An Axolotls Diet Calci- Worms - How A Commitment To Human Progression Created A New Us$75 Million Dog Chew Category - Commodity Handling Equipment November 2022 www.internationalpetfood.com www.perendale.com Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com

YOU CAN THINK

CAN PACK IT

IF

IT WE

Watch our sustainable packaging solutions at: www.the-packaging-group.com/videoportal

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor

Prof Simon Davies simond@perendale.com

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Community Manager

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Design PetFood Magazine

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

www.internationalpetfood.com

REGULAR ITEMS COLUMNS 6 Roger Gilbert 7 Joseph P Kearns November

9 Industry News 8 Professor Simon Davies

2022

International Petfood - Volume 4 - Issue 11 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at

www.perendale.com ISSN 2754-4680

26 Industry Profiles 28 Training 29 Troubleshooting 30 Production focus 37 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces

FEATURES 14 An Axolotls Diet 16 Calci-Worms 18 How A Commitment To Human Progression Created A New Us$75 Million Dog Chew Category 22 Commodity Handling Equipment

Have you managed to download our International Petfood App yet?

This is an easy way to quickly review the content of the magazine while on the move. And in today’s working environment time is precious as we cope with multiple tasks which pre-pandemic seemed to be easier and less stressful.

THE PUBLISHER

Roger Gilbert Publisher – International Petfood

Here, at IPF, our team wants to make life easier for you in your search for the latest in petfood manufacturing information and pass updates to you in a timely and seamless manner.

With that in mind I would like to offer you a small incentive - a code that will waive the cost of installing the App on your mobile device and also allow you to order a printed copy of our magazine - mailed direct to you each month for a full year!

To take up this offer please go to our website (https://store.magstand.com/ petfood) and apply the code IPFEng100 to waive the charge.

You may choose to subscribe (without the code) through your Apple or Google account by just accessing Apple Store or Google Play. However, you’ll miss out on being able to use the online library of back editions on your desktop computer through the linked ‘FlickRead’ account. Please be sure to record your username and password when setting up your account on MagStand, as this will be needed to activate your free subscription on the App which you download and provide access to ‘FlickRead’.

Despite the economic challenges most countries are facing due to the consequences of the pandemic, the war between Russia and the Ukraine and the impact of energy price increase - plus other more regional and local developments - ensuring our pets receive the right nutrition remains a priority.

In fact, during this time of cutbacks and minimising our domestic spend to remove unnecessary goods and services, we must pay even closer attention of the diets of our pets.

Reading the labels on the foods we are purchasing and comparing nutritional profiles along with understanding the dietary requirements of our pet is a great starting point which most pet owners will already be applying.

However, there is always good reason to consult your veterinarian or even an on online reputable source for information that may help you identify what is best value for money.

Petfood manufacturers everywhere are aware of the need to keep costs down and pass on only those increases that they are unable to absorb themselves. Please let me know if you are experiencing difficulties or have comments to make about the cost or availability of foodstuffs for your pets that has been exacerbated by these current, ongoing difficult circumstances.

Our edition this month focuses on cats and dogs once again with Professor Davies column, while we dedicate this edition to aquatic pets and open with a feature on the diet of Axilotls by our staff writer Shannon Parsons. Meanwhile Thomas Marriot, the feature editor at Peregrine Livefoods has provided a feature on alternative nutrients for aquatic pets when he writes about Calci-worms.

That’s before we get into the equipment involved in the processing and production of petfoods with commodity handling equipment, by Andrew Head of BDC Systems in the UK. We also carry our regular sections on product showcase and troubleshooting

A feature to look out for is the ‘Story behind the original Himalayan Dog Chew’ which has been submitted by Suman Shrestha, president of the Himalayan Pet Supply company.

There are many other good reads in this edition including our report on events and our interview towards the back of the edition.

Be sure to use the code above to enjoy this edition in the way you want to read it!

Did you miss our October 2022 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

Alternative proteins: Supporting Nutrition that’s best for the pets and the planets, by ADM, USA

With pets increasingly considered part of the family, this humanisation trend is rapidly expanding around the world. More and more, conscientious consumers demand that their pets eat sustainable, responsibly produced foods like they eat themselves.

To read more, go to: https://issuu.com/international_aquafeed/docs/ipf2210_web/20

MAGLINK: https://mymag.info/e/1685

The Interview

Denmark

With over 20 years’ experience in the pet food sector, Gunnar Hallmann started his career at Arovit (now C&D Foods) as a Project Manager in 1999. During that time, Mr Hallmann held a number of high-level positions in project, factory and product management, before progressing into more strategic operational roles.

Born and educated in Denmark, he holds degrees in production technology and business administration, and a Master’s in packaging technology and general management.

To read more go to: https://issuu.com/international_aquafeed/docs/ipf2210_web/40

MAGLINK: https://mymag.info/e/1686

With Gunnar Hallmann, Industry Director, Aqua & Pet, Andritz Feed & Biofuel,

Our last edition 6 | November 2022 - International Petfood

Joseph P Kearns Editor, International Petfood Magazine

WEIGHING, BACTERIA CONTROL, SOFT BITES AND WATER ACTIVITY

There are many important processes in petfood production and weighing or ensuring the formula is correct is a big one. The list of nutrients on a finished bag are minimums or maximums and usually guaranteed. The function of the raw materials area is to prepare the formula by weight with an assumed coefficient of variance, a plus or minus figure within a range. Adjustments are made to ensure correct levels of each ingredient are added, usually by computer control. The mixes can be checked with an NIR or other methods to guarantee nutrient levels are met. Micro ingredients also a part of the mix and usually added with an exact system due to costly ingredients added at a low level. Calibration of the scales and system periodically are recommended so as to maintain accuracy. Also, downstream equipment such as conveyors, holding bins, hammermills sifters etc. all play a part is getting the formula to the cooking device. Good designs in these areas will promote movement of the mix forward with low levels of mix being lost in the process.

Dependent on the mixture the system might have more than one weight scale allowing for increased weighing speeds and accuracy. Ingredient usage varies thus bin sizes and discharge devices including screw conveyors are sized based on the ingredient usage per batch. It is not unusual to see two speed screw conveyors used in this area to move volumes of materials at the higher speeds then slow down for the final correct weight.

Bacteria in petfoods is now regulated and the idea is to have a salmonella free kibble delivered to the pet owners. I believe this is easier said than done, consider the overall plant design needs to take this into account. Mainly the raw materials must be assumed to be contaminated and thus handled accordingly. Separate areas for raw materials and processing. No dust allowed into the production area and this is handled by plant design with walls and zonecontrolled air pressures and movement patterns. If this is managed and procedures are in place the mix can be processed by high temperature short time extrusion or other methods to achieve the kill temperature for salmonella, 77oC. Dr Fung outlined this as well as other contaminates where 125oC is another critical control point. At 125oC all bacteria spores and other questionable elements are eliminated. Properly placed sensors can control the flow and detect the temperature exiting the conditioning cylinder, 77oC minimum. The same is true for the end or the extruder barrel but at 125oC.

Again, the clean product exiting the extruder needs to be protected from reinfection. Conveying system and downstream equipment is designed to achieve this with care and properly outlined good manufacturing practices for sanitation and continuation of air movement control and wall placement.

Soft bites or what is known as semi moist, soft moist or other names of higher moisture kibbles are unique in texture and can contain elevated moistures. Typically, these are made via extrusion cooking and formulated to be cooled to maximize moisture retention. Thus, precautions must be made to ensure the shelf life of these products sold separately or sometimes mixed in with dry kibble. A liquid ingredient steam is usually added to the conditioning cylinder where it mixes with the dry ingredients. This mixture has ingredients which control bacteria and water activity. An acid to lower the pH, a water loving ingredient to hold or bind the water and a mold inhibitor. An example would be phosphoric acid, propylene glycol and potassium sorbate respectively. Lowering the pH protects against bacterial attack, a water loving ingredient by design allows for elevated water levels and the mold inhibitor protects against mold development.

Water activity is also a subject of great importance, method of determining if the water in the final product will allow bacterial growth. I recently attended the FIGAP Feed production School in Guadalajara Mexico and Rob Strathman of Famsun gave an excellent presentation on this subject. Bacteria cannot grow at reduced moisture levels thus the measurement of the Aw to effectively control the growth environment, the kibble. Typically, at an Aw of .70 at 25oC this is the upper limit to control microorganism growth. A target level of .63 to .65 is usual in a quality assurance program. Bacteria can multiply at a rapid rate, doubling every 30 minutes a single cell can reach 1 billion in 18 hours. An overall approach is needed at the factory level to have a winning program. Evaluation of incoming ingredients, both dry and liquid as well as environmental effects such as weather, trucks and personnel backed by a Certified Safety Program greatly assist in control of bacteria growth hot spots etc. All is needed is the organism, organic matter, time and water and you will have bacteria growth. Assume it is present and plan for its elimination and control.

International Petfood - November 2022 | 7

Professor Simon Davies Nutrition Editor, International Petfood

The skin; a natural barrier for nutritional implications in dogs and cats

The skin is actually one of the largest tissues or organs of the human body but of course also for our companions’ cats and dogs. The integument is the vital barrier protecting the animal from the exterior world and is the primary defence system against injury and disease (e.g., parasites and bacteria, viruses). It has a complex structure of layers from the visible epidermis to the underling dermal region with vascularisation and a network of intricate nerves. Skin is a dynamic tissue and with a constant turnover of cells undergoing routine division and replacement. The sloughing of squamous epithelial cells requires new tissue generation, and this is true of all regions as the animal grows and develops over time. Skin is easily damaged, and it varies in thickness and texture in the cat and dog. Of course, it is often subjected to injuries and wounds in life from diseases, infection, and accidents as well as lesions from fighting. Veterinarians can prescribe a plethora of drugs and chemotherapeutics such as antibiotics to treat skin ailments, but we must also evaluate the role of nutrition in skin management from the point of pet nutrition. It is therefore vital to appreciate that skin problems in dogs and cats need to be addressed from the inside out, not only the outside in. Alleviating the discomfort of your pet’s itching and inflammation requires a full comprehension of the root cause of the problem. Otherwise, symptoms will just keep materialising and become chronic in nature. Skin has a relatively high rate of metabolism and requires much energy fundamentally resourced from dietary intake. It also requires a well-balanced supply of essential amino acids like lysine, methionine, arginine, and threonine as protein components for skin maintenance and health. Structural proteins like collagen, chondroitin and elastin are vital to

form the supporting framework of various skin layers and these protein fibres can age and fail to function and lose plasticity in the older cat and dog. Also, many micronutrients are involved in skin maintenance such as the trace elements and vitamins. Trace minerals like zinc, iron, copper, and selenium play a major role as co-factors of enzymes in skin cells, but even macro-elements such as magnesium and phosphorous have crucial metabolic roles. Vitamin D3 and ascorbic acid (vitamin C) are important but although dogs and cat can synthesize the latter for normal conditions, it can however be important to have a dietary supplement during phases of stress and under acute disease scenarios. We have good scientific understanding the benefits of vitamin E in the condition of skin in all animals and for its repair and cellular turnover. Vitamin E can work synergistically with selenium as powerful antioxidants to mitigate the production of free radicals in skin tissues. It can be seen that nutrition within a well formulated pet food is paramount to healthy skin in our pets. The hair and coating quality are greatly affected by the presence of key essential nutrients especially selenium, vitamin E and in particular the omega-3 components of oils such as linseed (flax) and marine sources (fish and algae).

Fortunately, there are now numerous feed additives and medicinal herbs that can be used to support and augment the repair, regeneration, and restoration of healthy skin in dogs and cats. The use of prebiotics and probiotics and many photobiotic natural agents are now available for the formulator. There is no doubt that much scientific research can be directed to this interesting topic for more advanced pet foods in the future to give our cats and dogs their lustre.

AVA welcomes new biosecurity measures on petfood as mandatory Australian pet food standards remain in limbo

New biosecurity measures on pet food vital as mandatory Australian pet food standards remain in limbo.The Australian Veterinary Association (AVA) welcomed the Federal Government’s new biosecurity measures announced yesterday for imported animal-based pet food entering Australia.

The peak veterinary body said it would like to see precautions require that any imported pet foods or treats are compliant with Australian Standards. “It’s excellent to see new biosecurity measures put in place to control the risk of disease,” says Dr Bronwyn Orr, President of the AVA. “Most people would be surprised to know that there are no mandatory quality standards for pet food in Australia. There are no safeguards to ensure pet food is balanced, nutritious or even safe for pets. “The AVA believes that all pets in Australia should have access to safe, high-quality food, and if a problem arises, there should be a prompt and regulated recall and investigation.”

There have been many injuries and even deaths in the last 20 years associated with commercial pet food, pet treats and pet meats. The consequences of losing a beloved companion animal to unsafe pet food are profound and long lasting. Currently the national Australian Standard for the Marketing and Manufacture of Pet Foods (AS5812) for pet food is voluntary. It is now close to four years since the 2018 Senate Enquiry into Pet Food Safety recommended a mandatory Pet Food Standard to ensure pet food quality and safety.

“Moving from a voluntary standard to a mandatory one would guarantee that pet food meets a high standard of food safety and traceability,” Dr Orr says.

“It would also help to prevent potential contaminants from entering pet food and keep our pets safe.”

BARK expands food offering to serve ten breeds plus puppies

BARK, Inc., a leading global a leading global omnichannel brand with a mission to make all dogs happy, today announced the expansion of its breed-specific food offering to include seven additional breeds. Following an initial rollout of premium kibble, supplements, broths, toppers, and treats tailored to Chihuahuas, Labs and Pit bulls in August, BARK is expanding its food line-up to include a full suite of products for Dachshunds, French Bulldogs, Boxers, Australian Shepherds, German Shepherds, Golden Retrievers and Doodles, as well as mixes of those breeds. Designed by BARK’s team of dog food experts and nutritionists, BARK Food provides healthy meals and accessories tailored to the dietary needs and individuality of specific breeds to help them be their best, happiest, and healthiest dog-self. BARK’s Same Price Forever guarantee ensures the price that customers pay for their dog’s food will not change for as long as they remain active customers. The Company has made the same promise to its BarkBox subscribers since its founding in 2011. To date, roughly 70 percent of BARK Food customers have subscribed to recurring shipments.

“Over the past 11 years, we’ve had the opportunity to serve millions of dogs and have learned first-hand the value of serving each dog as an individual,” said Matt Meeker, Co-Founder and Chief Executive Officer of BARK. “Since launching our breed-specific food in August, customer engagement and conversion has improved significantly, and today’s announcement is a testament to the sizable opportunity we see ahead. With BARK Food now serving ten breeds and offering puppy-specific formulas, our addressable market has grown considerably, and we look forward to including

To celebrate this milestone, BARK is launching the Next Top Dog Model contest to enlist 10 dogs as the face of BARK Food. From today through November 17, dog parents can share a photo of their dog and why they should be BARK’s Next Top Dog Model via the submission post.bark.co/ models. The 10 winners will be featured on BARK’s social media channels.

PETFOOD NEWS

ADM unveils new premix production line

October 18-19, 2022 saw ADM host a ribbon-cutting ceremony at its new premix production line at its facility in Chierry, with the line ‘significantly expanding’ the company’s capabilities.

Added to help meet increasing consumer demand in pet nutrition, the new premix line will produce premium and functional premixes for use in dry and wet petfoods, treats and dietary supplements.

“Consumers increasingly turn to food and treats as a source of overall health and wellbeing for their pets,” says Jorge Martinez, president of pet nutrition at ADM. “We’re excited to continue investing in the pet nutrition space to help our customers meet

these growing demands for highquality, responsibly produced pet nutrition products.”

ADM’s customers also viewed presentations on the pet food market, pet treat innovations, biotics in pet nutrition, and the new opportunities ADM’s premix line can offer. The company also conducted a tour of the production line.

“Our new pet premix capabilities allow us to explore new ways of blending specific ingredients, opening up incredible potential for innovation that helps position ADM as a go-to partner,” Mr Martinez says.

The investment in the line is ADM’s latest within the pet nutrition space. In 2021, the company acquired a majority stake in PetDine, Pedigree

Ovens, The Pound Bakery and NutraDine, significantly expanding its pet treat and supplement offerings.

Among the acquisitions, ADM has also reinvested in its facilities, adding a new petfood culinary kitchen and an extrusion line at its Animal Nutrition Technology Center in Decatur, Illinois, US.

“More than ever, ADM’S expansive portfolio of top-quality ingredients allows customers to eliminate the complexity of sourcing ingredients and qualifying suppliers,” Mr Martinez says. “ADM is the strategic partner for developing on-trend pet food and treat innovations for today’s pet owner’s demands while ensuring unsurpassed safety and quality.”

World’s first cell-based meat product has been developed for the petfood market

US Based Wild earth has announced the development of the world’s first cell-based meat product on the pet food retail market, which is due to be launched for consumers in 2023.

The cell-based meat product will come in the form of a meat broth topper for dogs, created with the company’s proprietary technology at Wild Earth’s labs in Berkeley, California. Plans to develop this were revealed in 2021, and since the company has been cultivating beef, chicken, and seafood, utilising the US$23 million investment they managed to raise previously. The company grew significantly in 2020 after closing a deal with Mark Cuban (Shark Tank) and secured many big-name investors including Paul Wesley.

Wild earth is a sustainable pet food company, specialising in protein-packed, nutritious, 100 percent vegan and

cruelty-free products that simultaneously reduce the harmful effects on the environment within the industry with their sustainable practices. They’ve previously produced a line on koji-based dog food, and plan to feature plant-based dog foods in new flavours at lower retail prices.

Their products are developed by a team of vets and animal food scientists and contain clean ingredients and healthy formulas that are backed by science. 86 percent of customers reported health improvements after switching to Wild Earth. Among the health improvements reported were higher energy levels, fewer allergies, shinier coat, better digestion, healthier weight. The ingredients currently used are plant-based proteins (such as chickpeas or yeast), antioxidant-rich fruits, spinach, sweet potato, and pumpkin.

comes to you either in print or digitally.

way you want to receive, please sign up on our

for your personal copy which will give you access, from your desktop, to our back-issue library.

can be downloaded from your favourite app store. We invite you to use the code below for a free edition of our November magazine either mailed to you or via our App Use coupon code: Euro22

INTERNATIONAL Download your online version PETFOOD NEWS 10 | November 2022 - International Petfood

International Petfood

Whichever

MagStand

https://store.magstand.com/petfood The App

PETFOOD

symaga.com • +34 91 726 43 04 • symaga@symaga.com 50 million m3 built Projects in 145 countries Top Project worldwide Flexibility and adaptability A reliable team for a reliable project YOUR RELIABLE PARTNER Improve silo tightness. Double Vertical Joint. · Tightness is improved. Double sealing on both sides of the screws. · Butyl rolls are supplied with double strip to improve assembly times. GRAIN TECH INDIA, Bangalore, 26-28 August, Stand K-9 VICTAM, Bangkok, Thailand 7 - 9 September, Stand 1670 VISIT US

Anew report by Future market insights has stated due to the rising adoption rates of pets worldwide, pet food demand seems to be growing at a CAGR of 5.3 percent between 2022 and 2032.The pet food market was valued at US $104.96 billion by the end of 2021, and wet pet food accounted for 19.2 percent of that sum. Demand has risen over the past few years due to rising consumer awareness about the benefits of wet pet food, which include assisting in keeping pets hydrated (due to high moisture content), preventing urinarytract infections and preventing weight gain (due to the low-carbohydrate content). Wet pet food is ideal for overweight pets or pets who have

trouble chewing hard food due to dental problems and illness.

Pet adoption in high-income nations has increased due to the benefits of ownership, including pets boosting owners’ mood, reducing their stress, anxiety, depression, loneliness, as well as other health benefits such as encouraging exercise.Dogs are the most popular pets around the world and contribute a significant portion or revenue to the pet food sector, particularly in China - a country ranked third in the world in terms of dog ownership in 2020. The second most popular pets were cats and birds. A rising number of ecommerce platforms and growing demand for natural pet food are also significant factors driving

the wet pet food growth.

The rising sales of wet pet food has indicated a shifting preference for pet owners, with an Increase in demand for premium quality products that assure optimal nutrition and care has impacted the wet pet food market. Pet humanisation has likely inspired this since pet ‘parents’ are now spending more time and attention on their pets, demanding Higher quality ingredients similar to human-grade quality ingredients. Wet pet food offers nourishment, health benefits, and a great source of protein to help pets live longer and better lives, which in turn has encouraged companies to continuously produce new products to tackle new consumer demands.

Avivagen reports increased interest in OxC-beta product

Avivagen, has announced securing a “significant” order for its OxC-beta from AB Vista, its exclusive distribution partner in the US, Brazil and Thailand. Avivagen, which is a life sciences company, focuses on developing and commercialising products for livestock, pets and human applications to safely enhance feed intake and support immune function.

OxC-beta supports immune function and provides a “non-antibiotic means” of promoting health and growth, according to the company. OxC-beta Livestock is shown to be an effective alternative to antibiotics commonly added to livestock feeds and presents an opportunity to remove all in-feed antibiotics being used as growth promoters.

The order, which weighs at 1.2 tonnes, will be shipped for use in Brazil where AB Vista is in the process of running ongoing trials with large poultry and cattle producers. Brazil was ranked as the number three feed-producing country in the world in the 2022 Alltech Agri-Food Outlook as it produced 80.1mmt in 2021.

“We are excited to be making further inroads into one of the world’s largest feed production markets. The large size of this order is a testament to the growing demand for safe and effective alternatives to antibiotics and the market opportunity for our products,” explains Kym Anthony, CEO at Avivagen. “We expect this important relationship with AB Vista

to continue to play a significant role in the increased adoption and use of OxC-beta to promote animal health and growth in livestock throughout the Americas.”

Its product, OxC-beta, has applications in livestock health and supporting the health of pets. OxC-beta is used as a key ingredient by a leading producer of dog food in Taiwan, as the company in question expanded its product line of dog food containing OxC-beta to include canned food and dry kibble.

Last month, Avivagen announced significant sales of this product, including a 1500 unit order for Vivamune, Avivagen’s Taiwan-based distribution partner. This represents the largest single order from Vivamune and reflects increased consumer awareness and interest.

In the same month the company announced the first of two new customers in Mexico – one being an independent distributor of nutritional products for dogs which has ordered 4000 units of white labelled product which it will market under its own bread, and the second which has placed an order for 500 units of Vivamune. “We are seeing great interest and opportunity for Avivagen in the companion animal market today,” says Mr Anthony. “These new sales and customer wins in key markets like Taiwan and Mexico follow sales in Canada and the US, and are clear signs of growing demand for our companion animal product as an important part of promoting pet health. We are excited to be expanding our customer base and recurring business in these areas,” he concludes.

The Global wet pet food market is estimated to be valued at UD $21.5 billion in 2022, expected to rise to US $36 billion by 2032

PETFOOD NEWS 12 | November 2022 - International Petfood

3-5 OCTOBER 2023 NEW! SÃO PAULO BRAZIL LATIN AMERICA’S LARGEST DEDICATED EVENT FOR THE ANIMAL FEED AND GRAIN PROCESSING INDUSTRIES • Animal Feed • Agua Feed • Pet food • Poultry feed • Flour milling • Grain processing, handling & storage MORE INFORMATION � NICKMOUTHAAN@VICTAM.COM � +31 6 2126 4398 � WWW.VICTAMLATAM.COM MORE INFORMATION Scan the QR code or visit victamlatam.com FOUNDING COMPANIES International Petfood - November 2022 | 13

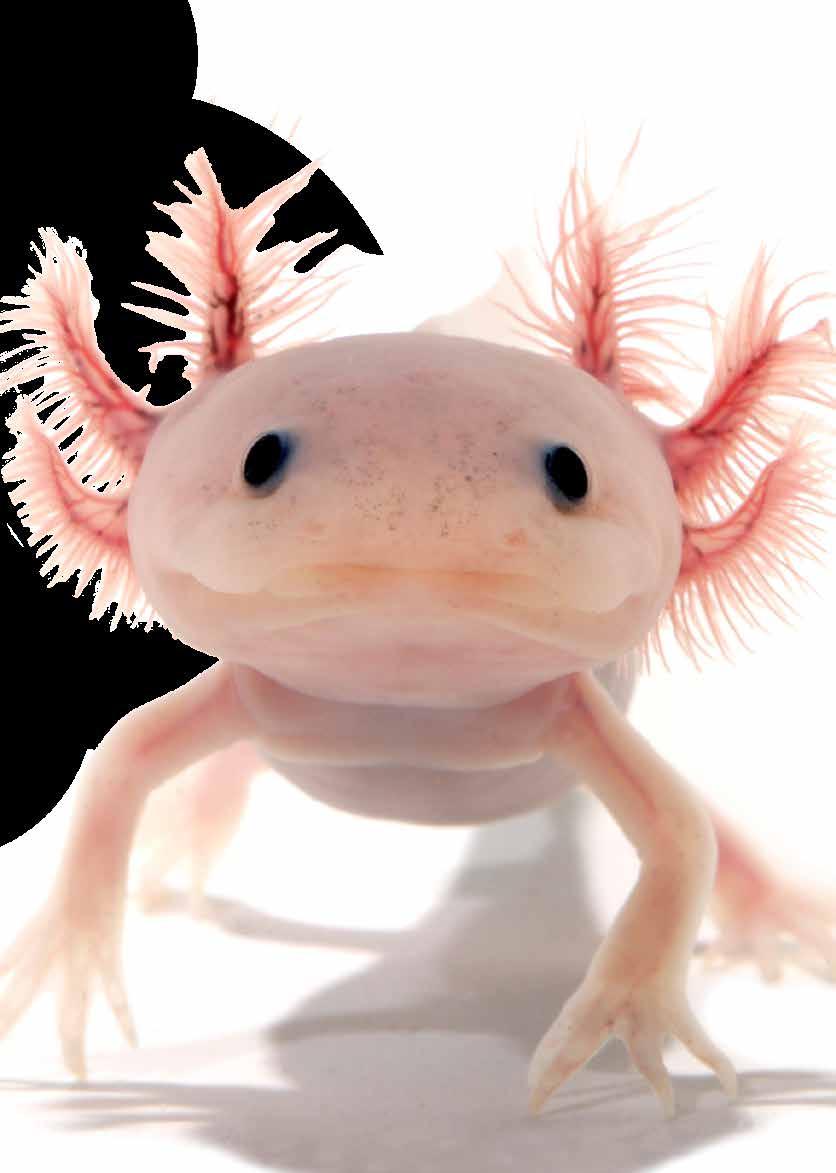

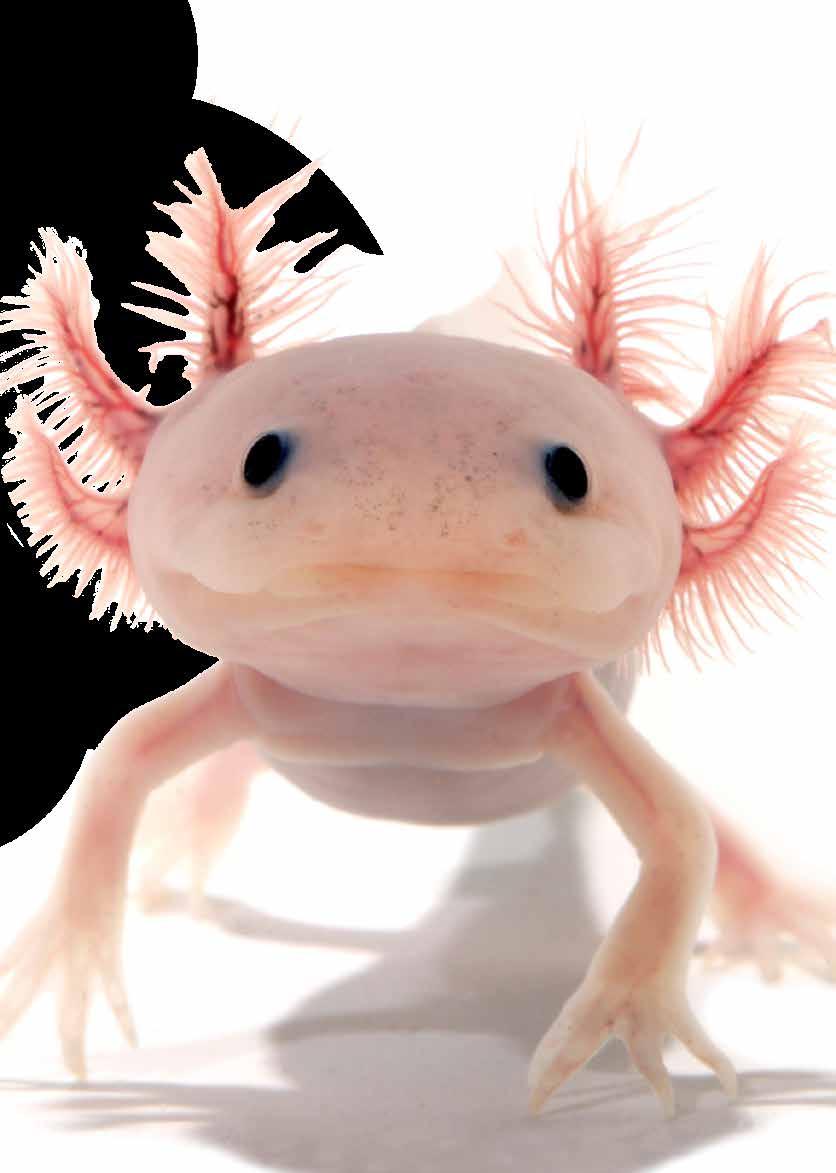

An Axolotls Diet

by Shannon Parsons, International Petfood magazine, UK

Axolotls are cute looking aquatic salamander that many people keep as pets. In the wild, axolotls are a critically endangered species that are native to Mexico and were first brought over to Paris in 1864, fascinating Europeans. They’re a type of salamander that doesn’t go through metamorphoses from larvae to adult form, meaning they continue to breathe through their feathery gills. They also have soft, delicate bodies with permeable skin, with most of their body being made from cartilage rather than bone. However, they can regenerate lost or damaged limbs, hearts, spinal cords, and even parts of their brains, which baffles many biologists due to the lack of permanent scarring left behind.

Wild vs Captivity

The diets between wild and captive axolotl differ but remain similar enough. Wild axolotls feed on a mixture of snails, worms, crustaceans, small fish and animals and more. Captive axolotls feed on brine shrimp, small strips of beef or liver, frozen fish food, commercial fish pellets and more. All axolotls are carnivorous though with cannibalistic tendencies if hungry enough. Don’t be fooled by the cuteness of axolotls, they will eat their own young.

If you do feed meat to your axolotl though, make sure it is cooked. Raw meat can contain bacteria that may be harmful to the axolotl and can cause them to become sick. It is similar to feeding self-caught insects or fish as these may contain parasites. If you plan to feed any worms or small fish to your axolotl, make sure they come from a reputable provider, so it minimises the risk of parasites possibly being passed onto your pet.

Nutrients and Live Food

Using a mix of both feed pellets and live/frozen worms, daphnia

and ghost shrimp, they all provide the nutrition required for an axolotl. Vitamins and mineral supplements are rarely needed when caring for an axolotl as they receive all the nutrients they need from their food.

Worms are some of the most common types of feed used, but there are various types of worms, each with their own benefits and drawbacks. Nightcrawlers are a popular choice with them tending to be an axolotl’s favourite, with choices ranging from Canadian earthworms, European earthworms and red wigglers. Two alternatives to nightcrawlers though are blackworms and blood worms.

Earthworms are incredibly nutritious, as are red wigglers, but unlike earthworms, axolotls do not enjoy red wigglers as much. In fact, they’ll actively avoid red wigglers because they taste bad due to them excreting a bitter substance when handled as a defence mechanism. The various worms are easy to obtain, tending to be rather cheap and typically found in bait shops. They do leave the tank rather messy however, causing the tank to need regular and thorough cleaning. Blood worms unlike the rest, are the least nutritionally valuable worm out of them all. While being a favourite to axolotls, they aren’t very healthy, so owners tend to use them as an occasional treat.

Other live feed that is mostly popular for feeding larvae axolotl are daphnia. Daphnia are a quick and easy cheap source of protein that is highly nutritious due to how high in fatty acids, lipids and vitamins it is. They’re also easily able to be homecultured, making it easy to have the desired number of daphnia for extremely cheap. Plus, they’re great for cleaning unwanted bacteria in the tank, so any leftover live daphnia from feeding puts them to good use. Despite all this, they’re an unnecessary food choice for full-grown axolotls as while they contain a high amount of protein for larvae axolotls, for adults the amount is rather small, making them almost pointless food choice proteinwise.

An alternative to daphnia that’s beneficial to full-grown axolotls are brine shrimp. They’re high in vitamins, lipids and fatty acids

The types of food that are both nutritional and enjoyable for axolotls

F 14 | November 2022 - International Petfood

whilst also being incredibly easy and cheap to buy or breed at home. A negative to using brine shrimp however is that whatever the axolotl doesn’t eat, the shrimp if not already dead, will quickly die and possibly leave behind diseases, alter the water hardness due to their salt content and makes the tank messy. A method to prevent this is by either freezing or freezedrying the brine shrimp into various portion sizes that can then be used when needed, preventing any unnecessary waste, mess and diseases.

Pellets

Axolotls prefer live or frozen food but aren’t averse to fish pellets. Some will refuse to eat them, but many will happily enjoy them. They’re also a wonderful option for owners who become squeamish with using live food. It’s incredibly important to ensure that the protein content is high enough in the pellet to compensate the lack of live food though. They should only be fed pellets occasionally though as it’ll cause axolotls to gain weight quickly. For a healthy diet, you need to make the diet a mix of both pellets and regular food sources, such as worms, shrimp, daphnia etc.

Sinking pellets are better than floating pellets due to axolotls being bottom feeders so the sinking pellets would be easier for the axolotls to feed on. Floating pellets are best not to be used because axolotls are amphibians that tend to dwell on the bottom of their cage. If they try to eat the floating pellets, they run the risk of gulping air by mistake which could cause bloating, hindering the normal mechanism of digestion.

Stress and Obtrusions

Axolotls become stressed easily which tends to lead to injuries, illness or worst case, death. To prevent this in feedings, never feed an axolotl anything larger than its head. All food should be smaller than an axolotl’s head, which ties into the environment of the axolotl’s tank.

Many people line the bottom of their tank with gravel to provide their axolotl with something to grip onto. However, axolotl will eat gravel sometimes, which can cause gastronomical obtrusions and death. To prevent this, make sure the gravel is a size they are unable to ingest or use to switch to sand as it will pass through the animal with no issues.

7th March 2023

IMPACT, Bangkok

Platinum- €1,245

Free registrations for clients x11/4 page advert to be included in conference brochures

X1-Side banner on the event page and o cial website

-Your company logo to be displayed on promotional material

Gold- €2495

Free registrations for clients x1-1/2 page advert to be included in conference brochures

X1-Side banner on the event page and o cial website

-Your company logo to be displayed on promotional material

For more information please contact:

Silver - €1245

Free registrations for clients x1- Full page advert to be included in conference brochures

X1-Side banner on the event page and o cial website

-Your company logo to be displayed on promotional material

For sponsorship enquiries contact: Tuti Tan - tutit@perendale.co.uk or : Roel Schoenmaker - roel@vnueurope.com

For sponsorship enquiries contact: Tuti Tan - tutit@perendale.co.uk or : Roel Schoenmaker - roel@vnueurope.com

Untitled-1 1 11/11/2022 16:59

International Petfood - November 2022 | 15 F

Axolotls are the Peter Pan of Salamanders who manage to stay ‘young’ throughout their lives by retaining their larval characteristics and thereby never growing out of their aquatic lives like other salamanders.

CALCIWORMS

An alternative source of nutrients for aquatic pets

by Thomas Marriot, Features Editor, Peregrine Livefoods

Black soldier fly larvae are considered a superfood in the world of exotic pet keeping. Across the globe, they have adorned various names including ‘phoenix worms’ and ‘repti-worms’ but in the UK, they are most commonly referred to as ‘calci-worms’. They are the grub of Hermetia illucens, which is a type of fly (though they do look like small wasps) that can be found across North America. ‘Calci-worms’ have earnt their name because they can contain over 20X the amount of calcium of a similar-sized cricket. Their calcium-to-phosphorous ratio is also near perfect (1.5:1), meaning that they can be fed to reptiles without additional supplements. They also contain large amounts of lauric acid. This compound is extremely beneficial to animals, as its anti-microbial properties can help flush out nasty parasites.

FishScience is a revolutionary brand of commercial fish food that utilises insect meal as a core ingredient, founded by David pool in 2013. After a 25-year career at Tetra, as well as several years studying Freshwater Fisheries at the University of Liverpool, David began building the FishScience brand using black soldier fly larvae (Hermetia illucens) as a key ingredient. By swapping the industry standard protein of fish meal, for a more sustainable insect meal, the brand gained wide praise from fish keepers. Not only do insects provide a far more naturalistic diet for aquarium fish, but they are also farmed in more sustainable ways. Farming insects typically produces ten times less CO2 than that of other commercial livestock. Black soldier fly larvae can be raised on organic waste and the entire supply chain can be more closely managed by suppliers, leaving less room for environmental damage whilst still producing vast amounts of protein.

Nutritional value of calci-worms:

“It only made sense that we should be feeding fish what they would naturally eat in the wild” explains David. “Fish have evolved for millions of years to digest and process insects. Yet, most fish foods in the aquarium industry are based on fishmeal – surely there’s something wrong with this.” The nutritional composition of calci-worms is already renowned across multiple industries. Although their nutrient profile will change as the larvae develop, research suggests the average calci-worm (farmed for the exotic pet food industry) is comprised of moisture (61.2%), protein (17.5%), fat (14%), ash (3.5%) fibre (3%) and contains calcium (9,340 MG/KG) and phosphorous (3,560 MG/ KG) as well as other beneficial trace elements. For example, Calci-worms contain more iron and zinc than lean meat which has led many experts to suggest they could make an excellent source of protein for human consumption. Farming insects for the dinner table requires rigorous monitoring and therefore it is unlikely that calci-worms will be available in supermarkets any time soon. However, their sustainability makes them particularly appealing to exotic pet keepers and as a primary ingredient in pet food. Researchers at the University of Melbourne discovered that 0.5 hectares of black soldier fly larvae farming can produce more protein than cattle grazing on around 1200 hectares of farmland or 52 hectares of soybeans.

Calci-worms, when manufactured into insect meal, retain much of their excellent nutritional value and therefore make the perfect basis for fish food. David’s specialist knowledge allowed him to build upon this idea to create a variety of new products aimed at specific species. Working with other industry experts, he launched a spectrum of pellets, flakes and tablets with other key ingredients. For example, adding an oak wood component to the brand’s Corydoras tablets helped create a product that mimics a natural diet. David has also manufactured Cichlid-

16 | November 2022 - International Petfood F

specific foods that are made up of various algae like that found in Lake Malawi, a shrimp food that is high in calcium for exoskeleton formation and a ‘worm pellet’ comprised of four different species of worm/larvae for strictly insectivorous species. Most products also contain carotenoidrich, natural ingredients such as carrot, paprika and chlorella algae to help boost the colouration of the fish. Garlic and omega oils are also excellent tools for maintaining fish vitality. Whilst many high-end fish foods will utilise these ingredients, FishScience carefully crafts every product so even foods aimed at beginner hobbyists contain expert ingredients.

Wheat germ based diet for Koi

Another product famed for its innovation is the FishScience ‘cold weather’ pond food. This is because the nutritional requirements of koi vary considerably throughout the year and thus, keepers should provide different diets. For example, protein is necessary for growth, but can only be used at warm water temperatures (over 15°C). Therefore, in summer, keepers feed high-protein food because the koi can use the protein to grow. Whereas, in winter, a lower protein food is sufficient because the koi are less active and not increasing in size.

Feeding protein-rich foods at low temperatures can even harm koi. Below approximately 10°C few if any of the proteins will be used for growth. Some may be used inefficiently to produce energy for movement etc, but the majority will pass straight through the fish. The resultant protein-rich waste can have adverse effects on the water quality as it decomposes. By formulating a wheat germ based diet that has a lower protein content, FishScience has produced a seasonal food that is much more suitable than the average pond pellet. It produces far less waste which helps maintain water quality throughout the winter and prevents any potentially harmful ammonia build up.

Peregrine Livefoods is a reptile wholesaler and insect breeding facility based in Epping Forest in the UK. It has been breeding insects since the 1980s and plays a pivotal role in the UK’s exotic pet industry. In February 2022 the company acquired FishScience and continues to work closely with Dr David Pool to improve and expand the business. Peregrine Livefoods is currently updating packaging and aims to launch a newly re-branded range of FishScience products in early 2023. FishScience will also be launching a range of new products as it continues to grow in the wider exotic pet industry.

Decades of Global Experience. 50 Years in Business 66 Countries Served 1,000+ Products Moved 32,000+ Conveyors Commissioned operation our systems are hard to compete against. Cablevey Conveyors Gentle Clean Reliable Conveying The Heart of the System CABLE & DISCS Cablevey® Conveyors is a registered trademark of Intraco, Inc. 07/2022 Worldwide Experts in Cable and Disc Conveying Solutions +1(641) 673-8451 www.cablevey.com www.cablevey.com +1(641) 673-8451 info@cablevey.com

FishScience and Peregrine Livefoods

International Petfood - November 2022 | 17 F

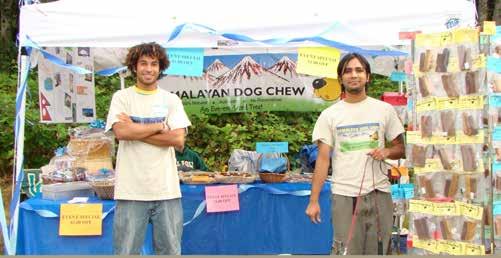

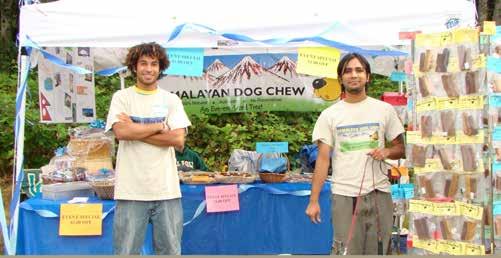

THE STORY BEHIND THE ORIGINAL HIMALAYAN DOG CHEW

How a commitment to human progression created a new US$75 million dog chew category

By Suman Shrestha, President, Himalayan Pet Supply

What started as a small family business born out of tradition and curiosity, has grown into a complex supply chain and an entirely new industry in Nepal that supports economic growth and social progress.

I accepted an invitation for a dinner gathering at a friend’s house in Bellingham, Washington, with a small group of relatives and friends who had also grown up in Nepal. It was over 20 years ago when I first saw my friend’s dog, Kaos, chewing on a piece of Churpi, a common food in Nepalese culture. For centuries, the traditional hard cheese chew was made by people of the Himalayas to dry and preserve cheese. Although I enjoyed Churpi throughout my childhood, I had never thought about feeding it to my dog – until then.

While I was curious if all dogs might share my love for Himalayan cheese, I quickly learned that the traditional recipe could upset a dog’s stomach. As an aspiring chemist, I knew there was an opportunity to improve the digestibility of the hard cheese chew. With the help of my brother and friend, we spent nearly four years reengineering the ancient recipe – we removed the lactose and lowered the fat content to make it perfect for dogs. And I think it was worth the wait.

In late 2007, we took our first batch of cheese chews from Nepal to a small pet fair back in Bellingham. We started with 100 pounds of chews and sold out within the first two hours. That was a positive sign for our new venture. The following year, we officially founded the Himalayan Dog Chew Company and introduced the first hard cheese chew in the pet industry, creating

an entirely new category.

Since our humble beginnings, we have focused on making the safest and highest-quality alternative rawhide chews in the industry and put human progression and economic growth at the heart of everything we do.

18 | November 2022 - International Petfood F

on People, Pets, and Progress

Our first step was to establish our supply chain to locally, and ethically, source the milk and process our hard cheese chews. We ended up building a logistical and training operation in Nepal that will continue to support the growth of this entire category for years to come. From the family farms and hillside collection sites to the dairy centers and production facilities, our supply chain is a bit more complex than you might expect for a hard chew made from one simple ingredient: Himalayan cheese.

With the help of my parents back in Nepal, we started working with small family farms throughout the Himalayas that get their livelihood from the milk from their cows. Small farms have always been a critical part of our global community and we’ve always tried to advocate on their behalf; we helped pass the first laws in Nepal to allow farmers to take out insurance on their livestock as capital, protecting the farmers and their families for future generations. In addition to providing these farmers with fair wages and a reliable income from the milk, we offer education on how to care for their cows to prevent disease and keep them in good health. We have multiple checks for safety and quality and follow the strictest production standards throughout our process.

Since the farmers typically have a small number of cows, we work with nearly 45,000 family farms to source the milk needed to keep up the demand for our original hard cheese chews. To help maintain strong relationships with all our farmers, we established an exclusive partnership with Manaram, a local company that is certified by the World Fair Trade Organization, shares our vision for human progression and economic growth

and strives to help to eliminate poverty in Nepal through production and trade.

Many farmers will travel long distances by foot, bike, or horse to bring their milk to one of about 1,000 collection co-ops located in the hilly region of Nepal, about 2,600 feet above sea level. Before accepting the milk, we confirm that its being sourced from healthy cows, test the fat-to-liquid ratio of the milk to ensure it meets our quality standards and verify that the farmers are supporting social change and providing education for their daughters. This is the first of many checks for safety, quality, and ethical standards across our supply chain.

We transport the milk collected at the hillside co-ops to one of our dairy centers, which follow the same strict production standards we have in our U.S. facility. We start making our chews by pasteurizing the milk. After separating and removing the fat,

Proven Performance Put Your Conveyor on Pole Position! • Reduce Downtime & Maintenance Costs • Quick and Easy Chain Assembly • Bolt on Flight Replacement (No Welding) • Forged and Hardened Chain Links DOWNTIME IS A RACE... TIME IS MONEY 'N' Go™ Drag Conveyor Chain www.go4b.com www.go4b.com 4B GROUP Bolt'n'Go Advet (Half Page) - No Email_Layout 1 30/06/2015 12:17 Page 1 Building

Dedicated Supply Chain

Focus

a

with a

International Petfood - November 2022 | 19 F

or cream, we use our special process to breakdown the lactose. Then, we add a little citrus juice to naturally thicken the milk to create curds that we press into a slab for about 24 hours before we cut them into our famous cheese chews. Much like making beef jerky, we use smoke to dry the chews – and this process takes nearly two months.

Our cheese chews are rigorously tested and inspected before they leave our dairy centers and, again, when they arrive at Manaram’s headquarters in the capital of Kathmandu. At both locations, we conduct testing for moisture, water activity and pathogens. At Manaram, our team sorts and buffs the chews by hand and visually inspects them to make sure they meet our quality standards and do not appear brittle or misshapen. The journey for our original cheese chews doesn’t stop there

– they are packaged and exported to our new, state-of the art facility in Arlington, Washington. Currently, our dog chews account for about six percent of the total native exports for the entire country, and we are continuing to strengthen this industry in Nepal. Once the chews arrive at our U.S. facility, which is certified for quality by SQF and APHIS, they undergo another physical inspection and round of testing to confirm they meet our strict standards before they are transported to our distributors and retailers to reach the pet parents.

From the family farm in Nepal to a pet parent’s home here in the U.S., it takes nearly six months to bring our original cheese chews to market. As a result of the care and attention we have put into this process, we are delivering the safest and highest-quality alternative rawhide chews in the industry.

F 20 | November 2022 - International Petfood

Supporting Human Progression and Economic Growth in Nepal

When I started this company, I wanted to make a positive impact on the people of Nepal – and it was my parents’ experiences that inspired me to support social change in my home community. My mother never had the opportunity to go to school because she was asked to take care of her brothers and married at a young age, and my father left school without completing 10th grade to help his parents raise his brothers and sisters. These experiences are far too common, which is why the country has a very low literacy rate. Since many public schools in Nepal do not have libraries, I recognized an opportunity to donate books and build libraries in remote areas of the country.

We work through the Manaram foundation to use the proceeds from the Original Himalayan Dog Chew to help protect and fulfill the right to education for children in Nepal. We donate one textbook for every pound of cheese we sell, which has resulted in more than 200,000 books being donated to local schools and libraries. Additionally, we’ve supported the building of more than 150 libraries in remote areas of the country and created dozens of annual scholarships for higher education

In addition to supporting childhood education, we are committed to improving the lives of women. About one out of four women in Nepal are employed and the vast majority (90 percent) of them engage in informal employment and earn below the government’s minimum wage rate, which means they are economically constrained by their employers. It is also customary for young girls to be married off into other families with little-to-no education. I knew education would lead to better job opportunities for girls in Nepal, while also empowering them to seek higher education through scholarships.

Since we introduced the first hard cheese chew for dogs in 2008, this new category of alternative chews has continued to grow and outpace the overall pet treats category. In fact, we have sold more than 35 million of our Original Himalayan Dog Chews in the United States, and interest continues to grow year-over-year. By continuing to build this category as well as our brand, we know the people of Nepal are seeing immediate and positive impacts in their daily lives and we are supporting the human progress and economic growth that has been important to me since the beginning.

International Petfood - November 2022 | 21 F

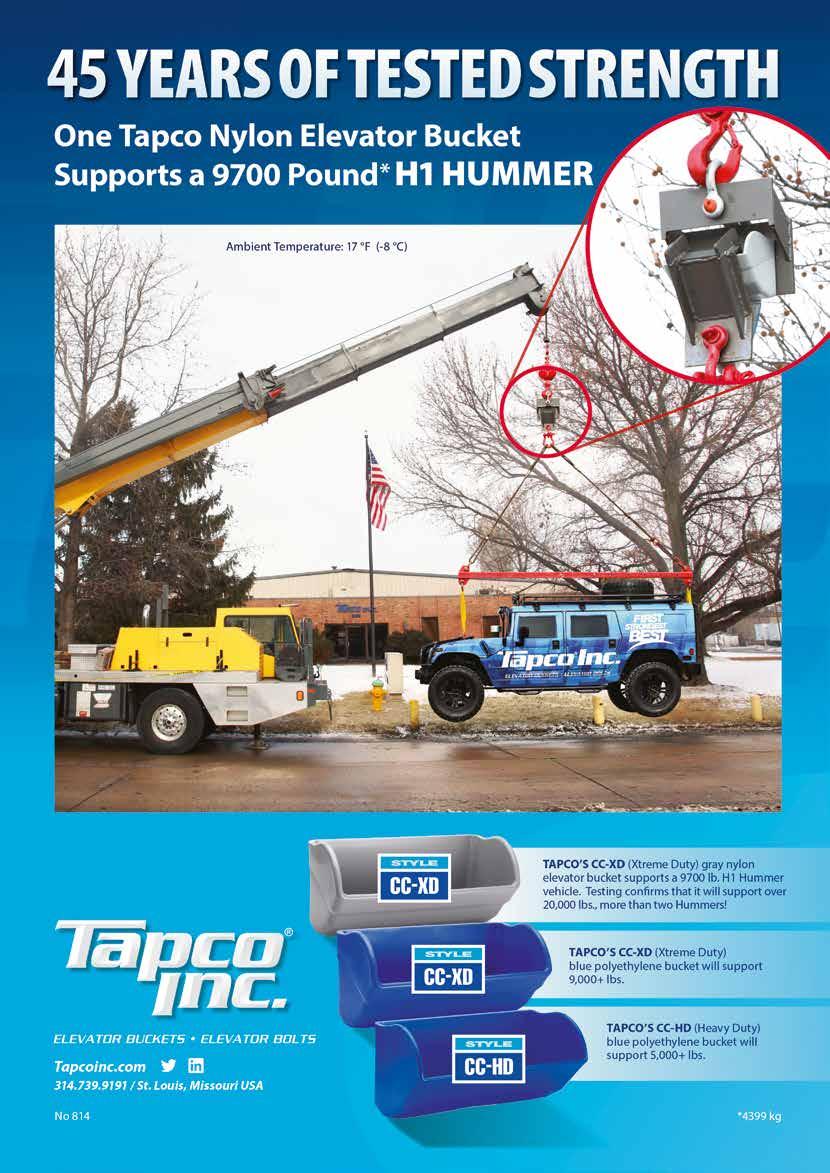

Commodity handling equipment

Why understanding what the right configuration for your operation is key

by Andrew Head, Sales Director, BDC Systems Ltd, UK

ith increased uncertainty around energy costs, both commercial grain operators, millers and farmers alike are struggling to make accurate forecasts as to exactly what they are going to have to pay.

It has perhaps never been so important for business organisations of all sizes, where grain handing is an integral part of their overall operation, to be using the right equipment for the right commodity. It is all about the right horses for the right courses.

Using the right equipment for the right commodity will help to ensure that each piece of machinery is working at optimal efficiency and therefore not wasting valuable energy attempting to handle commodities that can, and should, be handled more efficiently.

This article aims to provide advice for milling operators around what they need and what they should be considering when selecting the equipment for the mechanical handling of incoming commodities into their storage silos before the milling process begins.

However, much will also apply to commercial grain operators and farmers when handling grain, as it enters their

Wprocessing plants for storage, before being sold.

A chain & flight conveyor

When the commodity arrives at a milling plant it is tipped via a tailgate sock into a trench intake conveyor. The type of commodity determines the type of conveyor best able to handle it.

For free-flowing material such as wheat or oil seed rape we would recommend a chain and flight conveyor as the grain is able to self-flow into the machine and is easily moved inside the conveyor without damage to the crop.

Chain and flight conveyors are generally made from pregalvanised steel or mild steel which is then hot dipped for longer life. Normally these conveyors are fitted with direct drive motor gearboxes and the chains have plastic or steel flights. A variety of inlet and outlet options are available including hand operated, motorised or electro pneumatic (EP) slides.

Safety features include rotation sensors, blockage flap switches and inspection windows. Where it is important to prevent the escape of airborne dust, the commodity enters the milling plant via a conveyor which is located in an intake booth fitted with aspiration capabilities.

It is also important to understand the ability to install a rubble separator, magnet and simple aspiration system at the intake to remove any large foreign objects and airborne dust.

The removal of foreign objects is key in order to avoid potential damage to machines operating downstream with the

F 22 | November 2022 - International Petfood

milling plant. This can be achieved using a simple reciprocating or rotary screen machine.

If the commodity entering the milling plant is non free flowing, for example soymeal or soya, then we would recommend a screw conveyor. The advantage with the screw is that it draws the material into the conveyor and keeps it moving, avoiding bridging of the commodity.

Available options

From the trench intake the commodity is then transported via belt and bucket elevators to the storage hoppers before being transported to the milling process. As with chain and flight conveyors the majority of belt and bucket elevators are manufactured from pre-galvanised sheet, or mild steel which is hot dipped for longevity. These conveyors are fitted with direct drive motor gearboxes, oil resistant belting, boot rotation sensors and clean-out doors.

Available options include seed boots, front and back inlets, head access platforms and access ladders, explosion panels and belt alignment switches. The feeding of the belt and bucket elevators once again depends on the commodity being taken from the intake to the hoppers.

If the material is light and non-free-flowing i.e., soymeal, the belt and bucket elevator should be back-fed enabling the buckets to draw in and scoop the material into the elevator.

With free-flowing material the belt and bucket elevator is generally front-fed as it is easy for the buckets to lift the material

in flight. With the design of some elevators the capacity remains the same whether front or back fed.

Whether the material is front or back fed into the elevator, once it reaches the elevator head the centrifugal force discharges the material from the buckets. The material is then transported to storage hoppers via chain and flight or screw conveyors.

Determining the type of hoppers

Most of the material entering milling plants is stored in selfemptying hoppers and yet again the type of material being stored will determine the type of hoppers.

Free-flowing commodities are stored in 45 degree hoppers whereas those that are non-free flowing are stored in screw discharge or 60 degree hoppers, with expansion outlets. Milling operations are tightly controlled and the importance of avoiding downtime cannot be underestimated.

Operators who look closely at the build quality and reliability of the conveying and aspiration equipment they install are taking an important step in ensuring that, as far as possible, downtime is prevented from the conveying element of the milling process.

Before investing in new equipment or upgrading ageing systems it is key that operators carefully research the solutions and systems that are currently available. They should be investigating how equipment has been manufactured and whether suppliers can back-up their claims of robustness and reliability.

Has it been constructed from pre-galvanised steel or mild steel which has been hot dipped for longer life ensuring its ability to

F International Petfood - November 2022 | 23

withstand all weathers? Does it have overlapping seams and sealed joints to prevent the ingress of adverse weather conditions and dirt?

Withstanding the most stringent demands

Conveyors and elevators must be designed to withstand the most stringent demands of milling, commercial operators and large farming enterprises which rely on equipment operating all day, every day, all the time i.e., 24/7/365

Skandia Elevator has been designing and manufacturing grain handling equipment for more than 100 years. It has vast experience of the marketplace and the needs of its customers which include milling and commercial grain operators, and farming enterprises of all sizes.

With a clear understanding that time is money, Skandia Elevator designs conveyors, elevators and aspiration equipment that is robust, reliable and deployed throughout the world. In fact, some of its equipment has been in use for more than 30 years and is still in good condition - a testament to its high-quality build!

Its conveyors and elevators, able to transport most dry, granulated and pulverised materials, are manufactured from pre-galvanised steel or mild steel which has been hot dipped (in accordance with the EU Machinery Directive) and so, if necessary, can be safely installed outside.

An important feature of Skandia conveyors is that they are available in models that are capable of working horizontally, vertically, including at slopes of 15, 30 and 45-degrees and can be curved to fit within restricted environments.

Fitted with self-regulating inlets the equipment cannot be fed by more than the specified capacity which the machine can handle, regardless of the commodity. This feature takes place with no adjustments necessary and helps to achieve reliability.

Designed as a result of listening to Skandia customers its H-Line range, specifically designed to meet the stringent requirements of milling, commercial grain operators and large farming enterprises, has the capacity to handle up to 600 tonnes per hour (tph) based on clean wheat.

With a focus on the simplification of service and maintenance, the H-Line elevator hood is a two-piece unit, inspection hatches in the legs are larger and the boot has two extra cleaning hatches, as does the drive head. These smart solutions provide convenient access which helps to significantly reduce downtime.

A complete assembly

To further improve maintenance the H-Line elevator’s head pulley, bearings, top shaft and drive can now all be removed as a complete assembly.

The H-Line elevator’s hood and head design has been developed using extensive simulations and calculations. The result is that the hood follows the trajectory of the material minimising wear and, importantly, damage to the material itself. Additionally, all internal contact surfaces are fitted with plastic wearing plates which are all bolted in position so easily replaced if required.

Installed up to a height of 70 metres, the H-Line’s Very Long Elongation (VLE) belt means that although the elevator is high, the belt stretches considerably less so has a longer service life, reducing the need for re-tensioning.

The design of the H-Line range of elevators and conveyors shows the importance of equipment manufacturers continuously listening to their customers. The increased access allowing easier maintenance is a key need for mill intakes, commercial operators and large farming enterprises.

Whether you are looking to equip a new milling plant or upgrade an existing commodity handling facility, it is key that you take the advice of an expert within the marketplace.

One size does not fit all

Seeking the services of an advisor who understands the importance of listening to what customers are saying so that he/she has a real feel for the issues and challenges they are facing.

A trusted advisor will also understand that each individual customer has individual requirements and that very often a ‘one size fits all’ does not! Often, customers have a pre-conceived idea around what solution or which piece of kit will take their pain away.

Understanding exactly what a customer wants to achieve from a new piece of equipment, allows a trusted advisor to recommend solutions that exactly fit the bill. That very well may not be what you thought you wanted but exactly what you need.

F 24 | November 2022 - International Petfood

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT Mixers, conveyors, Ducting System, High Temperature enquiries@hydronix.com www.hydronix.com Contact us for more details Hydronix-Petfood-Advert Jan 2022 215x140mm.indd 1 20/12/2021 19:04 Course held In-Person & Live-Online Via Zoom Course Dates: 1/30 - 2/3, 2023 Early Bird Registration Rates: $1,495.00 In-person | $995.00 live-online Early Bird rates end 1/8/2023 32nd Annual Short Course: Feeds and Pet Food Extrusion This live-online course offers an extensive look into the principles and characteristics of feed processing, as well as support systems for effective processing 4.5 day short course with leading instructors from around the world Participants completing the course will be awarded a Certificate and are eligible for 30 Professional Development Hours (PDHs). Ready to Register? Click HERE Want to see more about on site course activities? Click the icon here! This course brought to you by: Questions? Contact Dr. Mian Riaz International Petfood - November 2022 | 25

Industry PROFILE

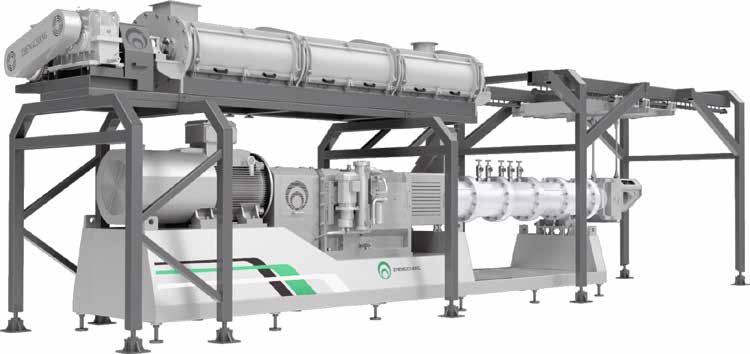

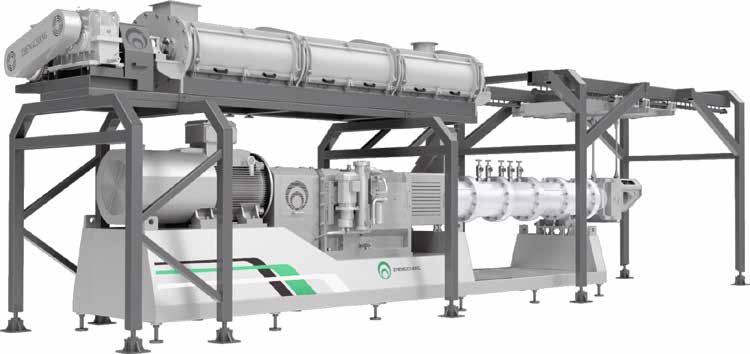

YEMMAK

Pioneering with 300 plus Turnkey projects around the globe

As one of Turkey’s largest manufacturers since 1965, Yemmak produces machines tailored to your needs and build turnkey factories, leveraging its strength as the first feed machine manufacturer in the Turkish private sector.

Yemmak primarily focuses on the following industries: Feed (Poultry, Ruminant, Pet Food, Aquatic, Flake), Biomass, Premix and Concentrate, Organic Fertilizer Processing, Rendering, Soybean Processing, By-Product Pelleting, Chemical, Handling and Storage.

It provides services in project consulting and engineering, special purpose projects, automation, modernisation, steel construction and after-sales support with a 300-strong staff led by specialist engineers. As one of Europe’s largest manufacturers of feed machines with 55 years of process engineering experience, Yemmak exports more than 70 percent of its production to four continents. In addition to being an industry-leader in Turkey and a major player in Europe, it is one of the few companies in the world that can

handle machine manufacturing, process engineering, and turnkey projects from a single headquarter.

Today, Yemmak is in a leading position not only with its knowledge and experience, but also with its global reach. Yemmak is ready to be your global solution partner with their worldwide representatives and technical service network. Yemmak knows that its customers rely on its expertise, high quality products and exclusively designed smart solutions, and develops its projects with the satisfaction in mind.

More than 300 Turnkey Projects

Around the World

Yemmak provides a wide range of top quality design, production, and assembly services to boost your efficiency and lower your energy costs. Yemmak sees each project as a complete system and identifies for its customers the optimal and most reliable solutions. Yemmak strives to transform factories to help them maximise their marginal benefit through pioneering projects.

Yemmak develops projects to meet your needs for a world that is changing faster than ever before. Yemmak’s R&D centre, the largest one in the industry, creates tailor made design concepts ensuring that you get the maximum benefit for the lowest cost.

Yemmak is among the few producers in Turkey and Europe that can manage machinery, process and turnkey projects from a single centre. Yemmak recognises the key role of advanced technology in improving Turkey’s prospects and believes R&D investments are crucial in this regard.

Yemmak’s vision is to protect nature for the future of our planet and to be the pioneer of innovative production with sustainable technologies, with goals to adapt to changing global dynamics and to take forward-looking actions, to carry out pioneering projects, to help maximise the marginal benefits of factories with advanced and user-friendly technologies, to develop high-quality and economic solutions that will increase productivity and reduce production costs.

26 | November 2022 - International Petfood Industry PROFILE

Your industry training platform Learn more – Learn onsite Enroll in the 12-week Course The Online Milling School provides a comprehensive 12-week remote learning experience covering all aspects of feed mill ing, from raw material handling through to final packaging and dispatch. www.onlinemillingschool.com FISH FARMING TECHNOLOGY International Petfood - November 2022 | 27

Industry Training

Hill’s Pet Small Animal Clinical Nutrition

December 10, 2022, will see the Kansas State University college of Veterinary Medicine (KSUCVM) host a continuing education day addressing small animal nutrition.

The event is designed for veterinarians, to learn more regarding pet nutrition, obesity, communication, and coaching pet owners through selecting the best pet food. The talks are led by experts, including board-certified internal medicine and nutrition specialists.

The day starts with an optional tour of the veterinary health centre and college, followed by a welcome from Dr Beth Davis, Associate Dean of clinical programs/Department Head, and Professor Dr Shirin Modaresi, Hill’s Pet Nutrition.

The first talk is presented by Neala Boyer, DVM, DABVP (Canine and Feline Practice), and will focus on how to address stress in canine and feline patients.

Next is a talk by MacArthur Hafen Jr, LCMFT, PhD, Clinical Associate Professor, Director of Counselling Services Adryanna Drake, PhD,

LCMFT, Clinical Assistant Professor. This talk is regarding the topic of navigating change.

Following is a talk presented by Catherine Ruggiero, MS, DVM, DACVIM (Nutrition), and will focus on nutritional recommendations for healthy pets, looking at life-stage nutrition and alternative feeding strategies.

Lastly, is a talk on how a healthy weight improves the well-being and longevity of pets, and how to approach appropriate feeding practices. This will be presented by Susan Nelson, DVM, Clinical Professor/Pet Health Centre at Kansas State University, and Paulina Macias, DVM, Hill’s Pet Nutrition Intern at KSUCVM.

The free program is face-to-face, with the option of watching virtually, and attendees will receive four complimentary continuing credit hours pending RACE approval. There will also be a Q&A opportunity for attendees at the end of the day.

TRAINING

28 | November 2022 - International Petfood

Troubleshooting

Part 10: The extruder barrel continued

Water activity is an effective method to manage or control bacteria in the kibble. The factory is assumed to be designed to current standards where air movement is controlled and walls separate the key processing areas from one and the other. The key is keeping the raw materials separated from the production area. All materials pass through the “kill step, extrusion generally”. Once processed it needs to be kept clean from reinfection. Ok, we have a clean kibble exiting the extruder and progressing to downstream equipment which is normally a dryer. The effect of Aw in an extruded product is that the problem can be overall throughout the product or in isolated areas. Dryer designs can be very effective in total as well as specific moisture levels in the kibble overall and in isolated areas. Uneven drying may lead to isolated areas of potential due to higher than normal moisture levels, wet spots in the dryer. Dryers are a time, temperature and air flow device designed to remove water. Typical industry standard dryers have a moisture variance of +/- 0.50 percent. Basically, everything being done evenly, the dryer time, temperature evenness in the dryer and the airflow being equal in all parts of the dryer yield a product where the final moisture can be controlled quite exactly. All dryers have a “bed” of product either horizontal or vertical dryers, what is the moisture at various locations in that bed measured evenly over the bottom, top and across the bed in case of horizontal dryers. This evenness in drying allows for elevated moisture levels near your target but also by design eliminates possible isolated high moisture areas. Typically, an effective evenly preforming dryer will not have any situations with regards to bacterial growth. One point would be product dried at too high of a temperature. The kibble gets hard quickly on the outer surface and becomes impervious to water movement and thus the high moisture centre of the kibble could cause situations. This effect is labelled as “case hardening”.

Pet treats vary wildly and in some cases the treats are co extruded where, for example, the outer shell is harder and the inner filling is soft and moist. The interface between these two materials is where two totally opposite Aw ranges exist. Formulation as well as processing conditions overcome this possible interaction location. Similar situations occur in mixed kibble, softs bits with dry chucks. Optimum drying on the dry kibble and a good semi moist liquid combination to control Aw allows these kinds of products to be produced effectively.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2.

Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The Extruder Barrel - Part 1

Forming extruders are used for some select products –thus this part of the discussion centres on single and twin designs.

6. Cook in the Extruder Barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - November 2022 | 29

Innovations this month

November 2022

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

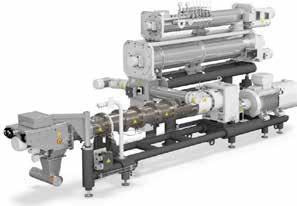

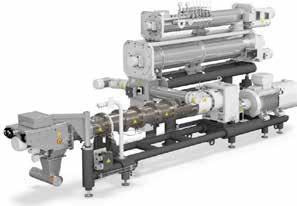

Single-screw extruder by Buhler

The multifunctional single-screw extruder offers a modular design to meet a wide range of process requirements for your pet food and aqua feed production. Capacity, screw speed, torque and pressure options provide excellent versatility.

The two-stage preconditioner separates the mixing zone from the retention zone. This ensures optimal, intensive mixing at high screw speeds, as well as gentle retention across a narrow time range at a low screw speed. The material inlet is positioned vertically above the outlet for ease of use.

The enforced infeed on the new feeder screw enables you to achieve higher throughputs with a higher filling degree. This also results in stable running conditions and improved production safety. To ensure the best accessibility and reduce the risk of cross-contamination during cleaning, access is from the side.

https://www.buhlergroup.com/content/buhlergroup/global/en/ products/single-screw_extruder.html

PRODUCTION

Made in Britain, Trusted Worldwide. We are Laboratory Inline OLM N H ® Portable WE PELLETS (not dust) Download your online version We invite you to use the code below for a free edition of our November magazine either mailed to you or via our App Use coupon code: Euro22 30 | November 2022 - International Petfood

Premix Mixer by Yemmak

It is a paddle mixer which has been designed in order to mix homogeneously raw materials, vitamins, minerals and compounds. Shaft housing have completely dust-proof design. Mixing capability is increased with the mixer is provided with pneumatically actuated butterfly valves and exit of it with the gate placed in the middle of machine. The shaft is driven by horizontal type reducer and belt-pulley system. Mixing (homogenization) is performed to evenly distribute the particles of different sizes and quantities in the mixture. Mixing is one of the factors that directly affect the quality of the pellet.