5 minute read

Zinc Frames Edgy, Contemporary Design

from commARCH - June 2014

by IdeaSoil

Free-standing emergency room described as metal origami.

Described by some as metal origami, the Legacy ER building in Allen, TX, functions as a state-licensed emergency facility and an urgent-care clinic. The emergency room is open 24/7. T he uniqueness of a free-standing emergency room is rivaled only by the distinctive design concept of the new Legacy ER in Allen, TX. Described by some as metal origami, the facility functions as a state-licensed emergency facility and as an urgent-care clinic. The emergency room is open twenty-four hours a day, seven days a week.

Advertisement

The owners of Legacy ER sought to redefine the medical-care experience. The building integrates the principles of evidence-based design and sustainability within its spatial, circulatory, and sensory structure. The workspace components were designed for peer collaboration, patient accessibility, and data privacy. Patient-care areas were crafted for hospitality and treatment efficacy.

This is the second Legacy ER building designed by 5G Studio Collaborative, Dallas. The success of the design of the first building, located in Frisco, TX, and the exceptional branding and business opportunities it enabled, convinced the client to push forward with an edgy, contemporary design for the Allen facility. The design is intended to advance the discourse on the architecture of the healing environment.

The 7,632-sq.-ft. facility features three emergency-department examination rooms, two trauma rooms, five urgent-care examination rooms, and an on-site laboratory and radiology suite, complete with CT scan.

According to Yen Ong, partner at 5G Studio and principal architect, “The architecture explores the spatially expressible relationship between the clinical administration of medicine and the emotional relation between the medical professional,

the patient, and the healing environment.”

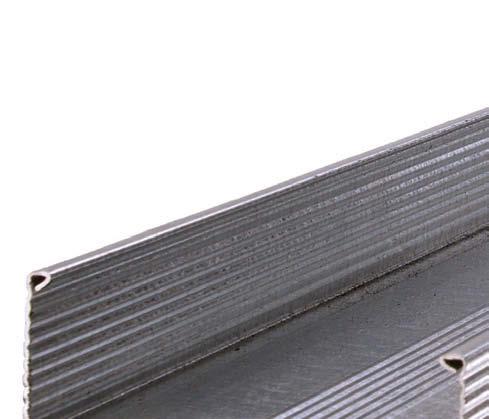

The exterior of the structure features an architectural robe of zinc panels with an integrated lighting system. Perforated Reveal panels from Rheinzink America Inc., Woburn, MA, clad the dramatic overhangs and soffits and Rheinzink standing-seam panels clad the façade. Approximately 17,000 sq. ft. of PrePATINA bluegray panels were used overall.

“The owners wanted to create a distinctive facility,” Ong said. “We presented this modern look and proposed Rheinzink because it’s a sustainable metal; it’s durable and, in spite of its cool hue, it’s still very warm and charming. We really wanted to capture the essence of an ER physician’s role in a patient’s life. I think we were successful in doing that, especially with zinc, because the material is very flexible, very durable, and very precise. It captures all of the attributes of physicians that patients in this situation want to see.”

The large, sloping soffits, clad with perforated panels, provide the signature look. “We used the perforations to create a diffusion for the building lighting,” Ong said. “The perforations are larger toward the outer edges and smaller toward the inside to achieve the gradient of light. At night, the diffused lighting pattern is quite evident.”

Long-time Rheinzink partner and distributor, MetalTech-USA,

Above. The large, sloping soffits, clad with perforated panels, provide the signature look. The perforations are larger toward the outer edges and smaller toward the inside to achieve the gradient of light.

Below. The architecture explores the spatially expressible relationship between the clinical administration of medicine and the emotional relation between the medical professional, the patient, and the healing environment, according to the architect.

Peachtree City, GA, was chosen to fabricate the zinc panels. The perforated panels were integral in executing the architect’s vision. The perforations help provide exterior views from within the building, as well as a method of peripheral lighting. Varying perforation patterns were carefully chosen and mapped onto each panel to achieve a gradient reading that adds to the perceptual depth of the building geometry. Five different perforation patterns had to be coordinated with two different panel types and sizes. “The greatest challenge was the set-up and programming that was necessary to get the panels fabricated properly,” said Metal-Tech project manager Michael Love. “But the end result was worth all of our hard work.”

Another interesting aspect of the panels is the trimless zero-edge detailing that suggests flight, lightness, precision, and speed, according to architect Ong.

Installation of the Rheinzink panels was done by Ramon Franklin LLC, Fort Worth, TX. “This was one of the most challenging jobs that we’ve faced,” stated senior project manager Mark Standifer. “I’ve never been on a roof where we didn’t trim it—there’s no fabricated 10-ft.-long trim pieces or eave pieces. The architect really wanted a trimless look. And you have the edge of the panel tying into another panel going into a completely different plane. There’s not a 90-degree corner on the exterior of the building. We’re familiar with Rheinzink through previous jobs, but we had never seen one like this.”

Yen Ong concurs that the job was challenging, particularly achieving the zero edge. “It took a lot of precision and structure behind the zinc panels,” he said. “One of the remarkable attributes of Ramon Franklin is that they really worked with us on the detailing of the panels. There’s no 3-in.-wide coping or flashing as you would typically see.”

The budget was a challenge, too. “We were initially a bit over budget, and the zinc was obviously the easy target,” Ong said. “But the owners insisted we keep it. They saw it as having that much value. It has become a branding staple of their facilities.”

Relating in contrast to the precise geometries of the exterior, the interior spaces are designed to blur edges and to softly receive daylight and artificial light. Multiple skylights are situated at strategic intersections of the circulatory loop to form a sensible system of way-finding and exits to the outdoors. The atmospheric quality of the interior continually morphs in re

sponse to the natural climatic conditions. The detailing of the interior skylights reads as frameless apertures that puncture the zinc exterior paneling.

The architectural wrap of zinc paneling provides not only the sought-after distinctive appearance and longevity, but it is environmentally friendly and 100% recyclable.

CBP

DATA CACHE

Want more information? The resources below are linked in our digital magazine at cbpmagazine.com/digital/jun2014.

Circle 2 on the Reader Service Card.

Download technical documentation at Download technical documentation at http://www.rheinzink.us/environmental/technical-documentation http://www.rheinzink.us/environmental/technical-documentation

See zinc-based exterior products at See zinc-based exterior products at http://www.rheinzink.us/products/ http://www.rheinzink.us/products/

Browse projects by type, application, and location at http://www.rheinzink.us/no_cache/project-gallery/

Get information on service, training, and education at http://www.rheinzink.us/value-added/