International PetFoodVolume 5Issue 7July 2023 Postbiotics - The New Generation of Functional Petfood Ingredients - Insect Based Petfood - Mycotoxins in Petfood - Horses - How to feed them well July 2023 www.internationalpetfood.com www.perendale.com Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor

Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Community Manager

Levana Hall levanah@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 3646457 mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721

tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 1242 267700

cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706

tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

July 2023 10 Industry News COLUMNS 6 Roger Gilbert 7 Joseph P Kearns 8 Professor Simon Davies

International Petfood - Volume 5 - Issue 7 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 26 Training 27 Troubleshooting 28 Production focus 9 The PetFood Journal REGULAR ITEMS 24 Industry Profiles 31 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces

FEATURES

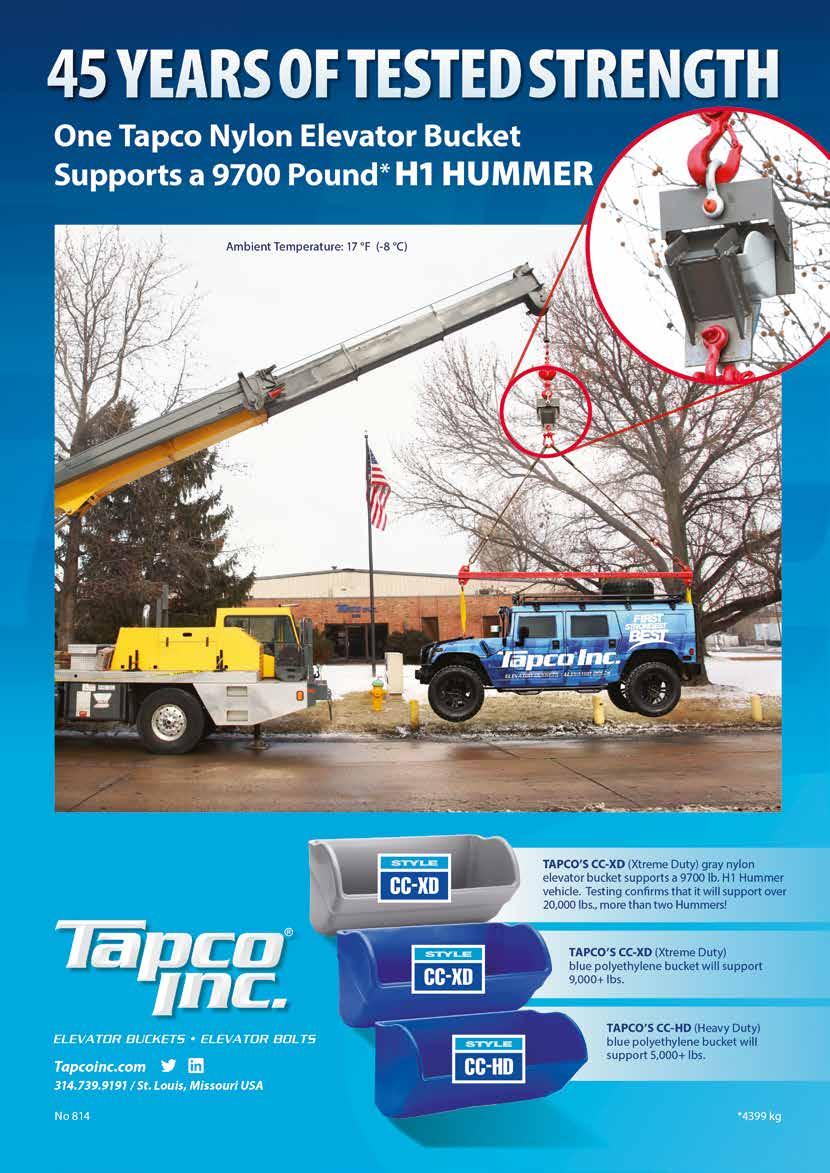

14 Postbiotics - The New Generation of Functional Petfood Ingredients

16 Insect Based Petfood

20 Mycotoxins in Petfood

22 Hourses - How to feed them well

It’s nice to see the world’s favourite pet on the cover once again and we are pleased to bring you some of the best images we can offer!

Often we have to talk specifically about other pet species and on this occasion, in this edition, we are focusing first and foremost on equine feeds and equine needs.

Roger Gilbert Publisher – International Petfood

Our editor Professor Simon Davies takes a look at horses (page 8) and tells us right away in his editorial that they are complex animals with specific dietary needs.

Professor Davies has a wealth of nutritional knowledge when it comes to pets and following the advice he is giving when manufacturing feeds will help us address the issues we come across.

Supporting our focus on horses, Managing Editor Jyothsna Nelloolichalil has prepared a feature on strategies to feed horses well. Her feature appears on page 22.

This edition offers a wide range of topics specific to petfood production.

So let’s get down to business. With our first feature of the edition on Postbiotics (page 14). This is a new generation of functional ingredients for petfoods as explained by Romona Cernat and Gustavo Zenaide of ADM writing from the USA. You will learn the definition of what a Postbiotic is and how to identify them for inclusion in rations.

While on the subject of ingredients we take the opportunity to once again look at insect-based petfood in the feature submitted by Ynsect of France (page 16). The company makes a strong case for those pet parents who are looking for alternative protein sources in their petfood which make a contribution to sustainability and reduced environmental impact.

As with other domesticated animal feeds, we should not overlook the impact and consequences from the inclusion of contaminated

Our last edition

Did you miss our June 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

The Concept of immunonutrition in animal and pet nutrition - The term immunonutrition originated from some human studies conducted in the 1950s and suggests a link between malnutrition and the occurrence of infections. In the 1980s and 1990s, other studies investigating population monitoring data for decades corroborated this concept. Read this article from ICC to find out more about immunonutrition!.

By Melina Bonato, Global R&D

feed raw materials in final rations.

I’m referring to the necessity of ensuring that any mycotoxins in raw materials selected for inclusion in animal feeds conforms with the national and/or international standards. Mycotoxins are becoming more understood, and their removal is more desired now than might have been the case in the past.

For grains and other granular raw materials, a colour sorter is a good option to assist in the removal of grains showing signs of contamination. However, materials storage protocols must also be followed to avoid any contamination becoming more widespread.

Our Industry Profile this month is on the company Minebea Intec (page 24) which leads us to our regular sections of Industry Training (page 25), Trouble Shooting (page 26) and Production Focus (page 28) - all worth the read.

We promote upcoming events and report on recent events IPF staff have attended.

The Zoomark 2023 held in BolognalFiere, Italy at the end of May was an excellent show to attend and may well become a mustattend event for petfood producers as both the range of petfoods and the visitors interested in these products were there in numbers. Our staff, Darren Parris and Tuti Tan, were present and their report is on page 32.

Finally, don’t overlook our Interview on page 40 with Dr Philippe Tacon who is the director of business development for animal health at Adare Biome, France. Many of us in the industry already know Dr Tacon but our interview brings out a little bit more about his background and his views on challenges the industry faces.

I hope you enjoy this latest edition. Let me know what else you’d like to see in International Petfood so that we can be sure we are addressing those topics that are most important to you.

Good reading!

and Technical Manager & Céline Villart, European Technical Supervisor, ICC, Brazil

To read more, go to: www.issuu.com/international_aquafeed/docs/ ipf2306_web/14

The Interview - Marco Prati, CEO, PLP Systems, Itally Marco Prati is the CEO of PLP Systems, an international company based in Italy specialising in the development and production of machinery for liquid and powder handling.

To read more, go to: www.issuu.com/international_aquafeed/docs/ ipf2306_web/14

THE PUBLISHER

Reviewing a few of the articles in this issue it is interesting to see the development and advancements in the postbiotic arena. It is mentioned the stability for production systems and thus an increase in heat stability is suspected to be improved greatly. Millions of metric tonnes of petfood are made by a wide variety of extrusion designs and most are good at cooking thus heat generation, reducing heat lability in this product in an advancement needed. This leads into one of the topics this month, conditioning.

Joseph P Kearns Editor, International Petfood Magazine

Conditioning also known as preconditioning is the area of an extruder that begins the process. Dry and liquid ingredients are metered into the preconditioner starting the process. Moisture and steam are the major liquids added but other liquids can include fat, digests as well as meats and liquid ingredients to control Aw, water activity, when making semi moist petfoods.

Basically, a preconditioner is a continuous mixer where a shell or tube surrounds rotating beaters or paddles with a dry material inlet at one end and liquid injection ports located along the conditioner with a discharge on the down steam end. What happens between the inlet and discharge is the science of material preparation for extruding petfoods and other materials. Mentioning other materials as an example, corn curls or balls, extreme high-pressure extrusion to yield 50 gm/l density requires virtually no water added and if it is added in the inlet of the extruder is sufficient for production thus no needed preconditioner. Not so with petfoods, highcapacity medium shear extrusion requires proper high-quality preconditioning to achieve the desired product and associated profitable capacity.

The style of petfood being made can be limited to the abilities of an extruder to make that petfood so determining the effective operational ranges is an important factor for your petfood production mix. Reviewing the styles available, single shafted preconditioners are not as popular now as they initially were due to limitations of capacity, moisture input and non-interruption of the flow which would improve mixing. Series of single shaft cylinders form multiple level preconditioners. This staged approach allows for various sets of conditions in each level. Higher speed for mixing, lower speeds to increase retention time. Double cylinders came into the picture and in one cylinder retention time and ability to increase moisture levels improved. Longer retention times allowed for moisture to be absorbed better and thus a huge reduction in a sticky mess between the cylinder and extruder inlet.

Differential diameter designs where the shafts had different diameters and speeds yielded a huge increase in ability to mix thus more meat could be added and flow homogenously out of the cylinder and into the barrel, most important for long continuous operation or running time. Improvements on this DDC design continues and elevating the abilities to new heights, CVs of right at 3, couple this with water and steam injection with improvements of eliminating escape of free steam. Couple this with controls to signal acceptance to discharge based on use of inline sensors for mainly a preset minimum temperature.

We would not be seeing improvements in preconditioning

if it was not effective. Historically, trends were for increased flexibility of ingredients use in extrusion and the conditioners coupled with barrel designs have fulfilled this need. The use of liquified meats, vegetables, fruits and any other liquids formulators are considering is increasingly possible. Overall system designs can result in limitations on the moisture levels allowed in the extrusion process. Standard extruder designs would usually operate in the mid 20 percent moisture ranges. As more energy and flow restrictors are used in the barrel coupled with matching the ability of conditioners the limits are upward with flexibility in non-traditional ingredient use. New systems exist with thermal cooking techniques where moisture levels approach 40 to 50 percent of the formula, high meat inclusion products.

Another topic of interest is shaping. The act of cutting the product out of an engineered and specifically design orifice to give a specific product shape. What can be done with die holes is amazing and interesting. Allows for production of unusual shapes if desired. When making general standard petfood the goal is perfectly shaped high capacity across the die face. There are guidelines for this in terms of open area per tonne using the desired final density and expansion rates based on the starch source and percent inclusion in the formula. These high-capacity product are usually sold for less per kilo then the exotic and unusual shapes usually due to the fact that the intricate dies automatically reduce capacity to make an acceptable product, quality of shape of the final product. Also, these advanced shapes usually have a more expensive formula, could be elevated meat and fat levels coupled with non-traditional starch sources.

Recycling under processed material is not unusual due to the cost of raw materials. Typically, this material which mainly comes from the extruder start up from the cylinder by pass and the die until the product is judged to be acceptable. Years ago, the product was sent to the dryer and a marker was used to determine when to collect the product out of the dryer to continue back to reprocessing. This allowed the dryer to dry the material out of the die and thus be reground and reincorporated in the mixing area. Developments with controls and the idea of why dry the materials, why not just put in a tank of water soften it up and have a solids content of approx. 10 percent. Pump this into the cylinder as you are adding water in any case and the rework is handled right at the extruder. Typically, a small amount is generated with today’s computer-controlled machinery. However, a 40-kilo collection of startup waste over a year, as an example, 1000 startups is 40,000 kilos of waste. Worthy of interest based on cost of the ingredient, the additional handling, drying, extra bin for rework and all associated with handling this material. It is contained in the processing area and leaves only when it passes through the extruder and reaching same temperatures for bacteria elimination. In conclusion systems not only handle the waste but use water from the head jackets as make up water, preheated, it also can create a vacuum to control the free steam from the atmospheric preconditioner and die knife area. Simply makes the extrusion area much cleaner, an allaround benefit.

THE EDITOR

International Petfood - July 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

Equine Colic: The Role of Nutrition and Diet in Regulation

The horse is a complex animal with specific dietary requirements and specialised feed management. As such, there are many nutritionally related issues depending on breed, husbandry, and environmental aspects but many are certainly dietary related. One common ailment is colic that can come about quickly in horses and involves nutrition and dietary modulation.

Intoduction

Equine colic is a term used to describe abdominal pain in horses, which can stem from various causes such as gastrointestinal disorders, obstruction, or inflammation. This condition can be potentially life-threatening if not promptly diagnosed and treated. While management practices play a crucial role in preventing colic, the role of nutrition and diet should not be underestimated. I explore how nutrition and diet can affect and regulate colic in horses, providing examples, case studies, and citing relevant research. Additionally, it outlines some commercial feeds that can help mitigate these conditions in practice.

Firstly, biochemical features of colic in horses includes dehydration leading to reduced water intake and increased fluid loss through sweating and diarrhoea. This can result to imbalances in electrolytes and other biochemical parameters. The stress and pain associated with colic can lead to metabolic imbalances in horses. These imbalances may include changes in blood glucose levels, alterations in acid-base balance, and fluctuations in blood electrolyte concentrations (such as sodium, potassium, and chloride). Some types of colic can cause inflammation in the gastrointestinal tract. As a result, biochemical markers of inflammation, such as C-reactive protein (CRP) and white blood cell count, may be elevated.

As stated, colic is primarily characterised by abdominal pain. Horses may exhibit signs of discomfort, including pawing at the ground, restlessness, kicking at the abdomen, lying down, and getting up repeatedly, rolling, or showing signs of distress. Colic can disrupt the normal movements of the gastrointestinal tract, affecting the propulsion and digestion of food. This can lead to symptoms such as decreased or absent bowel sounds, reduced passage of faeces, or abnormal gas accumulation. Severe colic cases may lead to changes in the horse’s cardiovascular system. These changes can include an increased heart rate (tachycardia), changes in blood pressure, and alterations in perfusion to different organs. In certain cases of colic, intestinal inflammation or damage can lead to the release of bacterial toxins into the bloodstream. This condition, known as endotoxemia, can result

in systemic effects, such as fever, depression, and increased heart and respiratory rates.

Nutritional Factors and Colic Risk

A diet high in fibre is essential for maintaining a healthy digestive system in horses. Research has shown that a deficiency in dietary fibre can increase the risk of colic. Feeding long-stem forage, such as hay, promotes proper gut motility and reduces the likelihood of impaction colic. Overfeeding grain and concentrated feeds can lead to an imbalance in the gut microbial population, which may result in colic. It is crucial to provide a balanced diet that meets the horse’s nutritional requirements without excessive reliance on grain-based feeds.

A study conducted by Smith et al. (2019) found that horses fed a high-grain diet had a significantly higher risk of developing colic compared to those on a forage-based diet. This highlights the importance of moderating grain intake to prevent colic incidents. Commercial feeds formulated with high-quality fibre sources, such as beet pulp, soy hulls, or alfalfa, can be beneficial for horses prone to colic. These feeds provide an additional source of fibre, promoting healthy digestion and minimizing the risk of colic.

Certain commercial feeds incorporate prebiotics and probiotics, which support a healthy gut microbial population. These additives help maintain the balance of beneficial bacteria in the digestive tract, reducing the risk of colic associated with gut dysbiosis. A study by Johnson et al. (2020) demonstrated that horses fed a diet supplemented with prebiotics and probiotics had a reduced incidence of colic compared to those on a control diet. This suggests that incorporating these additives in commercial feeds can have a positive impact on colic prevention. Electrolyte imbalances can contribute to dehydration, which increases the risk of colic. Commercial feeds enriched with balanced electrolyte formulations can help maintain proper hydration and electrolyte equilibrium, particularly during periods of increased sweating or intense exercise.

The regulation of equine colic through nutrition and diet is a critical aspect of horse management. Proper nutrition, including a high-fibre diet, moderation of grain intake, and adequate hydration, can significantly reduce the risk of colic. Commercial feeds enriched with high-quality fibres, prebiotics, probiotics, and electrolyte balancers offer practical solutions to mitigate colic incidents. Integration of scientific research and case studies, validates that a well-balanced diet plays a vital role in maintaining a healthy gastrointestinal system and reducing the risk of colic in horses.

8 | July 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - July 2023 | 9

Natural Farm now available through U.S and Canada distributors

Natural Farm, a leading provider of allnatural dog treats and beef bones, proudly announces its partnership with several esteemed distributors in the United States and Canada. The collaboration aims to enhance accessibility for pet specialty stores and farm and feed stores, ensuring pet owners can easily procure Natural Farm’s hormone-free products without any additives, chemicals, or colours.

“We are thrilled that more U.S. and Canada pet specialty stores now have another way to access Natural Farm’s exceptional lineup of all-natural dog treats and beef bones,” exclaims Marcelo Barbosa, CEO of Natural Farm. “Our commitment to quality and the well-being of pets remains at the core of everything we do. By expanding our distribution network, we aim to make the buying experience as seamless as possible for pet owners, providing them with the option to choose what works best for them.”

In addition to purchasing directly from Natural Farm, retailers now have the convenience of procuring Natural Farm products through trusted U.S.-based distributors, including AFCO, Generation Pet, Northland Natural Pet, Sunburst Pet Supplies, and John A. Van Den Bosch. Canadian retailers can also access Natural Farm’s range of offerings through the esteemed distributor Kane.

Natural Farm takes pride in its meticulous sourcing and production methods, ensuring that every product upholds the highest standards of quality, taste, and nutritional value. By using only all-natural ingredients and maintaining a hormone-free approach, Natural Farm provides pet owners with the peace of mind they deserve when selecting treats and bones for their beloved companions.

“We understand the deep bond between pets and their owners, and we believe they deserve the very best,” emphasises Mr Barbosa. “Through our expanded distribution channels, we aim to reach more pet specialty stores and farm and feed stores, enabling them to offer Natural Farm’s premium products to discerning pet owners who prioritise natural, wholesome options.”

As Natural Farm continues to evolve and expand its distribution network, the company remains dedicated to delivering top-notch products that meet the highest standards of excellence. Pet owners can trust Natural Farm to provide a delectable and healthy treat selection that contributes to their pets’ overall well-being.

UK£900,000 investment in a latest cold pressed production facility

Walker & Drake, the Barnsley based premium dog food manufacturer have just completed their £900,000 investment in a brand new cold pressed production facility.

The company, that only began trading after the first lockdown of 2020, has seen massive growth in their cold pressed dog food sales. Walker & Drake’s cold pressed dog food is built around a minimal processing ethos with the benefits of gut health at its core.

Walker & Drake director David Taylor, “Our cold pressed dog food is a premium product focused on gut health, and we are constantly talking with our customers to understand what they want for their dogs. The ability to develop new products in a dynamic fashion is fantastic, and the relationships we have already nurtured with our suppliers means we get the access to the best ingredients available at any time.”

“The requirement for continuing growth driven expansion, and the increased complexities around exporting into Europe, meant we really had to take all production and packing in-house, and built something bespoke to us that future proofed our production capacity.”

Sales director Tim Matthews, “We must be one of very few companies currently building a new petfood facility in the UK but we’re passionate about keeping our production here and having control over all aspects of it. Just like the ingredients we use in our products we’ve sourced the equipment, fabrication, and installation from UK companies wherever possible. In fact, apart from one item, all the major components, the design, and installation team are from within a 25 mile radius of our site.”

The company moved to larger premises last year to facilitate the extra space required for the new factory and warehousing. Tim Matthews, “By starting with an empty space we’ve been able to create an efficient workflow from goods-in, through the production process to bagging, warehousing and then back out the door as finished product.”

10 | July 2023 - International Petfood N

Amcor acquires Moda Systems

Packaging solutions company Amcor announced that it signed a definitive agreement to acquire Moda Systems, a manufacturer of automated protein packaging machines.

Moda, which is based in New Zealand, designs, assembles and supports innovative, highperformance modular vacuum packing solutions for the meat, poultry and dairy industries.

Amcor said the acquisition would complement the company’s strength in film, positioning the company to offer an endto-end packaging solution that encompasses primary packaging, equipment, on-site technical services and parts.

“This acquisition will enable Amcor to offer an exciting new option and choice in automated protein packaging, making us the only flexible packaging manufacturer to own a high-speed, rotary equipment solution for

fresh meat,” said Fred Stephan, president of Amcor Flexibles North America (AFNA). “Combined with our best-in-class film portfolio, we see great strategic value in adding Moda’s automation technology, and technical expertise and services for a range of customizable format solutions beyond a standard shrink bag. This transaction will enable Amcor to further enhance our winning value proposition for our global protein processing customers.”

Moda uses a rotary vacuum system to improve operational efficiencies for protein producers, enabling them to optimise labour, improve safety, and reduce waste. The system is designed for ease of use in connecting, operating, maintaining, and cleaning, and improves throughput and quality.

“Rising labour costs, employee attrition, and labour scarcity make automation a strategic imperative for fresh protein food processors,” said Scott Fallon, vice president and

general manager of meat, poultry and seafood at AFNA. “This presents an opportunity for Amcor to create additional value through segmentfocused automated packaging systems and solutions.”

With Amcor’s various meat, poultry, seafood, and cheese shrink packaging options, this new solution is expected to further enhance the value Amcor delivers to protein producers.

“We’re delighted to join forces with Amcor, an industry leader that shares our commitment to innovation and customer service and support,” said Richard Newcombe, founder and chief executive officer of Moda Systems. “Together, we will deliver innovative expertise at scale, with a mutual dedication to outperformance. Our complementary capabilities will accelerate Moda’s founding mission to offer the most advanced vacuum packaging solutions for our customers.”

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

International Petfood - July 2023 | 11 N

Pure Cravings Introduces New Minced Tuna Lin

It has a red-meat tuna base with one of five different added protein toppers: Tuna loin, Salmon, Mackerel, Sardine and Chicken.

Pure Cravings is an innovative new pet brand that addresses the mercury problem in cat food by rapidly testing fish to strict mercury limits. Pure Cravings is the only brand of pet food to test every tuna and salmon, and every catch of bait fish, to a strict mercury limit. The premium canned cat food brand is human-grade, non-GMO, 100% wildcaught, and sustainably sourced.

“Mercury levels in fish can vary widely. Two identical tuna of the same species and size can vary in mercury up to 10 times.” says Pure Cravings Cofounder, Sean

Wittenberg. “The only way to protect cats from mercury variance is to test every single tuna and salmon, and every catch of sardines and mackerel. Pure Cravings’ mercury-testing technology sets a new, unmatched standard for the pet food industry. Pure Cravings is the only brand to test each and every can of cat food to a strict mercury-limit.”

Studies have shown that mercury levels in cats with fish-based diets have been found to be 5X higher than those in people. Elevated mercury levels can contribute to hyperthyroidism and kidney failure – an issue particularly found in older cats. Pure Cravings’ industrycertified technology ensures every single tuna and salmon, and every

catch of smaller baitfish, like sardines and mackerel, are tested to a limit of 0.07ppm – a level experts consider safe for cats and far lower than average mercury levels found in many cat foods today. No other brand does this.

At Global Pet Expo 2022, Pure Cravings was awarded “Best in Show” in the cat category for the New Product Showcase.

Pure Cravings is a new pet-food brand created by the founders of Safe Catch – the internationally recognised seafood brand that tests every single tuna and salmon to strict mercury limits. Safe Catch Cofounders Wittenberg and Boches applied their revolutionary mercury-testing technology to cat food to develop pure cravings.

Yemmak improves Turkish petfood production

Yemmak, as one of the leading machinery manufacturers in Turkey, continue to achieve remarkable success both domestically and internationally.

The latest endeavors involve overseeing the establishment of four new plants for different cat and dog food producers across Turkey. These petfood plants are meticulously designed to commence production in 2023, and they proudly bear the Yemmak signature. Collectively, these petfood plants have a total production capacity of 30 t/h.

Maya Family Pet has entrusted Yemmak with the construction of a plant in Kırklareli (Thrace region Turkey), boasting a capacity of 10 t/h. Likewise, Hektaş, a prominent player in the industry, has selected Yemmak to implement a 10 t/h facility for their plant in Kızıksa (Marmara region Turkey).

Additionally, Petiva and Troya Pet companies have successfully realized their vision by establishing 5 t/h capacity factories, benefitting fromYemmak’s extensive 55 years of process engineering expertise.

12 | July 2023 - International Petfood N

BUY NOW

internationalmilling.com

https://flickread.com/edition/Petfood SUBSCRIBE Available ONLINE, IN PRINT and on you favourite APP store Create an account on Flickread to view all of our editions on desktop ... Use your account to sign into our app (available from your favourite app store) ... Or manage your print subscription Sustainability goes mainstream A re-invention of capitalism in the matrix of our anthropocene diet - Swift guide to the diet & nutrition, hygiene and housing requirements of aviary birds - Vegan petfood production - NIR technologies in petfood production - Rendering:The unsung hero of sustainable petfood June 2022 www.internationalpetfood.com www.perendale.com International PetFood Volume Issue 11November 2022 An Axolotls Diet Calci- Worms - How A Commitment To Human Progression Created A New Us$75 Million Dog Chew Category - Commodity Handling Equipment November 2022 www.internationalpetfood.com www.perendale.com Download your online version: International PetFood Volume Issue April 2023 Protection against stress! - Fresh nutrition for happy, healthy pets - The Diet of Horses April 2023 www.internationalpetfood.com www.perendale.com Download your online version: Nutrition from Nature Pet Food Plant Solution - Cat Food - Sharing Earth Animal's Wisdom on Sustainable nutrition - Sourcing Ingredients - Welfare in the Ornamental Fish Trade August 2022 www.internationalpetfood.com www.perendale.com Download you online version: IPF2208.indd 1 23/08/2022 09:43 PETFOOD SAFETY - Joint management & obesity in dogs - Developing effective natural nutritional support for joint ailments & weight management in canines - Insects in petfood - The continuing growth of the use of insect derived ingredients in petfood applications - Petfood technology in action - Achieving peak petfood packaging performance April 2022 www.internationalpetfood.com www.perendale.com International PetFood Volume Issue March 2023 VEGAN DOG FOOD? All your questions answered! - Insect Based Petfood - 4 reasons to include soy in diet - Providing right nutrition for your pet rats March 2023 www.internationalpetfood.com www.perendale.com Download your online version: International PetFood Volume Issue January 2023 Phytogenics in natural animals feed - Animal feed - The nutritional requirements of your froggy friend - Extrusion - Bucket elevator efficiency January 2023 www.internationalpetfood.com www.perendale.com Download your online version:

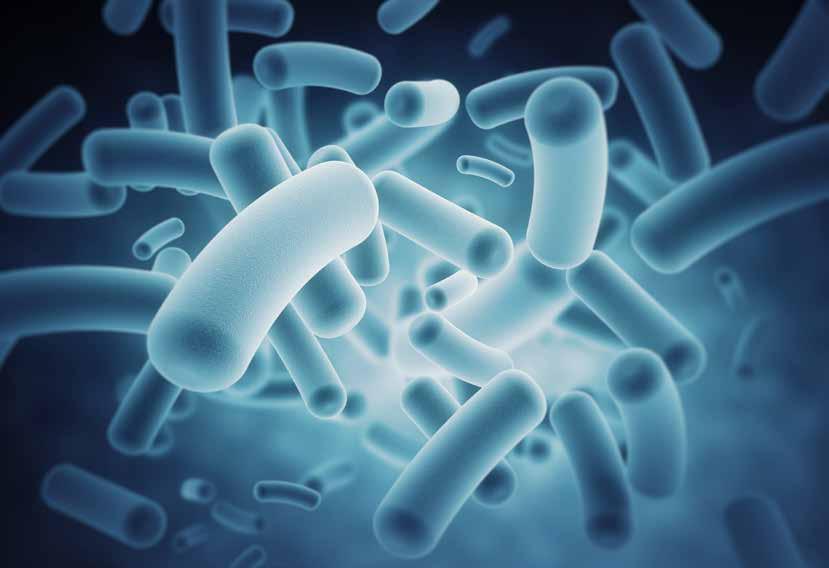

Postbiotics

The New Generation of Functional Petfood Ingredients

by Ramona Cernat, S&T Director, Health & Wellness & Gustavo Zenaide, Vice President, Pet & Animal Well-being, ADM, USA

Pet products with wellness benefits are increasingly of interest to pet owners who are taking a more proactive approach to their pet’s holistic health and well-being. According to Mintel, Biotic ingredients are gaining in the pet category across global product launches, with prebiotics currently leading adoption trends.

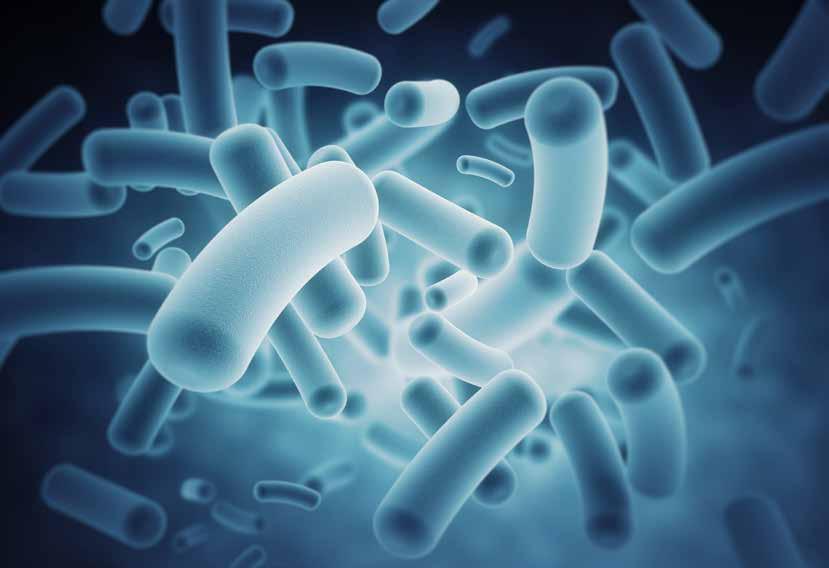

Postbiotics are the next generation of biotics, steadily emerging in the field.

An Introduction to Postbiotics

Although the term is relatively new, postbiotics have been studied for over 20 years. Recently a consensus on the definition and scope of postbiotics was established. ISAPP defines a postbiotic as “a preparation of inanimate microorganisms and/or their components that confers a health benefit on the host.”

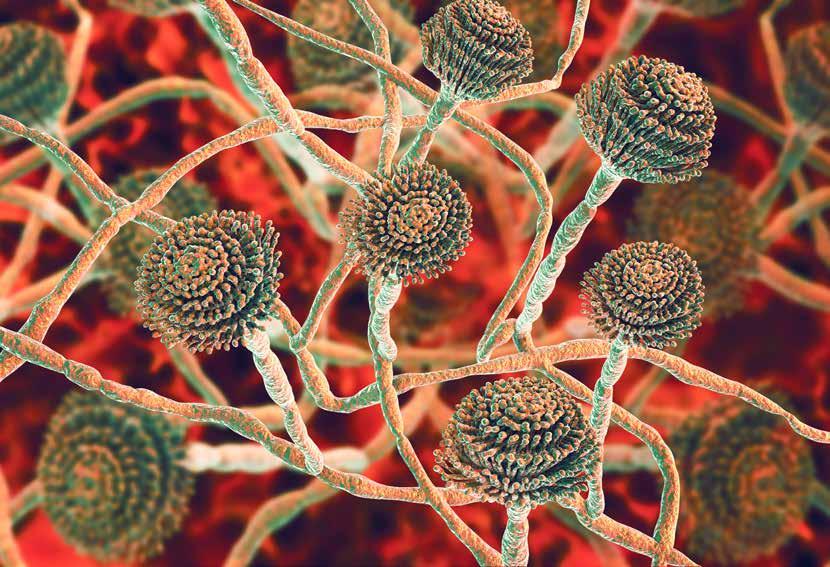

Various types of postbiotics exist, such as yeasts (e.g., Saccharomyces cerevisiae , S. boulardii ) and filamentous fungi (e.g., Aspergillus oryzae ). Bacteria-derived postbiotics include lactic acid bacteria (e.g., Lactiplantibacillus (former ly Lactobacillus ) reuteri, L. acidophilus ), bifidobacteria (e.g., Bifidobacterium lactis, B. longum), bacilli (e.g., Bacillus coagulans ), functional gut anaerobes (e.g., Akkermansia muciniphila, Eubacterium hallii, Faecalibacterium prausnitzii .) and gram-negative bacteria (e.g., Escherichia coli Nissle 1917 ).

Research indicates that postbiotics deliver their benefits through five main mechanisms of action, which in some cases could be similar to those known for probiotics and might act independently or in combination.

The mechanisms of action for postbiotics are:

‒ Beneficial impact on resident microbiome through molecules present in postbiotics (e.g., lactic acid, short chain fatty acids (SCFAs), quorum sensing, adhesins).

‒ Support for the barrier role of gut epithelium through molecules present in postbiotics (e.g., secreted proteins, exopolysaccharides, SCFAs).

‒ Impact on local and systemic immune response by the interaction of lipoteichoic acid, peptidoglycan, β-glucans, lipopolysaccharides or metabolites with specific immune receptors (e.g., indole derivatives of tryptophan, histamine, SCFAs). Impact on systemic metabolism by the metabolites or enzymes present inside and on the surface of the inactivated microorganisms in the postbiotics.

‒ Signaling via the nervous system by neurotransmitters present in postbiotics (e.g., serotonin, dopamine, acetylcholine, gamma-aminobutyric acid (GABA)) and which have the potential to affect behavior and cognitive function in animals and humans.

The Drivers of Postbiotics adoption

Postbiotics are an exciting development for both the human and animal nutrition segments. Recent market research of the human nutrition industry predicts that the total business-tobusiness global microbiome category, which includes prebiotic and probiotic ingredients for foods, beverages and dietary supplements, will have a CAGR of 8.6% during 2022-2027.

Postbiotics are an ingredient to watch, complementing established solutions like prebiotics and probiotics. Additional market research shows that postbiotics for human nutrition are predicted to have a CAGR of 9.3% during 2021-2026.

14 | July 2023 - International Petfood F

Compared to probiotics, postbiotics can be more easily incorporated into petfood products because formulators don’t have to make adaptations for live colony forming units (CFUs). Postbiotics have an inherent stability to withstand many industrial processes and shelf-life requirements. This characteristic also makes postbiotics suitable for geographic regions that lack reliable cold chains or where ambient temperature can cause problems for storage of probiotics.

Clinical evidence indicates postbiotics, particularly bacteriaderived postbiotics, are promising ingredients to support human and animal physiology. ADM researchers are focusing on bacterial strains belonging to bifidobacteria and lactobacilli and others to explore potential benefits ranging from digestive health, metabolic health, immune function, oral health, skin and coat health, and mental well-being. ADM’s portfolio of microbiome solutions is supported by extensive research that demonstrates biotic benefits associated with multiple human health areas. Clinical trials with pets are ongoing.

For example, ADM’s BPL1™ (Bifidobacterium animalis subsp. lactis CECT8145) strain and its heat-treated counterpart have shown to target factors relevant to metabolic health in humans. A published clinical trial of the postbiotic in adults showed emerging evidence that it supports reduction of visceral fat and a healthy waist circumference in combination with diet and exercise. In addition, a pre-clinical model of heat-treated BPL1™ demonstrated increased lean mass and ameliorated metabolic syndrome in cafeteria-fed obese rats. Furthermore, preliminary analyses show that the heat-treated version of ADM’s probiotic BPL1™ modulated the gut microbiome of dogs supplemented with the postbiotic.

Postbiotic Applications in Pet Nutrition

Today’s pet owners are actively seeking customized solutions to support their pet’s physical and behavioural health. More than 40 percent of global pet parents say they use nutrition products to support their pet’s wellness. Many consumers scan labels for claims like “clinically tested,” “scientifically studied” and “vet recommended” as evidence of a product’s effectiveness. Additionally, 60 percent of global pet owners say branded health ingredients in pet products are important, as many perceive them as more likely to be supported by clinical evidence.

With a growing body of research indicating the wellness benefits of postbiotics, it makes sense that their adoption in pet products is increasing across every region in the world. Notably, heat-treated BPL1™ is one of the ingredients in an all-in-one daily supplement for dogs. It also has applications in baked dog treats and other pet products.

Yet postbiotics are still considered quite novel. Pet owners in Europe and other regions are used to receiving messages about the benefits of “live and active bacteria,” or probiotics. However, they are likely unfamiliar with the concept of “inanimate bacteria,” or postbiotics.

It will be important for pet nutrition brands to help educate pet owners about why they should believe in postbiotics and the benefits they can deliver to dogs and cats. Many consumers want to see a visible benefit, whether that’s weight loss, a shiny coat or a return to normal bowel movements. Physical evidence that a product supports the pet’s digestive health (or another concern) may be the best “proof” to engage them with postbiotic solutions.

F International Petfood - July 2023 | 15

Insect Based Petfood

Genotyping chip for insect breeding

by Ÿnsect, France

by Ÿnsect, France

As pet owners become increasingly conscious of the diet and health of their furry friends, nutritionists are now looking for an alternative to conventional sources of animal protein. Insects have been identified as a promising source of protein for pets due to their high nutritional value, easy availability and sustainability compared to traditional sources such as beef or chicken.

Insect protein is especially beneficial for cats and dogs with allergies or sensitivities to common animal proteins, such as

Ÿnsect, the world leader in insect production, announced the creation of a genotyping chip named Axiom® YNS_Mol1, a world-first for insect breeding and a major step in the evolution of selection of larvae lines to produce insect-based proteins. This novel chip dedicated to the Tenebrio molitor mealworm will allow for selection based on the genomic diversity of the species. Made available to the wider scientific community, it represents a key element of Ÿnsect’s strategy, as well as a groundbreaking tool for fundamental research in the sector.

“Ÿnsect’s ambition is to contribute to the development of a new economic, social and sustainable model, which proposes new ways of consuming and producing, in order to meet the major environmental and climatic challenges of our era. For 12 years we have been innovating, with the goal of advancing the food industry and democratising the insect. Our genotyping chip for the Tenebrio molitor beetle is a world-first for our industry and will contribute to the sustainable structuring of the entomoculture sector.” Antoine Hubert, CEO of Ÿnsect.

Genomic selection today represents one of the most important levers of the ecological transition, making it possible to better characterise and enhance functional biodiversity1. Faced with the urgency of today’s environmental challenges, it is one of the fastest and most effective tools we have to improve the sustainability of our food systems.

This application of genomics is already being implemented by seed companies to identify the varieties that are most resilient to global warming. The identification of insect varieties with traits adapted for optimal development while requiring less water or fewer inputs, will make it possible to reduce our environmental footprint even further.

This announcement comes a year after Ÿnsect launched the ŸnFABRE project – with the CEA, Aprex Solutions and Thermo Fisher Scientific and supported by BPI France – with the aim of developing a pioneering unit for the selection of larvae lines with improved zootechnical and environmental performance.

16 | July 2023 - International Petfood F

A new tool to support the development of insect farms

This genotyping chip, developed with Thermo Fisher, represents a very powerful lever for the sustainable development of insect farms. Until now, producers have mainly focused on selecting the bigger larvae, but this kind of overly restrictive practice of mass selection could lead to inbreeding and its detrimental consequences.

For insect breeding in particular, it is essential for large-scale farms like Ÿnsect to select the best lines while ensuring real genetic diversity.

The genomic selection delivered by the Axiom® YNS_Mol1 chip makes it possible to achieve these objectives. It targets the genetic characteristics of interest while covering the entire genome to guarantee diversity. The selection is based on four families of phenotypes – or biological traits – linked to growth performance, reproduction, food conversion and disease resistance. In all, more than 4,000 individual insects were analysed to model this innovation.

“The chip is made up of 679,205 markers (SNPs or Single Nucleotide Polymorphisms), distributed throughout the genome and covering more than 99% of the gene regions. These SNPs, representing modifications of a DNA base at a precise position between individuals of the same species, were selected to represent the entire genetic diversity of the insect population at our farms.”

Comments Thomas Lefebvre, Biotech R&D Innovations Director, Ÿnsect.

“Thermo Fisher’s Axiom® technology allowed us to genotype the Tenebrio Molitor as we traditionally do for livestock and field crops. This is the first time that a chip of this type has been designed for an insect, and it truly marks the insect’s entry into

DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25

4B

F International Petfood - July 2023 | 17

conventional breeding. The design of the chip, which consists of defining and optimising its content in terms of markers, is the key step in the design. It requires close collaboration between the programme’s geneticists and the bioinformatics team. This development is a real step forward, made possible by all the partners in the ŸnFABRE project, a programme that is participating in an innovative way in the response to climate and environmental changes.” Adds

Pierre Garrabos Senior Key Account Manager AgriBusiness West of France at Thermofisher Scientic

A breakthrough innovation

ŸnFABRE is the world’s first industrial programme dedicated to beetle genetics for genomic selection applied to largescale insect breeding. It enables the creation of pioneering units for the selection and multiplication of high-

performance and resilient insect lines and help to better understand insect biology.

ŸnFABRE combines several areas of expertise and innovation for the development of phenotyping – the characterisation of biological traits – and genotyping – the identification of genome variations – tools, mathematical models and industrial processes.

As part of its R&D activities in collaboration with the CEA, Ÿnsect has already discovered and published the sequencing of the Tenebrio Molitor genome, which in turn led to the publication of the paper “Chromosomescale assembly of the yellow mealworm genome – A high-quality reference genome for Tenebrio molitor breeding and sustainable production2” (Eleftheriou et al. 2022). The high-speed chip was designed based on this reference genome, taking into account the genetic diversity observed.

Ultimately, ŸnFABRE will set up farms dedicated to genetics and having the potential to supply the Ÿnsect vertical farms with more performant lines of mealworms, which would increase their productivity by 15 percent per year while ensuring greater resistance to disease.

Continued support for academic research on insects

The chip will also be made available to the academic world to encourage international research on Tenebrio molitor.

By providing access to the genetic information of the species, Ÿnsect is actively supporting the development of knowledge of insects and their genetic characteristics and opening the way to the discovery of new industrial applications for the edible insect sector and beyond for biomedical and environmental applications.

18 | July 2023 - International Petfood

We invite you to use the code below for a free edition of our magazine either mailed to you or via our App

Use coupon code: HNY23

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Petfood-Advert Mar 2023 215x140mm.indd 1 01/03/2023 13:02 International Petfood comes to you either in print or digitally Whichever way you want to receive, please sign up on our Flickread for your personal copy which will give you access, from your desktop, to our back-issue library. https://flickread.com/edition/Petfood

store.

The App can be downloaded from your favourite app

PETFOOD INTERNATIONAL Download your online version International Petfood - July 2023 | 19 F

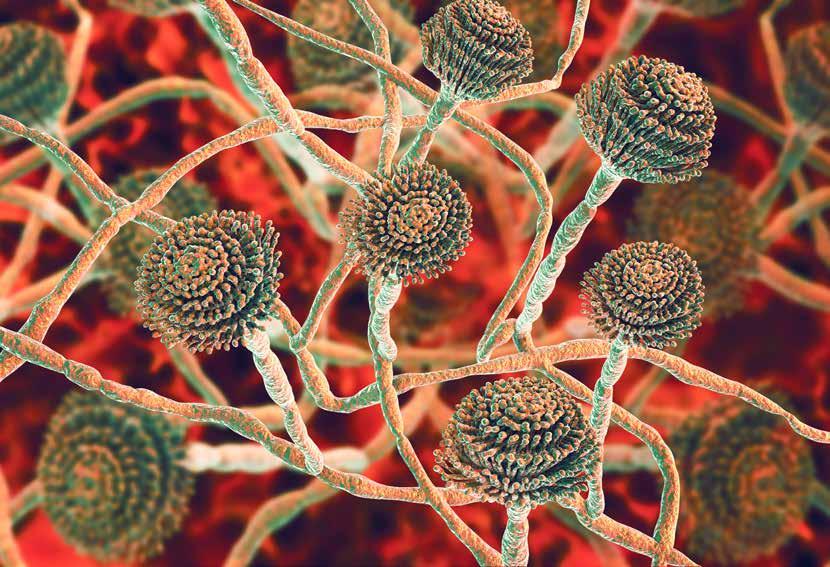

Mycotoxins in Petfood

by Bühler, Switzerland

ycotoxins, a poisonous chemical found in the corn used in petfoods, are causing animal sickness and irreparable brand damage. To solve this issue, SORTEX LumoVision, a solution developed by Swiss technology group Bühler, uses the spectral scale to kick out mold from petfood, keeping the costs of market recall down and pets safe.

In 2021, the FDA (Food and Drug Administration) alerted customers of fatal levels of aflatoxin, a strand of mycotoxin that attacks the liver, found in 1,000 lots of petfood. From the bad batch, it is reported that 130 dogs died. This statistic provoked lawsuits and anger from dog owners and the wider industry. However, the damage of mycotoxin contamination does not stop there.

Recalling product is expensive

One of the major costs of mycotoxin contamination is market recall. Recalling a product from the market is not cheap, in fact, the Grocery Manufacturers Association (GMA) discovered that the average cost of market recall is USD10 million in direct costs alone. The financial hits of recalling product include: disposing of the product, reimbursing customers, and business interruption. The GMA survey showed that 81 percent of respondents deemed the financial risk of market recall to be “significant to catastrophic”.

MContaminated product damages brand image

Financial costs and damage to health are not the only repercussions of mycotoxin contamination. Once the media are aware of the situation, brand image can take a significant hit. For consumers, it takes a lot to repair trust in a brand, and while brand damage is difficult to measure, this can further cost companies millions in lifetime value.

Contaminated product can cause mass waste

Before the LumoVision, contaminated grain would have been disposed of in large amounts. During testing, if the batch has a high concentration of mycotoxin, in many cases, the entire batch is destroyed. In fact, as few as two highly contaminated grains in 10,000 can render an entire batch unsafe. The Food and Drug Association (FDA) estimate that US$932 million is lost per year to crops contaminated with mycotoxin. This removal of the contaminated material may protect the consumer, but it costs businesses and the environment a lot more.

What can be done?

Bühler SORTEX faced the challenge of mycotoxin contamination head-on. After discovering a breakthrough “invisible indicator” of contamination on the spectral scale, Bühler created the LumoVision, an optical sorter that can reduce the aflatoxin level by up to 90 percent (as indicated by industrial trials). This reduction brings many samples to regulation levels, saving companies from the costs of large-scale material waste and market recall.

20 | July 2023 - International Petfood F

It works by analysing the colour each kernel fluoresces as it passes under powerful UV lighting in the sorter. It is known that contaminated kernels fluoresce a specific bright green colour, a substance called kojic acid, which is produced by the Aspergillus fungus at the same time as it produces aflatoxin. LumoVision’s proprietary, highly sensitive cameras and a powerful LED-based UV lighting system can precisely detect this color of fluorescence. Within milliseconds of detection, air nozzles deploy to blow contaminated kernels out of the product stream.

When dealing with toxins, early intervention is critical. This is not only important in reducing the toxins consumed by pets, but also to lower wastage and the environmental footprint. Without proper cleaning and sorting, poisonous mycotoxins can cause large-scale wastage of materials, mass market recalls, and harm to pets.

Dr Gerardo Morantes, Director of Food SafetyAmericas Region at Buhler, had the following to say, “Mycotoxins are a worldwide concern. However, technology made possible by Bühler SORTEX enables a preventative solution, meaning that mycotoxins can be dealt with early, stopping the spread and removing the contamination to meet regulatory standards.”

Without intervention, mycotoxin contamination can bare a large cost for businesses, including, brand reputation, market recalls and material waste. With the SORTEX LumoVision, brands can stay profitable, customers can stay happy and pets can stay safe.

International Petfood - July 2023 | 21 F

How to feed them well Horses

by Jyothsna Nelloolichalil, International Petfood, UK

Horses are great companions who encourage their owners to spend more time in the nature. Keeping a horse as a pet requires physical activity and it is proven to be beneficial on owners mental and physical health. Proper nutrition is the foundation of equine health and performance. The importance of a balanced diet for horses cannot be overstated, as it directly influences their growth, development, immune system, and overall well-being. This feature will delve into the fascinating world of equine nutrition, exploring the essential nutrients, feeding practices, and dietary considerations that contribute to maintaining healthy horses.

The Fundamentals of Equine Nutrition

To comprehend equine nutrition, it is crucial to understand the basic components of a horse’s diet. Horses are herbivores with a digestive system designed for grazing on forage, such as grass and hay. The primary nutrients required by horses are carbohydrates, proteins, fats, vitamins, minerals, and water. Carbohydrates, mainly derived from forage, are the main energy source for horses, while proteins are vital for tissue repair and growth. Fats are a concentrated energy source and play a role in thermoregulation and vitamin absorption. Vitamins and minerals are essential for various metabolic functions, and water is critical for digestion and overall hydration.

Balancing the Equine Diet

Creating a balanced diet for horses involves understanding their specific requirements and adjusting the feed accordingly. Forage, such as high-quality grass or hay, should constitute the foundation of a horse’s diet, making up the majority of their daily intake. Access to pasture grazing is ideal, as it allows horses to engage

in natural grazing behaviours. When pasture is limited, high-quality hay can serve as a suitable alternative. In addition to forage, concentrated feeds, commonly known as concentrates or hard feeds, can be used to supplement the diet. Concentrates typically include grains, such as oats, barley, or corn, along with protein sources, vitamins, and minerals. The amount and type of concentrate should be determined based on the horse’s activity level, age, body condition, and individual requirements. It is crucial to introduce changes to the diet gradually to avoid digestive upset.

Horse drink an average of 5-15 gallons of water every day, depending on the temperature and humidity. Fresh and clean water should be available for horses all the type. If that couldn’t be the case, horses should be watered at least twice a day. Lack of hydration in horses can lead to serious conditions like intestinal impactions and other forms of colic.

Special Considerations in Equine Nutrition

Equine nutrition requires careful consideration of various factors, including age, breed, body condition, and activity level. For instance, young growing horses have specific dietary needs to support skeletal development, whereas older horses may require adjustments to their diet to maintain optimal weight and support joint health.

Similarly, athletic horses, such as racehorses or show jumpers, have increased energy requirements. Meeting their nutritional demands involves providing a well-balanced diet with appropriate levels of carbohydrates, fats, and proteins. Additionally, the timing and composition of feedings before and after exercise play a vital role in replenishing energy stores and supporting muscle recovery.

22 | July 2023 - International Petfood F

Certain health conditions, such as insulin resistance or gastric ulcers, require specialised nutritional management. These conditions often necessitate modifications in the diet, such as reducing carbohydrate intake or incorporating specific supplements to support gut health. When looking through the overwhelming number of feed options, a good way to know which one you need is to compare the protein, fat levels, and carbohydrate levels between them rather than just look for a single magic number. Based on your horses needs and some suggestions from your vet you should be able to find one that will work best. Then we have to slowly introduce them to that feed and monitor changes while on it – how is their stool, how is their coat, energy, are any health issues better or worse on this feed? Also very important is -how is their body condition on this feed? Overweight/underweight we need to make adjustments. This may take 2-4 months of being on the feed before we can properly assess these things. If one feed doesn’t have everything you are looking for you can add the minerals, or fat separately rather than looking for a feed that does it all!

Equine nutrition is a complex and evolving field that requires careful attention to ensure the health and wellbeing of horses. By understanding the fundamental principles of equine nutrition, horse owners, trainers, and caregivers can make informed decisions about their horses’ diets. A balanced diet, consisting of high-quality forage, appropriate concentrates, and tailored adjustments based on individual needs, is essential for maintaining healthy horses throughout their lives. With proper nutrition as the cornerstone, we can unlock the full potential of these magnificent creatures, ensuring their vitality, performance, and longevity for years to come.

International Petfood - July 2023 | 23 F

Minebea intec

Minebea Intec is a leading manufacturer of industrial weighing and inspection technologies. Their mission is to increase the reliability, safety and efficiency of our customers’ production processes and they provide high-quality products, solutions and services that ensure a high level of safety.

Minebea Intec’s excellent performance is based on 150 years of experience, distinct German Quality and continuous investments in the development of innovative technologies. Their strong global presence and an extensive network of distribution partners ensure that our customers can rely on top Minebea Intec quality – any time, anywhere. Their goal is to set strong standards in all areas of the company, which is reflected in the brand slogan, ‘the true measure’.

By purchasing Minebea Intec products, customers all over the world are choosing more than just innovative technologies: they are also choosing top-quality service performance and comprehensive support throughout the entire life cycle of their product. The company’s aim is to fulfil customers’ requirements no matter what the industry, and to be the first port of call for weighing and inspection technologies.

In Petfood

Ensuring products are safe and contamination-free has always been the most important premise for the petfood industry. However, new trends in petfood production are forcing manufacturers to be flexible whilst complying with regulations and sustaining supply. With its broad product portfolio of weighing and inspection solutions, Minebea Intec offers manufacturers the right solution for future-proofing their business.

Metal detectors, Vision systems, X-ray inspection equipment as well as software are used at

several points in petfood production to exclude contamination by foreign bodies made of metal, stones, plastic or other materials. This starts even before processing, where the basic ingredients are examined for possible contamination. During later processing steps, such as mixing the ingredients, product contamination can be caused by rubbing from containers or machines and finally, packaging is also checked by inspection solutions. Dynamic Checkweighers such as Flexus® and Synus® are equipped with electromagnetic force compensated load cells for most accurate weighing which in turn can also automatically adjust fill levels to reduce give-away.

Minebea strongly invest in developing Leading Technologies and new products. To ensure that these investments truly support our customers in optimising the safety, reliability and efficiency of their processes, we encourage and facilitate a company culture of systematic and sustainable creativity and innovation.

At the basis of this culture is our attitude of putting customers at the center of our thinking and acting. Through methods such as Customer Process Monitoring, they obtain a clear understanding of their current and future needs. The process of finding innovative solutions for fulfilling these needs, includes both technical research as well as applying structured creativity. In many phases of this process, Minebea involve internal and external specialists from a variety of disciplines, partners and customers.

The company’s well established Quality Management System provides us with the necessary procedures and tools for effectively managing our innovation process and ensuring that they fulfill the requirements regarding time-to-market and returnon-investment.

24 | July 2023 - International Petfood Industry PROFILE

Pellet Durability Tester

*Place your order for an NHP100 Portable Pellet Durability Tester between 1st June and August 31st 2023, and receive the optional Digital Scales Absolutely FREE!^ ^Visit for full details of this offer. www.tekpro.com/specialoffers

––

NHP100

International Petfood - July 2023 | 25

Industry Training

IFF: Essentials of Feed compounding

technologies

The IFF are running their ‘Essentials of feed compounding technologies’ course this year, 5-7 September (10am to 3pm). The course will take place at IFF’s Research Institute of Feed Technology in Braunschweig, Germany.

Topics

The feed sector plays a key role within the animal sectors, for both animal husbandry and pets. Health, safe and high-quality feed is essential for healthy animals and the production of tasty and safe animal products such as milk, eggs, and meat. The quality of feed is partly safeguarded by good knowledge concerning the whole production process: What is the effect of refining processes on the quality of feed? Process technology is the central topic during this training course where participants will gain insight into the production process of feed manufacturers. Furthermore, attention will be paid to the use of various resources, quality control, energy management and safety assessment.

Target Group

This course is intended for advisors, technical staff and other interested personal working in the feed industry. It is also recommended to employees of the supplying industry, nutritionists, and policy makers.

Content

• Basic processes in compound feed production: storage, conveying, dosing, milling, grinding, mixing, steam generation and conditioning, Hygienisation, pelleting, cooling, expanding. Extrusion, vacuum coating, sample taking, material properties.

• Lab testing: milling, mixing, pelleting, and pellet quality.

• Operating feed mills: compound feed quality, HACCP, and energy management.

Registration

Register by 5 August 2023 at https://www.iff-braunschweig. de/wp-content/uploads/2023/04/Registration-form.pdf

The lectures will be given in English language. Imparted knowledge will be deepened in practical experiments in our technical lab.

Fees

For a first participant of a company, the fees are €1090 (IFF members), or €1450 (non-members). For the further participants of the same company the admission fee is €990 (IFF members) and €1350 (non-IFF members).

TRAINING

26 | July 2023 - International Petfood

Troubleshooting

Shaping of the final product involves the entire team - formulator, mixing and grinding to spec, extrusion and the downstream equipment. Starting with the formulation, it can be simple or very complex. In either case the device that sets the shape is the die and knife combination which is at the end of the extruder. This is where in most cases the extrudate is under pressure so as to create expansion which is caused by the water under pressure in the product transforming into steam upon exiting the die. Controlling this gives the desired shape. For a one shape product like a round kibble the die would consist of a set of evenly spaced holes of all the same design. If the flow and pressure profile is even to each and every hole in the die then the pellets will be equal in size. Gets a bit more complex when you go for multiple shapes with the same colour, the holes need to be designed with the same flow characteristics and specially the same open area. Some shapes yield a product with holes in them. This is accomplished with placing a pin or shape which fills the area inside the main hole restricting product flow to around the pin. Not complex enough, how about the pin is really an injection needle where another extrudate material can be pumped in at a rate matching the extrudate flow filling the hole. Now do it in multiple holes all at the same time to justify the system by making a decent rate for the product value.

Reviewing the die holes themselves, generally there are 2 areas noticed. The taper leading into the hole from the extruder, if any, and the actual straight part of the hole in length, called the land length. In general, a short land length with a tapered inlet yields radial expansion at a rate of 1.25 percent increase in size. I puffed up version of the die hole in all directions. The expansion rate can be controlled by various methods, more back pressure in the barrel more expansion. More holes in the die or cut the rate and expansion lowers, increase moisture or actual extruder control can vary the density or expansion of the kibble. If a longer land length is used then the expansion is more axial or more of a straight edged product like a tin can. The backside of the die can also be modified by design to increase the flow in an area of the product for example to create a wavy bacon like product.

Die designs exist where multiple colour and multiple shape product can all be made at the same time. The art of flow control with injection ports and mixing chambers where this can happen consistently. Another advanced design would be using 2 extruders at one time to make a product by use of advanced dies combining the two extruders flow into one final die. In many of the above cases reviewed special cutting devices needed to be developed to finish the shaping process. Downstream cutting is required for some shapes using rotary guillotine type designs. Some recent developments in thermal cooking extrusion are allowing rotary injection moulding of products due to the elevated allowable moisture levels during this extrusion process.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The Extruder Barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the Extruder Barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - July 2023 | 27

Innovations this month July 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

Feeder valve and micro dosing system by Dinnissen

Dinnissen’s Feeder Valve can be used in many applications, as it can process a wide range of quantities. The Feeder Valve is a butterfly valve, powered by a single drive unit. Thanks to its compact installation height, this feeder valve can easily be incorporated into a new or existing setup. The compact design and simple construction minimise product residue being left behind, allowing quick and easy cleaning of the installation. A feeder valve is always connected to a weighing system. The weight decrease or increase shows how much product is passing through the feeder valve at what speed meaning that you can determine how it should be adjusted.

The equipment has very high accuracy down to the gram and is suitable for both batch and continuous weighing systems for whatever you may require. Along with this the equipment is energy efficient and boasts short dosing times to keep things moving at a good pace.

www.dinnissen.com

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY23 CeF i ® pro –

| free

nucleotides | promotes intestinal integrity | stimulates metabolism | enhances palatability Visit our website: leibergmbh.de Leiber GmbH | Hafenstraße 24 | 49565 Bramsche Germany | info@leibergmbh.de Best in bioavailability! 210223_International Petfood_90 mm x 270 mm.indd 1 21.02.23 08:41 28 | July 2023 - International Petfood

Autolysed yeast!

amino acids &

FOCUS

Continuous Coaters by Ottevanger

The Ottevanger Continuous Coaters are perfectly suitable for adding and mixing liquids, evenly on pellets and/or extrudates. By dosing the liquids through a spray box, the product and liquids are slowly mixed together. The trough of the coater itself is executed in stainless or mild steel, with 50 mm thick insulated jacket. The heat tracing stimulates the absorption of the liquid and avoids contamination of the trough. The coater is equipped with hinged inspection hatches over the full length of the mixing trough, which allows easy access. Apart from oil and/or fat, also vitamins, enzymes etcetera can be added in small quantities. Dosing systems for these products are available upon request.

It has numerous features including Low power consumption, large doors enabling easy inspection/ cleaning, rigid construction and variable heating system with insulated jacket and also has a low rate of wear.

www.ottevanger.com

Hot Start Steam mixer by Van Aarsen

The Hot Start Steam Mixer helps to optimise the feed conditioning process and feed safety while minimising spoilage.

With the Hot Start Steam Mixer a guaranteed and accurate heat treatment is ensured. All the product exiting the hot-start steam mixer has reached the set temperature within ± 3°C tolerance. The Van Aarsen hot start steam mixer comes with a uniquely short start-up time.

Some of the ingredients in feed pellets are also suitable as ingredients for food for human consumption. Therefore also from a sustainable perspective it has become ever more important to make sure spoilage of raw materials is minimised.

The hot start steam mixer helps feed millers to ensure the desired feed quality while maximising capacity as a result of the uniquely short batch start-up time, thus keeping feed costs low.

www.aarsen.com

VisioPointer by Minebea

This equipment reliably automates inspection processes in food packaging lines using lead vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime and optimise the production. As a plug and play vision solution, the equipment makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

It handles an unlimited number of product variations, automated, compact end-of-line inspection along with an integrated operator panel with a touch screen built into the system which works using an intuitive interface ensuring the operation is always as efficient as possible. The VisioPointer also comes equipped with cloud-enabled Production intelligence, ERP connectivity and Central Product Management to ensure the product can be as much assistance to you as possible.

www.minebea-intec.com

Vertica by Bühler

One of Vertica’s major advantages is that it doesn’t require independent aspiration - the integrated air circulation in the feeder is all that is needed, keeping capital investment and operating costs low. Along with this the vertical hammer mill can reduce energy consumption by as much as 25 percent in comparison to horizontal hammer mills. The equipment’s small size means that it can easily fit into an existing space or can be planned to fit into a new plant without trouble.

The east access to the rotor, hammers and screens means that you can ensure that the machine is always well sanitised and any maintenance is easily performed. The two handed safety mechanism the Vertica is equipped with ensures that it cannot be operated improperly protecting both the machine and worker.

www.buhlergroup.com

SEE YOUR PRODUCTS IN THIS MAGAZINE If you produce a product that you think we should feature in International Petfood magazine, please get in touch To be considered for inclusion in the magazine please; Email: editorial@perendale.co.uk Include 75 words about the product along with a high resolution image and a web link to more information about the product in your email

International Petfood - July 2023 | 29

Industry Events

2023 July

6-8

VIV Turkey

Instanbul, Turkiye www.vivturkey.com

2023 August

4-5

Pet Trade Fair

Dehli, India www.iiptf.in

16-18

Pet South America

Sao Paulo, Brazil

www.petsa.com

16-18

Superzoo

Las Vegas, USA www.superzoo.org

2023 September

6-8

VIV Nanjing

Nanjing, China www.vivchina.nl

13-14