LEGRAND UK & IRELAND ANNOUNCES INVESTMENT IN UK MANUFACTURING WITH NEW FACILITY

LEGRAND UK & IRELAND ANNOUNCES INVESTMENT IN UK MANUFACTURING WITH NEW FACILITY

Apotential UK-US trade deal under President Donald Trump in 2025 could have significant implications for both nations’ economies and international relationships. Following the UK's exit from the European Union, the UK has sought to build new trade agreements, with a deal with the United States being a priority. Trump's return to office would likely see a renewed focus on achieving a bilateral trade agreement that reflects his "America First" policies, prioritizing American interests while reshaping the economic dynamics between the two countries.

For the UK, a trade deal with the US would help offset the economic challenges of Brexit. The UK’s departure from the EU meant it lost access to the EU’s single market, and a strong trade relationship with the US could help mitigate the economic disruptions, particularly for sectors like finance, agriculture, and technology. For the US, a trade deal with the UK would be seen as an opportunity to promote American exports and strengthen ties with a key ally, while continuing Trump’s legacy of challenging multilateral trade agreements in favour of bilateral deals.

In 2025, under Trump's leadership, a UK-US trade deal would be characterized by Trump's transactional approach. He would likely aim to secure favourable terms for American businesses, particularly in agriculture, manufacturing, and tech, while promoting American jobs.

A central feature of any UK-US trade deal would be the negotiation of tariffs and market access. Trump’s "America First" approach would focus on ensuring the US has better access to UK markets, especially for agricultural products such as beef, poultry, and dairy. For the UK, this could mean greater access for its financial services sector, crucial post-Brexit.

A significant challenge in these negotiations would be the divergence in regulatory standards. Trump’s administration has often favoured deregulation, particularly in environmental and health standards. The UK, by contrast, has its own stringent regulations, especially around food safety, pharmaceuticals,

and environmental protections. A potential deal could require the UK to ease some of these regulations, particularly on food products like chlorinated chicken or hormone-treated beef. These areas could lead to public opposition in the UK, where food safety standards are a sensitive issue.

Another key area would be intellectual property (IP) protections, which are important to the US, especially in the technology sector. Trump’s administration previously made IP protection a central issue, aiming to prevent intellectual property theft and promote American tech companies. The UK, a global leader in technology and financial services, would likely support stronger IP protections, as this could benefit its own industries. However, the deal might also raise concerns over data privacy and the handling of personal data, which are increasingly contentious issues in international trade.

Beyond economic considerations, a trade deal would likely be influenced by broader geopolitical concerns, particularly regarding China and Russia. Trump’s administration would likely see the UK as an important partner in countering China’s growing influence. The deal could include provisions for deeper collaboration in technology, defence, and cybersecurity. A UK-US deal would also help solidify the “special relationship” between the two countries, ensuring that they remain united on global challenges.

One of the main obstacles to a UK-US trade deal would be political divisions within the UK. While the Conservative government may be eager to secure favourable trade terms with the US, opposition parties, including Labour, may be more sceptical, especially regarding food safety and environmental standards. This political opposition could slow the negotiation process and make it harder to achieve a deal that satisfies both sides.

The economic imbalance between the two nations could also pose challenges. The US typically runs a trade deficit with the UK, and

Trump may push for changes to reduce this imbalance. This could involve demands for increased British purchases of US goods, particularly in sectors like agriculture, automotive, and technology. These measures could generate resistance from UK industries that feel they are being disadvantaged by the deal. The US might also seek to impose tariffs or quotas on certain sectors of the UK economy, potentially creating friction.

A strong UK-US trade deal could also complicate the UK’s relationship with the European Union. The UK has already taken steps to distance itself from EU trade regulations, but a deepening of ties with the US could further alienate EU member states, particularly if the UK aligns its policies more closely with the US. The EU may view this as a challenge to its own influence and could respond with trade barriers or other retaliatory measures.

Domestically, the UK may face significant resistance to some provisions of the deal, particularly in areas like agriculture and environmental regulations. The public in the UK tends to be cautious about accepting USstyle agricultural practices, particularly if they compromise food safety or animal welfare. This could lead to significant protests and debates in the UK Parliament, which might delay or hinder the deal.

A UK-US trade deal under President Trump in 2025 would be a complex, multifaceted negotiation, characterized by a focus on reducing trade barriers and securing better access to markets. The deal would be shaped by Trump’s desire to promote American economic interests, particularly in agriculture, technology, and manufacturing. However, the UK would also seek to protect its own industries, regulatory standards, and political autonomy. While the potential benefits of such a deal are significant, particularly for a post-Brexit UK, the challenges in balancing both countries’ economic priorities, political dynamics, and global strategies would make the negotiation process difficult and contentious. n

Katarzyna

110 Boundary Road, Norwich NR6 5JE, United Kingdom

Tel: +44 1133 281 173

Email: studio@industryeurope.net

Web: www.industryeurope.com

LinkedIn: www.linkedin.com/company/industry-europe

The concept of a "smart city" refers to the use of digital technology, data analytics, and connected systems to improve the quality of life for residents, enhance sustainability, and create more efficient urban environments. In the United Kingdom, the idea of transforming cities into smart hubs has gained significant traction in recent years, driven by technological advancements and a growing need for more sustainable urban development. As urban populations rise, the demand for smarter infrastructure, energy-efficient systems, and better governance has made smart cities an essential part of the UK's urban planning strategy.

Smart cities integrate a wide array of technologies to improve urban living. Key features often include:

Internet of Things (IoT) Devices: IoT sensors embedded in streetlights, buildings, vehicles, and other infrastructure allow for real-time data collection. This data can monitor traffic patterns, energy usage, pollution levels, and even public safety.

Sustainable Transport: Smart transportation systems are critical to reducing congestion and emissions. Innovations such as electric vehicle (EV) charging networks, smart traffic lights, and public transport apps help to optimize the flow of people and goods in urban spaces. These systems reduce reliance on fossil-fuel-driven transportation and promote green alternatives.

Energy Management: Smart cities use data to create efficient, renewable energy systems. For example, solar panels and smart grids help cities manage energy distribution and reduce carbon emissions. The use of renewable energy and energy storage systems is central to the sustainability of smart cities.

Data-Driven Governance: Smart cities often employ data analytics to improve urban planning and public services. For instance, city officials can use data to identify areas with high demand for healthcare, allocate resources more efficiently, and track the effectiveness of policies in real-time. This enables better decision-making, transparency, and citizen engagement.

Digital Connectivity: High-speed internet and wireless networks are the backbone of smart city technologies. With the advent of 5G, the speed and reliability of internet services will further enhance the capacity of smart city infrastructure.

Several cities in the UK have made notable progress in becoming smart cities, with a strong focus on sustainability, transportation, and innovation:

Bristol: Often regarded as one of the UK’s pioneering smart cities, Bristol is recognized for its commitment to sustainability and digital innovation. It has implemented a range of projects, including the use of sensor networks to monitor air quality, smart streetlights to reduce

energy consumption, and the promotion of low-carbon transport options like electric buses and shared bike schemes. Bristol has also worked to establish itself as a "smart city" in terms of governance, using data to improve public services and policy-making.

London: As one of the largest and most diverse cities in the UK, London has embraced the smart city movement with initiatives like the London Urban Observatory, which gathers and analyzes data to improve urban life. London's public transport system is a key example of a smart infrastructure, with contactless payment options like Oyster cards and mobile apps that provide real-time information on buses and trains. Additionally, the city has been rolling out smart initiatives aimed at making the urban environment greener and more sustainable, including smart grids, eco-friendly housing, and smart waste management systems.

Manchester: Manchester has adopted a forward-thinking approach to becoming a smart city, with a strong focus on digital connectivity and the integration of smart infrastructure. The city has developed extensive fiber optic networks, enabling high-speed internet access for residents and businesses. Additionally, Manchester’s "CityVerve" project, a collaboration between the public and private sectors, has brought innovative technologies into urban life, including smart streetlights, energy-efficient buildings, and apps that provide real-time information on traffic, parking, and public transport.

Coventry: Known for its innovation in the automotive industry, Coventry is also becoming a hub for smart technologies. The city has adopted smart mobility solutions such as autonomous vehicles and intelligent transport systems, which use data to improve traffic flow and reduce accidents. Coventry is also focusing on creating energyefficient and sustainable homes, with smart technology integrated into buildings to monitor energy use and reduce carbon footprints.

While the smart city movement offers significant potential, there are challenges that must be addressed to ensure that these initiatives are successful and equitable:

Data Privacy and Security: The vast amounts of data generated by IoT devices raise concerns about privacy and cybersecurity. Citizens’ personal data could be vulnerable to breaches if not handled properly. Ensuring that data is used responsibly and securely is paramount for the success of smart cities.

Digital Divide: Access to digital technologies is not equally distributed, with some communities lacking the infrastructure and skills to benefit from smart city innovations. Bridging the digital divide and ensuring inclusivity is essential to creating cities that serve all residents equally.

Funding and Investment: Transforming urban infrastructure into smart systems requires significant investment, and securing the necessary funding can be a challenge. Public-private partnerships, as well as government support, will be key to financing the implementation of smart technologies.

Sustainability: While smart technologies offer the potential for more sustainable cities, their implementation must be carefully managed to avoid creating new environmental challenges. The production, use, and disposal of high-tech devices and infrastructure could have unintended environmental consequences if not managed responsibly.

Smart cities represent the future of urban living in the UK, offering innovative solutions to address the challenges posed by growing populations, climate change, and the demand for more efficient public services. With cities like Bristol, London, and Manchester leading the charge, the UK is well-positioned to become a global leader in smart city development. By embracing data-driven technologies and sustainable practices, these urban centers can pave the way for more connected, resilient, and inclusive cities in the future. However, overcoming challenges related to privacy, inequality, and funding will be crucial to ensure that these advancements benefit all citizens.

Integrals power has made a breakthrough in Lithium Manganese Iron Phosphate (LMFP) cathode active materials for battery cells.

Applying its propriety materials technology and patented manufacturing process, the company has overcome the drop in specific capacity compared that typically occurs as the percentage of manganese in increased. The result is cathode active materials which support higher voltages and high energy density.

By overcoming this trade-off, these cathode active materials combine the best attributes of the Lithium Iron Phosphate (LFP) chemistries – relatively low cost, long cycle life, and good low temperature performance – with energy density comparable to more expensive Nickel Cobalt Manganese (NCM) chemistries. This means electric vehicle range could increase by up to 20 per cent, or – for a given range – allow battery packs to become smaller and lighter.

The LMFP materials feature 80 per cent manganese, instead of the 50-70 per cent typically found in competing materials, and have higher specific capacity: 150mAh/g, while delivering a voltage of 4.1V (Vs 3.45V for LFP). Third-party testing by experts at the Graphene Engineering Innovation Centre (GEIC) have been completed on coin cells and now evaluated using EV-representative pouch cells. The developed materials will soon be available for cell suppliers, battery manufacturers, and OEMs to evaluate and benchmark.

Integrals Power Founder and CEO, Behnam Hormozi, said: “The challenge that the automotive industry has been trying to overcome for some time is to push up the percentage of manganese in LMFP cells to a high level while retaining the same specific capacity as LFP. Using traditional methods the more manganese you add, the more specific capacity drops, and this has meant it can’t deliver a high energy density.

“Our proprietary materials and patented production processes have enabled us to overcome this trade-off and increase manganese con-

tent to 80 per cent, placing us at the cutting edge of LMFP chemistry. With the third-party evaluation from the Energy team at GEIC, we’re proud to have developed a world-class cell material in the UK that can rival the performance of NCM but is more sustainable and more affordable, and will accelerate the transition to e-mobility.”

GEIC’s Applications Manager in Energy, Nicky Savjani, said: “The dedicated team in the GEIC Energy labs provides comprehensive support in battery materials development and evaluation, bridging academic innovations and industry appetite to push next-generation technologies towards commercialisation. Our GEIC Energy facility, combined with its dedicated team of battery engineers, is driving the push for decarbonising the transport sector and reinforcing the UK’s leadership in developing sustainable battery technologies.

The battery cells we produced using Integral Power’s LMFP materials exhibited competitive specific capacity during testing, highlighting their potential to enhance EV efficiency and reduce costs by increasing range.”

Integrals Power produced the high-performance LMFP cathode active materials at its new UK facility, alongside its proprietary LFP chemistry. The capability to manufacture materials such as these in the UK is critical to the development of a sustainable domestic battery industry and supporting not just the 2030 ban on sales of new combustion engine vehicles but also 2050’s net zero emissions targets.

Establishing manufacturing in the UK will also enhance supply chain security and transparency, and mitigate geopolitical issues such as import tariffs on EVs and their components. Integrals Power sources all its raw materials from European and North American suppliers which ensures a purer, higher performance LFP and LMFP cathode materials with greater energy density compared to the Chinese-manufactured cathode materials which currently account for around 90%1 of production worldwide. n

Legrand UK & Ireland has announced the opening of a new electronics manufacturing hub in Northumberland next year, bringing 200 jobs to the local area and launching the latest electronics manufacturing centre of excellence for the Legrand Group in Europe.

The new site in Cramlington will be home, among other, to Legrand’s CP Electronics lighting controls and Legrand Care brands, offering the global specialist of electrical and digital infrastructures a facility in an area close to the clean energy sector and associated skills base.

The purpose-built site is designed to optimize processes, capability, efficiency and sustainability. It will be home to new manufacturing technologies, with increased digitisation of the manufacturing process and will boast a wide range of sustainable features, including solar PV. Planning permission has been granted for the 3,717m2 facility, which will also feature a 1,580m2 service yard and 107 car parking spaces on land at Crossland Park, Cramlington. It is expected that the new facility will be completed by April 2025.

Legrand’s mission is to improve lives by transforming the spaces where people live, work and meet, with electrical and digital infrastructures and connected solutions that are simple, innovative and sustainable. This new facility will not only help us to better deliver this for our clients, but it will also improve the experience for our people who will work in a safe, diverse and inclusive environment designed to be more comfortable and sustainable.

Pascal Stutz, CEO, Legrand UK & Ireland, said: “The opening of our new Cramlington facility underscores our confidence in the UK’s

manufacturing sector and particularly in the skilled workforce in the North East.

“Legrand has been a proud UK manufacturer for more than 40 years. During this time, the company has grown its expertise to become a trusted partner to contractors, specifiers, wholesalers, installers, facilities managers and building occupants, through our extensive catalogue of products, training opportunities and support services. Indeed, we are already proud members of the Made in Britain organisation, demonstrating our commitment to quality and UK manufacturing.

“Our investment in this state-of-the-art facility underscores our ongoing commitment to UK manufacturing.”

Tim Witty, Development Director at UK Land Estates, added: “This is an incredibly exciting project, and we are delighted to welcome Legrand to the region.

“We constantly invest in our portfolio, and Legrand’s new state of the art base on Nelson Park Industrial Estate delivers the highest possible energy efficiency standards as well as offering space for the global business to grow and flourish here in the North East.”

Additionally, Legrand is also looking to further develop its presence in the London area, with plans to also establish a state-ofthe-art research and development centre and testing laboratory. This second new facility will also house a Training Academy and the operations support teams. It will be conveniently located to welcome guests and will provide cutting-edge tools and collaborative spaces, fostering innovation and accelerating the creation of advanced solutions.

This strategic investment underscores our commitment to continue driving technological advancements and delivering exceptional value to our customers.

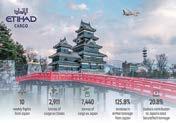

Etihad Cargo, the cargo and logistics arm of Etihad Airways, is celebrating the first anniversary of its successful operations in Osaka, Japan. Over the past year, the airline has expanded its presence in the Japanese market, contributing to the country's growing economy.

In 2024, Etihad Cargo has handled 7,440 tonnes of cargo ex Japan, with 2,911 tonnes moving through Osaka, accounting for 39.1 per cent of the carrier’s total tonnage in the country. With three weekly flights from Osaka and seven from Tokyo, Etihad Cargo now operates 10 flights per week from Japan, providing seamless connections to more than 100 global destinations via its Abu Dhabi hub.

Stanislas Brun, Vice President Cargo, said: “Celebrating one year of operations in Osaka is a significant milestone for Etihad Cargo. Our success in Japan, particularly in Osaka, demonstrates our commitment to being the Air Cargo Partner of Choice for our customers. By providing innovative and reliable airfreight solutions, we look forward to further supporting the growing Japanese market and helping our customers meet their evolving logistics needs.”

Rohde & Schwarz showcased a proof of concept for testing far field wireless power systems at the IEEE Wireless Power Technology Conference and Expo (WPTCE) in Kyoto, Japan. The radio frequency (RF) wireless power tester developed by Rohde & Schwarz utilizes the company’s test and measurement equipment along with wireless charging development kits available on the market. It also includes test automation features and a user friendly web interface. With this setup, Rohde & Schwarz supports the AirFuel Alliance RF Standard.

The past year has seen exceptional product growth in Japan. Etihad Cargo’s AirMail service recorded a 125.8 per cent year-on-year growth, with Osaka alone experiencing a 208 per cent increase. Osaka now accounts for 39 per cent of Japan’s total AirMail tonnage. In addition, the airline’s SecureTech product, launched earlier this year for the safe transport of high-value lithium battery-powered electronics, has seen strong uptake in Osaka, which now contributes 20.8 per cent of Japan’s total SecureTech tonnage.

Etihad Cargo plays a crucial role in transporting key commodities ex Japan, supporting various industries. The main commodities handled by the carrier include automotive parts, electronics, machinery parts, and gaming consoles, which are shipped via Etihad Cargo's IATA CEIV-LiBattcertified SecureTech product. In Osaka, the airline also handles large volumes of textile raw materials, and ship parts, reflecting the diverse and essential nature of the goods moved through the region.

Etihad Cargo’s digital transformation in Japan has also made significant strides, with e-AWB penetration in Osaka reaching 90 per cent in 2024, while e-AWB penetration across Japan stands at

in Japan and 3.31 per cent in Osaka, reflecting a growing reliance on digital solutions to enhance efficiency and streamline cargo operations.

Japan's economy has demonstrated strong growth in recent years, driven by advancements in technology and trade. Etihad Cargo has supported this growth with its high On-Time Performance (OTP) and quality service, backed by a sophisticated Road Feeder Service (RFS) network that connects major ports. The airline’s highly skilled sales and customer service teams work closely with customers to meet their evolving logistics needs.

As Japan prepares to host the 2025 World Expo in Osaka from 13 April to 13 October next year, Etihad Cargo is proud to contribute to the region’s dynamic growth and stands ready to provide reliable cargo solutions for the event and beyond.

As the number of wireless communication devices surges toward 29 billion by 2030, as estimated by Statista, the need for innovative power solutions becomes critical. Traditional methods of powering devices, such as manual recharging, battery replacements or wireless charging pads, are impractical and require costly regular maintenance. RF technology offers a promising alternative: devices can be wirelessly powered by converting RF signals into direct current (DC). At the recent IEEE WPTCE conference in Kyoto, Japan, Rohde & Schwarz showcased a proof of concept for this technology with a wireless power tester (WPT) system prototype. RF wireless powering is a contactless power transfer technology that enables multiple devices to be powered simultaneously within several meters of the power source. This eliminates the need for wires and the hassle of maintaining batteries. RF wireless powering has a wide range of applications, and its most prominent use cases are for low power IoT devices. For example, inside a smart building or

a smart car, this technology would enable the many sensors to be powered without manual recharging or battery exchange. Wireless power transmission also has environmental benefits. Battery manufacturing is a highly energy intensive process, and the toxic material in batteries can also enter water sources. Wireless power transfer enables the use of battery-less devices, which potentially reduces the impact of batteries on the environment.

The Rohde & Schwarz WPT project aims to develop a comprehensive testing solution for wireless power transmitters and receivers. Rohde & Schwarz is an active member of the AirFuel Alliance, a global coalition that is leading efforts toward a standardized RF wireless charging technology called AirFuel RF™. As a test and measurement provider, Rohde & Schwarz contributes its expertise to developing the industry standards that will define the future of wireless powering.

The Rohde & Schwarz WPT system supports the AirFuel Alliance Conformance Test Specifica-

tion for RF charging. The test setup comprises the R&S SMB100B RF and microwave signal generator, R&S FSV3000 signal and spectrum analyzer and R&S NGU source measure unit (SMU) used as a battery emulator, along with two R&S HMC8012 digital multimeters. The entire system can be controlled and automated via a web interface.

Dr.-Ing. Rania Morsi, head of the WPT project at Rohde & Schwarz, says: “Today, we have over 15 billion connected IoT devices, yet we

still power them manually. At the very least, low power IoT devices should be powered over the air and without human interaction. We clearly see that wireless RF energy can meet this need, offering a maintenance free solution that provides power on demand to multiple devices – even when the devices are in use or in motion. We are confident that the Rohde & Schwarz test solution for RF wireless power transfer will accelerate the adoption of this technology. We are excited to collaborate with AirFuel Alliance to

test device conformance to the AirFuel Alliance RF standard.”

Dr. Sanjay Gupta, President and Chairman of AirFuel Alliance, says: “I want to thank Rohde & Schwarz for their leadership in developing a wireless power tester (WPT) for the AirFuel RF standard. The WPT will enable companies to test and validate conformance to the AirFuel RF standard and accelerate the deployment of interoperable RF wireless power solutions.”

Electroplating specialist BEP Surface Technologies and nanodiamond manufacturer Carbodeon have announced a strategic relationship to develop a ‘world first’ copper-nanodiamond composite coating.

Nanodiamonds are particles of diamond so small that you could fit a million on a pinhead. Their unique structures and properties radically enhance thermal conductivity and improve wear resistance.

Blending nanodiamonds with metal coatings can offer game-changing improvements in components used in many existing industries and emerging industries.

The companies have signed a memorandum of understanding (MOU), which combines Greater Manchester-based BEP’s metal coatings expertise with Helsinki-based Carbodeon’s world-leading position in the manufacture of nanodiamond additives.

The agreement gives BEP the rights to develop and produce nanodiamond-infused copper, an innovative composite coating with the potential to radically enhance thermal conductivity and wear resistance. This will enhance BEP’s production of copper chill rolls used by the world’s leading paper and packaging manufacturers.

The MOU also gives BEP exclusive UK rights to process nanodiamond-infused electroless nickel, increasing wear and corrosion resistance. Carbodeon’s uDiamond® electroless nickel composite coating improves the service life of components used in on-shore oil and gas production, polymer processing, board cutting, agriculture and textile manufacturing.

Both activities will be pursued with a view to supplying several of Carbodeon’s well-established development programmes worldwide and enhancing BEP’s offer to customers.

BEP’s innovation arm, BEP Solutions, will carry out research and development activities. Established this year, BEP Solutions aims to forge new strategic partnerships across government, industry, and academia to develop solutions for long-standing barriers in manufacturing and engineering.

Andrew McClusky, Managing Director of BEP Surface Technologies, said: "I am delighted that Carbodeon has agreed to work with us to develop methods to create a novel composite surface material which we believe is a world first and has the potential to revolutionise a multitude of applications across multiple industries.

“This new relationship is further evidence of BEP’s commitment to leveraging half a century of engineering know-how, leading-edge digital techniques, and a research and development mindset to find innovative solutions to metal surface engineering challenges.

Established in 2006, Carbodeon produces chemically-modified nanodiamonds for applications where the service life of the end product is of particular importance.

They also enhance a material's ability to dissipate heat, improving the efficiency of electronics manufacture.

Current industrial uses include metal plating, thermoset and thermoplasticbased polymer thermal compounds, chemical vapour deposition (CVD) seeding, chemical mechanical polishing (CMP), sealings and other rubber products, and 3D printing filaments.

Carbodeon has patented all its products and key applications it supplies.

Dr Vesa Myllymäki, CEO of Carbodeon, said: “Diamonds dramatically enhance durability and tribology in a range of metal-plated finishes.

“I am delighted to find a partner with such a global reputation for expertise in metal plating who is willing to drive innovation in using nanodiamonds to enhance copper and electroless nickel. We are confident we are on the cusp of creating something unique with transformative capabilities.”

versions A and B of the alcohol-based fluxes EO-B-008 and EO-B-013, the Hessian flux specialist enables even better harmonisation with the soldering process in electronics production. Emil Otto is continuing to consequently pursue the path of different solid content levels in the fluxes in order to be able to offer its customers an extended standard product for the corresponding soldering process.

EO-B-008 has a high solids content of 4 wt.-% and was specially developed for short cycle wave soldering systems. It is ideal for applications in which the PCB remains in

the preheating phase for an extended period of time before the soldering process takes place in a particularly active solder wave. ‘By using the EO-B-008, excellent solder joints are achieved, while the PCB has an extremely clean, residue-free surface after the soldering process. This contributes significantly to the high quality and reliability of the end product. To optimize this quality even more, we have decided to develop further variants of the EO-B-008,’ explains Markus Geßner, Head of Marketing and Sales at Emil Otto GmbH.

EO-B-008A, for example, has a solids content of 2%. It is a high-performance No Clean-Flux based on alcohol with dicarboxylic acids and synthetic resin. This flux was developed for wave soldering processes as well as for dip soldering processes and cable assembly. The same applies to the EO-B-008B version, which has a solids content of 3%. This flux is also versatile and can be used for wave soldering as well as for special applications with good results. The EO-B008A variant has also been developed spe-

Lutz-Jesco Suisse SA specialises in the manufacture of universal electric motors with an power output of up to 1.5 kW, and motor components such as rotors and stators. The company’s product portfolio will in future also include pumps; dosing systems and water treatment systems suitable for sewage treatment plants, indoor and outdoor swimming pools, the chemical and pharmaceutical industries, the paper and pulp industry and agriculture.

“Switzerland is not only an important market for us, but also a hub for innovation and quality. By expanding the fields of activity of LutzJesco Suisse SA, we are strengthening our presence in Switzerland and taking another important step in our international growth strategy,” says Heinz Lutz, CEO of Lutz Holding GmbH, a global group of companies that also includes Lutz Pumpen GmbH from Wertheim and Lutz-Jesco GmbH from Wedemark. “Couvet offers us not only a strategically favourable location, but also provides access to a market that is known for its high standards of technology and reliability.”

Lutz-Jesco Suisse SA fulfils the desire of Swiss customers for closer proximity and shorter response times. “Today, most customers view outstanding technology as the obvious basis of a good suppliercustomer relationship, explains Lutz. Proximity to our customers and good service are therefore the key factors for continued success. “Our presence in Couvet enables us to provide customers in Switzerland

cifically for full tunnel nitrogen applications and guarantees significantly better soldering results than conventional adipic acid solutions under full nitrogen due to a wide process window and high temperature stability.

The EO-B-013 is a multiflux focussing on wave and selective soldering. The flux is also based on alcohol with dicarboxylic acids and a synthetic resin complex. The flux can also be used in the dip soldering process in cable assembly. The flux is applied using the spray flux method. ‘EO-B-013 is also a No Clean-Flux with exceptional properties and excellent residue behaviour. We are now offering versions A and B of these products as well,’ continues Geßner. The EO-B-013A has a solids content of 2% and, like the A version of the EO-B-008, it was developed specifically for full-tunnel nitrogen applications; the B version has a solids content of 3%.

All A and B variants of fluxes EO-B-008 and EO-B-013 are available in canisters of 5 and 20 litres. Other containers are available on request.

with even faster and more direct support, which gives us a decisive competitive advantage.”

Couvet is a village in the French-speaking part of Switzerland, located in the Val-de-Travers in the canton of Neuchâtel, and is known for its historical importance to the watchmaking industry. Lutz explains: “With the presence of Lutz-Jesco Suisse SA in Couvet, we are showing that modern industries are also active in this historical region.”

The oil and gas market can change at any moment. Unfortunately, infrastructure development takes so long that a good market outlook at the beginning of a greenfield project may have completely changed by the time offshore installation is done. It is therefore important for oil and gas companies to have adaptable, low maintenance corrosion solutions to preserve topside and subsea piping and pipelines in case of delayed commissioning from unexpected market drops.

Internal corrosion threatens the longevity and integrity of piping and pipelines, which are indispensable to offshore production. On the topside are water injection systems, gas piping systems, and crude oil lines that need protection. Subsea gas lift lines and pipelines carrying crude oil from platform to platform or from platform to land also need to be preserved. Even when other systems are commissioned, water injection and gas lift lines may need extended preservation until a drop in well pressure demands their use.

Vapor phase Corrosion Inhibitors increase the ease and flexibility of preserving tubular voids. The beauty of these inhibitors is that they

vaporize and disperse themselves throughout an enclosure, adsorbing on metal surfaces to create a self-replenishing protective molecular layer. As long as the space stays closed, there is no need to maintain constant pressure or continue frequent monitoring as for nitrogen blanketing. Vapor phase Corrosion Inhibitors can be added to fluids or oils or simply fogged as a vapor into enclosures. Typically, little to no removal and/or cleaning is required before commissioning.

There are many ways to apply Vapor phase Corrosion Inhibitors to offshore piping and pipeline systems. A creative option for short-term protection of subsea pipelines is to place Cortec® EcoPouches—breathable bags containing Vapor phase Corrosion Inhibitors—into a plenum and to blow the vapors through the system until they are detected at the other end. The system should then be closed to trap the vapors inside. Another option is to apply Cortec® VpCI®649 BD, a water-based liquid concentrate that can be flushed through the system to provide up to two years of preservation, depending on dosage. As VpCI®-649 BD circulates, it forms a thin protective film on the walls of the piping. This film inhibits corrosion on the metal it is

ABB reinforces commitment to circularity with first EPD

ABBhas announced its first instrumentation product with an Environmental Product Declaration, demonstrating its continued commitment to circularity and sustainability. The PGS300, an all-rounder gauge pressure transmitter, is used for measuring liquid, gas and steam pressure, and is key for the safety and efficiency in industries such as chemicals, oil & gas, and hydrogen.

Based on Life Cycle Assessment (LCA), EPDs are a declaration of the product’s environmental impact over its entire life cycle, from resource extraction to end-of-life. EPDs are verified by a qualified assessor.

“This is a major milestone on our circularity journey,” said Amina Hamidi, Managing Director, BL Instrumentation, ABB Measurement & Analytics. “For the first time we have been able to test and validate the environmental performance of one of

our instrumentation products against the existing, very demanding, rules and regulations. The way forward for sustainability is to work with facts based on credible numbers. This will provide our customers with a way to understand and compare the footprint of products on the market.”

As part of the verification process, the assessor performed a rigorous audit of ABB’s factory in Ossuccio, Italy where the PGS300 is manufactured. The assessor also checked relevant documentation from the five Assembly-To-Order sites around the world where the PGS300 can be assembled.

EPDs are developed according to the socalled Product Category Rules (PCRs), mandatory for specific product categories. While waiting for sensor-specific PCRs, ABB achieved a “Pre-certified EPD” through program operator EPD International. Going forward, ABB will participate in the development of a Complementary

directly touching but also emits vapors to protect surfaces in harder to reach areas that may have been missed during application.

A final example is long-term preservation of subsea pipelines. This task is often performed by using nitrogen to purge all oxygen out of the system. Constant pressure must be maintained to ensure effectiveness. Since it is difficult and costly to monitor this on unmanned offshore platforms, it is better to have a complete replacement for nitrogen or a backup system that will continue to work even if nitrogen pressure fails. A good answer is to fog an oil-soluble Vapor phase Corrosion Inhibitor through the subsea pipelines, either alone or in conjunction with nitrogen. Once the corrosion inhibitors are detected at the other end of the pipeline, the openings can be closed and (if nitrogen is used) the system pressurized. In the event of lost pressure and nitrogen, protection will continue thanks to Vapor phase Corrosion Inhibitors.

Whatever the market holds, it is important to have effective and efficient preservation methods that make it easier for oil and gas companies to respond to market demands. Vapor phase Corrosion Inhibitors meet this definition and can help greenfield project owners stay adaptable in uncertain.

PCR (c-PCR) for the “Industrial Sensor” segment which will tailor the “Electric and Electronic Equipment” PCR to the measurement business. EPDs are part of the ABB Circularity Roadmap. The roadmap encompasses products which fulfill the ABB Circularity framework. On gaining the EPD certification, these products are better positioned to meet the transparency on circularity performance required by the market.

developments in the Construction & Engineering

Specialist panel builders will be pleased to learn that FDB Panel Fittings Online store now has ex-stock availability of pedestal style hinges for enclosure and cabinet doors. Offered together with sales partner Enclosure Solutions this asymmetric design of hinge lends extra support to enhance door rigidity of large doors on cabinets and enclosures for industrial equipment such as electrical/electronic controls or distribution panels. Typically used in pairs they may also be used in further multiples where needed.

Their robust construction in zinc die is complimented with black powder coat finish, while integral M6 studs and fixings enable internal fixing for ease of installation and concealment, which adds to the security features of the housing.

FDB Panel Fittings and sister company FDB Electrical share their online shopping website at www.fdbonline.co.uk. Further information on FDB products and services may be found at: www.fdb.co.uk. Find the latest information and news on the FDB blog – www. fdbonline.co.uk/blogs/news, or follow them

Solivus, a leading UK provider of lightweight solar installations for commercial applications, has designed and delivered a £2m solar installation to Farnborough Airport, taking it one step closer to its commitment to reach net zero emissions by 2030. Located in Farnborough, Hampshire, Farnborough Airport is the home of British aviation and widely recognised as Europe’s leading airport for premium travel connectivity. In its ongoing efforts to be a sustainability showcase for other airports around the world, it has a clear strategy in place to reach net zero by 2030, well ahead of the industry standard.

As part of this, Farnborough Airport sought to reduce electricity and gas usage and invest in onsite renewable production. However, the path to self-generation proved less than straightforward. Foremost, due to operational and environmental restrictions on land-use, the installation of groundmounted solar at scale was not possible making rooftop solar the only option. At the same time, the iconic architectural curves of the airport building were not conducive to fitting traditional rigid solar panels while - in common with 40% of commercial buildings like aircraft hangars, the rooftops were unable to support the associated weight.

The solution to overcoming these challenges and installing the desired solar was provided through partnering with lightweight solar technology pioneers, Solivus. Offering a competitive performance without the bulk, Solivus’ lightweight solar solution provides a practical, efficient, and cost-effective option for commercial rooftops, allowing large premises to harness solar energy while minimising

structural concerns and installation complexities. Furthermore, Solivus’ lightweight solar solution can be used on a wide variety of roof surfaces, and is typically installed with no penetration of the roof itself and has much lower glare characteristics compared to conventional solar panels.

Constituting one of the largest rooftop solar installations in the region, the works will enable up to 25% of the airport’s annual electricity needs to be met, as well as enabling its growing operational fleet of electric vehicles to be charged using self-generated electricity. With approximately 75% of solar energy generated to be used on site, the remaining 25% will be sold back to the energy supplier, thus making the financial case for solar even more attractive.

In total, the installation will deliver over 1,700 kWp of installed capacity, generating over 1.2 GWh of clean energy every year while taking Farnborough Airport a major leap forward in its bold target of achieving carbon neutrality by 2030. In total the PV installation is expected to generate over 36 GWh of energy in its lifetime and offset more than 5,000 tonnes of CO2e in that time.

Safety was accounted for too. Working closely with the National Air Traffic Services, Solivus’ design was purposefully constructed to minimise any glint and glare. This included a comprehensive feasibility study, testing factors such as generation potential and shading to determine the optimal placement of panels.

Farnborough Airport’s ambitions for renewables are expressed by the Group’s CEO, Simon Geere: “In line with our ambition to become

a sustainability showcase for airports around the world, we’re proud to have partnered with lightweight solar technology pioneers, Solivus, to install one of the largest rooftop solar projects in the region. The lightweight solar installation is a significant step towards achieving our sustainability objectives, significantly reducing our controllable emissions, as set out in our Net Zero Roadmap, in which we have committed to be Net Zero by 2030 or sooner.”

Interestingly, the solar installation aligns with a recent government bill, which encourages the extensive deployment of rooftop solar on domestic industrial and commercial property to make effective use of available surfaces as a priority.

Solivus CEO, Jo Parker-Swift says: “Rooftop solar is crucial for decarbonising the built environment, but its application has often been constrained by the structural limitations of many commercial buildings. Put simply, traditional solar panels are too heavy for many rooftops. Our lightweight solar innovation addresses this issue, enabling large-scale, cost-effective solar deployment across nearly all large commercial buildings and sites.

“We are proud to have worked with Farnborough Airport to ensure the future supply of renewable energy, supporting the airport’s progressive net zero emissions journey. We encourage other airports to seize the opportunity to benefit from our lightweight solar energy installations and advance their own sustainability initiatives.”

The American Concrete Institute, through the work of ACI Committee 323, has released ACI CODE-323-24: Low-Carbon Concrete—Code Requirements and Commentary. The Code provides provisions for concrete where reduced global warming potential (GWP) is required. The Code was developed by a consensus process and provides commentary along with references for the user desiring to study individual questions in greater detail.

The Code may be adopted as a stand-alone code or can be used in combination with a structural design code or low-carbon material code adopted by an authority having jurisdiction. The Code is in a format that allows reference to a set of chapters based on the structure type. Adoption would include all of Chapters 1 to 4, the applicable Chapter(s) of 5, 6, 7, and/or 8, plus Appendix A. This Code is written in a format that allows reference without change to its language. Therefore, background details or suggestions for carrying out the requirements or intent of the Code provisions cannot be included with the Code itself. The Commentary is provided for this purpose.

The Code employs a carbon budget approach and emphasizes the use of Environmental Product Declarations (EPDs) for benchmarking, aiming to standardize methodologies for reducing carbon emissions associated with concrete construction.

“In the past, standards for lowering carbon in the built environment have been difficult to define and this Code represents a giant leap

forward,” said Matthew Adams, Chair, ACI Committee 323. “The Code provides references for various structures so that the guidelines can be applied to any project. Committee 323 members did a great deal of work to produce this Code, and it is just a beginning, as future versions will provide even more guidance to everyone designing and building with reduced-carbon concrete.”

ACI Committee 323’s mission is to develop and maintain code requirements for low-carbon concrete. An on-demand course, ACI CODE-323: Low-Carbon Concrete Code, is also available from ACI and explains the development and purpose of the Code.

Legrand UK & Ireland has announced the opening of a new electronics manufacturing hub in Northumberland next year, bringing 200 jobs to the local area and launching the latest electronics manufacturing centre of excellence for the Legrand Group in Europe.

The new site in Cramlington will be home, among other, to Legrand’s CP Electronics lighting controls and Legrand Care brands, offering the global specialist of electrical and digital infrastructures a facility in an area close to the clean energy sector and associated skills base.

The purpose-built site is designed to optimize processes, capability, efficiency and sustainability. It will be home to new manufacturing technologies, with increased digitisation of the manufacturing process and will boast a wide range of sustainable features, including solar PV. Planning permission has been granted for the 3,717m2 facility, which will also feature a 1,580m2 service yard and 107 car parking spaces on land at Crossland Park, Cramlington. It is expected that the new facility will be completed by April 2025.

Legrand’s mission is to improve lives by transforming the spaces where people live, work and meet, with electrical and digital infrastructures and connected solutions that are simple, innovative and sustainable. This new facility will not only help us to better deliver this for our clients, but it will also improve the experience for our people who will work in a safe, diverse and inclusive environment designed to be more comfortable and sustainable.

Pascal Stutz, CEO, Legrand UK & Ireland, said: “The opening of our new Cramlington facility underscores our confidence in the UK’s manufacturing sector and particularly in the skilled workforce in the North East.

“Legrand has been a proud UK manufacturer for more than 40 years. During this time, the company has grown its expertise to become a trusted partner to contractors, specifiers, wholesalers, installers, facilities managers and building occupants, through our extensive catalogue of products, training opportunities and support services. Indeed, we are already proud members of the Made in Britain organisation, demonstrating our commitment to quality and UK manufacturing.

“Our investment in this state-of-the-art facility underscores our ongoing commitment to UK manufacturing.”

Tim Witty, Development Director at UK Land Estates, added: “This is an incredibly exciting project, and we are delighted to welcome Legrand to the region.

“We constantly invest in our portfolio, and Legrand’s new state of the art base on Nelson Park Industrial Estate delivers the highest possible energy efficiency standards as well as offering space for the global business to grow and flourish here in the North East.”

Additionally, Legrand is also looking to further develop its presence in the London area, with plans to also establish a state-of-the-art research and development centre and testing laboratory. This second new facility will also house a Training Academy and the operations support teams. It will be conveniently located to welcome guests and will provide cuttingedge tools and collaborative spaces, fostering innovation and accelerating the creation of advanced solutions.

line at Štĕtí to meet the growing demand for sustainable packaging solutions

Mondi starts up new extrusion line at Štĕtí to meet the growing demand for sustainable packaging solutions

Mondi, a global leader in sustainable packaging and paper, has announced the start-up of its new extrusion line at Mondi Coating Štĕti (Czech Republic), marking another milestone in the Group’s commitment to support customers in their transition to sustainable solutions.

The extrusion line is part of a wider investment that includes a new production building with stateof-the-art machinery including coating and slitting capabilities. The investment expands the production of FunctionalBarrier Papers and other high quality

coated papers, offering paper-based solutions with customised barrier properties. Applications range from food and non-food contact packaging to industrial solutions, such as case linings for solid board and barrier liners for corrugated case materials. As part of Mondi’s re/cycle portfolio, the innovative range of FunctionalBarrier Papers offers solutions that can be recycled in existing paper waste streams across Europe.

Marko Schuster, COO Functional Paper & Films, Mondi, says: “The start-up of our new extrusion line at Štětí reflects Mondi’s commitment to helping customers on their sustainability journey. It further contributes to meeting our own MAP2030 commit-

ments by designing innovative packaging and paper solutions that keep materials in circulation and avoid waste. We are excited to continue collaborating closely with our customers and contributing to a circular economy.”

Avery Dennison announces the first range of INGEDE12-certified paper label solutions for paper and cardboard packaging on the market

Building on a wide portfolio of innovative label solutions that enables the recycling of various packaging substrates, this paper label range supports and improves the yield and quality of paper and cardboard package recycling.

Avery Dennison Corporation (NYSE: AVY), a global leader in materials sciences and technology, is thrilled to announce its first range of INGEDE12-certified paper label solutions. With this new range, Avery Dennison is advancing their mission to continuously develop solutions for brands that enable recycling for a more circular economy.

This range of paper label solutions uses a newly developed adhesive technology that cleanly screens out from pulp during the recycling screening process, resulting in higher quality output for new cardboard and paper production.

The range offers good print and conversion for a wide variety of use cases and industries. Solutions within the range include rVellum, Coated Paper, Thermal Eco and Thermal Top facestock combinations for both decorative labeling and variable information/barcode labeling options. In addition, rVellum facestock is made from 100% recycled materials, offering sustainable advantages such as reducing CO2.

“Paper and cardboard design-for-recycling guidelines and protocols are still in development, and will likely change in the future,” says Maarten Zubli, Marketing Manager Paper at Avery Dennison. “Still, we decided to certify our new paper label portfolio according to the INGEDE12 protocol. This is one of the most stringent protocols for label materials, testing product compliance against the recycling demands placed on the paper industry. The INGEDE12 certification shows our commitment to creating products that enable recycling without sacrificing performance, and that we’re doing so with the highest quality commitment in mind.”

To meet PPWR guidelines for packaging recyclability, all components of a packaging unit must meet certain design for recycling criteria. To ensure this range of label solutions meet this high standard, Avery Dennison submitted its label materials for independent testing using the INGEDE12 protocol and passed the European Paper Recycling Council (EPRC) requirements for recyclability.

Mondi, a global leader in sustainable packaging and paper, has recently completed a €95 million investment at its Świecie containerboard mill, which will increase kraftliner capacity by 55,000 tonnes. The upgrade comprises an extensive rebuild of paper machines PM2 and PM5, a new anaerobic treatment plant including an integrated cooling system, and upgrades to the pulp mill, the recycled fibre line and the energy recovery system.

These improvements will allow the mill to meet growing customer demand for heavy-duty packaging for large and heavy products, enhance product quality, and bolster its environmental performance by decreasing water consumption and wastewater emissions and increasing energy efficiency.

Since the project’s completion in June, Mondi Świecie has also expanded its ProVantage SmartKraft Brown portfolio with a broader range of grammage options. Offering exceptional strength and enhanced runnability, the brown Kraftliner product meets diverse packaging demands while championing environmental responsibility.

“The completion of this project marks a milestone for Mondi Świecie, enabling us to advance our operations and deliver even higher-quality paper to our customers. I am proud of our team’s exceptional skills and commitment, which were crucial in achieving these goals,” said Tomasz Katewicz, Managing Director of Mondi Świecie.

The completion of the investment further underscores Mondi’s commitment to operating efficiently and its progress in fulfilling the commitments set out in its Mondi Action Plan 2030 (MAP 2030) sustainability framework. It also reflects the Group’s strong commitment to the region, by providing competitive, high-quality employment and potential to further contribute to the area's economic prosperity.

AHT Cooling Systems is proud to announce a significant advancement in commercial refrigeration technology. Our recently launched refrigeration unit, BOREA, has achieved energy efficiency class A with the BOREA Standalone with Glass Doors version. This marks a pivotal

milestone for AHT, as it is the first device in our product range to reach the highest efficiency class.

We have significantly improved the energy efficiency index (EEI) of BOREA through targeted developments and optimizations in the design. This achievement is the result of intensive research and development efforts aimed at providing our customers in the food retail sector with highly efficient and sustainable solutions.

With the BOREA Standalone in energy efficiency class A, AHT is setting a clear example of environmentally conscious action and underscoring our commitment to developing innovative products that not only meet the highest standards of quality and performance but also significantly reduce energy consumption and operating costs.

This model is particularly suitable for use in supermarkets, convenience stores, discount stores and hypermarkets that prioritize energy efficiency and sustainability without compromising on cooling performance and product visibility.

With the launch of this unit, AHT once again reinforces its leading role in sustainable refrigeration technology. We are proud to have introduced the BOREA Standalone, a refrigeration unit that makes a substantial contribution to reducing the carbon footprint in commercial use.

Yokogawa Electric Corporation subsidiary

Yokogawa Europe has been awarded the tender for the front-end engineering design (FEED) phase for the control, telecoms, and overall system integration of the Aramis Transport System, Northwest Europe’s largest carbon capture and storage (CCS) project. A collaboration between several large energy companies, the Aramis project aims to contribute to the reduction of CO2 emissions for hard-to-abate industries by providing CO2 transport to unlock storage capacity for the industry. The CO2 will be stored in depleted offshore gas fields, deep under the North Sea.

Yokogawa Europe, together with Yokogawa Group company KBC and French engineering firm Ekium, will carry out the FEED study of the

integrated control and safety system (ICSS), telecoms, and system integration that covers the control room, CO2 pipeline, and distribution platform for the Aramis project. This backbone will provide the large-scale infrastructure needed to transport CO2 captured from various industrial companies out to the individual injec tion platforms and depleted gas fields. The FEED design is expected to be ready in 2024. The Aramis project aims to transport and store about 5 Mtpa (million tons of CO2 per year) in the start-up phase, with a final capacity of 22 Mtpa through phased expansion beyond 2030.

The project’s location in the Port of Rotterdam makes the CO2 transport and storage service accessible to various industrial clusters, and it will cooperate with other CCS projects in the

Port, such as Porthos, a project for CO2 transport and storage, and CO2next, an open-access storage terminal for liquid CO2.

ABB and Typhoon HIL create DriveLab ACS880: The next generation of HIL Compatible digital twin

ABB has partnered with Typhoon HIL to create the DriveLab ACS880 HIL Compatible digital twin. This collaboration between leading industry players will empower a wide range of industrial customers with a realistic, scalable, and easy to use real-time simulation platform.

DriveLab ACS880 is the next generation of Hardware-in-the-Loop (HIL) simulation technology. It is specifically tailored and geared towards simplifying the integration of ABB variable speed drives (VSD) systems. It will enable customers to quickly test and validate the system via a test automation capability which is a key component of top-tier customer support. HIL simulation is used to validate both component and system-level behavior of the drives and drive systems in real-world applications

ranging from compressors, conveyers, and cranes to large scale energy storage, microgrids and more. The DriveLab ACS880 serves as a digital twin, integrating the control hardware, firmware, and software of the ACS880 drives with Typhoon HIL’s high-fidelity digital models. These digital models virtually represent the ACS880 drive’s hardware, including its connected components, such as the grid, motors, filters, batteries, protection devices, and the electro-mechanical elements.

“Collaboration with partners such as Typhoon HIL is delivering innovation that directly benefits customers across different industries,” said Chris Poynter, President of ABB System Drives. “The HIL solution allows us to work with our customers to help them shorten their testing and validation cycle with improved speed, efficiency and quality of the process.”

“Typhoon HIL and ABB share common values on business excellence, and we are deeply aligned on technology. This positions us perfectly as a trusted partner that can be successful on both of these fronts” added Nikola Celanovic, Co-Founder & CEO, Typhoon HIL. "By making interoperability so much easier through our HIL Compatible solutions, we’re helping our and ABB’s customers to thrive in today’s changing energy landscape.”

Chris Poynter continued “we can test set-ups more rapidly, more reliably with HIL solutions so it’s a great opportunity to add this component to the eco-system.”

ABB and Typhoon HIL will be showcasing DriveLab ACS880 HIL Compatible at the Smart Production Solutions trade show in Hall 4 from 12-14 November in Nuremberg, Germany.

ABB research shows energy efficiency has become the decisive factor in electric motor choice for businesses

• Independent survey commissioned by ABB highlights the critical role that energy efficiency now plays in the sustainability agenda for global businesses with 91 percent saying this influences their choice of electric motors

• 94 percent of companies surveyed are already investing, or planning to invest, in sustainability initiatives, and have adopted a strategy of reducing operating costs through energy efficiency solutions

New research by ABB, in collaboration with Sapio Research, has surveyed nearly 2,400 global businesses to gain insight into the state of the market around energy efficiency, sustainability, digitalization, and the key role played by electric motors. Conducted in June 2024, the research gathered responses from industrial decision-makers across the UK, US, Germany, Italy, France, Australia, UAE, Japan, Thailand, Saudi Arabia, Brazil, South Korea, and India.

Respondents represented a range of industries, such as manufacturers of OEM machinery, energy/power, food and beverage, metals, and chemicals. A key finding was that 91 percent of businesses said that energy efficiency now had a critical influence on their choice of electric motors. Furthermore, 94 percent of businesses are either currently investing or planning to invest in sustainability initiatives.

“This survey provides a valuable insight into how businesses are prioritizing energy efficiency not just to meet sustainability targets but also to gain measurable financial returns, said Stefan Floeck, Division President IEC Low Voltage Motors, ABB Motion. “ABB is already playing a critical role in this development by demonstrating how investing in state-of-theart energy-efficient electric motors, such as our IE6 SynRM technology, can enhance operational efficiency and promote sustainable growth. With payback periods often measured in months rather than years the result is a win-win for both the environment and the bottom line.”

Nearly all businesses (94 percent) are investing or planning to invest in sustainability and especially energy efficiency. Most are aware of the role that energy efficient motors can play in achieving their sustainability goals, with 91 percent saying that this influences their choice. Nearly all businesses also recognize that energy efficient motors can add value to their products and business.

An emerging theme throughout the report is that end user businesses place a greater emphasis on sustainability, often due to increased pressure from customers which is reflected through their increased investment in energy efficiency. However, this also translates into what these businesses prioritize when it comes to energy efficient motors, with 88 percent considering it important that manufacturers can produce an environmental product declaration (EPD).

ABB is addressing this development through EcoSolutions, a comprehensive program designed to provide complete transparency on the environmental impact of its products across their entire lifecycle, from inception through to disposal.

motors are seen as higher upfront costs, concerns around integrating with existing systems and potential disruption in production capacity. Higher upfront cost is more of a barrier for higher turnover businesses.

Cost plays a role as both a barrier and a driver due to the investments required for plant and equipment upgrades. However, 99 percent of businesses are now tracking the long-term savings as the main return on investment (ROI) from their energy efficiency initiatives.

cost

(TCO) makes the case for

It is important to note that most businesses look at the total cost of ownership (TCO) as the most significant factor when purchasing new electric motors. In fact, over a long lifetime, the cost of an energy-efficient motor is far outweighed by the cost of the electricity to power it. For an IE6 SynRM, the upfront cost will be around 2 percent of its TCO, maintenance accounts for 1 percent and the remaining 97 percent is spent on electricity.

But it’s not all about cost. Quality and ability to integrate are also key attributes that businesses look for from a supplier.

Businesses are increasing their investment in innovative technologies to benefit from digitalization and E-commerce. What this investment is being spent on is multifaceted, but there is a focus on automation and AI-driven solutions.

When looking specifically at the digitalization of electric motors, there is a clear trend for electric motor suppliers to utilize data insights and remote monitoring to improve their service offering. 99 percent of Businesses believe there is added value in running in digitally connected electric motors, specifically for their capability for predictive condition monitoring to enhance motor availability and safety.

Since many of the respondents are already using E-commerce there is growing interest for its use as a business-to-business service. Nearly all businesses see some benefit to electric motor procurement through E-commerce, with being able to see a great range of options and easy product comparison coming out on top. ABB has already deployed E-commerce in 21 countries with the confirmed advantages including speed, flexibility in product selection and ease of configuration, order confirmation and tracking.

These findings further strengthen the trend for digitalization with even more reliable and precise solutions delivering operational value and enabling business model transformation.

More information on ABB’s approach to sustainability is available here: https:// global.abb/group/en/sustainability

Inspiration Through Innovation returns in 2024, marking a decade of breakthrough collaborations in aerospace and medical manufacturing. This year’s in-person event promises cuttingedge insights into overcoming shared challenges and propelling the next generation of innovation.

Celebrating 10 years of progress through partnership

Mark your calendars for October 16th and 17th, 2024, as we bring together industry leaders, innovators, and experts at our UK Innovation Hub in Alcester for dynamic discussions, insightful seminars, and live machining and digital demonstrations. The spotlight will be on transformative strategies and best practices in manufacturing. Join us as we explore advancements in manufacturing components such as the

Turbine Disc, Hip Cup, Femoral, and A-Frame, with in-depth insights from leaders at the forefront of the aerospace and medical industries. The event promises to reveal not just the latest trends, but collaborative solutions that address some of the most pressing manufacturing challenges.

• Aerospace and medical focus: Industryspecific sessions and live demonstrations designed to showcase cutting-edge innovations in these fields.

• Collaborative spirit: Engage with key partners that have been pivotal in making ITI a success over the past decade, offering fresh perspectives on the future of manufacturing.

Dexwell showcases coastal protection innovation with SeaPULSE platform, providing hands-on experience for Rady School of Business interns

Inc., a pioneer in real-time environmental monitoring and health assessment, proudly announces the successful completion of a groundbreaking project with interns from the Rady School of Business at UC San Diego. Under the expert supervision of Corina Shtir, PhD, CTO of Dexwell, interns Vishnu Mohan, Divyamsi Kunapareddy, Sandeep Pidaparthi, and Xintong Chen utilized Dexwell's proprietary PULSE platform to advance their knowledge and contribute to seawater health research.

The SeaPULSE project highlights Dexwell's commitment to enhancing environmental protection through advanced analytics, machine learning, and geospatial intelligence. Recognizing the critical role seawalls play in guarding against erosion and storm surges, this project aimed to create a predictive framework for monitoring seawater conditions. This framework supports the proactive planning, construction, and maintenance of seawalls, benefiting both industry and government sectors.

The interns conducted comprehensive research on seawalls, identifying key factors that influence their

integrity. They developed a detailed market analysis report enriched with geospatial data, highlighting buyer patterns and growth projections for seawall services. This extensive market research provided crucial insights into the current state of seawalls and the primary factors affecting their durability.

Using seawater sensor data, the interns extracted important metrics such as salinity, pH, dissolved oxygen, turbidity, and water temperature. They validated this data through site visits and integrated trend data with SeaPULSE’s geospatial mapping to facilitate real-time trends and correlations. This geographic trend analysis identified patterns affecting seawall resilience, enabling more informed decision-making for maintenance and construction strategies.

In addition, the interns employed the XGBoost Time Series Model to create a predictive framework for monitoring seawater conditions. This predictive modeling provided highly accurate insights, supporting proactive seawall maintenance and construction strategies. Their work in this area is pivotal in anticipating and mitigating potential issues before they become costly problems.

The interns developed a robust business model. This included detailed customer perso-

• Dynamic sessions: Interactive seminars and workshops that promise to push the boundaries of innovation and inspire the next generation of manufacturing solutions, by exploring topics such as sustainable manufacturing, additive manufacturing, artificial intelligence, and digital automation.

nas, cost analysis, diverse pricing strategies, and revenue projections. They also crafted a strategic market entry plan to optimize resource allocation and market penetration.

SeaPULSE is a transformative tool in seawall maintenance, delivering real-time, actionable insights that reduce maintenance costs, extend seawall lifespans, and enhance decision-making for coastal protection. The platform integrates a wide range of environmental data, providing a holistic view of seawater health metrics, including temperature, salinity, dissolved oxygen, pH levels, and turbidity. Leveraging robust machine learning models, SeaPULSE predicts future seawater conditions, facilitating proactive maintenance strategies and preventing costly repairs.

"Dexwell is thrilled to celebrate the achievements of the Rady School of Business interns," said Corina Shtir, PhD, CTO of Dexwell. "Their innovative use of our PULSE platform has not only contributed to their professional growth but also demonstrated the significant impact of our work in enhancing seawater health monitoring. We look forward to driving further advancements in environmental health monitoring."

Continue reading at: www.industryeurope.net

The perspectives on Artificial Intelligence (AI) in the medical and pharmaceutical industries range from excitement to scepticism, particularly concerning this megatrend’s yet-to-be-fully understood implications. While some embrace the technological advances, others fear being supplanted by machines.

However, these apprehensions often stem from a lack of understanding of this “new” technology. Despite AI’s prevalent integration AI into our daily lives, it is far from capable of entirely replacing human labour. While historical trends suggest that new technologies may displace existing jobs, they also invariably create new ones. Nonetheless, it is indisputable that Artificial Intelligence is set to fundamentally transform numerous industries, including healthcare and pharmaceuticals.

Artificial Intelligence encompasses a spectrum of variations rather than one single concept. It is necessary to differentiate between “generative AI”, which creates something new based on available datasets, like ChatGPT, and “discriminative AI”, which identifies and analyses correlations within large datasets. Recently, the focus has shifted towards decentralised, autonomous AI applications functioning independently of continuous server connectivity. In contrast to its centralized counterparts, which run on servers and thus rely on connectivity, the “Embedded-AI” approach offers a variety of new application possibilities.

In simplified terms, a decentralized or Embedded Artificial Intelligence operates locally on chips at the data generation site, thus eliminating the need for cloud connectivity. Although initially developed on large servers, this AI is then compressed through a complex and sophisticated process so that it can run on minimal computing units. Such chips with an integrated Embedded-AI only take a few centimetres in size and thus can be implemented in all kinds of systems.

Once trained, such decentralized AI can work autonomously on the device without depending on its original server connection. Through profound data analyses, the AI can then significantly enhance device performance and efficiency. While the processed data packages can hardly be transmitted to a server due to their immense size, an Embedded-AI enables advanced functionalities that significantly improve safety and precision, especially in medical applications.

Concerns about doctors losing their profession to machines are unfounded, asserts Viacheslav Gromov, founder of Embedded-AI developer AITAD: “While Artificial Intelligence stirs groundless fears about its potential of replacing our entire middle class, its real value lies in addressing more pressing and tangible problems. Particularly in healthcare, the new megatrend can address challenges like an ageing population and a shortage of skilled professionals.”

Subsequently, these concerns raise the question of how this technological progress can be slowed down or regulated when it should actually be encouraged. Embedded-AI, particularly in medical and pharmaceutical fields, already offers solutions to counteract these challenges. The technology can lead to significant societal advancements, such as in the realm of recurring routine tasks, through functions such as

intelligent user interaction, predictive maintenance, and other advanced functional innovations that were previously unattainable.