A healthy gut feeling - Automatic drum emptier - Aquatic Turtles - Environment & Cats May 2023 www.internationalpetfood.com www.perendale.com Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Community Manager

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706

tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

April 2023 10 Industry News COLUMNS 6 Roger Gilbert 7 Joseph P Kearns 8 Professor Simon Davies

International Petfood - Volume 5 - Issue 5 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com

2754-4680 www.internationalpetfood.com 24 Training 25 Troubleshooting 26 Production focus 9 The PetFood Journal REGULAR ITEMS 28 Industry Profiles 30 Industry Events 41 The Market Place 42 The Interview 40 Industry Faces

ISSN

FEATURES

14 A healthy gut feeling

18 Automatic drum emptier

20 Aquatic Turtles

22 Environment & Cats

Happiness is a frame of mind …

Striving to be ‘happy’ is not necessarily a state of mind we need to permanently be trying to achieve. Often ‘happiness’ is an illusion and yet we can clearly see it in others – which may be an illusion or our interpretation of how others might be feeling.

When it comes to our pets, do we consider them to be ‘happy’. It’s my view that they are more likely to be exhibiting signs of contentment rather than ‘happiness.’ That is how I interpret the picture of a pet on our front cover and reflected on our contents page - a very contented dog!

Roger Gilbert Publisher

What contributes greatly to this aura of ‘contentment’ is the freedom within the space an animal can move about, the recognition of its place and status within its environment and most importantly the food - and in particular the impact of the nutrition within its rations – that it has access to. The latter is critically important in not only maintaining a level of satisfaction through the consumption of food, but also the nutritional contents of that food, which provides the protein and energy needed for it to function while at the same time addressing health and wellbeing issues.

Petfood manufacturers play an important role in ensuring pet owners have ‘contented’ (and possibly happy) animals. Our magazine undertakes an important task in keeping petfood producers informed of topics and issues that ultimately impact a pet’s attitude and relationship with its owner.

Not only do manufacturers formulate diets correctly but ensuring those formulations are processed correctly and retain the nutritional balances of amino acids, energy and minerals and vitamins in the final food being offered to our pets is all important.

It might be difficult to understand how a conveying system or a grinding or mixing process can impact the quality of the final product, but it can and care and attention must be applied throughout the production process to ensure this happens.

This magazine is here to help inform and guide petfood manufactures in all regions of the world - through both our English and Spanish monthly versions of the magazine – through this complex process of producing functional foods and rations for all types and species of pet.

In this edition of International Petfood we feature our two editors Professor Simon Davies and Joe Kearns. Professor Davies looks at the ‘Poser of Zinc' in dog and cat diets while Mr Kearns explores energy efficiencies. Mr Kearns also provides his regular Trouble Shooting section in which he makes a case for dry extruded petfoods for dogs.

Following our news section, we have a feature on how to help ensure a healthy gut which addresses animal welfare and performance issues. That is followed by a report on an automated

drum emptier for the production line before we look at the nutritional needs of pet aquatic turtles. Rounding up the feature section is a report on what's in a climate-friendly cat food. We also have our regular Production Focus reports which looks at new equipment and processes available before we turn our attention to aquatic issues again with a report on the Aquafeed Extrusion Conference held in Bangkok in March as part of the VIV Asia 2023 event. This was an intensive workshop that highlighted all areas of aquafeed production, and as I’ve explained below there is great synergy between pet and aquafeed production processes especially where extrusion technology is being used.

Following our comprehensive event’s section you’ll find an interview with Betsy Flores the senior vice-president of public policy at the Pet Food Institute in the USA who talks about pet health in transitional countries.

Assisting petfood manufacturers

Talking of assisting petfood producers further, we are hosting a Pet-Aqua Conference in early October in São Paulo, Brazil. It will be held over two mornings prior to the commencement of the Victam Latam 2023 Exposition event.

It’s the first time Victam is hosting an expo in Brazil and we have taken the opportunity to offer a unique opportunity for both petfood producers and aquafeed manufacturers a conference that assist them in their daily tasks. Both petfood and aquafeed manufacturers can attend the same event that not only looks in detail at production processes but nutritional and dietary issues as well. Why should we be holding a conference for both sectors together, you may be asking?

Well, in both the production of petfood and aquafeeds the processes can be very similar, particularly when extrusion technology is in use.

However, this is not just about the extrusion process itself but the steps that need to be taken in the production pre- and postextrusion (and/or pelleting).

The Conference will be in two half-day sessions on October 3-4 (08:30-12:30 each day). You will hear from industry experts about aquaculture feed and petfood production.

To view the programme outline please go to this website (at: https://adobe.ly/3HhGcDE.

To register directly please go here: bit.ly/40HHP4C. The cost to attend is US$99 for the two sessions.

I hope to see as many of you as possible at this event. We are planning to host it in English with simultaneous translation into Spanish and Portuguese.

Enjoy this edition!

THE PUBLISHER

– International Petfood

The

We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY23 PETFOOD INTERNATIONAL Download your online version

International Petfood comes to you either in print or digitally Whichever way you want to receive, please sign up on our Flickread for your personal copy which will give you access, from your desktop, to our back-issue library. https://flickread.com/edition/Petfood

App

can

be

downloaded from your favourite app store.

A number of topics for this month are energy efficiency in petfood production, starch gelatinisation, preconditioning and in general aquarium feeds. Discussion below can be considered for both extrusion of pet and aqua products.

Energy efficiencies are improving in the various areas of a plant and each area more than likely has different requirements. What might assist in understanding this is every motor has a required duty factor, power, speed/range and torque requirement to achieve the desired requirement. Doing the intended job with the lowest energy cost over time can greatly save on electrical costs. The best bet for this discussion is to ask questions on motor efficiencies for your calculations and project specifications.

Joseph P Kearns Editor, International Petfood Magazine

Starch gelatinisation, a topic for the ages, is one that was initially judged in non-scientific methods, in fact the first test on this strange, expanded product from Sabetha Ks. At Kansas State univ. was 100 percent cooked method unknown. Recalling back in the day when there was no real easy method to test cook and you had some tested by labs, you reviewed the products accordingly and determined some physical characteristics. Two quick alongside the extruder tests were the kibble stretch test, good stretching of a caught kibble off the die showed good cook. A hand full thrown in a bucket of water caught after the die would swell about two times in diameter thus showing good cook. In today’s standards petfoods have become more complex and thus lab work is generally used in determining the degree of cook. My preferred method was the glucose amylase method of testing. It involved getting a sample and test for total starch and gelatinized starch with enzymes and a water bath. Prep a solution use a glucose analyser and the numbers are used in the equation percent Gelatinized starch/Total Starch X 100 is percent cook. Typical petfoods are in the 90 percent cook range based on this style test which is one of the harder tests to get the desired results. Do a comparison on methods of cook comparison, there are differences. NIR is being developed to do on line or in line testing of starch gelatinization, last search showed they are almost there with this being a predicable method of testing. This would be a big deal to be able to instantaneously reject non cooked kibble.

Another point of view is that advanced computer control is so exact that if you feed the system a raw mix which is predictably reproduced over time and the operational specs are slaved to this formula as well as the physical changes, the die, then the results should be predictable. Note over time extruders wear and if operational specs are saved over their lifetime and used accordingly the same product is produced every time. Backed up with scheduled testing to verify results on cook to confirm.

Preconditioning, the part of extrusion where the raw materials get metered in to begin the process with this area adding liquids so as to have a homogeneous mix going to the actual extruder barrel. Liquids include steam and water and liquid ingredient streams. It is amazing the designs and styles over the years ending up with today’s styles. My personal review, single shafted cylinders constant speed, double shaft counter rotating constant speed, double shafted

differential diameter counter rotating variable speed and now double shafted differential diameter with rotation and speed change abilities. What drove the changes in these cases. Mainly how much liquids were hoped to be added and have a flowable product so as to not jam up the downspout due to stickiness between the cylinder and extruder. Retention time was a big factor. Singles about 15 to 30 seconds, doubles about 60 seconds and then the differential diameter versions which took it up into the 240 second range maximum. At preconditioning temperatures and times lysine can be deteriorated if over 240 seconds retention. Traditionally, the old artist operators who had no idea of exactly what was being added into the cylinder felt the product in hand to see if it was too hot to hold and did it kind of form a ball when squeezed. Adjustments made accordingly. Now numeric flow details or computer controls allow for a much more exacting repeatable method of control. In fact, it seems computer control would be mandatory simply from the regulations required to meet FDA requirements, day in and day out, how about minute by minute? Not just flow rates and motor starting, we are talking about controlling in line temperature, pressure with sensors, flow restriction and readings used to automatically change the conditions to meet the immediate results out of the extruder in terms of density and moisture. Cameras can be used to verify appearance.

It boils down to what are the possible losses by not having a computer control system. Hard to give an exact number as it can be calculated in each instance. For me it is obvious, I used to stand there and watch the pile build up on the floor until it was correct and off to the dryer via a belt conveyor or air system. Hundreds of kilos if not tons and now you would be lucky to see 20 litres of waste on startup, same on shut down, the controlled system knows when the conditioning cylinder has emptied and in essence runs until the last possible moment yielding good product.

Back to losses, loss of raw materials on startup shut down and costs associated with rework. Higher percentage of quality product over time. More exacting moistures out of the extruder yields more exactly moistures out of a good dryer thus less shrinkage due to water loss. Quality products less possible returns. Exacting known amounts of energy used in product produced. Lower manpower requirements. In addition, many control system will inform you if the system is not ready to produce due specified line pressures etc. or if a problem develops. Maintenance schedules with reminders and abilities to record data makes computers a real tool in a modern 24 hour a day petfood facility.

As mentioned above on less shrinkage, computer control and dryers and are in the top two of how to increase profits in a petfood plant. Dryers can be computerised but if the moisture variance is not up to standard then no point. Steady state on product in feed rate, air movement, temperatures and bed level are among the top topics when achieving the standard of +/- 0.5 percent moisture variance. Lowering the moisture shrinkage out of the dryer and for every 0.5 percent reduced in a 60,000 tonnes per year plant is 300 tonnes of additional water sold. What is 300 tonnes of finished product worth?

THE EDITOR

International Petfood - May 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

The Power of Zinc in the nutrition of cats and dogs

Zinc is an essential mineral for cats and dogs that plays a key role in many bodily functions. It is necessary for the proper functioning of the immune system, wound healing, taste, smell, and the synthesis of DNA and proteins. Zinc also helps with the metabolism of carbohydrates, fats, and proteins.

In dogs and cats, zinc is absorbed from the small intestine and is transported to the liver, where it is stored. From the liver, zinc is released into the bloodstream as needed and is transported to various tissues and organs in the body. Zinc plays an important role in various biological processes in dogs and cats, including muscle, heart, and liver function. In muscles, zinc is involved in the regulation of protein synthesis, which is essential for muscle growth and repair. It also plays a role in the metabolism of carbohydrates and fats, which are important sources of energy for muscle function.

In the heart, zinc is involved in the regulation of cardiac function and the maintenance of the structural integrity of cardiac cells. It also plays a role in the metabolism of fatty acids, which are an important energy source for the heart.

In the liver, zinc is involved in the metabolism of various nutrients, including proteins, carbohydrates, and fats. It is also essential for the synthesis of several enzymes involved in liver function, including those responsible for detoxification and the production of bile.

Overall, zinc is an important micronutrient for the optimal functioning of the muscles, heart, and liver in dogs and cats. Adequate intake of zinc through a balanced diet is important to maintain optimal health in these animals.

The body has a number of mechanisms in place to regulate zinc metabolism. For example, the absorption of zinc from the small intestine can be increased or decreased based on the body’s needs. In addition, the amount of zinc Factors that can affect zinc metabolism in dogs and cats include age, diet, and health status. For example, older animals may have decreased zinc absorption and increased zinc excretion, while animals with certain health conditions such as kidney disease may have abnormal zinc metabolism that is excreted in the urine and faeces can be regulated to

maintain optimal levels in the body.

Cats and dogs require a certain amount of zinc in their diet to maintain good health. Zinc deficiency can lead to a variety of health problems, including hair loss, skin lesions, poor appetite, and impaired immune function. On the other hand, too much zinc can be toxic and cause vomiting, diarrhoea, and other symptoms. It is important to maintain a proper balance of zinc in the diet to ensure optimal health.

There are several sources of zinc for cats and dogs, including meat, poultry, fish, and grains. Zinc can also be found in some vegetables, such as beans and peas. Commercial pet food is often fortified with zinc to ensure that pets receive enough of this important mineral. However, it is important to note that the bioavailability of zinc from plant sources may be lower than that from animal sources.

In addition to diet, certain medical conditions can affect zinc levels in cats and dogs. For example, cats with chronic kidney disease may have reduced zinc absorption, while dogs with pancreatitis may have increased zinc excretion. In these cases, a veterinarian may recommend a zinc supplement to ensure that the pet is getting enough of this important mineral.

There are several signs that a cat or dog may be lacking in zinc. These include hair loss, dry and flaky skin, poor appetite, and decreased immune function. If you suspect that your pet is not getting enough zinc, it is important to consult a veterinarian for a proper diagnosis and treatment plan.

In conclusion, zinc is an essential mineral for cats and dogs that plays a key role in many bodily functions. It is important to ensure that pets receive enough zinc in their diet to maintain good health, and a veterinarian can help determine the appropriate amount of zinc for individual pets based on age, size, and medical history. It is important to ensure that dogs and cats are getting an adequate intake of zinc to support normal metabolism and overall health. This can be achieved through a balanced diet that includes a variety of high-quality dog or cat food, as well as supplements if needed.

8 | May 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - May 2023 | 9

Mars to acquire Heska

Mars, Incorporated, and Heska Corporation have announced that they have entered into a definitive agreement under which Mars will acquire Heska, a global provider of advanced veterinary diagnostic and specialty products for $120.00 per share.

The transaction price represents a premium of approximately 38 percent over Heska’s 60-calendar day volume weighted average price and a premium of approximately 23 percent over Heska’s closing stock price as of March 31, 2023. The agreement has been unanimously approved by the boards of directors of both companies. Upon transaction close, Heska will join Mars Petcare, a purpose-driven global business serving pets and pet owners through products and services within veterinary health and diagnostics, nutrition, innovation, and technology. This acquisition will enable the Science & Diagnostics division of Mars Petcare to expand its diagnostic offerings and broadly promote point-of-care veterinary diagnostics to the global pet healthcare community.

Nefertiti Greene, President, Mars Petcare, Science & Diagnostics, says, “We look forward to welcoming Heska to Science & Diagnostics as we share the belief that diagnostic

innovation is a critical enabler to providing transformative veterinary care.” Ms Greene adds, “This transaction will bring together highly complementary businesses with a strong strategic and cultural fit that furthers our purpose to create A BETTER WORLD FOR PETS™. This comprehensive diagnostic offering will mean broader coverage across diagnostic products, services, and technology, and will accelerate R&D for novel solutions.”

Kevin Wilson, Chief Executive Officer & President, Heska, comments “Today’s announcement is a great testament to the quality of our Heska family – we are small, but our people and their creativity, execution, expertise, and value-creation have made us exceptional. We are thrilled to join Mars Petcare on its quest to build A BETTER WORLD FOR PETS™. Working together, Heska’s innovations will more quickly reach more veterinarians to help more pet families live better, healthier, longer lives. That’s been our mission for over a decade and today is an incredible milestone towards realising it.”

Science & Diagnostics includes Antech Diagnostics (“Antech”), a global veterinary diagnostics business. Antech has brought innovative technologies and

solutions backed by scientific rigor and data-driven insights to veterinary professionals for more than 35 years. Antech’s range of businesses includes reference laboratories, veterinary imaging and education and telemedicine with board-certified specialist support services through Antech Imaging Services (AIS).

Founded in 1988, Heska sells, manufactures, markets, and supports diagnostic and specialty solutions for veterinary practitioners. Since its inception, Heska has been committed to bettering the lives of its veterinarian customers, their pet patients, and pet owners around the world through its point-of-care diagnostics and informatics platform. With a focus on investing in technology, research and development, and strategic partnerships with worldclass leaders in diagnostics and treatments, Heska seeks to provide the benefits of breakthrough innovations to pet healthcare providers across North America and internationally, including Germany, Italy, Spain, France, Switzerland, Australia, and Malaysia. The transaction includes customary closing conditions, including Heska shareholders’ and regulatory approvals, and is anticipated to close in the second half of 2023.

Houchens Industries acquires Feeders Pet Supply

FSP, based in Louisville, KY, is an omnichannel pet specialty retailer that operates under the names of Feeders Pet Supply and Chow Hound Pet Supplies. The company sells petfood, supplies and services through its emerging e-commerce platform in addition to its 58 brick-and-mortar locations across Michigan, Indiana, Ohio, Kentucky, Tennessee and North Carolina.

FSP was founded in 1959 and its growth accelerated in 2016 when PNC Riverarch, based in Pittsburgh, acquired the majority ownership. Now, 100 percent of the company is being sold to Houchens “as a pathway for … employees to share in not only the ownership and success of FSP, but the ownership and success of Houchens,” according to a press release.

Brannon Dixon, CEO of FSP, says, “We are very proud of our heritage and accomplishments to date and look forward to continuing that growth and success under the Houchens umbrella. We are aligned on the

strategic initiatives to expand and enhance not only our retail footprint but our service offerings to customers. Houchens provides us long-term capital that is critical to achieving our future growth plans. Our senior leadership team is excited to partner with a company that is retail rich in talent and experience.”

Dion Houchins, CEO of Houchens, says, “We are excited to invest in the growing pet retail segment. This strategic investment met every criteria on our investment philosophy checklist. Partnering with a strong management team only enhanced our interest. Brannon Dixon and the FSP senior leadership team have like-minded growth plans and embody an employee and customer centric approach. Having its headquarters in Louisville supports our growth strategy in our home state of Kentucky. This investment further diversifies our ESOP which is critical to our sustained success.”

10 | May 2023 - International Petfood N

H&H Group expands pet nutrition and care segment

Launched in Florida in 2014, Zesty Paws prioritises innovation to provide high-quality, functional products for both cats and dogs. The company was acquired by H&H Group in August 2021, signalling the Group’s continued expansion into pet health and wellness following its earlier acquisition of Solid Gold in 2020.

The global pet food and supplements market is currently valued at approx. USD 123 billion and is projected to continue its upward trajectory, demonstrating the consumer demand and increasing focus on pet health and wellness across the globe.

Mike Rondas, CEO for Europe, H&H Group comments, “This UK launch is an exciting first step into European expansion for our pet nutrition and care segment and rings true to our business mission at H&H Group to make people healthier and happier, which extends to our pets and our passion for holistic pet health. We know that Zesty Paws can bring transformative supplementation to pets worldwide, bringing efficacious solutions, powered by branded ingredients and in an easy-to give soft chew format that pets love. With over 330,000 5-star ratings and reviews in the US, Zesty Paws continues to deliver results you can see with ingredients you can trust.

“Looking at the UK specifically, the country has the third largest number of pets following US and China, with 35 percent of UK pet owners agreeing that supplements are the most efficient way of delivering functional benefits to pets, reflecting the desire for these products.

“Following the pet ownership boom which we saw occur during the pandemic, pet ownership continues to persist, alongside a growing demographic of older pets who require specialised products for their senior needs, which Zesty Paws supplements provide.”

Rafi Kalachian, CEO of North America, H&H Group, comments, “We’re thrilled to be expanding our Zesty Paws range into Europe, further realising the company’s vision of being recognised as a global leader for the health and wellness of pets and giving pet parents the tools to optimise their pet’s holistic health.”

Made in Britain, Trusted Worldwide. We are We can help you improve your pellet durability testing... Holmen NHP200 Series 2 Laboratory based, automatic pellet tester. Holmen NHP300 Inline, process based system. OLM N H ® Holmen NHP100 Portable, manual pellet tester.

PureeX adds new dimensions of freshness to pet food

In response to demand for fresh, healthy and sustainable petfood, leading insect ingredients company Protix launches fresh PureeX®, an appetising fresh insect meat. This new variant on frozen PureeX offers petfood manufacturers and their customers all the health benefits of proteins and lipids from insects, while also lowering the ‘pawprint’ of petfood. For this innovative product, processing is simple and rapid, resulting in an authentic and honest ingredient that is minimally processed and maximally nutritious.

In two lab studies with PureeX, the company found a stronger antioxidant activity compared to commonly used petfood ingredients. In the competitive pet market where consumers want to keep their four- legged friends healthier for longer, the higher antioxidant activity of fresh PureeX delivers a potential added benefit.

Thanks to straightforward rapid processing with a minimum amount of steps, fresh PureeX is an ingredient which is low in biogenic amines, a commonly used measure of freshness. It has a low footprint, just like its counterpart frozen PureeX. In a recently published DIL sustainability report, frozen PureeX scored 24x better in terms of global warming than poultry meat (0.439 kg. CO2 equivalent versus 10.33 kg. CO2 equivalent) and similar data are expected for fresh PureeX. Made in the largest insect ingredients facility worldwide, fresh PureeX promises reliable availability and an appealing price- quality ratio. It complements Protix’s broad portfolio of sustainable tasty insect ingredients, consisting of frozen PureeX®, ProteinX® (insect meal) and LipidX® (insect oil).

According to Statista, global consumer spending on petfood is expected to grow annually by 11.11 percent (CAGR 2023-2027), mainly driven by demographic changes such as the increase in the number of single-

person households, and pet humanisation. Adoring pet parents are prepared to spend on premium products that reflect their own diet. Fresh PureeX taps into the trend for fresh sustainable food among humans, and pet parents’ desire to feed their pets a similar diet. Antioxidants are on-trend in petfood. They are a part of cat and dog food to help maintain the cellular balance and keeping animals healthier for longer. In stressful situations such as diseases or infections, our furry friends may naturally produce an excess of ‘pro-oxidant’ molecules (for example free radicals). These pro-oxidants can disrupt the normal biological balance and damage the body. Antioxidants can help in suppressing the negative effect of these molecules. Including fresh PureeX in cat and dog feed is likely to boost the antioxidant capacity and may potentially support longevity and well-being.

Forward-thinking brands are already incorporating fresh PureeX in their wet and dry formulations and reaping the benefits of an ingredient that is good for pets and for the planet. Persuading owners to switch to a new formulation can be challenging, as Yora Managing Director Glenn Ranking knows.

In support, Protix has conducted two studies to assess the antioxidant potential of (frozen) PureeX, the latter together with Yora. The first study, completed in 2020, concerned a series of lab tests to assess PureeX alone. One of the tests shows that PureeX was able to suppress the negative effect of pro-oxidant molecules by 90%. Conversely, chicken meal and fishmeal could trigger the production of these harmful molecules by 5-15 percent. The second study was concluded in 2022 and evaluated -also in lab tests- the antioxidant potential of PureeX when used in wet and dry pet food formulas. A key outcome of the study is that greater antioxidant activity was seen in insect-based cat food compared to super premium cat foods in the market.

N 12 | May 2023 - International Petfood internationalmilling.com Buy now

Buhler’s solution to mycotoxins in petfood

Mycotoxins, a poisonous chemical found in the corn used in petfoods, are causing animal sickness and irreparable brand damage. To solve this issue, SORTEX LumoVision, a solution developed by Swiss technology group Bühler, uses the spectral scale to kick out mold from petfood, keeping the costs of market recall down and pets safe.

In 2021, the FDA (Food and Drug Administration) alerted customers of fatal levels of aflatoxin, a strand of mycotoxin that attacks the liver, found in 1,000 lots of petfood. From the bad batch, it is reported that 130 dogs died. This statistic provoked lawsuits and anger from dog owners and the wider industry. However, the damage of mycotoxin contamination does not stop there.

Recalling product is expensive

One of the major costs of mycotoxin contamination is market recall. Recalling a product from the market is not cheap, in fact, the Grocery Manufacturers Association (GMA) discovered that the average cost of market recall is USD10 million in direct costs alone. The financial hits of recalling product include: disposing of the product, reimbursing customers, and business interruption. The GMA survey showed that 81 percent of respondents deemed the financial risk of market recall to be “significant to catastrophic”.

Contaminated product damages brand image

Financial costs and damage to health are not the only repercussions of mycotoxin contamination. Once the media are aware of the situation, brand image can take a significant hit. For consumers, it takes a lot to repair trust in a brand, and while brand damage is difficult to measure, this can further cost companies millions in lifetime value.

Contaminated product can cause mass waste

Before the LumoVision, contaminated grain would have been disposed of in large amounts. During testing, if the batch has a high concentration of mycotoxin, in many cases, the entire batch is destroyed. In fact, as few as 2 highly contaminated

grains in 10,000 can render an entire batch unsafe. The Food and Drug Association (FDA) estimate that USD932 million is lost per year to crops contaminated with mycotoxin. This removal of the contaminated material may protect the consumer, but it costs businesses and the environment a lot more.

What can be done?

Bühler SORTEX faced the challenge of mycotoxin contamination head-on. After discovering a breakthrough “invisible indicator” of contamination on the spectral scale, Bühler created the LumoVision, an optical sorter that can reduce the aflatoxin level by up to 90 percent (as indicated by industrial trials). This reduction brings many samples to regulation levels, saving companies from the costs of large-scale material waste and market recall.

It works by analysing the color each kernel fluoresces as it passes under powerful UV lighting in the sorter. It is known that contaminated kernels fluoresce a specific bright green colour, a substance called kojic acid, which is produced by the Aspergillus fungus at the same time as it produces aflatoxin. LumoVision’s proprietary, highly sensitive cameras and a powerful LED-based UV lighting system can precisely detect this color of fluorescence. Within milliseconds of detection, air nozzles deploy to blow contaminated kernels out of the product stream.

When dealing with toxins, early intervention is critical. This is not only important in reducing the toxins consumed by pets, but also to lower wastage and the environmental footprint. Without proper cleaning and sorting, poisonous mycotoxins can cause large-scale wastage of materials, mass market recalls, and harm to pets.

Dr Gerardo Morantes, Director of Food SafetyAmericas Region at Buhler, had the following to say, “Mycotoxins are a worldwide concern. However, technology made possible by Bühler SORTEX enables a preventative solution, meaning that mycotoxins can be dealt with early, stopping the spread and removing the contamination to meet regulatory standards.”

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

International Petfood - May 2023 | 13 N

A healthy gut feeling

Why the gut is the key for animal welfare and performance

by Dr. Elisabeth Holl, Senior Technical Manager & Dr. Bernhard Eckel, Vice President, Dr. Eckel Animal Nutrition, Germany

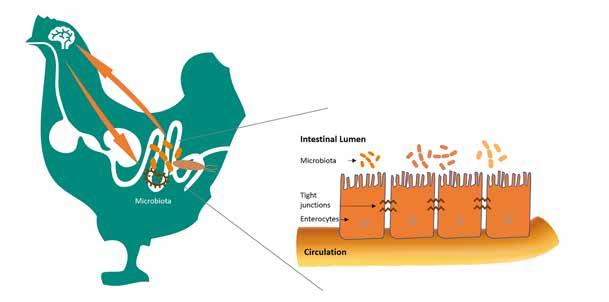

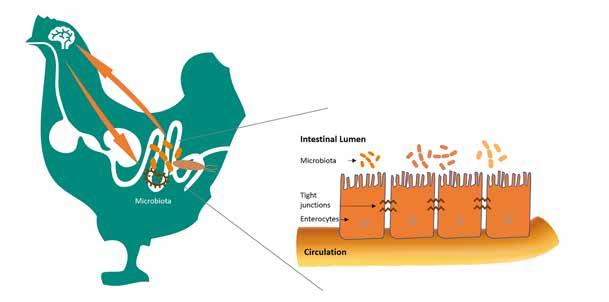

henever animal welfare and well-being is in focus, the term “gut health” comes up as well. But what defines gut health and how can it be maintained? Surely there is more to gut health than merely the absence of gastrointestinal illness. Good digestion and absorption of nutrients are as much a sign of a healthy gut as an effective immune system and a normal and stable microbiota.

There is no doubt that animal nutrition plays an important role in maintaining the integrity of the gut. The search for advanced dietary strategies to strengthen the resilience of animals to infections and non-infectious stressors is therefore a powerful driver for the development of innovative feed additives aimed at improving gut health and animal well-being.

The microbiota – a closer look

Many of the challenges we encounter in animal production can be related to poor gut health. Dysbiosis in poultry it is often associated with poorly digested feed, diarrhoea, and wet litter, leading to footpad dermatitis, reduced uniformity of the flock and ultimately to losses in productivity. Poor eggshell quality may also be linked to gut health problems, especially

Win older hens which rely on an effective calcium absorption for eggshell formation. In piglets, post-weaning diarrhoea caused by uncontrolled proliferation of E. coli is a threat to both animal welfare and production profitability.

Numerous studies describe the positive effects of a healthy and balanced gut microbiota and its metabolites on innate and adaptive immunity, metabolism, gut physiology and even animal behaviour. Stress factors such as early weaning, heat stress or diet composition may lead to a disruption of the intestinal barrier and impair the animals’ resilience. Only a healthy gut with a balanced microbiota can function as a barrier between the environment and the animal and provide protection from pathogens. It is therefore important to improve and maintain this barrier function of the healthy gut to prevent harmful or toxic substances from being absorbed into the body from the environment.

How to support a healthy gut

A key factor for regular intestinal biology are short chain fatty acids like acetic, propionic, and butyric acid. They are the product of bacterial fermentation in the intestine. A high concentration of short chain fatty acids lowers intestinal pH which in turn suppresses pathogen bacteria and facilitates mineral absorption. Butyric acid improves the epithelial integrity and defence systems and decreases intestinal permeability. To optimise the effect of butyric acid in the gut, it must reach the target site. Different forms of butyric acid, either supplemented or endogenous,

14 | May 2023 - International Petfood F

will have different effects in the animal, dependent on the digestive compartment they reach. Butyric acid in the stomach has an antibacterial effect and improves protein digestion. In the distal part of the intestine, it will strengthen the epithelial barrier, reduce inflammatory processes, and stimulate the production of antimicrobial peptides.

Nutrition impacts intestinal health

In other words, the more butyric acid in the hindgut, the better. How can this be achieved? Free short chain

fatty acids are rapidly digested in the stomach or the crop. Supplemented butyrate must therefore be specially protected so that it reaches the distal parts of the intestine. This may be done by encapsulating the butyrate, for instance with fatty acids. However, release of the butyric acid throughout the gut needs to be well-timed and may not be optimal.

A better way to maximise butyric acid concentration in the hind gut is to stimulate the endogenous production of butyrate in the lower part of the intestine. The strategy is to make substrates – known as prebiotics – available to

F International Petfood - May 2023 | 15

Figure 1: Gut microbiota and its metabolites communicate with the brain via several pathways, influencing animal health and well-being

specific micro-organisms, generating conversion products essential for the growth of the digestive system. Prebiotics are generally carbohydrates like fructo-oligosaccharides. They provide a useful energy source for beneficial bacteria. A different approach is the use of gluconic acid, which is structurally related to sorbitol, a slowly fermentable sugar. It is not or hardly absorbed in the small intestine of monogastric animals. Due to the microbial fermentation of gluconic acid, lactate and acetate originate as by-products. These are then converted to butyric acid by acid-utilising bacteria in the large intestine and the caecum.

PreAcid – it’s all in the blend

There is a solution especially developed to improve growth and the continuous self-renewal of the intestinal mucosa. PreAcid, a multifunctional feed supplement for highperformance animal feed, contains short-chain fatty acids and the GlucoFence complex which consists of a combination of gluconate and butyrate.

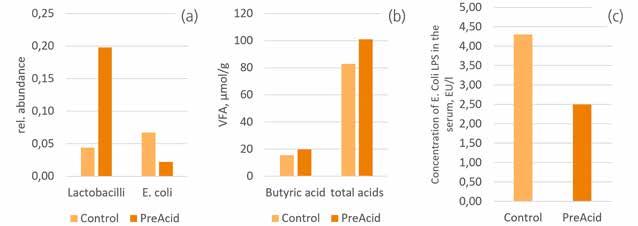

What effect does PreAcid have in the intestine? The organic acids in PreAcid inhibit pathogens and so prevent diarrhoea – still top of the list of common diseases. The prebiotic components butyrate and gluconate promote

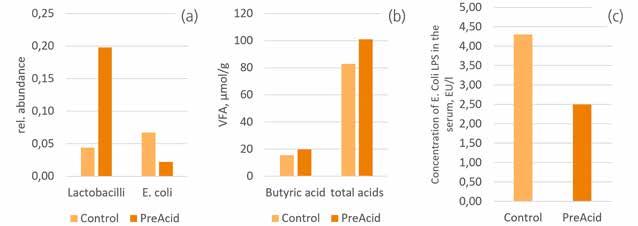

intestinal development. This has been proven in several trials, where for instance an increased production of butyric and total acids and the improvement of microflora composition in the caecum of broilers could be observed (figure 2a and b). Also, PreAcid reduced the concentration of E. coli lipopolysaccharides in the blood serum of broilers challenged with E. coli and Salmonella (figure 2c). The detection of LPS in the serum in that study suggests that the negative effects of E. Coli and Salmonella on the intestinal barrier of broilers could be mitigated by the prebiotic action of the GlucoFence complex in PreAcid.

Lower mortality and higher final weight

The benefit: PreAcid is the ideal source of butyrate in animal nutrition, improving performance and productivity. In a large-scale trial with broilers comparing the effect of PreAcid with butyric acid, the PreAcid concept clearly outperformed other sources of butyric acid. The animals were allocated to two groups. The control group received fat coated butyric acid, the treatment group received PreAcid. After eight fattening rounds the result for the PreAcid group was definitive: the animals reached higher final weights and a better feed conversion ratio. The mortality was reduced by up to 24 per cent (figure 3). Furthermore, the use of PreAcid reduced feed costs per kg meat by 2.8 per cent and markedly increased meat yield.

Strong gut – strong performance

Optimising the amount of butyric acid in the hind gut will benefit both animals and producers: the antibacterial and prebiotic action improves gut health, stimulates digestion, and improves nutrient absorption and animal welfare. So for a healthy gut and optimal performance in poultry, go for the full effect of butyric acid in the intestinal tract. PreAcid’s prebiotic approach with the GlucoFence will get you there.

16 | May 2023 - International Petfood F

Figure 2: PreAcid concept improves microflora composition in the hindgut of broilers (a), volatile fatty acid production (b) and reduces lipopolysaccharides in the blood serum (c) (Dr. Eckel research, 2020 and 2021).

Figure 3: PreAcid improves broiler performance (Dr. Eckel field trial).

F ––International Petfood - May 2023 | 17

Automatic drum emptier

A unique technology for toxic/explosive powdery products

by Dinnissen Process Technology, The Netherlands

ith personal protection and a safer workplace in mind, in mid-2015 an existing customer requested Dinnissen to think along about a solution for the automatic emptying of 200 dm³ drums containing toxic/ explosive powdery products

The reason for this was that although the drums were already being emptied mechanically at the existing customer’s premises, the employees had to wear gas masks during the emptying of these drums, which is undesirable, especially for long periods of time.

In the course of 2016, Dinnissen’s specialists set to work and, in conjunction and regular consultation with the client, they developed a fully 3D-animated pre-engineering in order to present the first draft designs.

Enthusiastic!

The first draft designs were received with so much enthusiasm that by the end of 2016, Dinnissen was awarded the contract. This was the beginning of an exciting process of adaptations, improvements, unique innovations and frequent consultation with the client.

In early 2018, after more than a year of development, testing and improvement, the worldwide first of this truly unique automatic drum-emptier was a fact. The process starts with the supply of the closed drums, which are placed on the roller conveyor via the operator. After the ‘release signal’ and confirmation that the installation is ready, the drum is transported towards the first cabin.

Opening of the drum: first part

During the first operation, the lid is removed from the drum fully automatically with a special head piece, after which the lid remains clamped in this head piece. The drum is transported

Wto the second cabin through an airlock. In the meantime, the clamped lid is pushed out of the head piece and placed on another conveyor belt. The lid that has just been removed is then transported to a separate cabin and cleaned with a neutral liquid, so after cleaning, it can be removed from the installation without any risk.

Inliner: second part

From the first cabin, and after removal of the lid, the drum now arrives in the second cabin. Because in some cases the drums are provided with a separate ‘inliner’ (a - usually - plastic lining on the inside of the drum) a provision had to be made to allow the operator to easily remove it. For this reason, the second cabin is provided with a special hatch that allows access not only to remove the inliner, but also to easily remove any powder residue. To further optimise accessibility and workability, the drum is positioned on a specially developed turntable, so the operator can work quickly and efficiently.

Emptying the drum

After the previous operation, the still filled drum is transported to the third cabin via another roller conveyor. Here the drum is fixed by a gripper arm, which rotates and empties the drum. At the express request of the client, this gripper arm is infinitely operable by the operator by means of a two-hand operation. This is a major advantage. After all, it allows the operator to look into the rotating drum and assess whether the use of a specially positioned ‘beater’ is necessary to knock any powder residues from the drum. In the meantime, possible powder chunks are reduced in size by a self-developed breaking knife.

Both the inliner, if there is one, and the removed powder continue their way via the roller conveyor, with the inliner being automatically transported to the shredder and shredded. Because these flakes may still be contaminated with the toxic/explosive residual product, they are stored in a special container that is eventually filled with a cleaning liquid. After a certain time, this liquid is drained and the flakes can be repacked and safely disposed of.

18 | May 2023 - International Petfood

Last step: cleaning the drum

After emptying, the drum is returned to the starting position with the same two-handed operation and transported to the cleaning cabin via the roller conveyor. Here the drum is fully automatically clamped, lifted, turned over, brought into the desired cleaning position and rinsed out with a large amount of liquid, then blown dry with compressed air and placed back on the roller conveyor, after which the clean drum is fully automatically released via a secured hatch.

Additional safety

For the sake of additional safety, each cabin is regarded as an isolated space, which can be locked securely by its own automatic doors or shutters. If required, the operator can inject nitrogen into any cabin containing potentially explosive products, eliminating the chance of a possible explosion. The installation is also equipped with a built-in air dryer, including filters that prevent vapours from spreading through the installation. Another equally innovative measure is the constant negative pressure, which ensures no toxic/explosive vapours can escape when the drums are introduced or released.

Naturally, the complete electronic control and monitoring, including visualisations, have been developed and implemented by Dinnissen. All in all, this is a technical tour de force which will be highly regarded worldwide.

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Petfood-Advert Mar 2023 215x140mm.indd 1 01/03/2023 13:02 International Petfood - May 2023 | 19

Aquatic Turtles

and all about their nutritional needs

by Niamh Cassidy, International Petfood, UK

Aquatic turtles are entertaining, quiet, and not too complex to care for once you understand the individual species needs. The life of an aquatic turtle can span more than 20 years, a significant commitment for anyone considering owning them as pets. When it comes to their necessities, caring for their specific nutritional needs is important to ensure they live a healthy, happy life.

Environment & Eating Habits

Aquatic turtles live partially in water, occasionally spending time on land. They eat and swallow with their head fully submerged underwater, so feeding them on land will not work for many species. The environment is important, and can significantly affect their eating habits, so the general advice is to feed aquatic turtles in a separate tank, to cater to their messy habits and allow owners to monitor their eating. They also will require constant variety in diet, as aquatic turtles become easily bored at the same old grub and may even refuse to eat if they don’t fancy it, so try switching it up every now and then!

The frequency in which turtles should be fed depends entirely on their age. Baby turtles may need to be fed, up to twice a day, smaller/juvenile turtles expecting daily meals. As they age, adult turtles eat typically every two to three days, provided the portions are decent.

Diet

The diet of an aquatic turtle varies across species, but should consist of protein and vegetables. Turtles are omnivores, eating both plants and meat – which can come from a myriad of sources when applied to captivity feeding.

Whilst a wild turtle’s diet cannot be exactly replicated in the wild, there are suitable store-bought alternatives for owners to try. Earthworms, bloodworms, glassworms (a type of seasonal mosquito larvae that are high in fat, so should only be fed occasionally for variety) are easily accessible options. Whole fish are a suitable balanced prey item, with live fish offering a source of environmental enrichment for a turtle’s meal. Feeder fish species that are recommended for an aquatic turtles dinner include Guppies, Platies, Swordtails, and Cyprinis fish (such as Minnows and Goldfish, however these should not be fed in excess). Avoiding Oily fish (Tuna, maceral, and herring etc) is suggested, as they are deficient in vitamin E and contain excessive quantities of unsaturated fatty acids. Dried ant eggs, larvae, shrimp, insects, or mealworms should be avoided due to their imbalanced nutritional value.

Commercially available pellets are a necessary form of protein for captive aquatic turtles. They are a great source of vitamins and minerals, filling the nutritional gap of the prey they’d usually have eaten in the wild. They’re much denser than whole foods, so should be fed in lower quantities. They come in many sizes and varieties, all catered for your pet’s specific needs, considering age and species. The larger sized pellets are ideal for large turtles, as they float well on water, whereas smaller pellets sink quickly, which is no problem for the smaller, or more juvenile turtles. The age-dependant pellet varieties include:

• Growth Pellets

• Maintenance Pellets

• Mature Pellets

Growth pellets are as you’d expect; pellets that promote and aid growth. They are packed with more protein and calcium, ideal for baby turtles, or more carnivorous turtles. Maintenance pellets are designed to imitate a change in dietary preference from animal to plant matter. This change applies to many turtles, as they age

20 | May 2023 - International Petfood F

and mature, so does their diet, in some cases becoming more omnivorous or herbivorous.

A balanced diet for aquatic turtles basically consists of protein and vegetables, and should be continuously varied. Vegetables are an important component, and should be the majority of their diet, as they provide necessary sources of calcium. Dark leafy greens are the advisable vegetables, we’d suggest romaine lettuce (not iceberg or head lettuce – they have little nutritional value as they’re mostly water already!), collard greens, mustard greens, dandelion greens, water cress, and turnip greens, to name just a few.

Anti-Nutrient plants to avoid

Some plants have naturally occurring phytochemicals that hamper the ability of nutrient absorption, so should not be fed frequently at the risk of serious health consequences.

Firstly, foods containing Glucosinolates, that interfere with the metabolism of dietary iodine, which include bokchoy, broccoli, cabbage, spinach, and cauliflower. Next up is Oxalates. Oxalates are phytochemicals found in many plants, that bind and inhibit the absorption of dietary calcium. Oxalatehigh foods include beet greens, broccoli, carrots, cilantro, pears, tomatoes, and strawberries. Another anti-nutrient phytochemical to look out for are Phytates. Phytates bind to calcium, zinc, iron, and other minerals, hindering their use in the body, as well as interfering with protein digestion. They are typically found in legumes and grains. Tannins are another notable phytochemical found in bananas, carrots, grapes, onions, and spinach, which render protein unusable in the body.

International Petfood - May 2023 | 21 F

Environment & Cats

What’s the most climate-friendly cat food?

Cats have a significant impact on the environment, namely, hunting native birds and wildlife populations in startling numbers. However, there may be an even more significant way in which cats are affecting the environment, and it’s due to their food.

Most experts agree that while wet food has long been touted as the best option for felines, it turns out that wet food results in eight times more climate-heating emissions than dry food. As cats are obligate carnivores, their meals must be made up of mostly meat, and according to stats, meat has one of the most significant environmental footprints of all foods

According to some estimates, animal agriculture accounts for up to 14.5 percent of total greenhouse gas emissions, and dogs and cats together are said to be responsible for 25-30 percent of the environmental impact of meat consumption in the United States.

Since wet food is made up primarily of meat, it’s easy to see why its impact would be so much more devastating.

In a recent study, the environmental impact of the ingredients of wet, homemade, and dry food diets was analysed, including factors such as emissions of greenhouse gases, land, and water use, and pollution resulting from production. Wet foods had the biggest environmental impact, homemade foods were somewhere in between, and dry foods the least—by a significant margin. And of course, none of this considers factory production, packaging, and transportation.

22 | May 2023 - International Petfood F

So, as a cat owner, how does one avoid this?

More and more companies are turning toward “ethical” or “sustainable” cat food, meaning the food production process and the product itself causes little to no harm to the environment. This includes meat ingredient sources that are labelled as free-range, naturally fed, dolphin safe, or sustainably fished and grown. The carbon footprint of production also needs to be taken into account, including transportation and packaging (recyclable materials like tin being ideal).

Excitedcats.com veterinarian Dr Lorna Whittemore BVMS, recommends other ways to help make your cat climate-friendly, “There are many ways we can incorporate environmentally conscious decisions into caring for cats. Food choice does play a large part, but cat litter, toys, bedding, and cat trees are all available in environmentally responsible options now.”

Of course—and thankfully—many of the products used in cat food are products that humans would be unlikely to eat, often referred to as “offal”. While even organic foods still contain this ingredient, they are still a great option as they are typically organ meats, which contain high amounts of nutrients and minerals. Meat-based proteins from lower in the food chain are also good options. Poultry and fish (especially sustainably caught wild fish) have a far lower carbon footprint than beef or lamb.

Another veterinarian at Excited Cats, Dr Paola Cuevas, says that alternative protein options are also becoming more and more of a reality. “Fly larvae, crickets, and other insects are promising sustainable protein alternatives, both for human and pet foods. Insects have a fast time to maturity and a high reproduction rate; they require less food, less water, and less landscape for their production compared to any of the conventional farm animals.”

She also mentions issues with food consumption by livestock. “Cattle require 12 times more food than cricket to produce a pound of product. Chicken and pork require at least double the amount of food than crickets. While alternative insect proteins are yet to be studied as a long-term feeding basis for cats, this is definitively a much more sustainable food source that we should be considering as a promising solution to this big problem.”

Lastly, making food at home for cats may be an option, as owners can choose the best, locally produced meats possible. However, this gets very tricky nutrition-wise, and it’s recommended to get a veterinary nutritionist to formulate a diet plan for you. This is especially true for cats with special dietary needs.

While pets may play a significant role in negatively affecting the environment, there are things owners can do to play their part. Purchasing sustainable cat foods wherever possible is a great start, and the more customers show a desire for these kinds of products, the more manufacturers will answer the call.

International Petfood - May 2023 | 23 F

Industry Training

Bühler Pet Food and Aqua Feed Workshop

A four day hands-on workshop at the Bühler extrusion pilot plant, utilising twin-screw extrusion technology. The Pet/ aqua feed workshop will provide you with an introduction to the basics of extrusion technology, focusing on preconditioning, energy, moisture and mass flow balance. The workshop will take place at Extrusion Application Centre, Bühler, Uzwil CH on September 5 - 8, 2023. This workshop is intended for operation supervisors, engineering or R&D personnel, etc. i.e. people, which are actively involved in technological aspects and feasibility considerations of extrusion. This course is an

introduction to the basics of extrusion technology.

Using hands-on. workshop-style teaching, you will learn:

Introduction to the basics of extrusion technology, focusing on preconditioning, energy, moisture and mass flow balance.

Discussion of single v/s twin screw extrusion technology, screw configuration, die and knife technology.

SME control and product density control and its significance in vacuum coating.

Micro-Feed for Aqua Fresh meat addition and filled pillow treats for pet food Practical demonstrations will help you to apply everything you

learn in our modern pilot plant.

What is included:

Hands-on training with our experienced extrusion experts

Training documentations

Lunch on all full training days

Transportation between hotel and training facilities

Certificate of participation

Invitation letter for visa application

Accommodation from

September 4 – 9, 2023 can be booked through Bühler on request. Costs however have to be covered by the participant. For more details visit: https:// www.buhlergroup.com/content/ buhlergroup/global/en/training/ Buhler-pet-aqua-feed-workshop.html

TRAINING

24 | May 2023 - International Petfood

Troubleshooting

We have been through many topics and I have one that is troubling me. Listening to the radio and TV commercials adds recently some can be seen/heard actually stating kibble (extruded) petfood is dead food and you have to buy their product to put onto the dogfood you buy? I have had many dogs, mostly bird hunting dogs and all lived great long lives in good health and we bought 40-50 lb. bags of extruded petfood. I think they should state the dry petfoods have their water activity under control, in my opinion it is not dead.

Of course, the general public does not have decades of working in this industry with the knowledge of how petfoods are made. What do we know? Formulations are very advanced and meet and exceed the nutrient requirements of the pet. There are many specialty feeds for all conditions and life cycles. The scientific knowledge and information available are out there and are endless. Example which counters the additive additions is vitamin in my opinion. Vitamin and nutrient survival data of extrusion at various temperatures allow for diet corrections to end up with the desired amount. Everyone tests to verify, has to be in there if labelled as such.

Relating to the losses at various temperatures, this relates directly to the style extruder used. If excellent preconditioning is used or more thermal energy then less friction or mechanical energy is needed in the actual extruder section, or less residence time, to achieve the desired cook level. The major nutrient losses based on testing is generated in the extruder barrel. Dryers could be a concern, elevated temperatures for extended periods. However, dryers exist that can manage the product temperature over the time in the dryer and never exceed 80 percent C. A key temperature mentioned many times as the point pre and probiotics might be damaged. It is true for some pigments used in the aquafeed industry and the main reason the lower temperature dryers were developed. Also, no doubt coating methods of both liquid and dry ingredients allow for additions topically to petfoods for many issues. There is no doubt in my mind that the major vast majority of petfood manufacturers are not making dead foods if any. Let’s put some kibble in the shelf and yes it will still be there in five years with no bacterial growth, it was designed to be that way. OK, in general one year shelf life but with a bit of forethought, an extra bag or two on hand you can survive a zombie apocalypse with your favourite pet.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The Extruder Barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the Extruder Barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - May 2023 | 25

Innovations this month May 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

Twin-Screw Extruder SPHS Series by Zheng Chang

The equipment is with good adaptability for the precise processing of various formulas such as low starch, high protein, and high fat. The design technique adopted of European die hole structure and hole patterning process ensures consistent particle size of products and good look. Screw and bushing can be made of new wear-resistant and corrosion-resistant materials to ensure a service life 3 more times longer than that of the current industry average, and the whole machine is more stable and reliable.

It adopts the first-class imported gear box with torque limiter, which is reliable in use and low in maintenance cost. The integrally forged bushing with one-piece molding minimizes the risk of cracks but maximizes the product service life.Through the Bush wear detection technology, the wear of each segment of the bushing can be detected without dismantling the machine, so as to ensure the production capacity and product quality of the equipment.

http://www.zhengchang.com/eng/index.aspx?cat_code=Pet_ Food_Equipment_Extruder&article_id=1899

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY23 Leiber YeaFi® –Brewers’ yeast bound to functional f ibres! | dietetic and prebiotic active ingredients | supports digestion | promotes skin and coat quality | technological advantages Available with different fibre carriers like spent grain, DDGS or apple pomace. Visit our website: leibergmbh.de Leiber GmbH | Hafenstraße 24 | 49565 Bramsche Germany | info@leibergmbh.de Unique synergy! 26 | May 2023 - International Petfood

FOCUS

The Pegasus® Conditioner by Dinnissen Process technology

The Pegasus® Conditioner is a double-axis mixer that uses steam or hot air to adjust the moisture percentage in a product. Different types of product, such as powders, steam, water and fats can be mixed homogeneously. The steam or hot air can be used as pretreatment or salmonella control. The amount of product to be mixed and the mixing time can be controlled manually. Maintenance and inspection are quick through the easily accessible hatches. In some manufacturing processes, different substances are first mixed into a homogeneous substance. After this, they go to an extruder, where the mixture is kneaded and cooked under specific humid conditions. With a Pegasus® Conditioner, these specific humid conditions can be met. In addition to mixing, the Conditioner can also regulate the moisture percentage. Steam can be injected into the sealed mixer to increase the moisture percentage and the entire mixture can be heated.

https://www.dinnissen.com/en/our-solutions/pegasus-conditioner

NHP200 Series 2 by Tekpro

The Holmen NHP200 Series 2, is our flagship pellet durability tester used worldwide for calculating the Pellet Durability Index (PDI) of feed and wood pellets by simulating the pellet transportation environment from mill to trough.

Once a sample of pellets is loaded into the machine it removes any fines, weighs the sample, tests the pellets by agitating them with air at a fixed 70mBar pressure, weighs the remaining sample and calculates the PDI. This automatic solution removes the chance of human error, providing an accurate and reliable test method. The reduction in human input also allows other tasks to be completed while a test is done, ideal in a busy laboratory or where a wide number of staff carry out the testing. The average test lasts only 4 minutes and the test time is automatically set according to the pellet diameter entered. Suitable for pellets 3mm12mm diameter.

The expander OE23 by AMANDUS KAHL

The machine is used in a variety of feed production processes, including mixing and kneading, homogenisation and agglomeration, as well as short-term conditioning. Thus, the all-rounder is not only used at the end of the production process to obtain Expandat, but already in preparation of pelleting. Due to the wide range of possible applications, the machine ensures a lot of savings, but at the same time also the specific improvement of individual feed components.

Using the crown outlet provides even greater flexibility. At the expander outlet, the pressure drops spontaneously. The product expands, and a part of the added water evaporates (flash evaporation).

The crown outlet ensures that, in contrast to conventional pelleting, coarse particles also remain coarse. Combined with low energy consumption, the crown expander allows high throughputs. Existing expanders can be easily modified to crown expanders. https://www.akahl.com/de/maschinen/konditionieren/expander/

https://www.tekpro.com/holmen-pellet-testers/

Premix Mixer by Yemmak

It is a paddle mixer which has been designed in order to mix homogeneously raw materials, vitamins, minerals and compounds. Shaft housing have completely dust-proof design. Mixing capability is increased with the mixer is provided with pneumatically actuated butterfly valves and exit of it with the gate placed in the middle of machine. The shaft is driven by horizontal type reducer and belt-pulley system. Mixing (homogenization) is performed to evenly distribute the particles of different sizes and quantities in the mixture. Mixing is one of the factors that directly affect the quality of the pellet. There are two different types of mixing: batch and continuous. While batch mixers vary according to the paddle types and number of shafts, continuous mixers vary only according to the number of shafts. There are two important properties of mixers: the duration and quality of mixing. These properties may vary depending on the desired CV ratio.

https://www.yemmak.com/en/premix-mixer/

SEE YOUR PRODUCTS IN THIS MAGAZINE If you produce a product that you think we should feature in International Petfood magazine, please get in touch To be considered for inclusion in the magazine please; Email: editorial@perendale.co.uk Include 75 words about the product along with a high resolution image and a web link to more information about the product in your email

Holmen

International Petfood - May 2023 | 27

FAMSUN

An integrated solution provider

FAMSUN Group Co., Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction and industrial automation. FAMSUN has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, FAMSUN has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

FAMSUN operates 5 production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. FAMSUN has successfully completed over 8600 referenced projects in more than 140 countries. FAMSUN’s vision is to provide optimal technology solution and make life better for all. FAMSUN value innovation, hard work, dedication, integrity, quick response and team work.

As world’s demand for quality and safe foods grows, food supply chains have become more connected. Most of their customers diversify their businesses and extend to upstream and downstream links in order to boost productivity, efficiency and sustainability. To meet with customer’s expectations of becoming a single-source supplier, which shares knowledge, experience and resource, provides convenient, flexible and consistent technical supports to customers and help them grow businesses, FAMSUN develop businesses along the value chains of their customers with four segments: 1) Feed Tech; 2) Oil/Fat Tech; 3) Grain Tech; and 4) Food Tech. Cutting edge technologies to manufacture excellent products. By cooperating with leading manufacturing tool companies, FAMSUN introduces such advanced manufacturing technologies as CNC machining centers, welding robots, automatic painting lines, and semi-automatic assembly lines in its workshops to produce extra precision and high quality for every piece of FAMSUN product from material processing to machining, painting and assembly. FAMSUN will speed up production flexibility and increase its local and regional production capabilities by launching an investment plan with several Industry 4.0 manufacturing plants built in some strategic markets of the world.

The success of FAMSUN as a leading solution provider in agri-food industry resides in its great research and development efforts. To maintain its innovation edge for a changing market demand, FAMSUN invests an average of more than five percent of annual revenue in basic research and applied development every year. With a stand of R&D Institutes in Asia, Europe and America, FAMSUN sophisticated specialists work around the clock in the development of existing products and solutions plus exploiting new terrain and unlock new business fields. Additionally, they cooperate with outstanding partners, inventive customers, renowned universities and institutes to constantly bring know-how together on technologies and transfer them to leading production systems in their customers’ facilities.

28 | May 2023 - International Petfood Industry PROFILE

We invite you to use the code below for a free edition of our magazine either mailed to you or via our App

Use coupon code: HNY23