HGA CORE TEAM

Design for Integration

Design for Equitable Communities

Design for Ecosystems

Design for Water

Design for Economy

Design for Energy

Design for Well-Being

Design for Resources

Design for Change

Design for Discovery

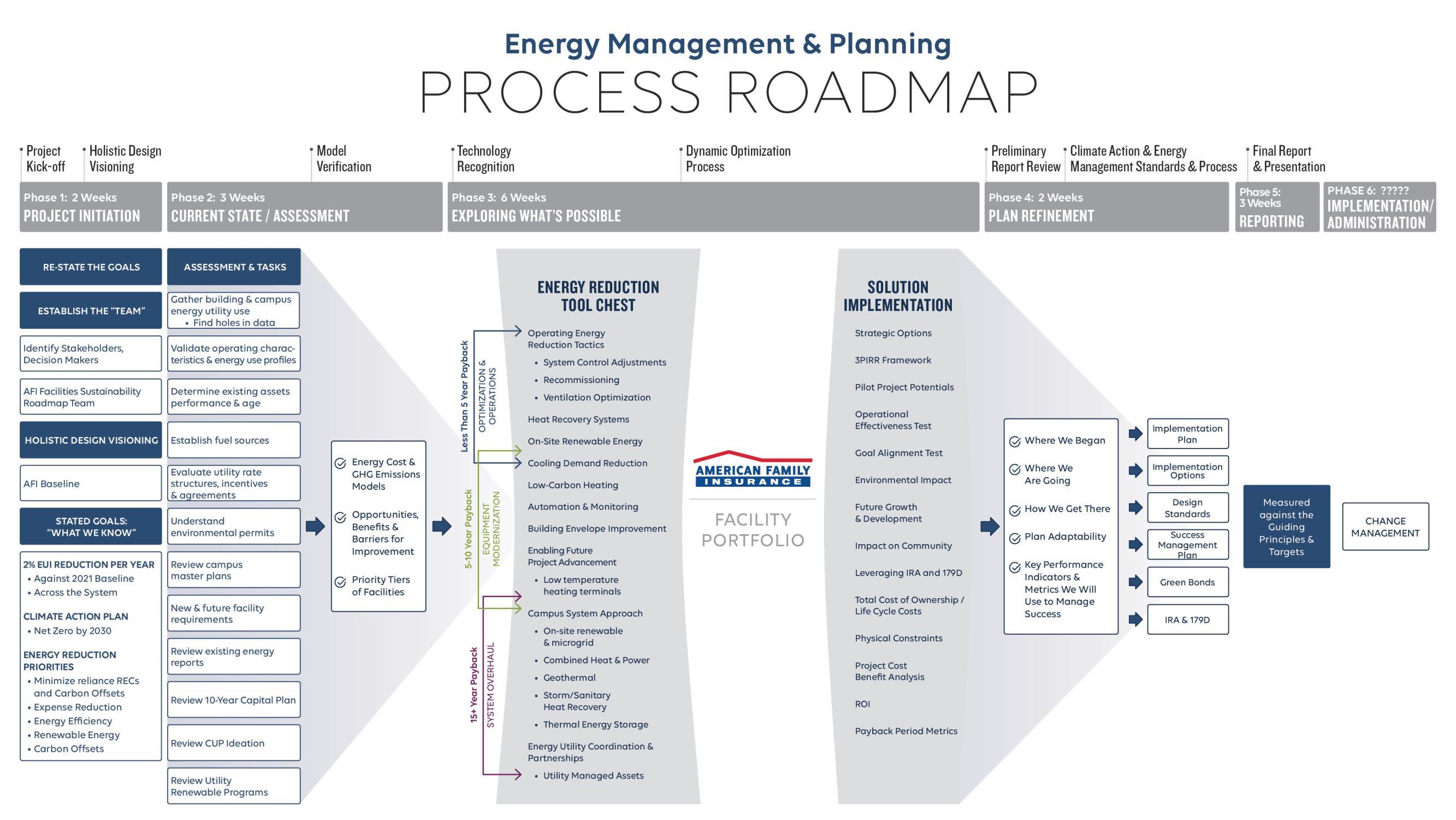

Tactical

Implementable

Practical

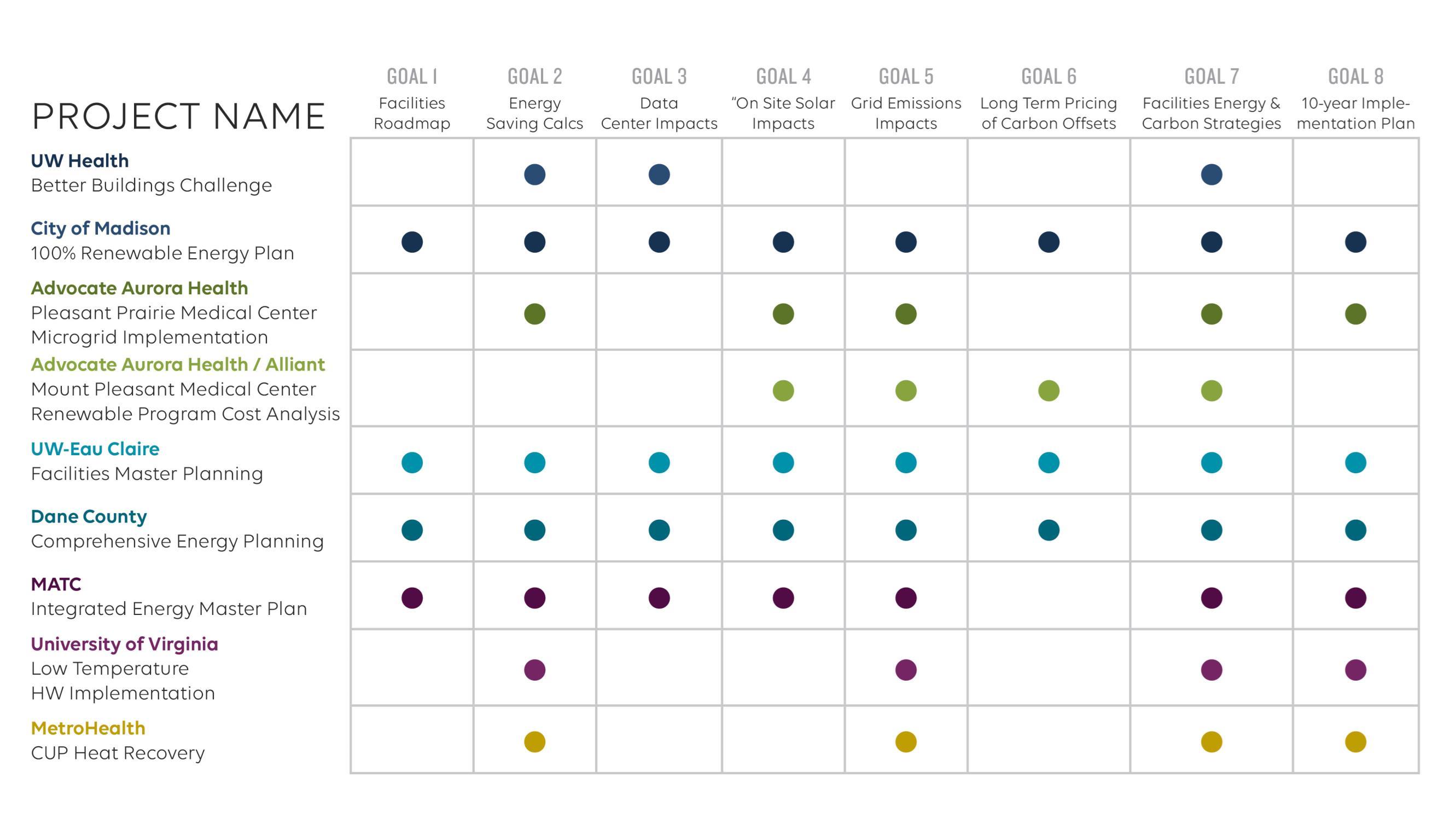

Challenge Partners with Greatest Energy Savings SAVINGS SINCE BASELINE YEAR

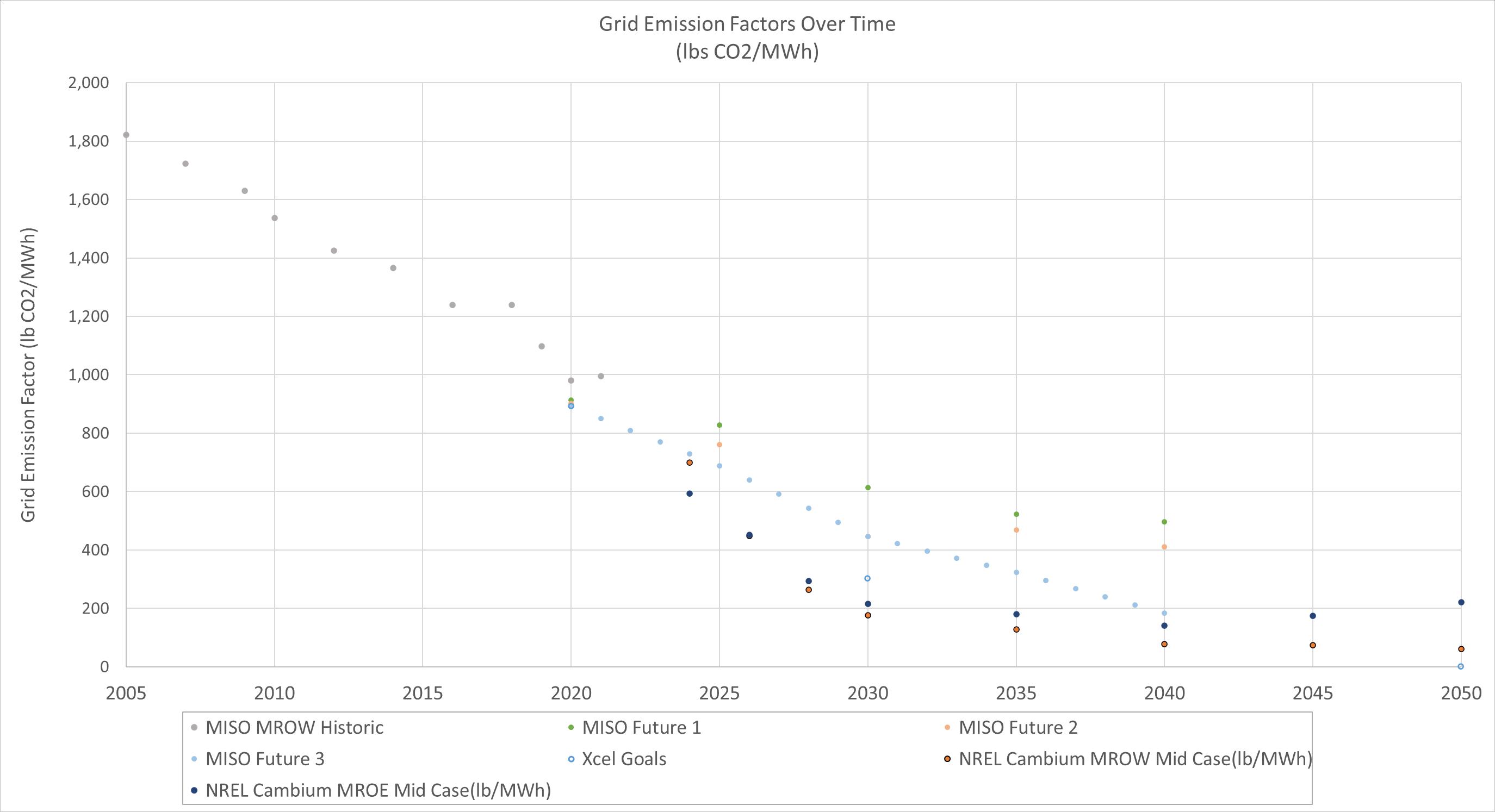

Cambium and AVERT Tools

Cambium and AVERT Tools

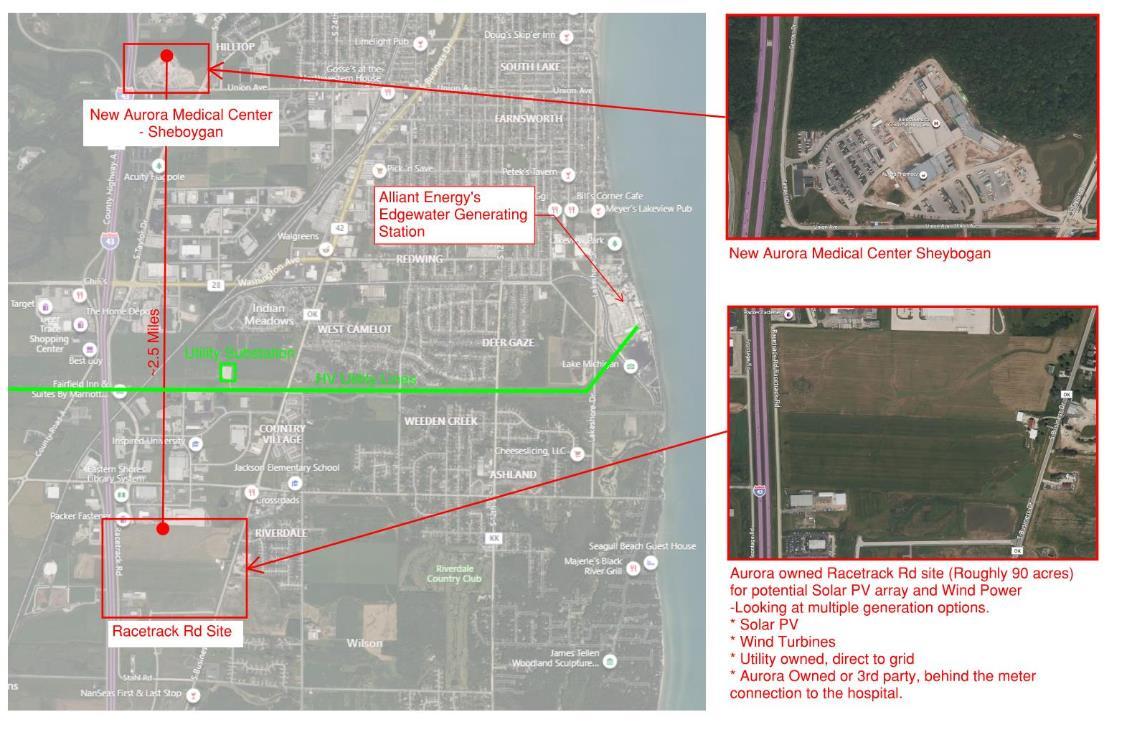

• 200,000 SF Surgery Center/MOB

• Completed in 2020

• Comprehensive Planning to grow into a bed tower potentially with ED and Women’s Health

• Engineering System Design – Planned for Growth

• I94 Corridor Growth

CURRENT ASC/MOB

FUTURE MASTER PLAN - HOSPITAL

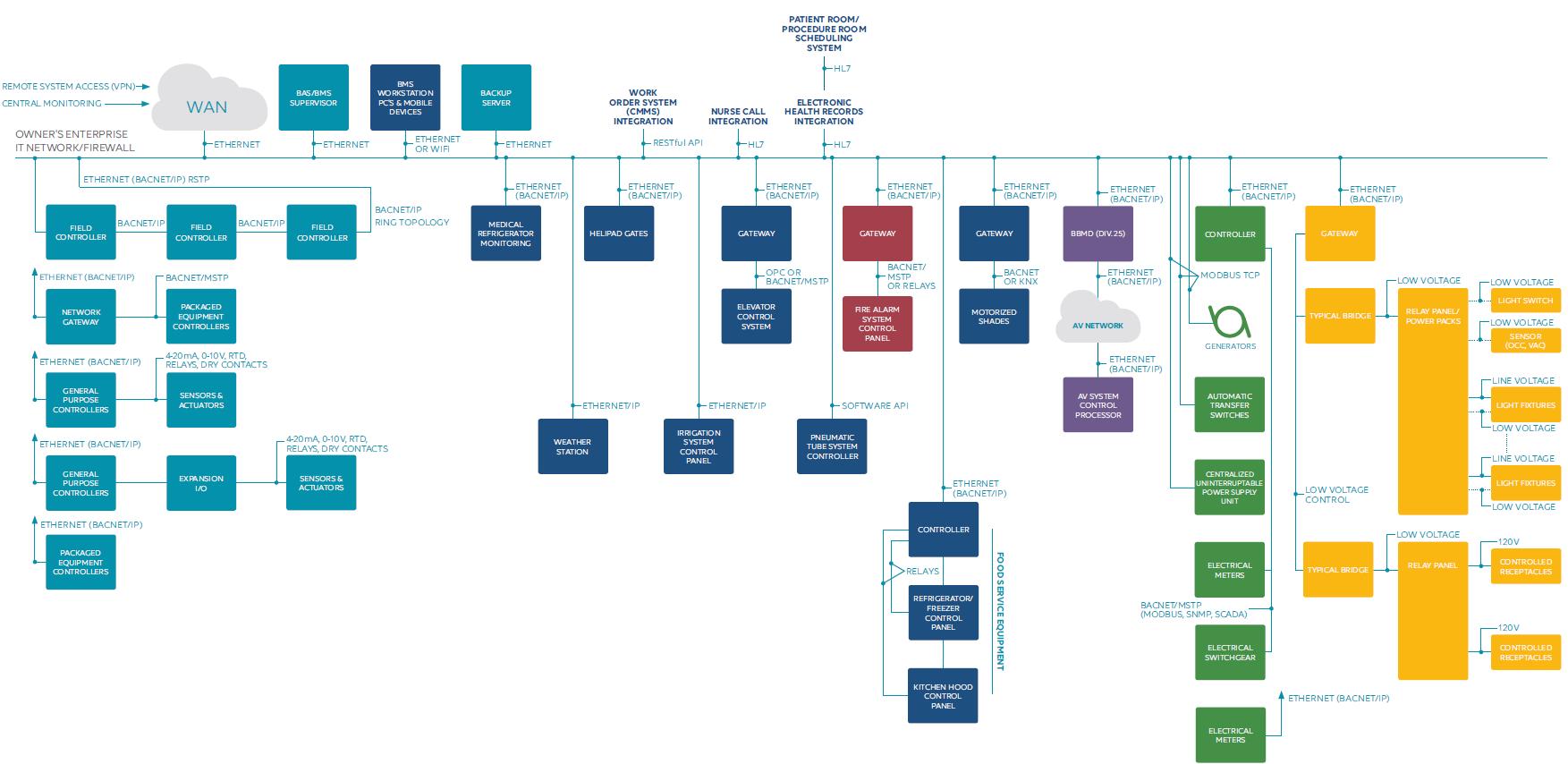

• Work together with Facilities and IT

• Coordinate BAS upgrade cycles with equipment

• Repair/Reprogram/Replace

• Equipment and Controls

• Reliable

• Efficient

• Connected

• Data Driven Decisions

• FDD and Analytics

• Dashboarding

• Reporting

BuildingLoads

Utility Feed

Microgrid Feed

Battery

Geo design for 70 facilities, comprising 7,400,000 SF

30 facilities in the Dane County area

Designing geo on both coasts of the U.S.

Most are 100% heated by geo

No natural gas service needed

Decarbonization vs Electrification

Maintain Steam System vs Conversion from Steam to Low Temperature Hot Water (LTHW)

Diesel Emergency Generators

Why Convert to Low Temperature

Hot Water?

Phased Approach to LTHW

Conversion

Full Central Plant, Distribution System, and Building Systems

Upgrade

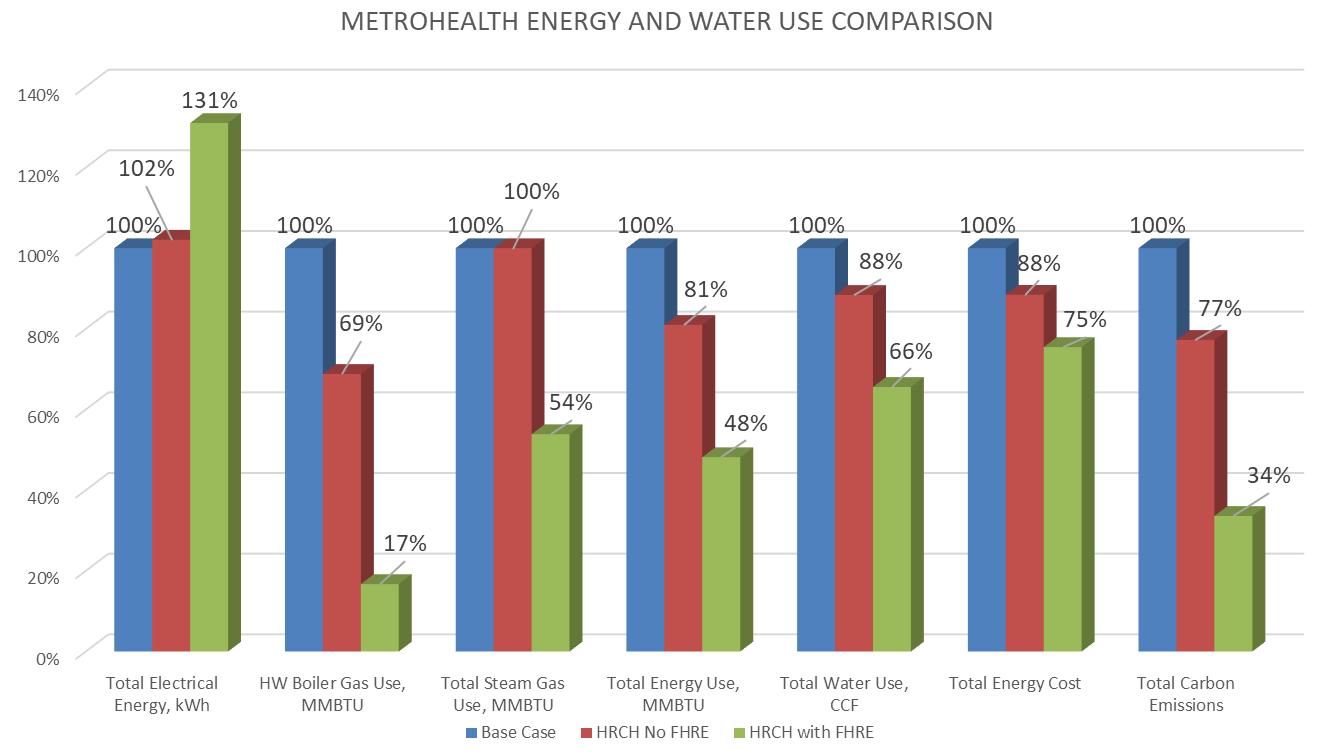

Why Utilize Heat Recovery Chillers?

•Electrify heating loads using as little as 25% of the energy as an electric boiler

•Provides simultaneous heating and cooling

•Can be incorporated into geothermal systems

Challenges with Heat Recovery Chillers

• Cost

• Maintenance

• Equipment Selection and System Design

• Controls

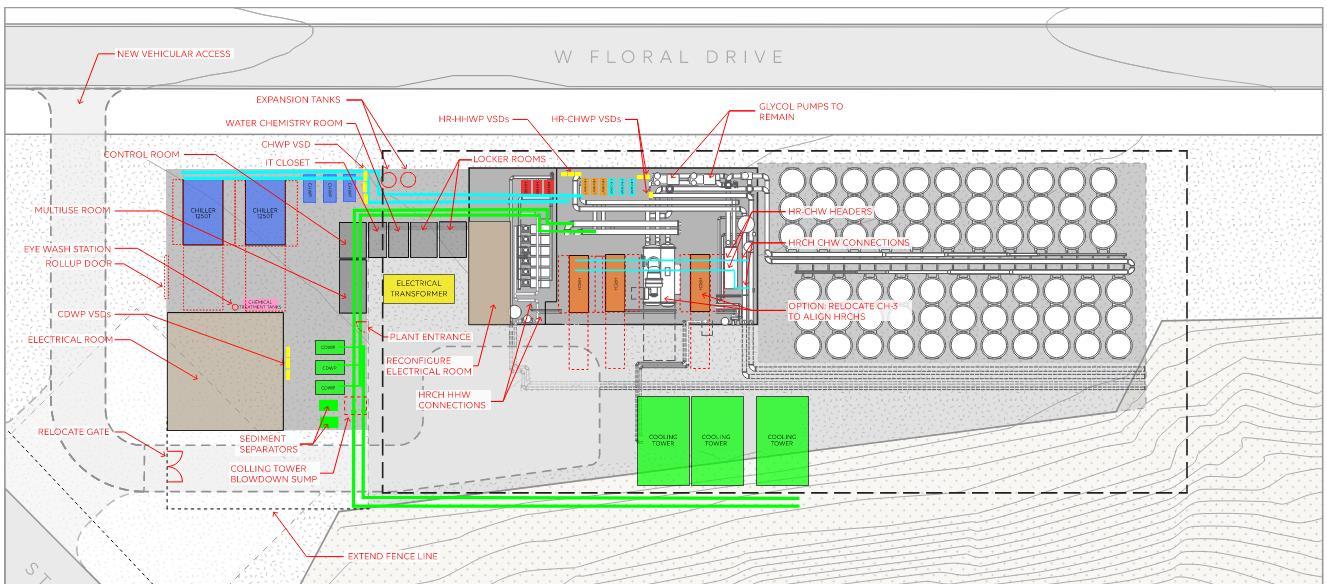

UVA Heat Recovery Implementation

•Installation of HRCH

•Implementation of HGA’s Predictive Optimization

•Reset from high temperature(200°F+) to Low Temperature (135°F) to maximize the use of HRCH

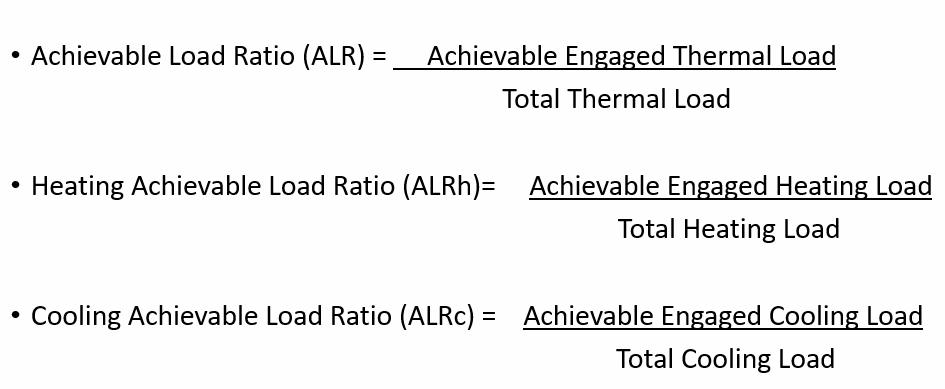

•Developed metrics for evaluatingHRCH systems

Select equipment based on the building load profile (peak loads, minimum loads, simultaneous loads) and temperature requirements

CR= Condenser Rejected BTU/ Evap Absorbed BTU

CR=1+ 1/(COPh-1)

Clg Load * CR = Heating Load

1. HRCH is controlled to the minimum of Phhwl, Pchwl*CR, HRCH Capacity

a. Pchwl can be controlled via FHRE

b. HRCH Capacity is a function of the #HRCH Online, and evap and cond

Temperatures

2. Control HRCH condenser flow so that Qhr = Phhwl

3. Control HRCH evaporator flow to maintain evaporator leaving temperature at setpoint

4. Calculate offset load as a function of (Thhwset - T_blr ent)

5. Add offset load to CHW system through FHRE or from central loop

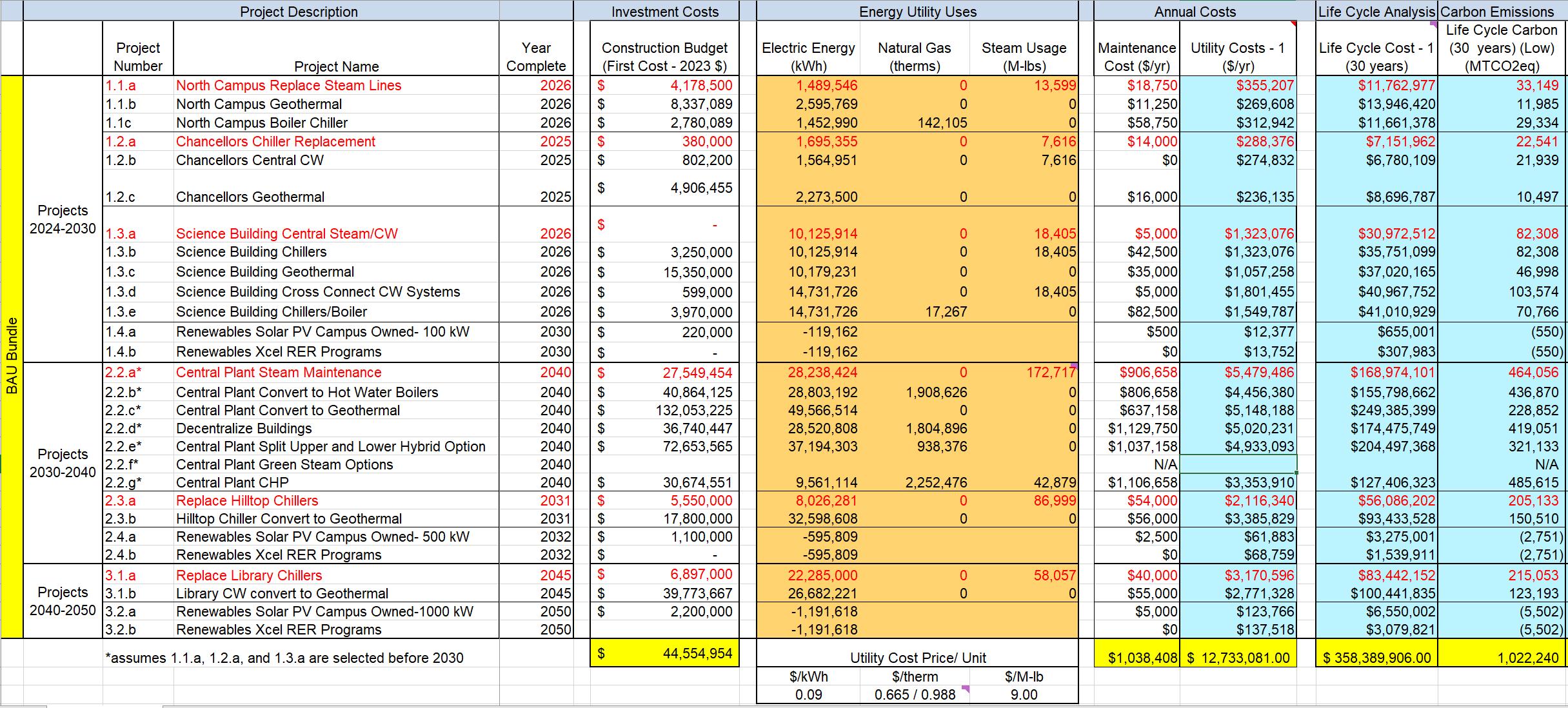

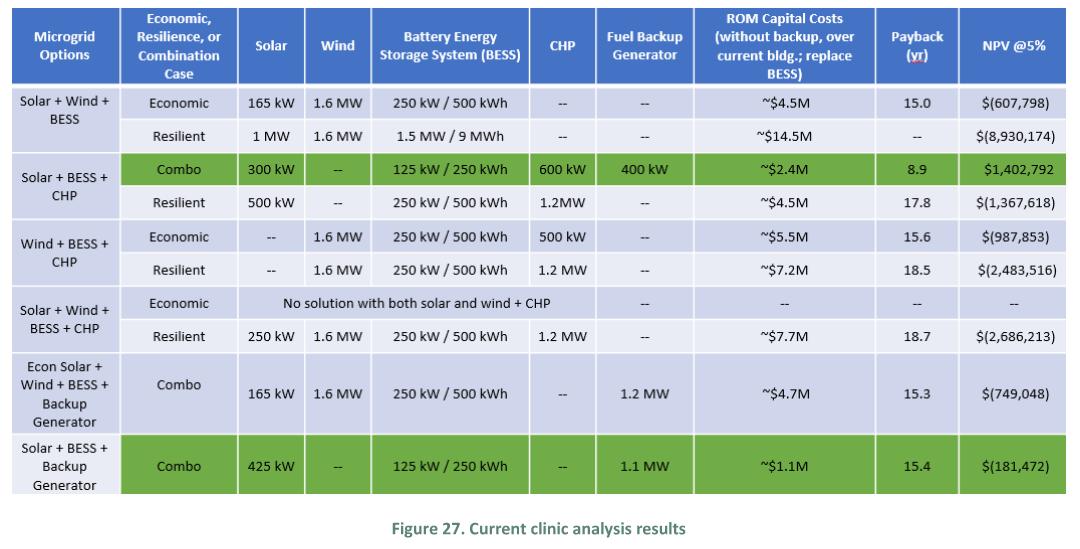

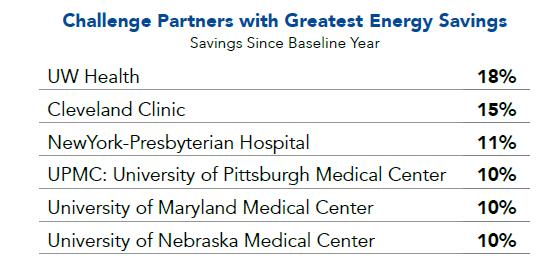

Alex Slides- UW Eau Claire Decarbonization Study

Alex Slides- UW Eau Claire Decarbonization Study