20 minute read

Products

Oxy-fuel technology helps glass producers take greater control

Advertisement

In the glass production process, accurate control of the molten glass flow temperature in the forehearth is crucial to achieving optimal results, including viscosity at the gob.

While air-fuel combustion and electric heating provide proven results for certain sectors, CO2 and NOx emissions regulations, combined with an increase in fuel costs, are pushing glassmakers to investigate new technologies for greater efficiencies, such as oxy-fuel.

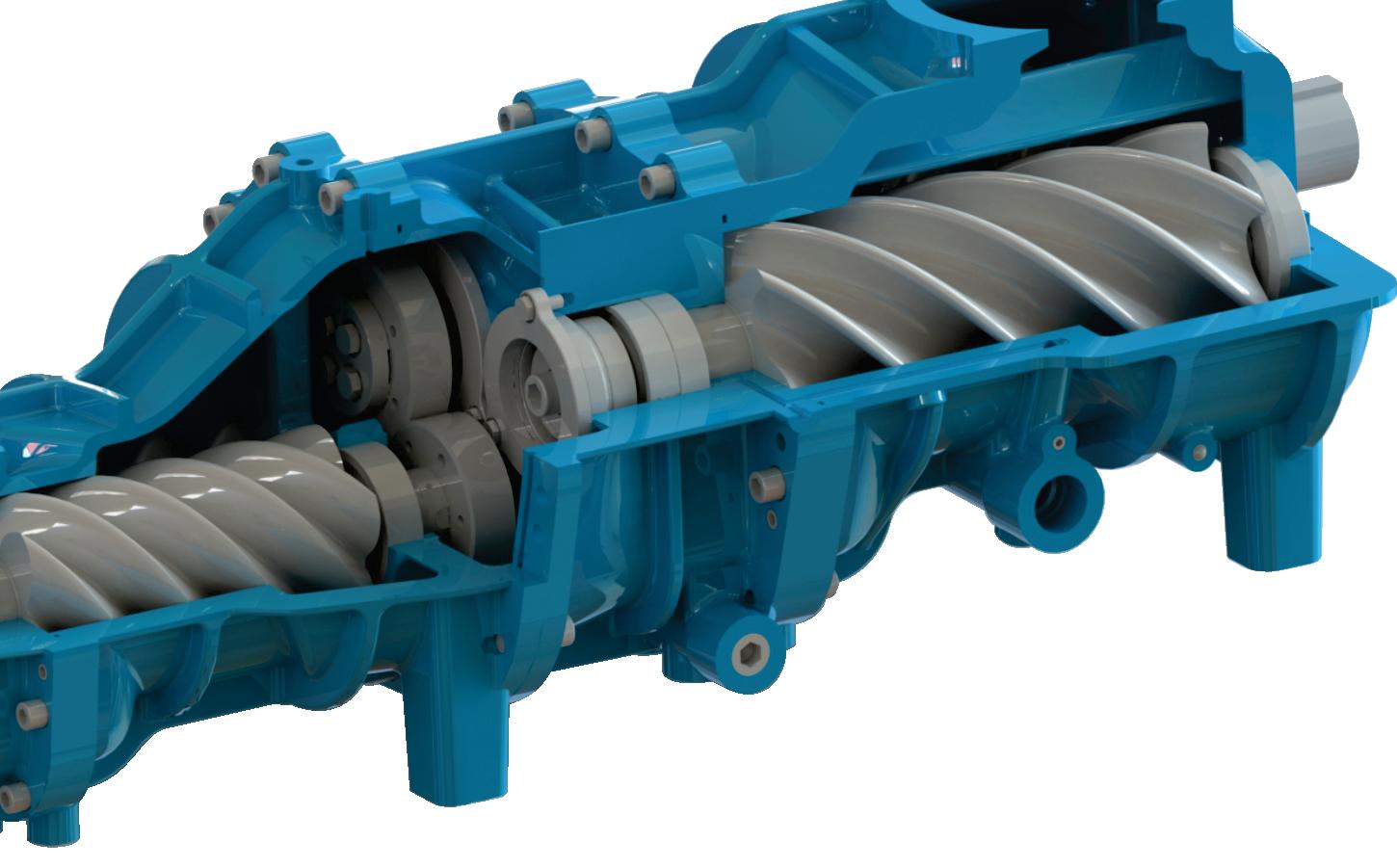

Air Liquide Oxy-Burner FH is an oxy combustion technology, specifically developed for glass forehearths, that provides a uniform distribution of heat by means of a constant flame length at variable power outputs.

The Oxy-Burner FH is based on an innovative method for fuel injection, with a ‘swirl’ effect to control flame length (200 mm to 300mm). The ‘swirl’ effect helps to maintain the hot spot of the flame at the same location even when the burner power is varied within a wide range. This is a patented technology that can be customized to customers’ feeders.

Another benefit of the Oxy-Burner FH design is its capability to improve and optimize heat transfer to the glass.

The flame hot spot is localized outside the refractory block by design, but not too far from the block outlet. Consequently, the maximum heat is transferred to the glass close to the forehearth walls to compensate for any heat losses through the walls of the forehearth line and to improve the homogeneity of the glass.

The burner geometry and external body can be easily adapted to a customer’s refractory block to meet the desired energy profile.

Air Liquide’s customers attest to the technology’s benefits, including primary energy savings of between 60 and 70% by converting air combustion to oxy combustion at the foreheath, as well as burner robustness, reliability and its flexibility to control flame length.

Air Liquide has a large range of burners that work efficiently with many types of glass melters, including burners that can switch from fossil fuels to hydrogen to reduce customers’ CO2 footprint. T oshiba smart gate driver photocouplers for industrial and green energy applications enable designers to make greater savings on space and system cost.

The range includes TLP5212 and TLP5222 devices suitable for applications including inverter circuits used in industrial control equipment, power conditions in solar power systems and UPS, and residential home battery systems.

“Design engineers can now enjoy enhanced availability of Toshiba’s products from Element14, coupled with rapid access to new-to-market technologies that support a wide range of IGBT and MOSFET control and power protection applications,” said Simon Meadmore, Vice President of Product and Supplier Management at Element14.

The TLP5212 and TLP5222 devices include various functions including VCE,(sat) or VDS,(sat) detection, Miller clamping and a ‘fault’ outputting function along with a general-purpose gate driver coupler to protect the IGBT from overcurrent generated in the inverter stage. The Miller clamping function suppresses gate potential rise and IGBT malfunction by bypassing the Miller current generated when the IGBT is turned off to ground. The TLP5212 requires an input-side signal to resume from shutdown protection while the TLP5222 resumes automatically after a specified time. All of this high-performance technology is packed into a low profile 16 pin SO16L package with an operating temperature of − 40 to 110 °C.

Other features of Toshiba’s new-tomarket smart gate drivers include: •The TLP5212 is a ±2.5A output photocoupler able to control IGBTs and MOSFETs, reliably protecting power devices from over-current and are suitable for high-speed applications requiring high levels of safety isolation and insulation (BVs = 5000Vrms). The SO16L package features 8mm creepage for use in space-limited applications. •The TLP5222 is a highly integrated and multi-functional high-current, high-speed output control photocoupler providing ±2.5A output current. Housed in a long creepage and clearance SO16L package, it includes desaturation detection, isolated

FAULT status feedback, soft gate turn-off, and active Miller clamp, under voltage lockout (UVLO) and automatic FAULT status reset.

Toshiba specialises in power systems and motor control solutions and supplies semiconductor solutions for automotive, industrial, Internet of Things (IoT), motion control, telecoms, networking, consumer and white goods applications.

Air Liquide

industry.airliquide.com.au

Latest Toshiba smart gate drivers at Element14

element14

au.element14.com

Keeping things moving

If you make something, you have to move it—often on a roller conveyor. These staples of material handling play a critical role in throughput and plant optimisation. Conveyor control systems can either be centralised, using a primary PLC, or decentralised using multiple smart field level devices such as block I/O.

Centralised versus decentralised control?

Centrally controlled plants or warehouses in which a PLC issues control commands for the entire facility are often subject to long cycle times. Even with high-performance controllers— especially when networks comprise many nodes, long cycle times can be a challenge.

When centralised control results in the PLC reacting too late, boxes or totes transported on a conveyor can jam or be controlled incorrectly. These errors require manual intervention in the facility. However, this problem could be avoided by implementing decentralised solutions.

Slow response vs long cycle times

As boxes or totes travel through the system and trigger field-level devices, multiple signals are sent directly to the PLC and wait in a queue for the controller to respond. This type of sequential control can result in slower response and long cycle times.

Slower response times can also cause box/tote control errors and jams that require manual intervention to correct the situation.

Added installation & commissioning costs

The cost to hard-wire multiple devices directly to a single stationary PLC can be costly depending on the amount of devices and their physical proximity from the PLC.

Reduce signals to lower costs

The key to increasing the speed and accuracy of an automated roller conveyor system is to reduce the number of signals sent to the PLC. Connecting multiple IO-Link sensors and actuators to a block that is running logic for local control is the first step toward a faster process. I/O modules with integrated logic, allow local independent control.

With a response time of two milliseconds, the decentralised solution in large plants works much faster than centralised controllers. If needed, the conveyor speed can be increased and this in turn increases the performance of the entire plant.

Signal lights can also be activated quickly and easily on site. The logic control function is integrated free of charge in all Turck block I/O modules (IP20/IP67).

Since block I/O modules are mounted directly on the roller conveyor and don’t require protective housing, they save on installation costs. They also offer a more convenient and efficient means of offline commission testing.

Access to the logic control functions of block I/O modules is available to users via ARGEE, Turck’s proprietary web-based programming interface.

TBEN-S & TBEN-L Block I/O Series

The TBEN-S and TBEN-L block series are ideal for decentralised control. They are incorporated in rugged and rated high-protection housing. Thanks to their multiprotocol capabilities configuration is easy: Once connected, the modules run automatically without use intervention in.

PROFINET, EtherNet/IP™ & Modbus TCP networks

For conveyor applications, IO-Link devices can be connected to the master via these I/O hubs, allowing up to 16 switching signals to be connected via a single IO-Link port. This massively reduces the cost of wiring.

In this application, the decentralised components process the large amount of data to identify relevant information that is communicated to the controller, thus reducing the amount of communication.

The bottom line is that choosing an on-the-machine logic controller such as the TBEN-S or TBEN-L reduces costs. The lack of protective housing on the module also saves installation costs, since the IP67 blocks are mounted directly on the roller conveyors.

Turck

turck.com.au

New Petersham RSL club welcomes visitors via impressive Boon Edam revolving door Move steel plates easily with tilting beam magnets

After nearly 100 years of serving the local community, the Petersham RSL club moved to a new home this year, in a redevelopment centred on style and comfort.

Part of the design brief for the architects and developers was that the indoor spaces were comfortable for guests, particularly in reception, which can often feel the effects of wind and debris entering through open doors.

The developers chose a fully automatic Tourniket revolving door from Boon Edam Australia to make a grand first impression to the classy new club, which was recently opened by Prime Minister Anthony Albanese.

It is the same type of cost-effective entrance used by leading hospitality venues globally to protect patrons and workers against wind, weather and pollution, while also controlling traffic flow and opening up new sheltered areas for productive amenities.

Petersham RSL CEO Danny Fitzgerald said “The Boon Edam revolving door creates an impressive entrance to our modern club, and was the perfect fit for our redevelopment. With this door, Boon Edam met two key specification requirements – enhancing climate control inside the club, and enhancing personal comfort in the reception area.”

A welcoming entrance

The 3-wing Tourniket revolving door pictured has a height of 2,650mm and diameter of 2,800mm to allow ample room for entry and egress. It has four LED warm white downlights for a pleasant and welcoming experience.

A powder coated black grey finish on the exterior of the door allows it to effortlessly blend in with the building’s overall aesthetic and design.

Boon Edam Australia Managing Director Michael Fisher says that a major benefit of revolving doors is that they allow visitors and staff alike to enter into a new world inside – one that is calm, quiet, and protected against allergens and climatic extremes.

“In addition to customising the door to the club’s aesthetic preferences, we worked closely with Petersham RSL to deliver the doors within a complex installation involving temporary doors while other elements of the façade and reception were completed, prior to the arrival and installation of the revolving door,” he said.

Boon Edam Australia is a part of the globally leading revolving door manufacturer, Royal Boon Edam, and the door selected by the Petersham RSL is a type already used by architects, builders and specifiers for Fortune 500 companies globally and for major Australian hotels, clubs, banks, offices, legislatures, and buildings.

“The teams worked well together, and the result was an outstanding front façade and entrance, which will have a longterm impact on climate control and comfort,” said Fisher.

Always Open, Always Closed

A key benefit of revolving door systems in addition to access control is energy conservation, with their “always open, always closed” functionality providing lower HVAC losses while increasing the temperature stability and comfort of people inside. These advantages have been proven in many of the world’s leading clubs, hospitals and hotels, where visitor comfort is paramount.

“Think about how much air escapes when a sliding door opens, or how much dust, pollution, or pollen can enter the front reception area. With a revolving door, only one quadrant of air is moving around each time, providing a highly effective method of controlling the indoor climate,” said Fisher.

Further economy and versatility are provided where required by night locking entrance options including electromechanical locks that can be unlocked with a key or by means of an optional key impulse switch.

“These climate control features are not always considered at the design stage, so Petersham RSL has shown great foresight by specifying these outcomes early,” added Fisher. S toring steel plate vertically is an efficient use of floor space but it can be time-consuming to lift and re-orient to horizontal. Vertical storage can also challenge safe handling.

Tilting beam permanent-electro magnets provide the fastest and safest answer to both these issues — and save energy as well as time.

Plates as long as 18 metres weighing up to approximately 20 tonnes can be handled with Mag-Autoblok-Tecnomagnete’s Permanent-Electro tilting modules, mounted on a beam arrangement.

Plates can be clamped and lifted in the vertical (or shear) position and then rotated to the horizontal position to load onto a cutting table or onto transport. Conversely, plates can be lifted in the horizontal plane and re-oriented to vertical.

Unlike conventional electromagnet systems that heat up and use large amounts of energy during the lifting cycle, permanent-electro magnet systems only use power momentarily during activate and deactivate commands. No battery back-up system is required with permanent-electro magnet systems.

Tilt beam systems can be supplied with wireless remote control that can easily be worn on a belt.

All Mag-Autoblok-Tecnomagnete systems are exclusively available in Australia and the Pacific region from Serpent and Dove Applied Magnetics.

Boon Edam

boonedam.com.au

Serpent & Dove Applied Magnetics

serepent-dove.com.au

The SpecialiSTS in elecTronic DriveS for over 30 yearS

• Repairing of complex electronic boards, including obsolete boards that are no longer supported by vendors • Design and construction of multi-drive systems • Professional Control Systems Integrators • Repairing/retrofitting of electronic AC, DC and servo drives • Laboratory & Clean Room • Large Stocks of Spare Parts • Australia wide 24 hour service Datafactory

LSP series pump delivers flexible and precise fluid management

SMC Corporation’s LSP series of liquid dispense pumps accurately dispenses fluids with high precision and stability, even at low flow rates. This compact, solenoid type diaphragm pump delivers reliable, leak-proof performance.

“The LSP series pump is proven to accurately dispense fluid volumes between 5 µL and 20 µL each time it is energised - with a repeatability of approximately 1%,” comments Guiomar Fernandez, Product Manager for SMC Corporation Australia New Zealand.

“The LSP is a truly flexible solution. The customer can easily adjust the armature stroke with an adjusting screw, to adjust the dispense volume to their specific application needs.”

Incorporating a built-in shut-off valve that prevents leaks, this pump efficiently handles a range of fluids, including reagents and cleaning liquids, with temperatures between 10 and 50° C.

In addition, the LSP pump is self-contained and does not require priming, even if the pump is dry and there is no liquid in the suction line. “A buffer ensures the longevity of the pump’s diaphragm,” comments Guiomar.

“This pump is ideal for use in medical or biomedical analyzers, in decontamination applications using hydrogen peroxide, in ink jet printers or in applications using semiconductors or solar cells,” elaborates Guiomar.

Weighing just 85 grams and featuring a compact diaphragm design, the LSP series is available in two configurations – body ported or base mounted – with a range of port and connection sizes.

“Where stable and repeatable liquid dispensing is required, this smart pump delivers an efficient and long-lasting solution,” concludes Fernandez.

SMC Corporation

smcworld.com

Tente’s Linea automatic locking safety brake means peace of mind

The Tente Linea safety brake system (deadman brake) automatically locks by default and can only be moved when the brake is actively released - so, no more runaway trolleys.

The wheel lock, which is permanently activated, can be released by hand or foot lever, giving more options.

As a result, the safety brake allows new possibilities for designers regarding the development of mobile furniture and devices.

As well, the spring used in the braking system is not under stress when the castor brake is engaged, which is an advantage for safety.

Why use the Tente Linea safety brake (deadman brake) system?

Because the default position is brake activated, no more forgetting to activate the brake lever. The deadman brake means safety: •in environments with slopes and mobile weights, such as public spaces, book shops, libraries, restaurants and airports •on boats or trains, where things move easily •in hospitals, where nurses can focus on the patient instead of the device, as now they can’t forget to activate a brake lever. As well, patients can move a table or a bedside cabinet

safely by themselves •in schools, where children won’t push around book carts like they’re skateboards.

Specific features

•When castors are mobile, the cable wire is activated. •Ball bearings prevent the cable wire from twisting, which allows for easier castor swivelling. •Ball bearings also hold the cable wire for better mobility.

Tente

Torque sensors are professional instruments used to measure and record the force and torque on a rotating system.

While normally small and compact, torque sensors are powerful and critical in their applications. Generally, torque sensors use a strain gauge applied to a rotating shaft or axel to measure the force and torque. Strain gauges are small and sensitive assemblies that can fit perfectly into a torque sensor.

There are two main types of torque sensors: static and dynamic. Static torque is easier to measure compared to dynamic torque. Dynamic torque sensors have short response times and high torsional stiffness. Measuring range needs to be strictly monitored to avoid overload for both static and dynamic torque sensors.

Torque and force can be measured both clockwise and counter-clockwise. Both dynamic and static torque sensors are suitable to measure static working torque. However, dynamic working torque can only be measured by dynamic torque sensors. The working principles between static and dynamic torque sensors are quite different. Static torque sensors convert strain generated by force into an electric signal, which has a linear relationship with it. Dynamic torque sensors can measure the electrical signal of the torsion from the elastic shaft; then a strain bridge is formed on the elastic shaft via strain electrical measuring technology, to provide power to the strain bridge. After amplifying the signal, it will be transformed into a frequency signal proportional to the response.

Dynamic torque sensors are widely used in many industries, such as waste-water treatment, manufacturing, and processing operations. Machinery and equipment, cars, aircraft and ships also rely on torque sensor to support their operation. Static torque sensors are generally used in testing machines, static torque detection and other test systems.

Torque sensors plays an important role in so many applications. Choosing the most suitable torque sensor is vital for owners and operators seeking to save costs.

ZHYQ Sensor

Keeping blackouts at bay

Sense AI technology incorporates high-resolution processing that can be built directly into smart meters. Sense technology can give consumers real-time insights into energy usage down to the individual device level

On June 15 this year, Australian Energy Market Operator (AEMO) suspended trading across the country’s east coast electricity power network as it faced an increasingly volatile situation. AEMO was set up in 2009 and this is the first time the operator took such drastic action across the entire network that it manages.

There has been much debate and discussion on the causes ranging from the onset of winter to the war in Ukraine and maintenance shutdowns at power stations.

While policy makers, regulators and power generators grapple with the situation, consumers are being asked to better manage their consumption. The conversation is evolving from generating more energy to better managing the energy we produce.

With domestic consumption, energy transmission terminates at the premises of the end consumer. In the current situation, a lot is being asked of this often-neglected group. They are being requested to reduce consumption by shutting down appliances in certain times or use them outside peak periods. Customers have also been warned about potential blackouts. Current policies around demand management are focused on industrial plants and other large energy consumers, and these are governed by clear policies and processes. Consumers meanwhile are bracing themselves for energy price hikes and power cuts. Fortunately, technology has advanced and, when implemented, can give consumers more visibility and control over their energy usage. A good example is Sense, which has developed AI that runs on smart meters. Over two million Sense-enabled meters have been announced in the US and this technology is now coming to Australia. Their machine-learning algorithms can assess domestic electricity right down to the appliance level in real time.

According to a directions paper released by the Australian Energy Market Commission (AEMC), only 25 per cent of premises in New South Wales, Queensland, South Australia and the ACT have a smart meter installed. The paper recommended accelerating the rollout of smart meters for households and small businesses, because digital smart meters will be a vital tool in the grid of the future.

If AEMO or the utilities put out a call to reduce power usage, Sense-enabled consumers know exactly what to turn down to have the greatest possible impact on their demand at any moment.

“The highest consuming discretionary devices can be identified, and consumers are able to turn off the appliances that have the greatest immediate impact on load, without disrupting their lives,” explains Michael Jary, Managing Director – International at Sense. “Consumers are not left to work it out themselves and don’t end up sitting in the dark.”

“Crucial to enabling these consumer benefits will be smart meter manufacturers ensuring that meters being made now are compatible with Sense AI technology,” said Jary.

It all comes down to device disaggregation which is referred to as the Holy Grail of energy management. It uses AI and data analysis to separate the wholehome electricity usage into device-specific individual consumptions.

Studies have shown that real time device disaggregation increases demand side flexibility. Senseenabled homes were able to shift 4.5 times more load than homes that didn’t have it. Sense can even measure and verify that the reduction action took place as expected.

A recent study commissioned by the AEMC found that 73% of the respondents are interested in working out ways to save money on their electricity bill by changing how and when they use electricity. Their main way of lowering bills is to turn off lights, avoid leaving appliances on standby and looking for more efficient appliances.

As Sense can analyse high-resolution energy data, its benefits extend outside the home. For example, tiny voltage sags in the grid can be identified and are indicative of vegetation brushing overhead power lines.

Similarly, corrosion in transformers or other grid assets are apparent when applying Sense AI to high resolution energy data. Across a fleet of meters, it is even possible to geo-locate the source of the error by comparing those meters that experience the same anomaly against a network map.

To properly benefit from real time device detection and the potential of AI, Australia will need to ensure that the next generation smart meters become intelligent hubs for the home and form the basis for a flexible, cleaner grid.

Simple, lightweight mixers for plastic tanks

Fluid mixing equipment company Mixquip locally produces a range of compact, lightweight mixers that are ideal for polyethylene tanks.

These high efficiency mixers can be used in plastic tanks with 500 litre to 10,000 litre capacity and can mix all types of chemicals, fertilizers, premix solutions etc.

All mixer components inside the plastic tank are 316 stainless steel and single phase, and 3 phase motors are IP56 minimum.

Applications

The Mixquip® 75 series range can be used for a diverse range of processes. Some examples include: •PH adjustment in wastewater applications •polymer additions prior to Direct

Air Flotation (DAF) •blending chemicals with waste water

The Mixquip® range of top entry mixers has been utilised across a broad range of industries and applications, including food, beverage, wine, chemical, dairy and wastewater.

Each application incorporates precise selection to balance power with efficiency while offering effective mixing.

Sense

sense.com

Mixquip

mixquip.com