www.internationalpetfood.com www.perendale.com New coursesPetfood at The Online Milling School See more on page 26 International PetFoodVolume 5Issue 8September 2023 Environmental transparency - Meeting Growing Demand for Plant Based & Hybrid Pet Foods - Scientific discovery unlocks new aspects of pet health - The Game-Changer September 2023 Up-coming International PETFOOD conferencesfind out more on page 36 Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 01242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons

Tel: +44 (0)1242 267706 shannonp@perendale.co.uk

Niamh Cassidy

Tel: +44 (0)1242 267704 niamhc@perendale.co.uk

Community Manager

David Harvey Tel: + 44(0)1242 267700 davidh@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 (0)1242303792

darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 364 64 57

mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor Tel: +44 (0)1242303791

jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 (0)1242 267700

cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 (0)1242 303790

tutit@perendale.co.uk

Development Manager

Antoine Tanguy

Tel: +33 6 78 57 76 45 antoinet@perendale.co.uk

September 2023 10 Industry News COLUMNS

6 Roger Gilbert 7 Joseph P Kearns 8 Professor Simon Davies

International Petfood - Volume 5 - Issue 8 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 26 Training 25 Troubleshooting 28 Production focus 9 The PetFood Journal REGULAR ITEMS 24 Industry Profiles 30 Industry Events 29 The Market Place 40 The Interview 42 Industry Faces

FEATURES

14 Environmental transparency

16 Meeting growing demand for plant based & hybrid pet foods

18 Scientific discovery unlocks new aspects of pet health

22 The game-changer

What’s trending in the pet sector that’s currently impacting petfoods you ask?

That’s a good question and one that our magazine should be answering for its readership.

However, with all the focus these days on social media and its wealth of both quality and questionable information, it’s not easy to find the information we are searching for and can place our trust in.

Roger Gilbert Publisher – International Petfood

Therefore, it is certainly worth seeking out and ‘following’ companies and information providers that have solid reputations for trustworthiness and transparency.

But the workings of the internet constantly re-expose us to ‘stories’ and ‘video/sound bites’ that match our profiles from a potential sales point-of-view. The profiles we have developed over time, through our use of the internet, pre-determine what we receive.

We are being tracked and our actions are being analysed so that we receive posts and information that are most likely to interest us and respond to regardless of its value to us.

Often times each item we find serves up attempts to engage us commercially.

Therefore, finding information that suits our purpose - without being side-tracked into something else - is proving more and more difficult.

That’s where magazines come into play. And here I’m taking petfood as an example.

We gather in news and information from ‘trusted’ sources and present reports that focus on the technology involved, be that mechanical or nutritional, so that you the reader has confidence in our independent selection.

But getting back to the question above - the five top trends in pet branding that are impacting petfood marketing (and which relate to the USA market in this instance), include: price increases; a corresponding reduction in product choices; the humanisation of pets; omni-channel shopping and finally the increase in pet ownership.

The impact of Covid and the resulting disruption caused, plus the increase in energy and raw material prices globally (and I include the cost of enzymes and vitamins and other key additives specifically), along with transportation and shipping

Our last edition

Did you miss our July 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

What you may have missed…

The Interview

Myriam Chang - CFO, Nutrition Technologies, Malaysia

She joined the company in 2023 with over 20 years

costs, have all contributed to the current market situation where the cost and choice of petfood found in your local supermarket or pet stores are challenging compared to those in the run-up to 2020.

Each of these five trends needs further explanation of course, and which we will provide in our next edition, but for now be careful out there when seeking information to base your decisions on. Treat the internet with respect and suspicion and ‘follow’ those companies and individuals who have proven track records for quality, trustworthiness and transparency.

In this edition

While cats and dogs dominate the petfood industries, our task is to also cover the nutritional and food manufacturing options for other pets. In this edition we kick off with Professor Simon Davies looking at the Tortoise and its nutritional needs in his editorial on the next spread; a news story referring to rabbits on page 12.

Dr Maygane Ronsman of the Beneo company in Germany addresses the growing demand for plant-based and hybrid petfoods on page 16 while ADM’s Ramona Cernat and Gustavo Zenaide ‘unlock’ scientific discoveries for pet health on page 18. Biocraft Pet Nutrition’s CEO Shannon Falconer from Austria takes a deep dive into the ‘Cultured Meat for Pet Food’ option coming available and identifies this technology as a ‘game-changer’ for our industry.

All these features are informative and unique to us. Their value is founded on the reputations of the companies involved and the individuals writing for us. We are privileged to have them in this edition.

Don’t overlook all the other good content in this edition and remember there is a Petfood Manufacturing Course taking place – and it’s not too late to join - which delves into the intricacies of petfood production. Don’t worry about joining late as there is an option at the end of the course to catch up on those sessions missed. See inside here for details.

Happy reading!

of experience in Finance in New York, London and Singapore, with senior roles as an investment professional in debt and equity. Myriam started her career at Credit Suisse New York and spent thirteen years at CS’s New York and London offices mainly as senior Trader in the Global Financing Group and as a fund portfolio manager focusing on emerging markets. Prior to joining NT, Myriam was Managing Director of Mandala Impact Capital, a private equity fund focused on the ag and food sectors in India and Southeast Asia, serving as board director for several of the fund’s portfolio companies.

To read more, go to: https://flickread.com/edition/html/64d49c304b824#41

THE PUBLISHER

This issue has a number of articles of interest. Cultured meat for petfood, pre and pro biotic and other additive research and plant use in petfood.

Cultured Meat for Petfood was most interesting as my view initially was it extrudable? How to handle, and other aspects associated with production. The article addresses all concerns up to this point, easily handled, nicely ground consistent in moisture and fat with availability seeming to be the only concern. As noted, no doubt it is a possible game changer to watch as costs goes down and availability goes up.

Joseph P Kearns Editor, International Petfood Magazine

and many more. Newer style advanced twin screw extruders cook more with thermal over frictional cooking styles greatly increasing these possibilities. Newer plant designs and production style modifications odours are greatly reduced over historic designs with huge volumes of steam and air being exhausted. It was always said if you did not smell the pet or aquatic feed mill, then they were not making the feed correctly! There are systems available from simple bioreactors to advanced chemical air scrubbers.

It is amazing how and what is being done to create and market an additive such as prebiotics, probiotics as well as postbiotics. Some of which are sturdy enough for extrusion parameters and handle conditions globally in ever increasing climatic temperatures.

Plant ingredient sources has always been a big part of petfood production, historically wheat mids, corn and soybean meal were near 75 percent of most formula. Obviously, this has changed greatly and now research shows the possibility ranges never expected. From a processing point of view all of these ingredients mostly likely will be fine but in some combination’s situations might arise. Having been involved for so many years older designs with older preconditioners and high shear, the go for the cook barrel designs may hinder hitting the proverbial product specifications. New and advanced extruded designs with all kinds of possible attachments allowing for an increasing range of operational conditions. Twin screws, dual conditioners of many designs and operational ranges, flow restrictors and die designs including rotary moulders are yielding new and attractive products. Making them from ingredients the customers are looking for is a new opportunity and extends the advancements again in this industry.

A few topics to discuss as suggested, twin screw extruders, special textures, odour control of a petfood plant and kibble moistures. Twin screw extruders as noted above are more flexible in operations ranges thus ingredient selections. For example, emulsified meat slurries, typically the amount injected is based on the ability of the extruder to handle the moisture. When going for a maximum inclusion added water is reduced and replaced with the moisture from the meat, normally in the 65 percent M range. Defining this and reviewing differential diameter cylinders and petfood production the typical max amount in a single screw was around 25 percent and 30 percent in a traditional twin screw. At the time this was the answer for the industries desire to increase meat and fat levels in petfood. The trend continues with advanced extruder designs allowing for a lot of meat inclusion. The volume is so high the formula is now expressed in the percentage of dry versus the level of meat inclusion. For example, 200 percent of the dry flow rate or 1000 kg of dry combined with 2,000 kg of meat slurry. This yields a whole new area of possibilities including higher moisture ingredients like liquified vegetables, insect slurries

Texture and kibble moistures are specifications or a product characteristic individually. Textures can be modified in several ways from formulation, hardware and operational conditions, or all three. Formulation with increased starch levels can be expanded more, inject a bit of oil and meat and the expansion is retarded due to slippage or reduced frictional development. Every extruder would have a range but as more water, oil, other liquid ingredients are added then densities get heavier. Hardware can change in terms of a more or less restrictive die which greatly effects the texture. Operationally speaking simply modifying the steam and water injected will cause a range of textural changes and it is more obvious when no oils of meats are injected. Generally, more water, the tougher the texture is and less water, the softer.

Moisture in the kibble is an important topic as profits are involved. Moisture is usually lower than incoming ingredients and needs to be accounted for. However, it can be controlled with the right approach. First, is your system giving the extruder a constant and even flow of fluids?

This directly effects the moisture out of the extruder, if this is not even, then naturally the dryer can’t dry evenly as the moisture in is in flux. Assuming the extrudate is even to the dryer, the dryer is under observation and analysis. Actually, this is simply how the industry advanced years ago, extrusion became more accurate thus dryer pressure improved their designs to current standards. Plus, or minus 0.5 percent is considered to be about as good as it gets today, great improvements over the usual +/- 3.0 percent. This control allows for processing control to meet the needs of petfood production in different areas of the world at different times of the year. Even drying is a result of fixing the design so as each and every kibble seeing an even temperature and air flow over a set time period. Keep records and or computer control and instruments can handle this automatically or adjustments need to be made manually to greatly decrease spoilage from incurred moistures and resulting water activity. Keep in mind water is your lowest cost ingredient and if you don’t over dry then you also don’t use excess energy.

Now you have exited the dryer and management of the product from here through the rest of the process, including packaging can have an effect on what goes in the bag and how long it lasts. What is in the bag besides the product, your last atmospheric conditions in the packaging room.

THE EDITOR

International Petfood - September 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

Tortoise nutrition: Feeding and caring for what’s under the shell

Other than the goldfish, the most common pet for children was the humble tortoise and I had one called Fred as a child. Now and quite rightly too, legislation has prohibited us in the UK from owning this most beautiful, advanced reptile and they are few and far to be seen these days gracing fenced off pens in our municipal and country gardens. However due to their very impressive longevity, there will be some remaining and in many parts of the world significant numbers will be kept in captivity and especially in our zoos and educational wildlife centres. With this in mind, I focus on aspects of tortoise nutrition and their health.

Diets of tortoises in the wild often contain >15 percent protein (dry-matter basis) in plant materials consumed, as natural vegetative based foods are usually high in protein especially in the pre-seed, young fresh stage, although some of that protein is often quite indigestible when older. Although small tortoises consuming pelleted diets can use plant fibre effectively, they should be fed more frequently than larger animals due to a comparably higher metabolic rate. Small and larger tortoises can also be maintained on appropriately formulated, extruded, pelleted, or coarsely ground bespoke tortoise diets. These are available from specialised commercial companies and suppliers.

Understanding the Natural Diet

Tortoises are herbivores and primarily consume plant material in their natural habitat. Their diet typically consists of grasses, leafy greens, fruits, and some succulents. Different species have evolved to thrive on various types of vegetation, so it’s essential to research the specific dietary preferences of your tortoise’s species.

High-Fiber Diet: A vital component of a tortoise’s diet is high-fibre foods. Grasses and leafy greens provide the necessary roughage to support healthy digestion. Fiber helps prevent digestive issues and keeps their digestive tracts functioning optimally. Leafy Greens and Vegetables: Dark leafy greens, such as dandelion greens, collard greens, and mustard greens, are excellent choices for tortoises. Other vegetables like carrots and squash can be offered in moderation. These foods provide essential natural sources of bioavailable vitamins and minerals.

Limited Fruits: Fruits can be given as treats but should be provided in moderation due to their higher sugar content. Safe fruit options include apples, berries, and melons.

Calcium and Phosphorus Balance: A proper calcium to

phosphorus ratio is essential for tortoises. An imbalanced ratio can lead to nutritional disorders like metabolic bone disease (MBD), which can be quite serious. To ensure the right balance, provide foods high in calcium, such as calcium-rich leafy greens and cuttlebone, while avoiding excessive phosphorus sources like high-phosphorus vegetables and commercial tortoise treats. Certain foods are toxic to tortoises and should be strictly avoided. Some examples include avocados, rhubarb, and anything treated with pesticides or herbicides.

Feed Supplements and Formulated Pelleted Diets: While a varied natural diet is ideal, some formulated pelleted diets can be used as a supplement or balancer ration. These commercial diets are designed to provide essential nutrients (water- and fat-soluble vitamins, macro-minerals such as Ca P and Mg, as well as trace elements like iron, zinc, copper, manganese, and selenium) that may be lacking in a tortoise’s regular diet. Always choose highquality products from reputable manufacturers.

Nutritional Diseases: As mentioned earlier, Metabolic Bone Disease (MBD) is one of the most common nutritional diseases in tortoises. MBD results from an improper calcium to phosphorus ratio, lack of exposure to UVB light, or insufficient dietary calcium. It leads to weak and deformed bones, shell abnormalities, and overall poor health. Exposure to natural sunlight is essential for tortoises, as it allows them to synthesise vitamin D3, cholecalciferol which aids in calcium absorption. If your tortoise is kept indoors, consider providing full-spectrum UVB lighting to simulate natural ambient sunlight conditions.

Young animals should be weighed regularly and should follow the growing curve to prevent too-slow or too-fast growth, which can cause permanent malformation of the carapace. Shell malformations in tortoises have been thought to result from too rapid growth rates associated with the intake of high-protein diets. Humidity and temperature also may play a role regarding shell deformation. To prevent MBD and other nutritional disorders, it is crucial to provide a balanced diet rich in calcium and vitamin D3, along with access to natural sunlight or UVB lighting. Another aspect to consider is that tortoises hibernate overwinter, and the diet must be carefully given when they become active again in the spring.

Always consult with a qualified reptile veterinarian or herpetologist for personalised advice on feeding and caring for your specific tortoise species, as individual needs may vary. It would also be wise to contact local zoos for specialist advice on housing, feeding and nutrition.

8 | September 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - September 2023 | 9

Kemin Nutrisurance opens first pilot lab for wet pet food

Kemin Industries recently introduced the Research and Exploration Services of Kemin Nutrisurance, the company’s pet food and rendering technologies business unit, with the inauguration of Kemin’s first-ever wet pet food pilot lab at its global headquarters in Des Moines, Iowa, US.

The wet food pilot lab is a key feature of Kemin Nutrisurance’s leading approach to research, development and service, allowing the business unit and its customers to create, test and validate pet food and treats, including kibble and wet retort products, to help better predict large-scale results.

The state-of-the-art facility has more production capacity and testing capabilities than most researchand-development (R&D) labs, but with the flexibility of a smaller scale. Kemin Nutrisurance can now expand its innovative product lines and partner with customers to help test every aspect of their products with data validation.

A ribbon cutting was held on July 20 to officially open the new wet pet food pilot lab. The event showcased how Kemin Nutrisurance’s Research and Exploration Services will enhance co-creation with customers and assist in replicating pet food formulas for both new and established products. With a dedicated space to develop wet pet food, as well as test dry kibble coating, Kemin Nutrisurance can now provide customers with all-encompassing analyses, from raw meat products to packaging to pet satisfaction.

“Our value-added Research and Exploration Services allow customers to speed up product creation and testing,” said Dr Jason Shelton, Vice President of R&D, Kemin Nutrisurance. “The accuracy and start-to-finish approach of Kemin’s testing provides third-party validation of pet food, giving customers assurance that they are meeting regulatory standards and consumer expectations.”

Kemin Nutrisurance’s Research and Exploration Services support customers at every stage of production by utilising industry-leading tools and rigorous evaluation to ensure customers’ pet food meet their flavour, aroma, texture, and nutrition requirements. By partnering with Kemin Nutrisurance early in product development, customers can improve solution application and reduce implementation and uptake time at their facilities, assuring confidence on a larger scale.

“With Research and Exploration Services, we are able to elevate our own R&D efforts, building on Kemin’s legacy of market-leading solutions and helping customers test, create and validate pet food products with unmatched accuracy and efficiency,” said Dr Shelton. “Now, with our expanded customer-service offerings, Kemin Nutrisurance delivers the industry’s most comprehensive approach to R&D.”

Kemin Nutrisurance’s Research and Explorations Services expand beyond the US with pilot labs and innovation centres in Brazil, Italy, and China.

Made in Britain, Trusted Worldwide. We are

Holmen

Inline,

OLM N H ®

Portable,

We can help you improve your pellet durability testing...

Holmen

NHP200 Series 2 Laboratory based, automatic pellet tester.

NHP300

process based system.

Holmen NHP100

manual pellet tester.

Native Pet announces US$11 million in Series B funding

The pet supplement company’s mission has been bolstered considerably with the funding led by Cavu Consumer Partners.

Since launching in 2017, Native Pet, a leading clean label ingredient pet supplement company, has been committed to helping four-legged friends live happier, healthier lives. That mission has been bolstered considerably with the closing of US$11 million in Series B funding led by Cavu Consumer Partners. It’s the latest milestone in Native Pet’s rapid growth as the leader in the fast-evolving pet supplement category.

“As of 2023, 50 percent of US households have a dog and that number continues to rapidly grow. At the same time, Dog Parents are waking up to the limitations of a kibble only diet,” said Dan Schafer, CEO and co-founder of Native Pet. “Consumer feeding habits are evolving. More than ever, the consumer is adding supplements to their dog’s bowl to customise their diet and use it as an opportunity to drive health outcomes.”

Native Pet is bringing a refreshing mindset to the pet supplements category. Their approach to product development bridges the gap between nutraceutical supplements and the popular demand for clean label, functional nutrition solutions for dogs. Consumers are more regularly reaching for products that utilise whole food ingredients that they recognise and trust. Native Pet has revolved their product R&D around the use of these functional whole foods as active ingredients (such as pumpkin, bone broth, and real chicken protein) that are research-backed for improving the health and wellness of our pets. This innovative approach has led to category-leading efficacy, while also delivering tasty products that dogs love. Conscious pet parents also love that Native Pet’s supplements are formulated alongside Board Certified Vet Nutritionists, PHDa food scientists, and of course – a large number of doggy taste testers that really put the products to the test. The team is driven by their ‘Native Pet Pact’ which encapsulates the company’s commitment to making the highest-quality products in pet nutrition.

“The next evolution in the ‘humanisation of pets’ is pets’ is pet wellness. Today’s pet parents are increasingly looking beyond the bowl to improve their pet’s health and well-being,” said Jared Jacobs, partner at Cavu Consumer Partners and Native Pet Board Member. With this funding, Native Pet will accelerate its continued growth through category innovations and retail expansion. Native Pet’s strategy remains simple: invent functional products that add targeted nutrition to our pets’ daily routine with effective results, clean ingredients and truly great taste.

Natural Balance wins Dog Wet Food Product of the Year

Natural Balance Pet Foods Inc, the premium pet specialty food brand, won a 2023 Pet Independent Innovation Award for its new Limited Ingredient Stews for Dogs. These hearty stews, which hit shelves earlier this summer, won the award for Dog Wet Food Product of the Year.

The Limited Ingredient Stews for Dogs feature single animal protein from chicken, beef or duck cooked in broth with a bounty of vegetables. Convenient, easy-open cartons make every day feeding easy – simply tear open, stir, and serve as a complete meal or pour over one of the Natural Balance Limited Ingredient Kibbles for a tasty feast. Stews are available in three flavours including Chicken Stew with carrots and green peas, Beef Stew with potatoes and pumpkin, and Reserve Duck Stew with carrots and potatoes.

“We are thrilled our Stews for Dogs were selected from over 2000 submissions as Pet Innovation Awards’ Dog Wet Food Product of the Year,” said Michael Lopes, director of product development. “Natural Balance knows the importance of our Limited Ingredient recipes for pets with food sensitivities, and we are proud to have won this award for our newest Limited Ingredient product.”

Natural Balance is a pioneer in the Limited Ingredient food category. Limited Ingredient recipes offer a complete and balanced diet with premium, single-source animal proteins with no added fillers, artificial colours, or flavours.

The Natural Balance Customer Care team of Registered Veterinary Technicians is available to pet parents for meaningful conversations to help find the best Natural Balance recipe for your pet. Natural Balance pairs proven ingredients and rigorous safety testing to make food pets love and pet parents’ trust. The Natural Balance Feed with Confidence program, which tests every batch of Natural Balance food for quality and safety, helps ensure pet owners feel confident in what they are feeding to their pets.

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

International Petfood - September 2023 | 11 N

RawTernative goes plastic neutral

RawTernative, the Air-Dried Food made by and for independent pet retailers now certified Plastic Neutral. The company is partnering with rePurpose Global – the world’s leading Plastic Action Platform –to fund the recovery of as much nature-bound plastic waste as it uses across its product packaging. This action on plastic waste is part of their wider SustaPak sustainability strategy.

Through this partnership, RawTernative is enabling the removal of at least 7500Ibs of plastic waste each year that would otherwise be ocean-bound and end up polluting the natural environment.

As a prominent player in the pet food sector, RawTernative recognises the serious threat that plastic pollution poses to the future of our planet. Certifying their products Plastic Neutral forms part of their Susta-Pak strategy, which includes the Grandma Mae’s country Naturals partnership with Clearloop-supporting the development of solar energy projects to reclaim the carbon emitted by transporting Grandma Mae’s products. This program will expand to include RawTernative beginning in 2024.

RawTernative is supporting rePurpose Global’s impact project Saaf Samudra in Goa, India and in doing so is not only tackling the plastic waste crisis, but also supporting waste workers’ incomes by attaching value to hard-torecycle plastics, and providing safe, stable, and fairlypaid employment opportunities through local waste management enterprises.

RawTernative is supporting rePurpose Global’s impact project Saaf Samudra in Goa, India and in doing so is not only tackling the plastic waste crisis, but also supporting waste workers’ incomes by attaching value to hard-torecycle plastics, and providing safe, stable and fairlypaid employment opportunities through local waste management enterprises.

RawTernative’s commitment to society can be traced back to their roots as a brand founded on the intention “Our mission has always been to put pets and their pet parents first and so it only made sense to extend this level of care to the environment said

Nathalie Berman, assistant

“Environmental protection is at the core of RawTernative. It is heartening to see them push the boundaries on tackling the plastic waste problem. We hope their commitment encourages more brands to take responsibility for the plastic that they Said

Natural Balance and Canidae join forces under Ethos Pet Brands

Ethos Pet Brands, the new parent company created by the merger of industry-leading brands Nature Balance Pet Foods Inc and Canidae Pet Food Company, was unveiled. The combination will leverage both companies’ shared passion for improving the well-being and lives of pets through simple nutrition, responsibly sourced ingredients and protein-rich products.

‘Ethos,’ the original and long-standing name of Canidae’s manufacturing facility in Brownwood, Texas. reflects both companies’ character, honesty and integrity while representing their commitment to providing high-quality nutrition and premium ingredients.

Natural Balance, known for its Limited Ingredient recipes and Original Ultra product

12 | September 2023 N C M Y CM MY CY CMY K

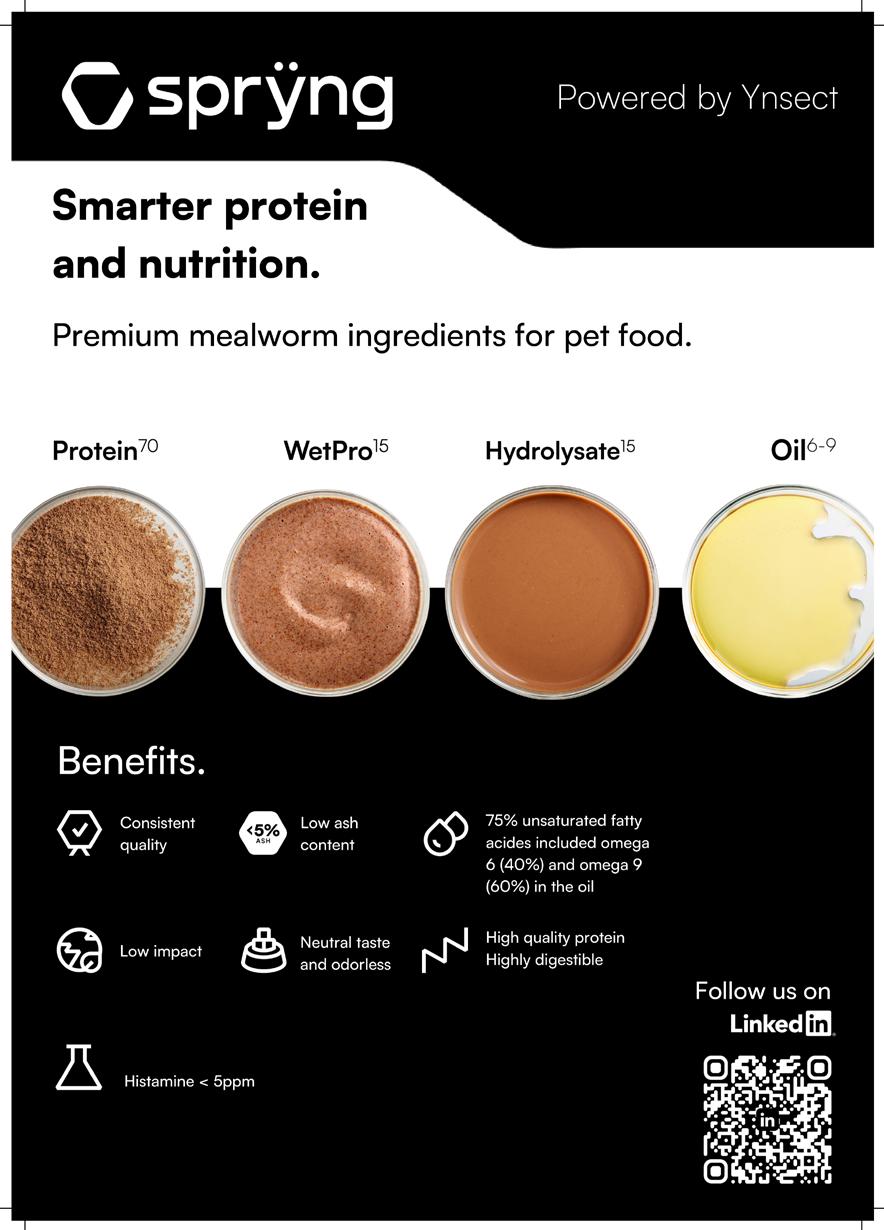

A life cycle analysis of sprÿng’s product line

n the context of the global environmental condition, it is the responsibility of any company to examine the environmental impact of their products and services. At Sprÿng, the pet food arm of Ÿnsect, we have performed a life cycle analysis (LCA)for our range of pet food ingredients. Here, we share the methodology, and what it shows us about our current performance as well as directions for future product development.

Environmental transparency I

An LCA is a systematic analysis of potential environmental impacts of products during their entire life cycle. All stages of product development are implicated, and the ‘potential impacts’ cover both inputs (such as use of water, land and fossil and non-fossil resources) and outputs (emissions into air, water and soil, including GHG emissions, pollutants, pesticides and plastics). An LCA is often referred to as a ‘cradle to grave’ analysis; or, in the case of B to B brands such as Sprÿng, a ‘cradle to farm gate’ analysis: our products are not an end in themselves but an input to the pet food manufacturing process, and as such the LCA of our ingredients will be used by those pet food manufacturers to calculate the LCA of their products.

Guidelines for carrying out an LCA are outlined in ISO standard 14044:2006; however, practitioners have the flexibility to interpret the guidelines as they deem most appropriate for their study. A more structured framework for the guidelines is currently being piloted: called PEF (Product Environmental Footprint), its aim is to improve comparability of results, particularly between similar products. Although not mandatory, we, at Sprÿng, have carried out the LCA of our products in adherence to this particular PEF framework. We have

also had our analyses peer-reviewed by an external company, which has verified our methodology and calculations.

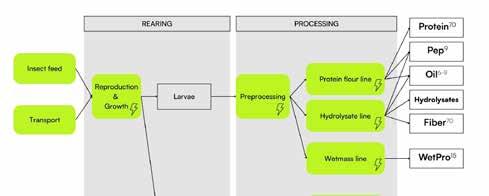

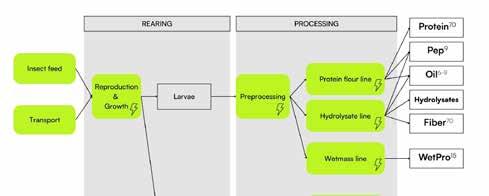

Breakdown of the LCA methodology

The production process for Sprÿng products is illustrated in Figure 1, which is based on our vertical mealworm farm at Amiens, France. The first stage is rearing the mealworms: our LCA must account for not only everything that occurs during this stage —principally consumption of electricity and gas —but also everything that occurs upstream of this stage. This means accounting for the environmental history of each ingredient (mostly agricultural by products) of our feedstock up to the point at which it left it’s supplier’s gate. For this information, we require access to an LCA for each ingredient: in some cases, this may be provided by the supplier directly; otherwise, we draw the information from recognised data bases dedicated to compiling such data. For feedstock ingredients, we use the French database Agribalyse, which is a comprehensive and respected public database of environmental indicators for food products, and contains specific data for our raw ingredients, sourced in France. The impacts (petrol/diesel consumption, GHG emissions etc) associated with transporting the feedstock to our farm are also accounted for, using data available in the Ecoinvent database. For each environmental impact category, we then add together the contributions from each input, based on our farm functioning at full capacity, to arrive at a total for this phase of the life cycle.

Economic allocation

At the end of the rearing phase, there are two outputs: the larvae themselves, which are both a product in their own right and also become the raw ingredients of several different protein and oil products in the Sprÿng range; and frass(excreted matter) which is our fertiliser product YnFrass. An important question at this point is: what proportion of the environmental burden associated with the rearing process should be attributed to the larvae, and what proportion to the frass? Since the larvae and frass are used in completely different ways, for different purposes, there is no relevant physical parameter by which to determine this allocation; so we use economic allocation: that is, the proportions are

Figure1: Ynsect - Elements of the LCA

14 | September 2023 - International Petfood F

by Maximilien Juoy, Impact Manager, Sprÿng powered by Ynsect, France

determined by the economic value of the final products. This method affords us consistency with other ingredients in the pet food sector, such as co-products from meat slaughtering; and it is also the method used by our feedstock suppliers.

Similar accounting then occurs for the production phase, again drawing on Ecoinvent to determine impacts of energy consumption and chemicals introduced in this stage. Products made from processing the larvae includeProtein70 (our protein meal) and Hydrolysates, both of which have associated co-products Pep9 and Oil6-9; and WetPro15 (our protein ingredient for wet pet food). Economic allocation is again employed to determine the proportion of each environmental impact that should be attributed to each of these final products. Once this has been done, our LCA is complete, and we have a measurement of each environmental impact of each of our products, to the point at which it leaves our farmgate.

Comparison to other products within the pet food market

Taking the example of our dry pet food ingredient, Protein70, our LCA has measured its GHG impact to be 3.20 kg CO2-eq per kilogram of the ingredient. As reported previously, this is considerably lower than other high-quality dry pet food ingredients, such as lamb (at 5.51 kg CO2eq) and soy protein concentrate (6.25 kg CO2-eq). Similarly, Sprÿng’s WetPro15 has a carbon footprint of only 0.80 kg CO2-eq, which is much lower than ingredients made from beef offal (14 times higher) or lamb (nearly 26 times higher).

Knowledge is power: our commitment to continual improvement

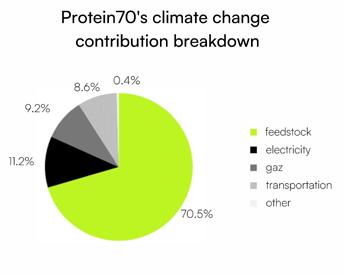

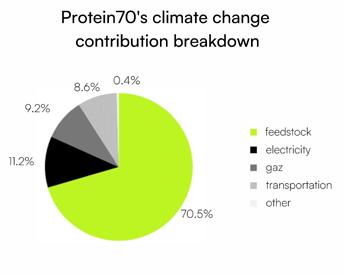

Even more importantly, the LCA also gives us clear directives for how we can continue to improve the environmental footprint of our product range. For example, if we ‘zoom in’ on ourProtein70, we can identify which part of the production process has the greatest environmental

impact: as illustrated in Figure 2, the upstream feed stock has a much greater impact than the energy used in the rearing process itself. In response to this insight, we are currently researching new feedstock recipes that use less impactful ingredients; we have launched the Terrha project (in collaboration with Noriap, a cooperative that federates 6500 farmers located near our farm) to improve the ecological footprint of these upstream agricultural activities; and we have a genetics research project investigating ways to further enhance the efficiency of our mealworm rearing.

The LCA analysis shows that Sprÿng’s product range is already performing well by environmental standards. Through an ongoing process of evaluation, reflection, innovation and re-evaluation, Sprÿng is committed to continual product refinements that minimise our environmental footprint even further.

4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25

F International Petfood - September 2023 | 15

Figure 2: Ynsect - Protein70 climate change breakdown

Meeting growing demand for plant based & hybrid pet foods

by Dr Maygane Ronsmans, Product Manager Animal Nutrition, BENEO GmbH, Germany

Figures show one in three petfood shoppers think that using plant-based ingredients make petfood seem a lot healthier. At the same time, petfood manufacturers are increasingly being faced with lower availability and price volatility, such as for meat (co)products. As a result, many producers are willing to explore new protein sources and diversify their portfolio. Here Dr Maygane Ronsmans, Product Manager Animal Nutrition at BENEO, discusses the interest in hybrid and plantbased petfood and how producers can meet changing consumer requirements with vegetal functional ingredients.

Meeting consumer needs

Around one in four pet owners globally say they like to see plant-based or vegan claims on pet products. This is mainly due to the fact that they perceive such products as healthier and better for the environment.

In addition, there is rising demand for understandable, cleaner petfood labels, with 76 percent of dog owners and 68 percent of cat owners always or usually checking the ingredients list when purchasing a new petfood product. At the same time, petfood producers are being faced with rising concerns around prices, the environmental impact of raw materials and supply chain issues. This is driving petfood producers to increasingly seek plant-based proteins, that still deliver in terms of their nutritional profile and technical properties.

As demand for plant-based, sustainable and clean label pet food gathers pace, BENEO has expanded its vegetal protein range to meet producers’ needs. Alongside its rice protein and vital wheat gluten ingredients, pet food manufacturers can also benefit from the company’s new faba bean protein concentrate.

A diverse portfolio to suit in any formulation

BENEO’s vegetal proteins are being well received by petfood producers, as they represent concentrated and non-GMO sources of high-quality. They provide excellent amino acid profiles, which can beneficially be blended and enable the development of plant-based or hybrid pet foods. They also offer high to very high digestibility. According to an internal analysis, the company’s rice protein and faba bean protein concentrate reach (ileal) digestibility scores close to 90 percent and vital wheat gluten well above 90 percent.

Besides its high protein density of approximately 80 percent, BENEO’s rice protein offers great nutritional benefits. It is hypoallergenic and highly digestible, making it suitable for pets with allergies, as well as sensitive pets such as puppies and older animals. Therefore, it is a particularly attractive solution to target the approximately six in ten cat and dog owners that are interested in allergen-free pet food. It is also a good source of several essential amino acids (methionine, cysteine, phenylalanine and tyrosine) that are involved in some major metabolic processes and support a pet’s normal and healthy growth. In addition, rice protein is a clean label ingredient which is perceived as (very) natural by 61 percent of pet owners globally.

Similar to the rice ingredient, BENEO’s vital wheat gluten also offers a high protein density of approximately 80 percent. It delivers an interesting amino acid profile, as it is rich in glutamine, which is the preferred fuel for intestinal cells that can help repair damaged cells, as well as tyrosine, which plays an important role in maintaining fur colour. Vital wheat gluten also has strong viscoelastic properties that can improve the texture of different types of pet food and offer great technological and application benefits. For example, it can positively affect the extrusion behaviour in dry pet food, as well as the chunkiness

16 | September 2023 - International Petfood F

and meat structure in wet pet food. Thanks to its excellent water absorption capacity, it also increases juiciness in semi-moist or wet pet food and is therefore a valuable alternative to spray-dried plasma.

Reaping the benefits of faba beans

Finally, BENEO’s faba bean protein concentrate, listed in the EU Catalogue of Feed Materials under entry 3.7.5 as “horse bean protein”, is a concentrated source of vegetal protein that serves as a good alternative to animal and soy proteins and is suitable for “no grain” claims in pet food. Its amino acid profile is relatively rich in lysine and can nicely complement cereals’ protein, meaning it can notably be blended with rice protein or vital wheat gluten. It also contains quite high levels of glutamine, which improves palatability and supports the growth of intestinal cells, as well as arginine, which is considered to be important for cognitive health. BENEO’s range of faba bean ingredients for petfood also includes starch-rich flour and hulls, offering a good source of starch and dietary fibre. When it comes to sustainability, faba beans help to reduce greenhouse gas emissions at farm level. The faba beans can capture nitrogen from the air, to provide it for themselves and subsequent plants, which reduces the need for fertilizer input. Also, the faba beans are grown in a region with good rainfall and soil with good water retention capacity, so that irrigation is not necessary. BENEO strives to source its faba beans at Farm Sustainability Assessment (FSA) Gold level from German farmers with longterm contracts, to ensure production and supply stability. Furthermore, the production process, being done locally in Germany, has been chosen for its low energy and water consumption in comparison to alternative processes; overall contributing to BENEO’s sustainability targets. These elements are key, considering that more than half of pet owners say they pay attention to sustainability and the carbon footprint as part of their pet food purchasing decisions.

Manufacturers looking to meet growing consumer demand for more sustainably sourced and plant-based pet foods are increasingly faced with the challenge of finding ingredients that deliver the necessary nutrients for their formulas. BENEO’s vegetal protein range offers producers sound nutritional and technological alternatives for their pet food recipes.

F International Petfood - September 2023 | 17

Scientific discovery unlocks new aspects of pet health

by Ramona Cernat, Science & Technology Director, Health & Wellness, and Gustavo Zenaide, Vice President, Pet & Animal Well-being, ADM, USA

People are taking a proactive approach to their own health and their family’s wellness – including their pets. For instance, 88 percent of U.S. pet parents say it’s important to take preventative measures to protect their pet’s health. Product claims like ‘clinically tested,’ ‘scientifically studied’ and ‘vet recommended’ are perceived by consumers as evidence of a product’s effectiveness. Additionally, 60 percent of global pet owners say branded health ingredients in pet products are important, as many perceive them to be more trustworthy.

Among consumers’ top concerns is gut health. A reported 60 percent of pet parents would like the pet products they purchase to have a digestive health benefit. Support for pets’ immune function and calming are also in high demand. Notably, each of these areas may be affected by the composition of the gut microbiome, which is believed to be one of the foundations of overall well-being.

Expanding Awareness of the Microbiome Scientific understanding of the gut, skin and oral microbiomes is continuously expanding as researchers investigate the next frontier in holistic wellness. Through strategic partnerships with research universities, entrepreneurial start-ups and crossfunctional coalitions, ADM’s global research and product development network is exploring multiple avenues of microbiome research. This incorporates studies and solutions that can be leveraged for humans, pets and animals alike. ADM’s discoveries are driven by industry insights and

consumer demands. Starting with a pre-clinical phase, researchers screen across various microbiome technologies, including prebiotics, probiotics, postbiotics, enzymes, bacteriophages and more. Once a specific strain is identified in vitro, it moves to the in vivo development phase. Caenorhabditis elegans is a nematode used for in vivo research that ADM scientists have demonstrated as particularly beneficial for the identification of bacterial strains that may be associated with potential health benefits. Following the C. elegans model, additional efficacy trials are conducted with murine models, humans, dogs, cats and/or farm animals. In vivo trials are critical to ensure maximum benefits of the bacterial strain for the intended end user. From there, production of the microbiome technology is scaled up and product stability is fine-tuned. A successful pilot phase then transitions to industrial scale production and commercialization.

In February 2023, ADM opened a new facility in Valencia, Spain: the world’s first facility to produce both probiotics and

18 | September 2023 - International Petfood F

postbiotics at the same site. The site will produce ADM’s award-winning probiotic BPL1™ and the heattreated BPL1™ postbiotic, as well as other proprietary strains, to supply a broad range of customers across human and animal nutrition. This production facility is located close to ADM Biopolis, a pioneering R&D center in the University of Valencia Scientific Park.

Developing Microbiome Solutions for Pets

Biotic ingredients are gaining traction in the pet category across global product launches, with prebiotics currently leading adoption trends. Probiotics and postbiotics are steadily emerging in the field. Spore-forming probiotics are an interesting type of strain, in that they can retain functionality through challenging processing conditions that may otherwise damage conventional probiotics. For example, Bacillus subtilis can survive gastric transit and germinate in the human small intestine, as well as endure harsh conditions of the stomach and bile salts. This level of robustness may be useful for applications like extruded and baked pet treats, as well as health supplements.

Another area of focus is postbiotics, the next generation of functional ingredients. As inanimate (heat-treated) microorganisms and/or their components, postbiotics can be more easily incorporated into pet food products because formulators don’t have to make adaptations for live colony forming units (CFUs). Postbiotics have an inherent stability to withstand many industrial processes and shelf-life requirements. This characteristic also makes postbiotics

Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Petfood-Advert Mar 2023 215x140mm.indd 1 01/03/2023 13:02 International Petfood - September 2023 | 19 F

World Leaders in

suitable for geographic regions that lack reliable cold chains or where ambient temperature can cause problems for storage of probiotics.

More than ten years of research are behind ADM’s flagship probiotic. BPL1™and its heat-treated counterpart have shown to target factors relevant to metabolic health in humans. A published clinical trial of the postbiotic in adults showed emerging evidence that it supports reduction of visceral fat and a healthy waist circumference in combination with diet and exercise. Additionally, a pre-clinical model of heat-treated BPL1™ demonstrated increased lean mass and ameliorated metabolic syndrome in cafeteria-fed obese rats. Most recently, preliminary analysis of an unpublished canine trial indicates that heat-treated BPL1™ modulated the gut microbiome of dogs supplemented with the postbiotic.

Prebiotics, many of which are fermentable fibers, are an additional area for innovation. Gnubiotics is a Swiss biotech company pioneering the use of glycopeptides that can support the microbiome and overall health. ADM has licensed AMOBIOME™ from Gnubiotics, an ingredient that is biosimilar to animal milk oligosaccharide, for use in pet product formulations. AMOBIOME is a unique class of compounds (glycopeptides) that possesses properties known to support digestive health and the growth of beneficial gut bacteria. Scientists at Gnubiotics have investigated the effect of the milk oligosaccharide biosimilar on the gut microbiome composition and have recently published intriguing data suggesting AMOBIOME™ may provide microbiome stability during disturbance by an antibiotic. In partnership with Gnubiotics, ADM will deliver the benefits of this ground breaking solution through its global supply chain.

Trailblazing the Future of Pet Nutrition

Today’s pet products are designed to address a variety of concerns for pets of all ages, including weight management, oral health, digestive health, behavioural health and skin health. Research finds that owners of younger pets usually want products to support immune function and general wellness for lifelong benefits, and parents of older pets often seek out tailored solutions, such as those that address liver and kidney function. Products that support the gut microbiome may hold the key to mitigate many of these ailments.

To that end, ADM is exploring microbiome-supporting technologies for potential pet applications, building on extensive pre-clinical work and positive results using ADM biotics in other species, such as humans. Its global network of scientists, engineers, veterinarians and nutritionists are dedicated to developing innovative solutions for the pet industry challenges of today and tomorrow.

20 | September 2023 - International Petfood F

––International Petfood - September 2023 | 21 F

The Game-Changer CulturedMeatforPetFood

by Shannon Falconer, CEO, BioCraft Pet Nutrition, Austria

eat is the central ingredient in commercial pet food. In the wild, meat is the only single source of complete nutrition for both cats and dogs. However, the demand for meat — from not only humans but also cats and dogs — has come with some devastating consequences, including climate change, animal cruelty and risks to public health.

Rising pet and human populations worldwide, plus increased standards of living, place added demands on meat production. Meanwhile, global uncertainties have led to meat supply disruptions for pet food manufacturers.

Yet when it comes to feeding cats and dogs, the nutritional value of meat cannot be matched. Cultured meat allows us to continue to feed our cats and dogs the foods they need without the negative effects of conventionally produced meat.

It’s a potential game-changer for pet food manufacturers, for consumers, for the environment, and for our cats and dogs.

Meat is cells

What is meat? All meat is simply a collection of animal cells. Meat in the traditional sense is produced when these cells grow inside a body. But, when given the right nutrients, these cells can also grow inside a specialised temperature-controlled chamber that allows for gas exchange called a bioreactor.

The end result in both scenarios is 100% meat. It is bioidentical to traditional meat and has the same nutritional value and composition as animal body-grown meat. In fact, as cultured meat is grown in a way that is tunable, nutritional profiles can be achieved that are even superior to that of traditional meat.

Cultured meat is a new application of a relatively old technology. For more than half a century, scientists have grown animal cells without the animal, mostly for the purposes of better understanding biology in order to treat disease. Now, there is new interest in cultured meat as a part of a more sustainable food system, for people and pets.

MWhether for disease research or food, culturing animal cells begins with taking a small sample from a living animal, normally from a single biopsy. From that sample the necessary cells are isolated and fed with vitamins, minerals, and amino acids inside the bioreactor.

As those cells consume nutrients, they grow and divide, producing more cells to yield a larger and larger biomass. At harvest time, the mass is collected from the bioreactor and the process starts again.

The petfood industry may call cultured meat a novel protein or an alternative protein, but it should not be considered a ‘meat alternative.’ Cultured meat is meat that is produced in an alternative way.

It’s important to understand that meat is much more than protein. In fact, protein is only one vital nutrient our pets need from meat. Meat inherently offers not only protein, but also free amino acids such as taurine, essential fatty acids, and many vitamins and minerals. Unlike plant- and yeast-based meat alternatives, and unlike recombinantly produced animal protein using microbes, cultured meat delivers these required components, naturally, just like conventionally produced meat.

F 22 | September 2023 - International Petfood

Cultured meat challenges

To realistically replace conventionally produced meat, especially in pet food applications where there is price sensitivity, cultured meat must be affordable at scale.

Whether growing inside or outside of the animal, those cells must have the right nutrients to grow and divide. A key challenge in cultured meat production has been ensuring the nutritional needs of those cells are met affordably.

During the past decades of cell culture research, especially in biopharmaceuticals and vaccine development, scientists have relied on a pivotal ingredient to feed cells: Fetal bovine serum (FBS). FBS, collected from unborn calves during the slaughter of pregnant cows, gives scientists a nutrient-rich blend of vitamins, trace elements, hormones and growth factors.

However, it carries with it grave ethical concerns, extremely high costs, supply instability, and batch-to-batch variation that complicates scientific output. For cultured meat producers, it has been imperative to find alternatives that are not only cruelty-free and consistent but are readily available and affordable. In our case, it was necessary to formulate a proprietary growth medium for our own use. This FBS alternative addressed the scientific, ethical and supply challenges, and reduced the cost of production significantly, which has been the most critical step towards commercialisation of our technology.

Another current challenge in scaling up cultured meat production is the high cost of acquiring specialised equipment and facilities, both of which are in demand by pharmaceutical and other biochemical companies. These concerns can be mitigated with investment capital into the human and pet food-tech industry.

and as a prophylactic to prevent disease, which contributes to antimicrobial resistance in pets. Since no antibiotics are used in producing cultured meat, none remain in the finished product.

Savvy pet food companies will also find cultured meat opens up new possibilities in formulating recipes for a variety of dietary and health requirements. As the technology matures, expect to see premium or prescription-diet foods from cultured meat that has been “tuned” and customised to deliver specific nutritional benefits, optimised for different life stages, or to be hypoallergenic.

Healthier for industry

In addition to its potential for new product formulas, cultured meat gives pet food producers many other advantages. Cultured meat currently being developed for the pet food market is in the form of a slurry that offers a one-to-one replacement for slurry from conventional meat. However, there are critical differences between cultured-meat slurries and the traditional format — chief among them, consistency.

Cultured-meat slurries guarantee uniform texture, moisture levels, and nutritional profiles, which radically simplifies the manufacturing process, contains costs, and maintains product quality from one lot to the next. While traditional slurries may require fortification, cultured meat is not subjected to rendering, leaving the nutritional consistency of cultured-meat slurries uncompromised.

Uniformity of product extends to its utility. Traditional meat slurries can contain high levels of bone and connective tissue that make them unsuitable for some pets and some diets but culturedmeat slurry contains no by-products. Not only is cultured-meat slurry usable in formulas for cats and dogs of all life stages and conditions, but it is also appropriate for wet or dry foods and treats.

Healthier for pets

The benefits of cultured meat for the environment, farmed animals and public health are clear: no animals raised inhumanely, fewer greenhouse gas emissions, less land and resource use, and less risk to public health such as zoonotic diseases from livestock. (The main trigger for all pandemics in human history has been the jump of an infectious agent from a farmed or wild animal to a human.)

However, cultured meat also provides health and safety benefits for our cats and dogs. Unlike meat used in current pet food, cultured meat is grown in a controlled environment that is entirely free of common pet food contaminants, including pathogenic bacteria (such as E. coli, Salmonella and Listeria), rendered ingredients from fallen animals, drugs (such as the euthanizing agent pentobarbital), or heavy metals (common in farmed fish).

Most FDA-issued recalls of pet food have arisen out of safety concerns associated with these contaminants — risks that are eliminated in cultured meat. Cultured meat also avoids the use of antibiotics administered to farmed animals to promote growth

Consistency in fat and flavour helps meet consumer (and pet) expectations for palatability, so that pets’ favourite foods remain their favourites, bowl after bowl. While the absence of contaminants and pathogens in cultured meat is a major advantage in avoiding reputation-blasting recalls, cultured-meat slurries are expected to meet a higher standard for ingredient transparency and traceability such as sourcing, production methods, and quality assurance.

But the most likely value to manufacturers is enhanced supply-chain resilience. Cultured meat offers a way to reduce dependence on the volatility of traditional meat sources.

The impact of farmed animal diseases, shortages, and price fluctuations has been hard on the industry, and cultured meat will bring a more stable, reliable, and efficient supply.

The first manufacturers to introduce cultured meat to the market will win environmentally and ethically conscious pet owners, promote sustainability and further ESG goals. The real gamechanger of cultured meat is not only its environmental and animal welfare benefits, but also the health benefits for cats and dogs, and healthier profits for manufacturers.

International Petfood - September 2023 | 23 F

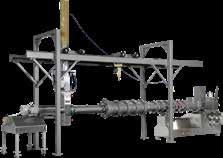

Ottevanger Milling Engineers

Ottevanger Milling Engineers is a leading global supplier of production equipment and processing lines for the grain processing and compound feed industry. Founded in 1909, Ottevanger Milling Engineers is today still an independent, privately owned, successful Dutch company, managed by of the fourth generation of the Ottevanger family.

Ottevanger does business world-wide as a dependable, high-quality component supplier, but also as a prime contractor or subcontractor on large-scale projects. They plan, design, manufacture and manage the construction of complete (turn-key) production facilities or individual lines for processes. Their expertise lies in; engineering, production and installation of machinery and complete installations in the dry-cereal and grain processing industry such as: feed mills, premix and concentration plants, aqua feed and pet food installations, cereal processing lines, biomass installations.

Company Feed Industry

Since the founding of our company, we have acquired more than 110 years of experience in a process of continuous development, improving and enhancing the performance of the equipment and processes by applying modern design standards and employing the latest production techniques. Our designers take full account of the norms and directives that apply to the intended installation, including CE, ATEX and GMP.

Cereal Processing

One of Ottevangers specialties is the design of complete process lines. They share our expertise by describing the basics of soy processing, premix & concentrates, grain storage & handling, compound feed, pet food and aqua feed. Every process line will be tailor made designed by the engineers. They do not promote or apply a ‘standard’ plant design and each project is assessed on its own merits. They take time consulting

with customers to ensure they fully understand customer requirements and more specifically requirements of the specific market the customer is serving.

Pet Food

Ottevangers acknowledge and understand how trends in the pet industry impact the design of pet food processing solutions. They took great care over many years developing technologies and equipment meeting and exceeding the growing demands of the global petfood industry.

Aquafeed

Aquatic feeds have very high requirements in terms of both nutritional and physical characteristics of feed. These nutritional and physical feed requirements are driven by the life stage of a specific species under consideration. Physical characteristics include issues such as pellet size and shape; pellet density allowing us to produce floating, slow sinking and sinking feeds; water stability and pellet durability. The challenge is to achieve all of these while having a negligible effect on the environment.

Premix and Concentrates

A very long history in the industry gave Ottevanger Milling Engineers the experience and expertise to supply tailor-made solutions for the complete spectrum of premix and concentrate applications. Engineering and Equipment solutions range from small mill-and-mix operations to large, dedicated feed mills.

Ottevanger equipment for premix and concentrate plants meet and exceed international standards in terms of design, hygiene, safety and efficiency. Innovative design results in exceptional mixing accuracy and end product quality. State-of-the-art engineering layout and process control design leads to negligible cross contamination.

24 | September 2023 - International Petfood Industry PROFILE

They may not say it, but you can see when your pet is feeling happy, healthy and loved.

With the highest quality ingredients to help boost their immune system, promote healthy coats, and build strong bones, Zinpro® is the best trace mineral nutrition for your loved one. It’s Nutrition You Can See™ .

See the difference Zinpro can make.

©2023 Zinpro Corp. All rights reserved.

International Petfood - September 2023 | 25

Industry Training

The Online Petfood School 2023

The online Petfood School began August 24, and is off to a great start! The course is designed to give an in-depth review of the process of making petfood’s, from simple and complex petfood, to treat production.

The live online webinars will consist of two and a half hours per week, for six weeks, and includes an additional inperson session at this year’s VICTAM LatAm in São Paulo, Brazil. Once the course is completed, attendees will receive a certificate, and the opportunity to watch the sessions ondemand.

The programme is jointly organised by Progressus Agrischools and Perendale Publishers, and sponsored by Agentis Innovations, Tietjen, Andritz, Wenger, PLP Systems and International Milling Directory.

Week 1

The first session began with a warm welcome from the session moderators, Yiannis Christodoulou, Managing Director at Agentis Innovations and also the session moderator for OPS, and by Roger Gilbert, CEO of Perendale Publishers. They introduced the trainers and provided an overview of the course and its structure.

The presentations for this week began with Joe Kearns, the editor for International Petfood magazine, and a consultant in Extrusion Cooking Consulting, Animal and Aquatic Feeds. Previously he was the Vice President Aquafeed Div. for Wenger Manufacturing, Inc. He spoke on the extrusion process in Petfood production, covering various topics including:

• horizontal & vertical extrusion

• project planning

• incoming materials

• processing

• plant and equipment design

• food safety

The second presentation involved Joe talking about ‘Petfood products and advancements’ discussing topics such as:

• simple petfood’s

• shaped products

• multi-colour products

• multi-shaped products

• co-extruded pet food products

• ultra-high meat twin screw extrusion

The session continued with Professor Simon Davies who is the editor for International Petfood magazine. He has also developed and led masters’ programmes in Marine Biology and Aquaculture at the University of Plymouth and Harper Adams University.

Professor Simon Davies is currently an Adjunct Professor at the National University of Ireland, Galway and Emeritus Professor at Harper Adams University, discussing ‘modern pet nutritionist’ covering topics such as:

• effects of diet on animal health

• the sustainability agenda

• insect meal

• prebiotics

• postbiotics

• plant protein

• advances in nutritional biosciences

Week 1 ended with a Q&A for attendees to participate in.

Week 2

Week 2 began with a warm welcome from the session moderator Roger Gilbert. He introduced the days topics and speakers, which started off with Joe Kearns.

The session began with a presentation from Joe Kearns on ‘basic ingredients, dry, wet and frozen materials’ which covered:

• storage bins

• conveyors

• liquid storage

• frozen/fresh chilled meat ingredients

• meat preparation

The second presentation was given by Giuseppe R Bigliani on ‘Ingredients receiving, conveyance and storage’ covering topics such as:

• unloading systems

• cleaning systems

• storage systems

• liquid systems

• free & non-free flowing ingredients

The final presentation came from Thomas Runde, who discussed ‘It all depends on the grinding – particle size reduction for premium pet food’ where he spoke on the topics of:

• grinding module

• grinding basics

• the importance of grinding

• recipe consideration

• dosing

• chamber design and impact areas

The session ended with Roger Gilbert thanking all of the attendees, speakers and sponsors.

Week 3

Takes place September 7, the remaining sessions taking place on the following dates:

Week 4

Thursday 14 September (14:00 Bangkok Time / 09:00 CET)

Week 5

Thursday 21 September (14:00 Bangkok Time / 09:00 CET)

Week 6

Thursday 28 September (14:00 Bangkok Time / 09:00 CET)

There’s still time to join the upcoming sessions, just visit https://www.onlinemillingschool.com/pet-food and pick which session you would like to be a part of!

TRAINING

26 | September 2023 - International Petfood E

Troubleshooting

In this edition, how about we discuss a different view on extrusion of petfood products. Previous discussions on four main areas of extruding a product were on formula, hardware, operations conditions and final product specifications. Which comes first, usually? I am sure contract manufacturers can answer this one as well as production managers. It is normally the final product specs that come first.

Working with various nutritionists, some begin the discussion with the extruder operators. What can the machine do and what can you do within reason. Obviously, this requires a knowledge of extrusion and what can be done, each case can be different as each extruder is possibly different. Been in many production facilities with multiples of the same extruder model with different main drive motor sizes and different conditioning cylinders. With all of the other possibilities, these questions are asked on the intended production machine. Extruders are tools and best used as designed for maximum efficiency. Lowest starch level, highest fat level, product dimensions, expansion ratios extruder barrel configuration, approximate capacities and others would allow discussions to plan and insure the best possible chance to make a new product. Are these answers based on when the extruder components are new or in a semi worn or completely worn state? Computer controls allow for recording running conditions at different wear conditions allowing for a better chance making similar spec products over the life of the parts. Running conditions allow for this with liquid additions, dies, screw speed, flow restriction control and capacity adjustments to hit the specs.

The trick is to know the trends and how to react when the specs move from the intended outcome. The hard part to explain is to determine which way to go. For example, steam injection in the extruder barrel, if you add more and expansion increases, add too much and the product might blow apart and have a rough surface. So, the general answer is increase or decrease steam. Another is cook. You can get the idea at the extruded discharge by placing in water, if it swells about two times, I would predict you are cooking well. Now, in modern times, instrumentation checks temperature, expansion, moisture levels and can even record specific mechanical energy inputs give a good indication the product is made under a set of specifications, and this will predictably be in ranges set. It is considered as a must to meet the FDA petfood production restrictions in cleanliness. There are many old school methods, and some are still using them, current plant and equipment designs place the plant and quality control in management hands. Operators still need to know how to react but within ranges set to maintain capacity and quality.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The extruder barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the extruder barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion

during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - September 2023 | 27

Innovations this month September 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk