Natural egg powder Integrated project delivery in petfood manufacturing - Magnetic Separation - Silkworm protein - The diet of the pet rabbit September 2022 www.internationalpetfood.com www.perendale.com Download you online version:

IF YOU CAN THINK IT WE CAN PACK IT

Watch

at: www.the-packaging-group.com/videoportal

www.the-packaging-group.com

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany ·

our sustainable packaging solutions

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor

Joe Kearns joek@perendale.com

Nutrition Editor

Prof Simon Davies simond@perendale.com

Editorial team

Andrew Wilkinson andreww@perendale.co.uk

Shannon Parsons shannonp@perendale.co.uk

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero

Tel: +44 1242 267700

cristinaperendale@gmail.com

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Design PetFood Magazine

Cristina María Roldán Otero

Tel: +44 1242 267700

cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

September 2022

REGULAR ITEMS

9 Industry News

Industry Profiles

30 Training

31 Troubleshooting

32 Production focus

36 Industry Events

39 The Market Place 40 The Interview

42 Industry Faces

6 Roger Gilbert

7 Joseph P Kearns

8 Professor Simon Davies

COLUMNS

International Petfood - Volume 4 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 28

FEATURES 12 Natural egg powder 16 Integrated project delivery in petfood manufacturing 20 Magnetic Separation 24 Silkworm protein 26 The diet of the pet rabbit

Rabbits as pets are one of the most suitable pets for a young family

In the UK alone it is estimated that we have 900,000 rabbits kept as pets. There should no surprises here as they are intelligent, responsive and take a great interest in their surroundings.

However, they are not a regular consumer of pelleted or extruded feeds.

Publisher – International Petfood

Their main diet consists of fibrous materials, such as grass and hay, which helps keep their digestive system working properly. We also know that feeding pelleted feeds must be managed properly as they may well substitute pellets for their normal diet of grass and hay and compromise their overall wellbeing.

Therefore, it is advisable to follow feed manufacturers recommendations.

And that is where International Petfood magazine can help. We have included reference to rabbits in Professor Simon Davies’ editorial column and our own staff writer, Andrew Wilkinson, contributes a thoughtprovoking and informative feature on rabbits and their diets. We also present a feature on the Farm brand from Estonia, a company producing rodent and reptile feeds as well as feeds for rabbits.

Elsewhere in this edition

Our magazine this month carries other features on the benefits of natural egg powder in pet diets submitted by Carlos Javier Ucero Serrano and Arent Arnout of Actipro, Spain. They look in detail at the functional and nutritional aspects of this ingredient for inclusion in petfoods.

Our last edition

Did you miss our August 2022 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

Welfare in the ornamental fish trade by Megan Jones, University of the West of Scotland

Keeping ornamental fishes as pets is incredibly popular, with the ornamental fish trade estimated to be worth annually between US$15 and US$20 billion globally. The enthusiasm for keeping pet fishes is increasing, with an increase of 14 percent in the trade since the early 1970s.

It is well established scientifically that food fish aquaculture can expose fishes to conditions that can compromise their welfare. Due to the extended length of the acquisition process within the ornamental trade, there is the potential for welfare to become increasingly compromised at each phase.

To read more, go to:

https://issuu.com/international_aquafeed/docs/ipf2208_w1/26

MAGLINK: https://mymag.info/e/1597

Industry Profile – Hill’s Pet Nutrition

In order to support the global growth of its Hill’s Pet Nutrition business, its parent company Colgate-Palmolive Company plans to purchase three dry pet food manufacturing plants in the US.

The acquisition of the plants from Red Collar Pet Foods for US$700 million, includes sites in Orangeburg, South Carolina; Clinton, Oklahoma

Another joint submission is by Matthew Lantzy and Chris Prokop at CRB in the USA, which continues to review the survey of the US petfood industry that may have significant findings and recommendations for a wider, worldwide petfood audience.

We have been talking a lot about insect meal as a protein source in recent months, and now we have a further insect meal wanting to join the revolution with the production of protein from the humble silkworm.

Insect biologist, Fabiola Neitzel of Prombyx, Germany takes us on a journey in a feature that outlines the history of the silkworm and the potential contribution it can make to our petfood protein sources. It’s a fascinating and informative read.

In addition to innovative new petfood ingredients, we also look at staff training through the eyes of the UK’s Guttridge apprenticeship program before highlighting new equipment and other products for the production of petfood in our Production Focus section.

There’s a lot to be gleaned from this edition and our Events Section should not be missed.

We report on recently held events that related to the production of petfoods and also identify and preview those coming up.

I hope you enjoy this edition. And once again you may like to subscribe by visiting our subscription page at: https://store.magstand.com/petfood where you can elect for either our digital delivery, via our App, the printed version mailed directly to you or a combination of both.

and Washington Court House, Ohio. The three additions to the company’s portfolio will be integrated into Hill’s global supply network to produce dry pet food for Hill’s Science Diet and Prescription Diet brands. The purchase agreement also includes the transfer of the approximately 350 employees involved in the dry pet food operations.

To read more, go to:

https://issuu.com/international_aquafeed/docs/ipf2208_w1/34

MAGLINK: https://mymag.info/e/1598

The interview – Alexander Döring, Secretary General, FEFAC Alexander Döring graduated as an Agricultural Economist at the University of Bonn in 1991. He has been the Secretary General of the European Feed Manufacturers Federation (FEFAC) for over 25 years. Through his work at FEFAC he has been a regular participant to European Commission Advisory and Civil Society Dialogue Groups; EFSA stakeholder platforms meetings; EC seminars and training workshops on Feed Hygiene; EU- TAIEX workshops on Feed Safety Management as well as meetings of International Organisations including Codex Alimentarius, FAO, OIE and IFIF.

To read more, go to:

https://issuu.com/international_aquafeed/docs/ipf2208_w1/40

MAGLINK: https://mymag.info/e/1599

Roger Gilbert

THE PUBLISHER

6 | September 2022 - International Petfood

To start I will say that I never had a cat, we only had dogs due to allergies to cats in the family.

Ranging from the most pristine indoor cats to the barnyard mousers and everywhere in between, the cat is a most unusual animal that operates in many different fashions.

As a result of this there are as many different types and styles of cat food available. Generally speaking, the two major categories are wet and dry cat food.

Joseph P Kearns Editor, International Petfood Magazine

Wet cat food primarily being canned are also available in pouches and other forms of delivery. Typically, wet cat foods are higher in moisture, lower in carbohydrates and very palatable.

However, some consider them smelly, expensive and to have a short shelf-life product once opened. I suspect the portion sizes are so small that once opened they are consumed but this also increases cost which is considered the major disadvantage in wet cat foods.

Dry cat foods are more affordable and have a long shelf life, but they are high in carbohydrates and lower in moisture. A good clean source of water is essential for cats and the wet cat food has advantages for cats that need more water as in nursing, pregnant and young cats.

Considerations based on the cat and the owner’s affordability tends to result in the product used, with some using both wet and dry for their feeding regime.

Wet vs dry cat food

Cat food sales are second only to dogs worldwide and in the USA. It is reported that over US$12 billion in cat food sales occurred in 2021. A steady growth over the years as lifestyle conditions have people considering cats as pets.

Wet cat foods are generally prepared canned or pouched retorted as in any canning procedure for elimination of bacteria under specific conditions based on what exactly is in the container with water being the main ingredient on a percent basis.

Dry cat foods predominately extruded contain more cereal grains or carbohydrates resulting in the dry cat foods as we know them. However not all extruders are the same and many different possibilities exist in the industry.

In general, expanded cat foods do have a minimum starch or carbohydrate level needed for the process of expansion, about 20 percent (give or take) based on the rest of the formula. Extruders with superior preconditioning can handle higher meat and fat levels and make very good quality shapes and kibbles.

Single screw extruders are limited at a lower level then twin-screw extruders in these cases but overall, I expect higher tonnages are produced on single screw extruders worldwide.

How our industry responds to issues

Referring back to articles in previous editions, Isabella Corsato Alvarenga discussed her studies on how to modify the extrusion

parameters to adjust the starch properties during extrusion for pet foods.

Another article revealed how newly developed extruders at Wenger were demonstrated where the elevated level of meats (and fats if desired) was possible. Elevated meats mean more moisture and lower carbohydrates as other sources of ingredients which include many vegetables and legumes offering possible binding ingredients of health choices.

These are a few examples of how the industry responds to issues discussed within the industry. There are other possibilities out there where proteins are being combined into meat like products from wheat gluten, soy isolates or concentrates, legumes and others including actual meat products to finalize possible formulations.

All types and styles of cat food are being made including the proactive and health condition cat foods now available for hairballs, skin, overweight and stomach conditions to mention a few.

The most efficient method of operating the dryer

Production of cat foods of the dry expanded style historically were produced at a lower production rate by about 20 to 25 percent due to the higher protein content and the shapes associated with cats being nibbling feeders. They tend to like smaller bits with appendages such as star shapes where the chew off the points of the stars or similar shapes.

Also, cats prefer a product of this style with higher energy inputs or a slight mallard reaction in the kibble. Having mentioned the lower production rates in the extruders resulted in a possible change in drying characteristics. This has been an area where dryer running conditions are often not changed when switching from dog food to cat food production, for example.

The total amount of water needed to be removed is reduced therefore energy usages can be improved if the dryer is adjusted. Simply stated the volume of air exhausted can be reduced increasing the amount of water per volume in the exhaust air, the most efficient method of operating the dryer.

This situation occurs when the maximum amount of water is in the exhaust air, but it is not raining or releasing water in the ducting. It used to be as simply as closing the exhaust vent gates proportionally along the dryer exhaust ducting but this adjustment was a guess.

Now the use of computers and added controls such as VFD driven exhaust fans, motorised exhaust gates matched up with wet bulb and dry bulb sensors allow for calculations and dryer condition modifications to take place quickly and efficiently.

Actually, dryer conditions should be modified for each product change for energy efficiencies.

THE EDITOR International Petfood - September 2022 | 7

Professor Simon Davies Nutrition Editor, International Petfood

‘What’s up doc?’

The healthy nutrition of the rabbit

One of the first pets I owned was a beautiful all white rabbit typically called ‘Snowy’. I think all white rabbits of my youth were called Snowy. I kept Snowy for many years and adored him.

However, in those days, animal nutrition science was in its infancy and scientific knowledge of the fundamental nutrition requirements of domestic animals and pets in particular was based on extrapolation of existing information on studies with small animals such as rodents like rats.

Pet rabbits have a mode of feeding and nutrition similar to their wild cousins and their nutritional needs compare favourably despite generations of selection and breeding for domestic strains. Rabbits are obligate herbivores and are physiologically adapted to only consuming vegetable/plant materials.

As such, they eat and digest plants, such as hay, grass, vegetables, and pellets. They also need plenty of highquality fibre to maintain healthy teeth (which continue to grow throughout their lives) and a healthy gut.

Feeding your rabbit the incorrect food or ration size can result in excessive weight gain, urinary and bladder problems, and often adverse dental health. The rabbit needs high fibre in the diet to stimulate a good digestive function overall and the caecum of a rabbit.

As a hind gut fermenter, the digestion system of a rabbit contains a rich microbiome of specialised microbes to assist in the degradation of cellulose, hemicellulose, pectins and all the other complex fibre classes constituting the cell walls of plants that would limit digestion in a strictly carnivore animal.

These bacteria also produce an array of short chain fatty acids that have localised function and can provide energy for intestinal cell metabolism for maintenance and replenishment. The role of the gut microbiome is at the heart of current nutritional research in companion animals.

It is imperative to mainly choose a superior quality hay product for rabbits as the main dietary component. This ideally will be dry in nature, possessing a sweet-odour, and free from grit, dust, and mould. Bespoke feeding hays are also available which provide a variety in flavour and nutrients. Rabbits can also enjoy the enrichment of being offered safe vegetables that may include asparagus, basil, broccoli, brussels sprouts, carrots, celery leaves, chard, and courgette.

It is important to avoid any plants that can contain toxins

and anti-nutritional factors to rabbits. Herbage such as hay or grass should make up around 60-80 percent of your rabbit’s diet, so they should have unlimited access to it. This can be fresh or dried grass, or meadow hay. These contain all the nutrients your rabbit needs while also grinding down their teeth to prevent overgrowing. A lack of fibre can promote painful spurs on their teeth which cut into their gums and tongue, making ingestion very difficult.

The amount your rabbit should eat relates to their breed, age, and size. An average-sized rabbit (around 2.5kg), should also have about 250g of fresh green vegetables and 60g of pellets. Pellets can be offered to supplement your rabbit’s food to ensure they receive a balanced diet. It is highly recommended to purchase high-quality pellets instead of muesli style foods that are mainly granular.

In fact, selection of muesli food is one of the most common mistakes by rabbit owners. The muesli style of feed encourages selective feeding, and your rabbit may not get all the nutrients they need due to specific preferences. Pelleting of fine and coarse ingredients offers much more stability for uniform intake of all nutrients and is a good balancer for the forage.

Also, there is a move to a more kibble format for rabbit concentrate feeds. It is the pellet or kibble level where the formulator and pet food manufacturers can support good rabbit nutrition and health by presenting a more complete nutrient dense accessory diet.

These products are unique, weight control formula assisting in maintaining optimum performance for both body maintenance and growth at the correct level for each stage. They often contain natural prebiotics for digestive health and are fortified with vitamins and minerals and essential fatty acids such as omega-3 for healthy eyes, skin, and coat. Additionally, natural antioxidants are also provided such as vitamin E and selenium to support the immune system.

There are studies of a substantial scientific basis reported in many peer-reviewed journals for defining the protein, essential amino acids, energy needs for the rabbit as awell as for vitamins and minerals. These are summarised periodically in the NRC National Research Council (US) data compilation for the nutrient requirements for all major animal species.

There is clearly a great interest worldwide in the nutrition and feeding of the humble rabbit as one of the most popular pets – and especially for children.

8 | September 2022 - International Petfood

New retail partnership for Karnlea marks its 100th

Karnlea has now secured its 100 th retail partner, five months after launching the UK’s first ambient bone broth for cats and dogs. This key milestone was boosted after the acquisition of Just for Pets as a new customer in April. The company has 21 outlets across the UK and emphasises natural products and ingredients.

The company has targeted independent retailers, using the expertise of shop staff to convey health benefits of their bone broth. The company’s founder Lara McCullough believes independent pet retailers are ‘key’ to influencing, educating and informing pet owners.

“We put independents front and centre our marketing strategy,” Ms McCullough explains. “Karnlea offers something totally new and we believe they are in the unique position as trusted retailers with expertly trained teams to convey our product’s benefits and help solve customers’ pet problems like skin, coat and digestive issues.”

Echoing her sentiments, Just for Pets Senior Merchandiser Leanne Blunn considers Karnlea the perfect fit for its stores.

“It’s great to be able to extend what we can offer our customers to assist the health and wellbeing of their pets,” she says. “With 100 percent natural ingredients, recyclable and sustainable packaging and off-the-shelf convenience, it made perfect sense for Just for Pets to showcase Karnlea to all customers, not just the one’s shopping in our raw department, so that more pets will benefit from it.”

Others backed Karnlea’s bone broth as a ‘must have’ product, among them Sammie Hunt owner of Redpaw in Plymouth.

“There are many reasons why pet owners should have bone broth in their cupboard: to hydrate their dog or cat on a hot day or before exercise, to supplement their diets and improve joint, skin and coat conditions and to provide a gentle food should their pet suffer from digestive issues or need to recuperate from sickness,” she explains.

“I am really excited about being able to stock Karnlea,” she adds. “The quality of the ingredients and the level of nutrients make it an ideal standby and unlike similar products, it doesn’t need to be frozen.”

In addition to brick and mortar stores, Karnlea is also stocking to online retailers in particular those specialising in products that offer health benefits. This includes Enzo’s Pet Pantry, which offers holistic and nutritional pet products to owners, and is the brain child of Vaneeta Bassi, who launched the company after investigating the products for her own dog.

“As a pet owner of a dog with health issues I can personally vouch for the benefits of the product. Enzo suffers from allergies, IBD, pancreatitis and hip dysplasia and Karnlea Bone Broth is perfect for helping me in managing all of his ailments as it is great for his joints, gut, skin and coat,” she comments.

“Its versatility is amazing, it can be given as a liquid, jelly and frozen, all of which appeals to even the fussiest of eaters. I’m grateful that I can now offer the same tried and tested benefits of Karnlea’s products to my customers,” she concludes.

Mondi’s investment to expand capacity of packaging plants

As part of a EUR€1 billion/ US$991.4 million investment programme to accelerate growth in sustainable packaging, Mondi is investing nearly EUR€65 million/US$64.4 million in three consumer flexibles packaging plants in Europe, in a move to meet growing consumer demand for sustainable petfood packaging solutions.

Work has already begun at the packaging plant at Mondi Korneuburg, in Austria, which includes new, stateof-the-art machinery and equipment alongside an expanded production area. This will lead to an increase in capacity and solidify the company’s position as one of the market leaders in pre-made retort stand-up pouches for wet petfood.

The company is also investing in advanced machinery at the plants

Mondi Halle and Mondi Steinfeld in Germany, to increase production capacity of sustainable pre-made solutions for petfood. The aim is to enable future growth in this area and support customers in their switch from non-recyclable packaging to more sustainable alternatives which include mono-material recyclable stand-up pouches and paper-based pre-made bags.

“We take pride in being an innovative, agile partner for our customers. With this investment, we continue to take the lead in packaging solutions that are sustainable by design, especially in the petfood industry,” explains Dirk Gabriel, COO Consumer Flexibles at Mondi. “This investment also supports our Mondi Action Plan 2030 sustainability framework which is focused on circular driven solutions, created by

empowered people taking action on climate.”

Mondi recently won the Swiss Packaging Award in recognition of their recyclable packaging, which is made of polypropylene based mono-material. Other companies are following in their stead, as Purina recently launched their ‘designed to be recycled petfood pouches,’ in recognition that to further advance sustainability in the petfood sector, packaging needs to be addressed.

“With these projects, we’re increasing operational efficiency and reducing our own energy consumption while also connecting our production network,” concludes Mr Gabriel.

International Petfood - September 2022 | 9 PETFOOD NEWS

Actor teams up with Jinx to ‘avenge’ unhealthy dog food

Petfood

brand Jinx announce that the actor, entrepreneur, and dog dad Chris Evans will play an active role in the business and creative direction of the brand.

Famous for playing Captain America in the recent reimagination of the Marvel Avengers franchise, his introduction to Jinx was first as a customer, after searching for a safer food brand for his beloved best friend, Dodger.

“I was thrilled to find Jinx – a food Dodger loves to eat and that I know is safe and healthy for him,” he says. “I’m excited to come on board and help grow awareness for the company so all dogs can have the highest quality food possible at an accessible price point.”

In his role, Mr Evans will be involved in the brand’s strategy and marketing campaigns, including a commercial campaign launching later in the year.

This is just the beginning as Jinx aims to be a single destination for all things relating to dog wellness. Jinx recently closed a Series A round of funding reaching over US$28M, allowing the company to expand its product portfolio to move beyond a direct-to-consumer model and bringing on high profile investors including Halsey, Odell Beckham Jr, Zachary Quinto, Trevor Noah, Lily Singh, NAS and more.

Jinx is redefining dog nutrition with better, healthier, and tastier food for dogs across the country, already available in over 2,000+ Walmart locations and on walmart.com. Every Jinx product has a transparent approach to ingredients; full of real, nutrient-rich superfoods, and free from preservatives or fillers.

Formulated by animal nutritionists and approved by certified veterinarians, Jinx’s rigorous vetting makes sure that dogs are getting the balanced nutrition they need, without anything they don’t.

They’re also expanding their audience in partnering with Evans: “We are thrilled to have Chris on our team. His entrepreneurship and his love for his dog, makes him a valuable addition to the Jinx leadership team,” says Sameer Mehta, Co-Founder of Jinx. “Our vision is to elevate the way we care for our dogs by providing premium, cleanlabel nutrition at an attainable price point.”

With this new addition to the team, Jinx has its short- and long-term focus set on making a high-impact difference in the lives of American dogs and their pet parents.

The full line of Jinx premium pet products includes all-natural kibble (US$10.88 – 45.88), limited-ingredient dental chews (US$8.97), slow-cooked jerky treats (US$4.98 – 9.48), and freeze-dried meal toppers (US$9.99).

Danish petfood brand launches insect & plant based dog treat line

NewDanish petfood brand Globe Buddy has now launched its first insect- and plantbased dog treat line. Globe Buddy Crunch is available in three recipes formulated with protein, fruits and vegetables.

Aligning itself with the UN’s Sustainable Development Goals (SDGs), Globe Buddy strives for sustainability in what it produces. ‘Insect Crunch’ is the company’s environmentally friendly, meat free alternative while Veggie Crunch is 100 percent vegan with vegetables and fruits and Spirulina Crunch, named after the algae spirulina, is also 100 percent vegan.

The new treats will be available for purchase from the company’s Shopify website, in addition through Amazon and select retailers. On top of this, the packaging for Crunch is plastic-free and fully recyclable.

“We want to inspire a sustainable pet life. Now we are giving pet parents a crunchy alternative to unsustainable, traditional meatbased treats,” explains Bjarne Gravesen Jensen, CEO and cofounder of Globe Buddy.

“We have recently started to offer our products via Amazon in Germany, France, Italy, and Spain. These expanding sales channels are helping Globe Buddy to meet the growing demand for premium and planet friendly products.”

A family-owned start-up, the company is looking towards the US market where cofounder of the company Palle Gravesen Jensen is based. The treats come after the launch of its first complete dog food product in 2021.

Globe Buddy also produces ‘Globe Buddy Blue,’ which is made from nutrient rich parts of salmon farmed responsibly in Norwegian fjords and uses upcycled salmon protein, providing dogs with a good source of protein and Omega 3 fatty acids.

PETFOOD NEWS 10 | September 2022 - International Petfood

Improve silo tightness.

Double Vertical Joint.

· Tightness is improved. Double sealing on both sides of the screws.

· Butyl rolls are supplied with double strip to improve assembly times.

symaga.com • +34 91 726 43 04 • symaga@symaga.com 50 million m3 built Projects in 145 countries Top Project worldwide Flexibility and adaptability A reliable team for a reliable project YOUR RELIABLE PARTNER

GRAIN TECH INDIA, Bangalore, 26-28 August, Stand K-9 VICTAM, Bangkok, Thailand 7 - 9 September, Stand 1670 VISIT US

Natural egg powder

A nutritional & functional ingredient for pet food

by Carlos Javier Ucero Serrano & Arent Arnout, Actipro, Spain

The relationship between human beings and animals has always been decisive for survival. What today are called companion animals were once defensive, hunting and working animals being crucial for the survival of our species.

In exchange for their faithful service, we humans provided these noble animals with food and shelter. This has not changed to this day and the premise of taking care of their well-being is still there. Nowadays only the way how has changed, evolving from intuitive domestic nutritionists to professional formulators.

Consumption habits and international trade have created a complicated conjuncture in which these professional formulators must balance the ingredients very well to provide the necessary nutrients, optimising the cost of the formulation, that is, choosing the raw materials wisely.

Within the immense, although not infinite, variety of ingredients available, the egg has an exceptional value thanks to its dual nutritional-functional nature. Being an old acquaintance for the human being, the egg has historically been one of the basic foods in the diet.

This article will explain the main reasons why the egg should be an essential ingredient in petfood formulation.

Natural, secure & sustainable

Powdered egg has been shown to be a highly safe ingredient to be included in formulations. Its production process includes different physical steps such as pasteurization and spray drying, in which pathogens are inactivated. Indeed, eggs are not suitable for raw feeding as this may cause foodborne diseases like

salmonellosis (Keerthirathne, 2017).

Moreover, consumption of raw eggs can cause egg white injury or biotin deficiency due to the anti-nutritional effect of active avidin, which is a biotin-binding protein present in raw egg white (Bolnave, 1977).

FEDIAF defines natural substances in petfood as those derived from plant, animal, microorganism or minerals to which nothing has been added and which have been subjected only to such physical processing as to make them suitable for petfood production and maintaining the natural composition, what is the exact definition of egg powder products. This makes egg products perfect for ‘natural labelled products,’ a very popular trend nowadays.

We do not want to forget to comment on two aspects that are becoming every day more important on the international scene: sustainability and circular economy. Egg by-products from the food industry are being collected and used for producing the Actipro egg powder range, which would otherwise be disposed of with severe environmental damages as a result.

Formulation flexibility

As we mentioned, the formulator must wisely choose and combine the ingredients used to achieve a homogeneous and replicable formula. Thanks to the variability of egg products in the Actipro® range, the formulator has different ingredients according to their fat and protein needs.

Thus, in the this range we can find powdered eggs with different protein/fat ratios, depending on the yolk and white content that is combined in the different products (Graph 1).

The need for industrialisation of food for pets requires that the ingredients are highly standardised. In this case, the egg has a very homogeneous composition and with little variability

12 | September 2022 - International Petfood F

between batches, also providing essential nutrients.

The composition of the eggs depends on the animal species, but we can roughly divide it into 60-65% white, 25-30% yolk and 10% shell. Nutritional components of white and yolk are mostly protein and fat, while the shell contains calcium carbonate.

Bioavailability

Unlike other production and transformation methods of animal-by products, the spray drying process is very gentle to the physicochemical properties of the ingredients, obtaining highly bioavailable products. It doesn’t only mean high absorption, but also a very high digestibility of nutrients within the body (>95%)

Focusing on the importance of lysine as a key element in pet food formulation, Donadelli et al, (2019) demonstrated a lysine availability of 96-97% in products obtained by spray drying,

compared to 78-84% of other severely heat-treated animal byproducts.

Protein & lipids

Egg products are excellent and highly digestible protein sources, containing all the essential amino acids, except taurine, to cover the basic maintenance, growth and reproduction needs of dogs and cats (Graphs 2 & 3).

Arginine is very present in the yolk and methionine and phenylalanine in the egg white, these being the main difference with vegetable protein ingredients, generally poor in these amino acids.

The well-known anti-proteinase activity naturally present in raw eggs is practically inactivated during the production process of egg powder and afterwards commercial petfood.

As we said before, given the clear nutritional division present in the egg, we can obtain different products depending on the relative composition of the white and the yolk.

Despite the differences in fat content, the fatty acid profile is always the same, containing 19 percent polyunsaturated fatty acids (PUFA), such as omega 3 (n-3) and omega 6 (n-6). Egg also contains monounsaturated fatty acids (MUFA) and saturated fatty acids (SFA) as represented in Graph 4.

Certain PUFA must be obtained directly from the diet, as they cannot be synthesized by the body, as Linoleic Acid (LA), Araquidonic Acid (AA), Alpha linoleic acid (ALA), Eicosapentanoic acid (EPA) and Docosahexanoic acid (DHA), among others (Graph 5).

The fat content not only provides energy, but also influences the absorption of fat-soluble vitamins and positively influences texture and palatability (Ahlstrøm et al, 2004).

Graph 1: Nutritional composition of Actipro egg powder products

Decades of Global Experience. 50 Years in Business 66 Countries Served 1,000+ Products Moved 32,000+ Conveyors Commissioned operation our systems are hard to compete against. Cablevey Conveyors Gentle Clean Reliable Conveying The Heart of the System CABLE & DISCS Cablevey® Conveyors is a registered trademark of Intraco, Inc. 07/2022 Worldwide Experts in Cable and Disc Conveying Solutions +1(641) 673-8451 www.cablevey.com www.cablevey.com +1(641) 673-8451 info@cablevey.com

International Petfood - September 2022 | 13 F

Minerals & vitamins

Egg powders generally have a much lower ash content than other ingredients of animal origin because calcium and phosphorus are very scarce in the liquid fraction of the egg.

The egg has a high concentration of Vitamins, except for Vitamin C, which also remain stable during the spray drying process (reviewed by De Ritter, 2019). In the yolk we can find fat-soluble vitamins (A, D, E and K), especially A and D, in addition to the eight water-soluble vitamins of the B complex.

We also find Choline, which is analogous to water-soluble vitamins and can be produced in small quantities in the liver. It is a very important molecule for metabolism, a member of cell membranes and a precursor of neurotransmitters. The extensive use of choline is not covered by endogenous synthesis, so it must be provided in the diet.

Egg yolk has a high content of highly bioavailable choline, requiring only an egg yolk contribution of 8 and 10 percent in the diet of dogs and cats, respectively, to cover the minimum daily needs.

Crude fibre & carbohydrates

The crude fibre content is very low in the egg (1% and 4% respectively). A low carbohydrate content in the diet prevents adverse digestive effects on pets such as diarrhoea, flatulence, or bloating. The sucrose content is also very low around 0.1%.

Beyond its nutritional properties and being an excellent source of highly digestible nutrients, in egg we can find an enormous number of molecules that are naturally available for the growth and defence of the bird’s embryo. These molecules have great functionality that can be used within animals that consume this ingredient.

Antioxidants: lutein & zeaxanthin

Just as the life expectancy of human beings increases, so does that of our pets, resulting in a progressively greater number of elderly animals in homes. The xanthophyll carotenoids contained in eggs are fat-soluble pigments from plants that, unlike other carotenoids, are not transformed into Vitamin A after intestinal absorption.

The bioavailability and absorption of lutein and zeaxanthin present in eggs is greater than that of vegetables and other lutein supplements.

The main benefits of its nutritional contribution are the improvement and prevention of eye health, delay in the aging of the retina and lens of elder pets.

There is also a modulating effect on the immune system, improving the humoral response after vaccination in Beagle dogs (Kim et al, 2000) and an attenuating effect on oxidative stress induced by exercise.

Bioactive lipids

The lipid content of the egg yolk consists out of 28% phospholipids, 66% triglycerides, 5% cholesterol and 1% free fatty acids. In turn, most of the phospholipids are phosphatidylcholine (75%), phosphatidylethanolamine, sphingomyelin and phosphatidylinositol.

As main effects we can find the decrease in cholesterol levels and its influence on hepatic metabolism of fatty acids due to interaction with PPAR alpha, which results in a reduction in the expression of hepatic genes that regulate cholesterol synthesis and increases the expression of bile acid-producing genes.

Lipoprotein metabolism plays a critical role in the atherosclerosis process, since egg consumption is associated with an increase in HDL, which removes excess lipids from the blood and transports them to the liver (reverse cholesterol transport), reducing cardiovascular risk.

Antimicrobial proteins

To protect the embryo against possible infections, egg white contains lysozyme, which constitutes 3.5 percent of the proteins in egg white. Lysozyme is a protein with bacteriolytic action, which destroys the peptidoglycan of the bacterial wall of Grampositive bacteria. Because of this it is used as a food preservative to control food bacteria (such as listeria monocytogenes and clostridium botulinum).

Another important antimicrobial protein is Ovotransferrin (12% of the protein present in egg white) that has bactericidal properties against Gram positive and Gram negative (Staphylococci and Escherichia) thanks to its iron chelating effect and its direct effect on bacterial membranes.

And as a last reference we can add ovomucin (3.5% of the protein present in white) which has been shown to have a powerful effect against bacteria that cause food poisoning.

Passive immunity

Like other products of animal origin, such as milk or spraydried plasma, the powdered egg contains antibodies from laying hens, which are an effective tool against viruses, bacteria and bacterial toxins (salmonella, coli).

These immunoglobulins are called IgY and are produced by hens when they are exposed to pathogens or are vaccinated against certain pathogens. Similar to other immunoglobulins produced endogenously (IgG, IgA), they have the ability to bind to pathogens to prevent them from binding to the intestinal mucosa, thus avoiding tissue damage (Figure 1). It is worth highlighting the technological applications of egg products, frequently used in both dry and wet pet food.

Graph 2: Dietary essential amino acids in egg products and FEDIAF (2019) minimum recommended values for pet food

Graph 3: Amino acids in egg

F 14 | September 2022 - International Petfood

Formation & stabilisation of emulsions

An emulsion is defined as a mixture of substances in the liquid phase that would normally not mix, such as the typical example of water and oil. Amphipathic emulsifiers, such as egg yolk lecithin, reduce the tension between the lipid and aqueous interface during mechanical homogenisation which leads to the formation of dispersed lipid droplets in the aqueous phase.

Thanks to this property, the powdered egg is used to improve the mixture between the lipid-providing ingredients and the water and steam in the extrusion process of pet food.

We can summarise gelation as a process in which a liquid substance passes into a gel form. In the case of the egg, this transformation is facilitated by an increase in temperature, producing heat-induced gelation.

In this process, the heat causes the denaturation of the native proteins, exposing the hydrophobic regions that gradually form a three-dimensional gel. Thanks to its gelling properties, egg powder is used to increase the viscosity and consistency of wet pet food.

Versatility, balance, functionality & sustainability

In short, the use of egg powder is a safe bet to provide all the nutrients necessary for the growth and development of companion animals.

The wide range of Actipro egg products is an ideal option for all those professionals who are looking for a solution to the complicated puzzle of pet nutrition formulation.

Versatility, balance, functionality and sustainability add an unmeasurable value to nutrologists, formulators and, in general, the whole petfood industry, even more if we take into account the natural labelling, safety, sustainability, functionality and the technical advantage it provides.

Graph 4: Fatty acids profile

Graph 5: Dietary essential fatty acids in egg products and FEDIAF (2019) minimum recommended values for pet food

Graph 4: Fatty acids profile

Graph 5: Dietary essential fatty acids in egg products and FEDIAF (2019) minimum recommended values for pet food

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT Mixers, conveyors, Ducting System, High Temperature enquiries@hydronix.com www.hydronix.com Contact us for more details Hydronix-Petfood-Advert Jan 2022 215x140mm.indd 1 20/12/2021 19:04International Petfood - September 2022 | 15 F

Integrated project delivery in petfood manufacturing

by Matthew Lantzy, Senior Project Director, & Chris Prokop, Project Director, CRB, USA

Youcan get anything for your pets these days, including television made just for them. DOGTV, a premium cable network which features colour and sound adjusted programming to suit a dog’s unique senses, has been available in the US for a decade, but the pandemic-era ‘adoption frenzy’ propelled it to new heights: late last year, they expanded into England, Australia and New Zealand. Today, the network is available in more than a dozen different countries.

DOGTV’s global reach is an indicator of the transformation underway among pet owners. Families are more inclined to treat their four-legged companions as humanised members of the household who deserve premium quality and choice in terms of their entertainment, their toys, and, significantly, their meals and treats.

This trend has generated a powerful consumer segment with money to spend—US$275 billion annually to be exact, which is the

value that some analysts predict for the pet care industry by 2030.

To understand how pet food manufacturers are responding to this shift in market dynamics, we surveyed more than 300 companies and compiled their perspectives in our Horizons: Pet Food report. Some of our most interesting findings centre on the need for manufacturers to invest in modern and flexible production capacity in order to prepare for future surges in demand.

Both large and small companies share this need, though they have very different CapEx spending targets (Figure 1A). What they do have in common is an interest in modernising their packaging installations and embracing automation (Figure 1B).

This illustrates the pressure shared by all pet manufacturing companies to design more sustainability into their operations, and to address labour constraints, demand dynamics, and other challenges by integrating smart, efficient technologies into their plants.

We set out to uncover how today’s pet food manufacturers are approaching these capital projects given that real estate is at a premium, costs are rising, and longer-lead equipment can take a year or more to arrive.

Integrated project delivery is the answer

When we asked survey respondents about their preferred project delivery method, 50 percent pointed to Integrated Project Delivery, or IPD (Figure 2). If we consider Design-Build (DB) as a close sibling of IPD, the number of respondents who prefer lean and highly collaborative methods grows to nearly 70 percent, leaving just 29 percent in favour of the more traditional DesignBid-Build (DBB) model.

These results set the pet food industry apart from industries we have polled in the past. For example, our 2021 Horizons: Life Sciences report revealed that only 13 percent of drug companies who responded to our survey embraced the IPD model. What

68% of survey respondents are looking beyond design-builddelivery for faster, leaner, more costeffective project delivery models

Figure 1A: For projects on your capital expenditure plan for the next five years, what do you anticipate will be the highest cost for a single project? 16 | September 2022 - International Petfood F

does this tell us about the unique nature of project delivery in the pet food industry?

To answer that question, consider the core attributes that pet food manufacturers look for when assessing a successful project delivery (Figure 3). What stands out is the fact that nothing stands out. To compete in a crowded marketplace, pet food companies are trying to juggle multiple priorities, each more or less equally weighted and important to project success.

This contradicts the classic wisdom that delivery teams have to choose between speed, cost, and quality. Not only are pet food manufacturers insisting on all three—they are also adding sustainability, flexibility, and team engagement to that list. In a marketplace crowded with competitors and constrained by labour and supply chain challenges, aspiring for a perfect score across all of these attributes is the only way to succeed. Achieving that vision, though, is a difficult and complex task.

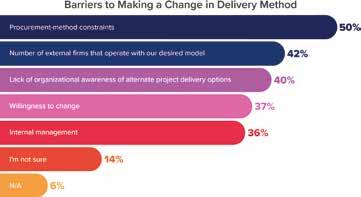

That complexity could be the reason why so many respondents are open to IPD and DB, despite the barriers that many perceive in switching delivery methods (Figure 4). Pet food manufacturers seem to know that traditional delivery methods deliver traditional results, and that to move from an idea on a piece of paper to an optimised and sustainable production line in today’s challenging environment, traditional simply will not cut it. IPD offers something different: a framework for completing capital projects faster and more cost-effectively through collaboration and shared accountability.

Team integration is the heart of IPD. When project owners, engineers, construction leads, and trade experts work together from day one, they are able to identify potential downstream roadblocks during upstream planning phases, giving them an opportunity to eliminate those roadblocks before they cause delays and cost overruns. That is the key to realising those highranking project delivery attributes in Figure 3.

Trade partners, for example, have a unique perspective on industry trends that impact things like equipment lead times, material costs, and availability. Bringing that perspective and knowledge to the design table during the development phase allows delivery teams to see further into the future of their project’s lifecycle, enabling earlier cost and scheduling certainty and eliminating downstream problems.

In addition to bringing valuable expertise to the table early, IPD gives project teams an opportunity to develop a shared vision for the project and a plan to make that vision a reality, with all project team members on board.

Take sustainability, for example. Nearly 90 percent of respondents are striving towards formalised sustainability

benchmarks. The work of meeting those benchmarks begins during early project planning and continues through procurement, facility construction, turnover, and operation, and that work is far more likely to pay off if all team members understand from the start that sustainability is a fundamental condition of project success.

From this shared understanding, the delivery team can work collaboratively to design more efficiency into the building plan, reduce waste on the jobsite, minimise the overall carbon impact of delivery activities, and make other impactful decisions that help drive sustainability during construction and beyond.

IPD is powered by lean design

Simply gathering design, construction and trade experts together is only part of the solution, though. To unlock the full benefit of IPD’s collaborative approach, project teams need to embrace lean design – that is, a relationship-oriented philosophy that strives for less wasted effort, less rework, and less overengineering.

The concept of lean design has roots in the manufacturing industry, which may explain why more than half of our respondents are at least somewhat familiar with it (Figure 5). For the 44 percent of those with little or no familiarity, the words that some respondents choose to describe lean design may incentivise change (Figure 6).

This is particularly applicable as cost and scheduling pressure builds, making lean design a crucial component of accelerated project delivery.

The value of subject matter expertise

Because of its emphasis on collaboration, IPD helps pet food manufacturers maximise the expertise that their project delivery partners bring to the table—a high-ranking priority for them when choosing those partners, especially for the largest and smallest companies (Figure 7).

Small companies are perhaps likely to seek expert help with translating their plan from an aspirational idea to a real-world process. Larger companies are equally keen to find the right

Figure 1B: What types of projects are on your capital expenditure plan for the next five years? [Multi Select].

Figure 3: How important are each of the criteria below for evaluating successful project delivery in the current market? [Mean score: 5= Extremely important, 1= Not at all important].

Figure 2: What is your company’s preferred project delivery method for capital projects? [Single Select].

Figure 1B: What types of projects are on your capital expenditure plan for the next five years? [Multi Select].

Figure 3: How important are each of the criteria below for evaluating successful project delivery in the current market? [Mean score: 5= Extremely important, 1= Not at all important].

Figure 2: What is your company’s preferred project delivery method for capital projects? [Single Select].

International Petfood - September 2022 | 17 F

experts, only their goals may be more subtle.

Since they likely have an established process already, they may be looking for incremental ways to refine that process and generate more value over time, such as a new approach for generating onsite energy, or an innovative modification that reduces downtime by eliminating frequent clean-in-place (CIP) cycles.

Flexibility is a key priority

As Industry 4.0 emerges, bringing with it successive waves of new and efficient technologies, pet food manufacturers need to keep up, or risk getting left behind by competitors. But keeping up is difficult when the innovation lifecycle moves faster than the project delivery lifecycle. By the time a facility has evolved from the concept phase to full operation, whole new manufacturing technologies may have entered the marketplace, changing the game completely.

The only solution is to think strategically and design for flexibility from day one, clearing the way for manufacturers to integrate the new technologies they need, exactly when they need them. Our respondents know this, which is why many of them rank flexibility of production lines and ability to innovate so highly when asked about the attributes of a successful project (Figure 3).

Relatively minor design decisions can play a big role when it comes to enabling this level of flexibility. Take the concrete slabs in a facility’s floor, for example. Cost-conscious project teams may choose to install thicker slabs only where necessary, such as in areas designated for palletisers and other heavy equipment. But this decision limits the plant’s ability to adapt.

What happens if, for example, when facility owners want to improve material handling efficiencies by installing automated guided vehicles (AGVs) or autonomous mobile robots (AMRs)? They can’t move those palletisers to clear a travel path – at least, not without the cost and downtime required to pour new slabs.

If the project team had taken the pulse of emerging technologies during the initial design phase, they would have understood the potential ROI of installing thicker slabs, wider columns, armour joints, and other features designed to support future technology integrations. These are the far-sighted decisions that deeply integrated project delivery experts know how to make.

To get capital project delivery right, choose the right delivery partner. In a world where made-for-dogs TV has a global viewership and pet owners expect as much choice and quality in their dog’s dish as they find in their own cupboards, petfood manufacturers must ready themselves for anything and everything.

That is why IPD is gaining momentum, and that’s why so many pet food manufacturers are turning to expert project delivery partners who know the industry and who understand how collaborative execution strategies support today’s accelerated, quality-focused and flexible petfood manufacturing projects.

Figure 4: If you are not satisfied with your current delivery method, what are the top barriers to making a change? [Multi Select].

Figure 5: How familiar are you with “lean” design and construction project delivery principles? [Single Select].

Figure 6: Describe what you believe are the most important aspects of lean principles in successful project delivery.

Figure 7: How important are each of the criteria below for selecting design and construction partners? [Mean score: 5= Extremely important, 1= Not at all important]

Figure 4: If you are not satisfied with your current delivery method, what are the top barriers to making a change? [Multi Select].

Figure 5: How familiar are you with “lean” design and construction project delivery principles? [Single Select].

Figure 6: Describe what you believe are the most important aspects of lean principles in successful project delivery.

Figure 7: How important are each of the criteria below for selecting design and construction partners? [Mean score: 5= Extremely important, 1= Not at all important]

18 | September 2022 - International Petfood F

About the Authors: Matthew Lantzy is a Senior Project Director with more than 20 years of experience in the design and execution of complex industrial projects. His projects have ranged from single production line installations to larger design-build turnkey projects with capital expenditures up to US$100M. Project types include food and beverage, industrial, manufacturing, and consumer products.

Chris Prokop is a Project Director with more than 30 years of experience leading complex projects through all phases of design, permitting and construction. He brings a passion for integrated project execution, working collaboratively with clients and project partners to deliver cuttingedge facilities that support their longterm values.

International Petfood - September 2022 | 19 F

Magnetic Separation

The essential item of safety equipment for the petfood industry

by Kyle Rhodes, Vice President – Business Development, MPI Magnetic Products, USA

Described

as being the “revolutionary next step in magnetic separation innovation and factory automation for the petfood industry,” IntellI-Mag® is the first intelligent magnet to self-monitor ferrous metal saturation in real-time and log system data.

This new piece of petfood manufacturing equipment monitors ferrous contamination of incoming ingredients

and detects equipment malfunctions before scheduled cleanings.

In addition to this it also ensures fully saturated magnets are cleaned before metal events occur, reduces shutdowns for premature magnet cleaning, and ensures the separator is always working at peak performance, capturing weakly magnetic materials, such as work-hardened stainless.

Intell-I-Mag features

Real time monitoring for peak magnetic performance

- Internal sensors monitor tramp metal saturation levels and alert staff before an incident can occur - once magnet reaches the designated level, it notifies plant personnel of required cleaning or can activate the automated self-cleaning system.

- Oversee vendors during material unloading for earlier metal detection to reduce damage in production process.

- Avoid challenges caused by equipment failures, inadequate magnet cleaning intervals or inaccessible equipment

Customised reporting for quality compliance initiatives

- Data collection improves analysis of magnetic separator performance, including magnet saturation, cleaning

F 20 | September 2022 - International Petfood

alerts, temperature monitoring, cleaning cycles and position location.

As captured metal increases and magnetic performance decreases, LED saturation level indicators indicate the current level of separator saturation with green, red and yellow lights.

Industry 4.0 and IoT ready the Intell-I-Mag’s Industry 4.0 compliant PLC controller allows for communication between controller and network for remote magnet monitoring and control. Built for the harshest environments, its controllers are rated for appropriate installation environments.

MPI products are also designed to be complete metal and foreign contamination control solutions for the food industry. MPI has always advocated that magnetic separators need to be installed in three key areas in the production process.

Intell-I-Mag is changing the way its customers use separators in these key locations including primary, secondary and finishing magnetic separation equipment.

Example 1: Primary Magnet Intell-I-Mag Impact improves:

- Plant protection from tramp metal.

- Vendor monitoring documentation.

- Receiving throughput.

At other facilities, the presence of metal may be known, but the user requires it to be removed prior to the product entering the facility. In this scenario, Intell-I-Mag can alert

Bolt'n'Go Advet (Half Page) - No Email_Layout 1 30/06/2015 12:17 Page 1

the user to stop the unloading process and clean the magnet prior to the separator reaching full metal saturation.

In either of these cases, the user can be confident that tramp metal has not entered the facility from a vendor. This helps the facility improve the quality of documentation with data collected by the Intell-I-Mag.

Finally, when metal is not present, the receiving process does not need to be stopped or shutdown to check the magnet, increasing throughput and speeding up delivery.

Facilities monitor vendor unloading to identify the presence of ferrous metal. The best way to keep metal out of the final product is to keep it from coming into the plant in the first place.

The product can also be set to the user’s specific requirements, enabling the user to help improve product quality and strengthen documentation at receiving locations. If the user has a strict no metal policy when receiving product, this product also helps identify the presence of metal as soon as possible, to ensure the unloading process can be stopped quickly.

Protecting processing equipment downstream Intell-I-Mag can also be used to protect downstream processing equipment, such as a hammer mill, airlock or mixer. To ensure proper protection of this equipment, it is important that the magnet not become overly saturated to the point that it cannot capture more metal.

It also empowers operators to set the level of saturation that they want to be alerted at, or to have the magnet automatically cleaned at. For a magnetic separator to protect processing equipment, the separator should not be

Proven Performance Put Your Conveyor on Pole Position! • Reduce Downtime & Maintenance Costs • Quick and Easy Chain Assembly • Bolt on Flight Replacement (No Welding) • Forged and Hardened Chain Links DOWNTIME IS A RACE... TIME IS MONEY 'N' Go™ Drag Conveyor Chain www.go4b.com www.go4b.com 4B GROUP

International Petfood - September 2022 | 21 F

more than 50 percent saturated, still allowing 50 percent of its power to capture more tramp metal.

In this case, the user can set Intell-I-Mag to notify them when the magnet is saturated to 50 percent, giving the operator time to shut down the process immediately or schedule an upcoming shutdown to clean the magnet.

Preventing this metal event saves the user from unplanned maintenance and repair costs, as well as downstream damage, including loss of product integrity.

If the magnet does not reach the targeted saturation level, the user may not need to shut down the system to clean the magnet. This information helps users increase uptime of their processing systems.

With multiple Intell-I-Mags in use at control points throughout a facility, users can quickly pinpoint processing equipment that is breaking down and minimise metal contamination to good product.

Ensuring exceptional final product quality

It is important to document and ensure exceptional final product quality. When a facility has a good upstream metal control program in place, the largest threat to final product quality can be weakly magnetic work hardened stainless steel.

Using Intell-I-Mag, helps increase the capability of capturing otherwise difficult to target tramp metal. To do this, the product helps to ensure that the magnetic separator is always working at peak performance, quickly removing the captured metal from the product stream before it can be ‘washed off.’

To operate Intell-I-Mag successfully in a configuration like this, the controller is set to a low threshold for saturation, for example, three percent. When it reaches this saturation level, the user is alerted to clean the magnet. The system can also be configured to automatically cycle when it reaches this level. This configuration is ideal to ensure the finishing magnet removes the small and weakly magnetic tramp iron that is difficult to identify by a metal detector or X-Ray machine.

Cycling the magnet quickly after capturing ensures the captured metal cannot be washed off into the product flow and end up in the final product. In the event of a metal recall or report of metal in a final product, the user can be confident that either the metal does not have ferrous properties, or that the contamination is from another source outside of the facility, such as a rail car or tractor trailer.

Adding Intell-I-Mag data to customers quality reports provides another layer of confidence that the customers are receiving product without contamination.

Another benefit of using this piece of equipment at the finishing magnet is the packaging or load out system does not need to shut down for unnecessary magnet cleanings. If Intell-I-Mag shows that no metal has been captured, the system does not need to be shut down for cleaning, resulting in higher uptime for the system.

The Intell-I-Mag (Patent #10,543,492) Controller is offered exclusively on MPI magnetic separation equipment. The intelligent magnet controller is available on most MPI gravity bulk free flowing, pneumatic conveying and liquid pipeline magnets to maintain peak magnetic performance.

22 | September 2022 - International Petfood F

Your industry training platform

Learn more – Learn onsite Enroll in the 12-week Course

The Online Milling School provides a comprehensive 12-week remote learning experience covering all aspects of feed mill ing, from raw material handling through to final packaging and dispatch.

www.onlinemillingschool.com FISH FARMING TECHNOLOGY F

by Fabiola Neitzel, Prombyx, Germany

SILKWORM PROTEIN

Lookinginto the shelves of a pet food vendor nowadays, it seems almost every brand has included an insect-based product into their portfolio. This trend reflects the customer’s rising awareness of sustainability, animal welfare and the hunger for innovation.

When customers take a closer look on the ingredients list, they will most likely read a certain percentage of ‘insect’. This generalisation seems rather vague, given the fact that insects are the most diverse group of animals. Taxonomists estimate that there are more insect species than species other animals, plants and fungi together.

The ‘insect’ in current pet food will most likely mean black soldier fly (Hermetia illucens), mealworm (Tenebrio molitor) or house cricket (Acheta domesticus). Major efforts were made during the last years to establish industrial rearing facilities for them.

However, insect rearing is not a new phenomenon. Bee keeping for honey and wax and sericulture for silk production have a history of thousands of years, to only mention two examples. We will hereafter take a closer look on the latter and its potential as a protein source for pet food.

A historic economic importance

The earliest known evidence of sericulture was found in China and dates back more than 5000 years. The historic economic

importance of this resource is reflected in the name of the major continental trade route between Asia and Europe, the silk road.

The silkworm as such bears potential for confusion. It is an insect, despite being called ‘worm’ for its trivial name. Furthermore, it goes through a complete metamorphosis. Depending on the life stage, it can appear as egg, caterpillar, pupae inside a silk cocoon or moth.

Thousands of years of selected breeding led from a wild silk moth to the silkworm Bombyx mori, as we know it today. It became tame, easy to handle and a diligent producer of highquality silk fibres in evenly formed cocoons.

China is still the biggest producer of silk today, followed by India. Many more countries in Asia, Europe and South America practice sericulture or have a history of doing so. Hundreds of thousands of tons of silkworm pupae are produced as a byproduct of silk production every year.

The unregulated disposal of large quantities of silkworm pupae leads to environmental issues. Only a fraction of it is used for local livestock feed after being rudimentarily sun dried.

In some areas, silkworm pupae are considered a delicacy for human consumption. These pupae are usually reared especially for this purpose and not used for silk production beforehand.

Feeding on a variety of substrates

Unlike black soldier fly larvae, which can feed on a variety of substrates, Bombyx mori silkworms are strict feed specialists. They only accept mulberry leaves as their food source. The

24 | September 2022 - International Petfood F

uniformity of their nutrition leads to a stable nutritional profile of the pupae. The amino acid profile of silkworms differs significantly from that of other insects and is therefore well-suited to supplement the range of pet food products for every need.

Silkworm oil for example, is liquid at room temperature due to its high content of mono- and poly-unsaturated fatty acids. This aspect opens new areas for applications of insect fat fractions. While silkworm oil is already an esteemed ingredient in human cosmetics, the connotation to silk makes it also especially suitable as additive in pet care products.

Silkworm protein got approved as livestock feed by the European Union in November 2021. This approval is an important step towards the use of an existing resource to their best potential and gives millions of small-scale silkworm farmers in developing countries perspectives for additional income.

However, large quantities of silkworm pupae in EU feed quality are not yet available for the industry, as silkworm pupae were not processed further according to the required quality parameters.

The right raw material

The new processing way starts with the right raw material: fresh, pesticide free pupae. To date, there is barely any official data available on the use of pesticides in sericulture. The types of pesticides used differ from region to region and the quantity fluctuates seasonally. Pesticide entrance ways can be found from mulberry plantation over processing to storage.

The EU pesticide residue limits in insect protein are set at the limit of detection, meaning no pesticide residues must be found. To achieve this, the control of the whole production chain from farmer over silk-reeler to pupae processing is key.

Once the pupae are reeled, they need to be collected from the reeling centres and being oven-dried within a few hours for sanitation and shelf life. As silkworm pupae are larger in diameter than black soldier fly larvae or mealworms, the drying process must be adapted accordingly. Whole dried silkworm pupae are great for wet pet food formulations.

A mechanical defatting step leads to a powder with around 70 percent crude protein, which is suitable for extruded products.

Wet processing and the transportation of the frozen silkworm protein fraction is also an option to be considered in the future.

Generally, the processes should fit the local circumstances, which differ greatly between China and India. Nevertheless, additional work is required to establish reliable high volume supply.

Sustainability and CO2 footprint of pet food products are much discussed topics in the industry nowadays. While insect protein has a low impact compared to traditional livestock in general, byproduct silkworm pupae are especially environmentally friendly with a footprint of only 1.9kg CO2 equivalents per kg protein.

Roughly two thirds of it account for the drying, while one third is produced by transportation (India to Central Europe, for example). Silkworm pupae are a great example of turning an underused by-product into a valuable resource and using existing materials to their best potential.

About the author

Fabiola Neitzel is an insect biotechnologist and founder of PROMBYX GmbH. Her startup was founded in 2021 and is located in Giessen, Germany. PROMBYX is specialised in silkworm-based ingredients and feed products. PROMBYX developed the first hypoallergenic canned dog food based on silkworms and had it successfully tested in a university feeding study. Further research for dog and cat food as well as livestock feed is on the way.

International Petfood - September 2022 | 25 F

The diet of the pet rabbit

Striking the delicate nutritional balance that the modern pet rabbit requires to survive

by Andrew Wilkinson, International Petfood magazine, UK

Consideredto be grazing animals, rabbits or Oryctolagus cuniculus to give their Latin name, are herbivores. As carriers of a very complex digestive system, rabbits are very efficient food processers. In addition to this, rabbits also have very specific dietary needs.

This can mean that if owners introduce new foods too quickly, or feed inappropriate food choices, the rabbit’s normal digestive flora (normal bacteria) will be disturbed, gas- and toxin-producing bacteria can overgrow, and the rabbit may become very sick and possibly die.

For that reason, getting a rabbit’s diet right is of critical importance – a genuine matter of life and death. Rabbits should be fed a daily diet that consists mostly of hay, a smaller quantity of fresh vegetables, and a limited number of pellets.

A balanced gut & good dental health

Hay is the most important part of a rabbit’s daily intake. Unlimited, high-quality grass hay, such as Timothy, orchard or brome, should make up the bulk of a rabbit’s diet, making up approximately 80 percent of its daily food intake.

This is largely because hay helps the rabbit’s gut remain balanced and maintains good dental health. It also helps to prevent hairball blockages in the gut and encourages curiosity and foraging

Grass hay is also high in fibre, which is critical to maintaining a rabbit’s healthy digestive tract. While young, growing rabbits can eat any type of grass hay, alfalfa hay is not recommended for adult rabbits, as it is too rich in protein and too high in calcium.

Timothy pellets can be offered at approximately 1/8-1/4 cup per 5 lbs (2.25 kg) of bodyweight. Over-feeding pellets to adult rabbits is a common cause of obesity and soft stool (caused by an overgrowth of abnormal bacteria in the gastrointestinal (GI) tract), as pellets are generally low in fibre and high in carbohydrates.

Timothy hay is the most fibre-dense type of hay and it is the most coarse. This makes it excellent for a rabbit’s digestive health and for their teeth. But there are other types of grass hay that owners can mix in with Timothy hay to offer the rabbit some variety.

The fibre and protein content of these grass hays make them ideal for regulating a rabbit’s digestive system. It also makes sure that the rabbit is absorbing nutrients and everything is running smoothly.

Fibre is essential

Hay is very high in fibre, which is absolutely essential to a rabbit’s diet. Because of the rabbit’s foraging ancestors, their long digestive tract is set up to break down fibrous vegetation.

This is because the long fibre strands of hay work much better than the ground-up fibre in commercial rabbit pellets for keeping the rabbits gut moving. One of the most common and dangerous

F 26 | September 2022 - International Petfood

conditions for a rabbit is known as GI stasis.

This happens when a rabbit’s digestion slows down or stops completely. Having a supply of hay always available helps to keep its digestion moving so these dangerous blockages are much less likely to threaten the rabbit’s health.

Hay is also very good for a rabbit’s teeth. This is because rabbit teeth are like fingernails and always keep growing, so they need to eat foods that help wear down their teeth. Hay is the best food for this since the long hard strands are abrasive enough to make a difference. Make sure to provide your rabbit with some wooden chew toys too, to help keep their teeth stay healthy and trimmed.

Pellets

The bad news for rabbit food producers is that dry rabbit food pellets should only make up a small percentage of its diet, making up about five percent of its daily dietary intake. Strictly speaking, pellets are not even a necessary part of a rabbit’s diet, but they can be an easy way to provide extra nutritional value, with rabbits typically loving them.

Another noteworthy point is that unlike some pets, it’s okay for them to have an empty bowl from time to time, as a rabbit should still have its unlimited hay available to forage on.

In fact, online rabbit adviser BunnyLady.com https://mymag. info/e/1660 suggests that owners should be encouraged to feed their rabbit more hay than pellets, so they shouldn’t replenish them until the next day.

The different types of pellets

Like hay, there are a lot of different types of pellets on the market. There are a couple of points to keep in mind when owners are choosing what kind to get feed their rabbit. They should also make sure it is getting fed a brand that is just the boring pellets.

This is because anything with colourful, fruity pieces is going to have sugar content that is far too high and is generally speaking,

Table

Table

not good for a rabbit’s health. Most rabbits will still love to gobble of those plain boring-looking pellets.

BunnyLady.com also recommends that owners take a look at the ingredients and make sure the first item on the list is timothy hay or timothy grass. Like with hay, alfalfa pellets are okay for young rabbits (less than 6 months) or underweight rabbits, but by the time the rabbit is reaching adulthood, owners should make sure to transition over to a timothy blend.

Kiwi Acorns

Kohlrabi Almonds

Apples Apple Seeds

Lemon Peels Leeks

Apricots Artichoke Leaves

Lemons Lentils

Asparagus Mandarins

Mango Avocado

Baby Sweetcorns Milk

Bananas Mushrooms

Bean Sprouts Beans

Nectarines Noodles

Beet Greens Nuts

Beetroot Olives

Oatmeal Bread

Beets Pasta

Okra Candy

Bell Peppers Peanut Butter

Blackberries Peanuts

Orange Peels Cereal

Oranges Cheese

Brussel Sprouts Popcorn

Peaches Potatoes

Cantaloupe Chocolate

Carrots Coffee

Cauliflower Sweet Potatoes