CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vol. 52 No.8

August

2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S. Kathy Sternenberg

Tel: 251-928-4962 • Fax: 334-834-4525 219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

Tel: 905-666-0258

29 Bugelli Dr.

Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA

Tim Shaddick

Tel: 604-910-1826

4056 West 10th Ave. Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett

Tel: +34 96 640 4165

Mobile: +34 66 931 5837

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription

SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S.

understanding

the advertiser and/or

authorized

publish the entire contents and subject matter thereof. The advertiser

advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written

(Founded in 1972—Our 611th Consecutive Issue)

Subscription Inquiries TOLL-FREE

Fax 888-611-4525.

to

and

the

to

the web. All advertisements for

are

permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA. POSTMASTER: Send address changes to: Southern Loggin’ Times, P.O. Box 2419, Montgomery, AL 36102-2419 FEATURES 4 ● AUGUST 2023 ● Southern Loggin’ Times Other Hatton-Brown publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy Southern Stumpin’. . . . . . . . . . . . . . 6 Bulletin Board. . . . . . . . . . . . . . . . . 20 Industry News Roundup. . . . . . . . 22 IronWorks. . . . . . . . . . . . . . . . . . . . . 33 Coming Events/Ad Index. . . . . . . . 38 Dynamic South Carolina duo Bud West, left, and his son Matt West, right, work hand-in-hand to run their companies, Brown Chapel Logging and West Forest Products. Bud also owns West Land Clearing, which focuses on rightof-way jobs; his other two sons, Travis and Jasen, run that. Bud and his sons represent the third and fourth generations of a family tradition that stretches back to origins in the hills of western North Carolina a century ago. Story begins on Page 8. (David Abbott photo) 14 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Information—

funds).

800-669-5613;

Go

www.southernloggintimes.com

click on

subscribe button

subscribe/renew via

Southern Loggin’ Times magazine

accepted and published by Hatton-Brown Publishers, Inc. with the

that

advertising agency are

to

and/or

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

By David Abbott • Managing Editor • Ph.

Survey Says: SOUTHERN STUMPIN’

personnel and supplies. Asked to estimate their pre-tax profit percentage for the prior year (2022), this year’s survey shows that more than a third of those who responded said they either broke even (17%) or lost money (21%). When 38% of the companies critical to the supply chain aren’t profitable, that’s a major cause for worry.

It’s interesting to look at the results from 2019 before the pandemic, as all the answers from four years ago slid downward as loggers have trended toward lower profitability: The group that reported pre-tax margins of 10% or more four years ago was 24% smaller this year; and the group reporting margins from 4% to 9% four years ago was 44% smaller this year. Meanwhile, the number of loggers reporting margins of 3% or less or outright unprofitability has increased 22% since the pre-pandemic 2019 Logger Survey.

(45%), trucking-DOT regulations (44%) and compensation (43%). Weather was cited as a top challenge by 27%, debt was tops for 26%, equipment downtime was the biggest challenge for 24%, while 23% cited timber availability-cost. Environmental compliance and product separations were big impact issues for 15% and 11%, respectively.

Faced with such challenges, a poor compensation structure makes things worse. Over the past two years, 40% of loggers report they’re getting paid less or being allowed to haul less (30% tighter quotas, with 10% reporting they’ve received rate reductions). Meanwhile, a combined 20% report the opposite: higher pay or more loads (16% report rate increases and 4% say they’ve had fewer quotas/more loads).

that was roiling log export markets, the forest products industry was on a general upswing, still recovering from the Great Recession of 2008-9. But since then, with the pandemic impacts beginning in spring 2020, lots of uncertainty has been injected into the logging industry and supply chain as loggers have been hammered with rising operating costs and labor instability.

Meanwhile, the past few years it’s been more of the same around the country as loggers struggle with challenges such as mill closures in the Carolinas, Florida and Louisiana. And weather events can quickly turn into huge business challenges as hurricanes, fires and even overly warm winters continue to create risk and hardship around the country.

Downsizing Trend

Logging is definitely a small business industry: The average number of employees reported by loggers responding in 2023 is nine.

On a related question that looks at company size in terms of logging crews, there’s definitely been some downsizing in the ranks since before the pandemic. In 2019, 53% of loggers reported they ran only one crew. Now, more than twothirds (68%) say they run only one. The 23% of loggers who reported running two crews in 2019 is now 18% in 2023.

While an industry run by small businesses, logging is also quite capital intensive: 44% of loggers report total logging business investment of more than $1 million, including 7% at more than $5 million.

Elusive Profitability

For years a concern among loggers is the annual ROI on all that investment in equipment,

As one logger who commented on the survey said, “You can break even for only just so long.”

In 2023, 21% of loggers rated their company’s health as poor or very poor (16% poor, 5% very poor), compared to only 6% who said poor or very poor back in 2019. Meanwhile, in 2023 30% of loggers rate their business health as “good” while 44% say “fair.”

“The cost of equipment, insurance, labor, fuel, and nearly every other necessary component has skyrocketed, but not the rates that loggers receive,” commented Idaho logger Justin Everheart of JEM Forestry. “If we want to bring young blood into the industry, offering full benefits has to be doable, and the money has to come from somewhere. The industry has to shift and loggers need to be viewed as a priority, making sure they can make a decent living running an operation, and offer one to their crews.”

Operating Challenges

One thing that hasn’t changed in the four years since 2019: more loggers (63% in ’23, 69% in ’19) rank insurance as their top challenge with a heavy impact on their business. Below insurance, the top challenges ranked by loggers in this year’s survey were limited markets, according to 50% of respondents, and labor issues, cited by 47%. In 2019 the top three heavy impact issues had been insurance, trucking/DOT issues and weather.

Labor concerns, of course, have risen to the fore for all personnel from entry level to truck drivers and equipment operators, and the number of loggers citing limited markets certainly reflects the multiple pulp-paper mill closures and realignments around the country along with reduced log buying for many mills due to markets and lumber prices.

Other heavy impact business issues cited by at least 40% of respondents include load quotas

“The only way to consistently profit is to increase production. And as soon as you’re able to, quotas begin,” says TJ Shafer of Forest Sales in Manning, Tex.

With labor such a challenge these days, how do loggers attract and retain employees? Competitive pay rate was the answer for 77%, and 50% provide production bonuses. Only 25% offer health insurance; 7% offer profit-sharing plans.

Many comments indicated a desire to offer more and better packages for employees, but the money is just not there, especially for health insurance.

Asked if they felt good about being able to find replacements for employees who leave or retire, 90% of loggers said “No.”

Looking Ahead

While the future always remains uncertain, the survey indicates limited optimism among loggers for what the next two years hold. In 2023, only 14% of loggers expect overall log and pulpwood demand in their area to improve in the next two years, while more than a third (34%) expect demand to diminish somewhat. Some 52% said they expect demand to remain about the same.

Results from the same question were different four years ago. Back then more than 30% were expecting demand to improve in their markets over the next two years, while only 13% were expecting reduced demand.

Asked to gauge their likely logging future during the next five years: In 2023, 36% of loggers say they plan to remain fully engaged with a growth- and opportunity-oriented business stance the next five years, while 33% say they’ll stay in the business but not with expansion or growth in mind.

It should be worrisome that roughly a third of those who responded (32%) say they will likely exit the logging industry in the next five years. SLT

6 l AUGUST 2023 l Southern Loggin’ Times

334-834-1170 • Fax: 334-834-4525 • E-mail: david@hattonbrown.com CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Two For One

roots in the timber industry back 100 years, when Bud’s grandfather, Herman “Bull” West, started logging in the mountains of western North Carolina in the 1920s, with a crosscut saw and a yoke of steers. “He skidded with steers and cut hemlock to take to a tannery,” Bud says.

The family business evolved from there. Herman had five sons, all of whom worked in the woods over the years, either in logging or land clearing, and then passed it on to the next generation. Bud went to work in the woods with his own dad, Whitie West, as soon as he was big enough, around age 12.

In those days, logging was seasonal work; the family split time off-andon between logging and land clear-

8 l AUGUST 2023

l Southern Loggin’ Times

■ Father-son team Bud and Matt West run Brown Chapel Logging and West Forest Products.

Trucks line up to take a load at Matt'sWest Forest Products job.

★ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

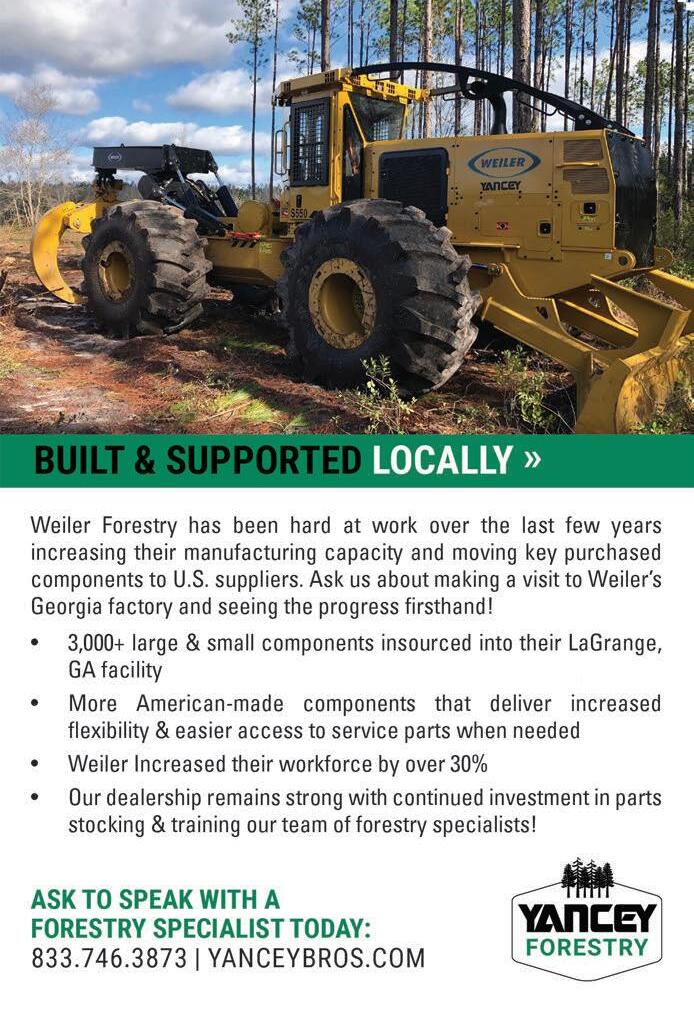

TheWests have converted from Cat to Deere in recent years,largely due to the tenacious efforts of Dobbs Equipment salesman RandyWilkes.

ing. When Bud started helping his dad in the late ’70s, they were cutting five-foot pulp and loading with a big stick loader. Back then, in Bud’s youth, the family still worked in that high country terrain of western North Carolina, where they were born and raised; Bud grew up in the little town of Marble, NC. “It’s pure mountains there, big mountains, along the Tennessee/Georgia border,” he says of the region.

In the early-mid 1980s, the family relocated their operations to South Carolina, following the work where they could find it. “We just couldn’t make a living in the mountains,” Bud explains. “We were working down here and driving back and forth on the weekends, so we finally just moved down here.” They planted roots and have been here ever since.

When they came of age, Bud’s three sons (Matt, Travis and Jason) all followed their dad’s example by going to work in the family business right out of high school.

Solo

In 2004, Bud went out on his own, not in logging but in clearing power line right-of-ways. He started his own company, West Land Clearing. “When we were clearing there was always timber to get rid of, and we couldn’t get a logger to come pick it up because it was just a small amount here and there,” he says. “So we wound up buying a buncher, then a skidder, then a loader, and the next thing you know we’re in the logging business.” He christened his second company Brown Chapel Logging, LLC, because their shop is located on Brown Chapel Road in Newberry.

Bud’s other two sons, Travis McGhee and Jasen West, still run West Land Clearing. They’ve been working for the South Carolina Dept. of Transportation doing vegetation grinding on interstates, using Cat excavators with tree grinding heads.

Like his brothers, Matt was working in West Land Clearing, but once Bud started Brown Chapel, “He took a liking to the logging, and wanted to look after that,” his dad says. He liked it so much that two years ago he started his own separate company, West Forest Products, while still helping his dad oversee Brown Chapel. “Matt has his plate full,” Bud says. “He runs things out here and then runs things on his own job as well. I’m awful proud of him.”

Equipment

For a while Bud and Matt had three crews between them: Bud had two under Brown Chapel Logging, and Matt had one West Forest Products crew. But recently they combined Bud’s two crews into one big

gets on the cutter, goes down in the minute and says, ‘We gotta buy this Wilkes won them over to the green machines, in part, Bud says, because “The regen (DEF) systems, Deere has got it figured out. We don’t have any regen issues.” Matt says they have never had a DEF issue other than re-

Bud adds, “We got that first cutter, it was like day and night difference. You couldn’t ask for any more comfort in the operator station. And it is just built tough. One machine barrel rolled down a hill in Chester County last year and you can’t even tell it. It’s

Also, “We never really have service calls,” Matt says. “That first buncher we bought is a ’19 model with 4,100 hours on it and there has

Southern Loggin’ Times l AUGUST 2023 l 9

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

TheWest family:Kim and Bud,their son Matt with his wife Kayce and their sons Brooks and Brody

laughs. Now they have, split between loader, two 748L-II and 648L-II skid-

soned guys and they know to send him. Normally when we pick up the phone somebody is out here pretty quick.”

maintenance and minor repairs, busted hoses and oil changes and the like, for themselves in the woods. If there is ever anything major, they’ll take it good service guys,” Matt says. “Mark Kibbler normally comes out here and takes care of us. He’s one of their sea-

Bud chimes in, “Randy has been super great at following up and getting us help anytime we need it.” If they’re in a bind, Matt adds, Randy is on it quick. “That helps a lot.”

Forestry Mutual Insurance covers their worker’s comp and other insurance; the Wests’ field agent is Phillip Sly. They also have some machines and trucks covered by another North Carolina-based outfit, TimberRisk Agency, a new insurance company

Production

Since 2017, the Wests have worked hand-in-hand with timber buyer Canal Wood. That company is based in Conway, but the Wests deal with the Edgefield office, working with foresters Chris Redding and Jeff Hughes. Matt describes the relationship as a partnership. “It’s not like, ‘Hey, we bought this one so you go cut it.’

formed last year by veteran agent Nick Carter to focus on the forest products industry.

10 l AUGUST 2023 l Southern Loggin’ Times

West Forest Products crew,from left:Grant Duncan,Hunter Berry,James“Cowboy” Davis,Trey Bonner,Kenny Nicholson and MattWest

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Brown Chapel crew,from left:MattWest,BudWest,Tony Qualls,Wesley Chastie,Tyrone Smith,Jonathan Bonner,Jeremy Price

Dad or me will go scope it out to see if it’s something we want before they decide to bid on it. They have been able to keep stumpage ahead of us pretty good, and we’ve been trying to buy stuff closer to home, and to the mills, due to logistics.”

When Southern Loggin’ Times visited in April, the Brown Chapel crew was working about 15 minutes from home—not a bad commute.

Conveniently, plenty of mills are close to Newberry, making it an ideal home base for a logger. “There’s a lot of mills around here,” Bud points out. “This is the logging hub of the state right here.” The Wests haul plywood material to Boise Cascade in Chester, saw timber and chip-n-saw to West Fraser in Newberry, ply log and chip-nsaw material to Georgia-Pacific in Prosperity, pine pulpwood mostly to West Fraser in Joana, and some fiber to Enviva in Greenwood and

New Indy Containerboard in Rock Hill. Poles go to South Carolina Pole & Piling in Leesville, and hardwood logs go to Beal Lumber Co. in Prosperity.

The baseline goal is 40 loads a week per crew, though, like many loggers, they have the capacity to haul a lot more if they could, but weather often limits production.

Also, Bud says, “Some of these mills now have us on a daily quota. It’s always a challenge. If you could come out here and just run wide open, it wouldn’t be a problem.”

Bud has four log trucks under his West Land Clearing company that haul for Brown Chapel: a 2001 International, ’13 Kenworth W900, and two ’16 Kenworth T8-80s. Bud

It’s a shame we didn’t save this one till the October issue, because loggers might want to read this hardwood horror story around a campfire come Halloween.

On December 21, 1981, Bud West was still a young man working on his father’s logging job, manning a Cat cable skidder with no brakes. Bud had jumped off to unhook the chokers and didn’t realize the machine was rolling backwards, until it was too late.

“When I turned around it knocked me down and rolled up on me,” he recalls. He was pinned under it all the way up to his waist before it stopped. Both legs were crushed. As if that weren’t scary enough, Bud was trapped lying there in terrible pain for an hour and a half before his dad found him.

“Back in 1981 there wasn’t a lot of physical therapy,” he says. “They just patched you up and put you back to work. So I was back in the woods before too long, probably three months or so.” Ultimately he recovered with no long-term ill effects, not so much as a limp, but in the short-term, this was assuredly no picnic.

also has a ’14 Kenworth W900 to pull the lowboy. He buys from Worldwide Kenworth in Columbia. Matt’s West Forest Products has five Mack CHU613s; he buys from Shealy Truck Center in Duncan. Trailers are mostly Pitts with a few Evans and McLendons in the mix. The Wests also hire several regular contract haulers.

Southern Loggin’ Times l AUGUST 2023 l 11

Fromleft:CanalWoodrepChrisRedding,MattandBudWest,DobbssalesmanRandyWilkes

Scary Story

12 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

➤

Challenges

“If you’re gonna be in the logging business, you better be tough, mentally and physically,” Bud stresses. Topping his list of concerns are insurance costs and fuel costs. Mills that paid a little extra for fuel last year were phasing it out by April of this year. “The thing about the surcharge is, they pay it on the trucks; they’re not paying any surcharge on all this equipment running out here in the woods,”

Bud notes. “This is where you’re burning all the fuel is out here.”

Overall, compensation has just not gone up enough to offset all the steep and rapid increases in the cost of doing business over the last few years, the Wests agree, reflecting the experience across the board in this and many other industries. “There’s nowhere to pass it on,” Bud shrugs. “You just have to absorb it. And the only way to absorb it is to work harder and work longer.”

Their partnership with Canal

helps, Matt interjects; they’ve agreed on a set number and won’t go under that. “They do a lot; I will give them credit. If we need extra loads, they will aggravate somebody about getting some extra loads. They are really good about that.” He explains that the relationship is more like friendship than just business. “I think if I told Chris Redding I was broke down on the side of the road somewhere two days away, he’d head out. I think a lot of him, and I think he thinks a lot of us.”

Manpower

The Brown Chapel crew includes loader operators Kenny Nicholson (who is the brother of Matt’s wife Kayce) and Wesley Chastie, cutter man Jeremy Price and skidder drivers Jonathan Bonner, Tony Qualls and Tyrone Smith, with truck drivers Charles Mace, Arthur Jones and Joe Flemon. On the West Forest Products crew, Trey Bonner runs the cutter, Grant Duncan is in the skidder and Hunter Berry mans the loader; truck drivers are Dave Devaney, Harry Ellis and James “Cowboy” Davis. Another driver, Randy Hare, helps part-time. Several of the drivers and operators are seasoned industry veterans who are good at their jobs, and the Wests feel blessed to have them on the team.

“You can’t forget the women,” Bud says; his wife Kim handles all the bookwork for the company. “They take care of the bills, and if it wasn’t for the women, nobody out here would get paid. Then they gotta put up with you after you have been out here and had a bad day.”

“They deal with a lot,” Matt concurs. “You don’t realize how much till you go into the office and sit down with them. You have to fill out this form and that form…and I think, I’ve gotta go.” His dad agrees, laughing, “Leave me in the woods!”

The West companies are truly a family business, Bud emphasizes. “This is not a job; it’s a way of life. Logging is not a 9-5; it’s all day, every day. You can’t get away from it; it’s here all the time. I love it. You gotta love it.” His son agrees. “If you don’t love it, you might as well quit it.”

Along with their three sons, Bud and Kim have two grandsons, Brooks, 5, and Brody, 2, both from Matt and his wife Kayce. Brooks is obsessed with logging, knows all about it, and has his own toy crew with a track cutter, skidders, loader and processor. Salesman Wilkes keeps him in the latest John Deere die cast metal toys as Christmas and birthday gifts.

“He FaceTimes me if I am driving a truck,” Bud says of his older grandson. “He’ll ask, ‘Poppa can I help you park the truck when you get home?’ And then he’ll get in the cab and help me park it. If you ask him what’s he going to be when he grows up, he says, ‘Like my daddy, in the logging woods.’” So it sounds like there will be a fifth generation of West loggers.

Looking ahead, Bud says, “I don’t want to retire, but I’d like to slow down. I been in the woods all my life. People don’t realize what they’re missing not working in the woods and seeing the day come alive every morning.”

SLT 12 l AUGUST 2023 l Southern Loggin’ Times 11 ➤ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Working Man

■ Brad Tomlinson is a simple man who gets to spend his life doing what he loves with the people he loves.

By David Abbott MABEN, Miss.

The company is called Big B Logging, but owner Brad Tomlinson, 50, swears he never meant for it to get quite this big. “I just wanted it to be small: one cutter, one skidder, one loader,” Tomlinson says. Instead, he’s fielding two whole crews.

He started the second crew, in part, for his sons Brennan, 24, and Brandon, 23. “I started a second crew because I intended to let them run one crew and me go to the other,” Tomlinson says. But, he

wouldn’t have this much equipment. But I try to teach them, and pass on some of what I have learned from the school of hard knocks.”

It’s a long road to graduation from that school. Tomlinson started out with just a log truck he owned and drove, hauling for other loggers, and ultimately, he thinks he might like to come full circle, get back to that simpler life. When his sons take over one day, possibly taking one crew each, he just wants to drive a truck for them. “I’m just getting old and ain’t able to do nothing else!” he explains. “I been broke up pretty bad. It’s a rough business…it can be. The job is not as dangerous as it

been very successful. In fact, they paid for their college educations at Northwest Mississippi Community

rodeo scholarships. Even now, they do pro rodeo about every weekend, traveling all over for it. “They’ve won a

★

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Tomlinson is a Deere fan,but his son wanted aTigercat.

together,” their dad says. “A man has to have a hobby if you work like this.”

Good advice, but what’s his hobby? “Work!” he laughs. “I love doing any of this, especially the tree cutter. I do race dirt track cars but I’m not serious about it.”

Tomlinson says as soon as his sons are ready, he’ll take a step back. But, he clarifies, “As soon as I think they're ready; they think they’re ready right now!” And in fact, he admits, they are ready to handle the work side, but they still need to learn more about the business side. “We are teaching them,” Tomlinson says. More so even than learning the numbers, he says, it’s establishing the connections like he has, something that takes a while to build. “I tell them that if I die, make sure to get my phone; there are so many contacts in there.”

For now, though, Tomlinson is still in the woods every day, usually felling, either with a feller-buncher or in some places with a chain saw. There’s not a lot of logging jobs anymore where the owner can be found running a chain saw all day; more often the boss is overseeing from the landing, or even working in an office. “Not me, buddy,” Tomlinson says empathically. He’d rather man a chain saw all day than spend his time trapped behind a desk. After all, that’s why he chose a logging career; he identifies as a

ple of years, very good,” Tomlinson says of the markets since 2020. “I see some slow down and some markets are demanding while others are

foresters and good friends, who find tracts for me, too. I do lot of it myself but a lot of it is repeat busi-

Winona and Southeastern Timber Products (the former PCA mill) in Ackerman. Most of their hardwood

Southern Loggin’ Times ● AUGUST 2023 ● 15

From left:BradTomlinson,his sons Brennan and BrandonTomlinson

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Tomlinson likes felling,with the cutter or a chain saw.

Teamwork

On crew one, Tomlinson runs the cutter, with Brennan on the loader and Brandon on the skidder. On the other crew, William Booth mans the loader, William Sykes drives the

skidder and Michael Lucas runs the cutter. Jason Fulghum is a contract driver. “All those guys have been with me for a long time,” Tomlinson says.

For equipment insurance he goes to Central Insurers at Grenada. His

broker agent is Lynn Casiday, and Tomlinson says he’d trust her with his own checkbook.

The logger’s wife Chrissy, a retired schoolteacher, is a good support for her husband and sons, Tomlinson says. “She’s our parts getter,

bookkeeper, check writer, lunch maker; whatever we need, she’s there. She helps a lot.”

Along with Brennan and Brandon, Brad and Chrissy have two daughters: Hailey works for a catering company in Starkville and Cortney Vinson is a doctor of physical therapy who lives in Nashville with her husband. They also have a few grandkids: CJ and Colton by Hailey, and John Allen by Brennan.

Equipment

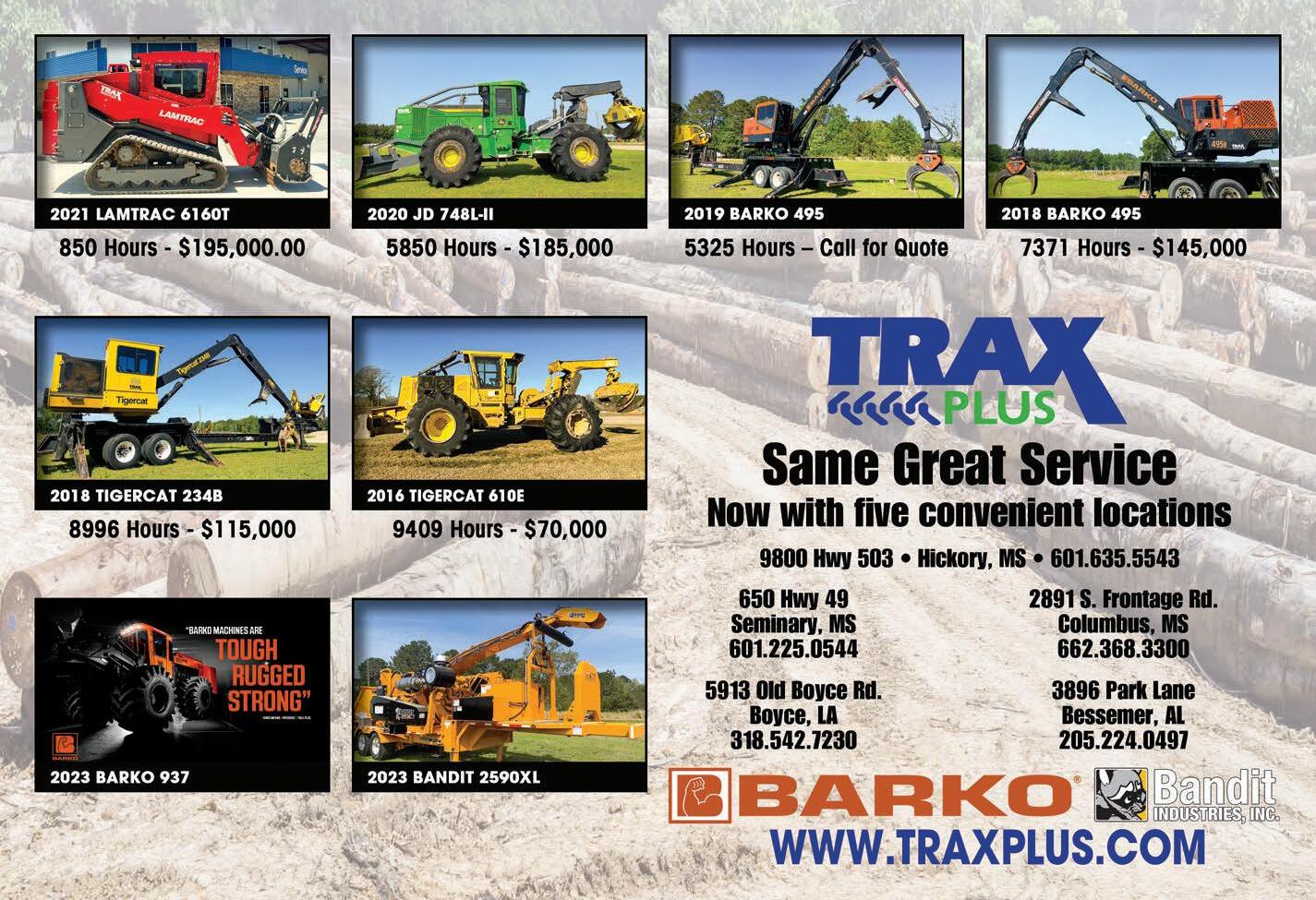

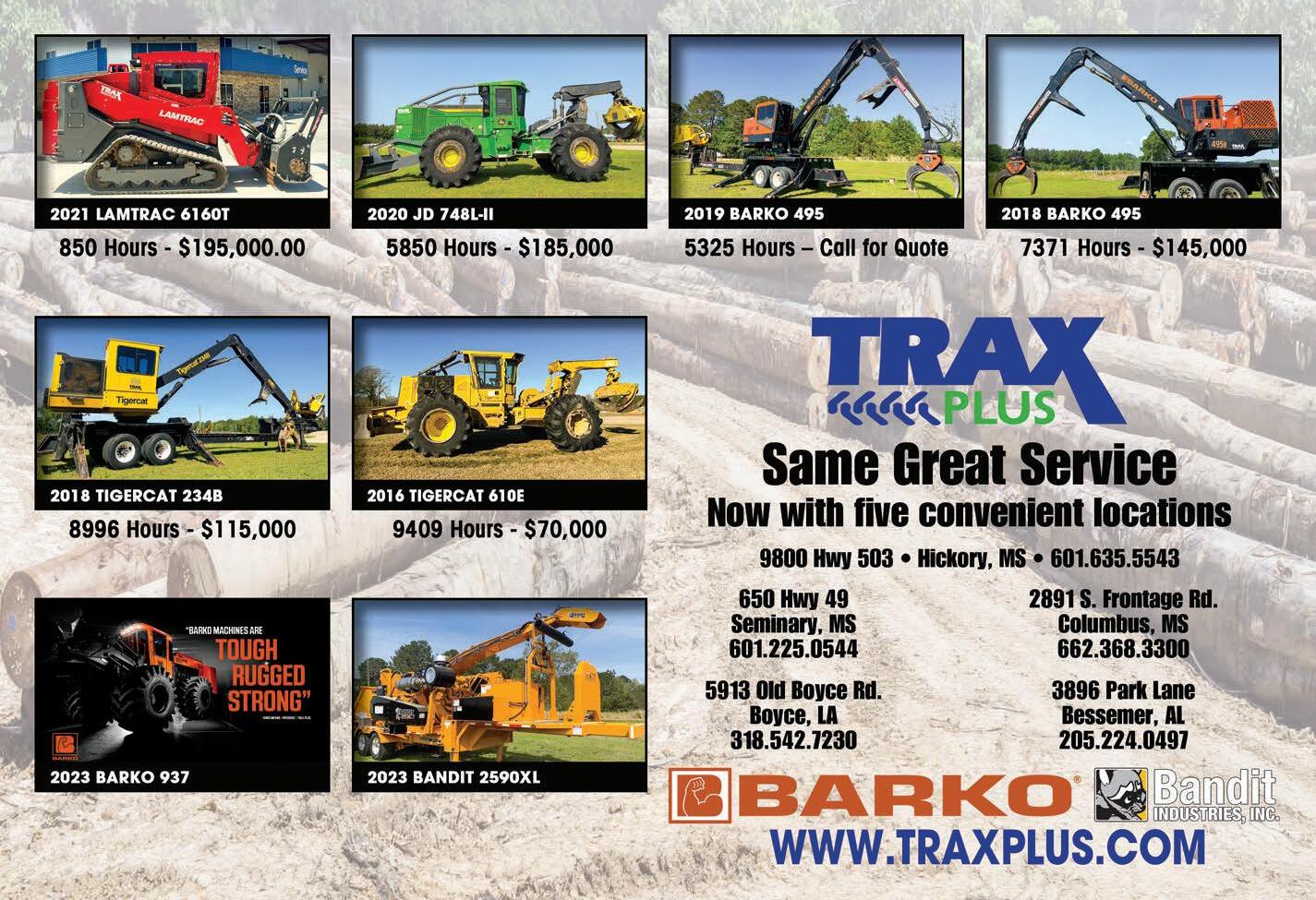

Between his two crews, Tomlinson has a Tigercat 234 loader, a John Deere 437 loader, a couple of 843J John Deere cutters, 748L and 848H Deere skidders, 843J cutters and a 39PX Komatsu dozer, which was the only machine he ever bought brand new, direct from Komatsu. The crew uses Stihl pole saws to trim loads and, sometimes, Stihl 462 chain saws when felling in terrain too steep for the cutters. He also keeps a fourth skidder, an older Deere 648H, parked at the shop as a spare. Every piece but one came from Trax Plus in Hickory; Tomlinson says, “They are good people who have been very good to me.” The

16 ● AUGUST 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

only exception is one cutter he bought used 15 years ago and still keeps for himself to run most days.

Big B runs six company trucks and contracts four others, of all brands: Kenworth, Freightliner, International, pulling Pitts, Magnolia and FMI trailers. “Gordon (Fryfogle) was the reason I bought Magnolia and now FMI,” Tomlinson says. “He’s a great guy.”

This logger is in no rush to trade in his machines for newer models. “I run my stuff till it’s used up,” he

says. “I wear it out; I’m not a new equipment kind of guy. We just keep it going. William is real good at that and I’m blessed to know that business very well myself too. I learned to work on this stuff because I couldn’t afford to take it anywhere, couldn’t call anybody, couldn’t pay them if they did show up. I don’t spend any money that I don’t have to spend.”

When the team needs extra help, he looks to Sam Gully at Noxapater Diesel in Noxapater, Miss. “If I call, he comes,” Tomlinson says. “Doesn’t matter what side of the state he’s on, he comes for maintenance, repairs, updates, anything we need. If we have a problem that William and I can’t get straightened out, then Sam comes and between the three of us, somehow we manage.”

Roots

Tomlinson says he grew up very poor. “We had what we needed,” he acknowledges, but evidently not much more than that. “My mother was a supervisor in a clothing factory and my dad worked in the state highway department.” He was introduced to the logging business through helping his grandfather, who cut short pulpwood. “We worked with horses, mules and tractors. I had a short pulpwood truck all the way through high school and every time I had a chance I hauled a load of shortwood.”

As a young man, he worked for other loggers, like the Brooks brothers and his childhood friend Link Nason, but all the time he was driving a log truck and hauling for others, his goal was always to start a small crew of his own. “I always wanted a shot and finally got one about 20 years ago,” he says. “I had no help; nobody signed notes for me, nobody paid anything down. I did it on my own.”

Honesty and character are very important to Tomlinson, and doing right by people. “Anything you do will come back to you,” he believes. “There is not a doubt in my mind that I have been able to stay in business because I’ve tried to be good to people, I’ve done what I said I’d do as much as I can and I’ve been honest. If I say it, I will do my best to do it. I hustle, but I’m not a hustler, I’m not a con man. At the end of the day, I am just a working man.”

He continues, “I have had some ups and downs and seen as many rough times as anybody. But God’s been mighty good to me. I’ve been a very, very blessed man. This business can promise you more and give you less than anything else I’ve ever seen. But all in all I have been blessed.” SLT

18 ● AUGUST 2023 ● Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Tomlinson runs his own trucks as well as contract haulers.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Coping With Disappointment

Disappointment is an inevitable part of life. Whatever the situation, dashed hopes can range anywhere from annoying to devastating. Rather than wallowing in the heavy weight of disappointment, why not learn how to effectively deal with life’s blows and to help you bounce back?

One way to cope with a letdown is to lean on the wisdom of others who have been there before and persevered. Time and perspective can help us to see a situation in a different, softer light. And remember that, “When one door closes, another one opens.” The other, lesser-known portion of this quote, by Alexander Graham Bell, is just as important to keep in mind: “But we so often look so long and so regretfully upon the closed door, that we do not see the ones which open for us.” The following quotes are reminders of all the doors that are available to us in any given situation; we just have to remember to look around.

l We must all suffer one of two things: the pain of discipline or the pain of regret or disappointment. —Jim Rohn, entrepreneur

l We must accept finite disappointment, but never lose infinite hope. —Martin Luther King Jr.

l Disappointment, when it involves neither shame nor loss, is as good as success; for it supplies as many images to the mind, and as many topics to the tongue. —Samuel Johnson, writer

l Sometimes good things fall apart so better things can fall together. —Marilyn Monroe

l Disappointment is really just a term for our refusal to look on the bright side. —

l A smooth sea never made a skilled sailor. —

D. Roosevelt

l You are never too old to set another goal or to dream a new dream. —Les Brown,

l Our greatest weakness lies in giving up. The most certain way to succeed is always to try just one more time.

Thomas Edison

l Disenchantment, whether it is a minor disappointment or a major shock, is the signal that things are moving into transition in our lives. —

tralian general

l Disappointment to a noble soul is what cold water is to burning metal; it strengthens, tempers, intensifies, but never destroys it. —Eliza Tabor,

l The size of your success is measured by the strength of your desire, the size of your dream, and how you handle disappointment along the way. — entrepreneur

l Disappointment is the nurse of wisdom. — Roche, Irish politician

Regarding Facebook

To others born in a certain generation who still do not, and cannot, comprehend why Facebook even exists, here’s what I’m doing to gain a better understanding. I am trying to make new friends without using Facebook, but I am applying the same principles.

Every day I walk down the street and tell passers-by what I have eaten, how I feel at the moment, what I have done the night before, what I will do later, and with whom. I give them pictures of my family, my dog, and of me gardening, taking things apart in the garage, watering the lawn, standing in front of landmarks, driving around

Special Pals

town, having lunch, and doing what anybody and everybody does every day. I also listen to their conversations, then give them the “thumbs up” and tell them I like them, and it works! I already have four people following me: Two police officers, a private investigator, and a psychiatrist.

INTERESTING ANAGRAMS

PRESBYTERIAN. Rearrange the letters—BEST IN PRAYER

ASTRONOMER. Rearrange the letters—MOON STARER

DESPERATION. Rearrange the letters—A ROPE ENDS IT

THE EYES. Rearrange the letters—THEY SEE THE MORSE CODE. Rearrange the letters—HERE COME DOTS

DORMITORY. Rearrange the letters—DIRTY ROOM

SLOT MACHINES. Rearrange the letters—CASH LOST IN ME

ELECTION RESULTS. Rearrange the letters—LIES. LETS RECOUNT

DECIMAL POINT. Rearrange the letters—IM A DOT IN PLACE

ELEVEN PLUS TWO. Rearrange the letters—TWELVE PLUS ONE

MOTHER-IN-LAW. Rearrange the letters—WOMAN HITLER

Rambling ‘Ponderisms’

—Atheism is a non-prophet organization.

—What if there were no hypothetical questions?

—If a deaf boy or girl signs swear words, does their mother wash their hands with soap?

—If someone with multiple personalities threatens to kill himself, is it considered a hostage situation?

—Is there another word for synonym?

—Where do forest rangers go to “get away from it all”?

—Why do some gas stations lock their rest rooms? Are they afraid someone will break in and clean them?

—Do infants enjoy infancy as much as some adults seem to enjoy adultery?

—If a turtle doesn’t have a shell, is it homeless or naked?

—If police arrest a mute, do they tell him he has the right to remain silent?

—Does the little mermaid wear an algebra?

—How is it possible to have a civil war?

—If you try to fail, and succeed, which have you done?

—Why are hemorrhoids not called asteroids?

—Why is there an expiration date on sour cream?

—Why do some shops display the sign “Guide Dogs Only,” when dogs can’t read and their owners can’t see?

Ringbearer’s Math

After the wedding, the little ringbearer asked his father, “How many brides can the groom marry?”

“One,” his father said. “Why do you ask?”

“Because the preacher said he could marry 16,” the boy said, puzzled.

“How’d you come up with that?” his father asked.

“Easy,” the little boy said. “All you have to do is add it up like he said said: 4 better, 4 worse, 4 richer, 4 poorer.”

20 l AUGUST 2023 l Southern Loggin’ Times

standingwaterinsoutheastGeorgia near the Florida line.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

INDUSTRY NEWS ROUNDUP

Dale Greene Retires As Dean Of UGA Warnell

After nearly four decades of leading future foresters through stands of pine trees and into successful careers, Dale Greene, dean of the University of Georgia’s Daniel B. Warnell School of Forestry and Natural Resources, has announced his retirement.

Greene has served as the school’s dean since 2015, though his tenure at Warnell began in 1986 when he joined the school’s faculty as an assistant professor. His retirement will become effective January 1, 2024.

“Dean Greene has had a remarkable career as a teacher, researcher

and administrator who prioritizes student success,” says UGA President Jere W. Morehead. “As a result of his exemplary leadership both as a faculty member and dean, Warnell is one of the top programs in the United States for forestry and natural resources and is well positioned to con-

tinue setting the national standard in these fields.”

Greene also researched and wrote extensively on the wood supply chain, including the condition and characteristics of logging businesses, harvesting techniques, thinning applications, log trucking efficiencies, mill policies and much more.

During Greene’s tenure, the Warnell School added several new faculty members; expanded outreach efforts; and grew funding for research, professorships and graduate assistantships. Nearly half of the school’s current faculty members were hired by Greene, with women now making up 20% of the faculty—a record high for the school.

Greene also led efforts to increase funding for teaching and learning, more than doubling the number of named professorships, scholarships and fellowships available to faculty and students. Additional donations have supported technology upgrades throughout Warnell’s facilities. And recently, the sale of 2,500 acres of property in south Georgia, which was donated to Warnell in 1989 by Charles Wheatley, secured $18.5 million that will be used for instruction, research and building improvements.

“Dean Greene has a clear commitment to UGA and to Warnell, and it has been a pleasure and privilege to work with him,” adds S. Jack Hu, senior vice president for academic affairs and provost. “His willingness to listen, to think through questions and issues and to act on new ideas have been assets to the school.”

Teaching has always been Greene’s passion, and he says his hours spent in the classroom are among his favorite memories. He has served as an advisor to 49 graduate students. Today they represent leaders in forest business, logistics, tree health, consulting and other fields.

Fellow professor and renowned deer researcher Karl Miller came to Warnell around the same year as Greene. They co-taught the school’s Senior Project capstone class for decades and developed a strong friendship that continues to this day. Miller, who retired in 2019, says Greene always put his students first.

“Dale was not very tolerant of mediocrity or failure to do the work that needed to be done, but he was also concerned about students and their performance and their welfare in general,” Miller says. “He would bend over backwards to help them, if they took the initiative.”

Over the years, four of Greene’s former students have been named Georgia Logger of the Year. Greene

22 l AUGUST 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

can also claim as his former students the state foresters for Georgia and South Carolina, Tim Lowrimore and Scott Phillips, respectively.

Among his numerous teaching and professional awards, Greene received the Herrick Award for Superior Teaching and the Warnell Alumni Assn. Award for Outstanding Teaching. He was inducted into the Georgia Foresters Hall of Fame in 2007, received the Wise Owl Award from the Georgia Forestry Assn. in 2011 and was named a fellow of the Society of

American Foresters in 2022.

Outside of Warnell, Greene is active in many professional and serv-

his son through Boy Scouts, he continued to volunteer with the organization. He received the Silver Beaver Award from the Northeast Georgia

Council of Boy Scouts of America in 2013 and the Billy Hudson Distinguished Citizen Award from the organization in 2023. Greene is also an active member or board member of the American Forest Foundation, the Georgia Forestry Assn. and the Georgia Forestry Foundation.

“It’s been an honor and a privilege to be a part of the University of Georgia community and to work alongside some of the best and brightest forestry and natural resources professionals in the country,” Greene sys. “I’ll always be a Bulldog, and Warnell will always be home.”

Greene received his B.S. from Louisiana State University in 1981, an M.S. from Virginia Polytechnic Institute in 1983 and a Ph.D. from Auburn University in 1986.

Article and photo provided by Warnell School of Forestry & Natural Resources communications office.

Auburn University Real Estate Foundation (AUREF) and the College of Forestry, Wildlife and Environment (CFWE) has accepted a gift of 415 acres of Crooked Oaks Farm, legendary and deceased Auburn football coach Pat Dye’s homestead. Located in Notasulga, Ala., the farm property includes Dye’s main house, a guest cabin, lodge, pavilion, gazebo, two barns and a nursery office.

“We had been longtime supporters of Auburn University through our charitable trust and in hosting fundraising events, and the timing was right to make the gift,” says Nancy McDonald, Dye’s longtime partner and retired nursing educator at Auburn University at Montgomery.

AUREF is holding the gift from the Dye/McDonald Trust and McDonald on behalf of the university and the college. The college plans to continue its operations as an event venue, while expanding its use for student instruction and community outreach.

“We both knew we would donate the farm to the College of Forestry,

24 l AUGUST 2023 l Southern Loggin’ Times

PatDyeathisfarminNotasulga

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Greenestoodtallforproperforestmanagementandloggingoperations.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Wildlife and Environment and seeing the work CFWE leaders have done since accepting the proposal, I could not be more confident that the land will be valued and held to the standard Pat and I always wanted to see,” McDonald says. “I feel his spirit in this, and I know what’s happening is something he would be proud of.”

Pat Dye Jr. adds, “Given everything that Auburn has done for dad and our family, he would be thrilled to know that Auburn will be great stewards of his beloved farm, hope-

fully for many generations.”

Dye began developing the property in 1998 and continued to improve all aspects of the land until his death in 2020. Ponds, pastures and woodlands contain numerous Japanese Maples, azaleas, camellias, native azaleas, boxwoods, gardenias, magnolias, oaks, pines, beeches, river birches and firs. Included in the area adjacent to the nursery is a two-acre retreat of walking paths along a stream with falls and pools winding among 200 mature Japanese Maple specimen

trees of 71 Japanese Maple cultivars.

When McDonald retired and moved to Crooked Oaks in 2004, the couple worked together on the farm and continued its development into a beautiful retreat and sanctuary for wildlife and rescued dogs, cats, donkeys and horses.

“To me, living on this place is like living in paradise,” Dye wrote of Crooked Oaks in his 2014 book, “After the Arena.” “The good Lord created it and then I just put a few touches on it so I can enjoy it and

appreciate it, because no one can paint a picture like Mother Nature.”

When not in use for private events, leaders within the CFWE plan to conduct educational programs and other activities at the farm.

“This incredible gift will have a tremendous impact on the college, our students and our academic programs,” says Janaki R.R. Alavalapati, the Emmett F. Thompson Dean of the College of Forestry, Wildlife and Environment.

(Article from Auburn University communications.)

Core Plans Facility For Pellets Handling

Core Industries plans to invest $8.75 million to construct a processing and storage facility at its port facility in Mobile County, Ala., to support a contract to handle wood pellets for CM Biomass, according to the Mobile Chamber and the Industrial Development Authority.

The project will create 28 jobs over the next five years. As part of its agreement with CM Biomass, Core Industries will receive, store and load wood pellets for shipment. To advance the collaboration, Core will build two warehouses, each spanning 57,600 sq. ft., at its existing location on Claudia Lane in Theodore, near Mobile.

“We are very pleased that CM Biomass selected Core Industries to handle its wood pellets,” says Michael Myles, principal owner of Core Industries. “This deal with CM Biomass is an example of Core’s diversity and build-to-suit capabilities. That and our close proximity to Interstates 10 and 65 and the Gulf of Mexico, make Core Industries a logical choice for cargo handling and logistical services.”

Core Industries operates one of the largest privately held port facilities in the Southeast and boasts impressive capabilities to handle multiple vessels simultaneously, with a depth of 40 ft. and two docking facilities.

Denmark-based CM Biomass, one of the largest independent wood pellet trading companies in the world, has a pellet production facility in Jackson, Ala.

Musser Expands Byproducts Business

Musser Biomass and Wood Products, a division of family-owned and operated Musser Lumber Co., will invest $7.5 million and create 10 new jobs to expand its operation at Rural Retreat, Va. in Wythe County. The expansion will more than double production of dried hardwood chips and sawdust the

26 l AUGUST 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

company supplies to composite decking manufacturers, plastic extrusion companies, and BBQ and heating wood pellet companies.

Musser Biomass and Wood Products will significantly increase its purchase volumes of hardwood residuals from regional sawmills, which will create a new market for this operational byproduct.

Established in 1968 by Mike Musser and his sons Ed and Mick, Musser Lumber specializes in drying,

surfacing and planing of hardwood lumber for flooring and paneling. The company sources lumber from dozens of sawmills.

In 2020, in an opportunity to expand its operations, the Mussers established Musser Biomass and Wood Products, which has enabled the company to purchase sawdust and wood chips from their mill supply base and grow its sales of these materials. Musser Biomass and Wood Products plans to bring on a second

dryer this year and then open a pulpwood and log yard to supply its dryer operations.

Virginia Dept of Agriculture and Consumer Services worked with Wythe County and the Joint Industrial Development Authority of Wythe County to secure the project for the Commonwealth. Governor Youngkin approved a $75,000 grant from the Governor’s Agriculture and Forestry Industries Development (AFID) Fund, which Wythe County will match with local funds.

Lucky Branch Tract Finds Some Luck

The Lucky Branch tract, an 80acre parcel of bottomland hardwood forest situated next to the Little River and Uwharrie National Forest in Montgomery County, North Carolina, has been conserved thanks in part to a grant provided by the Enviva Forest Conservation Fund. This grant enabled Three Rivers Land Trust to acquire a conservation easement on the property and safeguard the tract, which is part of a larger 520-acre easement, encompassing a variety of habitats.

“Thanks to funding from the NC Land and Water Fund, the Enviva Forest Conservation Fund, and a generous easement donation by the landowner, these 80 acres on the pristine Little River will remain free from development and maintained as a beautiful hardwood forest for the

enjoyment of future generations,” says Crystal Cockman, Associate Director, Three Rivers Land Trust.

Currently the site hosts habitat for two threatened species: the Carolina redhorse, and Villosa delumbis, a mussel species also known as the Eastern Creekshell. This stretch of the Little River is classified as the Yadkin/Upper Little River Aquatic Habitat natural area with a very high rating as determined by the North Carolina Natural Heritage Program.

Enviva Forest Conservation Fund’s goal is to be a catalyst for investments in forest and habitat conservation in southeast Virginia and North Carolina’s coastal plains. As the fund enters its eighth year of the planned 10-year partnership, 31 projects have been funded with a total commitment of more than $3.8 million.

Enviva Makes It Official At Epes

World-leading industrial wood pellet producer Enviva Inc. formally broke ground on its Epes pellet plant in Sumter County, Ala.

Enviva has been active in Sumter County since its initial assessment of the site in 2018. In 2020, Enviva acquired more than 300 acres in the Epes Industrial Park, located next to the Tombigbee River, to build its largest wood pellet production plant. In July 2022, the company began construction of its fully contracted Epes plant, which will have a nameplate capacity of 1.1 million metric tons per year and is expected to be in service by mid-2024, with production fully ramped by 2025.

“The fact that the world’s largest wood pellet producer is building its largest production facility to date here, in Sweet Home Alabama, is yet another testament to our nationleading business climate and worldclass workforce,” Alabama Governor Kay Ivey says. “Enviva’s significant commitment at the Port of Epes will undoubtedly breathe life into a community and region eager for new, long-term opportunities.”

When assessing and developing the project, Enviva chose to repurpose a former business site and construct a brand-new, state-of-the-art manufacturing facility to jumpstart economic growth and bring employment opportunities back to the community. Once operational, the Epes plant is expected to support approximately 100 direct jobs and 250 indirect jobs, including in adjacent industries such as logging, trucking and shipping.

Enviva plans to invest, on average, $375 million for each newly constructed plant going forward, including the Epes plant. The rich fiber basket and supply in Alabama, along with favorable transport logis-

28 l AUGUST 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

tics and a great local workforce, are some of the key factors which initially made the project sustainable and attractive for Enviva. Enviva will source fiber at the new plant by following the robust set of practices and principles that are employed successfully at Enviva’s other plants. The facility will sustainably and responsibly source wood from areas within approximately 75 miles of the plant.

“It is an honor to be here in Sumter County with Governor Ivey and local officials to celebrate this momentous occasion of breaking ground on a fully contracted, stateof-the-art wood pellet production facility in West Alabama,” says Thomas Meth, President and CEO of Enviva. “We have been humbled by the strong support we have received from the local community over the last few years, and we look forward to formally being a part of the community and to being a good neighbor for many years to come.”

Pellets produced at the Epes plant will be exported to international markets, mainly in Europe and Asia, and will help to fill international demand for secure sources of renewable energy.

30 l AUGUST 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

IRONWORKS

TOLL FREE: 1-800-669-5613

BENT SAWDISKS wear over time to extreme unbalance, occasionally requiring added weight to correct balance.

I specialize in straightening and balancing all makes of feller buncher sawdisks.

CARVER SAWDISK REPAIR Washington, NC 252-945-2358

2004 Barko 495ML Loader, Cummins power, joysticks, saw hydraulics, right off the job...$27,500 Call or Text Zane 334-518-9937 3939 visit us online

EUREKA! EUREKA! EUREKA!

OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE! We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts!

SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or

CLASSIFIED AD RATES: Classified advertising rates are $55 per inch. Space is available by column inch only, one inch minimum.

DEADLINES: Ad reservation must be received by 10th of month prior to month of publication. Material must be received no later than 12th of month prior to month of publication.

CONTACT: Call Bridget DeVane at 334-699-7837, 800-669-5613, email bdevane7@hotmail.com or visit www.southernloggintimes.com

Southern Loggin’ Times ● AUGUST 2023 ● 33

2687

EUREKA

NOW ACCEPTING CREDIT CARDS 7180 6209

Night/Weekends • 1-434-634-9185

566

FOR SALE

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

southernloggingtimes.com

34 ● AUGUST 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 4433 13905 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Southern Loggin’ Times ● AUGUST 2023 ● 35 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2687 2891 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

36 ● AUGUST 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 6288 13189 7393 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

COMING EVENTS

August

11-12—Southwest Forest Products Expo, Hot Springs Convention Center, Hot Springs, Ark. Call 501-2242232; visit arkloggers.com.

17-20—Virginia Loggers Assn. annual meeting, Hotel Roanoke, Roanoke, Va. Call 804-677-4290; visit valoggers.org.

23-25—Forest Products Machinery & Equipment Expo, Music City Center, Nashville, Tenn. Call 504443-4464; visit sfpaexpo.com.

29-31—Florida Forestry Assn. Annual Meeting & Trade Show, Sandestin Golf & Beach Resort, Miramar Beach, Fla. Call 850-2225646; visit flforestry.org.

29-31—Louisiana Forestry Assn. annual meeting, Golden Nugget Hotel & Casino Resort, Lake Charles, La. Call 318-443-2558; visit laforestry.com.

September

5-8—Tennessee Forestry Assn. annual meeting, Marriott Cool Springs, Franklin, Tenn. Call 615-883-3832; visit tnforestry.com.

7-9—Great Lakes Logging & Heavy Equipment Expo, UP State Fairground, Escanaba, Mich. Call 715-282-5828; visit gltpa.org.

southernloggintimes.com

10-12—Alabama Forestry Assn. annual meeting, Perdido Beach Resort, Orange Beach, Ala. Call 334-265-8733; visit alaforestry.org.

15-16—Kentucky Wood Expo, Masterson Station Park, Lexington, Ky. Call 502-695-3979; visit kfia.org.

15-17—Virginia Forest Products Assn. Annual Conference, The Omni Homestead Resort, Homestead, Va. Call 804-737-5625; visit vfpa.net.

22-23—Mid-South Forestry Equipment Show, Starkville, Miss. Call 800-669-5613; visit midsouth forestry.org.

26-28—Arkansas Forestry Assn. annual meeting, Oaklawn Hotel & Spa, Hot Springs, Ark. Call 501374-2441; visit arkforests.org.

27-29—North Carolina Forestry Assn. annual meeting, Biltmore Estate, Asheville, NC. Call 800231-7723; visit ncforestry.org.

October

3-6—American Loggers Council annual meeting, Sunday River Ski Resort, Newry, Maine. Call 409625-0206; visit amloggers.com.

18-20—Texas Forestry Assn. annual meeting, The Fredonia Hotel, Nacogdoches, Tex. Visit texasforestry.org.

Listings are submitted months in advance. Always verify dates and locations with contacts prior to making plans to attend.

American Truck Parts 38 888.383.8884 Big John Trailers 5 800.771.4140 BITCO Insurance 19 800.475.4477 Caterpillar Dealer Promotion 27 919.550.1201 Dobbs Equipment 2,32 844.469.3622 Eastern Surplus 16 855.332.0500 FMI Trailers 18 601.508.3333 Forest Chain 38 800.288.0887 Forestry First 36 803.708.0624 Forestry Mutual Insurance 17 800.849.7788 G & W Equipment 30 800.284.9032 Great Lakes Timber Professionals Assn. 22 715.304.2861 Hawkins & Rawlinson 12 888.822.1173 Interstate Tire Service 36 864.947.9208 Kaufman Trailers NC 3 336.790.6807 Mike Ledkins Insurance Agency 23 800.766.8349 LMI-Tennessee 25 800.467.0944 Loadrite Southern Star 28 256.270.8775 Logger Associations 16 Magnolia Trailers 31 800.738.2123 Maxi-Load Scale Systems 26 877.265.1486 Mid-South Forestry Equipment Show 29 601.354.4936 Midsouth Forestry Equipment 10 870.226.0000 Moore Logging Supply 28 888.754.5613 Morbark 1,13 800.831.0042 Panhandle Forestry 34 850-832-4164 Pitts Trailers 40 800.321.8073 Ponsse North America 39 715.369.4833 Prolenc Manufacturing 16 877.563.8899 Quadco Equipment 23 800.668.3340 Quality Equipment & Parts 34 386.487.3896 Smith & Turner Equipment 21 770.536.7521 Southern Loggers Cooperative 30 318.445.0750 Stribling Equipment 35 855.781.9408 Tidewater Equipment 33,35 912.638.7726 Tigercat Industries 7 519.753.2000 TimberRisk Agency 11 803.669.1003 TraxPlus 19 601.635.5543 W & W Truck & Tractor 37 843.761.8220 Waters International Trucks 36 601.693.4807 Yancey Brothers 30 800.282.1562 Yokohama Off-Highway Tires America 24 800.343.3276 38 ● AUGUST 2023 ● Southern Loggin’ Times

ADLINK is a free service for advertisers and readers. The publisher assumes no liability for errors or omissions. A ● D ● L ● I ● N ● K ADVERTISER PG. NO. PHONE NO.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!