MeettheInternationalAquafeedteamat:

AQUACULTURE UK Technology on display

- Monaco Blue Initiative 2024

- Insect ingredients: A turnkey solution for sustainable aquafeed

- Revolutionising Shrimp Farming: A quantum leap forward in very early pathogen detection

- Filtration: The power of upcycling in water management

FISH FARMING TECHNOLOGY

International AquafeedVolume 27Issue 5May 2024 www.aquafeed.co.uk www.fishfarmingtechnology.net

MAy 2024 Proud supporter of Aquaculture without Frontiers UK CIO

39 Fish Farming Technology - Volume 27 - Issue 5 - May 2024 40 EDITOR: Erik Hempel 42 Ace Aquatec leads new partnership to improve salmon farming 44 ASC supports blue food transformation in Ghana 44 Stolt Sea Farm receives top sustainability certification 44 Mowi’s law suit against ‘salmon tax’ dismissed 45 Tech update: Ocean Ark 46 From Local Breakthroughs to Global Impact 50 Revolutionising Shrimp Farming: A quantum leap forward in very early pathogen detection 52 FILTRATION: The power of upcycling in water management 56 Aquaculture UK - TECHNOLOGY ON DISPLAY 60 TECHNOLOGY SHOWCASE MAY 2024 Fish Farming Technology - Volume 27 - Issue 5 - May 2024 IAF2405.indd 39 26/04/2024 16:17 6-7THMAY-BERGEN,NORWAY

Your machines and process lines in top condition?

With periodic visits from our expert and dedicated technicians, your entire process is inspected to the highest standards. The result? Reduced downtime and optimised performance.

Let’s talk services »

www.ottevangerservices.com

Events have never been more important than they are today in driving our industry forward.

WELCOME

This is why we focus on them so much and attempt to bring the best from their wide array of presentations - be that conference papers, research and or equipment developments - to your attention. We feel that the speed of adoption of new technologies and applying the research that is being carried out around the world, is vitally important to not only the success of individual businesses involved but to the growing demand for nutritious foodstuffs that we supply.

Roger Gilbert

Publisher – International Aquafeed and Fish Farming Technology

Viewing the content that International Aquafeed and Fish Farming Technology provides each month in a positive and enthusiastic way will assist in this technology transfer. Our contributors, columnists and staff are dedicated to explaining the reasons behind the technological subjects they are writing about.

Protecting our oceans

But first let me comment on an event held in mid-March 2024…

The lead feature we carry this month is from the Monaco Blue Initiative (MBI) 2024 which, while aquaculture was not in itself fully represented, was referred to in several keynote presentations within the ‘private sector’ having an involvement in the ‘blue economy.’

It is not possible to side-line the aquaculture sector - and I refer to brackish water, coastal and ocean fish farming - when discussing a ‘blue economy’ that yields investment opportunities along with stewardship responsibilities for the environment.

The world’s population needs a secure protein food source with great potential and aquaculture has the scope over terrestrial animal production to meet the expected demand in an environmentally and sustainable way through greater marine fish farming.

We cannot rely on wild caught fish to satisfy demand forever. Fish are about the only wild animal that we feel relaxed at capturing and consuming, while all our other livestock proteins come from domesticated animals.

Ocean fish farming technology can be adopted by any country with a coastline and should not be seen as a blight on the seascape. Marine farming should be seen as a beacon of future sustainable food production which conserves the local environment in which it operates. Who better to ask to protect our oceans than those who work in it - and especially those that work ‘below water?’

Don’t overlook our annual Directory and Buyers’ Guide

For International Aquafeed and Fish Farming Technology magazines, this is an important month.

As we are published in the UK, May is the month in which we attend the bi-annual Aquaculture UK event in Aviemore, Scotland. This event is a major opportunity for Scotland and the rest of the UK to show off its best in fish farming and also attract to its expo facilities and conferences international companies, speakers and attendees.

We will be promoting participation on our 2024-25 International Aquafeed Directory and Buyers' Guide - with its new section on Fish Farming Technology. We welcome all companies providing equipment and services to consider listing their contact details in this year’s edition – free of charge. We publish the application form in Fish Farming Technology. Simply fill in and scan and return to Peter Walker at: peterw@perendale.co.uk.

Of course, you can add a logo and a text box to your entry for a small charge or even take a display advert - you can selecte a quarter, half or full page option - to attract greater attention and promote your products. Again, please contact my colleague Peter Walker to talk over any

additional inclusions, you would like.

We aim to make this coming year’s International Aquafeed Directory and Buyers Guide the most comprehensive and widely available directory in our aquaculture sector.

Elsewhere in this edition

Once again, we are stretching boundaries. And once again we are adding extra pages to make this a bumper edition. There is plenty to read.

We kick off International Aquafeed with Nutrition Editor Professor Simon Davies’ editorial taking us through the use of medicated diets and why we use feed as a significant method for their administration (page 8). He points out the requirement for careful pre-planning in the use of antibiotics in controlling diseases, etc to avoid antimicrobial resistance, which is a serious threat. He discusses the development of vaccines and their advantages over using antimicrobials and refers to their development as ‘significant milestones’ in modern aquaculture husbandry.

Dr Brett Glencross on the other hand (page 13) talks about the blurring of the line between feed and food and makes the point that, in many cases, the utilisation of a potential food source that humans could consume might be better off reaching us via an efficiently produced fish or domesticated livestock source - such as salmon and chicken rather than pigs or cattle - and better meets our needs not only nutritionally but also for enjoyment.

We look at the development of ‘A turnkey solution for sustainable aquaculture’ (page 18) based on a discussion that took place at the 2024 North Atlantic Seafood Forum (NASF) that suggests a roadmap is now required to secure insect protein as a key source of supply for the aquaculture feed industry. Michel van Spankeren, Business Development manager at Protix in The Netherlands takes us through the suggestion.

Yechiam Shapira, Senior Researcher at Phibro Animal Health based in Israel discussed ‘How nutritional feed additives can support shrimp gut health’ (page 22) and while on the subject of shrimp Stephanie Frouel, Julie Castie and Maxime Hugonin of miXscience, France (page 24) delve into the topic of a new feed solution to mitigate EHP prevalence. There is so much more in this edition before moving on to the latest edition of Fish Farming Technology (FFT) magazine (page 39).

Our Norwegian Editor of FFT, Erik Hempel of the Nor-Fishing Foundation, leads off with his thoughts on ‘well boats’ which are designed today to protect both the fish they hold and the environment. After all, the transportation fish to processing facilities in ‘well boats’ is a critical aspect of farming that ensures the investment in feed remains maximised.

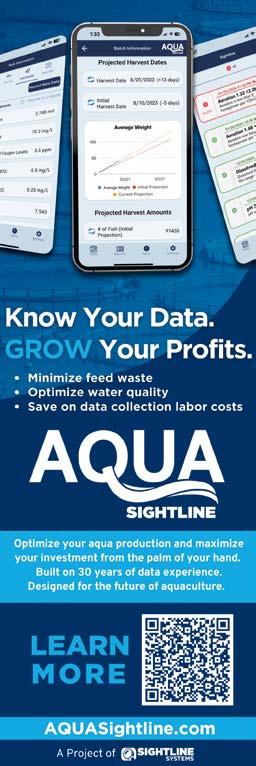

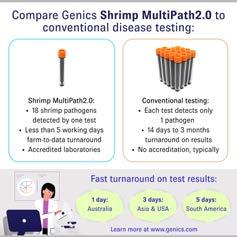

Heather Jones the CEO at the Sustainable Aquaculture Innovation Centre (SAIC) in Scotland writes for us on the impact local breakthroughs in innovation are having both at home and abroad (page 46). Technology is also helping to revolutionise shrimp farming as Melony Sellars, the CEO of Genics in Australia tells us in her article on page 50.

Our Managing Editor Jyothsna Nelloolichalil rounds out FFT with her reports on filtration and the power of up cycling in water management (page 52). And there’s much more as well.

Our focus

This is the edition that goes to Aquaculture UK in Aviemore, Scotland (May 14-15, 2024 - see page 56) and two other international events as well. We give you a head start to these and other happenings.

I look forward to receiving your application forms to list your companies and services in our annual International Aquafeed Directory and Buyers’ Guide 2024-25. Happy reading and eventing!

www.aquafeed.co.uk

REGULAR ITEMS

FISH FARMING TECHNOLOGY

Page 7 Page 27

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

International Editors

Dr Kangsen Mai (Chinese edition) mai@perendale.com

Prof Antonio Garza (Spanish edition) antoniog@perendale.com

Erik Hempel (Norwegian edition) erikh@perendale.com

Editorial Advisory Panel

- Dr Abdel- Fattah M. ElSayed

- Dr Alessio Bonaldo

- Dr Allen Wu

- Prof Charles Bai

- Dr Daniel Merrifield

- Dr Domique Bureau

- Dr Elisabete Matos

- Dr Eric De-Muylder

- Dr Noor Khan

- Dr Pedro Encarnacao

- Dr Philip Lyons

- Prof Dinesh Kaippilly

Editorial team

Prof Simon Davies sjdaquafeed@gmail.com

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 7854 436407 darrenp@perendale.co.uk

Costa Skotidas +44 7826 545952 costas@perendale.co.uk

Latin America Marketing Team

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

David Harvey davidh@perendale.co.uk Design Manager

James Taylor jamest@perendale.co.uk Circulation & Events Manager

Tuti Tan Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk Aquafeed Journal journal@perendale.co.uk

©Copyright 2024 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 1464-0058

62 Aquaculture case study 64 Industry Events 76 the market place 84 the interview 86 the industryfaces

Life, made easier. jefo.com Jefo PEAK Program Production & Performance Improves Feed Conversion Increases Digestibility Improves Environmental Sustainability Increase you profit in aquaculture with our Jefo Protease. DRAFT

1 International Aquafeed - Volume 27 - Issue 5 - May 2024

8 EDITOR: Professor Simon Davies

10 Shrimply the best – start-up aims to solve fishmeal ingredient crisis with modular, land-based system

11 Innovafeed expands to US

11 IFFO’s Members Meeting highlights the key role of science

14 Monaco Blue Initiative 2024

18

Insect ingredients: A turn-key solution for sustainable aquafeed

22 How nutritional feed additives can support Shrimp Gut Health

24 A new feed solution to mitigate EHP prevalence in shrimp

28

Circular Economy: Transforming Aquatic Byproducts into Premium Nutrition

32 Enhancing mediterranean fish robustness with a novel yeast-based functional solution

36 PRODUCTION SHOWCASE

In this section we normally tend to focus on areas concerning feed ingredients and feed additives in the main part. A fully balanced diet must obviously be a carrier for comprehensive nutrition and present within its matrix all the essential amino acids, protein, oils, and fats as well as the micronutrients like vitamins and minerals. However, there is a growing demand to provide in the feed, therapeutic agents such as antibiotics, vaccines and various antiparasitic compounds to treat fish and shrimp against a host of pathogens. These would be categorised as medicated diets.

Administering antibiotics and chemotherapeutic agents via fish feed in farm conditions is a common practice to combat bacterial and viral infections as well as parasites. Antibiotics are often incorporated into fish and shrimp feed to treat bacterial infections such as bacterial gill disease, furunculosis, and streptococcosis. These antibiotics can include oxytetracycline, florfenicol, and sulphonamides. They work by inhibiting the growth of pathogenic bacteria or killing them outright. The antibiotics are usually mixed into the feed pellets or coated during the manufacturing process to ensure uniform distribution. Antiviral agents like nucleoside analogues or protease inhibitors can be used to control viral infections such as viral nervous necrosis (VNN) in fish or viral infections in shrimp. These agents interfere with viral replication and can help reduce the spread of viral diseases. They are typically added to fish or shrimp feed formulations in precise amounts to ensure efficacy while minimising adverse effects. Parasitic infections like Ichthyophthirius multifiliis (Ich) or sea lice infestations in fish, and various parasites in shrimp, can be treated with antiparasitic medications. Compounds such as formalin, praziquantel, and emamectin benzoate are commonly used externally. For oral administration, antiparasitic medications are usually mixed into the feed pellets to ensure ingestion by the affected fish or shrimp. Apart from specific antibiotics and chemotherapeutic agents, various feed additives with therapeutic properties can be used to support the immune system and overall health of fish and shrimp. These additives may include probiotics, prebiotics, immunostimulants, and herbal extracts. They help enhance disease resistance and reduce the incidence of infections, thereby reducing the reliance on antibiotics.

To comply with regulatory requirements and ensure food safety, strict withdrawal periods must be observed to allow sufficient time for the antibiotics or medications to clear from the fish or shrimp tissues before harvesting. Proper disposal of uneaten feed and management of aquaculture effluents are essential to minimize the environmental impact of antibiotics and chemotherapeutic agents used in fish and shrimp farming. Regular monitoring of fish and shrimp health, as well as surveillance for antibiotic resistance and other potential adverse effects, is crucial to ensure responsible use of antibiotics and chemotherapeutic agents in aquaculture practice. However, it requires careful planning, monitoring, and adherence to best protocols to minimize the risk of antimicrobial resistance and environmental contamination while ensuring the health and welfare of the aquatic organisms.

In the rapidly evolving landscape of aquaculture, the development and utilization of vaccines tailored to combat specific fish diseases and pathogens stand as pivotal advancements. Fish vaccines serve as a proactive measure, offering a sustainable solution to mitigate the risks posed by diseases, enhancing fish health, resilience, and

Professor Simon Davies

Nutrition Editor, International Aquafeed

welfare. The process of developing vaccines for fish diseases involves meticulous research and testing. Initially, scientists isolate and identify the pathogens responsible for prevalent diseases in aquaculture. Subsequently, they employ various techniques such as inactivated pathogens, attenuated live pathogens, subunit vaccines, DNA vaccines, and recombinant protein vaccines to formulate effective products. One notable approach is the use of recombinant DNA technology to produce vaccines. This method enables the creation of vaccines containing specific antigens that trigger a robust immune response in fish without causing harm. Additionally, advancements in nanotechnology facilitate the development of nanoparticle-based vaccines, ensuring targeted delivery and enhanced efficacy.

Whist the aqueous route is common and also direct injection for vaccines, feed is becoming a main consideration as it would technical be easier than using skilled and trained personnel for routine vaccine administration. The oral route would be ideal in almost guaranteeing the vaccine can reach the systemic level across the gut barrier and become effective in ‘priming’ the systemic immune system. Many companies have worked on vaccine technology and faced the challenge of including these at an optimal dosage in fish feeds.

The application of vaccines in aquafeed offers several advantages. Firstly, it reduces the reliance on antibiotics and chemical treatments, promoting sustainable aquaculture practices and minimizing environmental impact. Secondly, vaccines bolster the immune system of fish, enhancing their resistance to diseases and reducing mortality rates. Consequently, improved fish health translates to higher yields and profitability for aquaculture operations. By targeting particular diseases prevalent in certain regions or species, aquaculture practitioners can effectively address local challenges, leading to more resilient and sustainable aquaculture practices.

In conclusion, the development and integration of vaccines for specific fish diseases and pathogens into aquafeeds represent a significant milestone in modern aquaculture husbandry. With ongoing research and innovation, the future holds promising advancements in fish vaccine technology, further revolutionizing the landscape of aquaculture.

Please enjoy our May issue and our interesting articles, news items and features. We continue to inform, educate, and expand your appreciation and knowledge of this dynamic and ever changing industry.

8 | May 2024 - International Aquafeed

Pole position – Great upgrade of your feeds.

Visit

The Leiber Animal Nutrition develops and produces sustainable brewers‘ yeast products that helps to improve the health and productivity of fish and crustaceans in the long term.

Real brewers’ yeast! Really effective!

Leiber® Beta-S

Highly purified ß-glucans

Immunity booster

Increased resilience

Improved vaccinations

Leiber® Beta-S Plus

The ß-glucan alternative

Synergistic blend of pure ß-glucans and MOS

We have been upcycling at world-market level since 1954 and keeping the environment and climate in mind.

CeFi® pro

Autolyzed brewers‘ yeast

Rich in nutrients and active ingredients

High bioavailability of the same

Stimulates the metabolism

Promotes feed intake and performance

For us, sustainable behaviour is a vital component of our core business. After all, upcycling brewers’ yeast is at the heart of what Leiber has always been about – Give Yeast a Second Life.

Leiber GmbH | Franz-Leiber-Str. 1 | 49565 Bramsche Germany | info@leibergmbh.de

leibergmbh.de

our website:

Start-up aims to solve fishmeal ingredient crisis with modular, land-based system

An Ediburgh-based start-up is aiming to support the growth of the global sector with the development of a new, modular farm system fuelled by food and drink byproducts, as a sustainable and decentralised alternative to producing a scarce fishmeal ingredient.

Aquanzo is working with CENSIS – Scotland’s innovation centre for sensing, imaging and Internet of Things (IoT) technologies – to farm artemia, a species of brine shrimp widely considered to be the best source of protein available for feeding fish and crustacea. The project has received funding from Innovate UK and Biotechnology and Biological Sciences Research Council (BBSRC), and is being supported by Boortmalt – one of the world’s largest malting companies.

Artemis are typically found in warm, salty water, occurring naturally in salt lakes in the USA, China and Eurasia. The specific conditions in which they grow means the supply of the shrimp is very restricted –particularly for countries far away from their natural breeding grounds, which need to import them. The situation has been exacerbated recently by the Covid-19 pandemic and the war in Ukraine, which have hit supply chains.

The growing scarcity of marine ingredients has meant that feed increasingly relies on plant-based alternatives to fishmeal as a protein source. The current global average for marine ingredients in fish feed is less than 10 percent according to experts – substantially down on 70 percent 30 years ago. However, research testing the composition of feed has found that not only do fish prefer feed containing marine ingredients, they also tend to be healthier compared with consuming plant-based protein.

Rémi Gratacap, co-founder and CEO of Aquanzo, said: “One of the biggest issues aquaculture faces is the sustainability of feed and the dependency of fisheries for fishmeal. It is well known there is a crisis in fishmeal ingredients and we need to decouple aquaculture from maxed-out fisheries and find new ways of providing sustainable sources of protein to help the sector feed a growing world population. Farming, rather than harvesting, important components of feed like Artemia is a better way of ensuring greater control and scale, and is similar to what

is already being done with insect farms, only with marine ingredients.”

The modular, recirculating aquaculture system (RAS) being developed by Aquanzo at Heriot-Watt University would allow Artemis to be grown wherever they are required using the co-product of agricultural processes – in the first instance, the production of malt for the whisky industry. The water used to process malt is rich in minerals and organic matter – that can be used to raise brine shrimp and is currently largely treated as waste.

Deployed on land near agricultural processing facilities so that there is no impact on the marine ecosystem, the Aquanzo RAS system is expected to reduce the amount of CO2 created in the production of fishmeal by 20 percent compared with harvesting fish. All of the water will be reused to further enhance its sustainability.

Rémi Gratacap added: “it has been proven that fish prefer marine protein in their feed – studies have shown they eat much more if feed contains marine rather than plant-based protein. The composition of their feed also influences how much they grow and their natural resistance to health challenges. The system we’re developing will give fish farmers long-term access to a sustainable source of marine protein, helping to continue aquaculture’s growth, enhance the health of their fish, make use of another industry’s waste, and support aquaculture’s net-zero goals.”

As part of the process and technical development, CENSIS engineer will collaborate with Aquanzo on the development of an IoT-enabled array of sensors and a ‘data lake’ – essentially a centralised repository for data – to help its production team collect, store and process data. The technology will help the company progress towards the development of a fully mobile recirculating system, which can be located wherever agricultural by-products are available and remotely monitor the welfare and growth of Artemia.

Corinne Critchlow-Watton, project manager at CENSIS, said: “The Aquanzo system could help solve one of the biggest challenges aquaculture faces – applying cuttingedge technology to a longstanding problem. The system will use an array of sensors to provide data on the environmental conditions within it and how the Artemia are growing, such as water temperature and pH levels. This project demonstrates how IoT and sensing technology can be used in a range of sectors to help solve what might have otherwise been considered a biological issue.”

THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT

POSITIONS RECRUITED:

� CHIEF COMMERCIAL OFFICER

� GENERAL MANAGERS

� MANAGING DIRECTORS

� CHIEF MILLERS

� FEED & POULTRY MANAGERS

� MAINTENANCE MANAGERS

� R&D NEWPRODUCT DEVELOPMENT

� SALES & MARKETING

� PLANT MANAGERS

� CFO’S

BOURNE AES R C H & RECRUITMENT SELE C T I NO

���� bournerecruitment.co.uk ���� +44 7764 465 897

RECRUITING GLOBALLY 10 | May 2024 - International Aquafeed aquafeed news

Innovafeed expands to US

Innovafeed, a global leader in the production of insect ingredients for high-quality animal feed, petfood and plant nutrition, inaugurated its North American Insect Innovation Centre (NAIIC) in Decatur, Illinois on April 18. This pilot plant is the first step of the rising French agtech’s industrial expansion to North America and aims to scale up production and commercialisation of insect protein in the USA.

Innovafeed breeds Hermetia illucens, also known as black soldier flies, in state-of-the-art indoor farms, while efficiently repurposing agricultural by-products for its strategic partner, ADM, in a pioneering zero-waste framework. This innovative process yields insect meal, oil and soil amendment, which Innovafeed markets under the brand Hilucia.

The inauguration of NAIIC will be a milestone in Innovafeed’s expansion in North America. The choice of Decatur, Illinois, is not coincidental: located in the heart of the corn belt adjacent to ADM’s North American headquarters and the world’s largest corn mill operations, with hundreds of processing plants across multiple States, the region offers high potential for multiple sites to be deployed in the future. The broader area is also a historical innovation hub for the agro-industry, making it a strategic location for Innovafeed to serve its core markets. Since 2023, the company in partnership with ADM, already has commercialised Hilucia insect ingredients for the petfood market in North America. As part of this effort, ADM has invested in a comprehensive R&D study at the University of Illinois at Urbana-Champaign, with results to be released later this year demonstrating the nutritional and health benefits of its ingredients. Future opportunities with other types of animal feed are also being explored as part of the comprehensive partnership between the two companies.

IFFO’s Members Meeting highlights the key role of science

IFFO’s Members Meeting took place in Miami from April 16-17, gathering 220 delegates from 29 countries, representing the fishmeal and fish oil sector, the aquaculture and nutraceutical industry as well as scientists and certification programme representatives.

At a time when the first anchovy season is starting in the North-Centre of Peru, the speakers shared positive expectations for a rebound in fishmeal and fish oil production to take place in 2024 after last year being marked by the El Nino/La Nina phenomenon.

With 20 speakers, the emphasis was very much on market trends and science and how evidence-based considerations can help frame the understanding of the sector and its contribution to the global food system.

“Everything starts with facts and data. These have to be our North Star to support informed decision making in a wide range of fields such as fishery management, traceability, mitigation of environmental impacts, enforcement of labour rights” stated Petter Martin Johannessen, IFFO’s Director General at the end of the meeting.

IFFO’s net meeting will be its annual conference in Lisbon on October 21-23, 2024.

Made in Britain, Trusted Worldwide. We are We can help you improve your pellet durability testing... Holmen NHP200 Series 2 Laboratory based, automatic pellet tester. Holmen NHP300 Inline, process based system. OLM N H ® Holmen NHP100 Portable, manual pellet tester. International Aquafeed - May 2024 | 11 aquafeed news

12 | May 2024 - International Aquafeed aquafeed news

Irecently came across an interesting paper [https://doi. org/10.1136/bmjgh-2023-013511] which suggested that instead of eating beef, we should rather eat anchovies. The logic was simple. Anchovies are healthier for humans to eat than beef, being packed full of omega-3 and other important micronutrients. Anchovies are also more efficient to grow than beef (being cold blooded and produce a much smaller carbon footprint on kilo per kilo basis), and therefore would have less impact on planetary boundaries. But what the paper failed to capture is that food is not just simply about nutrition, it is also about enjoyment and culture.

The simple fact is that much of the world could survive on anchovies, but if given a choice they would rather eat beef, or chicken, or salmon. Choice, and the ability to produce food that adds not only nutrients, but also enjoyment to life is a key part of the food story. And this brings things to the crux of the issue, it

is easy to sometimes get lost in the divide between what is food and what is feed. Yes, anchovies are packed full of important nutrients, but just because we use them mostly to make fishmeal, doesn’t mean we can keep those nutrients in our food-chain. In fact, we do, through indirect consumption.

Feed ingredients in effect are indirect food. This the reason why regulatory bodies put stringent regulations on things like contaminants in feed ingredients because these nutrient sources are only one-step removed from our direct food. So, if a choice is made to not consume something directly, like anchovies or wheat, but instead feed those nutrient sources to a salmon or a chicken respectively, then this often represents the next best option of using resources not desired in our food directly. Indeed, the more efficient the animal production system, the better the choice arguably as it represents more efficient transfer of those nutrients as well.

So, options like salmon and chicken being fed anchovies and wheat, represent much better options than feeding pigs and cattle those same feed ingredients for that same reason, and the reality is that throughout the world we still do use fishmeal (anchovies) and wheat in feeds for pigs and cattle respectively. In many cases the alternative option of wasting valuable fish resources or valuable grain resources, though bioenergy (bioethanol/ biodiesel) or fertiliser represents a much worse scenario. In those cases, the nutrients are completely lost from our feed-food-chain. So maybe next time you eat some salmon, chicken or even beef just remember you are helping connect the feed-food divide and ensuring we don’t waste valuable nutrients. And probably enjoying it more than what the alternative option might have been as well.

Brett Glencross

Dosing & weighing experts since 1973 Easy maintenance Track & trace Reporting Continuity Employee shortage Health safety and environment Accuracy Short batch times Micro dosing and weighing equipment for: Offering a solution to your challenges such as: www.ksegroup.com International Aquafeed - May 2024 | 13 aquafeed news

Blurring the Feed-Food Division...

Monaco Blue Initiative 2024

by Roger Gilbert, Publisher, International Aquafeed, UK

As the world grapples with the urgent need to safeguard its oceans, the Monaco Blue Initiative (MBI) continues to serve as a beacon of hope, catalysing action and fostering collaboration towards a more sustainable future for our planet’s most precious resource

The discussions at Monaco Blue Initiative (MBI) 2024 cantered around key themes such as ocean protection, governance, the blue economy and the role of the private sector.

In addition, it discussed the challenge by the Mediterranean in achieving its 30x30 target; a target that refers to the 195 countries that make up COP15 signing at the end of 2022, the 30x30 agreement, which aims to protect 30 percent of oceans and land by 2030 and ensure that at least 10 percent of these areas have strict protection.

The day-long meeting in the Monaco Oceanographic Museum heard of success stories and lessons learned with updates being provided on international discussions concerning deep-sea mining, the plastic treaty, fisheries subsidies and upcoming ocean conferences.

The MBI, a platform for ocean conservation and governance, convened for its 15th edition in mid-March 2024.

This annual event, under the patronage of HSH Prince Albert II of Monaco, invited representatives from governments, international organisations, civil society, NGOs, the private sector, the scientific community along with the media to deliberate on the challenges facing oceans and to foster a sustainable blue economy.

In its digital report following this year’s event, the MBI outlined a program that comprised keynote speeches, panel discussions and updates on international initiatives related to ocean conservation and governance.

International Aquafeed reports here some highlighted statements from presenters that relate to the overall objective of conservationists, but also hinting at the role private investment,

including that from the aquaculture sector, could undertake to assist in meeting the challenges being faced; particularly in the area of funding and stewardship which many of the sustainable aspects and visions-for-the-future of the world’s oceans will come to rely upon.

Highlights from each of the keynote presenters, as reported by the MBI in its post-event press release, include:

1: No longer powerless …

“We are no longer powerless in the face of the degradation of the planet. We have the knowledge gained from our experience, new tools and greater resources. It is this knowledge, these tools, and these resources we will be talking about today. We will be doing so by examining the prospects offered by the blue economy and through it, the role of the private sector in ocean protection. We will be doing so when discussing the protection of the Mediterranean Sea and the achievement of the 30×30 target, and when looking at the more specific challenges of a future Treaty to combat plastic and the strict regulation of deep-sea mineral exploration.” says HSH Prince Albert II of Monaco in opening the 15th edition of the MBI in Monaco

2: The oceans can provide food …

“One of the major solutions to the climate crisis are the oceans, because the oceans can provide food for human and animal species, can provide substitutions for plastics and fertilisers, can provide innovative medical developments, can restore biodiversity, can protect the coastal communities that are threatened by the decline of fish stocks.

To do that, you need a multi-dimensional approach, changing the economic model, developing the renewables, but also looking

14 | May 2024 - International Aquafeed

to the oceans,” says the Minister of Economy and Maritime Affairs for the Republic of Portugal HE Antonio Costa Silva.

3: We gather here as guardians …

“If we are all here, it means that we assume the roles and responsibilities which are important in achieving global objectives in the conservation and preservation of our world’s marine ecosystems. As we gather here as guardians of our beautiful and rich oceans, we cannot refute the fact that we are still concerned by the urgency in regard to their proper protection and governance. Globally, when it comes to marine protection we should, claim some important successes (.) the Biodiversity Beyond National Jurisdiction Treaty (BBJ) which our Parliament proudly ratified … making us the first country in Africa and

Honourable Minister Designated Minister for Fisheries and Blue Economy for the government of the Republic of the Seychelles, Jean-Francois Ferrari.

4: We are all in the same boat …

“We need to realise that we are all in the same boat. And the key word here is ‘collaboration.’ In particular ‘cross sectoral collaboration.’ To create synergies with all stakeholders involved in the blue economy sector and to discuss transparently at all levels - at the local, the regional, the European and the global level. At the same time, we need science ... to develop realistic solutions. This approach fosters innovation, resilience and collective action and ensures the necessary balance between economic prosperity and environmental conservation. It is a

International Aquafeed - May 2024 | 15

The inside workings of the 15th Monaco Blue Initiative (MBI) in the Monaco Oceanographic Museum

Calls on ‘private sector’ investment to help protect oceans

The UN’s SDG 14 - ‘Live under water’ – vastly underfunded

incentives, facilitate and promote such discussions” says keynote presenter HE Christos Stylianides, Minister of Maritime Affairs and Insular Policy, Hellenic Republic, Greece.

5: The role of the private sector is decisive …

“We need public investments to address the scope. But we need private investments to reach the scale. To mobilise more private investment, the EU is blending public funding with private finance. The role of the private sector is decisive in driving the transition towards a sustainable blue economy, which ultimately aims to improve the health of our ocean. Both the public and private sectors are crucial in shaping the future of a more sustainable, regenerative and resilient blue economy,” says the Director General, Directorate-General for Maritime Affairs and Fisheries European Commission, Ms Charlina Vitcheva.

6’: Life below water’ is vastly underfunded …

“Promoting a blue economy based on sustainable activity, thereby ensuring the well-being of populations and ecosystems, is absolutely essential. This is especially important given the lack of funding. For example, among the United Nations’ Sustainable Development Goals, number 14 dedicated to ‘Life below water’

is vastly underfunded: funding amounts to around US$25 billion a year, whereas the needs are estimated at US$175 billion a yearseven times more!” adds Robert Calcagno, the CEO of Monaco’s Oceanographic Institute

7: The real game-changes is system change …

“Developing disruptive business models and blue-finance tools is vital for the transformation of the ocean economy, but the real game-changer is system change. The path towards system change could incorporate a human-centred, equitable and resilient ocean economy that delivers on both sustainability and commercial criteria, a regulatory framework that is clear but also simple enough for thriving ocean business based on pre-competitive data-sharing and collaboration based on trust,” says Olivier Wenden, the CEO and Vice-President of the Prince Albert I of Monaco Foundation.

The MBI, established in 2010 by HSH Prince Albert II of Monaco, is co-organised by the Oceanographic Institute, the Prince Albert I of Monaco Foundation and the Prince Albert II of Monaco Foundation. It serves as a platform to promote dialogue, collaboration and concrete action towards the protection of the marine environment and the development of a truly sustainable blue economy.

HE Christos Stylianides, Minister of Maritime Affairs and Insular Policy, Hellenic Republic, Greece

Ms Charlina Vitcheva, Director General, Directorate-General for Maritime Affairs and Fisheries European Commission

HSH Prince Albert II of Monaco in opening the 15th edition of the MBI in Monaco

HE Antonio Costa Silva, the Minister of Economy and Maritime Affairs for the Republic of Portugal

Robert Calcagno, CEO of the Monaco’s Oceanographic Institute

Minister Designated Jean-Francois Ferrari for Fisheries and Blue Economy, The Republic of the Seychelles

16 | May 2024 - International Aquafeed

Olivier Wenden, CEO and Vice-President of the Prince Albert I of Monaco Foundation

Translate

e

Your fish feed specialist

out more at: alltechcoppens.com/sustainability Working together to

Alltech Coppens awarded EcoVadis golden medal for sustainability

orts

Find

science

into sustainable farming

Insect ingredients

A turn-key solution for sustainable aquafeed

by Michel van Spankeren, Business Development Manager, Protix, Netherlands

Over the past 15 years, insect ingredients have evolved from a little-known concept to a proven aquafeed component. Increased recognition of their value is due to a number of challenges being solved, and real-life success stories providing solid substantiation for their use. At the 2024 North Atlantic Seafood Forum (NASF) an illuminating discussion between eminent experts and the audience took place about how insect-based nutrition is low-hanging fruit for a low-footprint aquaculture industry. The conclusion? Now is the time to step in with a collaborative approach to create applications and a roadmap to secure supply.

Sustainability increasingly in the spotlight

A growing sense of urgency for sustainable solutions is becoming apparent as well as different sustainable initiatives. Some initiatives are prompted by the upcoming deadline of the European Green Deal and the accompanying EU Taxonomy,

aiming for a 55 percent cut to EU greenhouse gas emissions by 2030. Others are motivated by the chance to lead in meeting evolving consumer preferences and to bolster reputation by shrinking environmental footprints. Numerous retailers for example are taking steps to address scope 3 emissions to reduce their environmental impact and enhance their reputation with the increasingly environmentally conscious consumer.

This heightened focus on sustainability is also underscoring the importance of reducing the environmental footprint of the aquaculture sector.

Focus on feed

CO2 emissions from feed account for 57 percent of the aquaculture total, according to the science journal Nature. The independent research organisation Stiftelsen for industriell og teknisk forskning (SINTEF) says the share for Norwegian farmed salmon is even larger, at 83 percent. Considering that feed is the largest contributor to CO2 emissions in aquaculture, it is essential to prioritise efforts to mitigate its environmental impact.

Some retailers have already taken proactive steps with regard to

18 | May 2024 - International Aquafeed

aquaculture feed. In April, Dutch retailer Albert Heijn introduced shrimp in its stores that are fed with a lower-footprint feed. The company aims to halve the ecological footprint of fresh and longlife products chains by 2030. In collaboration with value chain partners Klaas Puul, Nutreco, Veramaris, and Protix, Albert Heijn spearheaded the development of this more sustainable feed based on insect meal and algae oil.

Insect ingredients: a proven solution

Insect ingredients, particularly black soldier fly (BSF) ingredients, have established themselves as a working aquaculture feed solution. The low footprint of the black soldier fly has been proven in a Life Cycle Analysis (LCA) conducted by the renowned German Institute of Food Technologies (DIL) on high-quality insect meal (ProteinX) and insect fats (LipidX) from Protix. Compared with fishmeal, insect ingredients produce 28 percent fewer CO2 emissions and release 86 percent more land for nature.

Multiple studies have shown black soldier fly ingredients to be safe and compatible in aquafeed formulations, as was highlighted by Erik-Jan Lock, Research Director at Nofima, at the NASF. This is endorsed by the industry representatives at NASF who participated in a Mentimeter survey, with 40 percent even stating that the environmental performance of insect ingredients makes them more compatible than other feed ingredients.

World Leaders in Microwave

Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55 International Aquafeed - May 2024 | 19

Moisture

Ready to fly

Insect ingredients are not just a technically viable solution. Over the last years, the insect industry has addressed a number of challenges to come up with a feasible commercial offer. Part of the solution lies in upscaling supply for which insect ingredients company Protix, as an example, has been preparing. Protix has been operating a factory at industrial levels since 2019. With this facility, the company has been uniquely positioned to perfect its insect solutions to satisfy feed manufacturers’ needs and prepare for a robust upscaling of its operations.

Investors have recognised the readiness of players in the insect sector. Investment in Protix by the European Investment Bank and a joint venture with industry giant Tyson Foods mark milestones for the industry and allow the sector to expand rapidly.

Thanks to the pooling of scientific insights, technological advancements and heavy investment, the insect industry is now well-positioned to deliver consistently high-quality ingredients in larger volumes. The Mentimeter research conducted at the NASF event shows that the 84 percent of survey respondents have insect ingredients on their agenda and see the solution’s potential.

Stronger together

But although the larger-scale production of insect ingredients in a consistently high quality is rapidly becoming a reality, there are still steps to be taken to exploit the full potential of insect

ai1659709269130_IRIDA_PRINT_AD_05-08-22_OUT_102.5x280_ENG.pdf 1 05/08/2022 5:21 pm 20 | May 2024 - International Aquafeed

ingredients in the aquafeed industry. Two clear areas emerge from the responses of the Mentimeter audience:

1. Collaboration between the insect and aquaculture industries to showcase successful applications

2. Attraction of further investment through a clear roadmap with clear long-term commercial benefits

To address the first point, Protix calls out to innovative feed manufactures to connect and develop applications together. There is a plethora of (ongoing) research underpinning the potential health benefits to fish and shrimp. While a huge body of evidence supporting insects already exists, there are still potentially very attractive economic benefits to be realised. This is where feed manufactures and insect companies need to pull together, develop applications with potential health benefits, and share success stories. First moving feed manufacturers enjoy the benefit of an enhanced reputation and the whole sector could benefit of a comprehensive set of data proving long-term commercial benefits. At the same time, feed manufactures and insect companies should work together on a joint roadmap to hand-in-hand grow demand and supply in the sector. This way, both sectors can grow responsibly and attract further investments.

Take-off time!

With insect products now available internationally on a commercial scale, the time is ripe for insect ingredients in aquafeed to take off in a responsible way. As pioneers in what was a fledging industry, Protix remains at the forefront of bringing insects into the mainstream. Insect-based feed will truly become mainstream if the aquaculture value chain collaborates with insect ingredient companies such as Protix to secure demand for new production capacity and attract further investment. Now is the time for cross-industry collaboration to create lasting change that will benefit producers, consumers and marine life.

DISCOVER

Our wide range of value-added services and understanding of production and market challenges worldwide, allows us to find the right technology and the most cost-effective solutions for your business in Livestock, Aquaculture/ Aquafeed and Pet industries

Offers customized development, formulation and manufacturing services for efficient and effective Vitamin and Mineral Premixes, Additives, Farmac, Organic Acids, Pigments, Organic Bypass Fats, etc. with the highest quality standards and according to the needs of its customers in animal nutrition, with exclusive Technical, Professional and Personalized Consulting worldwide

E S E has developed and manufactures its own line of innovative and specialized equipment and systems, with exclusive and worldwide technical services for different processing situations in several capacities, from unique components to full line and complete solutions ENGINEERED SYSTEMS & EQUIPMENT, INC 1564 Hwy.166 E. Industrial Park. P.O. Box 99, Caney, Kansas 67333 USA - Phone: + 1 (620) 306-4100 – Fax: +1 (620) 840-2087 Email: info@eseintec.com - www.eseintec.com Carretera Córdoba a Veracruz Km 342, Zona Industrial, C.P. 94690 Cordoba, Veracruz, México Tel: (+52) 271 751 7350; (+52) 271 751 7396 www.intecmx.com - contacto@intecmx.com INTEC – INTERNATIONAL FEED & FOODS TECHOLOGIES S.A. DE C.V. Supported and Guaranteed with its own very complete and equiped Laboratory with latest Technologies

International Aquafeed - May 2024 | 21

HOW WE CAN HELP WITH YOUR NEXT PROJECT

How nutritional feed additives can support

Shrimp Gut Health

by Yechiam Shapira, Technical and Professorial Services, Phibro Animal Health, Israel

Over the last decade, we have seen a significant growth of the global shrimp industry. Total imports in 2022 were 3,248,338 tonnes (Van der Pijl, 2023), with additional production in China estimated at 1,487,501 tonnes (Fu-Chi, 2023).

China and Vietnam (total 945,791 ton) and the US (837,622 tons) absorbed most of the growth in shrimp production. Ecuador has seen a compound annual growth rate (CAGR) of 17 percent from 2012 to 2019 and a very significant CAGR of 25 percent from 2020 to Q2 2023 (Villarrea, 2023).

Today, shrimp production is challenged by several problems that affects its’ growth worldwide. A Global Seafood Alliance 2022 survey that was presented to industry stakeholders mentions the most relevant challenges as: feed cost, market prices, diseases, and broodstock quality (Nikolik, 2022). Therefore, understanding the main environmental, nutritional, and operational factors that affect shrimp health may support the global efforts for promoting sustainable shrimp aquaculture.

Among the challenges mentioned above, shrimp health has the dramatic effect on the global industry. Asche (2021) evaluated the impact of disease outbreaks on the shrimp industry and concluding that the presence of disease increases the breakeven price significantly, and thereby increases the probability of losing money as well as increasing the risk.

To meet the growing consumption demands of the future, the focus on shrimp health is increasing, and more specifically how optimizing the functions of the gut can produce a more healthy, robust and profitable shrimp.

What is a healthy gut?

The shrimp digestive tract, and the digestive tract of that of all Crustacea, is made up of three sections (Holt, 2021). The foregut, containing the oesophagus and the two chambered stomach; the midgut; which begins at the junction of the hepatopancreas and traverses the length of the cephalothorax and the majority of the abdomen; and finally; the hindgut, containing the rectum and anus. These regions of the gut differ in their cell structure and function (Ceccaldi, 1989).

For shrimp, a healthy gut comprises various elements which include a robust intestinal structure and morphology, and efficient production of digestive enzymes. This allows optimal digestion and absorption of important nutrients. Also, an active non-specific immune response will promote the ability to eliminate invading pathogens such as viruses, bacteria and fungi, improving survival rates and productivity. A balanced intestinal microbiota can support the shrimps’ ability to survive, grow, and develop.

The benefits of a healthy gut in shrimp aquaculture:

Digestion and absorption of nutrients

The digestive tract is responsible, for many animals, and crustaceans in particular, for the nutritional function (Ceccaldi, 1989). This function includes ingestion, transit of nutrients, mechanical digestion, chemical and biochemical hydrolysis, cellular absorption, and transfer of excreta in the digestion tract. The lumen of the digestive tract is considered to be exposed to the external environment. The lateral wall of shrimp digestion tract is covered, in its fore and hind parts, with complexes of chitin and proteins which are removed at each molt with the exoskeleton. Another original aspect of the shrimp digestive tract relies on the fact that most reserves of the animal are accumulated here, and they are utilised at each inter-molting cycle. Optimal digestion and absorption of nutrients can lead to improved Feed Conversion Ratio (FCR), yield and better growth performance.

A balanced immune response

The shrimp non-specific immune system employs several hemolymph-borne factors in its fight against infection (Sis, 1992). Most of these factors are inducible, although they have no specific activity or memory. These factors serve to immobilise and agglutinate invaders as well as to sensitise them to phagocytosis. Both hemagglutinins and bactericidins have been identified in shrimp hemolymph. The agglutinins are protein molecules which play a role similar to that of antibodies. They also serve as opsonins and display some degree of binding specificity. Studies have also identified lectins involved in the immune response. These inducible hemolymph components are absorbed onto the surface of gram-negative bacteria where they enhance phagocytosis and the production of bacteriolysins and agglutinins. The carbohydrate receptors to which they bind are common ones, explaining their nonspecific response. Optimising the non-specific immune response in shrimp can reduce the impact of disease challenges and ultimately improve survival rates, and therefore, production yield.

Gut health can influence shrimp immunity

A function of gut epithelial cells is to act as a physical barrier against pathogens, and a healthy gut is composed of epithelial cells that are tightly joined together to form a protective layer.

A healthy gut microbiome plays a crucial role in shrimp immunity by competing with pathogenic bacteria for space and nutrients, producing

22 | May 2024 - International Aquafeed

antimicrobial compounds, and modulating the immune system mainly by stimulating the production of antimicrobial peptides, enhancing phagocytosis, and regulating inflammatory responses.

The gut-associated lymphoid tissue (GALT) contains immune cells, such as lymphocytes and macrophages, which are responsible for detecting and eliminating pathogens.

The gut plays a multifaceted role in shrimp immunity, encompassing physical, microbial, and immunological aspects. Maintaining gut health through proper nutrition, environmental management, and disease prevention strategies is essential for promoting shrimp health and productivity.

The role of functional feeds in optimizing the gut health

In response to the global increase of intensive shrimp farming, the shrimp feed industry has been developed using several strategies (Mansour, 2022). Among these strategies, feed additive supplementation is one of the most important industries that has gained great importance for several shrimp species as growth promoters, immunity enhancers, and an alternative strategy for fighting disease (Sharawy, 2022). Common feed additives are astaxanthins (Goulin, 2024), β-glucans (Huifeng, 2019), organic acids (Wangquan, 2017), probiotics (Bacillus subtilis) (Zokaeifar, 2012) and many other natural herbs like rosemary, oregano and essential oils.

Among the natural feed additives, saponins are one of the major groups that are used in the last decades of shrimp culture. Saponins, widely found in plants, contain either a steroid or triterpenoid aglycone to which one or more sugar chains are attached (Oda, 2003). In addition, saponins have the potential to act as prebiotics by influencing gut microbiota and promoting the

growth of beneficial bacteria (Hierro, 2008).

Saponins as beneficial additives

Saponins from the Quillaja saponaria tree and Yucca schidigera plant have been shown to have immunomodulatory, anti-inflammatory and antioxidant properties and may help to modulate the intestinal microflora. In addition, these specific saponins can increase cell membrane permeability, activate digestive enzymes and improve protein retention. Bo-Kun (2008) showed that Pacific White Shrimp (Liptopanaeus vannamei) that had been immersed in seawater containing 0.5 mg/l saponin showed increased resistance against Vibrio alginolyticus with a concomitant increase in phagocytic activity and clearance efficiency to V. alginolyticus. Martínez -Cordova (1998) evaluated the effects of Pacific white shrimp fattening rations containing Yucca schidigera extract, concluding that the additive has a positive effect in the quality of the water as well as in the production of the shrimp.

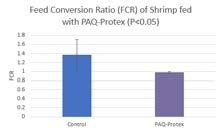

In addition, Hernandez-Acosta (2016) tested the inclusion of Yucca schidigera and Quillaja saponaria extracts in juvenile shrimp (L. vannamei) feeding with up to 2.0 g of saponins per kg of feed. The final average body weight and feed conversion ratio from shrimp feeding with 1.0 and 2.0 g of saponins per kg of feed had a significant improvement compared to other treatments.

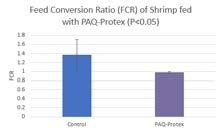

PAQ-ProtexTM –a natural feed additive

Sourced from specific species of Quillaja saponaria trees and Yucca schidigera plants, PAQ-Protex is a hundred percent natural nutritional specialty product, a proprietary blend of triterpenoid and steroid saponins and polyphenols, also known as flavonoids. However, not all saponins are the same. The saponins and polyphenols in PAQ-Protex have been shown to produce meaningful changes in the digestive tract, supporting optimal gut health and immune function in shrimp and fish.

Increasing the gut surface area and activating digestive enzymes such as lipase and protease can lead to increased nutrient absorption, feed efficiency and production yield.

Moving to intensive shrimp cultivation requires optimal design of the culture system: origin of the post larvae’s, biosecurity, water quality, operations, feeding, feed quality and functional feed additives. The challenge for the shrimp in these intensive conditions is to maintain optimal health status through good gut health. By adding PAQ-Protex, these goals can be achieved – improving the guts’ ability to function in the digestive track, and in addition, supporting immunity to maintain a good health status.

Figure 1: Control - Grade 0 (low level intestinal folds)

International Aquafeed - May 2024 | 23

Figure 2: PAQ-Protex - Grade 4 (high level of intestinal folds)

A new feed solution to mitigate EHP prevalence in shrimp

by Stephane Frouel, Julie Castier & Maxime Hugonin, miXscience, France

Aquaculture is a complex industry with multiple variables that strongly impact its performance. Among these, sources of stress, disease outbreaks and occurrence of new pathogens such as parasites are a huge threat.

Enterocytozoon hepatopenaei (EHP) is a microsporidian parasite that was first characterised in the black tiger shrimp Penaeus monodon in 2009 in Thailand. EHP is restricted to the shrimp hepatopancreas (HP) and its occurrence was usually given scant attention because of the overwhelming focus on some other diseases, such as early mortality syndrome (EMS) and white faeces syndrome. However, although EHP does not appear to cause high mortality, it is associated with severe growth retardation and depressed feed conversion ratio (FCR) in shrimp, leading to economic losses for the farmers who may need to resort to an early harvest.

To date, no reliable and sustainable solutions have shown real efficacy on the reduction of impact of EHP in shrimp. The aim of the current research at miXscience (France), is to design a specific solution against EHP in shrimp aquaculture. Efficacy was demonstrated from the laboratory to the field, focusing on the reduction of germination of EHP spores and its associated effect on shrimp performance. Complementary studies have been performed to explore, by

microscopy, the fine mechanisms of action of the solution and demonstrate how this new product disturbs the EHP spores.

A reminder: The EHP cycle in shrimp

The life cycle of this microsporidian parasite can be divided into three phases: the infective, the proliferative and the sporeforming phase (Figure 1).

Figure 1. Illustration of Enterocytozoon hepatopenaei (EHP) infestation cycle.

Adapted from Chaijarasphong et al., 2021

Figure 1. Illustration of Enterocytozoon hepatopenaei (EHP) infestation cycle.

Adapted from Chaijarasphong et al., 2021

24 | May 2024 - International Aquafeed

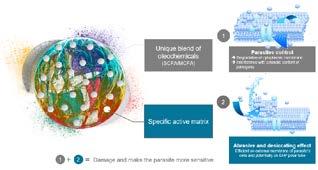

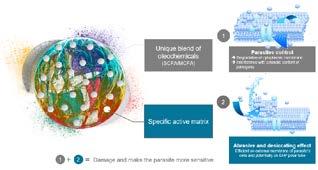

Figure 2. Illustration of the mechanisms of action of the tested product

The infective phase is the only phase that can survive without the host since spores are outside of the host’s cells in a dormant and more resistant form. Once in the host, the dormant spore will become an infective one through the key phase of the cycle: the germination. This phase is notably marked by the expression of an essential tool for the spore to replicate: the polar tube.

Thanks to it, the germinated spore will puncture the plasma membrane of the host’s cell, releasing sporoplasms (infectious material) inside the cytoplasm of the cell. The sporoplasms start to replicate in many copies which are released into the environment after killing the cells, and eventually infect other shrimps.

Since EHP has an internal phase during which spores enter host’s cells, it is important to ensure that the parasite is inhibited from host cell entry during its external phase when spores are free, non-protected and before the emergence of their polar tube. This is a fundamental point when deciding on recommendations for application of this new biosecurity tool.

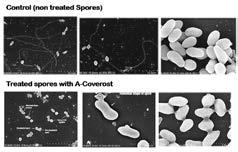

A specific solution designed to reduce the EHP load and its impacts

Laboratory and field trials demonstrated that a feed solution (A-Coverost, MiXscience) based on an innovative blend of oleochemicals associated to a specific active matrix (Figure 2) significantly reduces the capacity of EHP spores to germinate and express the polar tube directly linked to their capability to be infective. This effect clearly impacts the final EHP load in hepatopancreas, impacting the whole infection dynamic in the pond/farm and helps to maintain good shrimp performance to reach commercial sizes.

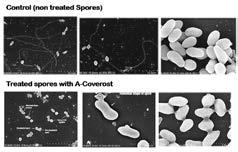

In vitro results

At the laboratory scale, the EHP spores used were purified according to a standard protocol developed by the center (Aldama-Cano et al., 2018). The purified spores were aliquoted and incubated with the experimental product (A-Coverost) for 30 minutes at room temperature (27°C) in Eppendorf tubes and a total volume of 1mL per reaction. The effect of the product on germination and spore viability was measured by microscopic observation after a staining step with phloxine. The germination rate or percentage of spore extrusion was calculated from the number of spores extruded (or germinated) out of the 100 spores observed.

Results showed that A-Coverost significantly reduced (>60%) the germination rate of EHP spores. It has been expressed by a lower expression of polar tubes visible under microscope. This trend has been observed in the two consecutive trials demonstrating a certain robustness of the efficacy of the product (Figure 3).

Complementary studies involving scanning electron microscopy (SEM) coupled with epifluorescence microscopy (and in

Join the fish revolution

Phileo’s probiotics and active yeast fractions are designed for hatcheries and growing farms to support health, feed efficiency and growth performance . Our sustainable solutions bring innovative responses to fishmeal reduction stakes and environmental challenges. Act with nature for animal care.

Figure 3. Germination rates of spores (%) – Results from two consecutive tests with two different EHP batches

Visit our new website www.phileo-lesaffre.com International Aquafeed - May 2024 | 25

particular with markers of cellular integrity and viability) demonstrated the fine mechanisms of actions of the products to explain how the it disturbs the EHP spores and their germination.

These involved the evaluation of the direct effect of A-Coverost tested at 2, 4, 6 and 8g/L on EHP purified spores. Monitoring by SEM allowed us to understand the impact of the product (tested at different dosages) on the morphology of the spores, their ability to germinate and therefore their potential in infecting shrimp. In parallel, a marking with acridine orange (AO) and propidium iodide (PI) was implemented to measure the impact on spore viability.

Acridine orange (AO) is a red/orange-fluorescent dye used in epifluorescence microscopy and flow cytometry. When AO is used, it helps to detect DNA denaturation or to detect DNA damage (Darzynkiewicz et al, 2004 and Evenson et al, 1980).

Propidium iodide (PI) is a red-fluorescent dye. The use of PI is not exclusive only to live cells, it is also commonly used to detect dead cells in a population. Propidium iodide is used as a DNA stain in flow cytometry or epifluorescence to evaluate cell viability. Propidium Iodide is not membrane-permeable, making it useful to differentiate necrotic, apoptotic and healthy cells based on membrane integrity (Suzuki et al, 1997).

SEM and Epifluorescence microscopy studies

The EHP spores used were purified according to a standard protocol developed by the center (Aldama-Cano et al., 2018). The active purified spores (1x107 spores) were mixed with A-Coverost at the final concentration of 8g/L. The solutions were incubated for 120 minutes at room temperature (25-26°C), before being subjected to centrifugation at 10,000rpm for 5 min.

The treated spores were washed twice with 1X PBS (phosphatebuffered saline) and 10 µL were placed on a round coverslip which were then placed in a 24-well plate and allowed to air dry. The dried coverslips were fixed with 2.5% glutaraldehyde in 0.1M buffer incubated at 4°C overnight. Treated spores on coverslips were washed twice with 0.1M PB for 10 min each and fixed with 0.1% osmium tetroxide in the dark. Spores were washed twice with 0.1 MPB for 10 min and dehydrated with alcohol in series, drying with liquid CO2, and spray coating with gold. The morphology of EHP spores was examined using a Hitachi SU8010 scanning electron microscope.

Acridine orange (AO) and PI were diluted in PBS. The two products were mixed at a ratio of 1:1 and 3μL of AO/IP mixture were mixed with approximately 20μL of spore sample. The solution was placed on a slide then analyzed under an epifluorescence microscope

The In vitro results indicated the following bullet points :

• The A-Coverost product interacted with the membrane of EHP spores, causing disruption; abnormal morphology of the spores was observed and they were no longer able to germinate (which confirmed our previous results) and tended to clump together (Figure 4).

• The A-Coverost product induced a loss of sealing of the spores, which involved the marking of the DNA with PI and therefore a reduction in the viability of the spores. We observed a very marked dose effect with an average mortality of the spores of 73% when they were exposed to a dose of A-Coverost of 4g/L and a mortality of 95 and 97% when the spores were respectively exposed with doses of 6 and 8g/L (Figure 5).

In vivo results

Based on the previous results, the product has been tested directly in shrimp to confirm its observed potential at lab scale.

Experimental shrimp studies were performed at the BIOTEC facilities (Thailand) and at SHRIMPVET facilities (Vietnam). Following the laboratory tests, the experimental product A-Coverost was incorporated either by top coating or directly during the pelletising process. The recommended dose was 4 kg/ tonne of feed for both applications.

The trials were set up as a completely randomised designs in which two groups (Challenged CTRL and Challenged A-Coverost) were compared (Table 1). Each tank contained at least 200 shrimp with an initial weight of about 3g (water volume 320L; salinity 20ppt) and shrimp were pre-fed with the indicated feed for a pre-feeding period of seven days. On day 7 of feeding, 12 shrimp from each group were collected for the detection of EHP level by qPCR. Each group had three replications.

Determination of EHP load

Shrimp hepatopancreas was collected individually from 12 shrimp per tank for DNA extraction. DNA template for qPCR was obtained by homogenising hepatopancreas tissue in DNA lysis buffer (Munkongwongsiri et al., 2021). The 20µL of qPCR reaction mixture contained 1x SYBR green-qPCR, 0.2 µM SWP primers and 10ng of DNA template. To calculate the EHP load, the samples were compared with the standard obtained from plasmid DNA

a concentration of 1.0x106 copies/µL.

Parameters studied

The shrimp growth performance indicators including initial weight, final weight, weight gain, average daily growth (ADG), feed conversion ratio (FCR) and survival rate were determined.

at

Figure 4: SEM study of the impact of A-Coverost on the germination and morphology of EHP spores

26 | May 2024 - International Aquafeed

Figures 5: Top = Epifluorescence microscopy study of the impact of A-Coverost on the viability of EHP spores. Bottom = Dose-response effect for A-Coverost concentrations ranging from 0 to 8g/L

The in vivo results indicated the following bullet points :

• The shrimp trials, carried out from 2021 to 2023, notably with EHP cohabitation approaches (EHP infection by cohabitation model (Salachan et al., 2017)) confirmed the effect of the product under different contexts and breeding conditions: country, Vietnam versus Thailand; shrimp genetics; EHP strains; food, pond conditions, etc.

• A-Coverost, applied at 4 kg/tonne of feed, has the same efficacy when applied directly by pelleting or indirectly by top coating (Figure 6).

• Based on the cycle of infection of EHP, the preventive approach remains our recommendation to ensure that spores are killed or inactivated during their free phase out of the hepatopancreas cells. The sooner is the application, the better is the result. Our trials showed that it’s more pertinent to apply

After the pre-feeding period, shrimp from each group were transferred to three aquaria with 35 shrimp each (water volume 30L; salinity 20ppt) and placed into three cohabitation tanks (water volume 300L; salinity 20ppt) for induction of EHP infection by cohabitation model (Salachan et al., 2017).

A number of 10 EHP heavily infected shrimp, determined by a nested PCR method were added into the challenge tanks. During cohabitation, shrimp were continuously fed with the indicated feed formula. On day 17, 12 shrimp per basket were collected for the detection of EHP level by SWP-PCR.

Experimental timelines are described in Table 1.

The shrimp trials confirmed the ubiquitous potential of the product to control EHP infestation in shrimp.

We understand that a direct interaction between the product and the EHP spores during their extracellular phase is a prerequisite to initiate the inhibition process and to kill the spores. This will slow down the whole dynamic of infection to control the EHP load and allow the shrimp to reach commercial sizes.. Prevention remains/ is then the key approach.

However, it is clear that a single solution is not sufficient to fully eradicate EHP occurrences.

A-Coverost needs to be used as a tool in a complete management program based on biosecurity practices to implement at the farm level in order to limit the presence of the

International Aquafeed - May 2024 | 27

Figure 6. Summary of trials results conducted in Thailand (2022-2023) where A-Coverost was applied by top coating application and in Vietnam (2021) where A-Coverost was applied by pelleting application

Circular Economy

Transforming Aquatic Byproducts into Premium Nutrition

by Costa Skotidas and Jyothsna Nelloolichalil, International Aquafeed, UK

We are a point where we need to rethink our food system globally and the impact it has on the environment. Today, sustainability is an imperative that companies need to fullfill rather than an option. There are a few many models the industry follows to minimise the impact it has on the nature One such model is circular economy. The circular economy model for food products focuses on the reuse of “waste” byproducts, such that the valuechain outputs become inputs for other value-chains. For example, fish processing produces fillets as well as leftover scraps, skins and trimmings of fish. These scraps can then be used as ingredients in pet feed. The circular economy also encourages valorising byproducts that might otherwise be disposed of and reusing or recycling other items at the end of their useful life.

Norway based feed company biomega® is a key player in this field. Biomega Group AS (biomega®) is a producer of premium Norwegian salmon-based innovative ingredients, both for premium petfood and human nutrition. biomega®’s business model is fully sustainable and uses proprietary biotech to transform high quality raw material into premium food and petfood ingredients. In its modern food grade biorefineries, biomega® produces salmon oil and peptides using continuous enzymatic hydrolysis. biomega®

continuously invests in R&D to ensure best-in-class technology and respond to customers’ needs, including traceability and sustainability.

The methodology

The cornerstone of their approach lies in the gentle enzymatic hydrolysis process, which preserves the integrity of nutrients while ensuring precise separation of components.

“Our philosophy is centered around treating raw materials with utmost care, employing low temperatures and enzymatic reactions to achieve optimal results,” Stig Petersen, CEO of biomega®, explained. “Whether it’s salmon offcuts or visceral parts, our goal is to maximize the nutritional value through meticulous refining. It is critical to get the off-cuts and viscera into the biomega® production cycle as quickly as possible so that they remain fresh. This will ensure the limited degrading of the natural quality of the ingredients.”

“When we investigate the rest remains of salmon, it has a matrix consisting of protein structures and bones that hold the fats. Some of these proteins are water soluble, and some are not. Those that are water-soluble can be separated and when concentrated you have a liquid fraction featuring 60 percent of these proteins. This is very easy for an animal to digest while offering a nutritional boost, coupled with a good taste and smell that will stimulate appetite. We are doing some studies in partnership with the University of Illinois, where we will be looking at the specific impacts on animals using

28 | May 2024 - International Aquafeed

these products, in comparison with other sources”, he explains.

Petersen elaborated on the customisability of biomega®’s reactors, which are tailored for specific uses and maintain strict control over the refining process. This attention to detail not only ensures product consistency but also underscores biomega®’s commitment to quality and precision.

In addressing sustainability challenges, Petersen outlined biomega®’s multifaceted approach, which includes decentralised production facilities to minimise transportation emissions and a concerted effort to utilise as much of the fish as possible for human consumption. By upcycling fish byproducts and focusing on resource efficiency, biomega® aims to reduce its carbon footprint and contribute to a more sustainable aquaculture industry. Along with this, biomega® takes pride in how they handle their raw materials as well.

Petersen elaborates, “We have designed production, that we now have proven, can be positioned at different locations. So instead of moving all our raw materials to one main factory, we have now set up a factory where we have a sufficient volume of raw material available within a few hours’ transportation. That is supposed to control quality, but also that we reduce the road transportation and energy to remove water.”

…and the outcomes

The company delivers high quality products to the aquaculture, petfood and human nutrition sectors. biomega® produces and sells salmon peptides and collagen in powder form and salmon oil in liquid form under trade names SalMe Peptides, SalMe Collagen Peptides and SalMe Salmon Oil for human nutrition, and liquid and powder products under the Salmigo® brand name that are high in protein for the petfood market.

Animal proteins and fats as sustainable feed materials

At PCE, precision engineering meets custom design to produce dies that fit all pellet press models. Our dedication to quality ensures your operations are seamless, efficient, and high-quality. Our dies are essential for top-notch performance in feed, biomass, or any material pelleting.

Moving the salmon through the value added process

biomega®'s patented enzymatic hydrolysis process

Moving the salmon through the value added process

biomega®'s patented enzymatic hydrolysis process

MAXIMIZE YOUR PELLET PRESS’S POTENTIAL WITH TAILOR-MADE DIES.

biomega biorefinery in Skaganeset, Bergen, Norway

Elevate your pellet production now. Visit www.pce.eu www.pce.eu www.ge-pro.de

For more information, visit us online: International Aquafeed - May 2024 | 29

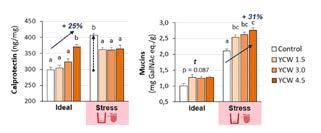

biomega® was founded in 2000 on the premise of advancing innovative biotechnology to release the full nutritional and functional value of side streams from the salmon industry. And later in 2002, it built the world’s first biorefinery with its patented continuous enzymatic hydrolysis process in a building owned by Sekkingstad AS and in 2012, they build their own factory next to it. Later in 2021/2022, they opened their new biorefinery in Hirtshals, which was built with a focus on energy efficiency and with the potential for industry symbiosis among the surrounding production sites in mind.