concept of Immunonutrition

& Pet

“test drive” conveyors

world-class facility

digestibility kinetics in petfood June 2023 www.internationalpetfood.com www.perendale.com Download your online version:

The

in Animal

nutrition - Petfood processors

at

- Protein

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Community Manager

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

International Petfood - Volume 5 - Issue 6

©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com

ISSN 2754-4680

www.internationalpetfood.com

June 2023 10 Industry News COLUMNS

Roger Gilbert

Joseph P Kearns

Professor Simon Davies

6

7

8

26 Training 27 Troubleshooting 28 Production focus 9 The PetFood Journal REGULAR ITEMS 25 Industry Profiles 31 Industry Events 39 The Market Place 40 The Interview 41 Industry Faces

FEATURES

14 The concept of immunonutrition in animal & pet nutrition

18 Test Drive

20 Protein digestibility kinetics in petfood

Achieving greater sustainability in food and feed production is a key goal of our time.

If we can get our act together as a human race, we might just be able to feed ourselves without depleting the planet beyond its capacity to support us all.

At present we need 1.8 ‘planet earths’ to provide the resources we use and absorb our waste each year.

Roger Gilbert Publisher – International Petfood

The challenge we face is to limit our use of resources and manage the waste produced within the constraints of our one planet. Is that achievable I hear you ask? Maybe - maybe not. But we should make the ultimate attempt to achieve this goal for the sake of future generations.

To do this we have to ask ourselves what contribution we could make by modifying the way we live. And as supporters of pet owners we have to consider the feed resources utilised and consumed by pets and the waste they produce.

Petfood is not just getting the best from our raw materials, but we must also consider what happens beyond the point of sale and after the feed has been consumed by a pet. Not to put too fine a point on it, how are we disposing of pet waste?

In reality we have to deal with Scope 1, 2 and 3, all aspects of the environmental impact of a product produced - its production and life cycle. This is an issue we will dealing with in an upcoming edition.

Coming back to this edition I’m pleased to say we have a great line-up of news and features.

IPF Editor Joe Kearns, on the next page, sets the scene with his views on sustainability in the use of electricity and talks about the

Our last edition

Did you miss our May 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

A healthy gut feeling -Why the gut is the key for animal welfare and performance by Dr. Elisabeth Holl, Senior Technical Manager & Dr. Bernhard Eckel, Vice President, Dr. Eckel Animal Nutrition, Germany

Whenever animal welfare and well-being is in focus, the term “gut health” comes up as well. Surely there is more to gut health than merely the absence of gastrointestinal illness. But what defines gut health and how can it be maintained? Read this article from Dr. Eckel Animal Nutrition to find out!

To read more, go to: https://issuu.com/international_aquafeed/docs/ipf2305_web/14

need to monitor, control and document.

Overleaf is our resident Nutrition Editor Professor Simon Davies, who once again chooses an unusual pet to focus on - the Iguanas - discusses the challenges that their biology presents in terms of behaviour and needs. He uses the Iguanas, a reptile with over 800 species of lizards in its family. There are much useful observations regarding nutritional needs in his editorial.

Our news section is led by the announcement of the merger of two companies to form the new dsm-firmenich of Switzerland. We report on the 2023 World Nutrition Forum in this edition (page 32) - which was held in Cancun, Mexico from May 8-10, 2023 –also hosted by this company. In addition we report on the dsmfirmenich’s next generation of premix plant (page 13) as well.

We carry features on the Concept of Immunonutrition in Animal and Pet Nutrition followed by a Petfood Processors ‘Test Drive’ of Conveyors (page 18) before we deal with Protein Digestibility Kinetics in Petfood (page 22).

Our industry profile this month is the company IDAH of Taiwan which has been recently acquired by CPM of the United States.

Of course, we have our Industry Training section prompting our Online Milling School with the plans well in place to have an OMS session, a last session in the Autumn calendar of all three training courses - Livestock, Aquafeed and Petfood Milling courses - to be held during Victam Latam in Saõ Paulo, Brazil between October 3-5, 2023. Be sure to visit our www.onlinemillingxschool.com website to register for the course and to plan your attendance of the seventh session live during Victam Latam.

Good reading!

Aquatic Turtles- and all about their nutritional needs by Niamh Cassidy, International Petfood, UK

Aquatic turtles are entertaining, quiet, and not too complex to care for once you understand the individual species needs. The life of an aquatic turtle can span more than 20 years, a significant commitment for anyone considering owning them as pets. Read more on how to meet their nutritional needs to ensure they live a healthy, happy life.

To read more, go to: https://issuu.com/international_aquafeed/docs/ipf2305_web/20

THE PUBLISHER

Plant sustainability is a topic all on its own.

My opinion is this would centre on energy consumption, percent rework and percent of potential production. Every faucet of production requires energy, mainly electrical therefore efficiency in all of the drive systems for each device does affect cost per tonne produced. Getting them defined correctly for maximum required load, duty factor, motor size and ratings will lower costs per hour. Maximum production and minimum rework are goals that also greatly change the cost of tonnes produced. The major larger motor devices have the greatest impact and can more easily be reviewed and documented while the hundreds of smaller motors due add up to an impact level. Meeting the requirements of sanitation for petfood plants also have a cost and thus the plant design would also be of major importance also due to energy requirements to maintain the environment in each sector of production.

Joseph P Kearns Editor, International Petfood Magazine

separation exists from the production plant to this dusty area or the dust is contained or controlled. So basically, we have a dry ingredient stream, various liquid streams, steam, water both to multiple locations, fat, meats and other possibilities. How much waste of each do you think you might have if you did not control each with flowmeters with timing sequences etc. for this process? How many product changes per week? Well, the answer is most every new system is computer controlled to meet the demands and to be substantiable in this industry. In short, these systems pay for themselves in controlling the process and greatly reducing rework while keeping capacity up or give you a reason why it dropped.

Monitoring, controlling and documenting critical process parameters fit in nicely having stated the above. Advanced production plants monitor everything and has an instant view of each device and its conditions are not unusual. In the case of motors heat, RPM, load would be a few which would allow notices of changes to prepare for possible replacement thus lower costs/increase profits by minimising downtime. Plant air filters, the fans blowing into or pulling through them will change motor load thus indicate filter load if you are not using air pressure sensors. We could outline multiple examples but some are noteworthy. When your system is computer controlled and has all the monitoring systems you can see the flows from dry to liquid into the process. Having seen some issues in my time, when you see the pump delivery system fluctuate up and down you might have something to check, it obviously is searching for the set point but can’t hold it. A similar situation with a feeder screw from a loss in weight bin would not settle down. High RPM showed there was a blockage in the screw not allowing flow. Wonder where the missing screen piece for the screen went? Another note on feeder screws to a conditioning cylinder, if excess free steam is in the cylinder good chance over time some will escape back up the feeder screw. Check and clean on a schedule, build up changes the screws volume and capacity to convey.

Controlling a petfood system, it can be completely by hand or by computer control start to finish. Major comment on this topic from owners of petfood plants is that the computer control and monitoring system puts the plant back in managements hands. More predictable throughput hour in and out. Having worked in many plants of different control levels work but it is different for sure. Definitely by hand methods experienced operators learned what to do or more importantly what not to do! The effect however of non-computer controlled is the magnitude of rework. Let’s bypass the dry raw material section and make assumptions it is working OK and dust is not flying everywhere and

Critical Control Process Parameters can cover many areas. Production, plant, emergency and many other topics which require a specific process. When you get down to it, they all relate to product quality and production. Everything needs to be working in unison to achieve the top end of production goals. Loss in Weight, liquid flow meters and timing allow for preconditions in today’s standards where there is virtually no waste out of the system including free steam. All is timed to begin as needed and the possibilities exist to monitor the material between the conditioner and extruder barrel for select parameters. Temperature mainly, with 77OC being the minimum for salmonella control. Same exit the extruder barrel but usually a bit higher temperature is desired. If all bacteria, moulds and spores are to be eliminated then about 125OC in this area. Note this can be controlled where the extruder temperature can be adjusted by controlling the system accordingly. Heat liable ingredients can thus be incorporated if desired in many cases. However, in making these changes the actual capacity of the system will most likely be lower due to the reduced load, moisture level increase, die open area and other changes associated with reducing temperature in the extrudate. Obviously, the last critical control point is the product in the bag. There are systems now that remove human contact from the product by using advanced monitoring and sample collection gear. Grabs samples convey to a testing unit and confirm the nutritional values by NRI, report density and moisture all on line in real time. Usually, a plant wide system where raw materials and samples mid line or select spots as before the dryer and after are taken as well.

Dextrinising, how is this associated with petfood production? Dextrinisation in our case is the reaction to starch by dry heat. It can happen when the extrusion process gets so hot and a bit on the dry side. Much like cookies, crackers or toast in the morning a slight burnt flavour due to oven use. Honestly back in the day it was felt/ noted that cats like a bit of this effect, much more then dogs. A system can be controlled to do this or to avoid this effect. One of the control points in petfood production. Systems exist to allow for production of a kibble or piece and then carefully set and dry in an oven like setting to develop textural and taste qualities.

THE EDITOR

International Petfood - June 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

Feeding the domesticated Iguana - the cool ectotherm

Iguanas are a popular choice for pet reptiles, but their care can be challenging and requires a deep understanding of their biology, behaviour, and unique needs. In this article I discuss the keeping of iguanas as pets, focusing on their biology and the various aspects of their care, including diet, feeding, and nutrition. I will also relate these aspects to the broader field of ectothermic vertebrates and reptilian bioenergetics, citing relevant academic research wherever feasible.

Iguanas are a reptile belonging to the family Iguanidae, which includes over eight hundred species of lizards. They are primarily found in tropical regions of Central and South America, as well as in certain Caribbean islands. Iguanas are large, herbivorous lizards, and their size can range from two to six feet in length, depending on the species. They have a distinctive appearance, with a long tail, strong limbs, and a prominent dewlap, which is a flap of skin under the chin used for communication and thermoregulation.

Iguanas are ectothermic, or cold-blooded, which means that they rely on external heat sources to regulate their body temperature. As a result, their bioenergetic demands and metabolism is closely tied to their environmental temperature, and they are often inactive during cooler periods. Iguanas are also highly social animals and are known for their complex social behaviour, including territoriality, dominance hierarchies, and courtship displays.

As ectothermic animals, iguanas have a lower metabolic rate than endothermic animals, such as mammals and birds. This means that they require less food to maintain their energy needs, but they also have a lower digestive efficiency and slower growth rates. Iguanas are primarily herbivorous and require a diet that is high in fibre and low in protein and fat. In captivity, they are often fed a variety of fruits and vegetables, such as kale, collard greens, and squash, along with calcium and vitamin supplements. One of the most critical aspects of iguana care is providing a balanced and nutritious diet. In the wild, iguanas have a varied diet of leaves, flowers, and fruits, and they spend most of their day foraging for food. In captivity, it is essential to replicate this natural diet to ensure that they receive all the necessary nutrients. It is also important to provide fresh, clean water at all times and to monitor their food intake to prevent overfeeding and obesity. As such, Iguanas require a specific diet to maintain their

health, and inadequate nutrition can lead to several nutritional diseases. Here are some of the most common nutritional diseases that affect iguanas:

Metabolic bone disease (MBD): This is a common nutritional disease in iguanas that occurs due to calcium and vitamin D3 deficiencies. Iguanas require UVB light in the correct spectrum and intensity to synthesize vitamin D3, which is essential for calcium absorption from the diet. Without sufficient calcium and vitamin D3, iguanas can develop MBD, which results in weak bones, fractures, and deformities. Recent research has highlighted the importance of calcium in the diet of iguanas. A study by Willette et al. (2018) found that captive iguanas are often deficient in calcium, which can lead to a range of health problems, including metabolic bone disease. The authors recommend supplementing the diet with calcium and monitoring the levels in the blood to ensure proper absorption.

Vitamin A deficiency: Iguanas require vitamin A for proper eye and skin health. Lack of vitamin A can cause skin infections, eye problems, and even blindness.

Protein deficiency: Iguanas require a diet high in protein to maintain muscle mass, but many commercial iguana diets are deficient in protein. A lack of protein can lead to muscle wasting, weight loss, and poor growth.

Obesity: Iguanas are prone to obesity, especially if they are fed a diet that is high in fat and low in fibre. Obesity can lead to various health problems, such as heart disease, liver disease, and joint problems.

To prevent these nutritional diseases, it is essential to provide domesticated iguanas with a balanced diet that meets their nutritional requirements. A diet for iguanas should consist of leafy greens, vegetables, fruits, and a small amount of protein from insects or boiled egg whites. It is also important to provide UVB lighting to help iguanas synthesize vitamin D3.

It’s important to note that while pelleted feeds can be a useful part of an iguana’s diet, they should not be the only food that they are given but used a balancer. Pelleted feed is designed to be complimentary for the maintenance, growth and development of iguanas and contain formulated blends of natural ingredients, vitamins, and minerals to support their health and wellbeing. There is active scientific research into diets for use with the hobbyist and zoo market.

8 | June 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - June 2023 | 9

dsm-firmenich launches as innovators in nutrition, health and beauty

dsm-firmenich is excited to confirm the successful merger of DSM and Firmenich and the resulting launch of a new company that brings together one of the largest innovation and creation communities in nutrition, health, and beauty. With a nearly 30,000 strong team and unparalleled capabilities built on more than a century of cutting-edge science, dsmfirmenich will be a trailblazer in the reinvention, manufacturing, and combination of vital nutrients, flavours, and fragrances.

Combining the essential, desirable, and sustainable

By creatively applying proven science and drawing on data-driven innovation capabilities as well as exceptional standards of operational excellence, dsm-firmenich seeks to tackle the tension between what society needs, what people individually want, and what the planet demands in the areas of nutrition, health, and beauty. By working closely together with customers to create what is essential for life as well as desirable for consumers yet simultaneously more sustainable for the planet, dsmfirmenich is poised to bring progress to life for billions of people around the world.

Geraldine Matchett and Dimitri de Vreeze, Co-CEOs of dsm-firmenich, comments, “Today marks a new beginning for us all that is the culmination of more than a century of ground-breaking science from two great companies. dsm-firmenich now stands out as a category of one, uniquely working at the intersection between what people individually want and what we collectively need, without costing the Earth. After all, what is essential has limited impact if it is not desirable, and that impact is not positive if it is not sustainable. And sustainable things that people don’t want or need don’t help much! We are truly global, built on an incredible foundation of proven world-class science with the broadest portfolio of nutrients, flavors, and fragrances. We are delighted to embark on this journey together as a single force for good as innovators in nutrition, health, and beauty.”

Structured for success

dsm-firmenich is organised in four distinct highperforming businesses, rooted in complementary worldclass scientific research and manufacturing excellence. Together they are uniquely positioned to help our customers realise their ambitions and address evolving

consumer needs and wants.

Perfumery & Beauty creates superior scents with proven benefits – always with the consumer in mind. Creating fragrances that smell amazing and make people feel even better, using the best and largest palette of natural, synthetic, and biotech ingredients.

Health, Nutrition & Care provides people a way to look after their health by adding critical nutrients to diet. Driving medical innovation forward, speeding up recovery, and enhancing quality of life.

Animal Nutrition & Health delivers healthy animal proteins efficiently and sustainably, harnessing power of data to make animal farming practices more sustainable, productive, and transparent.

Delivering for all stakeholders

dsm-firmenich is a purpose-led company where people and planet as well as financial success are at the core of its strategy. As a company formed of two growth companies that are also global sustainability leaders, dsm-firmenich is determined to keep growing its positive impact and keep raising the bar in helping to tackle climate change, protect nature, and care for people all along the value chain. Working together with customers and partners, the company strives to tackle the challenges of today and tomorrow while making a positive difference for the planet and enhancing the lives of millions.

A new name and identity

To mark the launch of the new company, dsm-firmenich has revealed a new brand that captures the spirit of bringing two iconic organisations together in a merger of equals. The brand reflects the company’s purpose and values and is the expression of a shared identity. The brand symbolises the company’s mission to combine what is essential for life, desirable for consumers, and more sustainable for the planet. The purpose of dsmfirmenich is to bring progress to life, together with customers and partners, to achieve positive change and make a difference in the world.

Following the successful completion of the merger, Geraldine Matchett has decided this is the right time to further her career elsewhere and will move on, as of September 1, in full alignment and with the thanks of the Board of Directors. Dimitri de Vreeze will be the dsmfirmenich CEO.

10 | June 2023 - International Petfood N

MicroHarvest announces strategic partnership with Simon Capital

Award-winning agrifoodtech startup, MicroHarvest, a leading biotech company on a mission to champion the protein ingredients of the future, has announced a new partnership with Simon Capital. The partnership will strengthen the teams’ operational know-how within the food and production space and bring in additional funds to fuel the company’s growth.

After successfully closing a EUR 8.5 million Series A financing round last September, led by Astanor Ventures, FoodLabs, Happiness Capital and Faber, MicroHarvest has raised EUR 1.5M from new investment partner Simon Capital.

Katelijne Bekers, MicroHarvest Co-Founder & CEO, comments on the announcement, “Choosing the partnership with Simon Capital will bring a significant long-term edge to the growth of MicroHarvest. Simon Capital doesn’t just bring extra funding: through them, we gain access to an incredibly experienced team who understands the ins and outs of a manufacturing company in the food & beverage space. We share a result-oriented mindset and are purpose-driven, with the bold ambition of building a resilient food system. I believe this combination of operational and cultural match is what makes this partnership a critical milestone for our company’s success.’’

The investment, which will bring the total funding into the Hamburg-and-Lisbon-based start-up to over EUR 10 million, will allow the company to work towards key commercialisation milestones. As part of its efforts to enter the market by the end of 2023, the company is building a pilot plant at its new location in Lisbon. This plant will enable them to produce prototypes and accelerate research, as production is being ramped up together with a contract manufacturing partner.

Dr Friedrich Droste, Managing Partner at Simon Capital, adds, “We are excited to join the MicroHarvest team on their mission to combine best-in-class research know-how and operational expertise for reshaping the B2B protein ingredients industry, by unlocking the full potential of microorganisms. It is impressive to see what the team has built-up in the last months on its path to improving the resilience of tomorrow’s food system and, in addition, driving impact for more sustainable consumption. Simon Capital is looking forward to working closely together with the team and a renowned set of investors.”

Inline sample & transfer system

The Samplex Inline Transfer System from TekPro Ltd. efficiently samples and transfers products from the production line to the reception chamber using Air Flow Motors. Capable of transferring a vast range of free flowing dry products, the system is fully programmable and can be operated in single or multiple modes. An optional external start facility allows for remote operation. With its advanced capabilities, the Samplex Inline Transfer System is a valuable tool for automating product sampling and transfer at busy manufacturing facilities.

Samplex IL50

To access further free information on the entire range of Samplex inline samplers, exclusively Made in Britain by Tekpro, or to find out how you could join the ever growing number of leading companies already trusting Samplex equipment to sample their products, scan the following QR code or visit the website:

Product Spotlight - Samplex

www.tekpro.com

Purina PetCare, Texas A&M Gastrointestinal Laboratory join forces to advance pet microbiome health

The five-year partnership is set to yield new diagnostic and nutritional tools through the US$2 million Purina PetCare Research Excellence Fund.

The veterinary industry can anticipate exciting new breakthroughs in the frontier of pet microbiome health thanks to a new partnership between Nestlé Purina PetCare Global Research and the Gastrointestinal Laboratory at Texas A&M University’s School of Veterinary Medicine and Biomedical Sciences (VMBS).

The partnership is made possible through a US$2 million Purina PetCare Research Excellence Fund, which will run from 2023-2028 and will support diagnostic and interventional research conducted at the Texas A&M Microbiome Research Laboratory. The fund also will facilitate the training of future research leaders in the understanding of the pet microbiome, a community of microorganisms that inhabit an animal’s gut.

In addition to supporting the Microbiome Research Laboratory, Purina has supported a new endowed chair position, the Purina PetCare Endowed Chair for Microbiome Research, at the Texas A&M GI Laboratory. The recipient, Dr Jan Suchodolski, serves as a professor and associate director for research at the GI Lab.

Unique Pet Health Management Approaches

Texas A&M researchers and Purina scientists have long shared an interest in the pet microbiome. Research at the Texas A&M GI Lab for more than 25 years has focused on gastrointestinal function testing, GI pathogens, and intestinal microbial ecology, with an emphasis on how intestinal pathogens upset the balance of the intestinal microbiome and how the application of probiotics and prebiotics can help this imbalance.

Nestlé researchers, meanwhile, were among the first in the world to study the interaction of probiotic bacteria with host intestinal cells to activate immune signalling, and Purina was the first pet nutrition company to offer shelf-stable probiotic supplements for dogs and cats to support dietary management of GI conditions and anxious behaviours.

“In recent decades, scientists have learned a great deal

about the intestinal microbiome and its role in longterm pet health. This has led to discoveries such as a new way of evaluating the microbiome of individual animals,” Mr Suchodolski says, referring to the PCRbased Microbiome Dysbiosis Index developed by his group at the GI Lab. “Through the Purina PetCare Research Excellence Fund, we look forward to seeing how learnings such as these will help us discover new strategies for veterinarians to use in our approach to the management of patients with chronic GI disease and other conditions believed to be associated with dysbiosis.”

The shared goals of Purina and the Texas A&M GI Laboratory are to understand the intestinal microbiome of dogs and cats and how it relates to overall health. Through this partnership, researchers from Texas A&M and Purina will collaborate to push the field of companion animal microbiome research forward with the goal to develop new diagnostics and nutritional solutions for pets. The Purina PetCare Research Excellence Fund also allows Texas A&M to continue its role as a global expert in the microbiome and build its investment in the training of future research leaders in this space.

“We believe the research projects and training made possible through our Research Excellence Fund and the newly endowed chair at the GI Laboratory will shape a future where the veterinary profession has safe, novel tools to diagnose and nutritionally manage a range of pet health conditions that result from microbiome imbalance,” says Sheri Smithey, senior vice president, Global Petcare R&D at Purina. “We are confident this Purina PetCare Research Excellence Fund will yield benefits to veterinarians and their patients for many years to come.”

Dr Michael Criscitiello, associate dean for the Texas A&M VMBS Office of Research and Graduate Studies, says, “I am most excited that this partnership with Purina will further elevate the excellent research and training for which Drs. Suchodolski and Jörg Steiner (University Distinguished Professor and GI Lab director) have attracted international acclaim.”

N 12 | June 2023 - International Petfood

DSM to build next-generation premix plant in KC region USA

DSM, a global purpose-led health and nutrition company, has announced that it plans to build a next-generation nutritional premix plant in Tonganoxie, Kansas, creating 28 jobs. The new location will supply the petfood industry with highquality nutritional premixes for use in branded petfood products worldwide. The facility is expected to break ground in July 2023 and be fully operational by early 2025.

“The petfood industry has been looking for a better source for the highest quality, traceable and reliable nutritional ingredients for their products and we are thrilled to be able to deliver for the industry and for ‘pet parents’ with this new facility in Tonganoxie,” says DSM Co-CEO, Dimitri de Vreeze. “We appreciate the support of Kansas Governor Laura Kelly, the Kansas Department of Commerce, the Leavenworth County Development Corporation, the City of Tonganoxie, Evergy and the Animal Health Corridor in making this state-of-theart facility a reality.”

“DSM is a welcome addition to Kansas and the Animal Health Corridor,” says Kansas Governor Laura Kelly. “Having another industry leader locate here further enhances the globally recognised animal health ecosystem that is anchored in Kansas.”

The facility will be strategically located in the KC Animal Health Corridor, close to many of the industry-leading petfood manufacturers, reducing supply chain risk and logistics expense.

“Leavenworth County Development Corporation would like to thank all the regional, state, and local entities that have worked cooperatively on this project,” says president of the Leavenworth County Development Corporation, Jeremy Greenamyre. “This is precisely the type of company we hoped would consider our community as a place to invest and locate. We welcome DSM to the Tonganoxie Business Park.”

“We’re excited to learn more about DSM becoming a new corporate neighbour in our community,” says Tonganoxie Mayor David Frese. “This is another smart growth opportunity to continue building our future with high-quality jobs and sustainable development.”

The Kansas facility will feature precision micro-batching capability, allowing for precise automated micro-addition of numerous ingredients to premixes in a fully traceable manner. This will support the use of a broader range of DSM and third-party ingredients, allowing the company to create more inclusive and unique premix offerings to meet the evolving needs of the petfood industry and creating peace of mind to customers in regard to quality, safety and reliability.

Importantly, the increased process automation of the stateof-the-art plant will allow for greater traceability, accuracy and automated weight verification, as each batch moves in its own containerised transport system

in an automated manner through the facility. This will allow DSM to provide the speed and accuracy in high demand by customers in the pet food industry.

“As the highest concentration of animal health assets in the world, the Kansas City region is home to a robust industry network, as well as abundant manufacturing and distribution resources,” says Kimberly Young, president of the KC Animal Health Corridor. “The region continues to attract top companies in the industry, and we’re proud that DSM has selected the Corridor for this state-of-the-art, innovative new facility.”

In addition to meeting all food safety requirements and exceeding current standards for petfood production, the facility is designed with sustainability in mind. The plant’s automated mixing vessels will reduce waste by decreasing flushes necessary for sequencing and will operate on 100 percent renewable electricity, consistent with all DSM facilities in North America.

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

International Petfood - June 2023 | 13 N

The concept of Immunonutrition in Animal & Pet nutrition

by Melina Bonato, Global R&D and Technical Manager & Céline Villart, European Technical Supervisor, ICC, Brazil

The term immunonutrition originated from some human studies conducted in the 1950s and suggests a link between malnutrition and the occurrence of infections (Shetty, 2010). From the 1970s onwards, this concept began to be broken down into four general guidelines on how nutrition can impact the immune response:

- Malnutrition (especially protein-energy related) and nutrient deficiencies.

- Nutrition as a determining factor on the immune capacity of newborns and older people.

- The influence of obesity and excessive intake of nutrients on the individual’s immunocompetence.

- How interactions between nutrition and immunity impact clinical medicine and public health (Chandra, 1993).

In the 1980s and 1990s, other studies investigating population monitoring data for decades corroborated this concept. Since then, the immunonutrition in humans has been investigated in many broader aspects and is considered a multifactorial science since nutrition is related to nutrient digestion and absorption in the gastrointestinal tract, microbiota, immune system, organs involved in the inflammatory processes (and their secondary effects), nervous system, hormone production, etc. This concept has been understood and applied to animal nutrition for a long time due to the advances in knowledge of nutrition and health. However, the term immunonutrition has been effectively applied in recent years.

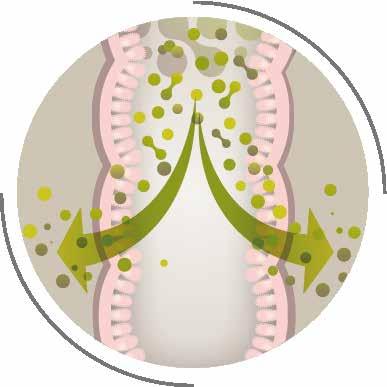

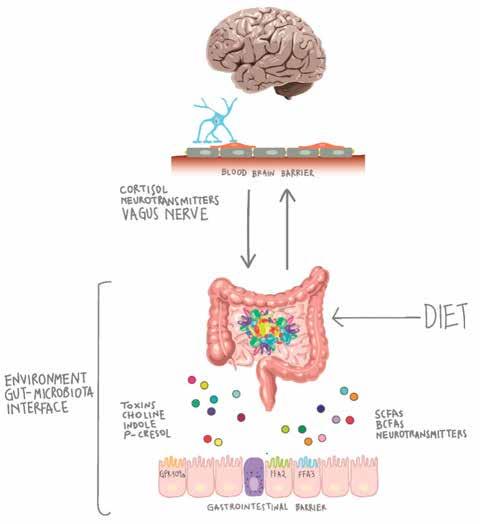

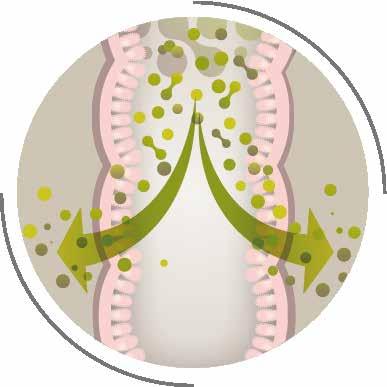

It is essential to understand that, besides being responsible for the digestion and absorption of nutrients, the gastrointestinal tract is a crucial organ for the immune response. Approximately one-quarter of the intestinal mucosa comprises lymphoid tissue, and over 70 percent of it consists of immune cells (Wershil & Furuta, 2008). Gut-associated lymphoid tissue (GALT) is the main component of mucosal-associated lymphoid tissue (MALT). It is also a significant immune cell source that monitors and protects intestinal mucosa layers. GALT is continuously exposed to dietary antigens, microbiota, and pathogens (Dalloul & Lillehoj, 2006). Then, the development and maturation of the immune system can be affected by external factors (environment, diet) and factors inherent to the animal (genetics, age).

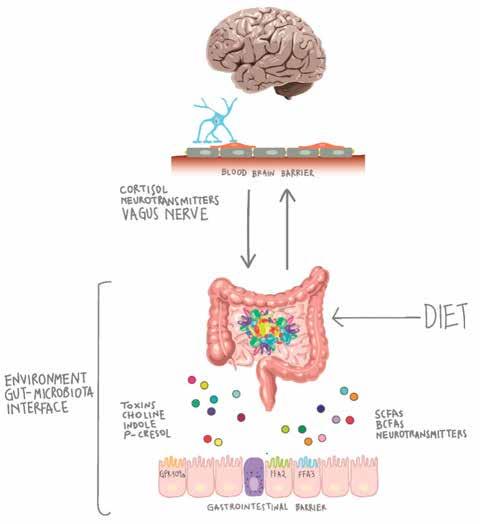

These factors also impact the microbiota and intestinal health. The intestinal microbiota has many functions in the organism and plays a vital role in the gut-brain axis bidirectional communication (Cryan & Dinan, 2012). In other words, the central nervous system (CNS), via the hypothalamus-pituitary axis, can be activated in response to stress factors, thus releasing cortisol (Image 1). Cortisol affects the immune cells, releasing pro-inflammatory cytokines, influencing intestinal permeability, and leading to microbiota changes (Landeiro, 2016).

The physical barrier

Besides having the function of absorbing nutrients, the intestinal epithelium acts as a physical barrier. If intestinal permeability is impaired, microorganisms and

14 | June 2023 - International Petfood F

lipopolysaccharides (LPS) can pass through the lamina propria, activating the immune cells and releasing proinflammatory cytokines, which will affect the central and enteric nervous systems (Gareau et al., 2008). Several physiological changes may result from these responses, including fever, metabolic inefficiency, skeletal muscle catabolism, and synthesis of acute phase proteins (Korver, 2006). Also, an impact on energy and nutrients used for growth or maintenance may be observed.

Therefore, the pro-inflammatory response caused by any of the above- mentioned factors can result in compromised immunocompetence. The animals must develop their immune response and protection abilities throughout life, i.e., these abilities are modulated each day since the metabolic cost vs. an induced immune response is low and directly affects the maintenance of metabolic homeostasis. According to the established concept of immunonutrition, amino acids (glutamine, arginine, cysteine, taurine), nucleotides, lipids (monounsaturated and polyunsaturated fatty acids, omega-3 fatty acids), vitamins (A, C, and E) and trace minerals (zinc and selenium) (McCowen & Bistrian, 2003) are classified as immunonutrients. Some immunomodulating substances are not absorbed like nutrients but can directly or indirectly modify the immune system response, such as prebiotics, probiotics, and phytogenic compounds.

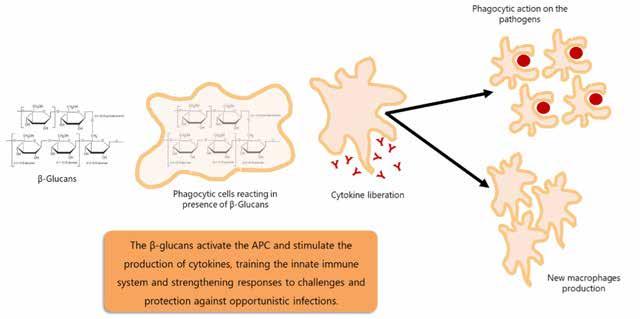

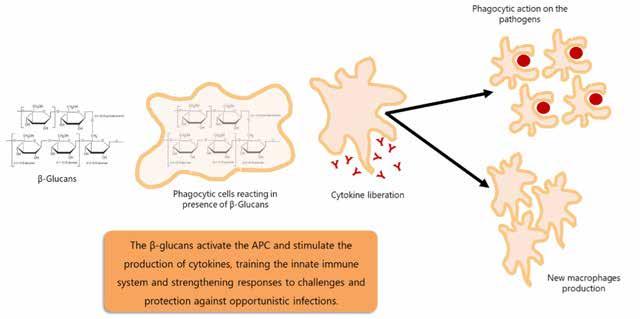

β-glucans are among the most studied immunonutrients in the literature and are derived from the yeast cell wall (β-1,3 and 1,6-glucans). Their mode of action consists of recognising phagocytic or antigen-presenting cells (APC)

F International Petfood - June 2023 | 15

Image 1: The microbiota-gut-brain axis scheme (Verduci et al., 2020)

in the lamina propria just below the intestinal epithelial cells. These cells have a toll-like receptor on their surface, which recognises microbial patterns and induces an immediate innate immune response. After this activation and phagocytosis, the phagocyte presents a processed antigen fragment and stimulates a chain response (Image 2). Pro-inflammatory cytokines are released and activate the production, release, and mobilization of additional phagocytic cells and proliferation of goblet cells (mucus production), among other effects. The recognition of pathogens and antigens by the innate immune system triggers immediate innate defenses and the activation of an adaptive immune response (Lee & Iwasaki, 2007).

Immunomodulation and animal diet

Activating the innate immune system by β-glucans is known as immunomodulation since there is no damage to the intestinal epithelium or invasion of epithelial cells. The result is putting the innate immune

system cells on alert and preparing the animal to face the day-by-day challenges with low metabolic costs. This is a key factor in diets for:

- Young animals (puppies) in which the immune organs are under development and immune response are under maturation. Vaccination in this period is a great challenge, as it is essential to succeed in the face of immunological immaturity and maternal antibodies (Klein et al., 2014). During the first year of age, alterations in the quantity and proportion of circulating leucocytes will impact general immunocompetence. It is also related to genetic breed determination factors (Day, 2007).

- Special diets for animals with intestinal problems or diseases that may unbalance the intestinal microbiota or cause depression in the immune response (chronic problems).

- Senior diets due to the immune system’s susceptibility in advanced ages.

- General adult diets to support the daily challenges.

These benefits can be measured by quantifying antigen-presenting cells circulating in the blood, helper T and cytotoxic T lymphocytes, immunoglobulins (Bonato et al., 2020), vaccine titers, and others. Thus, effects on maintaining intestinal permeability may also be observed since, as mentioned previously, there is a close relationship between the microbiota, intestinal permeability, and the immune system. Given the complexity of the associated factors, there is still much to be studied about the microbiota-intestine-brain axis. However, using immunonutrients, individually or associated, has been proven to promote benefits for the health, welfare, and growth of the animals. Therefore, it is crucial to fully understand their mode of action to enable the correct application in each phase and type of diet.

References available on request

16 | June 2023 - International Petfood F

Image 2. β-glucans mode of action scheme

The App can be downloaded from your favourite app store.

We invite you to use the code below for a free edition of our magazine either mailed to you or via our App

Use coupon code: HNY23

4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25 International Petfood comes to you

in

or digitally Whichever way you want to receive,

up on our Flickread for your personal copy which

give

either

print

please sign

will

you access, from your desktop, to our back-issue library. https://flickread.com/edition/Petfood

PETFOOD INTERNATIONAL Download your online version F International Petfood - June 2023 | 17

Test Drive

Petfood processors

by Del Williams, Technical

conveyors at world-class facility

Even when people love the look of a car or SUV, most would not complete a purchase before a test drive to confirm how the vehicle performs on the road. Similarly, today an increasing number of pet food processors are realising the importance of “test driving” conveyor equipment at OEM test facilities, which use their actual product to ensure the equipment meets processor quality, flow, and cleaning requirements before they make the purchase.

In response, some OEMs have invested in state-of-the-art test facilities that allow pet food processors to run product on the same type of equipment they are considering for purchase, while benefitting from expert consultation to optimise their process.

“We encourage pet food processors to test their products [at our facility] and observe the results to ensure it meets their needs. They can ask questions in real time. They can test for fines or degradation. They can see for themselves how the product flows in the conveyor and how easy it is to clean,” says Larry Van Zee, Executive VP, retired at Cablevey Conveyors, a mechanical conveyor manufacturer that serves the pet food, specialty food, coffee, powder, nut, and frozen food markets. In more than 66 countries, the company has designed, engineered, and serviced enclosed cable and disc tube conveyors for over 50 years.

At its full-service product test center in Oskaloosa, Iowa, the OEM has tested more than 1,900 products, including pet food, beans, rice, grains, cereals, coffee, chocolate, and caramel corn

peanut snacks, for some of the largest global brands. All products are run through a tubular disc and cable conveying system to observe the effects and fine-tune the results.

Why visit the test centres?

According to Scott Berning, Cablevey’s Product Testing Manager, there are multiple reasons pet food processors decide to visit the test center. “Customers may have products that we know will run well on tubular cable conveyors, but they want to see it in operation with their own eyes,” says Berning. “They want to ensure the product will run properly, and their quality department typically checks as part of their due diligence before purchasing equipment.” Berning adds that when Cablevey’s applications department designs and quotes a conveyor and the manufacturer lacks sufficient experience conveying a specific product, the email quote states it is “pending successful product testing.”

Some pet food processors want to evaluate tubular cable conveyors against other conveying options they may also be considering, such as bucket elevators or chain conveyors. Others are already familiar with tubular cable conveyors based on experience and want to show their managers that a similar solution could be implemented at their current facility.

Once the pet food processor is at the site, Cablevey product specialists and engineers typically consult with the customer to determine their specific goals and issues to be resolved. From this, they can proceed to design a conveyor with a set of features that addresses specific challenges. “Our technicians and engineers can diagnose and prescribe a solution whether the concern is

At state-of-the-art OEM testing facility, pet food processors can verify the performance of their product and receive expert consultation on tubular disc and cable conveyors

writer, USA

18 | June 2023 - International Petfood

“TEST DRIVE”

breakage, temperature, stickiness, abrasiveness or other issues,” says Berning. He notes that when pet food processors test products at the facility, they are provided full documentation of the results, including a detailed report with video and recommendations.

According to Berning, testing for product fragility and damage is usually the primary concern of processors. “No matter the product, pet food processors want to keep their product intact and avoid damage during conveying,” says Berning. He points out that tubular drag cable conveyors excel at reducing product damage since the units gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which push the product through the tube without the use of air.

These conveyors can transport delicate, precise blends for a wide variety of food types, and up to 2000 cubic feet per hour of materials in versatile layouts and configurations.

Still, quality assurance checks can be essential for processors, even those transporting products that seem hard to damage. bReducing product loss and maintenance is also important to pet food processors. “Processors want to place their material in an inlet and then have all of it emerge from the discharge with minimal losses,” he says. Since tubular cable conveyors are sealed from end-to-end with product traveling one way in enclosed tubes, there is essentially no product loss and no issue with carry-back.”

Ease of cleaning the conveyor is also a top priority of pet food processors. Surprisingly, many processors visit the facility to

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Petfood-Advert Mar 2023 215x140mm.indd 1 01/03/2023 13:02

International Petfood - June 2023 | 19 F

witness how easily the conveyor can be cleaned. “People come here from across the United States just to watch me perform a conveyor wet-clean and washdown even though it is something I have to do every day,” says Berning. Traditional alternatives like screw conveyors can be difficult to clean and require time-consuming disassembly, as well as some heavy lifting after each product changeover.

“One processor told me that it took six of his technicians about eight hours to clean their screw conveyor system. They had to pull a big auger out of the screw conveyor, which was dangerous to handle,” says Berning.

Tubular drag cable conveyor systems offer easier, safer options for dry and wet tube conveyor cleaning. Equipment

such as brush boxes, urethane wipers, air knives, inline sponges, and inline bristle brushes can facilitate multi-step, essentially automated Clean-In-Place (CIP) wet cleaning.

The wet cleaning process internally cleans the cable conveyor tube in several steps, starting with a water rinse followed by foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which “act like a squeegee” to remove any residual water.

For those unable to visit the test facility in person, Cablevey now offers the ability to view and respond to product testing live in a “virtual visit” with a link to real-time video and a

––20 | June 2023 - International Petfood F

Zoom meeting type format - an option developed during the COVID-19 pandemic.

With this technology, the tubular cable conveyor manufacturer can host both in-person and virtual visits simultaneously, which is helpful when larger work groups such as quality assurance teams have an interest in evaluating the conveyor. “In one recent product test, a team of four visited our facility in person while twelve others watched virtually,” says Berning.

For those who wish to experience the world-class facility in greater detail, Cablevey has created a 360-degree immersive virtual tour of its product test center (https://cablevey.com/ test-your-product/). Embedded within the virtual reality (VR)

experience is product information as well as videos. The video library demonstrates how tubular cable conveyors transport different materials such as pet food, coffee beans, grains, bird seed, tea leaves and breakfast cereals. How-to videos illustrate potential layouts, components, technologies, cleaning, and maintenance options.

With easily accessible, advanced product testing facilities, pet food processors can view and verify in real-time that their investment in new conveying equipment will meet their requirements. Processors who “test drive” their product in this way will not only enhance their product quality and productivity, but also experience a significant advantage over competitors.

International Petfood - June 2023 | 21 F

PROTEIN DIGESTIBILITY KINETICS IN PETFOOD

by Bruno bertaud, Technical

Tsearch for innovative protein sources is on the rise as a result of increasing global food consumption and consumer concerns about sustainability, animal welfare, and strain on agricultural land. In line with the humanisation trend, pet owners are likely to select a pet food based on their own dietary preferences. Moreover, the increased awareness of the importance of proper nutrition has led pet owners to become more and more careful when looking at pet food labels. Clean label is amongst the top trends in the pet food market and seems to be driven by the perceived link between health and naturalness. Consequently innovative protein sources are of great interest in the Pet Industry as a way to meet the growing market demand for pet nutrition.

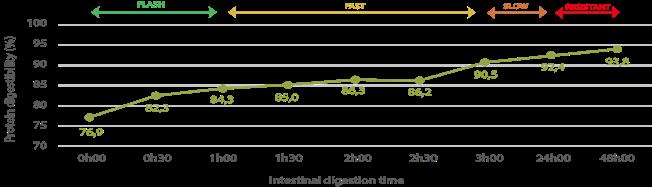

The importance of absorption kinetics

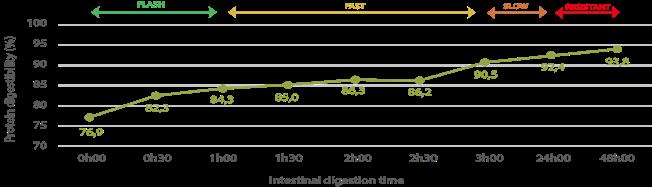

Protein bioavailability is strongly related to its amino acid composition, size, and mass range. Large proteins, proteinassociated molecules and nucleic acids have lower digestibility compared to free amino acids and small peptides. Protein digestibility of feed materials is an important information for nutritionists. However, it is not expressing timing of absorption in the gut. The kinetics of protein absorption should be considered in addition to protein digestibility. It allows nutritionists to properly assess the quality of the protein source. Many properties and functionalities of proteins are related to their absorption kinetics. The kinetics of protein absorption helps categorise the protein fraction according to its speed of absorption. Four categories can be defined as flash, fast, slow and resistant along the digestive tract (Figure 1).

Flash digestibility is important for young animals, especially as their gut is not yet mature and still not able to easily absorb

and utilise the protein fraction from the diet. Supplying young animals with a flash digestible protein source that is rich in free amino acids and small peptides will help them easily absorb and use those nutrients.

Hydrolysed yeasts: a source of highly digestible and quickly absorbed proteins

Yeast is an incredible bioengineering factory and a source of valuable nutrients and functional molecules. Yeast experts at Lallemand have worked on the screening of different yeast

Figure 1. Kinetics of protein absorption: key parameters for protein functionalities

Figure 1. Kinetics of protein absorption: key parameters for protein functionalities

22 | June 2023 - International Petfood F

manager, yeast derivatives and swine solutions, lallemand animal nutrition, france & Francesca susca, Global pet product manager, lallemand animal nutrition, Italy

biomasses and on the optimisation of their production processes, both of which led to the development of a specifically designed hydrolysed yeast, YELA PROSECURE.

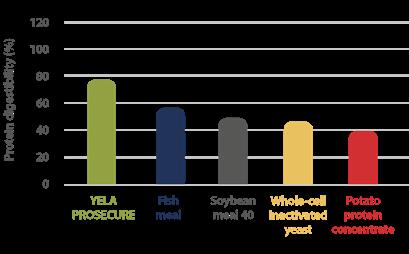

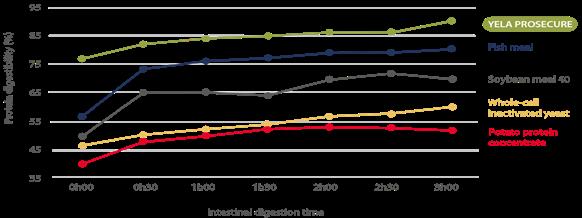

YELA PROSECURE’s kinetics of protein absorption has been analysed with the Boisen standard method (Figure 2). YELA PROSECURE’s protein digestibility starts at 77 percent at the beginning of the intestinal phase (right after the stomach) to 94 percent after 48 hours. Moreover, YELA PROSECURE is close to its maximum in vitro digestibility after 3 hours of intestinal digestion, meaning 90.5 percent of the protein content of YELA PROSECURE has flash and fast digestibility kinetics and only 9.5 percent is slow and resistant. The proteins from YELA PROSECURE are, therefore, highly bioavailable for the animals.

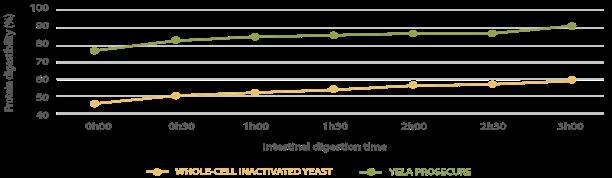

Effect of the yeast process on the protein digestibility kinetic

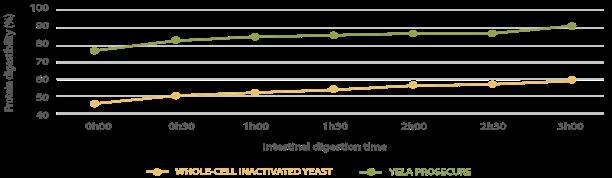

The protein digestibility kinetic of YELA PROSECURE was compared to a whole-cell inactivated yeast with a focus on the three first hours of the intestinal phase as the process of digestion is already quite complete at that time for young animals.

In whole cell inactivated yeasts, no lysis process is applied, and most nutrients (including the proteins) are in the cytoplasm of the yeast cell making them less accessible. As shown in (Figure 3), their protein digestibility is low right after the stomach (46 percent) and increases slowly, up to 60 percent after 3 hours.

Thanks to the oriented and controlled hydrolysis process used to produce YELA PROSECURE, proteins and nucleic acids are fragmented into small size peptides offering highly digestible nutrients. We can conclude the yeast lysis process strongly benefits protein digestibility and therefore nutrient bioavailability in the gut.

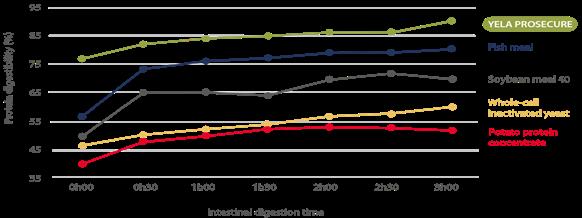

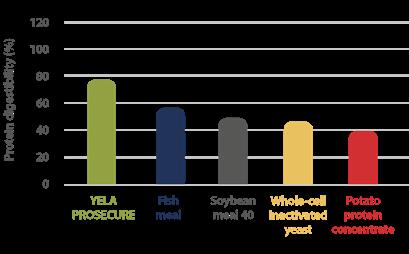

Hydrolysed yeast protein digestibility compared to five other feed materials

YELA PROSECURE, a yeast-based product, fish meal, soybean meal, and potato protein concentrate were assessed for protein digestibility and kinetics of absorption based on the Boisen method with an adjustment to the gastric pH as previously explained (Figure 4 and Figure 5).

Protein sources are absorbed differently by

animals right after the stomach phase:

- YELA PROSECURE’s well controlled hydrolysis process makes the protein highly available and quickly absorbed. With a protein digestibility of 77 percent right after the stomach, we can define YELA PROSECURE as having flash digestibility.

- Fish meal has a digestibility pattern of between 56 to 61 percent.

Soybean meal and whole-cell inactivated yeast have a lower protein digestibility at the beginning of the intestinal phase, with 49 percent and 46 percent respectively, while the potato protein concentrate is around 40 percent digestibility.

- Soybean meal protein digestibility increases up to 70 percent after 3 hours of the intestinal phase.

- The kinetics of protein digestibility for fish meal is between YELA PROSECURE and soybean meal, starting with 56 percent digestibility after the stomach, increasing to 81 percent after 3 hours in the intestine.

- The potato protein concentrate appears to have a slower protein digestibility kinetic over time (52 percent after 3 hours of the intestinal phase). Being rich in crude protein (77 percent), the potato protein concentrate will contribute to a high amount of non-digested protein in the animal gut.

Compared to these feed materials, YELA PROSECURE shows interesting kinetics of protein digestibility with more than 90 percent of the proteins digested after 3 hours of the intestinal phase.

Figure 2. YELA PROSECURE: kinetics of protein digestibility

International Petfood - June 2023 | 23 F

Figure 3. Kinetics of protein digestibility: YELA PROSECURE vs. a whole-cell inactivated yeast

One direct consequence of that is a negligeable amount of non-digested protein that reaches the lower gut. YELA PROSECURE is, therefore, a valuable protein source that can help reduce the risk of gut dysbiosis associated with non-digested proteins. In addition, a flash and a fast protein digestibility is important in terms of protein functionality with direct and indirect benefits for the animals.

Benefits of a flash and a fast protein digestibility for animals

Free amino acids are known to be beneficial for digestive health at three main levels:

- Free amino acids and especially the branched chain amino acids (BCAAs) — leucine, isoleucine and valine — are involved in the maintenance of the gut mucosa mass and integrity. When they are quickly absorbed, BCAAs play a positive role on the cellular multiplication by supporting the cell proliferation and the amino acids transporters. The direct consequence is a protein synthesis increase and a reduction of the protein degradation mechanism in the intestinal crypts (Duan et al., 2018)

- Glutamic acid, glutamine and glycine help support microbiota growth

- Arginine, glutamine, methionine, tryptophane and threonine help support the gut immune system activity as the gut contains around 70 percent of the total immune cells of the body.

Palatability in Petfood

Some free amino acids are also involved in the mechanism of taste and eating behavior including feed intake, therefore playing a role in feed appetibility.

In a trial conducted in the Netherlands with 40 adult medium size dogs, the consumption of the diet including YELA PROSECURE was significantly higher by 26 percent (P=0.054) than the control diet.

YELA PROSECURE has shown the potential to enhance petfood appetibility, likely related to the high natural content in specific free amino acids.

Conclusion

To meet growing pet food market demand — and to face the current challenges around global health and digestive care of pets — petfood manufactures and nutritionists are looking for alternative functional protein sources. Hydrolysed yeasts are a promising and innovative functional protein source to consider, mainly due to the free amino acids and the small peptides obtained from the cracking (lysis) process of the protein. When the hydrolysis process is controlled, yeast has a standardised profile of free amino acids, which plays a positive role in the maintenance of pet gut health, contributing to pet food protein balance and enhancing palatability. This is particularly of interest when applied to the diets of junior animals or in specialty pet food such as Hypoallergenic diets.

Figure 4. Raw material protein digestibility after the stomach phase

24 | June 2023 - International Petfood F

Figure 5. Kinetics of protein digestibility of various protein sources

IDAH

IDAH is the total solution provider for food, feed, and biofuel production and offers a complete selection of machines and parts for worldwide customers.

IDAH Company today is the produces industry best sold pellet mill, dryer with patented Uniform Moisture Control, and have become the leader in texturised vegetable protein (TVP). They provide one-stop service which includes: R&D Prototyping, Education, Consultancy, Turnkey solution, Single Machine, and Spare Parts that helped our customers always stay one step ahead in the market.

With over 40 years of experience, they have enabled their customers to rapidly grow with processing machines and complete turnkey project solutions in aquafeed, pet food, animal feed, extruded snack, textured vegetable protein (TVP), high moisture meat analogues (HMMA), plant-based meat, and wood pellets.

IDAH understand that innovation grows from collective wisdom and experience. IDAH Innovation Center, an extrusion research lab, fosters an environment of innovation through open experiment by providing direct hands-on access to industry experts and machinery. They are committed to provide built-to-last machinery while also supporting our customers by providing robust OEM brand spare parts. The top

10 leading feed companies in Asia all rely on IDAH’s innovative technologies. IDAH provides one-stop service which includes: R&D Prototyping, Education, Consultancy, Turnkey solution, Single Machine, and Spare Parts that helped our customers always stay one step ahead in the market.

IDAH applied a 3D design program to simulate the process flow, to reduce the time and money needed while manufacturing machines, constructing machine towers, and machines installation.

At IDAH, we understand that innovation grows from collective wisdom and experience. IDAH’s Innovation Center, an extrusion research lab, fosters an environment of innovation through open experimentation: providing direct hands-on access to industry experts and machinery. We can develop the competitive and innovative product with you.

In petfood industry

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers a complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide a high-quality machine for feed and food production.

Idah has a patented contratwin shaft extruder that utilises a combination of steam and

mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which can precisely control temperature, producing uniform moisture with quick product change-over. IDAH firmly believes in a strategy of design fit for purpose. They recognise the constraints our customers face with rising ingredient costs, energy costs, and overheads costs, yet in the face of these challenges, it is still expected that high-quality products be supplied into a very competitive market. Our design philosophy is to work continuously to refine and improve processes and equipment to maximise the success of our customers. The following describes some of the features and benefits resulting from this philosophy. The company constantly undergo revolutionary breakthrough in research and development, using scientific data to develop new techniques and technologies in producing robust and tailored machinery for food, feed, and biofuel industries. Their philosophy of research and development revolves on our IDAH Innovation Center. This Innovation Center is the center of collective wisdom, they have collected the experience from their customers, IDAH expert team, and experts from Taiwan, Europe, and the US to keep us one step ahead of competitors.

Industry

International Petfood - June 2023 | 25

PROFILE

Industry Training Online milling school Petfood

International Petfood Magazine and Progressus are happy to announce the return of the Online Milling School, which will offer a Petfood course beginning August 2023. The Autumn Online Petfood School course will offer six weekly sessions starting August 24th, running until September 28th.

Topics covered over the six weeks include:

• Petfoods, Basic Nutrition, Ingredients, and special additives.

• Plant design, raw material area, and raw material prep.

• Extrusion cooking of petfood, pet treats, standard through super premium styles.

• Drying and cooling of Petfoods.

• Coating, final cooling, conveying, and quality control.

• Plant design, plant sanitation, and troubleshooting discussions.

The Delivery of related material to the topic by selected industry experts, followed by a dedicated question and answer session that allows for participants to interact with the program facilitators.

Why attend Credo Online Milling School?

You will be able to update yourself with the latest technologies and machinery for feed plants, whilst taking the time to review key milling operations and gain ideas and knowledge that help further improve the feed production process. The course will allow learning and development without having to leave your workplace, in the form of short sessions that are spread across a period of time to accommodate for busy schedules. It’s an excellent platform for anyone that would like to fully understand the

feed milling process and what it takes to produce quality sustainable feeds.

Who should attend?

The course is open to all, including Feed Mill Plant Owners, Feed Mill Managers and Plant Operators, Quality assurance and Maintenance staff, Nutritionist and feed formulators, Feed Additive and Animal Health suppliers, Industry advisors, and technical consultants.

OMS at Victam LaTam

We will be hosting a seventh Credo OMS Off-Line Session at the Victam Latam event in Sao Paulo, Brazil from 13:30-15:30 on October 3, 2023. The topic with be Trouble Shooting for All including Milling-Aqua-Pet Food Production and will comprise of a discussion panel and a Q&A session from the Autumn Courses and from within the room. During this Off-Line Session we will be awarding Certificates of Attendance to those who have completed one of the 2023 six-week courses and who are in attendance. Training is fundamental to developing a business’ efficiency and ensuring a return on your investment.

To see the programmes and to sign-up please visit: www. onlinemillingschool.com

TRAINING

26 | June 2023 - International Petfood

Troubleshooting

Extruder barrels designs are intriguing and considering the variety of designs it might be interesting to cover some of what goes on inside the barrel and the reasons behind some designs. We will center on medium shear designs. The two general other options would be low shear, pasta style or high shear, light density snacks type extruders. Note going into preconditioning the extruder barrel is fed atmospherically or force feed usually in both cases by feeder screws. Force feed designs don’t let much air in thus no venting out the top for air escape in older extruder designs. Today’s standards are closed systems or systems with recapture designs of hot moist air off the cylinder/extruder inlet and end of extruder barrel.

In any case extruder barrels can be defined in 2- 3 sections, the feed or inlet section, middle or kneading sections and the final one third of the barrel or cooking section. If an extruder barrel is changed internally then the sectional parts allow for relocation or different designs. If you consider the disruption of flow causes increased motor load and increased energy input and thus cook by friction, happens in all extruder designs. If you consider low shear virtually no restrictions while high shear has severe restrictions to achieve the desired effect.

Ok, medium shear or petfood, aquatic and in general animal feed extrusion. Typically, about 17 to 32 percent moisture out of the barrel thus some sort of frictional development is needed and at various amounts greatly depending on the moisture levels. Having stated this the inlet zones are generally designed to get material in and forward because some is right behind constantly, it is called a starve feed condition within a range because you can over feed and back up the inlet if the die can’t handle it for example. So, the feed is moving forward into the kneading zone where shallower flight double flight single screws, larger shearlocks and or kneading lobes start to appear dependent on the formula and what you are cooking. Some barrel designs simply pump forward and everything happens at the die with restriction to cause the back pressure barrel fill to create the frictional cook.

In a barrel where sectional control single or twin, counter or co-rotating, including end of barrel pressure controls is used the set up can be tailored to handle many different formulas. Sometimes multiple kneading sights along the barrel allow for more additions and cooking effects. Most of these changes centred on meat and other possible liquid injects or both. Basically, in general about 16 to 17 percentage moisture can be added to a single screw and about 20 to 25 in a twin screw. (12 % in dry raw material) This translates into about 80% moisture meat slurry being added at 20 or 25 % respectively as a percentage of the total mix. Dried down the meat level would end up somewhere in the mid-teens as a finished product percent. Tie this in with a correct die and you have the ability to make a wide range of products.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The Extruder Barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the Extruder Barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - June 2023 | 27

Innovations this month June 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

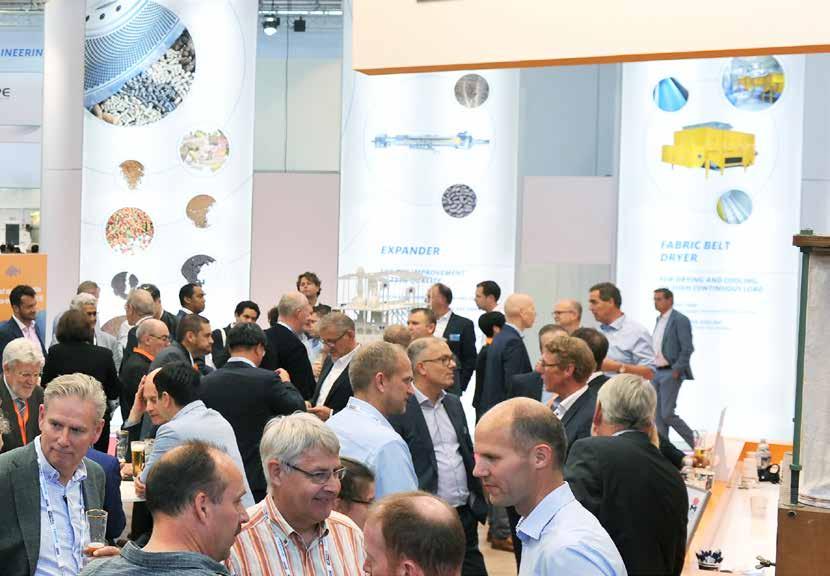

Expanders by Ottevanger

Ottevanger offers a range of expanders which improve the quality of finished feed as well as more efficient production process flow. The Ottevanger Contivar expanders have a reliable and sturdy design and are equipped with a unique Active Disk system (AD-system) in order to control exact product output and assure the quality of the product. The AD-system is easy to control and it is easy to exchange wear parts. The robust and simple design of the Ottevanger Contivar guarantees years of trouble free and economical production.

• Eliminate heat sensitive bacteria (salmonella)

• Addition of higher fats and liquids inclusions

• Gelatinisation of available starches

• Improved end product durability and strength

• Increased output of pellet mill

• Reduces wear costs of pellet mill

• Improved water stability for fish feed www.ottevanger.com

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY23 CeF i ® pro –Autolysed yeast! | free amino acids & nucleotides | promotes intestinal integrity | stimulates metabolism | enhances palatability Visit our website: leibergmbh.de Leiber GmbH | Hafenstraße 24 | 49565 Bramsche Germany | info@leibergmbh.de Best in bioavailability! 210223_International Petfood_90 mm x 270 mm.indd 1 21.02.23 08:41 28 | June 2023 - International Petfood

FOCUS

Airflow II by Wenger