1 minute read

DIGITAL DESIGN LASERCUT FABRICATION

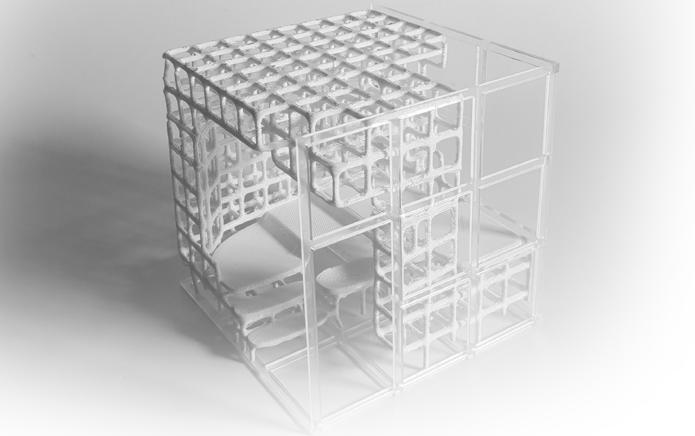

Grasshopper parametric techniques, lasercut fabrication. By uti lizing grasshopper, multiple iterations were performed in order to create the best form for fabrication and concept. The panels were designed to change with the sun’s rotation with point attractors, giving the structure an ephemeral quality changing through time and space in accordance with the sun.

The waffle structure created with grasshopper creates the struct ural framing, giving the model clear boundaries and circulation paths developed through its spiral formation and defined edge. The rigid triangulated pa nels have been juxtaposed against the loose flow of the waffle to create a unified and dynamic form.

Advertisement

PHYSICAL MODEL: LASERCUT

PERSPECTIVE: HYPOTHETICAL USES

GRASSHOPPER PROCESS & ITERATIONS

Strip cuts in panels allows for directional light to protrude into internal space

Triangulation allows for a structurally rigid panel surface join creates enclosure

Exploded Isometric

Panel cuts create a transient space, able to change throughout the day in accordance with the sun

Flowing waffle structure creates structural framing with clear boundaries and circulation paths developed through its spiral formation and defined edge Triangular form, filters light creating gentler internal lighting

Panels Designed to change with the suns rotation through the use of point attractors, giving the structure an ephemeral quality