GREEK AQUACULTURE:

Looking

Looking

a

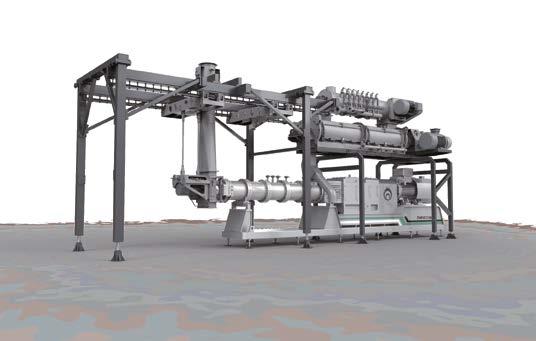

As industry experts, we fully understand the unique challenges you face in the aquafeed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation. We are fully equipped to bring your vision to life!

Events have never been more important than they are today in driving our industry forward.

It’s June and I’ve just returned from Puerto Vallarta, Mexico, where we were invited to attend the International Society of Feed Nutrition and Feeding (ISFNF) 2024 biannual meeting, which took place in the last week of May.

And what a week that was! Intensive, invigorating and insightful.

It was a full week of conference sessions starting with a workshop organised by Dr Brett Glencross of the IFFO, who is also the ISFNF’s immediate-past chair of its international scientific committee - and also our columnist in International Aquafeed.

That workshop took place on Monday and Dr Glencross will be reporting on its outcome in our July edition. Needless to say, communications and how our sector should tackle using modern day digital means to get our messages across to future consumers was a point of discussion.

The rest of the week was devoted to the ISFNF’s scientific program which had a focus on presentations from Latin America. Puerto Vallarta after all is a major resort location for visitors from both North and South America attracted to its old town, fabulous isolation, long summers and friendly people.

For Europeans and Asians reaching Puerto Vallarta was a longer challenge and transiting through the USA is never easy nor stress free. However, there was a good turnout of members from these regions although the normal attendance from China was missing.

Our report on the conference itself will also follow in next month’s edition, but for now it’s timely to thank local organisers Dr Mayra L. González-Félix and Dr Martin Perez-Velazquez, both of the University of Sonora, Mexico, for their superb organisation and running of the event in the city’s new Congress Centre.

Over four days the 340 delegates heard 65 presentations and viewed 200-plus posters.

I can’t help believing that our industry is in good shape with this intensive focus on fish nutrition and fish feeding from this extensive pool of scientists and specialists.

Of course, there is the World Aquaculture Society also addressing nutrition and feeding and these two combined is helping to ensure fish, this valuable food source, can meet rising demand while taking pressure off the harvesting of wild caught fish and associated over exploitation.

A related topic - our Directory

June is the month in which we compile the contents of the annual International Aquafeed Directory and Buyers Guide. The 2024-25 edition will be expanded to include companies providing equipment to farmers.

The directory - now called the International Aquafeed Directory and Buyers’ Guide including Fish Farming Technology - will be available on our website from mid-July and mailed to our readership with the August edition.

There is still time for suppliers to register their companies and choose their product heading (free of charge) in the Product Guide as well as an opportunity to place a classified advert, or a logo and/or synopsis in the company A-to-Z listing section or alternatively to place a display advertisement in the book itself.

Please be sure to use the QR Code below to access the registration form and to see more details about how to expand your presence.

Professor Simon Davies has been with our International Aquafeed magazine for over 16 years and is now stepping down from the position of Nutrition Editor to pursue other avenues of animal nutrition and science, particularly in the livestock sector.

He has brought to our readership a wealth of information and understanding, which I’m sure has influenced the way aquafeeds are formulated and used today. He has covered a complete range of nutritional topics, from insights into ingredients and feed additives to disease and health management through diet and references to the complete range of fish species we farm. He has also contributed features to the magazine.

It has been a privilege and a pleasure to work with him and to provide the platform from which he has been able to express his views and to inform.

We could not have asked for a better, more dedicated editor to guide us over this long period of development for the magazine. In his time with us, we have gone from a bi-monthly, compact publication to a multilingual, monthly magazine with the development of a Fish Farming Technology section that has now become a publication in its own right (although still published within the covers of International Aquafeed magazine).

Most recently, Dr Davies has been instrumental in assisting us in establishing a Journal for the aquafeed industry and for the fish farming technology sector within aquaculture.

We will always welcome contribution from Dr Davies in the future as I’m sure he will remain a regular reader.

As with many other topics he covered we will be continually addressing them. One in particular I would like to pursue is the possibility that vitamins and minerals might play an even greater role in fish health than being seen from an ingredient that helps fish to express their growth potential perspective. That was a topic raised on the last day of the ISFNF Conference I mentioned above.

We wish Professor Davies all the best in his future endeavours and thank him for his contributions over the past years.

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

International Editors

Dr Kangsen Mai (Chinese edition) mai@perendale.com

Prof Antonio Garza (Spanish edition) antoniog@perendale.com

Erik Hempel (Norwegian edition) erikh@perendale.com

Editorial Board Chairman

- Dr Daniel Merrifield

Editorial Advisory Panel

- Dr Abdel- Fattah M. ElSayed

- Dr Alessio Bonaldo

- Dr Allen Wu

- Prof Charles Bai

- Dr Domique Bureau

- Dr Elisabete Matos

- Dr Eric De-Muylder

- Dr Noor Khan

- Dr Pedro Encarnacao

- Dr Philip Lyons

- Prof Dinesh Kaippilly

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Costa Skotidas +44 7826 545952 costas@perendale.co.uk

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Geeji Madathil +91 7994903650 gigigigs@gmail.com|

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

David Harvey davidh@perendale.co.uk

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

Aquafeed Journal journal@perendale.co.uk

1 International Aquafeed - Volume 27 - Issue 6 - June 2024

9 HiProMine increase protein production to support sustainable aquaculture

11 Positive outlook for global fishmeal and fish oil production

11 Scottish salmon with label rouge approved for insect-based feed

14 Digestive enhancers: Reduce shrimp feed cost and optimize profitability

16 Feed solution to compensate fish meal reduction in Aquafeeds

22 Nettle in Aquaculture Feeds: The Terrestrial Green Power Plant for better Fish Health

28 Sustainable fish Nutrition: Harnessing the Power of Seaweed

The International Aquafeed Directory Buyers’ Guide including Fish Farming Technology was launched in 1997 as an easy-to-use directory for manufacturers of fish feed and for fish farmers to source suppliers.

As a practical guide for aquafeed mill equipment, fish farming equipment and feed materials available throughout the world, the International Aquafeed Directory and Buyers’ Guide continues to maintain its unique position.

Today this is the world’s most comprehensive directory for:

Ingredients, raw material feedstuffs, feed additive directory specifically designed to identify all micro-ingredients.

Fish farming equipment and technology including feeding systems, cages, nets, barges and RAS systems

Aquafeed milling equipment and plant for the production of all feeds including for example extrusion, hammer mills, mixers and equipment used in complete turnkey projects

HiProMine has opened another European plant, specialising in the production of insect protein and fat, which is becoming increasingly desirable in the aquaculture industry. Many aquafeed producers recognise not only the health benefits of insect-derived products, but also the ecological and economic aspects.

“When it comes to healthy and sustainable nutrition of farmed fish insects are the future” explains Maciej Szumiński. “Aquaculture production has become a key sector in food production, providing high-quality protein for an increasing human population. However, as production increases, challenges arise in ensuring sustainable and efficient production. In recent years, interest in insect-derived products as a valuable raw material in aquaculture nutrition and as a tool for aquatic environment protection has been growing significantly” he adds.

Due to their high protein content and efficient feed utilisation, insects are a promising and ecological source of nutrients for aquaculture. Larvae of insect species, such as Hermetia Illucens, can transform agricultural by-products into high-value protein, which makes them ecologically and economically attractive.

The Polish company HiProMine SA has just launched a large plan in Karkoszów (Lubuskie Voivodeship), located only 100km from Berlin. The year capacity of livestock is estimated for 25,000 tonnes and the same amount of organic fertiliser. It is the largest plant in Central Europe, with proprietary technology for insects breeding and rearing, employing many scientists conducting numerous research on the properties of protein in the nutrition of various animal species.

“Insect protein, which in the natural environment is a basic component of fish diets, is characterised by optimal amino acids profile” reveals Dr Monika Dudek. “Moreover, ingredients with functional properties contained in insect-derived products play an important role in improving the fish health” she adds. How is insect protein digestibility in fish?

“When insect-derived products are used in salmonid diets, both high digestion of crude protein and crude fat can be noted. In other words, nutrients in insect raw materials are characterised by high availability for

gastrointestinal tract, especially in case of carnivorous fish. Additionally, favourable rearing results are noted and improvement in intestinal microbiota composition, which is crucial for fish health” explains Dr Zuzanna Mikołajczak, fish nutrition specialist in HiProMine.

The usage of insect protein as a dietary component in fish nutrition can bring a number of benefits, such as increase of feed efficiency, improve of fish growth and reduce of mortality.

“Our production is ecological, minimises the carbon footprint and fits into the ideas of broadly understood care for environmental protection and sustainable developement” says Maciej Szumiński. “Building a plant where we will produce insect protein and fat was enormous challenge. However, we believe that our scientific achievements, translated on a large scale, will bring tangible results both for the environment and aquaculture development.”

Maciej Szumiński emphasises that fish production requires the usage of huge mounts of feed. One of the raw materials used in fish nutrition are fishmeal and fish oil, partly produced from unsustainable fishery. Overfishing of oceans to produce aqua raw materials lead to overuse of raw natural resources.

The usage of insect-derived products can reduce these negative effects by lower inclusion of conventional raw materials in feed, which brings sustainability benefits and decrease negative impact of aquaculture on natural aquatic environments. This trend has therefore become a topic of interest due to its high nutritional value and ecological features.

ecruiting for the aquaculture industry presents a distinctive array of challenges, rooted in the specialised nature of the field and its varied demands, which can extend to specific species or production methodologies. At its core, this industry requires individuals with a robust foundation spanning biology, marine science, feed management, operational expertise, and potentially engineering, setting a high bar for recruitment. This necessitates innovative approaches or a deep understanding of the industry to attract suitable candidates.

Interdisciplinary skills are pivotal in aquaculture, as professionals must navigate diverse domains to address multifaceted challenges. Identifying candidates who not only excel in their respective fields but also possess strong collaborative abilities crucial for supporting business success is a key focus in our candidate selection process.

The dynamic nature of aquaculture underscores the importance of industry-specific experience, particularly in niche areas like recirculating aquaculture systems (RAS). However, sourcing individuals with diverse exposure and expertise across production and engineering, especially for senior roles, remains a significant challenge, highlighting the necessity for targeted talent acquisition strategies.

Geographic dispersion adds another layer of complexity, with remote locations often deterring potential candidates due to logistical constraints or lifestyle preferences.

Overcoming this hurdle requires innovative incentives and a comprehensive assessment of candidates’ willingness to relocate, emphasising alignment with the company’s vision.

With sustainability becoming increasingly central, recruiters must identify candidates who not only excel in traditional aquaculture practices but also advocate for environmentally responsible approaches. Moreover, as technology continues to integrate into the sector, recruiters seek individuals who embrace innovation and demonstrate adaptability.

To overcome these challenges, recruiters must adopt innovative strategies such as leveraging social media, utilising existing networks and referrals, employing targeted approaches, and collaborating with educational institutions or regional governing bodies to cultivate specialized training programs. Offering competitive compensation packages and fostering a culture of continuous learning are also crucial for talent retention and meeting the evolving needs of the aquaculture industry.

In essence, recruiting for the aquaculture industry demands a multifaceted approach to be successful in delivering on the brief.

THE

POSITIONS RECRUITED: RECRUITING GLOBALLY

Based on its membership, which accounts for 55 percent of global marine ingredients production, IFFO reports on the main trends observed from January to March 2024 in a selection of countries.

In Peru’s North-Centre, almost 50 percent of the 2.475 million mt anchovy quota has been caught during the first 23 days of the 2024 first fishing season. Peru’s quota setting is of critical importance considering that the country accounts for 20 percent of global fishmeal and fish oil production in an average year.

When we look at the first three months of 2024, global fishmeal production dropped by approximately 27 percent compared to the same period in 2023. Such a decrease is driven by the early onset of the second fishing season in Peru’s North-Central region back in 2023, along with a lower-than-average granted quota, resulting in a diminished catch at the tail of the fishing season at the beginning of 2024. Chile, the USA and the African countries have been showing a positive trend in fishmeal production compared to 2023.

As for fish oil, globally, cumulative output through March 2024 was 30 percent down year over year, mostly due, here again, to the timing of the Peruvian fishing season last year. In 2024 so far, the USA and the African countries are the only ones that have registered a positive trend compared to January-March 2023.

The aquaculture industry is struggling to reduce stocks given the current tepid demand among consumers. Initial estimates indicate that aquafeed production in the first quarter of this year is expected to be lower compared to the same period last year, reflecting a subdued trend in feed ingredients consumption.

Thanks to cooperation between value chain partners in the Scottish aquaculture industry, salmon sold with the prestigious ‘Label Rouge’ (Red Label) can now be fed diets containing insect-derived ingredients during the juvenile stages. Label Rouge production represents 12 percent (8900T) of Scotland’s salmon exports, a significant and growing segment of the industry. It is thus the ideal breeding ground to support premium responsibly sourced ingredients.

The highly-regarded endorsement was achieved in an initiative that brought together INAO, the French Label Rouge regulatory authority; Landcatch, the Hendrix Genetics’ genetics brand for salmon breeding; Scottish Quality Salmon which acts as the management organisation (ODG) for Scotland’s salmon producers and companies; and the leading company in insect ingredients worldwide, Protix.

The internationally recognised Label Rouge requires compliance with stringent standards to ensure the best quality product for consumers. This includes specifications for feed that limit the types and amounts of ingredients that farmers can use across the lifecycle of the salmon. In a recently approved update to these specifications, insects can now be included in the diets of juvenile (freshwater) salmon – marking a significant shift for the Scottish industry is also increasingly putting larger smolt to sea.

Questioning what the ‘S-word’ really means...

The word “sustainability” gets thrown around a lot these days. So much in fact that everyone is adopting its use in some format or other.

However, like that famous line from the movie The Incredibles, “when everyone is special, no one is…”, it makes you question if everyone is as sustainable as they claim. So, if everyone is (supposedly) adopting sustainable practices now, how do we tell truth from the greenwashing? The issue is becoming so pervasive that the European Commission is now introducing legislation (Green Claims Directive 2023/0085) to ensure that there is substantiation on the communication of environmental claims going forward.

Much of the problem in this regard comes from the basis by which different sectors claim something is sustainable. Many

would have you believe just because something comes from a plant product that this makes it sustainable. Afterall this is much of the claim of the vegan-lobby, in that we should all eat plants and save the world. However, a quick review of some of the literature on the impacts on biodiversity, climate-change potential, water use and so on quickly shows that agriculture has a huge impact. And this is even before we add in the impacts of land clearing and pesticides. Clearly crop production is not without its baggage.

An alternative that many pundits opt for now as a sustainable alternative is insects. While insects sit nice and low in the trophic-system-of-things, they still need to be fed. They are animals after all and still need organic carbon and nitrogen to grow. So, recently I was chasing some life cycle assessment (LCA) data on insects to get some clarity on the topic and came across a good paper on a commercial Dutch insect production system [https://doi.org/10.1016/j.resconrec.2019.01.042] and the environmental impacts of insect meals. I was surprised when I read that it took 32.24kg of feed (spent brewery grains) to produce 6.26kg of outputs of which only 1kg was insect meal. I was even more surprised to read that the carbon footprint (global warming potential) that they reported in that paper was 5300kg CO2-equivalent per tonne of insect meal. Compare that against Peruvian anchoveta meal at 624kg CO2-equivalent per tonne and Brazilian solvent-extracted soybean meal at 4257kg CO2equivalent per tonne [EF3.1 economic allocation GFLI v2.0 database], and it makes you question things, like what it really means when you say something is sustainable.

ready for substantial reduction in batch time ?

The current trends in aquafeed formulation force the nutritionist to optimise nutritional inputs and ingredient selection as affordably as possible.

Cholesterol is an essential nutrient for shrimp. It is a key compound of membranes and a precursor for the synthesis of ecdysteroid molting hormones. Reducing fish meal (FM) and fish oil (FO) in shrimp feeds will directly affect the level and availability of cholesterol. Practical shrimp diets are usually formulated with cholesterol levels starting from 0.07 – 0.1 percent. Lower levels than 0.07 percent are considered as non-sufficient. Purified cholesterol can also be added to reach a targeted level. These sources are, however, becoming very expensive so requiring more costeffective alternative options.

In times of high FM and FO prices or low shrimp prices, it is important for nutritionists to search for strategies to fulfil the cholesterol requirement and reduce the cost of shrimp feeds. One of the solutions is Lipogest®, a digestibility and metabolic enhancer based on bile salts. Bile salts constitute an alternative source for the steroid ring and therefore can maintain the synthesis of molting hormones in situations where cholesterol levels are deficient in the diet (Lin et al. 2017). Furthermore, bile salts improve the digestive capacity for lipids in the digestive system of shrimp by improving lipid emulsification and micelle formation, resulting in a faster absorption of lipids in the hepatopancreas.

A feeding trial with white shrimp (Litopenaeus vannamei) demonstrated effective replacement of fish oil and purified cholesterol with Lipogest®. A positive control feed (CHOL8) was formulated to reach an optimal cholesterol level of 0.08 percent. A negative control feed (CHOL6) was formulated at a cholesterol level of 0.06 percent by lowering the fish oil and by omitting the purified cholesterol compared to the positive control diet. To this diet, 0.125 percent bile salt-based Lipogest® was added and compared to CHOL8 in an 8-weeks feeding trial.

Reducing the level of cholesterol significantly affected growth

and feed conversion in white shrimp (Table 1). However, the addition of Lipogest® improved the growth compared to the negative control and restored the performance of the shrimp to the same level as that of the feed with higher cholesterol level. FCR of the Lipogest® treatment was similar to that of the feed with higher cholesterol level. Such improvements can be attributed to a more optimal digestion efficiency and regulation of cholesterol metabolism. In this line, Lin et al. (2017) demonstrated the significant effects of adding bile salts in cholesterol deficient soybean meal-based diets for white shrimp. Furthermore, this study showed that several ecdysteroid signaling response genes, such as the expression of ecdysteroid receptor, chitin synthetase and muscle growth markers were improved by adding bile salts in cholesterol deficient diets. In a more recent trial, the supplementation of bile acids at 0.025-0.1 percent in 14 percent FM shrimp feeds reduced the FCR and increased weight gain (Wang et al. 2023). Altogether, these results show that bile salt supplementation can mitigate the adverse effects of cholesterol deficiency caused by low FM inclusion.

Another approach to cope with higher prices raw material is the application of lyso-phospholipids. Aqualyso isa highly concentrated lyso-phospholipid (LPL) based digestibility enhancer developed for application in fish and shrimp. It delivers emulsifying properties that optimize lipase activity

Table 1: Effect of LIPOGEST® on the performance of white shrimp L. vannamei fed a diet containing a low level of cholesterol. Different letters show significant differences (p<0.05) . CHOL8: positive control with cholesterol level of 0.08%, CHOL6: negative control with cholesterol level of 0.06%; LIPOGEST: 1.25 kg/MT added to the CHOL6 feed.

Figure 1: Effects of dietary lyso-phospholipid based digestive enhancer (AQUALYSO®, AQL) on feed intake (A), weight gain (B) and specific growth rate (C) of white shrimp fed diets with high fishmeal/fish oil (HIGH FM/FO) or low fishmeal/fish oil (LOW FM/FO). Bars with different letters indicate significant differences (p<0.05).

and improves transport and processing of lipidic nutrients in shrimp hepatopancreas. Such metabolic optimization is also key in supporting the reduction of fishmeal, fish oil and lecithin in aquafeeds.

A growth trial was conducted to investigate the benefits of LPL-based Aqualyso in shrimp feed formulated with reduced proportions of fish meal and fish oil. Four isoproteic and isolipidic experimental feeds were formulated Two control feeds containing one percent lecithin were designed: high fish meal/ fish oil diet (HIGH FM/FO: 20%FM, 3%FO) and low fish meal/ fish oil diet (LOW FM/FO: 7%FM, 1%FO). LPL-based Aqualyso (AQL) was supplemented at 0.1 percent into both formulations: HIGH FM/FO +0.1% AQL and LOW FM/FO +0.1% AQL.

Supplementation of the lyso-phospholipid-based Aqualyso supported feed intake and growth performance of shrimp fed high as well as low levels of cholesterol in the feed (Figure 1). Feed intake significantly improved by 13 and 21 percent with supplementation in the high and low fishmeal/fish oil feeds, respectively. The best growth effects were found in the high fishmeal/fish oil feed supplemented with the additive, showing significant improvements of 16 percent and 11 percent in weight gain and specific growth rate (SGR), respectively. A similar pattern was observed in the low fishmeal/fish oil feed; with supplementation the numerical improvements were 10 percent and 8 percent in weight gain and SGR, respectively. More interestingly, supplementation in the low fishmeal/fish oil feed matched the performance of the high fishmeal/fish oil feed, proving the efficacy of Aqualyso to reduce formulation cost while maintaining the performance of a high quality feed. Additive supplementation did not significantly affect feed conversion efficiencies of the diets containing high and low fishmeal/fish oil levels.

In conclusion, within the current context of high prices of ingredients and low shrimp prices, aquafeed formulators can count on Lipogest® and Aqualyso® to make aquafeeds perform with less marine ingredients and cholesterol and therefore achieve significant cost-reductions without losing the performance.

CeFi ® pro Autolyzed brewers’ yeast

| Rich in nutrients and active ingredients

| High bioavailability of the same

| Stimulates the metabolism

| Promotes feed intake and performance Visit our website: leibergmbh.de

Aquaculture production has undergone remarkable growth during the past few decades, and it will continue to rise in the coming years to meet higher demand for safe, healthy and convenient seafood products.

For economic, ecological and societal reasons, a lower usage of finite marine-harvested resources has been a major trend in the aquafeed industry. Grain and oilseed by-products are promising sources of protein and energy for aquaculture feeds.

However, high dietary inclusion levels of plant proteins have often been associated to detrimental effects on growth, feed efficiency, intestinal dysbiosis and immune response, threatening the profitability of major aquaculture species like Gilthead Seabream (Sparus aurata).

Food manufacturers are looking for sustainable natural solutions that would compensate for these deficiencies and the associated stress and therefore at least maintain performance compared to an optimal feed.

Raw materials and feed additives with specific functional properties are increasingly important to support the industry in many of these challenges. Functional feed additives that enhance digestive and metabolic processes have shown to be crucial to make these new feed formulation scenarios work, while reduce the environmental impact of aquaculture and promoting fish welfare.

Among these alternatives, plants extracts have shown interesting benefits like growth performance improvement, feed efficiency optimisation and host resistance. One of them, based on a specific combination of plants extracts has been developed by Mixscience (France). The aim of this study is to examine the impact of this new solution on the zootechnical performance,

nutrient digestibility, intestinal mucosal health and stress resilience in gilthead seabream (Sparus aurata) challenged by a nutritional stress and some additional environmental stress.

The experimental solution (EXP) was supplied in a ready to use powder form. It was incorporated in the mash, prior to extrusion. The trial comprised 3 dietary treatments [Table 1]. A positive control diet (PC) mimicking a practical diet for the targeted species, with 44 percent crude protein, 17 percent crude fat levels and 21 MJ/kg gross energy in order to cover all known nutritional requirements. A negative control diet (NC) with similar levels of crude protein (44%), crude fat (17%) and gross energy (21 MJ/ kg) to the PC diet, but slightly lower levels of digestible protein (-0.3%) and digestible energy (-0.4 MJ/kg). This reduction on digestible protein an energy levels is achieved by replacing fishmeal (Super Prime quality) by an equivalent protein supply derived from defatted soybean meal (Soybean meal 44) and sunflower meal, which tend to lower digestibility and negatively affect intestinal integrity. All other nutrients like essential amino acids (e.g., lysine, methionine), phosphorous and EPA+DHA are balanced among the diets. One additional diet, based on the NC

formula was supplemented with test product at 200 g/ton (EXP). Test product was added in the mash prior to extrusion at the expenses of wheat.

Diets were isonitrogenous (44% crude protein), isolipidic (17% crude fat) and isoenergetic (21 MJ/kg gross energy) as illustrated in Table 2.

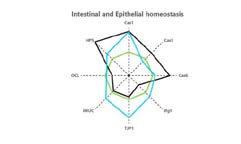

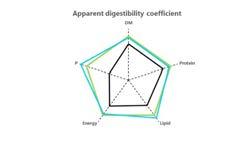

Figure 2: Results of the relative overall activity of EXP solution (in blue) on immune response, oxidative stress, intestinal and epithelial homeostasis and apparent nutrient digestibility compared to the negative control (NC in black) and the positive control (PC in green)

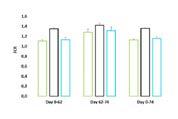

Feed conversion ratio (FCR) and growth performance (Body weight) after 62 days of feeding (normal conditions) and after 12 days of additional environmental stress (74 days) EXP solution (in blue), Negative Control (NC in black) and Positive Control (PC in green) [0-62 days] = Nutritional stress; [62-74 days] = 12 days of nutritional stress and environmental stress

Diets were manufactured by extrusion). Diets were manufactured by extrusion. All powder ingredients, including the tested solution [EXP], were mixed accordingly to target formulations in a double-helix mixer and ground (below 400 µm) in a micropulverizer hammer mill. Diets were manufactured by means of a pilot-scale twin-screw extruder with a screw diameter of 55.5 mm and temperature ranging from 117 to 120ºC. Feeds were dried in a vibrating fluid bed dry.

The trial was conducted in indoor facilities in Portugal. The experimental species under testing was gilthead seabream (Sparus aurata). The initial fish stock was kept for two weeks in two 1500 L tanks supplied with recirculated saltwater (temperature 20 ± 1ºC, salinity 35 ppt and dissolved oxygen >6.6 mg/L). During this period, fish were fed the PC diet, in two daily meals, at approximately 1.4 percent biomass/day. At the start of the trial, fish were manually sorted by weight to constitute homogenous

The growth assay included two distinct experimental phases

[Figure 1]. During the first 62 days (phase I), the fish were raised under normal breeding conditions to allow optimal zootechnical performance. Subsequently (phase II), the fish were subjected to stressful rearing conditions for 12 days, which involved a combination of a chronic stressor (higher rearing density and, therefore, oxygen levels dissolved lower in water) and a repeated acute stress factor (voluntary reduction in the arrival of oxygen). Apparent nutrient digestibility was measured alongside the performance test, in separate tanks equipped with faecal settling columns.

In order to evaluate the impact of the nutritional stress (phase I) and environmental stress (phase II], the Table 3 indicates the full list of monitored parameters during the study.

Zootechnical performance

The results indicate very clearly that in seabream, a challenging food (NC) in which part of the fish meal has been replaced by plant ingredients induces negative metabolic reactions: reduction in general immune status, reduction in antioxidant defences, degradation of intestinal homeostasis with in particular a deterioration of intestinal morphology (increase in the

Our wide range of value-added services and understanding of production and market challenges worldwide, allows us to find the right technology and the most cost-effective solutions for your business in Livestock, Aquaculture/ Aquafeed and Pet industries

Offers customized development, formulation and manufacturing services for efficient and effective Vitamin and Mineral Premixes, Additives, Farmac, Organic Acids, Pigments, Organic Bypass Fats, etc. with the highest quality standards and according to the needs of its customers in animal nutrition, with exclusive Technical, Professional and Personalized Consulting worldwide

histopathological score and genes induced in the cleaning of damaged caspase-type cells), a decrease in the digestibility of nutrients, compared to an optimal food (PC) [Figure 2].

This results in lower feed efficiency, in particular a deterioration of the feed conversion ratio and the protein efficiency ratio inducing an overall drop in performance which remains when environmental stress is added to nutritional stress [Table 4 and Figure 3]. Overall, intestinal homeostasis and permeability are damaged and the host expends a lot of energy to restore its basal level.

Conversely, a product such as the experimental solution EXP compensates for the side effects associated with nutritional stress by increasing the overall immune response (pro inflammation, innate immunity, sanguine antimicrobial activity), by reducing oxidative stress through overexpression of related enzymes. to the capture of free radicals and thermal protection, by preserving intestinal integrity and its homeostasis and increasing the digestibility of nutrients. This results in a restoration of feed efficiency and the final performance of the fish, which returns to levels similar to those of the positive control [Table 4 and Figure 3].

The positive effect of EXP solution has a certain persistence on the stress response of the fish because even additional environmental stress does not impact the overall performance of the fish [Figure 3].

The negative impact of a challenging food can be offset by specific plants extracts that activate key metabolic activities to save energy and maintain overall resistance that limits dysbiosis and intestinal disorders under stressful conditions and helps maintain a healthy optimal feeding efficiency and overall fitness of the host.

The present study confirms that dietary supplementation is an effective strategy to improve the zootechnical performance of gilthead sea bream and provide additional benefits related to nutrient digestibility and overall mucosal barrier functions at the intestinal level, under conditions of dietary and environmental stress.

Table 3: Monitored parameters during the study

Targeted function Specific parameters

Performance Initial mean body weight (IBW), Final mean body weight (FBW), Specific growth rate (SGR), Feed conversion ratio (FCR), Feed intake (FI), Protein efficiency ratio (PER)

Digestibility Apparent digestibility coefficients (ADC) of dietary nutrients and energy

Analysis of diets, whole-fish and faeces

Intestinal inflammatory status

Intestinal histomorphology

Dry matter, crude protein, crude lipid, gross energy, total phosphorus, Yttrium concentration in feed and faeces.

Faecal levels of calprotectin and mucins

Villus height, villus width and number of goblet cells per area of epithelium layer

Neutral and acid mucins

Immune response Expression of selected genes : Interleukin-6, Interleukin 1 beta, Interleukin 8, Tumour necrosis factor alpha, Membrane bound Immunoglobulin M, Immunoglobulin Tau, Piscidin 2, Pentraxin

Antioxidant status Expression of selected genes : Catalase, Manganese superoxide dismutase, Glutathione peroxidase, Glutathione reductase, Heat-shock protein 70

Intestinal status Expression of selected genes : Tight junction protein 1, Claudin 12, Occludin, Intestinal mucin, Intestinal Fatty acid binding protein

Epithelial homeostasis Expression of selected genes : Caspase 1, Caspace 3, Caspae 6, E-Cadherin, Tumour protein P53, Insulin like growth factor 1

Table 4: Growth performance after 62 days of feeding (normal conditions)

Values are means ± standard deviation (n=4).

Values within a row with different superscripts, denote a statistical difference (P<0.05

www.pce.eu

We have discussed in International Aquafeed numerous products that have been produced by companies globally that have bioactive properties and functionality as feed additives and supplements. There is no question of their value as immune modulators and antiinflammatory agents for animals such as poultry, swine and even for our companion animals in petfood applications. These natural ingredients have been widely used in fish and shrimp with enormous success revolutionising the aquaculture industry with their potential to enhance health and offer some protection from disease and stress. One of the most interesting novel terrestrial source plants for development is the humble stinging nettle Urtica dioica. Nettle belongs to family Urticaceae native to Europe, North Africa, and America. It is herbaceous perennial flowering plant with a rich array of soft green serrated leaves covered in trichomes (stinging apparatus).

Properties of nettle

Nettle has received much popular attention for human health as a medicinal but increasing wider appeal in animal feed applications. It has been advocated for fish and other aquatic production species due to these attributes that will be the focal point of this article.

Urtica has unique properties in terms of a complete nutritional profile with a spectrum of nutrients from macronutrient components to micronutrient content (Bhusal et al 2022; Devkota et al 2022) There have been numerous publications covering chemical composition and articles in the food science domain. A comprehensive review was produced by Jan et al (2016) that described nettle as a reservoir of key nutritional and bioactive components with great functional properties. Bioactive agents include phenolic compounds such as p-hydroxybenzoic acid, gentisic acid, quinic acid, rutin, quercitin. It is also a rich source of aldehydes, alkenes, amines, amides and various organic halogen compounds and aromatics.

Oxidative stress is a consequence of metabolism leading to oxidative events in animal tissues in both normal active life processes and in disease states. The antioxidant capacity of nettle

has been reported with its ability to enable the reduction of free radicals. Hydrogen peroxide scavenging and quenching of the superoxide anion have been assessed using in vitro and in vivo models with excellent validation of these beneficial effects by nettle. This is due to a combination of mechanisms including its prominent levels of ascorbic acid (Vitamin C) and other factors such as flavonoids.

Nettle also has potent antimicrobial activity due to specific phenolic classes. The phenolic compounds in aqueous extracts exhibit appreciable antimicrobial activity against specific grampositive bacteria and some yeasts. It has been shown to be quite effective against Streptococcus pneumoniae, Staphylococcus aureous and various Enterobacter-bacter strains. These can be related to many other bacterial pathogens found in fish and shrimp. The alcoholic extract of U. dioica has demonstratable fungicidal activity against various fungal strains found in animal systems. Nettle extracts from either the leaves or root has modulatory and suppressive effects on the degree of hyperplasia in tissues and this could be of interest in fish, especially to curb pathogenic agents that cause widespread disease in the industry. These can initiate various tumours and enlargement of organs and nettle could mitigate these.

As well as in humans, there have been several studies to examine the potential of nettle and product derivatives for animals with more attention given to species like pigs and poultry for commercial dietary inclusion. Work to date has provided excellent evidence for the enhancement of health with a focus on improved nutritional status, metabolism, and immune response. For example, nettle imparts nutrients and bioactive components, which stimulate growth and feed utilisation, modulate metabolic processes, and support the immune system in broilers (Milosevic et al (2021).

In aquaculture, the use of nettle seems most promising from the few studies to date. Actually, De Vico et al (2018) has stated that ‘nettle is a neglected plant with emerging growth promoter and immunostimulant properties for farmed fish’. These authors provide compelling evidence for its use in commercial fish diets as a bioactive and functional ingredient. The scientific literature has primarily evaluated nettle powders in diets from a feed additive perspective. In this regard, Awad and Austin (2010)

Phileo’s probiotics and active yeast fractions are designed for hatcheries and growing farms to support health, feed efficiency and growth performance . Our sustainable solutions bring innovative responses to fishmeal reduction stakes and environmental challenges. Act with nature for animal care.

website www.phileo-lesaffre.com

assessed Urtica doica as a feed additive to prevent Aeromonas hydrophilia infection in rainbow trout, Oncorhyncus mykiss. They recorded after 14 days post pathogen challenge, higher survivability with nettle dietary supplementation. There was also elevated serum bactericidal activity, and respiratory burst associated with the collective innate immune mechanisms (leukocyte respiratory burst activity, neutrophils, monocytes, and macrophages) as combined strategies of the immune system for several pathogen destruction processes. Nettle also gave higher haematocrit and red as well as white blood cell counts compared to a control group of trout without nettle inclusion.

Most studies in fish have focused on the effects of nettle on the immunological status of fish. A comprehensive review on using Nettle additive for both growth promotion and immune stimulation in fish was presented by Zare et al (2023). Saeidi Asl (2017) reported that Urtica could be highly effective for rainbow trout (Oncorhynchus mykiss). Dietary supplementation of stinging nettle on growth performance, skin mucus, immune response, and pathogen resistance of rainbow trout fed with diets supplemented with U. dioica at 0, 1, 2 and three percent was tested after a two month feeding trial. At the three percent inclusion level, improved weight gain, specific growth rate and superior feed conversion ratio was observed compared to the other fed groups. A previous investigation by Ngugi et al (2015) to assess the effects of dietary nettle powder inclusion for the Indian carp Labeo demonstrated that the immune function of fish could be significantly enhanced. Fish were assigned into four treatment groups and fed for 4 and 16 weeks with 0%, 1%, 2% and 5% of U. dioica levels into the diet. Use of U. dioica in the diet resulted in superior metabolic, haematological, and immunological parameters. Among the biochemical parameters; plasma cortisol, glucose, triglyceride and cholesterol decreased, while total protein and albumin in Labeo increased

with incremental dietary inclusion of U. dioica. Among the haematology parameters: red blood cell (RBC), white blood cell (WBC) counts, haematocrit (Htc), mean cell haemoglobin (MCH), mean cell haemoglobin concentration (MCHC) and neutrophils became elevated with increasing dietary inclusion levels of U. dioica, some linked to fish size and stage of growth. Serum immunoglobulins, lysozyme activity and respiratory burst were the main innate immunological parameters in the adult and juvenile L. victorianus recorded and were raised with dietary levels of U. dioica. A post-trial challenge infection with A. hydrophila, U. dioica at 5% showed significantly higher relative percentage survival (up to 95%) against A. hydrophila. Conclusions were drawn that U. dioica can stimulate fish immunity and make L. victorianus more resistant to bacterial infection.

Mehrabi et al (2020) assessed nettle meal on rainbow trout performance with incremental levels of nettle powder added to the fish feed at three doses, 0.5,1 and 1.5 percent respectively. At the end of an eight-week feeding period, the fish were exposed to Saprolegnia parasitica over a three week period. All groups receiving nettle diets displayed significant elevation in weight gain and Specific Growth Rate (SGR), and decreased Feed Conversion Ratio (FCR) compared to the control trout. Feeding the fish with dietary nettle also produced significant increases in blood indices and non-specific immunity in comparison with the control treatment. Interestingly, rainbow trout fed 0.5 percent of dietary nettle yielded higher expressions of TNF-α, IL-1b, IL-6 and IL-8 genes following eight weeks of feeding. A significant reduction in mortality rate was observed in the fish fed with 0.5 percent of nettle compared to the control following the regulated infection with S. parasitica. On termination of the trial, mucus samples obtained from the integument of trout were examined for composition and activity. Fish fed stinging nettle exhibited enhanced antagonistic actions against specific bacterial pathogens (Streptococcus iniae, Yersinia ruckeri, Vibrio anguillarum and Lactococcus garviae) in mucus. Skin mucus enzyme activities (alkaline phosphatase, lysozyme, protease, and esterase) improved and elevated protein levels in 2 and 3% fed groups were detected with the highest being for the three percent supplementation group.

Other work on fish has centred on modulatory effects to obtain more detailed evidence of the effects of nettle as a functional feed supplement. In general, nettle was reported to play a positive effect on many parameters associated with blood biochemistry markers, liver enzymes, antioxidant status and immunological system components. The optimal dietary inclusion rate ranged from 0.5 percent nettle powder up to three percent and a 1-2 percent nettle content in diets showed significant effects on growth and feed utilisation metrics giving superior performance. The reduction of several liver associated enzymes in blood serum of fish such as lactate dehydrogenase (LDH), Alanine transaminase (ALT) and aspartate aminotransferase (AST) are indicative of a healthier liver and less leakage of these marker enzymes into the blood. It is likely therefore that nettle can lead to greater integrity of the hepatocyte cells of fish.

In a more recent investigation for fish, Martin and Hardy (2023) were the first to pioneer research on the potential of Urtica in experimental diets for Atlantic salmon (Salmo salar). This trial examined how the Atlantic salmon performed when fed nettle supplemented diets from a high-quality consistent source

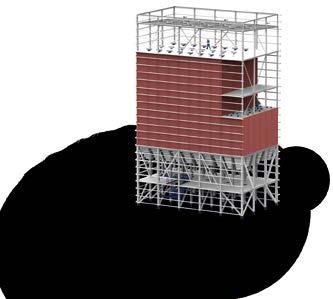

“In Tasmania, they had plans to convert a former cardboard factory into a fish feed factory. And so it happened. An almost 30-metre-high silo tower for storing raw materials for the fish feed, all according to the applicable Australian codes.”

Sven Konings, Commercial managerLocation: Application: Tasmania, Australia Aqua Feed, storing block

www.tsc-silos.com

Scan for references!

Get your FREE field guide to feeding fish

Discover the power of knowledge in this meticulously crafted compendium on fish, feed utilization, and farm maintenance.

Learn how to grow sustainably and apply modern practices to your fish farm.

Download a free copy today and immerse yourself in the sea of holistic knowledge on fish farming!

Something

Anticipating data facilitates predictive maintenance

Recommendations for optimisation

Increases user expertise of steam dosing

(Urtica+plus®). The nettle was generated by a leading industrial partner Urtica+ plus who farm nettles in the UK and generate a highly consistent product used extensively as an animal feed additive.

Three main objectives from the study were 1) to refine diet design and conduct a feeding trial, 2) evaluate selected intestinal health and blood parameters, following the feeding trial, and 3) assess the response and status of the immune system following pathogen challenge using various criteria. Overall, the conclusion was that salmon fed one percent and three percent nettle supplemented diets had blood parameters which are within the normal expected ranges for healthy Atlantic salmon. Several parameters would suggest a marginal increase in key health-associated biomarkers, but further work would need to be carried out and an independent trial to confirm these results. Histomorphology of the distal intestine examined six key parameters to characterise intestinal health for structural integrity. Here it was observed that two parameters i.e., subepithelial mucosa and supranuclear vacuolisation gave superior scores in three percent nettle compared to one percent and control fed salmon. For remaining histological parameters there were no significant differences between control and nettle fed fish, however there was a non-significant improvement in several parameters observed in the one percent nettle fed fish.

The ability of salmon to generate an efficient immune response following the feeding trial was definitively tested by using a bacterial pathogen challenge test with Aeromonas salmonicidia the etiological agent of furunculosis (a well described salmonid disease). A further nine fish per diet were used as control which were injected with Phosphate Buffered Saline (PBS). These authors reported highest survival in the salmon receiving

a 3% nettle powder diet at 43.3%, with fish fed 1% having 36.7% survival and those fed the control diet exhibiting lowest at 33.3% survival (although this did not reach significance) indicating a trend of improved survival with increasing nettle supplementation. All the fish that were injected with PBS (control group) survived the full 15 days trial.

Atlantic salmon are a very lucrative and highly valued farm fish species as are rainbow trout in Scotland, Norway, Chile, Canada, and USA. Other important marine fish are seabass, seabream, grouper, and flounders such as turbot and halibut. There is also significant production of warmwater fish species like tilapia and pangasius as well as many carp species within the Indian subcontinent and extensively in Southeast Asia and China. Given the scale and intensity of production, building resilience, and mitigating disease and use of antibiotics is paramount. Nettle can therefore play a vital role in our armoury of functional natural feed additives and supplements for the aquafeed sector. More research is required for nettle in diets for these other fish species and shrimp.

Conclusion

In summary, the common stinging nettle Urtica dioica has been shown to have a plethora of functional characteristics having been evaluated under rigorous research trials with several animal species from production animals such as poultry, pigs, and young ruminants, companion animals, dogs, cats and equine and now increasingly for aquatic species. The work on fish provides validated and authoritative preliminary evidence regarding efficacy and safety of nettle with much relevance to sustainable aquaculture.

(References are available on request)

In the evolving landscape of animal nutrition, the use of innovative and sustainable solutions has never been more critical. Ocean Harvest Technology (OHT), a pioneering feed company with its headquarters in London, stands at the forefront of this transformation, leveraging the potent properties of seaweed to enhance animal health and productivity.

Ocean Harvest Technology was established with a clear mission to research and commercialise the diverse applications of seaweeds. Initially focused on various sectors, the company has now honed in on animal and fish nutrition. The driving force behind OHT’s products is extensive research demonstrating that polysaccharides and other bioactive compounds in different types of seaweed act as prebiotics in animals. This research has consistently shown significant benefits, including higher growth rates, lower mortality, and greater feed efficiency across various animal trials.

OHT’s flagship products is OceanFeed Aqua, a natural feed additive that sets itself apart from conventional products. Unlike many feed additives that rely on synthetic ingredients and preservatives, OceanFeed Aqua are harvested from their natural habitats, processed into various forms such as powder, pellets, or crumbles, and have an impressive shelf life of up to three years. This all-natural approach not only ensures the purity of the product but also meets the growing consumer demand for

sustainable and environmentally friendly solutions.

CEO Mark Williams elaborates, “We’ve consistently seen shrough the animal trials that we’ve done, for aqua products and others, that this product leads to higher growth rates, lower mortality and greater feed efficiency. And so the business now is very much about maximising the commercial expansion of blended seaweed product into aquaculture and other animal nutrition sectors. We don't need to add any additives, carriers,

preserving agents or whatever. So it's an all -natural product which is being processed easily to powder, pellets, crumble, whatever your production system needs."

Nico Stein, CCO, added, “And it has three years shelf life. So that’s for me, being around that industry for over ten years, absolutely unique. It is very well perceived by the market and customers. It’s the first product I’ve seen in the additive business that is being actively searched and asked for.”

animal feed products from OHT, covering a wide range of recipes of the various seaweeds that they use.

“It protects pretty much the whole scope of the business that we have. I think it also represents, because it’s such a wide ranging patent, as close as you can get to an external verification of first mover advantage”, says Mark.

Sustainability is at the core of OHT’s operations. The seaweeds used in their products are sourced globally and are predominantly invasive wild-blooming varieties. These seaweeds, which thrive on excess nutrients from agricultural and human activities, can be ecologically damaging if left unchecked. By harvesting these invasive species, OHT not only mitigates environmental damage but also creates a sustainable supply of raw materials.

The company’s initial manufacturing facility in Vietnam has expanded its sourcing to other parts of Southeast Asia, including Indonesia and the Philippines, as well as Eastern Africa. This global diversification of the supply chain ensures a steady and sustainable supply of seaweed, enabling OHT to meet growing demand while maintaining environmental integrity.

OHT’s stock price has seen a significant rise, reflecting investor confidence in the company’s strategic direction and market potential. The company continues to invest in three core areas - sales and marketing, supply chain, and intellectual property development. By expanding sales channels, diversifying supply sources, and investing in ongoing research and trials, OHT aims to demonstrate new applications and benefits of its products.

One notable trial involved shrimp, where OHT’s product demonstrated significant performance benefits, including improved survivability in the presence of disease challenges. As the company continues to expand its global reach and innovate, it stands poised to lead the way in the next generation of animal nutrition.

UNDERSTANDING YOU. STANDING BY YOU. NEVER STANDING STILL. We provide complete plant solutions for aqua feed production to your exact specifications and with industry-leading cost efficiency by leveraging our extensive processing expertise and experience. By harnessing the power of automation and digitalization, we ensure continuous innovation to keep you at the forefront. AND with the industry’s most trusted services, we are always there for you.

ANDRITZ FEED & BIOFUEL andritz.com/feed-and-biofuel-en

For more information, visit our website.

In aquaculture, fish and shrimp are constantly exposed to pathogen pressures, environmental fluctuations and other production stressors, negatively impacting survival and productivity.

At dsm-firmenich, we offer solutions to protect aquatic animals, reducing the risk of health and welfare challenges throughout the production cycle.

Learn more at dsm-firmenich.com/anh

The coating system MT is a complete machine able to mix in line pellets, kibbles, and other granulated products with additives such as liquid enzymes, fat, digest, aromas, oil, medicines, vitamin. The machine is used in combination with the powerful sprayer MicroSMOG and guarantees a perfect coating of the product. Paddles are tiltable for a better performance of the machine.

• Allows to apply additives and ingredients after mechanical and thermal processes without ruining their physical properties

• Allows to reduce the risk of cross-contamination in the production line

Reduces the consumption of liquid additives with a consequent economic saving

It is also suitable for large flow rates

https://plp-systems.com

http://myaqua.info/JImi

The strict demands placed on the mixing operation in feed mills built the foundation for the design standards of the Anderson Feed Technology line of high accuracy mixers. One of the most widely used solutions is the Anderson Feed Technology single shaft paddle mixers. All Anderson Feed Technology paddle mixers are designed for mixing dry ingredients regardless of their bulk density or shape with the option for liquid addtion as well.

The Anderson Feed Technology paddle mixers are equipped with pneumatic operated bomb doors under the full length of the mixing trough. This shortens the discharge time to approximately 15-20 seconds. The mixing plant can operate fully automatic with a capacity up to 15 batches per hour.

www.andersonfeedtech.com

http://myaqua.info/ihGM

The large inspection hatches of the Wingdoor Sifter allow the operator to access all relevant parts quickly and easily for inspection and maintenance. In addition, sifting baskets can be replaced ultra-quickly. This is the reason that when there are many product changes, the Wingdoor Sifter is preferred. Because of its ergonomic design, cleaning the sifter does not take much time and effort from the operator. And because the sifting baskets can be replaced ultra-fast, it is possible to change quickly between products.

Suitable for many product changes

Designed for ultra-fast sifting basket changes

• Easy to clean due to large inspection hatches

www.dinnissen.com

http://myaqua.info/tzmt

Do you have a product that you would like included in our pages?

Send your product information to editorial@perendale.co.uk

Selected Bacillus spp. strains

Iwas watching the traffic on TV one morning. Very heavy traffic going into town. And especially this particular morning, for the authorities have closed the public transport (bus/taxi) lanes to electric cars, as of today. Owners of electric cars have enjoyed a number of privileges in Norway, including the right to drive in public transport lanes. But now the number of electric cars is so great (nine out of ten new cars registered are electric!) that these privileges have had to be withdrawn.

Transport in and out of city centres has become very difficult in all metropolitan areas. So I can fully understand those who subscribe to the idea of producing food inside the urban centres. Some time ago, I was reading a report on the ten most important trends in aquaculture, and right on top of the list was urban aquaculture! Producing all kinds of aquatic animals in the city, close to the market. A wonderful idea, but is it practical?

There appears to be two major drivers behind the move to urban aquaculture: the need for freshness, and the need to cut down on transport (both time and cost).

Freshness is of course a major concern when it comes to seafood. Seafood spoils easily, and the sooner you can consume it after it has been killed, the better. This need for freshness was behind the trend in Asian cities, where many restaurants installed seawater tanks to store live fish and other seafood until customers ordered these items. And now, the trend is to move even production into the city centres.

Not surprisingly, we find modern examples of urban aquaculture in the city state of Singapore. Singapore has very limited space available, both on land and sea areas. At the same time, Singapore is a city that really loves seafood. So the market is definitely there. Singapore does not produce enough seafood for its domestic consumption. Most of the seafood sold in Singapore has to be imported, mainly from surrounding countries (Malaysia, China, Vietnam, Indonesia, Thailand,). In fact, just over 75 percent of Singapore’s seafood imports (by volume) came from these five countries in 2021.

No wonder that smart entrepreneurs are seeing an opportunity for urban aquaculture here. Top restaurants are always looking for high quality seafood, and that means fresh seafood.

The company Vertical Ocean was started as just an idea in 2016 and has recently become fully operational. The company offers ultra-fresh seafood (shrimp) delivered to your home or to restaurants on a same-day basis.

The technology that goes into production is complex and consists of no less than 83 different technologies that have been

adapted and combined into one whole. Because of space, the operation had to go vertical, and it had to be compact (land costs in Singapore are astronomical).

The production setup consists of a number of movable tanks, and the company focuses on shrimp, which is a highly priced and popular seafood item in Singapore. Vertical Ocean can deliver completely fresh shrimp, harvested the same day, in a matter of hours, and thus satisfies even the most quality-conscious chefs.

Transport is short, quick and cheap. Singapore is a small island, and it never takes more than an hour to drive from one end of the island to the other.

Thus, the two main considerations are taken care of: freshness and transport.

One concern that comes to mind is of course: is it profitable?

I found no definitive answer to that in my research about Vertical Ocean. But based on experiences with land-based operations elsewhere, urban or land-based aquaculture may be facing problems. The “flag-carrier” of land-based salmon farming, Atlantic Sapphire, has certainly had its share of problems, mainly biological and technical, and is still not turning a profit. Whether a much smaller operation, producing shrimp in Singapore, can do better, remains to be seen.

Eventually, urban aquaculture will probably have to succeed. But at what price? The urbanisation of most countries will force the development of urban production in many areas. Or it may force people out of the cities and back into the countryside. I, for one, have chosen the latter solution. I chose to move from the city to the countryside to get away from traffic, exorbitant car park costs and toll road charges that have just become prohibitive. I now enjoy life in the countryside, with the fjord as my nearest neighbour and plenty of fresh seafood available right here.

The only manufacturer worldwide that covers all feeding stages of fin fish and shrimp, for land or sea based systems.

Sustainability is on the agenda and we see that trade associations and salmon producing companies are on the path to calculating and publishing their carbon footprints. To support this salmon farming process, Garware Technical Fibres has created Renew Ropes: the first rope made from 100 percent recycled materials, the use of which leads to a 50 percent reduction in the carbon footprint.

“The introduction of 100 percent recycled ends shows our commitment to the Clean Production Agreement (CPA), circularity and the reduction of plastic waste, contributing to sustainability throughout the life cycle of the products. In addition, it has exhaustive quality control of its raw materials: 100 percent reprocessed copolymers so that it meets the required quality,” comments Marcos Jofré, Business Associate Garware Technical Fibres Chile.

The company recently developed this 100 percent recycled product, which meets the need to be more sustainable, while maintaining its quality standard. The properties it equates are: useful life, density, weight, resistance to traction, fatigue and abrasion. Its use is wide: maritime, sports, fishing and aquaculture; available in three and eight strands.

Plastic waste takes thousands of years to decompose, “by manufacturing Renew Ropes with 100 percent recycled material, we ensure that the waste is used in a final application, along with reducing the need to produce new material, and this rope can also be used again. The Norwegian market is already being supplied with a good reception and we hope that Chile follows this trend,” says Jofré

X2 Aqua Neo: high-performance ropes that is ideal for exposed centres

For its part, X2 Aqua Neo has high resistance at a smaller diameter, low elongation, and is lighter. “The quality of the fiber is such that with smaller diameters, it manages to deliver higher resistance than other anchor ropes. It also presents great resistance to cyclic loading stress, with a very good result, measured under the OCIMF standard (of the international marine forum of oil companies), with an excellent fatigue life over tension. Our tensile fatigue test (TCLL) is higher fatigue than common ropes. In addition, it is quick to handle, with lower installation costs and also in anchoring items, easy to splice, it reduces the load on the anchoring system, due to its lower drag and weight,” says Jofré

Both have Norwegian Standard 9415 (NS9415) certifications, which confirms that it works technically and OCIMF standard. Since aquaculture centres use a large volume of ropes – for all types of applications – these occupy an important place on the agenda. “Now offering a rope made of recycled raw materials, such as renew ropes, which reduce the carbon footprint by 50 percent, is a contribution to the clients’ sustainability strategy,” emphasises Jofré.

It should be noted that Prodalam is the one that distributes ropes for the aquaculture industry in Chile, through a strategic alliance for a decade. “We support the development of this Garware line, with large and small ropes at good costs and with a large stock availability for salmon production regions,” says Alberto Pino, aquaculture manager at Prodalam.

Mat-Kuling, a Norway based RAS equipment manufacturer company, recently confirmed its focus on the fast-developing Aquaculture RAS solution market in Asia with Wonjin Fisheries Co.Ltd. in South Korea. Wonjin has been involved in Aquaculture of Seafood for more than 30 years and brings onboard deep insight into the South Korean market specialties.

Wonjin’s team, recently visited Mat-Kuling’s factory in Izmir, Turkey, to receive training on the RAS equipment produced by Mat-Kuling. This technical visit is part of our ongoing efforts to enhance their capabilities in ongoing land-based aquaculture projects involving shrimp, grouper, salmon, and seaweed, for which Mat-Kuling supplies equipment.

International Aquafeed met with Nil Llussà, RAS Specialist and Biologist at Mat-Kuling at the Fish International show in Bremen recently. He emphasised, “We are a one -stop supplier of RAS equipment. That’s our biggest strength, in the industry, because fish farmers can come directly to us and we can provide all that’s necessary to get their RAS operation started.

“Also, we also supply other equipment in other types of land-based systems as well. Our equipment are of very good quality, all manufactured in Turkey by our engineers and personals working in our factory.

“We built this facility last year as an expansion and we generally produce our equipment with high grade polypropylene.”

Mat-Kuling’s aim is to cooperate with fish farm developers and third-party consultants to provide comprehensive filtration equipment that would exceed their yield production targets and meet local environmental legislations. Their RAS department is available to be subcontracted by aquaculture consultants and fish farm developers, as well as, fish farm owners, to fabricate customised equipment under their own design, brand and needs.

Leveraging expertise in artificial intelligence (AI) and marine biology, BiOceanOr, a French start-up, is using AI technologies to help manage water quality and promote sustainable practices. They have developed AquaREAL, a unique service predicting water quality. Their mission is to deliver bio-guided services that optimise fish welfare and growth, while supporting sustainable aquaculture practices.

“I am delighted by the invaluable support from BlueInvest for our fundraising efforts, which has substantially enhanced our brand visibility.” said Samuel Dupont, CEO and co-founder.

Thanks to BlueInvest support, the start-up successfully raised its first round of funding in June 2023, amounting to €2.5 million.

The journey towards aquaculture innovation

Starting from its roots in oyster farming, BiOceanOr’s has expanded their sales range to diverse aquaculture products, including salmon, seabags, bream, tilapia, shrimp and algae. However, as they secured contracts with major French water companies like VEOLIA, concerns arouse regarding the environmental impact of their operations.

Driven to minimise their ecological footprint and mitigate potential repercussions for both downstream and fellow aquaculture enterprises, BiOceanOr set their sights on developing a tool that would ensure safe, environmentalfriendly and efficient operations at farm level.

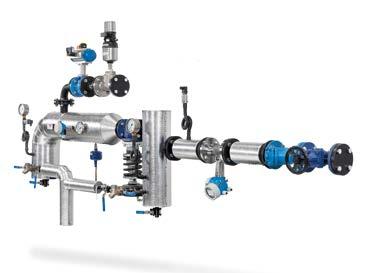

Smir Group has entered into a contract with Andfjord Salmon for the delivery of the waterborne feeding system Smirfeeder to their land-based facility on Andøya in Norway. The two companies will also look at the possibilities for extended cooperation around the delivery of solutions and services linked to other parts of Andfjord’s production in the years ahead.

Frode Rygh, Sales Manager of Smir Group, commented “We are very proud to be chosen as supplier of feeding system to this project. Andfjord Salmon aims to build and operate the world’s most sustainable fish farming facility of its kind, and it is inspiring to be able to help them

To address the data gap, BiOceanOr embarked on creating a digital solution to advance aquaculture. Going beyond simple monitoring, their innovation aimed to offer real-time insights and AI-powered analytics. This empowers aquaculture producers to foresee environmental shifts and proactively manage risks.

Real-time data from an underwater weather station BiOceanOr’s AquaREAL water quality assistant provides real-time data for farmers and customers. The tool predicts crucial water quality parameters such as dissolved oxygen levels and assesses their impact on production and the marine environment.

Their innovation can work with different types of sensors and monitoring devices. It benefits aquaculture by enhancing downstream applications, boosting fish growth and ensuring fish welfare. Furthermore, it aids water utilities in managing wastewater discharge and optimising operations in the watershed.

BlueInvest has played an important role in BiOceanOr’s journey. The programme provided them with valuable guidance and connected them with partners across Europe. Through pitching and coaching sessions, they were able to gain insights from experienced members of the BlueInvest community. In particular, the programme’s support and visibility have been crucial for BiOceanOr in attracting new investors, clients and partners.

Samuel Dupont, CEO and co-founder, acknowledges the value of BlueInvest support in fostering financial partnerships. The investment raised during its first round of funding (€2.5 million) will fuel the expansion of the company’s activities in the salmon farming industry, particularly focusing on water quality prediction to mitigate risks and delivering actionable insights for production optimisation.

Furthermore, BiOceanOr has recently announced its collaboration with ScaleAQ Software, a major player in the tech-aquaculture industry. Together, they aim to improve fish farming by offering fish farmers unrivalled digital services through reference integration platforms.

to achieve this goal by using our waterborne feeding system.

“By being able to gently transport feed with different properties and structure, such as a softer pellet, we firmly believe that we can challenge existing feeding systems by delivering significantly better fish welfare

“We’ve had a good dialogue with Andfjord Salmon over a long period, and as we have gotten to know each other we have come to realise that we have much in common regarding the design of tomorrow’s technology and services, which also includes areas other than just feed logistics. We do look forward to taking a closer look at which synergies we can collaborate on in terms of technologies and services in the coming years.”

Christian Torgersen, COO of Andfjord Salmon, said “To ensure the good biological results we achieved in

the Pilot and a further development of the performance, we are very pleased to have entered into a collaboration with Smir on the delivery of waterborne feeding system. We believe we have found an innovative partner who is as highly focused as we are with biological results and technological development.

“It was about finding a feeding method that was best suited to the concept and choice of feed type.

“By further developing the technology for feeding, we will also together with feed supplier Skretting, shape the future structure of pellets and its nutritional content.

“In addition we’ll get all the significant benefits when it comes to matters such as low energy consumption, no microplastics and the integration to the infrastructure on land.”

With light sensitivity of as much as 0.0001 Lux, Orbit FHD Fixed is one of the most light sensitive cameras in the market. The camera is designed to be fixed either upwards, horizontally or downwards in the pen, and is not delivered with typical pan/tilt solution. It has a resolution in full HD, and increased field of view by 120 degrees, which means that the operator gets a good overview even with a fixed camera. It also comes with simplified infrastructure requirements –power and signal in the same cable.

ScaleAQ is a world class supplier of cameras for the global aquaculture industry. Since 1985, they have been helping aquaculture operators to perfect feeding using video images from their pens.

Optimising production with the use of new innovations in fish farming technology is proving invaluable in the industry. Methods include AI and data-driven solutions, such as ‘transfer learning’, to monitor fish health and growth to improve decisionmaking.

In the heart of Oslo’s historic centre, a team of young engineers and software developers gather at their company’s quirky offices. Brimming with creative energy, they work on a challenge far removed from their urban environment: offering fish farmers realtime tools and insights to optimise production.

With its origins in the oil & gas industry, Solution Seeker might at first seem an unconventional partner for fish farmers. The tech company was founded over a decade ago as a spin-off from the prestigious Norwegian University of Science and Technology (NTNU); it is now turning into one of Norway’s most promising Industrial AI companies by building solutions driven by real-time sensor data.

As Vidar Uglane, Solution Seeker’s CCO and co-founder – who grew up overlooking oil rigs and fishing vessels in Norway’s

scenic west coast – puts it: “Both industries have more in common than topping the list of Norwegian exports: they often lack direct measurements as inputs for production optimisation. So, they require innovative solutions to infer crucial parameters indirectly, called ‘soft sensors’, which we happen to specialise in. For instance, flow rates for individual wells in oil & gas, and biomass/growth rates in aquaculture, all of which can be derived from other measurements and displayed in your browser.”