AUSTRALIA'S LARGEST CIRCULATING MANUFACTURING MAGAZINE ®

Issue 117 November 2020

$12.00 INC.GST

MANUFACTURING MAGAZINE

DESTINATION INDIA THREE-FOLD INCREASE FORECAST FOR OUR EXPORTS The growth of India over the next 15 years will see opportunities for Australian manufacturers increase three-fold, with the potential for the nation to rise from Australia’s eighth-biggest trading partner to one of our top three export markets. The blueprint for this transformation is contained in the India Economic Strategy to 2035, compiled by former Department of Foreign Affairs and Trade secretary Peter Varghese and endorsed by the Morrison government. The target set out in the report would see Australian exports to India grow from $14.9 billion in 2017 to around $45 billion, and outward Australian investment to India rise from $10.3 billion to more than the $100 billion mark, reflecting a transformational expansion of the relationship.

DELPHI TAKES BESPOKE MANUFACTURING TO WORLD PAGE 49

Prime Minister Scott Morrison intends to strengthen Australia’s trade relationship with India, which were the subject of discussions in a virtual summit with Indian Prime Minister Narendra Modi at which both leaders pledged to further develop bilateral relationships.

Lisa Singh ... deputy chair of the Australia India Council

Mr Varghese recommends that Australia should strive by 2035 to lift India into our top three export markets, to make India the third largest destination in Asia for Australian outward investment, and to bring India into the inner circle of Australia's strategic partnerships.

POWER YOUR PowerCONTINUITY continuity FOR for your WINNING EDGE - PAGE 23 winning edge.

The expansion of our trade relationship with India comes at a critical time for Australian exporters, with China – the recipient of 32.7 per cent of Australian exports last year – applying aggressive trade practices on Australian products and produce. While India would not surmount China in terms of its economic dominance, its rapid growth, as well as the opportunities emerging post-Brexit from CANZUK – a free trade organisation with Continued page 5

ALCOHOL AND DRUGS $6B HANGOVER - PAGE 42

Advertising options to grow your business!

4-page pull-out Page 27

FORREST IN HUNT FOR MORE AUSSIE BRANDS

Tattarang, the private investment company of mining billionaire Andrew Forrest, is keen to boost local manufacturing and is looking to purchase more iconic Australian brands after his purchase of RM Williams from French fashion house Louis Vuitton. See page 11

INTERVIEW SCOTT PHILBROOK PAGE 48

In these times, ensure the availability of backup power for your critical IT infrastructure with Vertiv’s range of uninterruptible power supply (UPS) solutions. Our robust UPSs are built for even the harshest environments, providing the highest level of efficiency so you can focus on what matters the most: growing and protecting your business. That’s your edge.

Liebert® GXT5

Liebert® GXT RT+

Intelligent, Versatile, and Reliable Power Protection for Your Critical Applications

Essential, Affordable UPS for High Performanc Protection

Features and Benefits • Available in 750VA, 1-1.5-2-3 kVA & 5-6-8-10 kVA ratings • Unity output power factor (PF=1) • On-line (VFI) mode efficiency up to 95% • Active ECO mode efficiency up to 98% • Controllable and programmable output sockets

Features and Benefits • Available in 1-1.5-2-3 kVA ratings • High output power factor (PF=0.9) • Compact dimensions (2Us height) including batteries • External battery cabinets (upto 6) for applications requiring long runtime • Flexible communications via USB, Serial port or SNMP and relay card options

Liebert® ITA2

Liebert® EXS

Compact, Efficient, & Robust UPS for Critical Applications

Optimized and integrated three-phase UPS solution with high efficiency power protection

Features and Benefits • Eco-Mode provides a superlative efficiency of up to 99% • Integrated Ethernet port with HTTP protocol compatibility & streamlined remote monitoring • Robust structure with cutting edge channelized airflow design • Dust and moisture resistant • Can now be used as a dedicated power conditioner with no battery connected for harsh industrial environments

Features and Benefits • Output power factor up to 1 • Double conversion efficiency up to 96.2% • ECO mode efficiency up to 99.3% • Compact footprint with multiple internal runtime configurations • Available in 3/3 and 3/1 versions (10-20kVA)

Vertiv.com/WhatsYourEdgeAsia

KEEPING HOT HANDS

COOL, DRY & PRODUCTIVE

www.atrix.com.au | Email: sales@atrix.com.au | Phone: 08 8371 0228

Register for FREE Glove Trial

*Terms & Conditions apply

CONTENTS PUBLISHER SCOTT FILBY

scott@industryupdate.com.au

FROM THE PUBLISHER............... 6 INDUSTRY NEWS.......................... 9 INDUSTRY POLITICS..................16

ADVERTISING SALES MANAGER DOMINIC TUSA CIRCULATION ASSISTANT EMILY PRICKETT

16

ACTING EDITOR IAN MOORE

editor@industryupdate.com.au

SUB EDITORS ANNAMARIE REYES & TREVOR ALLEN

subeditor@industryupdate.com.au

INDUSTRY POLITICS

IT AND HARDWARE................... 22

CREATIVE DIRECTOR MATTHEW LAM

production@industryupdate.com.au

PRODUCTION MANAGER JULIET NELSON

copy@industryupdate.com.au

27

WORK HYGIENE-COVID-19..... 34

TV SHOW

MANUFACTURING MAGAZINE

Readership 76,968 as at September 2018 ABN 25 083 502 783

www.industryupdate.com.au

OFFICE MANAGER NICOLE CHARLES

nicole@industryupdate.com.au

ADVERTISING COORDINATOR copy@industryupdate.com.au WEB DEVELOPER JINI M R

michelle@industryupdate.com.au CONSULTANT TRACY FILBY

tracy@industryupdate.com.au

34

COVID-19

PRODUCTS.................................. 49 Circulation 19,242 as at September 2018

VIDEO EDITOR & PRODUCER

video@industryupdate.com.au

FINANCE & ACCOUNTS MICHELLE ALCOCK

AUSTRALIAN MADE................... 38

INDUSTRY UPDATE VIDEOS... 46

ADVERTISING SALES REP GLYN SMITH

glyn@industryupdate.com.au

IU MEDIA ADVERTISING SNAPSHOT...................................27

ALCOHOL AND DRUG AWARENESS................................ 42

ADVERTISING SALES DIRECTOR SCOTT FILBY

scott@industryupdate.com.au

38

AUSTRALIAN MADE

ACCOUNTS RECEIVABLE LYN SLIGAR

lyn@industryupdate.com.au

SUBSCRIPTION ASSISTANT info@industryupdate.com.au CIRCULATION ASSISTANT circ@industryupdate.com.au PRINTER OVATO

INDUSTRY UPDATE MEDIA PTY LTD Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 Phone: 02 9439 1288 Fax: 02 9439 3233 Email: sales@industryupdate.com.au

All material in this publication is copyright to the publisher and/ or its contributors.No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2020

Full range of cables & accessories from stock in Sydney, Melbourne, Brisbane & Perth

Australian owned & managed 4

INDUSTRYUPDATE.COM.AU

www.treotham.com.au

info@treotham.com.au

1300 65 75 64 NOVEMBER 2020

NEWS

DESTINATION INDIA

Three-fold increase forecast for our exports Continued from cover Canada, Australia, New Zealand and the United Kingdom as members – represent fresh avenues for Australian products. There is also the Regional Comprehensive Economic Partnership agreement signed by Mr Morrison on November 15, which includes Japan, China and South Korea. However it changes little as Australia already has free trade agreements with each member country. It also will not stem aggressive trade policies. India is not a signatory, which leaves it open to an expansion of bilateral deals.

Matthew Hayden

As Mr Varghese points out in his report, India's scale is extraordinary.

“There is already a lot for a roadmap for Australia to build on its continuing relationship with India,” she says.

“By 2025, one-fifth of the world's working age population will be Indian. By 2030 there will be over 850 million internet users in India. By 2035 India's five largest cities will have economies of comparable size to middle income countries today,” he wrote.

“The Australia India Council will help create awareness about opportunities for partnerships between Australia and India that will promote high quality programs and establish innovative and sustainable strategies for the future.”

“The opportunities however will not fall into our lap. They require a sharper national focus on India by government, an unambiguous commitment by Australian business and a deeper understanding by both government and business of the magnitude of what is unfolding in an Indian market place which will only get more crowded. “They will also require an approach to the investment relationship with India that markedly differs from the trajectory of Australian investment in most other Asian markets.” To help develop the opportunities, The Department of Foreign Affairs and Trade has expanded the Australia India Council with the appointment in September of former Tasmanian senator Lisa Singh and businessman and former Test cricketer Matthew Hayden. Mr Hayden also is a board member for the Institute for Australia India Engagement for two years.

As well at the Australia India Council, there is Australia India Business Council which has an ongoing business relationship with Austrade as well as bodies such as the Australian Manufacturing Growth Centre. Long-standing AIBC member Vish Viswanathan says the body aims to forge business to business collaborations in manufacturing, using bilateral technologies for the business partnership. “We both can offer business values for both sides, supported by financial investment on either side and use of capabilities from both our global markets,” Mr Viswanathan says. Australian companies also have benefited from the Make in India campaign launched by Mr Modi in 2014, of which Mr Viswanathan is the Australian chair. The Indian Prime Minister’s plan was to sell to every country in the world, but manufacture in India. The campaign has been supported by at least 25 business sectors in the country.

He believes it is time for Australia to get down to understanding India’s culture to make the most of market opportunities under the India Economic Strategy. The advocacy work of the council will be crucial to help develop this and to strengthen business links and trade investment growth, Mr Hayden says.

Business partnerships were explored in automobiles, chemicals, IT, pharmaceuticals, manufacturing, machinery, food processing, agribusiness and services infrastructure; allowing 100 per cent direct foreign investment in most of these sectors.

“We are at an important phase of that relationship.”

The Tata-BlueScope Steel venture with several branches in India is one success story in manufacturing. Another is the Australian aviation manufacturer Ferroscope, which makes precision engineering aircraft parts for Boeing and Lockheed Martin, also with plants in India.

Ms Singh says the India Economic Strategy set ambitious targets of increasing Australian investment to grow 10-fold across 10 key sectors and 10 states in India.

NOVEMBER 2020

INDUSTRYUPDATE.COM.AU

5

EDITORIAL PUBLISHER SCOTT FILBY

INDIA A GROWING MARKET THAT CANNOT BE IGNORED

The rapid growth of India provides opportunity for Australian businesses and manufacturers at a time when it is most needed.

The India Economic Strategy endorsed by the federal government indicates that the nation will rise to Australia’s eighth-biggest trading partner to one of our top three export markets within 15 years. The importance of the stronger economic relationship cannot be overstated, given India’s status in the region, defence ties, a diaspora in Australia of more than 700,000 and the aggressive nature of China’s policy in the region. China, our major trading partner in two-way trade, has displayed a petulance bordering on disdain for western values and has imposed tariffs and trade restrictions on Australian exports and those of other western countries. China wants to dominate the region. Its encroachments through the militarisation of atolls in the South China Sea poses a threat to freedom of navigation and is an affront to international law, its intimidation of Taiwan a risk to regional peace, while its restrictions on the freedoms of Hong Kong citizens are in breach of the handover agreement with Britain. Its Belt and Road Initiative is nothing more than a

ACTING EDITOR IAN MOORE

POWERS NEEDED TO PULL STATES INTO LINE

transparent attempt to gain dominance over the west in the region through creating economic dependence. In doing so, it overlooks the fact that it was the support of the west and favourable trade terms that help transform the country into a global powerhouse.

The federal government’s response to the COVID pandemic and the blatantly self-serving attitude of some states provides one of the most instructive lessons from the crisis: that our federation of close to 120-years is broken.

For Australia to seek to lessen its reliance on China for trade is nothing more than sound economic sense – and India is growing faster than any other country.

In March when lockdowns and restrictions were placed on the community and businesses, Prime Minister Scott Morrison formed a national cabinet which included the state and territory leaders. Instead of a being a vehicle for consensus, it displayed the inability of the federal government to counter state rights.

As former Department of Foreign Affairs and Trade Peter Varghese said in his India Economic Strategy, the key question for Australian companies with a global focus is whether they can afford not to be in what is the fastest growing large economy in the world. As we enter 2021 with government support for the sector through the $1.5 billion Modern Manufacturing Initiative, there is no better time to turn our eyes towards India and a burgeoning bilateral trade relationship. That is a wrap for 2020 Merry Christmas & Happy New Year to all of our readers and advertisers. "Behold, a virgin shall be with child, and shall bring forth a son, and they shall call his name Emmanuel, which being interpreted is, God with us.” Matthew 23:1

When in September – Victoria aside – there were negligible cases of new transmissions, Labor states defied calls by Mr Morrison to re-open state borders. As a result, businesses have gone to the wall, countless thousands of jobs have been lost and the federal government is left counting the cost. According to an analysis by the Business Council of Australia, the border closures cost more than $2 billion a week in business forgone and welfare received. State rights need to be qualified to ensure emergency powers remain with the federal government and are not left to the whim of recalcitrant states.

There must be special mention here of Victoria – which decided to go it alone and defy the national cabinet recommendation to use defence personnel or police to supervise hotel quarantine of overseas travellers. Instead, for reasons as yet undisclosed, it decided to use ineffective, ill-trained security guards, which triggered a deadly second wave through the state.

As a consequence, the effective unemployment rate in Victoria in September was 14 per cent, up from 10.5 per cent in July. In the rest of Australia, the figure was 7.8 per cent in September. The extraordinary difference lifted the amount that the federal government has contributed to Victoria through JobKeeper and JobSeeker alone to more than $35 billion. A recommendation by the Royal Commission into National Natural Disaster Arr¬angements at the end of October could show the way to restore proper powers to the federal government. The commission noted that the Commonwealth needed new powers to intervene in natural disasters, which would enable it to deploy the ADF more swiftly and override the states in “exceptional” circumstances. It is a recommendation that should be heeded and extended to other areas of state responsibilities.

INCREASE IN CYBER THREATS AS REMOTE WORK CONTINUES

Cyber criminals are coming up with new and more dangerous tactics to target organisations amid the COVID-19 pandemic. Data on the state of industrial cybersecurity worldwide by security group Claroty found that a majority of IT professionals experienced an increase in threats since March. Some 1,100 security professionals within large enterprises across Europe, North America and Asia Pacific were surveyed, examining how their concerns, attitudes, and experiences have changed. In Australia and New Zealand, almost 65 per cent said their networks were “completely connected” yet only 8 per cent are prioritising operational technology security. This is despite 81 per cent saying IT and OT have become more connected as a result of the pandemic. Additionally, 70 per cent have seen cyber criminals using new tactics to target their organisations in this timeframe.

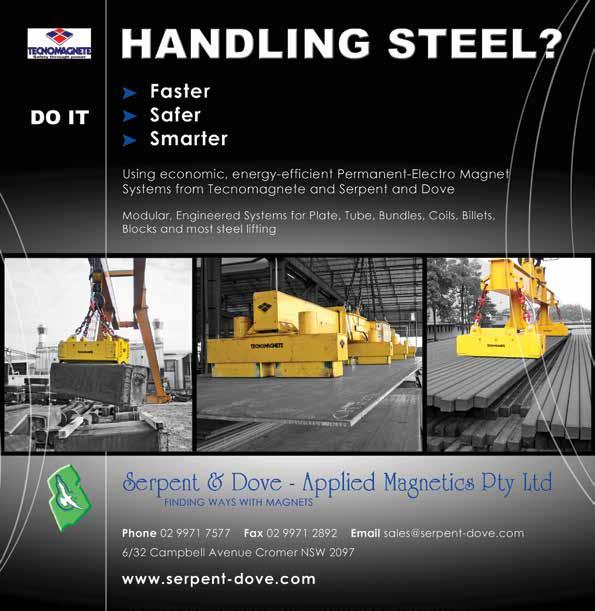

Phone 02 9971 7577 Fax 02 9971 2892 Email sales@serpent-dove.com 2/6 Taronga Place, Mona Vale, NSW 2103 www.serpent-dove.com.au

6

INDUSTRYUPDATE.COM.AU industry update update ad.indd ad.indd 11 industry

The report also detailed the top five industries that hackers are targeting. Globally, the respondents ranked pharmaceutical, oil and gas, electric utilities, manufacturing and building management systems as the most vulnerable to attack. NOVEMBER 2020

30/08/2011 5:25:30 5:25:30 PM PM 30/08/2011

INDUSTRIAL LAW

COURT OVERTURNS DECISION ON SECURITY FOR FAIR WORK CLASS ACTION COSTS

The Australian Industry Group has expressed its disappointment at the Federal Court overturning the decision that compelled litigation firms to provide security for costs in Fair Work class actions. Justice Michael Lee had ordered Augusta Ventures – a UK-based litigation funder – to provide security up front for the costs likely to be expended by the relevant employers in defending a class action. The decision in the Turner v Tesa Mining case was regarded as a landmark ruling because it could deter some of the growing number of class actions being launched under the Fair Work Act. In this case, the applicant brought representative proceedings in the Federal Court on behalf of employees, who had worked at the Mount Arthur Coal Mine through two labour-hire firms from 2012 to 2018. The proceedings alleged that a number of employees were wrongly being treated as casual employees by the labourhire firms and sought compensation for unpaid entitlements as well as orders for pecuniary penalties. The labour-hire firms sought security for costs directly against the funder of about $1 million each, which Justice Lee granted. However, Federal Court Chief Justice James Allsop ruled that an order could not condition, or threaten to condition, the rights of the applicant and the group members’ rights because of a prospective liability of AVL for cost

Contact Tente Castors & Wheels To Find Your Product Solution Phone: 1300 836 831

8

sales.au@tente.com

INDUSTRYUPDATE.COM.AU

tente.com.au

Ai Group chief executive Innes Willox said the decision by the full bench was disappointing, but the court did not rule out Augusta Ventures being required to pay the employers’ costs at the conclusion of the litigation, if the claims were rejected. Mr Willox said Justice Allsop highlighted the absence of regulation that

required foreign litigation funders to have proper capitalisation or sufficient funds in Australia. “This could impact upon employers being able to recover their costs in class action litigation and this regulatory gap needs to be addressed without delay,” Mr Willox said. He said comprehensive litigation funding legislation needed to be implemented requiring licence holders to: • Have sufficient capital in Australia; • Act in the best interest of plaintiffs at all times; • Fully disclose funding arrangements to plaintiffs and the court; • Ensure that any returns are reasonable, having regard to Returns on Invested Capital (ROIC) being earned at the relevant time for other classes of investments with similar risks; and • Pass, on an ongoing basis, a “fit and proper person” test. “A parliamentary inquiry is currently looking at the need for reforms to class action and litigation funding laws and Ai Group has put forward a comprehensive reform plan,” Mr Willox said. “An Australian Law Reform Commission report last year on Class Actions Proceedings and Third-Party Litigation Funders reported that, in cases involving litigation funders, the median return to plaintiffs is only 51 per cent of the amount awarded. In cases not involving litigation funders the median return to plaintiffs is 85 per cent. This highlights that the current arrangements are not benefiting plaintiffs and that reforms are urgently needed.”

NOVEMBER 2020

turing surges into expansion in October

p Australian Performance of Manufacturing reased by 9.6 points to 56.3 points in d), indicating expanding conditions for the ove 50 points indicate expansion with higher of expansion.

MANUFACTURING EXPANDS FOR THE FIRST TIME SINCE JULY

s noted a jump in sales and new orders as a Australian IndustryThe Group the initialThe activity restrictions. jump into Australian Performance of Manufacturing improvements in New South Wales, which increased by 9.6inpoints to 56.3 inbut ctoria,Index which remained contraction indicating expanding conditions on in October, September.

TES

NEWS

October 2020

for the first time since July. October

September

Change

56.1

44.3

+11.8

PMI readings above 50 points indicate expansion with higherpoints results pointsin activity, points indicating 56.3 a faster rate 46.7of expansion. +9.6 The manufacturing sector grew solidly 47.3 37.6 +9.6 in October with production, employment, 47.5 43.3 +4.2 sales and exports all moving convincingly 68.4 67.4 +1.0 into growth territory.

Once again, the large food & ABSbeverages real manufacturing output sector led the way with strong contributions from machinery & equipment manufacturers. Food & beverage produced $26.5 billion in real value-added output in the year to Q2 2020, lifting two points on the index to 61.6. Machinery & equipment produced $19.5 billion in real value-added output in the same period, rising 0.4 points to 53.9. There also was firmer growth in the textiles, clothing, footwear, paper & printing group. The chemicals sector stabilised in October while the pace of contraction eased in both the metal products and building materials sectors.

MEDIA CONTACT Tony Melville Australian Industry Group Tel: 0419 190 347

Australian PMI®

▲ 9.6 points (seasonally adjusted)

56.3

Australian PMI®

53.6

Food & beverages

61.6

▲ 1.8 points (trend)

▲ 2.0 points (trend)

Machinery & equipment

▲ 0.4 points (trend)

53.9

Metal products

47.4

Chemicals

▲ 2.3 points (trend)

50.9

Building materials, wood & other

46.1

TCF, paper & printing

53.7

▲ 0.6 points (trend)

▲ 2.6 points (trend)

▲ 2.1 points (trend)

some manufacturers anticipate higher production in the coming months as Respondents across all sectors noted activity restrictions are eased. Sales a jump in sales and new orders as a result also climbed significantly (up 14.9 of pent up demand from the initial activity points to 56.4) in October, while the restrictions. The jump into expansion was www.aigroup.com.au/resourcecentre/economics/ employment index returned to positive driven by large improvements in NSW, which territory (up 7.6 points to 55.3). rose into expansion, and Victoria, which remained in contraction but improved from a deep contraction in September. Ai Group chief executive Innes Willox was buoyed by the figures. "With the quantity of fiscal support easing in October and with the tax cuts only just starting to flow through, the lift in sales and the strong growth of new orders are particularly encouraging signs of improving household and business confidence,” he said. “The solid national performance was achieved despite another month of contraction in Victoria. With restrictions in Victoria being lifted there are very good prospects of further strength in the closing months of 2020," Mr Willox said.

Australian PMI®: Key Findings for October • All seven activity indices in the Australian PMI® were in expansion in October, with supplier deliveries (up 16.0 points to 58.8) and new orders (up 13.3 points to 58.4) experiencing large increases – possibly because

NOVEMBER 2020

• Among the six manufacturing sectors in the Australian PMI® the food & beverages (up 2.0 points to 61.6) and machinery & equipment (up 0.4 points to 53.9) manufacturing sectors expanded, as did the smaller, diverse TCF, paper & printing sector (up 2.1 points to 53.7). Contraction was evident in the metal products (up 0.6 points to 47.4) and building materials (up 2.6 points to 46.1) sectors, while the chemicals sector was broadly stable (up 2.3 points to 50.9). • The input price index increased to its highest result since April (up 8.7 points to 66.6), with some respondents noting difficulty transporting goods across state borders was increasing costs. Selling prices, on average, increased for the first time since April (up 4.3 points to 53.6). • The average wages index improved into expansion (up 5.0 points to 57.3), recording its highest result since March.

INDUSTRYUPDATE.COM.AU

9

BUSINESS AND FINANCE

ST.GEORGE ANALYSIS: WHAT THE RATE CUTS MEAN FOR BUSINESS RBA governor Lowe also said that if this amount proved to be wrong, it would adjust the numbers. Dr Lowe’s speech, following the changes to monetary policy, stressed that the RBA intended to play its part in assisting the recovery and creating jobs. “The RBA is concerned about the long-lasting effects from the pandemic, especially on jobs, and hopes the delivery of these new stimulus measures will reduce the risk of high unemployment,” Ms Deda said. “A sharp bounce back in jobs is unlikely but the priority is clearly on job creation.

The Reserve Bank tapped hard on the accelerator in October, reducing a range of interest rates, including the cash rate, and announcing a more aggressive approach towards quantitative easing, according to an analysis by St.George chief economist Besa Deda. The cash rate was reduced from 0.25 per cent to a new record low of 0.10 per cent. “These days, monetary policy is more than adjusting the cash rate,” Ms Deda said. “The RBA also seeks to influence yields across the yield curve.” In March, the RBA began setting a target for the three-year government bond yield by buying and selling bonds across the curve (called yield-curve control). The target was set at “around” 0.25 per cent and was reduced to 0.10 per cent on Tuesday. RBA governor Philip Lowe, in his accompanying press conference, stressed this was the new lower bound and reasserted that negative rates remained “extraordinarily unlikely”. He did concede, however, that if other major central banks all have negative rates, then the RBA would have to consider them. “In its effort to support businesses and job creation, the RBA in March also introduced a Term Funding Facility whereby lenders could borrow from this fund to on-lend to clients,” Ms Deda said. “The borrowing rate from this fund was initially set at 0.25 per cent and was also reduced on Tuesday to 0.10 per cent.” Another arm of the RBA’s monetary policy is the operation of its Exchange Settlement account. Banks and other authorised deposit institutions (ADIs) hold

10

INDUSTRYUPDATE.COM.AU

accounts with the RBA and bank funds can sit there. The rate on those accounts, prior to the RBA board meeting, was 0.10 per cent. On Tuesday that rate was reduced to zero. “With a zero rate, there is no incentive for banks to hold funds in these accounts,” Ms Deda said. “The expectation is that banks will seek out better yielding alternatives. When lent out, these funds can assist business activity.” In a new move, the RBA will introduce a bond-buying program (i.e. quantitative easing) for maturities beyond three years. It now plans to purchase $100 billion of government and state bonds in the five- to 10-year range over the next six months, thus impacting on yields further along the yield curve. Ms Deda said the RBA now had a price target (for the three-year bond yield) and a quantity target (for its bond buying program for maturities of five to 10-years). “The new bond-buying program matches the QE programs of other central banks, which the RBA hopes will bring down yields at the longer end of the Australian yield curve and reduce the demand for the Australian dollar (than otherwise would be the case),” she said. “A more competitive currency would help bolster the trade sector and economic recovery. “Why is $100 billion the magic number? The governor explained that international experience suggests 5 per cent of gross domestic product (GDP) is what has a meaningful effect on the currency and bond yields. For Australia that is around $100 billion.”

“Importantly, the governor stated that the RBA board is prepared to do more if necessary. The board will keep the size of the bond purchase program under review, particularly in light of the outlook for jobs and inflation. “Tuesday’s rate changes, and the forward guidance it has given, reduce the cost and the risk of borrowing. They should also aid recovery via their impact upon business and household balance sheets.

St.George Bank chief economist Besa Deda

“Given the slack in the labour market, the RBA notes that wages growth will be weak over the next few years,” Ms Deda said. “This is important for its inflation outlook given that wages are a major business cost. “With wage growth low, it will take longer for inflation to reach the RBA’s 2-3 per cent per annum inflation target. From this flows the remark made by the governor that ‘the board is not expecting to increase the cash rate for at least three years’.

“But will they really work? The RBA is of the view that with lockdown restrictions across the economy lifted, its policies will gain more traction. Recent statistics on home lending, building approvals and consumer sentiment suggest that green shoots are emerging in the economy.

“The governor explained in his press conference that there was less certainty beyond three years, but he hoped within the next five years, the economy would begin to show signs of recalibrating and policy would begin to normalise.

“Tuesday’s announcements will encourage growth.

“Is the RBA out of firepower? The governor says ‘no’ and it has additional policy tools if needed.”

“The governor’s statement acknowledged that recovery was underway. It also acknowledged that some of its early concerns were not met. Accordingly, it now forecasts that the rate of unemployment will peak a little below 8 per cent rather than the 10 per cent expected some months ago.

Tuesday’s policy package is designed to work via three channels, Ms Deda said. •

Lower lending rates should lift cash flows and so lift spending.

•

There will be downward pressure on the Australian dollar because of lower bond yields. This will aid export industries and those receiving income from abroad.

•

Lower yields and access to credit will put upward pressure on asset prices. This will strengthen personal and business balance sheets allowing more scope for spending.

“It now also expects the unemployment rate to sit around 6.0 per cent by the end of 2022 (down from 7.0 per cent previously forecast).” The RBA also upgraded its near-term economic growth forecasts. GDP growth in the year to June 2021 is now anticipated to be 6 per cent, compared with 4 per cent previously. However, Dr Lowe made it clear that the economy remained in the grips of a recession, although the narrow definition of a technical recession would not be met – with solid growth in the September quarter expected by the RBA.

“Together, the RBA policy package and the recent Budget announcements should help create jobs and aid in the recovery of the economy,” she said.

NOVEMBER 2020

NEWS

RM WILLIAMS PURCHASE A WELCOME KICK TO LOCAL MANUFACTURING Australian actor Hugh Jackman is also selling his 5 per cent stake in RM Williams to Tattarang but will remain a brand ambassador. The Forrests have also pledged to keep manufacturing jobs in Australia and plans to grow RM Williams, after watching other Australian brands like Bonds, King Gee, Hard Yakka and Blundstone move offshore.

Billionaire Andrew Forrest’s private investment company has flagged an intent on keeping local manufacturing jobs, after buying renowned Australian brand RM Williams for almost $190 million. The deal ensures the iconic leather boots will continue to be manufactured in Australia at the company’s Adelaide plant. The Forrest family’s private investment company Tattarang beat out private equity giant TPG Capital to secure the purchase from French fashion house Louis Vuitton.

“I’m just so glad it is now back and I’d have to say the family has a big solid lump in its throat about returning RM Williams back to Australia,” Mr Forrest said when he announced the purchase. The business employs more than 800 people, with some 400 workers at its Adelaide plant and a similar number across 60 stores nationwide. It also has one store each in New York and London. Tattarang chief investment officer John Hartman said that while some production had moved offshore, most was made locally. “There are a few products made offshore

Hugh Jackman ... will remain an RW Williams ambassador

controls more than $20 billion of assets, was seeking to target other iconic Australian brands that may have fallen into foreign ownership.

but it’s only 1 or 2 per cent,” he told the ABC. “In this time of reflection on our manufacturing base, we’re certainly committed to maintaining the Australian manufacturing focus,” he said.

“I was fortunate enough to go to the workshop in Salisbury in Adelaide back in December before coronavirus started to have its impact,” he said, adding the opportunity to purchase presented itself during the pandemic.

“We’ll commit to more Australian jobs and particularly keeping the boots made onshore,” he said. The Forrests also view RM Williams as a long-term investment and say there is a focus on getting to 100 per cent local production.

“In business, sometimes you have to take an approach to get a reasonable deal,” he said.

“We’d like to employ more Australians and get more of these fantastic boots out to people who just love to wear a quality boot which you can pass on from mum to daughter and from father to son,” said Mr Forrest.

Tattarang sees potential for RM Williams to triple earnings in the next five years, partly though boosting online sales and also redoubling efforts to take the boots to international markets.

Mr Hartman said Tattarang, which

Whatever you need to lift & move . . . there's an Altrac crane for that! CUSTO M BU ILT T O Y OUR S PEC IF IC NE EDS AUS TRALI AN MA DE FULL WARRAN TY A N D SUP PO RT Altrac Monorail Crane

Altrac Gantry Crane Altrac Jib Crane

Each crane is engineer-designed to suit your specific manufacturing process and facilities.

Made in Australia with high-quality materials for quick turnaround from design to install.

If you need advice, spare parts or are expanding your business, we'll be here to help.

Contact us for a free quote est. 1984 NOVEMBER 2020

(03) 9796 5300 www.bomac.com.au/get-a-quote INDUSTRYUPDATE.COM.AU

11

BM-1600

$51,950 ex GST (M639D)

BM-2000

$57,950 ex GST (M640D)

(X) 1200mm (Y) 700mm (Z) 500mm

(X) 1400mm (Y) 700mm (Z) 500mm

Automatic Oil Lubrication System

Universal Head Swivels 360°

Electic Brake & Rapid Feed on X, Y & Z-Axis

Control Panel with 3-Axis DRO System

Cast Iron Table Extensions Large Work Table Area

Servo Feed Motors X, Y & Z Axis

Automatic Slideway Lubrication

Hardened Ballscrew X, Y & Z-Axis

BM-1600 & BM-2000 This extra heavy-duty BM-1600 universal milling machine NT50 spindle taper is built with ultra-high precision hardened preloaded ballscrews in X, Y & Z axis that will provide accuracy for many years to come. Another superior feature that is included standard with this massive beast of a machine is the servocontrolled feed system to ensure constant torque when removal metal under extreme load. All this is combining with and extralarge hardened & ground working table with extremely long travels to match.

MODEL Code

BM-2000

M639D

M640D

Digital Readout Work Table Area (LxW) Spindle Taper (Universal Head)

3-Axis DRO mm

1600 x 500

NT

2000 x 500 50

Longitudinal Travel (X-Axis)

mm

Cross Travel (Y-Axis)

mm

Vertical Travel (Z-Axis)

mm

500

Spindle to Table Max.

mm

50 - 550

Tilting Head (Left ~ Right)

deg

Types of slides Ram Travel

To sum it all up, If you require to remove large quantities of metal from big & heavy jobs, and need a machine to maintain its capabilities from start to finish, then this universal milling machine is what you need.

BM-1600

1200

1400 700

360Âş Dovetail (X), Square (Y & Z)

mm

45 - 745

Power Feed - Longitudinal / Cross (X / Y) mm / min

10-1000

Power Feed - Vertical (Z)

5 - 500

Work Table Capacity

mm / min kg

1800

Spindle Speeds (Universal Head)

steps / rpm

27 (30 - 2050)

Motor Power (Universal Head)

kW / hp / V

7.5 / 10 / 415

6 | Sent 12-10-20

IPG Laser Source

Motion System

IPG Photonics is the leading developer and manufacturer of high-performance fiber lasers

The machines motion system utilises a HIWIN dual linear rail design on both sides to ensure accurate motion control and Motion System superior cutting accuracy

IPG Laser Source IPG Photonics is the leading developer and manufacturer of high-performance fiber lasers

PRICED FROM

$89,000 ex GST

The machines motion system utilises a HIWIN dual linear rail design on both sides to ensure accurate motion control and superior cutting accuracy

PRICED FROM

$89,000

ex GSTEnclosure Safety

The fully enclosed guarding system is designed so that machine stays compact, yet full Safetyaccess Enclosure is available to all areas of the machine through lockable The fully enclosed guarding and safety interlocked doors system is designed so that

Laser Cutting Head The METALMASTER laser is supplied as standard with a RAYTOOLS focusHead head Laser Auto Cutting

machine stays compact, yet full access is available to all areas of the machine through lockable METALMASTER servo system and safety The interlocked doors

The METALMASTER laser is supplied as standard with a RAYTOOLS Auto focus head

and drives from Japan, this Servomotors System

Servo System

utilises YASKAWA AC servo

enables speeds up to 40m/min with

The METALMASTER servo system acceleration of 0.5G (5m/s2) whilst utilises YASKAWA AC servo maintaining superior and repeatable motors and drives from Japan, this positioning accuracy enables speeds up to 40m/min with acceleration of 0.5G (5m/s2) whilst maintaining superior and repeatable positioning accuracy

Available in several machine sizes we can customise the size to suit your needs Available in several machine sizes we can customise the size to suit your needs

MM-1390

MM-1313

1300 x 900 MM-1390

MM-3015

1300 x 1300 MM-1313

CUTTING 1300CAPACITY x 900

3000 x 1500 MM-3015

CUTTING CAPACITY 1300 x 1300

CUTTING CAPACITY

CUTTING CAPACITY 3000 x 1500

CUTTING CAPACITY

CUTTING CAPACITY

CHOOSE YOUR LASER POWER The METALMASTER Fiber laser is a compact yet fast and powerful machine with high speed servo motors coupled to CHOOSE YOUR LASER Type POWER The METALMASTER Fiber laser is a compact yet fast and Laser Power 1000W (1kW) 2000W (2kW) 3000W (3kW) 4000W (4kW) ball screwsmachine to give the its servo high speed powerful withmachine high speed motorsacceleration coupled to Laser Power Type 1000W (1kW) 2000W (2kW) 3000W (3kW) 4000W (4kW) mm 10 14 16 20 of ball 0.5G. The machine moves at top speed of 40m/min rapid Mild Steel screws to give the machine its high speed acceleration traverse always maintaining measured mm 10 14 16 20 of 0.5G.whilst The machine moves at topaccuracies speed of 40m/min rapid Mild Steel Stainless Steel mm 5 6 10 12 in traverse microns.whilst always maintaining accuracies measured Stainless Steel mm 5 6 10 12 Aluminium

Aluminium

Laser

10

10

Type IPG Photonics Precitec-Trumpf Precitec-Trumpf Precitec-Trumpf

Type

CYPCUT

CYPCUT

CYPCUT

CYPCUT

Cutting Head

Type

Auto Focus

Auto Focus

Auto Focus

Auto Focus

CNC Motion System

Type

Type

CYPCUT

Auto Focus

CYPCUT

CYPCUT

Auto Focus

Auto Focus

CYPCUT

Auto Focus

Type Yaskawa Servo Yaskawa Servo Yaskawa Servo Yaskawa Servo

Type Yaskawa Servo Yaskawa Servo Yaskawa Servo Yaskawa Servo

PERTH BRISBANE MELBOURNE MELBOURNE PERTH BRISBANE (07) 3715 2200 (07) 3715 2200 625 Boundary 625 Boundary Rd,Rd, Coopers Plains Coopers Plains

(08) 9373 9212 9999 9999 (03)(03) 9212 44224422 (08) 9373 4 Abbotts 4 Abbotts Rd, Rd, Dandenong Dandenong

11 Valentine St, 11 Valentine St, Kewdale Kewdale

Specifications are are subject to change without notice. All prices exclude exclude GST and GST are valid 30-11-20 Specifications subject to change without notice. All prices and until are valid until 30-11-20

06_IU_091120

1/2Windsor WindsorRd, Rd, 1/2 Northmead Northmead

8

8

CNC Control Unit

CNC Motion System

(02)9890 98909111 9111 (02)

6

6

Type IPG Photonics Precitec-Trumpf Precitec-Trumpf Precitec-Trumpf

Cutting Head

SYDNEY SYDNEY

2.5

2.5

Laser

CNC Control Unit

drive systems.

mm

mm

06_IU_091120

in microns.

METALMASTER Fiber Lasers are built with the highest METALMASTER Fiber Lasersfrom are built with the highest quality components sourced reputable suppliers quality components sourced from reputable suppliers around the world such as IPG Laser, Precitec Laser, around autofocus the world such as IPG Laser, Precitec Laser, Raytools cutting heads and Yaskawa CNC Raytools autofocus cutting heads and Yaskawa CNC drive systems.

CASE STUDY - A-SAFE

HOW A SAFETY BOLLARD FORGED A LASTING PARTNERSHIP It seems strange to say, but a humble yellow bollard helped change the way one business worked.

as pedestrian walkway barriers, height restrictors, wheel stoppers and column protectors.

But for Sigma Healthcare, that is just what happened when it installed A-Safe products in its warehouses.

The iFlex Pedestrian Barriers can withstand the impact of a 3.2 tonne vehicle and are designed to flex and absorb the collision.

It all started with just one bollard in 2016, explains Program Manager Peter Petito, and it greatly facilitated the safety message. From there, it kicked off a long-lasting partnership between Sigma and A-Safe that has continued to prosper. “Before we had them installed, we were tossing up whether to have concrete core drilled and filled bollards or have them bolted to the ground,” says Peter.

FlexiShield Column Guards help to avoid impact with Sigma’s fire safety equipment and the Height Restrictors ensure the forklift drivers maintain a safe working environment and flow of traffic. The A-Safe products are abrasionresistant, non-corrosive and are UV protected and tested.

pretty simple products but they work and are cost effective,” says Peter. Mr Petito has been in the industrial space for some 25 years and says he has found A-Safe products “have enhanced how we protect our team members and equipment”. There is enough flex and rigidity to withstand impact from collisions while limiting external damage. Independently tested and certified by TUV Nord and compliant with PAS13 Code of Practice for Safety Barriers used in traffic management within the workplace, A-Safe products are designed to keep personnel and company assets

“How high should they be? We also mulled over whether they needed to be dug into the ground and of course, comparing how much they cost.

“We found it did little to no damage to the forklift and more importantly, didn’t damage the concrete flooring that the bollard was attached to,” says Peter. With the testing complete, Sigma installed more A-Safe bollards as well

Flexible barriers guard against forklift accidents

Sigma’s healthcare products, including temperature-sensitive products, demand highly specialised climate and temperature control, sophisticated monitoring and experienced operators through the entire supply chain. The company is a leading Australian full line wholesale and distribution business of pharmaceutical products to community and hospital pharmacies. Sigma was so impressed, it now has A-Safe products installed at its Perth, Sydney Melbourne and Adelaide locations. Having invested around $300 million in its distribution centres across Australia over the last three years, Sigma Healthcare’s logistics infrastructure now provides market leading services to community pharmacies, hospital pharmacies and pharmaceutical manufacturers. “Not only are they a great visual aid for staff as they look good, but they are fit for purpose and are cost effective,” says Peter.

Height restrictors ensure traffic flows smoothly

14

INDUSTRYUPDATE.COM.AU

“There’s continual improvement, meaning there’s no risk of resting on your laurels and letting your standards slip in any way.”

A-Safe has seen its products implemented in a range of industries including manufacturing, warehousing and distribution, airports, carparks and services sectors that span from automotive to food and drink.

So how else do you test a bollard? Use it to deflect a forklift, of course!

“It worked a treat!”

“It’s a constantly evolving safety management system, which is brilliant,” says Mark.

“We’ve been getting a lot of feedback about potential safety improvements,” he says. “They’ve been approaching us, which is fantastic. It means we are getting input from the ground up.”

“In the end, we decided to get just one A-Safe bollard and trial its effectiveness ourselves,” he says.

Sigma safely tested the bollard at its Brisbane site to determine whether the product was effective.

Clear yellow markings help make problem areas stand out

“The bollards use a rotating sleeve which allows them forklifts just roll right off them in the event of an accident. They’re

protected all year round. Unlike AS1170.1 which does not give guidelines for the placement of barriers and personal gates to safely segregate pedestrians from moving vehicles and machinery, PAS13 Code of Practice has been implemented by Sigma for maximum protection. A-Safe complies with the International Organisation for Standardisation (ISO) 45001, an occupational health and safety management system designed to create safer working conditions around the globe.

Not only does it manufacture pedestrian safety barriers, traffic barriers and corridor and wall protection, but has diversified into cold storage asset protection, airport equipment and baggage conveyor protection. The partnership between Sigma Healthcare and A-Safe’s products has helped to ensure Sigma maintains high safety standards well into the future.

A-Safe Australasia Pty Ltd 02 9625 8927 www.asafe.com

Director of workplace safety at A-Safe Australasia, Mark Collins, says becoming ISO 45001 certified was a stringent process but ultimately is worth the effort. “When two companies are compliant with one internationally recognised standard, it makes the process of conducting business together a whole lot simpler.” A-Safe has offices in 16 nations across the globe and is a market leader in innovation in the safety sector. In 2001, it invented the world’s first fixed polymer safety barrier and is now onto its third generation of barrier.

Bollards protect vital fire safety equipment

NOVEMBER 2020

‘We have always received excellent service and back up from Applied Machinery. Knowing we would be fully supported is why we ultimately chose the Yawei brand.’ PAUL BUTKO, JC BUTKO ENGINEERING, WODONGA, VIC

At Applied Machinery, we treat our customers business’ as an extension of our own. We view ongoing service, training and support as critical to ensuring our customers can extract maximum return from their machinery investment.

they need, with the support they expect. With nearly 30 years’ experience, and thousands of satisfied customers across the country we’re here for the long term. We’re a true machinery partner – just ask Paul Butko.

Our number one priority is ensuring that our customers across the country get the machinery

Real Service. Real Support. Real People. That’s Applied Thinking.

INDUSTRY POLITICS THE HON. KAREN ANDREWS MP – PARLIAMENT OF AUSTRALIA, MINISTER FOR INDUSTRY, SCIENCE AND TECHNOLOGY

By pursing the philosophy of “what if” it has also changed the market, outpacing China on the manufacture of prescription glasses frames, producing them at a cheaper price than anywhere in the world.

USING SCIENCE AND TECHNOLOGY TO GROW AUSTRALIAN MANUFACTURING

We know there is much more that must be done to see more manufacturers realise their potential.

WiFi and GPS are so entwined in our lives. They have transformed the daily commute, our daily interactions and how businesses do business.

changing business conditions, it is now more important than ever for industry, and particularly our manufacturers, to wonder “what if”?

In 2020, they have helped families learn, live and work from home, getting food and supplies delivered to their doorsteps.

What if we were to change our materials?

Take, for example, NSW optical company Dresden. It worked in a market where glasses were costly, fragile and made from non-ecofriendly materials.

What if we were to switch up that process?

But they wondered what if they could do something different.

What if we were to collaborate with someone new?

Dresden made science and technology work for their vision, finding entirely new partners from the research and university sector alongside other manufacturers.

They have helped businesses go online and take their business direct to customers. These two now seemingly indispensable technologies were born by science and the one simple question that drives all innovation: “what if”? Science and technology have tremendous power to change our lives and to revolutionise industry.

As we look to chart our economic recovery now and for future generations, it is crucial we get science and technology working for industry – a key pillar of the Morrison government’s $1.5 billion Modern Manufacturing Strategy.

And with the seismic impacts of COVID-19 restrictions and their legacies, affecting supply chains, and fundamentally

The clever use of both science and technology can be a game changer for our manufacturers. It can improve productivity,

make them more competitive and it can create new jobs.

By pushing the envelope of the possible and utilising research, Dresden now manufactures glasses that are 100 per cent recyclable – transforming milk bottle tops, beer keg taps and discarded fishing nets among other items. But that’s not the end of the story.

THE HON. SENATOR ERIC ABETZ, A MEMBER OF THE POLITICAL ADVISORY BOARD OF CANZUK AND A FORMER LIBERAL MINISTER FOR EMPLOYMENT

CANZUK, CHINA, COVID-19 AND OUR MANUFACTURING FUTURE It is frequently (yet incorrectly) stated that the Chinese word for crisis is composed of two Chinese characters signifying "danger" and "opportunity". Recently, Chinese state media announced a halt on exports from Australia worth more than $6 billion a year that included wine, lobster, copper, sugar, timber and coal that arrived in China after November 6 2020. This announcement came after China placed tariffs on Australian barley and meat earlier in the year. Months before that, a virus spread from Wuhan across the globe and continues to devastate economies as they deal with its health implications. A few years before that, the UK decided to unshackle itself from the European Union and forge a new economic destiny. With these events, Australia is presented with the dangers of uncertainty but also with an opportunity to lay the foundations for Australia's manufacturing future. This once-thriving industry

16

INDUSTRYUPDATE.COM.AU

is still capable of producing quality goods for export and domestic markets. The events of 2020 can therefore be the catalyst for an overdue discussion on the future of Australia's manufacturing and how to reorganise it effectively as we face such severe challenges. Some view Australian manufacturing as a product of a bygone era, obsolete in the age of globalisation, ever-dwindling comparative advantages and a flood of cheap imported goods. Yet manufacturing employs some 860,000 Australian, and before COVID-19 it generated more than $100 billion in annual value to the Australian economy and over $50 billion in exports. It is more important than ever to keep producing goods in Australia. Manufacturing contributes around one-quarter of total research and development investment in Australia, roughly four times its share of the economy. It is particularly important to regional economies, and in my home state of Tasmania, 1,465 manufacturing businesses employ almost 15,000 people.

Last month the federal government announced a new era for Australian manufacturing with the $1.5 billion Modern Manufacturing Strategy to help rebuild the economy and recover from the COVID19-induced recession. The strategy will make Australian manufacturers more competitive, resilient and able to scale-up to take on the world while building upon our nation's self-sufficiency. It is an opportunity to grow into new and emerging local and global markets. With increasing global economic uncertainty, there lies the opportunity for Australia to increase its economic cooperation with nations it shares close cultural and historical ties, particularly Canada, New Zealand and the UK. In 2019-20, trade between CANZUK nations included: •

manufacturing exports to Canada totalling $512.6 million;

•

elaborately transformed manufactures

That is why our Modern Manufacturing Strategy, with the $1.3 billion Modern Manufacturing Initiative at its heart, is designed to supercharge our manufacturing businesses to lead us out of this pandemic We want to encourage our businesses to seize the opportunities to scale up, become more resilient and more competitive. We want to back our businesses to leverage their bright ideas and to collaborate with our world-class researchers and scientists. We want to encourage our businesses to invest in innovation – because by improving their processes and practices to be cuttingedge they can reinvent their products and take on the world – just like Dresden. For it is embracing science and technology and asking “what if” that will have people exclaiming in wonder, “how many?!” How many manufacturing jobs have you created? comprising over 90 per cent of exports to New Zealand with more than 51 per cent engineering products at $3,690.4 million; and •

exports to the UK that were elaborately transformed manufactures and comprised more than 67 per cent of exports, with 46 per cent engineering products at $867.4 million.

According to the DHL Export Barometer 2019 report, growth in export orders from New Zealand topped the list. Growth in export orders from the UK has steadied since 2016, reaching 35 per cent in 2019. The report goes onto highlight the potential of the CANZUK nations, stating: This year's results show a more significant number of small to medium-sized businesses entering the export market. For companies new to exporting, we typically see a trend where they concentrate their expansion in markets with familiar consumer buying preferences, cultures and languages. For Australian export businesses, these markets are likely to be other Western nations, such as New Zealand, the US or Canada. For Australia, there is a high level of uncertainty about the likely impacts of Brexit – with agreements still to be reached between the UK and the EU. Negotiations are continuing with an Australia – United Kingdom Free Trade Agreement and an Australia-European Union Free Trade Agreement. As Australia – and the world – faces a profoundly uncertain economic future, the nation's manufacturing sector can, with careful nurturing, overcome the problems of the past to be a solution for the COVID-19 economic recovery. NOVEMBER 2020

INDUSTRY POLITICS THE HON: BRENDAN O'CONNOR - MP PARLIAMENT OF AUSTRALIA, SHADOW MINISTER FOR EMPLOYMENT AND INDUSTRY

LABOR PLAN TO BOOST AUSTRALIAN JOBS AND PRODUCTS It has been 30 years since Australia last faced the daunting prospects of a recession. Many reading this now probably would not have experienced such a situation as an adult employed, or running a business. It will take years to recover, but there is no doubt about the important role manufacturing will play in the future of our country as we navigate our way out of the recession our country is facing. Australian manufacturers were pivotal in the midst of the pandemic as they quickly adapted operations to provide crucial Personal Protective Equipment. The production of hand sanitiser and face masks helped manufacturers through the pandemic, but COVID-19 exposed the vulnerability of our commodity-based economy to global shocks. In doing that, it revived the importance of a strong Australian

manufacturing sector with products made here in Australia. That is why Labor has launched a plan for a Future Made In Australia – a plan to boost Australian jobs and Australian made products that will benefit our Australian economy. The initial part of this plan was outlined in the Budget-in-Reply speech by Leader of the Opposition Anthony Albanese, in which he outlined our national Rail Manufacturing Plan. Liberal governments have consistently said we cannot build trains here, yet the ones they have bought from overseas have been too long for our stations, too narrow for our tracks, or too tall for our tunnels. Our country has the skills and the knowhow. By manufacturing trains here, Labor’s plan would create up to 659 full-time jobs, as well as a rolling stock export industry and boost Australia’s GDP by up to $5 billion.

Manufacturing is critical to Australia’s economic future, to the prosperity of our regions and to the capabilities that underpin the success of so many other industries. Federal Labor welcomes the government’s new focus on manufacturing, however we remain concerned about what we perceive as a lack of ambition. While the Morrison government has announced $1.5 billion of funding, less than 3 per cent of that money – only $40 million – will be available to manufacturers this financial year. The Coalition government continuously talks about the importance of medical technology and manufacturing as we deal with COVID-19 and the recession, which begs the question, why won’t this government provide greater support to Australian companies at the time they need it most?

A lack of immediate action will jeopardise Australian jobs and will mean the recession will be deeper and longer than it need be. As we look to the future and how we best emerge from the health crisis and recession, we have to focus on how to establish well paid, skilled and secure jobs. Active Australian industry policy will see jobs in Australia, will prevent Australian talent leaving our shores for opportunities overseas, and grow our economy. Industry policy should foster greater collaboration between industry, small and medium enterprises, and government bodies like the CSIRO; a comprehensive public procurement policy; and encouraging start-ups to scale up. I am optimistic about the future of manufacturing in this country. We have shown in the past that we are an innovation nation and we can continue to be. In Bruce Springsteen’s 1978 ode to factory workers he said “men walk through these gates with death in their eyes”, but the factories and workshops of the future will be vastly different to that. Manufacturing workers – men and women – will go to work safe in the knowledge that in this country a career in manufacturing can be prosperous and lifelong.

HELP IN WORKING THROUGH THE WORKPLACE REGULATORY MAZE Many employers and business owners have to deal with an array of regulative guidelines to which their workplaces need to adhere to operate sustainably and productively. The area of safety and occupational health, in particular, can be a minefield. This is where the Occupational Health and Safety Consulting (OHS) and Software company Safety for Life can help. Based in Brisbane, it is active face-to-face and online, providing skills in OHS, Er-gonomics, Risk Management, Auditing, Injury, and Business Management. Director/Principal Consultant Caroline Kingston says the group always keeps up-to-date with legislative changes to ensure ciients receive the latest relevant information for businesses to operate safely and riskfree.

NOVEMBER 2020

“We have 10 years of experience, knowledge and real-life application behind us, with as varied sec-tors such as professional services, health, mining and quarrying, manufacturing, government, transport and warehousing,” Ms Kingston said. Safety for Life uses SHERM software systems (Safety, Health, Employees, Risk Management), designed by Ms Kingston. SHERM was built with the intent of streamlining business efficiencies for administration and management of compliance, risk management, training as well as auditing. “SHERM can easily be configured and its simple functionality makes it easy for all staff to apply re-porting, documentation, notification, tracking and alerting process, daily in their working lives,” Ms Kingston said.

Safety for Life also has kept up with the times making sure that SHERM software is scalable for any new client needs and can be set up as a mobile phone app. Ms Kingston also says that SHERM covers management systems for, safety, quality, and environ-mental management, including what is applicable during the post-COVID-19 business environment. SHERM software is hosted in the cloud with leading technology in the application design, and users have access 24/7. It is a web-based application that operates on Internet Explorer, Chrome, Fire-fox, Mozilla, Safari browsers “Clients’ feedback had been really valuable for me in terms of building a software application that can meet a broad range of specific requirements

Safety for Life's Caroline Kingston

across the range of sectors that I’m dealing with,” Ms Kingston says. She said Safety for Life could help businesses obtain certification to increase their competitive edge and meet necessary Australian standards. Safety For Life www.safetyforlife.com.au

INDUSTRYUPDATE.COM.AU

17

INDUSTRY POLITICS THE HON. SENATOR KIM CARR, FORMER MINISTER AND SHADOW MINISTER FOR INNOVATION, INDUSTRY, SCIENCE AND RESEARCH

QUESTIONS REMAIN OVER DEPARTURE OF TWO SENIOR PS HEADS In any kind of business, the effectiveness of the organisation depends in large part on the quality of its leadership.

products. ANSTO has been prominent in building Australia’s profile as an advanced manufacturing nation.

That is true at any time, but especially now when global trade relations have been disrupted by the pandemic and increasing tension between the United States and China.

So why are Mr Seymour and Dr Paterson no longer required at their posts? I sought answers to that question at the most recent Senate estimates hearings, but neither the government, nor officers of the Department of Industry, Science, Energy and Resources, nor Dr Paterson’s interim successor at ANSTO were inclined to provide them.

It is therefore profoundly disturbing that the Morrison government has decided to replace the Anti-Dumping Commissioner, Mr Dale Seymour, and the CEO of the Australian Nuclear Science and Technology Organisation (ANSTO), Dr Adi Paterson. All manufacturers know that the work of the Anti-Dumping Commission is vital in preventing unfair competition from cheap – and often substandard – foreign imports. And, ANSTO is an important manufacturer in its own right, as a producer of the radiopharmaceuticals that are increasingly widely used in diagnostic and treatment procedures. ANSTO estimates that two in three Australians receive one of its products at some point in their lives, and the organisation has a thriving export business because of the quality of those

What is clear, however, is that in neither case did the decision have anything to do with allegations of incompetence or inefficiency. Both men are highly regarded public servants with deep knowledge of the fields in which they work. There has not been even a hint of mismanagement, and the quality of their leadership is acknowledged by all who have come into contact with them. In Dr Paterson’s case, the government has taken refuge in the fact that he was not officially dismissed but resigned. It is, however, a curious kind of resignation. His tenure as CEO would have run until March 2022, so to describe his departure in the language of ANSTO’s official announcement as “slightly ahead of

time”, is, to put it mildly, a breathtaking understatement.

told he is no longer required, but that is clearly what has happened. Readers of Industry Update will know that the effectiveness of Australia’s antidumping regime depends heavily on the capabilities of the Commissioner. The person who fulfills that role has to understand the complexities of domestic and international law affecting trade, to be able to assess fairly claims of dumping or unfair subsidisation of foreign imports, and to make appropriate adjudications.

This so-called resignation has been contested. We will know how bitter the contest has been when the lawyers send their final bills, even if the terms of settlement are confidential.

A likely consequence of the pandemic is that there will be increased dumping as markets reopen around the world. Why, at such a time, would the government decide to dispense with someone of Mr Seymour’s undoubted experience and abilities?

We do not know what conversations the government might have held with Dr Paterson before he submitted his resignation, but we do know that the Department of Finance is conducting a study of ANSTO’s “governance and financial arrangements”.

Mr Seymour is Australia’s first AntiDumping Commissioner, appointed in 2013 and reappointed in 2018. The fact that he has been denied even the opportunity of seeking another term suggests that the government is pursuing a partisan agenda, rather than one based on Australia’s needs.

The inquiry is considering possible privatisation of ANSTO, and it is difficult to avoid the likelihood that Dr Paterson was placed in a position in which he felt he had no option but to resign.

Like Dr Paterson, Mr Seymour happens to have been first appointed under a Labor government. Neither man could be accused of having ever acted in a partisan manner in the conduct of their office, but it may be that they have been identified as partisan targets nonetheless.

Mr Seymour continues in his job for the present, but the position of Anti-Dumping Commissioner was advertised in August this year. He told the estimates hearing that he had had a brief conversation with the Industry Minister about her plans and had not reapplied for his job. Nor is he involved in the process of choosing his successor. Mr Seymour did not say that he was

If so, the nation stands to lose two excellent public servants for no fault of their own. These are uncertain and even dangerous times, and the lack of judgment the government has demonstrated in this matter will do nothing to increase certainty and stability – for business, for industry, and for the people of Australia.

BID TO INCREASE FEMALE PARTICIPATION IN STEM JOBS The federal government has launched a new initiative to inspire girls to see their future in a range of jobs using science, technology, engineering and mathematics (STEM) skills. Minister for Industry, Science and Technology Karen Andrews said the Future You initiative would help raise awareness of the exciting career possibilities in STEM for the next generation. “We know that a lack of role models and understanding of STEM careers reduces girls’ interest and confidence in STEM subjects as early as Year 4 – but we want to change that,” Ms Andrews said. “Future You is all about increasing girls’

18

INDUSTRYUPDATE.COM.AU

participation in STEM subjects and opening their eyes to a career which uses these skills. “Empowering girls to see a future for themselves in a STEM career is a crucial part of our efforts to ensure everyone has the opportunity to benefit from the jobs of the future, which is not only good for the girls and women themselves, but also for our economy.” The Future You initiative is led by the federal government’s Women in STEM Ambassador Professor Lisa Harvey-Smith. “STEM subjects are not just for scientists and engineers – they are for everyone. Future You shows young people just how exciting,

vibrant and rewarding a STEM skilled career can be,” Professor Harvey-Smith said. The Future You online platform is aimed at children aged 8 to 12, as well as their parents and carers, and features 12 diverse and relatable characters, including a builder, miner, game designer, farmer, nurse, ecologist and a Moon to Mars Mission Director.

The campaign includes a website with video animations, skill-based games and information about STEM and can be found here www.womeninstem.org.au/futureyou. Future You is funded through the $1.5 million Women in STEM National Awareness Raising Initiative, as part of the Australian Government’s Advancing Women in STEM strategy.

NOVEMBER 2020

Our industry experts are a phone call away. Get industry advice from our Manufacturing and Wholesale banking specialist, Todd. Call Todd to find out how your business can benefit from our Manufacturing and Wholesale banking expertise. Todd May, Executive Manager | 0466 493 740

Š BankSA – A Division of Westpac Banking Corporation ABN 33 007 457 141 AFSL and Australian credit licence 233714. BSA08171 1019

AUTOMATION

SWISSLOG AUTOMATION TECHNOLOGY WINS MAJOR INTERNATIONAL AWARD A fully automated mixed case palletising solution developed by Swisslog has been recognised for delivering new levels of efficiency. The company’s ACPaQ system has won the prestigious German Logistics Award 2020 for its use at retail chain dmdrogerie markt. The same technology was first installed at Coca-Cola Amatil’s New Zealand distribution centre in Auckland and is widely applicable to logistics, distribution, food and beverage and retail applications in Australasia.

The ACPaQ technology is an evolution of the company’s advanced automation technology, which combines robotics solutions for palletising and depalletising with Swisslog’s CycloneCarrier shuttle technology to create a fully automated process that facilitates high throughput and reliable picking of orders. Using the Load Build Manager functionality from Swisslog’s ‘SynQ’ software, the robots perform palletising in

a sequential packing order – individually adapted to the depalletising or shelf-filling routes in each dm store, according to the last-in-first-out principle. At dm-drogerie markt, its innovative new distribution centre is part of the group’s investment in automation and robotics with a focus on sustainability and competitiveness. “As dm’s automation partner for intralogistics at Wustermark, a lot of

Coca-Cola Amatil New Zealand has collaborated with Swisslog on automated storage and receival systems for more than 10 years, and sought to make further improvements to its customer service and costs, to meet rising demand.

passion and innovation has gone into this project,” said Swisslog CEO, Dr Christian Baur. “We are very pleased that dmdrogerie markt has won this prestigious award. On behalf of the entire Swisslog team, I would like to sincerely congratulate dm,” he added. “We have worked closely together on the robotics and material flow over the last few years so I am therefore all the more pleased that the distribution centre has been presented with this accolade.”

“Swisslog’s ACPaQ automation solution replaces a manual, voice-directed picking system, and will link with the existing automated pallet store to create a seamless operation,” said Mr Sean Ryan, Head of Sales and Consulting, Swisslog Australia.

Swisslog Australia Pty Ltd 02 9869 5900 www.swisslog.com

TURNING AN ORDINARY BOX, JAR OR BOTTLE INTO A TAMPER EVIDENT CONTAINER This is just one example that illustrates how easy it is to add tamper evidence to a container. The label used to seal the jar was a HR residue security label from Harcor. It is ideal for multiple applications for most non-porous surfaces. The size and design of the container to be sealed will determine the quantity of labels needed. Security labels are available in a variety of styles. Self-destruct labels work by breaking into fragments when removed to stop them from being replaced after application.

Due to the changes in local regulations, Australian scientists running quality control programs rapidly needed ways to ensure that all jars containing toxic waste and being collected for destruction were both security sealed and had not been subject to tampering.

20

INDUSTRYUPDATE.COM.AU

Instead of replacing the jars, simply adding a tamper evident label over the jar head, not only met the required level of security, it also had plenty of room to add signatures. New procedures required that the person sealing the jar had to sign the label.

The HR residue label shows a “void/ open” message on the label face and container surface when removed. If a container is not going to be reused again, a HR residue security label could be ideal for the application. The HNR non-residue security label does not leave a film behind on the surface; it does however show a void/open message on the label face when removed.

This is perfect for use on containers that are going to be regularly reused. Unique serial numbering is a security feature that enables traceability. Harcor is known for the proprietary track and trace technology used to manage serial numbering. This is used to prevent number duplication and enable fast tracking. Harcor’s in-house specialists can assist with security label selection. Strategically located throughout Australia – with branches in Sydney, Melbourne and Brisbane – Harcor works in partnership with clients to provide tailored solutions supported by the best possible service. Harcor Master Security Licence No. 407319937 Web: harcor.com.au Email: sales@harcor.com.au

NOVEMBER 2020

ENERGY

PILBARA ENERGY HUB GIVEN MAJOR STATUS BACKING The Morrison government is helping fast-track the world’s largest green hydrogen and ammonia production facility, which is expected to create tens of thousands of jobs in Western Australia. The proposed Asian Renewable Energy Hub (AREH) in the Pilbara region is expected to support more than 20,000 direct and indirect jobs during construction over 10 years, and 3000 jobs when fully operating. In granting it Major Project Status, Minister for Industry, Science and Technology Karen Andrews said the facility will include the world’s largest wind and solar electricity plant. “The Asian Renewable Energy Hub has the potential to transform the East Pilbara and neighbouring Broome shire and to contribute to a major new export industry for Australia,” Ms Andrews said. “Not only will the plant be able to export at scale, it will also be able to supply industries in the region while creating new job opportunities and economic growth.” Minister for Energy and Emissions Reduction Angus Taylor said the project would build on Australia’s strengths as a major energy exporter while helping to

reduce global emissions. “This project has the potential to help lower global emissions while building a new Australian industry that creates jobs and opportunities in regional Australia,” Mr Taylor said. “Projects like the Asian Renewable Energy Hub will help us achieve our ‘H2 under $2’ goal and position Australia as a world leader in clean hydrogen.” The 'H2 for under $2' target is a goal set by the government to produce hydrogen fuel for under $2 per kilogram. Mr Taylor said the Government’s Technology Investment Roadmap highlights hydrogen as one of the priority technologies to deliver a cleaner future for Australia. Australia’s emerging hydrogen industry has the potential to generate 7600 new jobs by 2050, with exports estimated to be worth around $11 billion a year in additional GDP. The government has committed more than $570 million to back the development of an Australian hydrogen industry. AREH Project Director Brendan Hammond said securing Major Project

Part of the hub site in the Pilbara

Status represented a significant project milestone. “It sends a strong signal to everyone involved, including potential customers and investors, that our project is at the forefront of an emerging green hydrogen industry for Australia, and the opening of a massive new export market to the fastgrowing Asian economies to our north,” Mr Hammond said.