4 minute read

A lasting legacy Alutech

A LASTING LEGACY

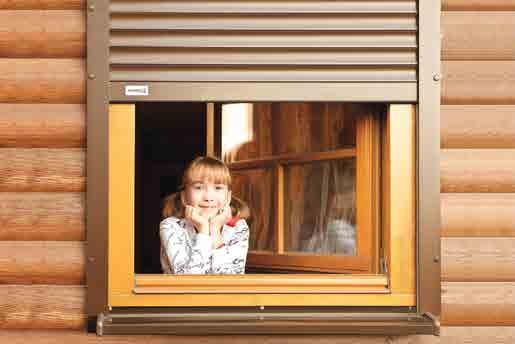

Since the Alutech Group was first introduced to Industry Europe readers a few years ago, the company has maintained its position as the eastern European market leader in roller shutters, aluminium profile systems and sectional doors. Vanja Švačko reports.

Afocus on new key brands, advanced technologies and improving quality have been the distinguishing characteristics of the Alutech Group in recent years. In only two decades it has managed to grow from a small business handled by six people to a holding with six manufacturing enterprises and almost 30 sales representatives and local warehouses all over Europe (including Belarus, Russia, Ukraine, Czech Republic, Germany and Austria).

Shared responsibilities

Alutech has three production sites in Belarus, two in Russia and Ukraine and one in Germany. Its diverse portfolio consists of coated aluminium/steel lath roll-formed profiles, components and accessories for roller shutters, manufactured at its 25,000m2 production site in Minsk.

A new production plant, Alutech Door Systems, was launched in 2013 as a result of more than $75 million of heavy investment deals with a wide range of doors (garage and industrial sectional doors, entry groups, sandwich-panels for sectional doors, steel guide channels etc.) and an annual capacity of 250,000 door units.

Alumin Techno boasts the largest production of extruded aluminium profiles, powder coating and anodic treatment in eastern Europe. It is equipped with an up-to-date foundry shop, six high-tech extrusion lines, two vertical powder coating lines and the largest anodising complex in the region.

The other enterprises within the group are in charge of roller shutters and door production. The experienced German producer Günther-Tore GmbH, specialised in garage and industrial sectional doors, roller doors and grids etc., was purchased by Alutech in 2013.

The group’s production is organised so that every single stage of the process can be controlled and supervised. All its equipment is purchased from manufacturers who are global leaders in their respective fields, and the entire management and produc-

tion system is certified according to the ISO 9001 standard. The success of the group’s trade is in combining high quality raw materials with the implementation of the most advanced technologies. Although the main market for Alutech is Europe, its products are sold with an equal success in Asia, Africa and North America (for example, products such as aluminium profile systems for façades, as well as interior systems, are in increasing demand, especially for high-rise buildings).

Apart from its own products, Alutech also distributes electric motors and automatic control systems for roller shutters produced by other manufacturers.

Market potential

Alutech Group regularly takes part in specialist trade fairs all over the world. In 2013 the company exhibited at GlassBuildAmerica in Atlanta, the largest US fair for the glass, window and door industries. Mr Vladimir Rybakov, Deputy General Director of Alutech Group, remembers how successful this proved to be. “It was the first time we had showcased our product that far from Belarus. The US market is a very specific territory with its legendary customer care and exceptional requirements when it comes to product quality. I think we have done a good job, because visitors voted our booth as the most Innovative Product Booth of the show.

“Our patented engineered solutions for easy connections for architectural system

components and integration between different systems attracted a lot of attention.”

Alutech’s products are available in more than 200 colours, both anodised and powder coated. Its systems are compatible with remotely controlled automatic hardware which is an excellent security option.

“In fact, our products became very popular in the USA,” continues Mr Rybakov, “because we care about quality and service. We supplied our curtain wall systems and window components for remarkable projects on the East Coast, including New York City, and received positive feedback from our customers.”

Alutech recently took part in the R+T Stuttgart exhibition, the leading fair for roller shutters, doors/gates and sun protection systems, which celebrated its 50th anniversary this year. As one of the key exhibitors, Alutech Group launched new sectional doors, insulated roller garage doors and commercial roller shutters. Some of the innovations included a new type of anti-hurricane shutter, rollers with integrated anti-mosquito systems,

new anti-intrusion solutions, new fillings for panoramic gates and a wider colour palette for garage doors.

An effective collaboration

Alutech takes pride in its long-standing partnership with one of the leading global players: the year 2014 marked five years of collaboration with BASF Coatings GmbH. They began working together on coil coatings and a cutting production complex for aluminium and steel coil, and continued with both companies working on new technologies for lacquer coating quality assessment.

The two companies were pioneers in applying the crockmeter test for this assessment. The new technology, which includes an electronic device for the simulation of constant movement (opening and closing of the roller shutter curtain), enabled Alutech to significantly improve the abrasion resistance of the coating (more than twice) and to prolong the life cycle of its products. n