FISH FARMING TECHNOLOGY

XFM Filters: A cost-effective technology for the fine particle problem

- Atlantic salmon : How choline from krill can help improve gut health

- Governance and aquaculture development

-

Aquaculture Engineering: How to measure large pump discharge?

- The biology and aquaculture of sea urchins

International AquafeedVolume 26Issue 5May 2023 www.aquafeed.co.uk www.fishfarmingtechnology.net

MAy 2023 Proud supporter of Aquaculture without Frontiers UK CIO

Find out more at: alltechcoppens.com Your fish feed specialist ensure Working together to your fish thrive for a brighter future

WELCOME

This month we will witness the Coronation of King Charles III.

It’s a momentous occasion for the United Kingdom and all the supporters of the Royal Family; as a newly nationalised United Kingdom citizen, myself, who has lived here on an indefinite-right-to-remain visa for the past 40 years. I am very proud to be celebrating a commitment to the UK along with King Charles III this year.

Supporting King Charles III, who in turn supports all Great Britain and Northern Ireland nationals including those in 14 other Commonwealth realms, is I believe our duty.

With long service as the Prince of Wales, and the access that this gave him to all areas of society and industry, King Charles III comes to the throne with a comprehensive understanding of UK life and a great appreciation of global issues and in particular our food production systems. In fact, it is likely he will be the most informed King to come to the throne in history.

I am pleased to read Professor Simon Davies’ editorial on the next page that looks at the connections between the Royal Family and the seafood industry with reference to the credentials of the new King and the support her Majesty Queen Elizabeth II gave during her 70year reign.

In this issue

Erik Hempel who is the editor of our Fish Farming Technology section of the magazine deals with the negatives that confront us at present with his views on the way forward and makes a case for ‘proper seafood’ and the future demand for animal proteins.

Meanwhile columnist Brett Glencross is searching for sustainability and highlights the need for setting measurable targets against which to determine how effective we are in moving towards and becoming more sustainable as an industry.

We review Governance and Aquaculture Development as presented by Carlos Wurmann, President of the International Centre for Strategic Studies for Aquaculture based in Chile on page 20.

Gut health in Atlantic salmon is featured on page 16 while farming sea urchins is another must-read feature on page 26. And krill features again on page 38.

We review XRM filters and present our Technology Showcase in the FFT section of the magazine, starting from page 31. All that before we get to our Market Place, The Victam Showtime section and Events, and not to overlook our interview with José Antonio Camposano, the Executive President of National Chamber of Aquaculture in Ecuador. There’s lots to enjoy in this edition!

Online Milling School

It is timely to announce the 2023 Online Milling Courses for both aquafeeds and petfoods. This year there is a Spring Course and an Autumn Course, each of six weekly sessions of two hours per session. The course culminates in a Certificate of Attainment that validates the course attendance and can be used in your CV or work history.

Both courses take you through the complete process, from raw material reception and preparation to processing and finally to coating and bagging. The courses also look at nutrition as well as plant and equipment design and layout.

These courses are introductory for those planning to work in the area of aqua and pet food processing and will also provide insights for those already in these areas of operation on specific topics such as steam generation and management for example.

Feed production, whether for livestock, fish or for our pets, is more than just the pelleting, extrusion or other centralised process. Much of the success in terms of efficiencies, maximised throughputs and quality of final product is down to understanding the interaction of each step of the process.

Achieving the nutritional package that a farmer or pet owner expects requires a completed understanding of the whole production process from start to finish.

So why not join us for one of these courses this year?

The OMS Schedule

• Our SPRING 2023 Aquafeed Courses include:

• OMS Aquafeed Milling offers six weekly sessions

Starts Tuesday 20th June - to - 25th July

• OMS Petfood Milling offers six weekly sessions

Starts Thursday 22nd June - to - 27th July

• Our AUTUMN 2023 Petfood Courses include:

• OMS Aquafeed Milling offers six weekly sessions

Starts Tuesday August 22nd - to - September 26th

• OMS Petfood Milling offers six weekly sessions

Starts Thursday August 24th - to - September 28th

To see the programmes and to sign-up please visit: www. onlinemillingschool.com

Note: We will be hosting a seventh Credo OMS Off-Line Session at the Victam Latam event in Sao Paulo, Brazil from 13:30-15:30 on October 3, 2023 - The topic with be Trouble Shooting for All including Milling-Aqua-Pet Food Production and will comprise of a discussion panel and a Q&A session from the Autumn Courses and from within the room.

During this Off-Line Session we will be awarding Certificates of Attendance to those who have completed one of the 2023 six-week courses and who are in attendance.

Training is fundamental to developing a business’ efficiency and ensuring a return on your investment.

International Aquafeed supports the OMS as we are here to support manufacturers in producing the feedstuffs the aquaculture industry in particular that ensure success.

Finally

The last item I wish to draw your attention to is the 31st Edition of the International Milling Directory which is now in print and available. What is unusual this year is the fact we have combined the companies supporting aquaculture feed production within the document and within the website of the IMGD.

This Directory contains the names and addresses of companies selling products and services into the aquaculture sector when it comes to manufacturing aqua feeds.

Please contact enquiries@internationalmilling.com if you need assistance with either the website access at: https:// internationalmilling.com IMGD also has an app which can be found through our subscription link: https://store.magstand.com/IMGD.

www.aquafeed.co.uk

Roger Gilbert

Publisher – International Aquafeed and Fish Farming Technology

This month we hold the coronation of our new monarch, His Majesty King Charles III succeeding our late Queen Elizabeth II after her incredible 70-year historic reign, the longest in British history.

It is well known that Royalty and seafood have connections with many monarchs having been engaged in fishing management and expressing an interest in the subject in varying ways over the centuries. The Worshipful Company of Fishmongers in London is a well know Livery that has a long historic association with fish and shellfish. My late friend Dr Eric Edwards was a clerk at the organisation and was Chairman of The UK Shellfish Association for many years and was responsible for awarding annual scholarships for the MSc programme at Plymouth enabling many students to study Fish Nutrition and Aquaculture under my direction in the 1980s and 90s. The Worshipful Company of Fishmongers records an unbroken existence for 750 years, forming as City of London fishmongers began to collaborate for mutual benefit developing into a guild which managed London’s fish trade according to their defined set of rules and regulations. The earliest evidence of such a group date back to 1154, when a number of London fishmongers were fined for trading without Royal Warrant with the Company receiving its first Royal Charter from Edward I in 1272. The regulation of fishing and rights for landing fish and marketing was strictly controlled. Salmon and oysters and many sea fish were managed by laws and legislation linked to the Crown as no effective government as we know today existed. It should be also noted that in the UK, sturgeon is also classed as a ‘Royal Fish’ and any sturgeon caught are the right of the Crown. Near the English coast they belong to the monarch immediately upon being caught, while ownership is also transferred to the monarch when a catch from any location is cast up on the shores. The kings of Denmark and the dukes of Normandy enjoyed a similar prerogative. The monarch's right to royal fish was recognised by a statute enacted during the reign of Edward II. How they would have viewed aquaculture and fish farming is open to question, but I am sure that taxes and tariffs would have been applied to gain income especially for our Norman friends.

Her late Majesty Queen Elizabeth enjoyed grilled Dover sole and wild salmon, but high end organic farmed salmon is often served at dinners and banquets and state occasions. King Charles is aware of the fish farming industry and has visited salmon operations in Scotland and engaged with salmon farm owners and stakeholders. As The Prince of Wales, he visited Lochaber salmon farm to see first-hand the advantages of using wrasse to reduce sea lice infestation. He also visited Loch Leven salmon farm, near Fort William, the first in the UK to be approved by the international Aquaculture Stewardship Council (ASC). He offers interesting perspectives given his strong interests and commitment to food production and its traceability. As the former Duke of Cornwall, the Dutchy once owned an oyster farm in Cornwall, UK. The King is also fond of trout, and he

would be pleased to see some of the best of British trout farms working sustainably and producing excellent quality fish respecting environmental stewardship.

I think he would be keen to find out more about the UK and global efforts in science and technology to develop sustainable aquaculture and the use of novel feed ingredients and natural supplements we are always reporting.

An interesting story is that when forensic archaeologists discovered the remains of King Richard III a few years ago in Leicester, England, molecular genomics, and the use of proteomic techniques were able to confirm that the medieval King’s bones had specific residual dietary proteins originating from sturgeon (and peacocks) indicating that the body was indeed of a royal person of significance.

Another Head of State who is well known to IAF is His Serene Highness Prince Albert II of Monaco who is passionate about the environment and has a particular interest in fisheries conservation and has regularly highlighted the plight of the bluefin tuna for many years. I had the privilege to meet and interview him for IAF in Nantes in 2011. The article appeared featuring my interview with Prince Albert where he was delighted to respond to my questions on topics like climate change, fisheries, and aquaculture research with emphasis on feed ingredients for aquaculture. His Monaco Blue Foundation supports some key areas for funding and works closely with NGOs, educational institutions, scientific research institutions and societal interests to promote the oceans and resources for human health and welfare. The Foundation has raised public and government awareness regarding fisheries conservation and thanks to such efforts we are seeing improvements in bluefin tuna populations in the Atlantic.

Last month, I mentioned in my editorial my visit to VIV Asia 2023 in Bangkok that included the special Aquatic Asia meeting that I hosted and moderated as well as my role as the keynote speaker. We highlight this in our current edition. Also last month, I was most honoured to address the University of Bristol, School of Veterinary Medicine in my 9th year as a visiting professor to second year students. I found this to be so satisfying bringing the world of aquaculture nutrition and health to students who do not experience fish in depth on their curriculum. This was timely as the British Veterinary Association (BVA) has just launched a new directive statement on UK sustainable finfish aquaculture, advocating for more research into the welfare requirements of fish and the impact of aquaculture on the environment. My lecture in Bristol covered much of this and provided a good platform for the students to think about possible careers in fish farming.

In this May edition we have our regular features and special topics of interest including novel aquatic animals for aquaculture and technical nutrition/feed and aquaculture technology aspects. I shall for certain intend to enjoy the best poached salmon sandwiches as I watch King Charles’ coronation and reflect on the changing era. There may be no sturgeon on my menu, but caviar is allowed if affordable?

Professor Simon Davies

4 | May 2023 - International Aquafeed

Nutrition Editor, International Aquafeed

Lately, I have been reading reports about the global economic outlook. We hear a lot about the state of the world economy, and most of what we hear is negative at the moment. And we feel it in our daily life, too. Prices are sky high, inflation is galloping, energy prices are at record levels, and there seems to be little good news on the horizon.

And yet, The Economist, in its “Global economic outlook for 2023”, predicts growth in the global economy, albeit modest. The economic recovery will be very slight in 2023, but for 2024, The Economist expects a global GDP growth of 2.5 percent. But on one hand, the magazine is pessimistic: it harbours fears about global food supplies, both in the short term and in the longer term. In the short term, the war in Ukraine is having a negative effect on supplies, but in the long term, - and this is far more serious -, the world will just not be able to produce enough food for the growing population.

“Everybody” agrees that aquaculture is the most efficient producer of animal protein that exists today. But aquaculture is facing a number of challenges. Among the more important challenges are the rising costs of just about everything, including energy, materials, feed, and technology. But we also face a challenge in that many groups with certain agendas seem hellbent on stopping us from expanding the industry, in spite of the fact that aquaculture would make a major contribution to global food production.

Seafood competes with other foods, especially chicken and meat. We now also see a growing interest in vegan food. The range of vegetable substitutes for "proper" seafood is constantly growing. But the world will still want animal protein, and fish and seafood will probably become more popular than red meat. The demand for food is dependent on population growth, and the world's population is increasing faster than we want it to. I am reminded of what was claimed in the book "Limits to growth",

which was published by The Club of Rome in 1972. One of the conclusions of this study was that population growth is linked to the availability of food. The only way to ensure adequate food availability and slow down food price developments is to keep population growth under control. It hasn't happened. There is every reason to believe that population growth will continue as it is now, and therefore we are facing a difficult time, both in terms of food availability and in terms of the danger of large-scale wars. A sequel to the original “Limits to growth” report came in 2012 and was written by one of the original authors, Jørgen Randers. Here he shows that as the population increases, the supply of food per capita, industrial production per capita, and access to resources all decline. The development will lead to a sudden and uncontrollable decline in both population and industrial production, including food production. We need a massive increase in food production, and aquaculture is the most likely candidate to contribute significantly to this. But in order to succeed, we need better technology, and we need to apply this technology, not only in industrialised countries, but everywhere. The world is facing a monumental task of spreading not only the “gospel of aquaculture”, but the science of modern aquaculture everywhere.

At the global level, we have not been able to avoid the developments outlined in 1972 and again in 2012. Unfortunately, the predictions of The Club of Rome have come true, and we have little reason to believe that this development will not continue.

Therefore, I believe that we are on the way to a big, - very big -, crisis in the food sector. Our industry, the aquaculture industry, is part of the solution to this crisis. We must push on with the development of aquaculture, and I believe that we will need to focus on developing better technologies, especially for open sea aquaculture. The ocean is vast, and we have barely started to make most of the possibilities it offers.

aquafeed.co.uk

FISH FARMING TECHNOLOGY

Erik Hempel

The Nor-Fishing Foundation

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

International Editors

Dr Kangsen Mai (Chinese edition) mai@perendale.com

Prof Antonio Garza (Spanish edition) antoniog@perendale.com

Erik Hempel (Norwegian edition) erikh@perendale.com

Editorial Advisory Panel

• Prof Dr Abdel-Fattah M. El-Sayed

• Dr Allen Wu

• Prof António Gouveia

• Prof Charles Bai

• Dr Daniel Merrifield

• Dr Dominique Bureau

• Dr Elizabeth Sweetman

• Dr Kim Jauncey

• Dr Eric De Muylder

• Dr Pedro Encarnação

• Dr Mohammad R Hasan

Editorial team

Prof Simon Davies sjdaquafeed@gmail.com

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

Levana Hall

levanah@perendale.co.uk

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

Aquafeed Journal journal@perendale.co.uk

IN THIS ISSUE

COLUMNS ©Copyright 2020 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 1464-0058 REGULAR ITEMS 8 Industry News The Aquaculture case study

FISH FARMING TECHNOLOGY

3 Roger Gilbert

4 Professor Simon Davies

66 Industry Faces 64 The Aquafeed Interview 60 The Market Place

5 Erik Hempel

May 2023 Volume 26 Issue 5 42 Industry Events 36 Technology showcase

14 Brett Glencross

38 Krill fishing in the Antarctic impacting predator population

THE BIG PICTURE

The biology and aquaculture of sea urchins

See more on page 26

FEATURES

16 Atlantic salmon : How choline from krill can help improve gut health

20 Governance and aquaculture development

22 Aquaculture Engineering: How to measure large pump discharge? It is simple!

26 The biology and aquaculture of sea urchins

FISH FARMING TECHNOLOGY

42 XFM Filters: A cost-effective technology for the fine particle problem

Looking for Milling and Grain in your language? Find links to all of our editions in one place

See more at:

http://flk.bz/xxsY

The Aquafeed Journal

Aquafeed Journal is a new online publication by Perendale Publishers Ltd, United Kingdom, with a distinguished track record of technical and trade magazines in the agricultural and aquaculture sectors. This new peer-reviewed scientific journal will serve academia and the commercial aquaculture industry with high-quality papers relating to aquafeed science and technology for different species of farmed fish and crustaceans. It is envisaged to address fundamental nutritional requirements for effective and optimal production and applications to advanced feed formulations. This will include essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to fish and shrimp growth, feed efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to marine derived materials like fishmeal and fish oil. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of fish and shrimp are very topical and of much interest to the commercial aquafeed sector. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Please do not hesitate to contact us with your queries at journal@perendale.co.uk.

2023

Useful links

Benchmark enters exclusive agreement with STIM Scotland to distribute Salmosan® Vet in the UK

Benchmark Animal Health, the aquaculture biotechnology company, has entered an exclusive distribution agreement with STIM Scotland Ltd for Salmosan®Vet in the UK. The agreement was signed on 28 March 2023 and will take immediate effect with the stock now transferred to STIM’s Glasgow warehouse ahead of distribution.

Salmosan® Vet is a market leading azamethiphos treatment for sea lice and one product within Benchmark’s Animal Health portfolio. The product is used throughout the global salmon industry for the control of pre-adult to adult stages of sea lice. Used by Benchmark customers throughout the UK, it is well recognised as a reliable, gentle and effective treatment option.

The agreement, which took effect from 28th March, will increase the technical support available for UK customers, providing them with additional resources with both Benchmark and STIM on hand to support their effective sea lice management. STIM Scotland Ltd are professional distributors with a well-established and trusted network of delivery, which will ensure customers can access secure and consistent supply.

Announcing the agreement, John Marshall, Head of Benchmark Animal Health, says, “At Benchmark, we are committed to helping customers manage the ongoing challenge of sea lice. Our exclusive agreement with STIM

Scotland offers us the opportunity to further support our customers in their use of Salmosan® Vet. I am confident this will have a positive impact on our customer’s operations”.

Campbell Morrison, Key Account Manager at STIM Scotland Ltd, adds, “In the UK, as well as in Norway and Chile, STIM strives to supply a complete range of the most important fish health products available. Salmosan ® Vet is certainly one of those and we are pleased to add the product to our growing product catalogue.”

Managing sea lice carries an annual cost of approximately £40m in Scotland alone each year and is considered to be the greatest biological challenge to the growth of the aquaculture industry.

Benchmark Animal Health is the Marketing Authorisation holder for Salmosan® Vet in the UK and will remain so after the agreement. Since 2009, Benchmark has been supporting farmers across the globe in controlling sea lice through this treatment.

International Aquafeed - May 2023 | 9 News

New Brunswick’s aquaculture facility achieves environmental approval

Kelly Cove Salmon Ltd. (KCS), of the Cooke family of companies, has received a Certification of Determination to Proceed from the New Brunswick Department of Environment and Local Government for the construction of its proposed US $72 million land-based Atlantic salmon post-smolt aquaculture facility in Bayside, N.B. This approval is an important step achieved upon successful completion of an Environmental Impact Assessment (EIA).

Located in the Champlain Industrial Park alongside the Passamaquoddy Bay, the new facility will be a worldclass recirculating aquaculture system (RAS). KCS began planning the high-tech project in 2017 and received EIA approval earlier this year for ground source wells to supply the facility with water. Associated with this facility are two water pipeline corridors and a marine loading facility.

“Hybrid systems, involving a mix of land and marinebased fish farming will continue to be part of our future. We have been operating land-based salmon hatcheries and marine farms sustainably for 38 years,” says Joel Richardson, Vice President of Public Relations for Cooke. “Innovative scientific technologies bring a new

opportunity for greater production in ocean waters by shortening time Atlantic salmon spend in marine cages.”

In March of last year, Agriculture, Aquaculture and Fisheries Minister Margaret Johnson, released the New Brunswick Finfish Aquaculture Growth Strategy 2022-2030. Its guiding responsible development in the province’s finfish aquaculture sector with a focus on land-based production through the implementation of new technological advancements.

It is expected the multi-phased project will take three years to complete and create more than 340 direct construction jobs and 222 indirect and induced jobs.

The post-smolt facility is just one of the investments Cooke is making in Charlotte County. Earlier this year, Cooke’s new, $21 million freshwater hatchery in Pennfield became operational, and the company recently completed a $50 million expansion at its salmon processing plant in St. George.

The project team for the new aquaculture facility includes Sorensen Engineering Ltd. of Saint Andrew’s, NB and Sweeney International Marine Corp. (SIMCorp) of St. Stephen, NB.

10 | May 2023 - International Aquafeed News

Prevention before Treatment

The new upgraded formula

Aller Aqua’s functional fish feed SUPPORT L is a series of aquafeeds based on a blend of functional ingredients that promote growth and survival in fish as well as bacterial disease resistance and prevention. Now with even better results:

Microbial balancing

SUPPORT L reduces risk of bacterial disease outbreaks by supporting and preserving beneficial bacteria.

Improved health

SUPPORT L improves organ quality and health parameters, higher mucus production and increased gut integrity.

Long-term effectiveness

SUPPORT L can be used continuously, without the need to change feed, no exhaustion or side effects.

Increased production

SUPPORT L ensures lower FCR and higher growth, leading to higher farm turnover.

WWW.ALLER-AQUA.COM TM

LSUPPORT L

LET’S GROW TOGETHER

International Aquafeed - May 2023 | 11 News

Global Salmon Initiative welcomes Huon Aquaculture

The Global Salmon Initiative (GSI) is pleased to welcome Huon Aquaculture, a Tasmanian farmed salmon producer, as a member of the industry’s leading sustainability initiative. With the addition of Huon, GSI membership now includes 15 salmon farming companies alongside eight supply chain member companies. Together, the member companies are committed to advancing the sector’s environmental performance through greater transparency and cooperation.

“Sustainability is at the heart of Huon’s operations; it guides every step of production and processing, and we recognise how important this is to our stakeholders,” says Henrique Batista, CEO of Huon Aquaculture. “We join GSI with a commitment to engage in critical global dialogues on shared environmental challenges, participate in solutions-oriented technical discussions and contribute to industry-wide initiatives to improve environmental performance. This will further strengthen the sector’s resilience and commitment to responsible practices.”

Huon previously was a GSI member between 2014 and 2017, and under new management, now re-joins the initiative, demonstrating the company’s commitment to

collaboration for continued sustainability improvements. Huon Aquaculture, founded in Tasmania’s rugged far south, is a vertically integrated company that produces and sells high-quality Atlantic salmon and rainbow trout products to domestic and international markets.

Huon Aquaculture is proudly operated by JBS Australia, which is part of JBS foods, the world’s largest food company and leading animal protein processor. “Responsibly-farmed salmon is one of the most sustainable animal protein sources and we look forward to sharing our learnings and expanding our knowledge through GSI,” adds Mr Batista.

“Farmed salmon has a great story to tell as a contributor to healthy, sustainable and climate-resilient diets,” says Sophie Ryan, GSI CEO. “In Tasmania, Huon is a major contributor to the local economy and is committed to continuous sustainability improvements and raising awareness about the health benefits of consuming salmon. This is where collective efforts like GSI can make a difference, by focusing in on the right trajectory and motivating and measuring progress to hold the sector accountable to its potential.”

Visit our website The premier information source for the feed milling industry internationalmilling.com PCE PELLETING CONSUMABLES EUROPE YOUR PARTNER FOR TOP QUALITY RING DIES available for all major pellet press brands WWW.PCE.EU Scan the QR-Code to find your die! 12 | May 2023 - International Aquafeed News

ScaleAQ going for carbon-free sea transport

In collaboration with the carrier Kuehne+Nagel, ScaleAQ are now taking a big step towards their goal of a carbonfree supply chain. With this initiative, they are the first in Norway to have a large-scale and traceable investment in a biofuel-supported supply chain for sea freight.

The measures ScaleAQ take in collaboration with Kuehne+Nagel remove or offset the CO2emissions from their entire sea-based supply chain. Together with Kuehne+Nagel, they will in 2023:

reduce their emissions of CO2 by 960 tonnes WTW. be the first in Norway with a biofuel-supported supply chain for sea freight of equipment for the aquaculture industry

transport 1,000 containers of next-generation biofuel.

“We are working with Kuehne+Nagel to create a carbonfree supply chain for us and our customers,” says Hanne Digre, sustainability director at ScaleAQ.

“As a logistics partner for ScaleAQ, Kuehne+Nagel is honoured to contribute to our shared ambition for a sustainable future, which is a main priority in our Roadmap for 2026,” says Arne Faaberg, Director of Kuehne+Nagel Norway.

Immediate reduction of greenhouse gas emissions

The scheme enables emission-free transport for suppliers who otherwise do not have the opportunity to reduce their emissions – for example because fossil-free ships do not operate along their trade routes.

ScaleAQ’s emissions are reduced with immediate effect by:

1. The CO2 emissions from our shipments are calculated in detail.

2. Kuehne+Nagel buys biofuel equivalent to what is needed to offset our emissions.

3. The biofuel is used on container ships – this does not mean that our cargo is necessarily on board.

4. Biofuel consumption is attributed to their cargo, and they receive documentation that confirms the reduction in greenhouse gas emissions.

The scheme is of course fully traceable, which benefits ScaleAQ’s customers.

Immediate deductions on the bottom line in the climate statement

Many companies in the aquaculture industry have set specific targets to cut their own greenhouse gas emissions. For them, the scheme with emissions-compensated transport will be a welcome addition to the climate account.

In concrete terms, the reduction can be seen in the environmental documentation for the products bought from ScaleAQ, which now have a lower footprint than before. Initially, this applies to flotation collars, nets and mooring equipment.

These are figures ScaleAQ customers will soon be able to enter in their own climate accounts directly, with associated deductions on the bottom line.

“We want to do as much as we can, with immediate effect. At the same time, we recognize that we are not home free yet. We continue to deliver the necessary products and solutions for the production of one of the world’s most sustainable protein sources, while the work to find new and even better ways to cut emissions from our operations continues,” promises Ms Digre.

The next generation of biofuel

ScaleAQ’s shipments will be transported or compensated with the next generation of biofuel (second and third generation). The first generation of biofuel was a controversial form of energy for a long time – largely because the fuel was produced from foodstuffs such as sugar, corn and vegetable oil.

Today’s biofuel is produced from waste raw materials with no other useful value, such as waste oils, fats and algae, municipal solid waste and cellulose-containing biomass.

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY International Aquafeed - May 2023 | 13 News

Brett Glencross

Searching for Sustainability...

It seems everyone is searching for sustainability at the moment. In the feed sector it seems most of the big feed companies have made statements to the effect of decreasing their impact by 30 percent by 2030 or something to that extent. What is encouraging in these ambition statements is the move to set measurable targets, because if you can’t measure something, you can’t manage it. Starting with a carbon-footprint analysis of feed production quickly demonstrates that between 70 to 90 percent of the footprint of feed is linked to its raw materials, so anything we can do to improve what we use, has significant impacts straight away. So, what are some of those things being considered in terms of positive actions?

First up is responsible sourcing. Making sure that the resources we use come from well managed fisheries (whether forage or human consumption). But this isn’t just a fisheries story, the other important natural resource we rely on is soil and natural terrestrial systems. We can limit the amount of land conversion involved in our raw material supply chains, and better manage

our agricultural practices, thereby protecting the soil and valuable carbon stores in those critical ecosystems.

By increasing the use of circular ingredients, we can reduce pressure on production and harvest demands by better utilising resources that are already available. This doesn’t necessarily need to extend to conversion of those resources into novel and alternative ingredients like insect meals. Many by-products of existing food production systems already have useful nutritional attributes. Fishery by-products are a classic example here that is frequently overlooked. Most of the world’s fishoil and about a third of global fishmeal supplies are now from such by-products, using about six million tonnes of food waste each year. But this is estimated to be less than a third of the fishery by-product biomass available from fish harvested for food. We still need better coordination of waste collection to capitalise on the potential scale of available ingredients in an economically feasible way while maintaining quality and safety standards. And finally, one of the often-overlooked ways of improving sustainability is through nutritional innovation. Those innovations that enhance feed efficiency and health, have multiplier effects in decreasing the footprint of production. A simple look at the way things like forage fish dependency ratios (FFDR) are calculated quickly shows that feed conversion (FCR) is a multiplier part of the equation. So, any improvement here has a marked effect on reducing impacts throughout the chain. However, nutritional innovation is a broad area and includes improved formulation specifications, ingredient quality enhancement, better feeding and management models that provide many options for improving efficiency. And I’m sure there are more that I haven’t yet found. But then we’re all searching for sustainability in some format or other. Sustainability is the north star. Responsible practices are the way to progress in this direction.

14 | May 2023 - International Aquafeed News

Bigger landing craft is direction of travel for salmon farmer

Scottish Sea Farms has taken delivery of its biggest landing craft to date, designed to support the company’s move to farms of fewer but larger pens. The 19m Hollie Rose was built in Scotland by Bute Boatbuilders to a design by Argyll-based naval architect AG Salmon.

The vessel, equipped with a PK32080 Palfinger crane and twin MD196TI Doosan diesel engines, will be based between Mull and Oban, and deployed across Scottish Sea Farms’ mainland estate, assisting with net washing, inspections and treatments.

In a first for Scotland, the boat is fitted with a state-of-theart ROV (remotely operated vehicle) Manta net washer –supplied by Norwegian company Mainstay – that removes marine debris from pens during washing, helping create an optimum environment for fish.

The Manta net washing system also has hole detection software, recording any possible damage to the nets and further improving containment surveillance. In another departure, the landing craft has on-board accommodation for two crew, enabling faster reaction times and greater flexibility.

Scottish Sea Farms Mainland Marine Engineering Manager Craig Cameron, who was involved in commissioning the new boat, says the Hollie Rose will be ready to go where needed at short notice.

“Having accommodation on a landing craft is new for us. It gives the farms a better service and makes the vessel more flexible.

“The two crew will work two weeks on/two weeks off, which is becoming an increasingly popular working pattern in rural areas where housing is scarce.”

The skippers, David McKie and Jacob Ellis, were appointed via internal promotion, with each bringing 10 years’ experience with Scottish Sea Farms, most recently in managerial roles at Bloody Bay farm.

Mr Cameron says the company’s future landing craft are likely to be at least the size of the Hollie Rose, if not bigger, in line with the move towards installing wider diameter pens at farms.

Scottish Sea Farms installed its first 160m circumference pens at its Fishnish A farm, off Mull, late last year, with four of the larger pens replacing the 10 existing 100m pens, while maintaining the same biomass.

The switch to fewer, but heavier and safer, pens not only provides better conditions for the fish but also frees up the farm team’s time so they can focus on the stock’s health and welfare. It is a strategy due to be rolled out at other Scottish Sea Farms locations.

Mr Cameron says there are several Scottish yards that could build boats to the Hollie Rose’s specifications.

“We contacted different yards in Scotland to get prices and availability and Bute was the best fit for us. We always look to local builders first.”

The Hollie Rose has been in service since the beginning of April, says Mr Cameron, who adds he was ‘given the honour’ of naming the boat after his two daughters.

Made in Britain, Trusted Worldwide. We are We can help you improve your pellet durability testing...

NHP200 Series 2 Laboratory based, automatic pellet tester.

NHP300 Inline, process based system. OLM N H ®

NHP100 Portable, manual pellet tester.

Holmen

Holmen

Holmen

Atlantic salmon

How

choline

from krill can help improve gut health

by Kiranpreet

by Kiranpreet

The global market for salmon is on the rise, with expectations of 7 percent annual growth in the years to come. Farmed salmon continues to lead in efficiency and sustainability as well, unrivaled by its land-based competitors due to its low carbon footprint and high edible yield. Salmon also has rightly earned its position as an important source of nutrition – rich in protein, omega-3 fatty acids and other minerals and vitamins that humans need.

The nutritional benefits that the salmon delivers to the consumer, as well as the health and robustness of the fish itself, are highly dependent on the nutrients the fish receives through its own feed. These nutrients were once commonly supplied through fish meal and fish oil in the aquafeed. But due to instability of supply and price, many producers have sought out less expensive, plant-based feed ingredients as a substitute.

The trend towards plant-based feed substitutions has led to an imbalanced supply of essential nutrients in farmed salmon, choline in particular. Choline is present in low quantities in plantbased ingredients – and when the choline concentrations are low, intestinal problems can emerge that negatively impact fish health.

Choline is an important nutrient for preventing a condition called intestinal steatosis, which can evolve into lipid

malabsorption syndrome (LMS) in severe cases. This is a common syndrome among farmed Atlantic salmon that is characterized by excessive fat accumulation in the intestine. When too much fat collects in the gut, it means that the fats (or lipids) are not being absorbed by the fish, thus negating the nutritional benefits and hindering development.

Choline sources’ impact on Atlantic salmon health in new study

The research team from the Faculty of Veterinary Medicine at the Norwegian University of Life Sciences, along with scientists from Aker BioMarine, recently conducted a new study that aimed to find out whether the type of choline in krill oil and krill meal (phosphatidylcholine) could help prevent intestinal steatosis or LMS, as compared to a synthetic form of choline (choline chloride). This marks the first time that this phosphatidylcholine from krill, as a source of choline, has been tested in salmon.

Eight-week feeding trial to assess choline effect on gut health

With a clear, choline-focused mission, the scientists set up an eight-week feeding study at the Center for Fish Research at the Norwegian University of Life Sciences in Ås, Norway. The Atlantic salmon were stocked 35 fish per freshwater tank, with 12 tanks in total. The salmon were fed three times each day for a duration of 30-minutes per meal. The fish received one of six diets that had been established for the study: two diets with krill oil (at different inclusion levels), two diets with krill meal (at different inclusion levels), one diet with high levels of choline

Kaur, Director R&D, Fish Health & Nutrition, Aker BioMarine, USA

In a first-of-its-kind study, where aquaculture scientists conclude that choline from krill can help prevent lipid malabsorption syndrome in salmon, while stimulating better growth.

16 | May 2023 - International Aquafeed

chloride, and one reference diet with no choline supplement.

“To truly put krill to the test, we use two different dosages of choline from krill meal and krill oil. One does was low with 1.5g/kg and the other was slightly higher but suboptimal at 2.6 g/ kg of choline. We measured these doses against a completely non-supplemented diet, in addition to another diet that included a high dosage of choline chloride (4g/kg), in an amount above the optimum requirement. We wanted to see whether krill, even in low doses, had a more significant impact on gut health than the other choline source,” explains Dr. Kaur.

After 8 weeks of this feeding trial, scientists randomly selected six fish per tank for sampling. The sampling involved an analysis of the intestinal tract of the fish to assess the gut contents, with a particular focus on the amount of fat inside.

Choline from krill delivers highest growth rates and better fat absorption

Following the analysis of the study results, the group of scientists conclude that phosphatidylcholine from krill meal and krill oil are equally effective. Both krill forms outperform the other choline and non-choline diets in the experiment in delivering greater growth. In addition, the suboptimal levels of phosphatidylcholine from krill meal and krill oil improved intestinal health in the same extent as the high levels of choline supplementation with choline chloride.

To dig deeper in the results, a look at the fat accumulation in the salmon intestine at the conclusion of the study shows less fat in the fish consuming either of the krill diets. This means that more of the fat was absorbed into the fish consuming krill, thus decreasing

P R O F I U S

Policy recommendations impacting EU aquaculture Reduce waste & environmental impact of feed production New applications for tuna side-streams profius-project.com | aquabt.com The PROFIUS project has received funding from the European Union's Horizon 2020 Research and Innovation programme under grant agreement 817992. BlueBio - ERA NET co-fund scheme.

International Aquafeed - May 2023 | 17

the likelihood of intestinal steatosis and/or lipid malabsorption syndrome in these groups. Besides the fat accumulation was reduced to the same extent in krill groups with suboptimal levels of choline and in the group with high levels of choline supplemented with choline chloride, indicating again that lower levels of organic choline from krill is equally effective as the high levels of inorganic choline.

The growth performance of the salmon was also evaluated during the study. The fish consuming the krill diets exhibited the highest growth rates, particularly in comparison to the choline

Pole Position! Leiber GmbH | Hafenstraße 24 | 49565 Bramsche Germany | info@leibergmbh.de Great

your feeds! Leiber ® Beta-S Highly purified ß-glucans | Immunity booster | Increased resilience | Improved vaccinations Leiber ® Beta-S Plus The ß-glucan alternative | Synergistic blend of pure ß-glucans and MOS Visit our website: leibergmbh.de 070223_Leiber_Anzeige_International Aquafeed_90 mm x 270 mm + 3 mm Beschnitt.indd 1 07.02.23 11:00 18 | May 2023 - International Aquafeed

upgrade of

deficient diet. Salmon growth was significantly higher in the group consuming 2.6 g/kg of choline, which indicates that even sub-optimal levels of choline from krill are sufficient to satisfy the needs of choline for growth in salmon.

“In summary, what we learned is that natural choline from krill is an effective source of this nutrient, and it plays a key role in ensuring that salmon absorb fat rather than having it accumulated in the gut – which can lead to steatosis or in worst case, LMS,” concludes Dr. Kaur.

Adequate choline levels in salmon lead to better quality consumer products

Overall fish health has an impact on its overall quality as a consumer product. A fish with LMS is an unhealthy one, which can hinder the overall results for salmon producers. A plantbased diet may be a more affordable and available option, but the benefits may not outweigh the risks related to a choline-deficient diet.

Thanks to this study from leading fish health experts, the aquaculture industry now has a better understanding of how various sources of choline can play a role in growth and intestinal health. This experiment offered salmon producers an inside look at how krill meal and krill oil, even at lower inclusion levels, can be an impactful way to ensure that the fish are getting the nutrition they need to grow and thrive – so that these nutrientpacked fish can, in turn, give us humans what we need to stay healthy.

For humans, The Nordics will in 2023 update their nutritional advice. Up until now choline was not a part of the recommendations, but now it is getting attention and will be included in the guide, (https://www.nrk.no/nordland/ kolin-er-et-livsviktig-naeringsstoff-_-na-kommer-det-med-ikostholdsradene-1.16272559)

Phileo’s probiotics and active yeast fractions are designed for hatcheries and growing farms to support health, feed efficiency and growth performance . Our sustainable solutions bring innovative responses to fishmeal reduction stakes and environmental challenges. Act with nature for animal care. Join the fish revolution Visit our new website www.phileo-lesaffre.com International Aquafeed - May 2023 | 19

by Carlos Wurmann G, President

espite its growing global importance and the decline in extractive fishing in many countries, aquaculture in Latin America and the Caribbean (LAC), with harvests of almost 3.8 million tons valued at the producer level at about US$15.6 billion in 2020 (excluding algae) is still an emerging activity in most cases. So much so, that only three countries (Chile, Ecuador and Brazil) contribute more than 76 percent of the regional harvests in 20182020; 24 of the 44 countries with aquaculture statistics in LAC produce less than 1,000 tonnes per year in that three-year period, and 31 nations in the region harvest less than 10,000 tons per year in that period. In fact, many nations in the region have not yet determined their specific potential, do not clearly define their strategies or their future intentions although neighboring countries such as Ecuador, Chile, Brazil and others to which you could try to emulate them, show flourishing industries, with great positive impacts on their economies, on employment, etc. In this way, important possibilities for sustainable development, food supply and eventual exports in the region are missed, ignoring that we have enormous sectoral potential, and that we occupy the second place of importance in world crops, after Asia. Here, however, LAC shows average values per kilo cultivated (producer level) of US$ 4.2, compared to US$ 2.9 for Asia, and US$ 3.0 as a world average in 2020.

Now, when the political-strategic decision to develop the sector is made, it is not unusual for improvisations, zigzags, vagueness and discontinuities to begin, a situation that, in cases headed by governments, leads to frustrations and/or failures that discredit aquatic crops, given the lack of tangible and sustainable results of any significance. In many cases it is intended to request support from the local university and/or R&D sector, so that it provides the necessary technical knowledge, when these same they are probably not trained for these purposes or to deliver concrete results in reasonable terms. If, on the contrary, production is led by private companies, and probably in the face of an illprepared State, they probably acquire technological packages or invite foreign experts, to save time and resources, and the productive results can be more encouraging, and invite to make larger investments. In these cases, if the Government of the case does not perceive these movements on time, undesirable environmental and/or social impacts can be generated, and

thus invalidate the productive achievements, given the possible rejection in the markets, the social environment, etc.

GOVERNANCE AND AQUACULTURE DEVELOPMENT D

Thus, the aquaculture development process should not only be based on recognising the advantages and limitations of each country, be they geographical, environmental, social, economic and/or political, but also, and as soon as possible, governments should exercise strong leadership to adequately direct these important processes, through realistic visions of the future, adequate regulations and institutional arrangements, and fundamentally, through duly trained personnel, who understand the particularities of the sector, the realities in other parts of the world, and are familiar with the trends in technology, market, sustainability and many other matters.

It is then a question of generating a propositional 'governance' (not a castrating one, as sometimes happens), which invites growth, taking advantage of market opportunities, but in accordance with clear rules of the game that create an adequate environment for sustainable aquaculture development. If this does not happen, and it is poorly improvised, the country in question limits or impedes sectoral growth, discredits aquaculture, and a self-destructive spiral occurs as a result of what we can call 'aquaculture misgovernment'.

Governance, together with sustainability, market and technological factors, is then one of the fundamental pillars on which the process of establishment and/or growth of aquaculture in our countries must rest. This series of regulations, policies, institutional arrangements and agreements with the productive, support and civil society sectors are essential to guide successful and lasting processes, and consequently we must take care of them very conscientiously, under penalty of alternatively transitioning to misgovernment and/or failure. Thus, let us not let technological, biological, market and/or good competitive conditions illusions, considered by themselves and in isolation from aspects of good governance, blind our understanding of the processes that we want to detonate or amplify. Let's conduct our aquaculture growth sustainably, based on well-designed and agreed-upon government premises, to guarantee clean production, well-paid jobs, in a friendly way with the environment and communities, and with adequate economic profitability.

LAC is already a leader in world aquaculture, especially in the West. Let us then take advantage of the opportunities offered by our geography and other favorable conditions, let us grow sustainably by applying adequate governance, and generate wealth, well-being and food for our populations and for the world.

20 | May 2023 - International Aquafeed

of International Center for Strategic Studies for Aquaculture, Santiago de Chile.

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect fish food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Aquaculture Engineering

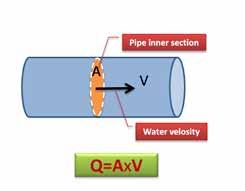

How to measure large pump discharge? It is simple!

by M. E. Esmaeili, Aquaculture engineer and shrimp farmer, AFTM Ltd, Iran

If you are a farmer or a technician who goes to a farm for work, you may need to know how much the discharge or flow of a pump is. If you look at the pump label, it is simple to find the H (Head) and Q (Discharge), but pumps are usually not working at the written rates. It is essential for you to know how much water is pumped and transferred to your pond in an hour. Then what to do? It is simple, just follow the article!

If your pipe is small, suppose 4" or less, you can buy a flow meter and install it on the pipe. The counter is the most accurate way to find the flow, but if your pump and pipe is a large one, this solution is expensive. For such cases, we introduce an easy method as follows.

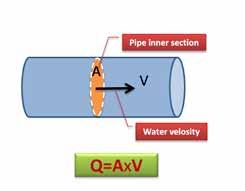

The Basic equation

The basic equation to calculate the discharge rate is Q= A*V

Q: Discharge (m3/sec)

A: Pipe or canal inner section (m2)

V: Water velocity (m/sec)

Any flow rate either in a pipe or in a canal or a river can be measured by this general equation. To find the area you may use a simple equation for a circle or rectangle, but to finding the velocity, some more work you have to do. Let us start with area calculation, A.

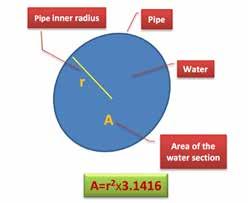

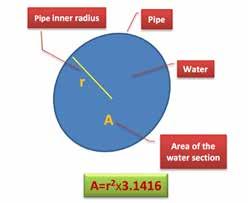

How to measure the area

Pumps are connected to the outlet pipe, we shall calculate the area of the inner section of the pipe. Use this simple equation as you know in fig.2, A= r2x3.1416.

A: Pipe inner section area (m2)

R: Pipe inner radius (m)

Figure 1: Basic equation for discharge

Figure 2: Calculation of pipe section

Figure 3: Segment area equation

22 | May 2023 - International Aquafeed

What to do if the pipe is not full of water? A new equation is shown in fig.3. All you need is shown in the equation.

A: Water section area (m2)

R: Pipe inner radius (m)

h: Depth of empty segment in the pipe (m)

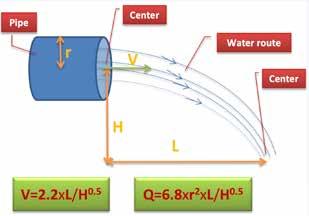

How to measure velocity in the pipes

In order to calculate the discharge you need two data; one is an area of the water pass and the second is the water velocity. You can use the area using your own equation, or use the above equations, but how to calculate water velocity? Two simple ways will be given below.

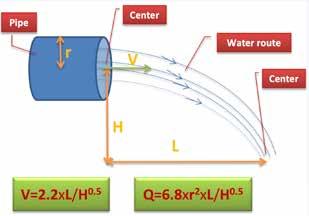

If the water comes from a horizontal pipe and releases into the pond, you can use this simple equation shown in fig.4 and 5.

V: Water velocity (m/sec)

Legal business advice:

• Mariculture and Aquaculture leases

• Aquaculture and mariculture disputes

• Commercial fishery issues

• Acquisition and ownership of fisheries

• Registration of fishing rights

• Defence of fisheries prosecutions

• Seizure of fishing vessels

• International fishing licenses

• High seas fishing

Q: Discharge (m3/sec)

By using the equations in fig.4, you can find the water velocity and discharge.

How to measure the area in canals

If the water is flowing in a canal, there is another way to calculate the discharge. The same equation in fig.1 is used again. To find the area, see fig.6, fig.7, and fig.8

How to measure velocity in canals

If you have a water flow in a canal, get a bottle and put some

Figure 4: Discharge calculation in a pipe

WWW.AQUARIUSLAWYERS.COM.AU +61 (02) 8858 3233

Figure 5: A sample to measure H, L

International Aquafeed - May 2023 | 23

The Future Awaits

Built on partnership and innovation, Wenger is providing more opportunities for client success.

For almost a century, Wenger has delivered extrusion-based innovations to our partners. We’ve worked alongside you to develop new processing solutions and better products, providing our industry-leading expertise and ongoing support every step of the way.

We don’t plan on stopping any time soon. Wenger’s global food processing family is growing, and we look forward to the exciting opportunities that lie ahead. We will continue to deliver even more innovations and technologies to benefit companies that share our vision of tomorrow.

Wenger.com

www.kaeser.com/aquaculture

Aquaculture with KAESER reliable as the tides

24 | May 2023 - International Aquafeed

running water. Measure the speed of the bottle while moving near the center of the canal. By recording the time and the route of the bottle, you can find the speed using the equation in fig.9. Then you can calculate the discharge. A correction factor (C) is considered for smooth canal surface and rough surface because the average speed is less than the central speed of the water flow. This factor may change more or less and this is only an assumption.

If you want to measure the water velocity in a river or earthen canal, use a lower correction factor. Find a general value of C in Fig.9.

Unit Exchange

There are different units for your calculations. These equations are useful:

- 1 feet = 30.5 cm

- 1 In = 2.54 cm

- 1 lit/sec means one liter per second

- 1 m3/sec = 1000 lit/sec

- 1 m3/sec means one cubic meter per second

- 1 m3/hr = 3600 m3/sec

- 1 m3/hr = 3.6 lit/sec

- 1 gpm = 3.79 lit/min

(Note: The above data and calculation are simplified for common use. For more accurate calculations, you should follow the hydraulic and fluid mechanics rules.)

ADISSEO, LEADER IN LYSOPHOSPHOLIPID SOLUTIONS FOR AQUACULTURE

Dedicated production platform

Superior product specifications

Scientifically proven mode-of-actions

Hands-on application expertise

Effective feed cost reduction

More sustainable production

Figure 6: Area calculation in a rectangle canal

Figure 7: Area calculation in a trapezius canal

Figure 8: Area calculation in a river

in a

Figure 9: Water velocity and discharge measurements

canal

TAKE A CLOSER LOOK AT AQUALYSO

IF YOU THINK ALL LYSOPHOSPHOLIPIDS ARE THE SAME...

www.adisseo.com International Aquafeed - May 2023 | 25

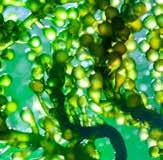

The biology and aquaculture of sea urchins

By Matt E. Bell (Hons) Marine Biology and Oceanography, University of Plymouth, UK Professor Simon J. Davies, International Aquafeed Nutrition Editor, and Dr Alex Wan, University of Galway, Ireland.

Sea urchins are marine echinoderms belonging to the class Echinoidea. They are characterised by their spherical or discshaped body covered with spines and a hard, calcareous test. Sea urchins are found in various habitats ranging from shallow intertidal zones to deep-sea environments, and they play important ecological roles in marine ecosystems.

Sea Urchin Biology

The anatomy and physiology of sea urchins are well-adapted to their marine environment. Sea urchins have a complex water vascular system that helps them move, feed, and respire. The water vascular system consists of a series of fluid-filled canals connected to tube feet that are used for locomotion, feeding, and gas exchange.

The diet of sea urchins primarily consists of algae, which the animal scrapes off rocks or other substrates using their specialised feeding appendages called Aristotle's lantern. These have a unique dental apparatus which are composed of five calcium carbonate teeth that are used to scrape and crush food

particles. The ability of sea urchins to feed on various types of algae makes them important grazers in marine ecosystems, helping to control the growth of algae populations.

Life Cycle and Breeding

Sea urchins have a complex life cycle that typically includes a planktonic larval stage followed by a benthic adult stage. The reproductive cycle of sea urchins is influenced by various factors such as temperature, food availability, and photoperiod. Sea urchins are usually dioecious, with separate male and female individuals, although some species can change sex during their lifetime.

Fertilisation in sea urchins is external, with eggs and sperm released into the water column. After fertilisation, the embryos develop into free-swimming planktonic larvae, which undergo a series of developmental stages before settling on the seabed and metamorphosing into juvenile sea urchins. The larval stage is a critical period for sea urchins, as they are vulnerable to predation and environmental changes.

In aquaculture, sea urchins are commonly bred in hatcheries to produce juveniles that can be grown to marketable size. Various techniques such as induced spawning, artificial insemination,

26 | May 2023 - International Aquafeed

ai1659709269130_IRIDA_PRINT_AD_05-08-22_OUT_102.5x280_ENG.pdf 1 05/08/2022 International Aquafeed - May 2023 | 27

nutrients for their growth and reproduction. Several studies have shown that artificial diets can support the growth and survival of sea urchins in aquaculture. Although their nutritional requirements and feeding behaviour can vary among species and life stages. Further research is needed to optimise artificial diets and feeds for sea urchins in aquaculture, taking into consideration factors such as palatability, digestibility, and nutritional content (essential vitamins and macro and trace metals) and pellet stability.

Sea urchin gonads are well known for their characteristic yellow, orange and sometimes strong crimson colour due to the retention of varying classes of carotenoids. β-echinenone has been isolated as a major carotenoid in the gonads of edible sea urchins. It is oxidatively synthesised from β-carotene via an intermediary β-isocryptoxanthin. Such carotenoids are important and play a functional role in urchins, affecting gonad colour, reproduction, development, antioxidant status and phagocytosis against bacteria in the sea urchin. Xanthophylls such as fucoxanthin, lutein, and zeaxanthin do not affect gonad colour as in fish species but have significant effects on fecundity and survival of larvae. Most of the β-echinenone fraction in the gonads (ovaries and testes) consists of the 9'-cis-isomer. The cis carotenoid may have a specific function in the sea urchin, possibly related to reproduction. Commercial sea urchin diets will need to consider carotenoid sources and stability to provide colour and meet market expectations.

Disease and Health

Sea urchins are susceptible to various diseases and health issues in aquaculture, which can impact their survival and growth. Common diseases in sea urchins include bacterial infections, fungal infections, and parasitic infestations. These diseases can be caused by poor water quality, stress, overcrowding, and other environmental factors.

To maintain the health of sea urchins in aquaculture, proper water quality management, hygiene, and disease monitoring are essential. Quarantine measures, regular health checks, and appropriate treatment protocols can help prevent and manage disease outbreaks in sea urchins. Additionally, optimising their diet and nutrition can also contribute to their overall health and disease resistance.

Market Value and Costs

The market for sea urchins, particularly their gonads or roe, is driven by demand in high-end culinary markets, where they are considered a delicacy in many countries, such as China, Japan, South Korea, and Europe. Sea urchin roe, also known as uni, is highly valued for its unique flavour and texture, and it is used in various gourmet dishes, sushi, and sashimi.

The market value of sea urchins can vary depending on factors such as species, size, quality, and market demand, one example of this can be seen by the Loxechinus albus (Molina, 1782) sea

urchin. In 2020, over 37663 tonnes per year (live weight) of L. albus was recorded according to the FAO. The cost of sea urchin aquaculture can also vary depending on location, production scale, and production methods. Initial setup costs for sea urchin hatcheries, equipment, and infrastructure, as well as ongoing operational costs for labour, feed, and water management, can all contribute to the overall production costs.

Challenges and Future Directions

Despite the potential for sea urchin aquaculture, there are several challenges that need to be addressed for sustainable production. These challenges include maintaining water quality, managing diseases, optimising nutrition, and developing costeffective and environmentally friendly feeds.

Furthermore, there is a need for further research and development of artificial diets and feeds that can provide optimal nutrition for sea urchins, improve their growth rates, and reduce dependency on natural food sources. Advances in feed technology, such as the use of microencapsulation and biotechnology, may hold promise for developing innovative and sustainable feeds for sea urchins in the future.

Conclusion

Sea urchins are highly sort after seafood with a biology and lifecycle. They are important grazers in marine ecosystems and have potential for aquaculture production, particularly for their gonads. Proper nutrition, disease management, and market value considerations are critical factors for successful sea urchin aquaculture.

In conclusion, sea urchin aquaculture has gained attention as a potential sustainable seafood production practice. Understanding the biology, life cycle, breeding, and diet of sea urchins is crucial for successful aquaculture. Proper nutrition, disease management, and market value considerations are important factors in sea urchin aquaculture, with ongoing research and development needed to optimise production practices. Advances in artificial diets and feeds, along with effective disease management strategies, can contribute to the sustainable production of sea urchins in aquaculture. However, challenges such as water quality, disease outbreaks, and production costs need to be addressed to ensure the long-term viability of sea urchin aquaculture. With further research and technological advancements, sea urchin aquaculture has the potential to meet market demand while minimising environmental impacts and promoting sustainable seafood production.

(References can be made available on request)

28 | May 2023 - International Aquafeed

Craftsmanship in the aquafeed processing industry.

Ottevanger Milling Engineers is a leading global supplier of processing lines and production equipment for the aquafeed, grain processing and compound feed industry. Our expertise in project management, engineering and production ensures the successful realization of your complete project.

Would you like to know more about our approach? Let’s talk aquafeed.

www.ottevanger.com

Scan the QR-Code for more information

FISH FARMING TECHNOLOGY Tech update

FIFISH V-EVO QYSEA’s V6 series

The rapidly growing market for compact underwater drones is being revolutionised by QYSEA Technology, a leading manufacturer redefining the capabilities of small remotely operated machines. FIFISH V-EVO, QYSEA's latest addition to the award-winning V6 series, is the first underwater drone to feature a 4K 60 FPS camera with 360-degree omnidirectional movement, allowing explorers and filmmakers to capture stunning underwater moments in high-resolution video.

Featuring a 4K 60 FPS professional-grade camera system, FIFISH V-EVO can capture increased detail and smooth slow-motion videos in ultra-high definition. The drone is equipped with dual 5000 lumens 5500K white LED lights, capable of illuminating dark underwater surroundings to reveal their vibrant colours. QYSEA's unique six-thruster layout enables unrestricted movement, facilitating creative and dynamic underwater filming. The drone also utilises AI-powered image enhancements to filter out plankton-induced white marine flakes and improve footage clarity.

The FIFISH V-EVO's hydrodynamic, fluid, and rugged water droplet design ensures minimal resistance against ocean currents, allowing for longer dives. An attachment port accommodates a variety of tools, enabling integration and versatility for various tasks and scenarios. Suitable for both leisure and professional use, the compact FIFISH V-EVO is ideal for filmmaking, deep-sea exploration, marine monitoring, scuba diving excursions, and more. QYSEA is excited to continue inspiring curiosity and exploration of the oceans.

31 | May 2023 - International Aquafeed

Flocell XFM Fines Filters

A cost-effective technology for the fine particle problem

by Gavin Haywood, M.S.c., Director, Flocell, UK

Aquaculture is rapidly evolving, there’s no escaping it and now advances in technology and best practice make land-based intensive fish-farming a viable option for our food supply needs.

It has long been known that rearing fish at sea has challenges that have now become unsustainable. Apart from commercial viability, increasing scrutiny is given to our environment and therefore maintaining control of a more sustainable and balanced system is increasingly deemed to represent the way forward for our industry.

Rearing fish on land brings control back to the farmer, we are now able to optimise the living conditions for brood-stock whilst at the same time preventing escapees and the known damage they inflict on local, wild populations. Where very difficult to manage in the past, biosecurity can be maintained and pollution is now more manageable.

Environmental, social and governance (ESG) factors are becoming increasingly important to all stakeholders and taking a more sustainable approach to rearing fish, whilst requiring

investment, is now paramount and coming at a time where Global inflation and energy costs are rising, this is something that all operators are under continuing pressure to try and mitigate.

Fines continue to be a problem

One of the significant hurdles the industry has faced since RAS became popular, is the management of fine particle removal. Fish produce waste that needs to be managed but biological filtration by way of Moving Bed Bio-Reactors (MBBRs) produces particles as bacterial communities used in nitrification are replaced by new organisms. Fixed Bed Bio Reactors are used by some but some of these run into significant design issues surrounding cleaning, aeration and associated sludge removal which leads to anoxic conditions within the bed, poor nitrification and critical danger of H2S.

The multitude of pumps managing inline systems results in a continuing degradation of larger particles to smaller ones which then become increasingly complex to manage and reduce.

FISH FARMING TECHNOLOGY 32 | May 2023 - Fish Farming Technology

Flocell XFM filters and media have been designed to effectively control this problem and are highly flexible as to their deployment.

A unique solution for aquaculture

Flocell XFM Fines filters are currently the only solution that provides effective filtration with no hydraulic head loss. As they can be used under gravity, the cost savings on a power alone basis is substantial, moreover XFM filters have in excess of 100 times the retention capacity of similar sized sand filters meaning that less interaction is needed, increasing profitability and reducing downtime. At a time when sustainability is now paramount and low-carbon solutions are always being sought where possible; XFM filters will deliver exceptional performance whilst lowering the carbon balance.

Jefo Protease

Increases Protein Digestibility

Enhances Intestinal Health

Promotes Environmental Sustainability

FISH FARMING TECHNOLOGY 33 | May 2023 - Fish Farming Technology

The solution to REDUCE FEED COSTS

Contact our Aquaculture Specialists info@jefo.com

Exceptional performance with even the heaviest of solids load

XFM filters use a high-performance proprietary media element that has been specifically designed to capture fine particles and retain them within the structure until cleaning. This means that whilst suffering no head loss, a huge solids load (over 200mg/l) can be easily accommodated with no loss of performance.

A single XFM unit can retain over 100kgs of solids and still filter at optimal efficiency, this means that they can be operated for extended periods with no requirement for cleaning.

Very low water loss

Typical sand filters require significant volumes of water to effectively clean themselves. XFM units are cleaned by air sparging for a short cycle and therefore only a small volume of water is sent to waste unlike other technologies where multiple volumes of water are lost, and far more frequently.

Exceptional retention capacity

XFM Media can be used in large installations with high flow rates to capture particles down to 20µm with 100 percent efficiency (at 10µm the media is 80 percent efficient). Solids management is undertaken on a periodic basis by vigorously aerating the basin before sending the concentrated waste to final settlement or treatment nearby.

XFM Filters are also highly effective when continuously filtering a body of water and in situations where they can be deployed on individual fish tanks on a permanent loop, they can be used to keep particles present at an absolute minimum, requiring very infrequent cleaning and taking the pressure off other systems downstream.

Hatcheries

Keeping water in optimal condition is vital in ensuring lower mortalities and better fish health. XFM filters are used to both effectively manage particles within the RAS loop or feed-water sump. A single low-cost filter can comfortably manage flows of

20m3/hr and where constant filtration is required, units can be placed in series and cleaned independently when needed. These filters can be simply specified with manual valves or automated for completely independent operation.

Water recovery and recycling

Water is a valuable resource and in many parts of the World a scarce one too. With waste water a very significant part of any land-based system, XFM filters have been successfully used to seamlessly recover over 95 percent of previously lost water back to the systems in which they are integrated.

The commercial importance of recycling is further enhanced when looking at scenarios where water is temperature controlled and thus being able to recycle back to the loop further reduces operating costs.

XFM filters have been used in conjunction with large scale drum filter effluent and as long as an effective screening system is in place to manage gross solids and prevent them entering the unit, they are able to comfortably accommodate even the heaviest suspended solids loading rates.

Large-scale RAS systems can lose up to 5 percent of their water daily as until now there has been no way to manage large flows coupled with heavy solids loading rates.

FISH FARMING TECHNOLOGY 34 | May 2023 - Fish Farming Technology

INTERNATIONAL TRADE SHOW FROM FEED TO FOOD FOR THE MIDDLE EAST AND AFRICA

Animal proteins and fats as sustainable feed materials

For more information, visit us online:

www.ge-pro.de

• SEA LICE POPULATIONS

• CATARACT PREVALENCE

• AGGRESSION DURING FEEDING

• ENERGY CONSUMPTION

• STORAGE SPACE & COSTS

• MEDICAL TREATMENTS

• FISH HEALTH & WELFARE

• MORTALITY RATES

• STABLE, CONTROLLED GROWTH

• LONGEVITY & EFFICACY

• PRACTICAL FEEDING METHODS

• DAILY OPERATIONAL COSTS

THE INNOVATIVE SOLUTION TO CLEANER FISH

SEA

in the UK by www.vitaaquafeeds.uk

MANAGEMENT &

LICE CONTROL COMPLETE, TAILORED FEED BLOCK DIETS FOR LUMPFISH & WRASSE REDUCED IMPROVED Produced