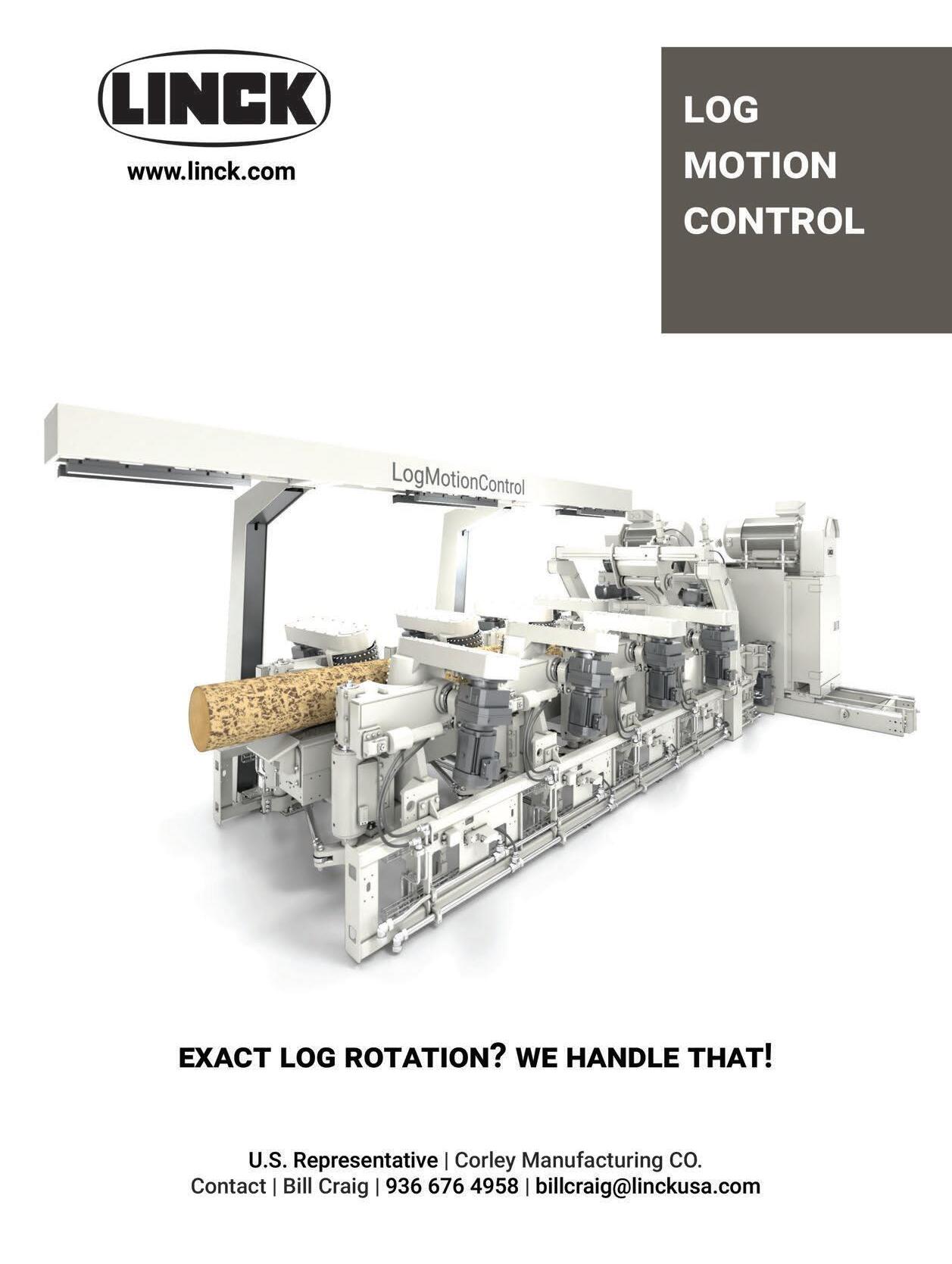

Bill Craig, longtime Linck representative in the U.S., said it was good to be back at Ligna after the COVID interruption, and that The Linck Group’s exhibit booth was an impressive 8,800 square feet and showed a number of new innovative products and innovative upgrades to existing products. He pointed to the high precision rotation “never-let-go” log positioning system; a profiling line designed for short logs (as short as 4 ft.) for high speed

26 ■ JULY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Carbotech teamed with Autolog for the first time at Ligna.

stud or pallet stock production; new capability of continuous maintenance while running the VPM model profilers; and saw arbors with instrumentation for conditionbased preventative maintenance.

Craig noted that attendance from North America was 2,900 of the 80,000 visitors.

Valutec stated that its success in launching TC continuous kilns in North America “has clearly reverberated” around the global industry, and was one of the key takeaways from Ligna.

Eric Johansson, marketing manager at

Valutec, commented, “When we entered the North American market six years ago, we were prepared to make a long-term commitment, and so we have. The TC model is a flexible type of kiln suitable for markets around the world, and we see continued great potential, especially in North America.”

Mühlböck reported that Ligna once again showed that the energy-efficient technology developed over many years by

the Upper Austria company is particularly in tune with the spirit of the

“Among the many discussions we had with customers, the topic of energy saving was certainly the most important,” confirmed Richard Mühlböck, managing director.

“Whether in drying kilns, in progressive drying systems or in belt dryers for wood chips and shavings drying, depending on the design, high energy savings can be achieved with Mühlböck technology in combination with the 1306 PRO and 1003 PREMIUM heat recovery systems.”

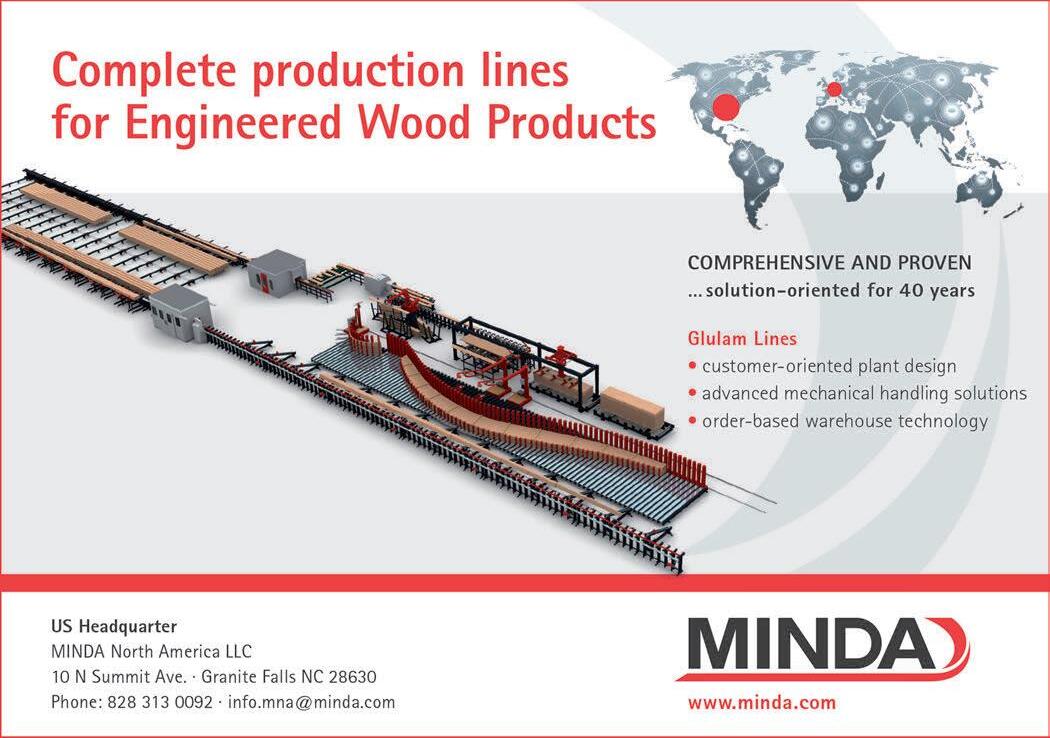

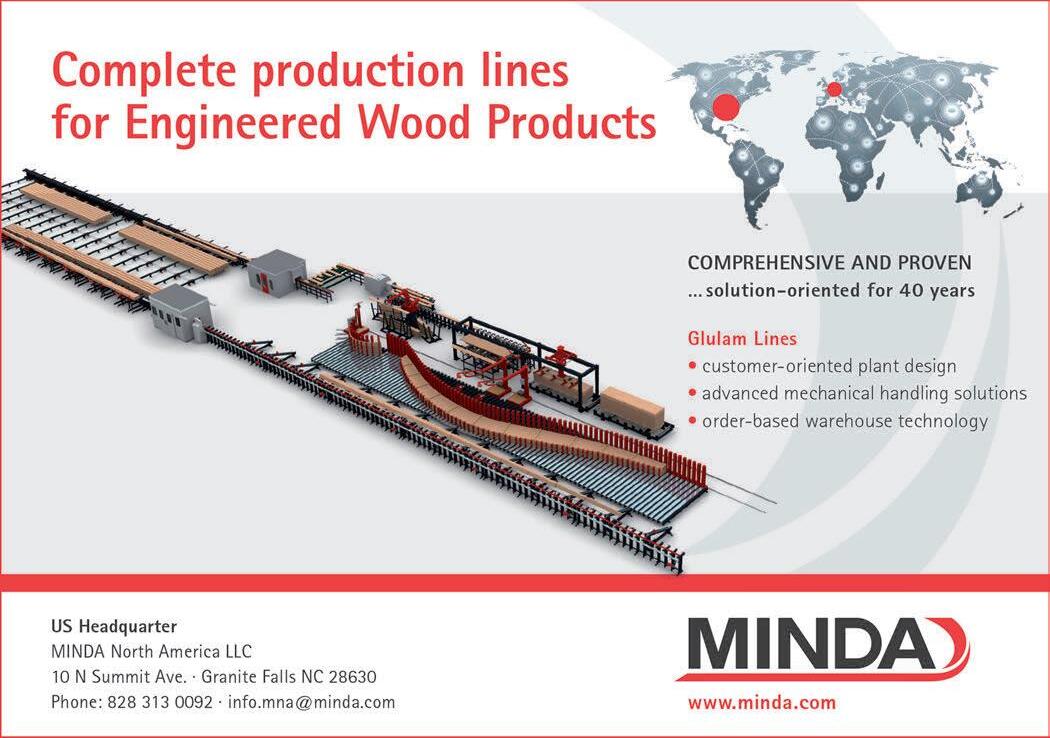

Minda had two locations. At its booth for engineered wood products, Minda showed an innovative, woodsaving manufacturing concept in which window and door openings are already created in the CLT billet.

The presentation of its new production control technology, FlowMate, attracted a lot of interest because it perfectly integrates into the user’s software environment. The further development of its automatic, horizontal architectural beam press for engineering timber construction also met with a positive response because of eliminating the manual insertion of heavy

TIMBER PROCESSING ■ JULY 2023 ■ 27

Mahild had several recent orders for its dry kilns.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Minda was big into big timber.

tie rods and pressure shoes.

Minda demonstrated the production of extra-wide beams up to 510 mm using the example of so-called split beams or multilamella beams. There are more and more inquiries from Europe for this product.

For the first time Minda presented with cooperation partners Obel-P and Howial.

“The customer benefits of the innovations were discussed in numerous talks during the

show,” Minda stated. “Therefore, we are in a positive mood about new incoming orders in the follow-up to the show.”

The Weinig Group was satisfied with the results of the trade fair. Weinig and Holz-Her brands met with lively interest from visitors from more than 100 countries. Weinig also announced a cooperation with Italian timber framing specialist Essetre. In conjunction with the majority takeover of equipment manufacturer H.I.T., Weinig now offers a complete profile covering the entire spectrum of solid wood processing, from band saws and multi-blade rip saws to machinery for planing, cutting, profiling and AI-assisted scanning to systems for constructive woodworking, supplemented by the panel processing technology of the HolzHer brand.

In terms of order inflow, trade fair targets were achieved and orders from 28 countries were booked.

The Weinig Grecon plant in Alfeld near Hannover also enjoyed great interest from visitor groups, who took the opportunity to obtain detailed information about innovations in fingerjointing lines directly in the production plant, in addition to the HS 200 high-performance flat fingerjointing line shown at the fair.

At the press conference on the first day of the trade fair, CEO Gregor Baumbusch reported the Weinig Group achieved sales of 586 million euros in 2022. Chief Technology Officer Dr. Georg Hanrath reported on the record investment program at the company’s headquarters in Tauberbischofsheim, where 70 million euros are being invested in state-of-the-art infrastructure.

TP 28 ■ JULY 2023 ■ TIMBER PROCESSING

Hildebrand Brunner lined up with style.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

It was planers and more planers at Gilbert. Left to right: Heidi Danbrook, Sales Manager; Audrey Gilbert, General Secretary; Alexandre Guy, Parts Sales Rep; Sylvain Lefebvre, Sales Rep.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

EDITOR’S NOTE: The following companies submitted these editorial profiles and images to complement their advertisements placed elsewhere in this issue. Please refer to those advertisements for web site and contact information. All statements and claims are attributable to the companies.

ANDRITZ

The Andritz Iggesund TurnKnife System is a disposable chipper knife system designed to replace the “old style” re-grindable knife system and produce the highest quality wood chips in the safest and most cost-efficient manner. The unique shape of the TurnKnife combined with the proper materials in the clamping assembly has evolved as a further improvement of the TurnKnife System, which has proven its effectiveness in hundreds of applications worldwide. The distinctive design features of the Andritz Iggesund TurnKnife not only produce a product with handling components that are much lighter than old systems, but also allow for more precise control of critical knife positions.

In 2008, we introduced our newest knife system, the TurnKnife System IV. This system offers the same reliability, knife life, and chip quality as the Super TurnKnife - Next Generation. The form and function of the knife have been further optimized to meet the rising demand to economize materials with the added benefit of faster and easier knife changes with lightweight tools. The TurnKnife System IV has been further improved over the most recent years, as we’ve introduced the TurnKnife System IV+ for both whole log and waste wood chippers.

Over the years, Andritz Iggesund Tools has carried the disposable knife innovation from chippers to other wood-chipping equipment in the sawmill industry.

l In 1992, the first Chip-N-Saw machine with TurnKnife was installed.

l In 1997, the first “Bent Knife” canter machine with TurnKnife was installed.

l In 1998, the first curve-saw gang with TurnKnife was installed.

l In 2003, the first PowerHeads with TurnKnife were installed.

Since then, TurnKnife has been adapted to all the most recent sawmill chipping equipment, including profilers, multi-profile drum heads, small and large log canter lines, rotary drum chippers, and much more.

Andritz Iggesund Tools has also been working in the field of chip quality measurement with our ScanChip system machine since 1993 and can offer comprehensive chip testing and quality measurement to our customers at anytime

DELTECH

Sawmills are constantly seeking innovative solutions to streamline their operations and enhance productivity. One such solution that has garnered attention is the Deltech Storage Bin with Walking Floor. Designed specifically for fuel storage and delivery, this modular bin offers a multitude of benefits and features.

One of the key advantages of the Deltech storage bin is its ability to ensure that the fuel never touches the ground. With a dry storage area and a design that prevents foreign debris from contaminating the fuel, sawmills can rest assured that their fuel remains clean and ready for use. This feature not only improves the overall quality of the fuel but also minimizes the risk of equipment damage and malfunctions caused by impurities.

The modular design of the Deltech bin allows for efficient customization according to specific fuel and energy requirements. It can store a substantial amount of fuel, ensuring uninterrupted operations during scheduled downtime or weekends.

Unlike many of its competitors, the Deltech storage bin offers independent control of each hydraulic cylinder on all 4, 8, or 12 rake sections. This intelligent system ensures even distribution of weight across the bin, preventing overloading or underutilization of certain areas. Furthermore, the bin’s robust design, including replaceable steel floors, adds to its durability and longevity, reducing maintenance costs and downtime.

The negative slope design of the bin’s walls is another standout feature. By preventing bridging, this design minimizes the risk of fuel jams, ensuring smooth and efficient fuel flow, and maximized uptime.

Maintenance is a breeze with the Deltech storage bin. Its design requires less maintenance compared to traditional silo-type storage bins, providing peace of mind to operators. The bin’s basic maintenance requirements, coupled with the company’s long-standing reputation for exceptional service, result in a reliable and hassle-free experience for customers.

Furthermore, the Deltech storage bin’s construction allows for easy installation, even during busy periods. It can be built alongside existing infrastructure and seamlessly integrated over a long weekend or scheduled downtime, minimizing disruption to operations.

The Deltech Storage Bin with Walking Floor is a game-changer. Its versatile and modular design, coupled with its innovative features such as independent cylinder control and negative slope walls, make it a superior choice for sawmills seeking efficient, reliable, and low-maintenance solutions.

BYPRODUCTS

Andritz Iggesund Turnknife disposable chipper knife

30 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Deltech storage bin with walking floor

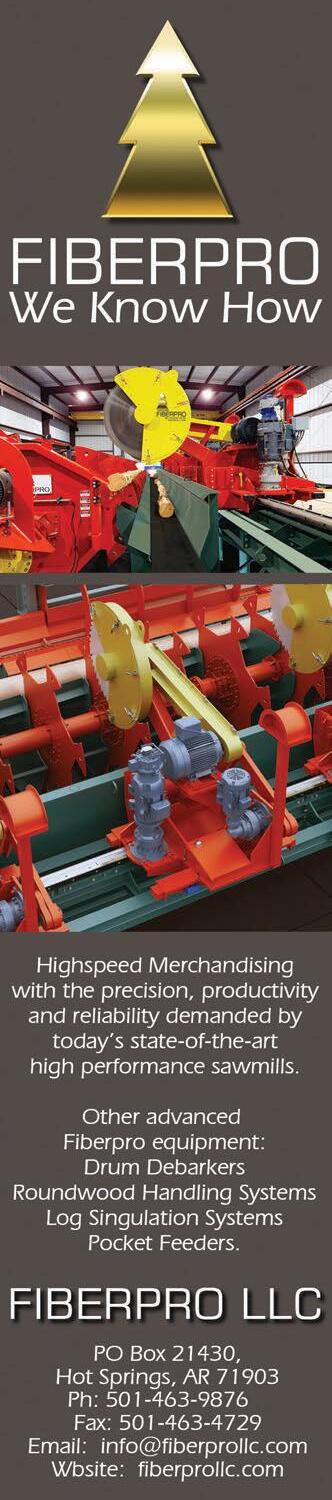

FIBERPRO

FiberPro specializes in roundwood fiber handling systems and processing solutions—log bucking/merchandiser systems, drum debarking systems, log cranes and log/stem singulation systems. Our mission is to use innovation and personalized service to create value for chip mills, paper mills and sawmills nationwide.

Our engineers have worked in the industry for decades designing log processing equipment. The company’s history and expertise reflect a customized approach, so each client has a system designed for their specific needs and future mill production/recovery expansion plans.

FiberPro’s priority is to supply our clients with the highest performing engineered solution that has the highest safety and re standards in the industry. Our latest generation of roundwood systems have redundant safety systems integrated into the design oversized components for increased reliability/uptime compared to past designs. It has taken more than 25 years of constant dev ment and improvements to reach the speeds and productivity the latest generation systems are currently achieving.

l Our new stem and log singulation systems utilize innovative design changes that include a new drive design and are self-cleaning on the infeed side of the feeder system with either a fully plated design or screw technology.

l Our engineered Drum Debarking Systems have been recently upgraded for safety and redesigned for a more cost-effective solution when processing roundwood to a chipper.

l Our engineered log truck unbinding stations have been recently upgraded to meet new OSHA requirements for safety and redesigned for a more cost-effective solution.

FiberPro also offers a wide range of cost-effective parts to better service customer needs. Our goal is for customers not to have to shop around but to grow their business with FiberPro.

FULGHUM INDUSTRIES

Fulghum Industries offers chippers from a 48 in. diameter sawmill chipper to a 120 in. diameter wood yard chipper. The standard for Fulghum chippers is a horizontal or vertical feed with a top or bottom discharge, but our customization doesn’t stop there.

In the picture shown here is a horizontal feed chipper with a rear/side discharge to fit a customer’s exiting sawmill. This is essential when replacing an odd, angled discharge chipper and when height clearance is limited. We strive to meet all our customers’ needs. Contact us to help you customize and design your chipper to fit your mill.

USNR

Through acquisition USNR now offers LogPro-brand biomass, residuals, and wood byproducts processing to complement our popular line of chippers and screens.

USNR’s wastewood chipper produces uniform chips for various applications including biomass, mulch, or livestock bedding. It comes in four sizes and three configurations, handling logs from 11-25 in. diameter. All models accommodate bottom, rear and top discharge.

USNR’s Super Chip Screen is an extremely low-maintenance solution that delivers excellent performance and reliable operation. Significantly faster rotary speeds provide better material agitation for improved separation, especially for small chips.

USNR’s LogPro-brand of material handling systems are optimizing wood yard operations with extra heavy-duty design, premium efficiency electric drives, and various handling arrangements. The result is reliable chip handling, less downtime, and a safe easy-tomaintain system.

The chipper discharge conveyor system uses the proven live-bottom surge bin concept that allows the chipper to freely surge more than twice the design production without plugging under the chipper or stopping the chipping system. This enables continuous uninterrupted production.

USNR now offers a complete line of biomass and wood byproducts processing systems.

USNR now also manufactures major support systems like chip screen towers and bark hog towers to supplement our drum debarking line. Custom built to meet the specific needs of your operation, these versatile structures allow for high-volume screens, re-chippers, cyclones, and various chute-work and conveyors needed to transport the material.

When it comes to conveyors, belt conveyors are the most affordable and economical method for conveying solid materials over long distances. They’re ideal for handling abrasive, irregularly shaped, heavy fuels like wood and other forms of biomass. We also produce heavy-duty belt and chain conveyors that are designed for continuous use at maximum capacity.

The chip and bark reclaim conveyor system uses proven designs that reduce plugging under the pile, allowing for continuous uninterrupted production. Designed with transfer redundancy, it enables mills to continue operating even if a transfer/reclaim chain breaks.

USNR also supplies custom radial stackers and bark stackers that can be fixed or traveling. Systems are designed with a “complete

TIMBER PROCESSING ■ JULY 2023 ■ 31

BYPRODUCTS

Fughum 66 in. horizontal feed chipper

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

BYPRODUCTS

system” philosophy that considers material bulk density, topography, feed rate, accessibility, and many other factors.

Committed to superior customer service, USNR offers 24/7 support and training worldwide.

VECOPLAN

Vecoplan, a world leader in size reduction and material handling systems, is the industry's first choice for solutions that address wood scrap needs. For more than 50 years, Vecoplan has served the primary and secondary wood markets with installations in more than 120 countries, leading the way in innovation, quality and experience. Vecoplan offers a comprehensive range of cutting-edge shredders, systems and services designed to optimize wood processing operations, increase efficiency, and enhance sustainability.

Vecoplan continues to be the innovation leader in wood grinding and shredding applications, offering a diverse range of advanced shredders and systems tailored for wood applications throughout the wood processing lifecycle.

Shredders: Vecoplan's high-performance shredders exceed the demands of even the most challenging applications. The VTH range of horizontal feed grinders and drum chippers offer a robust size-reduction solution for sawmills, flooring plants, architectural millwork shops, or any manufacturer generating large amounts of linear waste. The VTH line makes short work of all types of lineal waste produced by straight-lines, gang-rips, panel saws, and similar.

The VHZ, VAZ, VIZ, and VNZ series of vertical feed grinders offer multiple rotor configurations, drivetrain options, screen sizes, and other unique innovations that can process any wood waste into a revenue stream instead of a constantly increasing cost.

Vecoplan designed the VPC 1600VHZ 1600 combination specifically for the size reduction of large or bulky wood waste materials. This powerful combination creates an industry-first, two-stage size reduction solution with the highest throughput, lowest power consumption, and smallest footprint available today.

Material Handling & Complete Systems:

In addition to industry-leading shredders, Vecoplan's engineering teams specialize in developing complete system solutions tailored to meet each customer's unique needs that optimize productivity and deliver superior results.

32 ■ JULY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vecoplan provides a range of grinding and chipping machinery solutions.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CONCERNS MOUNT FOR LOGGERS

Inflation, labor, reduced log and fiber demand…

industry, and is an affiliate magazine of Timber Processing.

By Dan Shell

The 2023 Annual Logger Survey Report looks at a “before” and “after” situation comparing business conditions and survey results from 2019 before the pandemic hit in early 2020 to now—a depressing new normal in many ways. Along the way, there has been unprecedented forest products prices and soaring inflation, pandemic dynamics leading to labor issues and much more.

In spring 2019, despite a tariff war with China that was roiling log export markets, the forest products industry was on a general upswing, still recovering from the Great Recession of 2008-9. But since then, with the pandemic impacts beginning in spring 2020, lots of uncertainty has been injected into the logging industry and supply chain as loggers have been hammered with rising operating costs and labor instability.

Meanwhile, the past few years it’s been more of the same around the country as loggers struggle with challenges such as ongoing public lands access and overall regulations out West, major clo-

quickly turn into huge business challenges as hurricanes, fires and even overly warm winters continue to create risk and hardship around the country.

Downsizing Trend—Logging is definitely a small business industry: The average number of employees reported by loggers responding in 2023 is nine.

On a related question that looks at company size in terms of logging crews, there’s definitely been some downsizing in the ranks since before the pandemic. In 2019, 53% of loggers reported they ran only one crew. Now, more than twothirds (68%) say they run only one. The 23% of loggers who reported running two crews in 2019 is now 18% in 2023.

The downsizing is also reflected in two answers on a cost-cutting question deeper in the 2023 survey: During the past two years, 12% of loggers say they’ve downsized in response to operating conditions. That includes 10% who say they’ve eliminated one crew and 2% who have cut two or more crews from their operations.

The 2023 survey asked: Has your company expanded, remained about the same or downsized in the past two years? More than half (61%) say their operations have stayed roughly the same, while 10% report expanding and 28% re-

ging business investment of more than $1 million, including 7% at more than $5 million.

Profitability Elusive—For years a concern among loggers is the annual ROI on all that investment in equipment, personnel and supplies. Asked to estimate their pre-tax profit percentage for the prior year (2022), this year’s survey shows that more than a third of those who responded said they either broke even (17%) or lost money (21%). When 38% of the companies critical to the supply chain aren’t profitable, that’s a major cause for worry.

It’s interesting to look at the results from 2019 before the pandemic, as all the answers from four years ago slid downward as loggers have trended toward lower profitability: The group that reported pre-tax margins of 10% or more four years ago was 24% smaller this year; and the group reporting margins from 4% to 9% four years ago was 44% smaller this year. Meanwhile, the number of loggers reporting margins of 3% or less or outright unprofitability has increased 22% since the pre-pandemic 2019 Logger Survey.

As one logger who commented on the survey said, “You can break even for only just so long.”

34 ■ JULY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

The responses from four years ago compared to now are striking when loggers were asked to rate their company’s financial health.

As with the pre-tax margin question, the responses to the same question all moved negatively during the past four years until now, when half as many loggers rate their financial health as “very good” (6%) in 2023 compared to the 13% who said so in 2019.

Likewise, 21% of loggers in 2023 rated their company’s health as “poor” (16%) or “very poor” (5%), compared to only 6% who said poor or very poor back in 2019. Meanwhile, in 2023 29% of loggers rate their business health as “good” while 44% say “fair.”

“The cost of equipment, insurance, labor, fuel, and nearly every other necessary component has skyrocketed, but not the rates that loggers receive,” commented Justin Everheart of JEM Forestry in Bonners Ferry, Id. “If we want to bring young blood into the industry offering full benefits has to do be doable and the money has to come from somewhere. The industry has to shift and loggers need to be viewed as a priority making sure they can make a decent living running an operation and offer one to their crews.”

Operating Challenges—Sadly, one thing that hasn’t changed in four years since the 2019 Logger Survey is that loggers across the country (63%) rank Insurance as the heaviest impact business challenge they currently face, same as 2019, when 69% of loggers said so.

In 2023, after Insurance, the top heavy impact business challenges ranked by loggers include Limited Markets, cited by 50%, and Labor Issues, cited by 47% of loggers. (In 2019 the top three heavy impact issues were Insurance, Trucking/DOT issues and Weather.)

Labor concerns, of course, have risen to the fore for all personnel from entry level to truck drivers and equipment operators, and the number of loggers citing limited markets certainly reflects the multiple pulp-paper mill closures and realignments around the country along with reduced log buying for many mills due to markets and lumber prices.

Heavy impact business issues cited by 40% of more include Load Quotas (45%), Trucking-DOT Regs (44%) and Compensation (43%). Weather was cited as top heavy impact business challenge by 27% of loggers, Debt was tops for 26% of loggers, Equipment Downtime was the biggest challenge for 24%, while 23% cited Timber Availability-Cost. Environmental Compliance and Product Separations were big impact issues for

15% and 11%, respectively.

With such challenges out there, a poor compensation structure only makes things worse. Looking at the past two years, 20% of loggers report rate increases (16%) or fewer quotas-more loads (4%). However, twice as many—40%— loggers report either rate reductions (10%) or tighter load quotas (30%) during the past two years.

“It is very hard right now. Finding additional crews to increase production is almost impossible. The only way to consistently profit is to increase production. And as soon as you’re able to, quotas begin,” says TJ Shafer of Forest Sales in Manning, Tex.

With labor such a challenge these days, loggers were asked what they do to attract and retain employees, and 77% said ensure a competitive pay rate, followed by 50% who provide production bonuses. Paid vacations and regular raises were cited by 39% and 33% of loggers, respectively.

Only one in four loggers who responded—25%—say they offer health insurance, which is a key benefit to maintaining a stable workforce. Another 7% of loggers say they offer profit-sharing plans.

Labor issues drew a big share of the comments across several questions, including multiple touching responses about the desire to offer more and better packages for employees but the money is just not there, especially for health insurance.

And of course 90% of loggers said “No” when asked if they felt good about

being able to find employees to replace those who leave or retire.

Equipment, Technology—Taking a look at loggers’ equipment maintenance and repair practices, the survey shows 87% of loggers report they handle routine maintenance and repairs within their organizations, and 43% of those who responded said they maintain a shop to help them do so. Another 43% said they maintain at least one service truck-trailer to help with repairs and maintenance, and 18% of loggers said they employ at least one full-time mechanic. Meanwhile, 24% of loggers say they pay a dealership or independent mechanic to handle routine service work.

Logging is also very consumable intensive, and 25% of loggers report they spend more than $200,000 annually in parts, supplies, tires, maintenance and repair (not fuel). That includes 8% who say they spend more than half a million annually. Meanwhile, 56% of loggers say they spend $100,000 or less on parts supplies and maintenance. Another 19% say they spend between $100,000$200,000 annually.

Noting that equipment is becoming more technologically advanced and with performance and production data logs and analytics, built-in GPS systems and more, the survey asked loggers about using such features, and 56% reported they don’t run equipment with such features. Of the 44% who have such features on their machines, 20% don’t use the technology at all, 18% says they take advantage of certain key metrics but not

TIMBER PROCESSING ■ JULY 2023 ■ 35 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

all, and 6% say they try to take advantage of all data generated.

Looking Ahead— While the future always remains uncertain, there’s not a

lot of optimism out there for what the next two years holds: In 2023, only 14% of loggers expect overall log and pulpwood demand in their area to im-

prove, while more than a third (34%) expect demand to diminish somewhat. Some 52% said they expect demand to remain about the same.

Results from the same question four years ago show a big shift in logger optimism, as back then more than 30% were expecting demand to improve in their markets over the next two years, while only 13% were expecting reduced demand.

Asked to gauge their likely logging future during the next five years: In 2023, 36% of loggers say they plan to remain fully engaged with a growth- and opportunity-oriented business stance the next five years, while 33% say they’ll stay in the business but not with expansion or growth in mind. Meanwhile, it’s got to be worrisome that roughly a third of those who responded say they will likely exit the logging industry in the next five years.

TP 36 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

JD Irving Orders MiCROTEC CT Log

Wanescan installation at the Dixfield facility in 2023. Their recent investment of the CT Log is accompanied by a commitment of 5 MiCROTEC Logeye Stereos, which execute 360° scans during rolling, adding to the information gained before the log is sawn.

Speaking to the solutions provided by MiCROTEC, Jerome Pelletier, Vice President of JD Irving, Ltd. Sawmills Div., comments, “We are very excited to further grow our partnership with MiCROTEC. We firmly believe that this strategic investment in the newest scanning technology will allow us to maximize log yield as well as improve the value of the products offered to our customers.”

Can., continues its commitment to sustainability and innovation with the purchase of a MiCROTEC CT Log for installation at its operation in St. Leonard, New Brunswick, Can.

MiCROTEC’s CT Log computed tomography scanner will allow JD Irving to scan and digitally reconstruct the internal features of their logs in 3D. Delivering the optimal cutting solution in real time, this technology is consistent with JD Irving’s mission to ensure the use of 100% of every tree. The computed tomography scanner provides a complete reconstruction of the internal features of the logs, allowing the logs to be graded and sorted by quality and optimization.

The CT Log solution provides quality grading and virtual grading information in addition to the full 3D log description.

Integrated with MiCROTEC’s Maxicut Pro, Winlog, and MiCROTEC Connect, the CT Log communicates with the Logeye Stereo, providing the headrig operator the exact degree of log rotation to provide maximum value. Working with the CT Log, MiCROTEC’s Maxicut software optimizes cutting patterns based on value.

The newest investment is part of JD Irving’s continued partnership with MiCROTEC. Beginning in 2014 with a Lucidyne scanner installation at the Dixfield, Maine location, JD Irving has since installed Lucidyne scanners at the Doaktown and Kedgwick, New Brunswick locations, with another

The CT Log solution and Logeye Stereo applications will be installed early 2024.

BID Group Plans Major Investment

BID Group announced a capital investment of $4.7 million toward the modernization of its equipment to increase production capacity in its SaintGeorges and Saint-Éphrem-de-Beauce facilities in Quebec.

In Saint-Georges, preparations are underway to introduce state-of-the-art equipment, including a new large band saw, a plasma cutting table, two CNC machine tools and a CNC Multi-task Mazak Integrex to increase its machining capacity. These changes represent a cumulative investment of $2.4 million.

Similarly, BID’s Saint-Éphrem-deBeauce facility is actively being prepared to accommodate new equipment, namely an Automated Part Storage System, a CNC boring machine and a grinder with a robotic feeding system to increase production for Comact BLADE cutting tools. The collective investment for this equipment amounts to $2.3 million.

Through the incorporation of this new equipment, BID Group aims to increase its ability to deliver an extensive range of innovative technologies to its highly valued customers while enhancing operational efficiency.

“We are grateful and privileged to receive the ongoing trust of our customers, whose achievements are propelling the

38 ■ JULY 2023 ■ TIMBER PROCESSING

MACHINERYROW

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Left to right: Bob Bell, Sales Account Manager, MiCROTEC; Norvin Laudon, Director, MiCROTEC Vancouver; Arianna Giudiceandrea, CSO, MiCROTEC; Susan Coulombe, General Manager J.D Irving Ltd.; Frank Jöst, CEO MiCROTEC; Jerome Pelletier, Vice President, J.D. Irving Ltd.; Jody Gallant, Business Improvement Manager, J.D. Irving Ltd.

demand for such investments. We are enthusiastic about our efforts to modernize our presence in Quebec’s Beauce region and to contribute additional employment opportunities to our current workforce,” comments Simon Potvin, President of Wood Processing.

Startup and installation of the new equipment began in April 2023 and will be carried out until June 2024. The equipment modernization initiative will result in the creation of multiple new jobs, primarily for industrial mechanics and machinists. Applications for these positions may be sent to jobs@bidgroup.ca.

MACHINERYROW

Caribou Purchases StumpGeek Software

Caribou Software, a forestry software company that services more than 300 timber companies across North America, announced its acquisition of the StumpGeek forestry software system to extend its product offering to smaller logging contractors and sawmills.

“Over the years, we’ve spoken to many, many logging contractors and small sawmills who move 10 to 30 loads a week and need a simple way to pay trucking subs and ensure they are receiving pay-

ment for all their loads, but they don’t need the full capabilities of our Logger’s Edge and Cutting Edge systems,” says Teresa Hannah, President and Co-Founder of Caribou. “StumpGeek allows us to assist those smaller, simpler companies at a price point that works for their budget.”

The StumpGeek product was designed by Wesley Bushor, a logging contractor in Wisconsin, who wanted a better system than the interlinked spreadsheet he had developed over his 30 years of harvesting timber to keep up with his own logging business. He partnered with a professional software developer.

TIMBER PROCESSING ■ JULY 2023 ■ 39

➤ 42 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

MACHINERYROW

German Machinery Outlook Still Solid

Production by the woodworking machinery industry in Germany reached a record level of €3.6 billion in 2022, an increase of 8.3% on the previous year, according to a report from German-based VDMA Woodworking Machinery Assn..

In 2022 the export value of German manufacturers of woodworking machinery increased by 4.5% to 2.4 billion euros compared to the previous year. The largest individual markets were again the U.S. (307 million euros, up 20% ) and the People’s Republic of China (255 million euros, down 1%), followed by France (154 million euros, up 14%), Poland and Austria.

Exports to Great Britain (119 million euros, up 36%) and Italy (126 million euros, up 26%), both countries with pronounced investment promotion programs, reached record levels. A striking and gratifying development was a near quadrupling of exports to India to 46 million euros.

For the traditional markets in Europe, manufacturers do not expect further growth in the current year in view of the weaker order intake. By contrast, the outlook for business in North America remains good. China, too, will foreseeably retain its outstanding position as the largest sales market in the Asian region despite all trade policy differences. The Indian woodworking industry is increasingly establishing itself as a firm customer for European manufacturers of woodworking machinery and tools.

Overall, a pronounced boom phase is coming to an end for many customer industries, which experienced a peak during the Corona pandemic, according to VDMA. In addition, financing investments is becoming much more expensive, which often leads to reluctance to place orders. On the other hand, the pressure to innovate is undiminished, if only because of the shortage of skilled workers, and digitization and automation are therefore massively driving customer industries, which was reflected in the topics set at Ligna 2023. Another important trend topic is building with wood, which is enjoying growing demand and which is why the general decline in construction activity in Europe is not affecting manufacturers in this segment as much.

42 ■ JULY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ATLARGE

Hancock Lumber Hits Stride At 175

Let the anniversary celebrations continue! On June 1, the Maine State House of Representatives formally recognized Hancock Lumber for the 175th Anniversary of the company and its commitment to Maine business, the economy and Maine’s natural resources.

A group of Team Hancock leaders gathered in Augusta during the House Special Session and received the honor, which was presented to Team Hancock in front of the 151 legislators by Representative Lynn Copeland and Representative Jess Faye. Each legislator also received a copy of Kevin Hancock’s book, The Seventh Power, and Hancock Lumber commemorative pins.

Hancock Lumber was item 5-61 on the special sentiments calendar and joined a handful of other individuals, school groups and businesses on this day of special sentiment and celebration. The House Speaker read aloud the following excerpt to the legislators:

“Hancock Lumber Company, of Casco, which is celebrating its 175 Anniversary. The company was started on October 4, 1848 and has been passed down through seven generations, and it was recognized by Family Business Magazine as the 71st-oldest family business in the United States. There are currently over 700 employees at 11 lumber yards, 4 sawmills and 6 kitchen design locations throughout Maine and New Hampshire. Hancock Lumber Company is a 9-time recipient of the Best Place to Work award and is a steward for Maine’s

44 ■ JULY 2023 ■ TIMBER PROCESSING

Team Hancock is honored at Maine House of Representatives.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

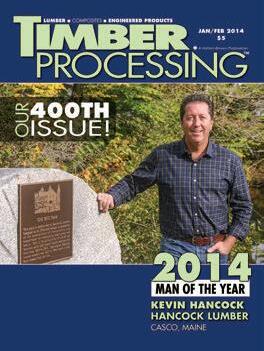

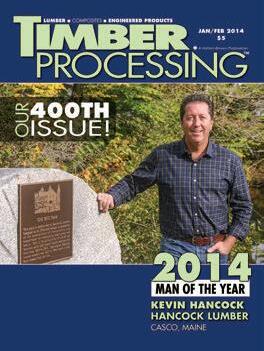

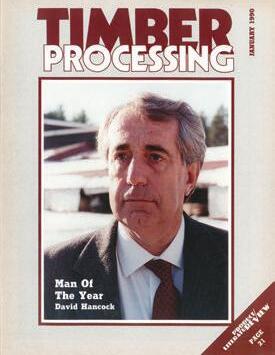

Father and son have received TP’s Person of Year award.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ATLARGE

forests, producing lumber in an environmentally sustainable fashion. We extend our congratulations and best wishes.”

Indeed Hancock Lumber’s roots go back to 1848 in Casco. The formative years began when Milton Hancock built the company’s first stationery mill, powered with diesel fuel until electricity came on. That site was adjacent Hancock’s current administration office building in Casco.

After Milton passed away at age 57, the reins of the company were handed to his oldest son, Kenneth, under which timberland management practices were put on the front burner and the family business ventured into retail.

Kenneth died at age 67, upon which his son, David, took over during the boom years of the mid to late 1980s, during which the Casco mill was upgraded and a new mill built in Pittsfield. David was also known as an activist for the timber industry, spearheading the development of the American Forest Resource Alliance. Timber Processing magazine named him Person of the Year in 1990. David passed away in 1997 at

Based in Brattleboro, Vermont, Cersosimo is a third-generation family operation and celebrated its 75th year in operation in 2022. The company also has mills in New Hampshire and New York, and processes high-quality northeastern hardwoods and eastern white pine.

Cersosimo is committed to the complete utilization of all products from the woodlot, adding value to locally harvested wood and creating jobs in the rural economy. They use modern technologies and time-tested practices in manufacturing, making use of low-grade materials and byproducts.

Fifteen years ago, the lumber company built a stand-alone chip plant to feed their own kilns for drying lumber and to

46 ■ JULY 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Cersosimo Lumber receives NELA Outstanding Sawmill Operator Award during annual meeting.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

produce clean chips for paper companies and public and private institutions.

Cersosimo has a reputation as being both a strong advocate for good forest stewardship as well as employing a collaborative approach to business.

Stuart Bevin, Forester, Stillwater Forestry LLC, comments, “It has always been apparent to me they want to see those they do business with succeed and prosper.”

Ben Coll, a logging contractor in the Brattleboro area, wrote a letter to NELA that Cersosimo Lumber is an important asset for all loggers, foresters, landowners, and the local people of the areas in which they operate. “The ability to move as much product as close as possible to where we are harvesting…[makes] the whole process from landowner to forester to logger to the final destination of the mill yard a seamless one for all involved,” Coll says.

Company President Michael Cersosimo accepted the award on behalf of the company and its employees. “Winning this award in 2022, the year of our 75th anniversary, feels a little extra special.

My grandfather Tony Cersosimo, the company’s founder, would have been proud not that we just made it 75 years, but that we kept it in a condition worthy of winning the award,” Cersosimo says.

NELA was founded in 1952 and is headquartered in Old Forge, NY. The organization has nearly 2,000 members in the region from Maine to Minnesota and Missouri to Maryland.

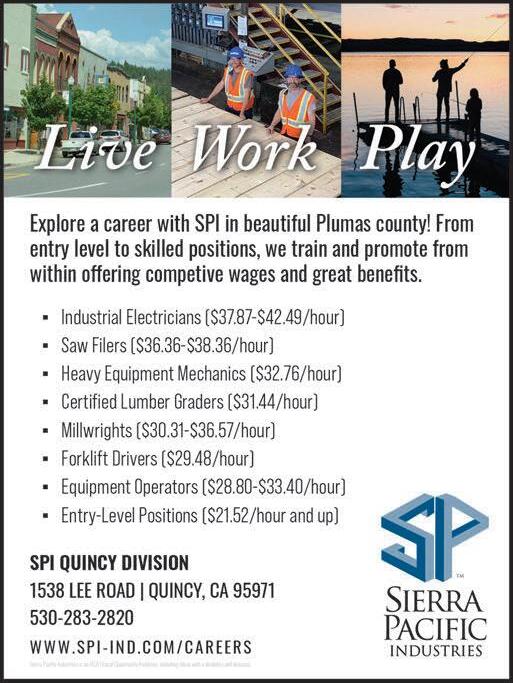

SP Foundation Grants $521,000 In Scholarships

Sierra Pacific Foundation is awarding more than $521,000 in scholarships to 169 students as they attend colleges, universities, and trade schools during the 2023-2024 school year.

“It is both an honor and a privilege for our family to continue to offer this ongoing support for these students,” says Carolyn Emmerson Dietz, Foundation President. “We remain committed to helping and to investing in tomorrow’s leaders and in the generations to come.”

Sierra Pacific Foundation grants scholarships to qualified, dependent chil-

dren of Sierra Pacific Industries’ employees. Recipients are eligible for the scholarship for four years, with some granted a fifth year based on their school and finalizing their undergraduate degree or trade school program.

Sierra Pacific Foundation is the philanthropic organization founded by the Emmerson family in 1979. Over those years, it has donated more than $9.3 million in scholarships. In addition to scholarships, the Foundation contributes to youth activities and other organizations in the communities where Sierra Pacific Industries operates. In 2022, the Foundation contributed more than $5 million to organizations in the local communities.

Hancock Co-Launches Executive Training

Kevin Hancock, chairman of Maine’s Hancock Lumber, and California-based consulting firm, SSCA, held its first Business of Shared Leadership executive workshop in San Diego in March. This executive leadership training is based on the concepts of Kevin’s book, The Sev-

ATLARGE 48 ■ JULY 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

enth Power, and Hancock Lumber’s reallife experience transforming its work culture. These ideas and experiences are paired with SSCA’s teachings which apply behavioral science to corporate and personal change creation.