New coursesPetfood at The Online Milling School See more on page 26 International PetFoodVolume 5Issue 10October 2023 www.internationalpetfood.com www.perendale.com β-glucans & MOS in Pet food - Continuous Coating Technologies for premium quality petfood - Guinea pigs October 2023 Download your online version:

The Packaging Group GmbH Gerberstraße 50 · 51789 Lindlar, Germany · www.the-packaging-group.com If you can think it we can pack it The Packaging Group (TPG) Visit our NEW YouTube channel and find your perfect pet food packaging solution HDG RB-600 FAWEMA FA 456 WOLF VPC

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 01242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy Nelloolichalil joyn@perendale.co.uk

Technical Editor Joe Kearns joek@perendale.com

Nutrition Editor Prof Simon Davies simond@perendale.co.uk

Editorial team

Shannon Parsons

Tel: +44 (0)1242 267706 shannonp@perendale.co.uk

Niamh Cassidy

Tel: +44 (0)1242 267704 niamhc@perendale.co.uk

Community Manager

David Harvey

Tel: + 44(0)1242 267700 davidh@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 (0)1242303792

darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta clarissag@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 364 64 57

mehmetg@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839

mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Design Manager

James Taylor Tel: +44 (0)1242303791

jamest@perendale.co.uk

Production Assistant

Cristina María Roldán Otero

Tel: +44 (0)1242 267700

cristinaot@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 (0)1242 303790

tutit@perendale.co.uk

Development Manager

Antoine Tanguy

Tel: +33 6 78 57 76 45 antoinet@perendale.co.uk

October 2023 10 Industry News COLUMNS 6 Roger Gilbert 7 Joseph P Kearns

Professor Simon Davies

8

International Petfood - Volume 5 - Issue 10 ©Copyright 2022 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 2754-4680 www.internationalpetfood.com 26 Training 27 Troubleshooting 28 Production focus 9 The PetFood Journal REGULAR ITEMS 24 Industry Profiles 31 Industry Events 39 The Market Place 40 The Interview 42 Industry Faces

FEATURES

16 β-glucans & MOS in Pet food

18 Continuous Coating Technologies for premium quality petfood

22 Guinea pigs

One course finishes – another to start Yes, the first ever Online Milling School (OMS) Petfood Course has finished with students having the whole of October to attend any missed Sessions through our on-demand service.

It’s important to ensure that all six two-and-ahalf hour sessions are completed in order to gain the Certificate of Attainment that is issued as confirmation of the knowledge and understanding gained by student about the complete petfood process.

Roger Gilbert Publisher – International Petfood

This is the first course and unlikely to be the last. The importance of getting petfood production right is paramount now that the US has adopted regulations treating food for our pets as equivalent to food for human consumption. The move towards this change from a ‘feed’ to a ‘food’ has been gradual but steady given the determination by the US to protect human health.

Under these new requirements pets are now seen on an equal footing as their owners in expecting the highest quality and safest food possible.

And why not?

Food for our pets is on supermarket shelves, is carried in our food baskets to our homes and is stored in our food cupboards and most often served up in dishes and bowls that find their way onto our food surfaces and into our dishwashers and onto our kitchen draining boards for cleaning.

The regulations that have been adopted in the USA are likely to be adopted elsewhere if not already being applied on a voluntary basis.

This is one good reason for our petfood manufacturing plants to be constantly training staff in all aspects of petfood production, from raw material reception (where many undesirable bacteria and other contaminants may be brought unwittingly into a production plant) right through to the packaging of ‘clean’ and hygienic foodstuffs that have guaranteed and extended shelf lives.

This is also the reason why I and our Technical Editor Joe Kearns decided to introduce a new two-day conference called ‘Pet-Aqua,’ which we will host for the first time at the upcoming Victam Latam show set down for São Paulo from October 3-5, 2023.

Our last edition

Did you miss our September 2023 edition? If so, don’t panic!

You can still read all of the great quality content that we published last month on our App – which you can download from Apple Store, Google Play or online at: https://magstand.com/petfood – with the latter platform granting you the opportunity to see all of our back editions on the screen of your desktop computer.

By the time you are reading this column the event will most likely have passed - you can look forward to learning all about its outcome in our November edition.

Why Pet-Aqua you may be asking?

As well as hosting OMS Petfood (with our partner Progressus AgriSchools of Thailand) we also run an OMS Aquafeed. It occurs to us that these two production processes have synergies around the use of extrusion processing and it’s very likely that many aquafeed and petfood establishments would like to consider producing both products to take full advantage of their equipment and technologies.

Let’s see how the Brazilian industry responds to the program we have put together for ‘Pet-Aqua.’

While on the subject of Victam Latam, it is interesting to note that we are holding an OMS Live Session on the last day of the show. We want to raise awareness of the OMS’s Courses in Latin America and this seems like a good opportunity to show visitors what they can expect from our courses. More about this in our next edition as well.

But what about this edition?

While Technical Editor Joe Kearns looks in detail at the role hammer mills and grinding plays in the production of petfoods, Editor Professor Simon Davies kicks off with a review of coenzyme Q10 and its role in pet nutrition. Both worthy of your time to read and consider.

We also look at B-Glucans and MOS on page 16 and coating technologies on page 18. There’s a feature on page 22 about the eating habits of Guinea Pigs before we turn our attention of a report from a company which provides the equipment we need in our production plants on page 24.

Don’t overlook this month’s Production Showcase for the latest updates on equipment and ingredients that may help you in becoming more efficient and effective producers.

There’s lots to read in this issue and I’m sure you will enjoy what’s on offer. Let me or my editors have your thoughts on what areas you’d like to see us cover in upcoming edition!

What you may have missed…

Meeting Growing Demand for Plant-Based and Hybrid Pet Foods by Dr Maygane Ronsmans, Product Manager Animal Nutrition, BENEO GmbH, Germany

Figures show one in three petfood shoppers think that using plant-based ingredients make petfood seem a lot healthier. At the same time, petfood manufacturers are increasingly being faced with lower availability and price volatility, such as for meat (co)products. Here Dr Maygane Ronsmans, Product Manager Animal Nutrition at BENEO, discusses the interest in hybrid and plant-based petfood and how producers can meet changing consumer requirements with vegetal functional ingredients.

To read more, go to: www.flickread.com/edition/html/64ff3ecfeab72#16

THE PUBLISHER

Topics of the month interesting are quite varied. Hammermills, unadulterated production, organic and functional, the extruder barrel, moisture analysis, recycling packaging and the pet of the month is reptiles and amphibians.

Hammermills, needed for particle size reduction as this process is important for a number of reasons. Product appearance, a nicely ground mix give a much more appealing product to the pet owner. It also adjusts the method of cooking. The goal is for all particles ground to be of a similar size. Ok, some fines and some overs but generally all similar. From a micro perspective, the finer particle will absorb moisture faster, the larger particles will take up less water and when they are all the same then they moisten evenly. This allows for improved cooking throughout the mix and with enhanced or good preconditioning this could result in somewhat higher capacity with a product that has potentially a higher expansion possibility. Don’t want more expansion than the possibility to add die opening can control the expansion and increase capacity.

Joseph P Kearns Editor, International Petfood Magazine

for your product range. What can vary in an extruder barrel for the above topics. Standard low fat low meat extrusion does not require tremendous development of heat via friction or at least not as much as when you have elevated fat and meat levels. Sleeves and/or heads are usually set and don’t change often other than for wear reasons. Designed to promote forward flow early in the barrel followed by an area of frictional development and back to forward flow up to the final die. When elevated fat and meat is used then the barrel usually has some method to increase the friction development. Change is screws, shearlocks, kneading lobes or restriction of flow in or before the die creates more friction needed for these kinds of diets. This is up to a point as above 15 percent fat and meat addition above 20 to 25 percent there are advanced designs as it is very hard to cook high moisture fresh meat with friction cook. Needs to change at a point to a thermal cook process.

Unadulterated production begins with the raw material suppliers giving you a good quality product, of course you will be probing the materials for inspection prior to unloading to ensure delivery of what is expected. The next big goal is to keep undesirable products out of the process stream. Proper clothing, watch and jewellery removal, hair and beard nets, shoe sanitisation, personnel movement control, plant cleanliness are just a few points where your Good Manufacturing Practices get involved. The system itself, needs to be designed to eliminate or keep products out of the flow stream that are not desirable. Equipment and plant designs are a big factor here controlling product carryover and possible bacteria developments. It is a total plant approach. Organic and functional ingredients are good choices. Define functional, to some it is an ingredient that assists in the process such as binding the product from protein cross linking. Another definition might be the ingredient selection for the effect on the pet. Extrusion has practically no restrictions except a few, minimum starch levels to hold the product together, maximum moisture and fat addition which can affect pellet quality. How about 10 to 20 percent starch, dependent on balance of formula, and maximum of about 32 percent in the barrel moisture with 15 percent total fat max. If you get outside of these areas then a more advanced extruder might be in order. The idea is to define your potential products with approximate formulas etc. so the manufacturer of the equipment can respond accordingly. If you don’t know then ask a bunch of questions so you find out what their possibilities are with regards to ranges of operation. The extruder barrel, has quietly been advancing over time, matching the desires of the industry. Extrusion is a process, start to finish, can your feed system deliver evenly, what is the quality of your conditioner, do you need a versatile extruder barrel for a range of products or just one product. Product size or shape, high meat, high fat, what is the maximum total fat desired in the extruder, meat? All of these can point you into a single screw, twin screw or more advanced designs ready

Moisture testing is great for records and for repeatable results in production. Computer control has been a great advantage in monitoring the moisture in the extrusion process. It is so accurate that the computer can tell you what the moisture will be out of the die, you need to input the dry raw materials moisture. Near the extruder or in the lab moisture meters can be used for quick reference and verified in the lab. Out on the floor small bench top devices which run on electrical heating elements and or electrical conductance is normal also with their use in the lab or an actual oven where samples are weighed in and out for accurate results. Meters are getting more accurate and faster at giving the results. These devices have been added and are in use in the process with in-line moisture and density meters and are quite successful as they can actually with a computer automatically control the process.

I am in Brazil now for the Victam Latam event and in the Pet and Aquatic Production Seminar we will be hearing about circular economy regarding diets in aquatic feeds. This topic will be interesting as the discussion include a review of how diets control the output and advanced nutrition can affect the costs all along the chain. An example in petfoods could be collection of used petfood bags which can be recycled. An example for every 1,000,000 kilos produced and bagged in 20 kilo bags we use 50,000 bags. Imagine the real numbers if available. This can actually create a whole industry where people are employed let alone greatly reduce materials to the land fill.

The pet discussion of the month is reptile and amphibians. These animals are generally small thus the production of feeds for this use normally requires a much smaller kibble. Extrusion is now successfully making pellets of 0.5 mm and above in whatever increment you wish within reality. At one point an evaluation of capacity of a 1-2 mm product on a small twin screw system could actually pay for itself in a few months.

In closing, we would like to hear from you if you have any specific topics you would like to be discussed. Send us your comments and questions to be reviewed and addressed in future issues.

THE EDITOR

International Petfood - October 2023 | 7

Professor Simon Davies Nutrition Editor, International Petfood

Coenzyme Q10 and its Role in Animal Nutrition

Coenzyme Q10 (CoQ10), also known as ubiquinone, is a vital molecule found in the cells of animals, including cats and dogs. It plays a crucial role in cellular energy production and serves as a potent antioxidant. CoQ10 is synthesised endogenously in animals, but dietary intake can also contribute significantly to its levels. Over the years, extensive research has been conducted to explore the potential benefits of CoQ10 supplementation in animal nutrition, particularly in cats and dogs, to enhance their wellbeing, physiology, and metabolism. CoQ10 primarily functions as a key component in the electron transport chain of the mitochondria, where it facilitates the production of adenosine triphosphate (ATP) – the energy currency of cells. This fundamental role in energy metabolism makes CoQ10 essential for various physiological processes, including muscle contraction, maintenance of membrane potential, and overall cellular functions in anabolic and catabolic pathways.

Beyond its role in energy production, CoQ10 also acts as a powerful antioxidant, protecting cells and tissues from oxidative damage. This is particularly relevant in animals like cats and dogs, where oxidative stress can result from various factors including metabolic processes, environmental pollutants, and age-related changes. CoQ10’s ability to neutralise free radicals contributes to overall cellular health and longevity. Numerous studies have investigated the potential benefits of CoQ10 supplementation in cats and dogs, aiming to enhance their overall wellbeing, physiology, and metabolism. CoQ10 has shown promise in supporting cardiovascular health by promoting efficient energy production in the heart muscle cells and enhancing blood vessel function. This can lead to improved cardiac performance and reduced risk of heart-related issues in cats and dogs. CoQ10 supplementation has been linked to enhanced exercise performance by improving energy availability in muscles. This could be especially valuable for working

dogs and those engaged in physically demanding activities. CoQ10’s antioxidant properties are believed to contribute to cognitive health and may aid in slowing age-related cognitive decline in older cats and dogs. Some research suggests that CoQ10 supplementation might assist in managing certain metabolic disorders, such as obesity and diabetes, by optimising energy metabolism and reducing oxidative stress. CoQ10’s antioxidant and immune-modulating effects could potentially enhance the immune response in cats and dogs, aiding in their ability to combat infections and diseases. Indeed, this very important molecule within every cell and located in their hundreds of individual mitochondria are paramount co-factors in the intermediary energy assimilation and to power your cat and dog for routine and various levels of bioenergetics. It is not to be ignored in the overall nutritional context and requirements for certain scenarios.

We know much more about Coenzyme Q10 metabolism and benefits in humans with many scientific publications in the leading peer-reviewed journals involving fundamental studies at tissue culture and whole animal models. There has been renewed interest in human nutrition with a plethora of commercial products containing different potencies of the molecule. It remains to see how best we can optimise its use in dog and cat nutrition within diet formulations.

In summary, Coenzyme Q10 holds great promise as a nutritional supplement for enhancing the wellbeing, physiology, and metabolism of cats and dogs. Its pivotal role in cellular energy production and antioxidant defence makes it a valuable addition to animal nutrition. While the mentioned studies provide insights into the potential benefits, further research is warranted to establish optimal dosages and application protocols for various health conditions in cats and dogs. Integrating CoQ10 supplementation into animal nutrition could contribute to improved overall health and longevity for our furry companions.

8 | October 2023 - International Petfood

The PetFood Journal

Petfood Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with a distinguished track record of technical and trade magazines in the agricultural sciences. This new peer-reviewed scientific journal will serve academia and the commercial petfood industry with high quality papers relating to the science and technology of petfood development and production for the rapidly expanding companion animal sector. It is envisaged to address fundamental and applied nutritional research addressing requirements for advanced feed production manufacturing for dogs, cats and many other species such as guinea pigs, rabbits, rats and exotics e.g. reptiles, amphibia and fish (aquatics). The journal will embrace information on essential amino acids, proteins and energy sources as well as key vitamins and minerals pertaining to maintenance, growth, feed utilisation efficiency and health. A major area will be studies that focus on feed ingredient assessment and in particular those that are sustainable alternatives to traditional sources. Therefore investigations directed towards plant and next generation proteins like insect meal, algae and microbial sources would be desirable areas. Novel oils and lipids that provide essential fatty acids would be of considerable importance. Studies on functional ingredients affecting the health and immune function of pet animals are attractive. We would welcome papers researching the role of prebiotics, probiotics and phytobiotics on gut health, mucosal immunity and their interaction and modulation of the intestinal microbiota. Petfoods play a significant role in animal behaviour due to palatability and smell. Research on these interactions would be welcome and of interest to the scientific community and stakeholders. Given the diversity of different types of commercial diets ranging from wet, canned and extruded dry diets as well as treats and speciality diets, there is much scope to provide information on these advances. We also cover papers on feed production manufacture such as milling, pelleting, shaping and texture of petfoods such as extrusion. The journal recognises that petfood science & manufacturing technology plays a vital role in promoting the health and well-being of our pets. Optimal feed management and environmental impact of diets are worthy of inclusion.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Petfood Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral, researcher, being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief. These OA papers will be available on our official website Internationalpetfood.co.uk and printed as well as being downloadable. Links will be provided within our existing International Petfood magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

International Petfood - October 2023 | 9

We can help you improve your pellet durability testing...

RawTernative goes plastic neutral

RawTernative, the Air-Dried Food made by and for independent pet retailers now certified Plastic Neutral. The company is partnering with rePurpose Global – the world’s leading Plastic Action Platform –to fund the recovery of as much nature-bound plastic waste as it uses across its product packaging. This action on plastic waste is part of their wider SustaPak sustainability strategy.

Through this partnership, RawTernative is enabling the removal of at least 7500Ibs of plastic waste each year that would otherwise be ocean-bound and end up polluting the natural environment.

As a prominent player in the pet food sector, RawTernative recognises the serious threat that plastic pollution poses to the future of our planet. Certifying their products Plastic Neutral forms part of their Susta-Pak strategy, which includes the Grandma Mae’s country Naturals partnership with Clearloop-supporting the development of solar energy projects to reclaim the carbon emitted by transporting Grandma Mae’s products. This program will expand to include RawTernative beginning in 2024.

RawTernative is supporting rePurpose Global’s impact project Saaf Samudra in Goa, India and in doing so is not only tackling the plastic waste crisis, but also supporting waste workers’ incomes by attaching value to hard-torecycle plastics, and providing safe, stable, and fairlypaid employment opportunities through local waste management enterprises.

RawTernative is supporting rePurpose Global’s impact project Saaf Samudra in Goa, India and in doing so is not only tackling the plastic waste crisis, but also supporting waste workers’ incomes by attaching value to hard-torecycle plastics, and providing safe, stable and fairlypaid employment opportunities through local waste management enterprises.

RawTernative’s commitment to society can be traced back to their roots as a brand founded on the intention of prioritising pet nutrition above profits. “Our mission has always been to put pets and their pet parents first and so it only made sense to extend this level of care to the environment we all live in as well” said Nathalie Berman, assistant to the president at RawTernative.

“Environmental protection is at the core of RawTernative. It is heartening to see them push the boundaries on tackling the plastic waste problem. We hope their commitment encourages more brands to take responsibility for the plastic that they are generating.” Said Aditya Siroya, co-founder and chief impact officer of rePurpose Global.

Made in Britain, Trusted Worldwide. We are

Inline,

OLM N H ®

Holmen NHP200 Series 2 Laboratory based, automatic pellet tester.

Holmen NHP300

process based system.

Holmen NHP100 Portable, manual pellet tester.

Healthy bud to launch new superfood for brain health

On the heels of a successful preview at SuperZoo 2023, leading Canadian pet wellness brand Healthybud is preparing to launch its game-changing new product: lowcal, superfood-packed ‘mini training treats’ for dogs made with all-natural ingredients that promote brain health.

Many pet parents forget an essential first step when training their pups. According to top trainers, you should always start by ensuring dogs are receiving an adequate balance of nutrients so they have the energy and attention span needed to learn. Healthybud’s ‘mini training treats’ take this to the next level. The new ‘mini training treats’ are enriched with specific science-backed superfoods known to boost doggy brain power, such as:

• lion’s mane

• reishi

• salmon oil

• pumpkin

Each pack contains more than 500 mini treats – all human-grade, grain-free and irresistibly delicious to dogs. Perfect for all breeds and stages of life, every treat has just one calorie so dogs remain in top shape no matter how many tries it takes before they sit, stay or roll over.

“The Healthybud team has been hard at work crafting the best possible training treats and we’re so excited to finally be releasing them –our first new product launched in two years. We previewed the ‘Mini Training Treats’ at SuperZoo last month and everyone went wild for them. People loved the mini size because it makes it easy to dish out multiple treats while training. They were also intrigued by the unique, healing superfoods the treats are made with. These treats are not only ideal for training, they are also the perfect low-calorie, high-value goodie for any occasion.” – Dana Ben David, co-founder & creative director at Healthybud Healthybud’s ‘Mini Training Treats’ are scheduled to be available across North America in October 2023.

Pure treats announces new value-size dried trainers

Pure Treats Inc is announcing the introduction of new value size Mini-PureBites beef liver freeze dried trainers and New Mini-PureBites salmon freeze dried trainers. Made in the USA with only one human grade ingredient: 100 percent pure beef liver and 100 percent wild-caught salmon. MiniPureBites Trainers are specially cut small pieces of pure protein for training and small dogs. Specifically designed for the exploding small dog segment, as well as helping puppy parents needing training treats for their new family members, Mini-PureBites offers a tailor-made incremental merchandising opportunity for puppies and training. Since their launch, the Mini-PureBites line of training treats has been a hit with pet parents, so now PureBites is expanding into a new protein, salmon, as well as a large size to address the higher consumption rate of training treats.

All Pure Bites are made fresh and pure using a delicate freeze-drying process to ensure more raw protein and nutrients are packed into every bag. With nothing added to get in the way, the aroma & taste that dogs and puppies love are locked into all their treats, food and toppers. Dog parents love PureBites because they are 100 percent pure and rich in nutrients for a happy and healthy life. PureBites are the ideal treat for dogs with health issues, are overweight, diabetic, have allergies, gastrointestinal disorders, or are on a restricted diet, as limited ingredient treats allow pet parents the peace of mind knowing exactly what they’re giving their furry loved ones.

Mini-PureBites raw freeze-dried treats are the ultimate limited ingredient high value treat and joins a growing family of simple, pure, limited ingredient treats, and toppers that include raw freeze dried, gently air dried & wet treats, toppers and mixers for dogs and cats.

Mini-PureBites trainers are available now through your preferred pet supplies distributor in either the US or Canada. Mid-size treats are available in beef liver, lamb, chicken and salmon and carry a suggested retail price of US$8.99-9.99. Value size Mini-PureBites beef liver treats carry a suggested retail price of US$23.99-24.99.

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

International Petfood - October 2023 | 11 N

Cult Food Science announces launch of Noochies

Cult Food Science Corp, a pioneer in the investment, development and commercialisation of cellular agriculture technologies and products, announces Noochies freeze-dried dog snacks are available for sale.

The launch of Noochies freezedried dog snacks marks a significant milestone for Cult as its first product available for sale in North America. Noochies! treats are crafted using a patented manufacturing process to produce an ultra-premium, cruelty-free, and climate-friendly product.

The launch of Noochies! freezedried dog snacks mark a significant milestone for Cult as its first product available for sale in North America. Noochies treats are crafted using a patented manufacturing process to produce an ultrapremium, cruelty-free and climatefriendly product.

With the launch, Cult Food Science has developed the world’s first

commercially available freeze-dried cultured protein. The formulation was specifically designed to be high in protein to meet our pets’ daily protein requirements, but also provide the animals with meaningful amounts of fibre, immune-boosting B vitamins and gut-pleasing fermented ingredients. Independent third-party testing has shown that Bmmune, the foundational ingredient in Noochies, exceeds industry-defined standards for protein and amino acids, and is viable if not better alternative to popular premium animal ingredients like chicken and lamb.

Outlook and future plans

Cult anticipates strong demand for Noochies dog and cat treats, projecting substantial revenue growth in the coming quarters. With an increasing focus on responsible pet ownership and the growing awareness of sustainable food sources, Noochies are wellpositioned to capture a significant market share.

The company will be announcing the availability of cat treats in the near future and is planning to

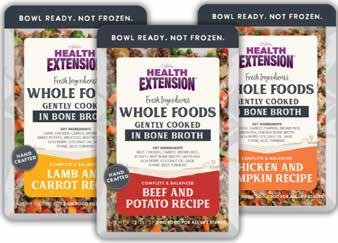

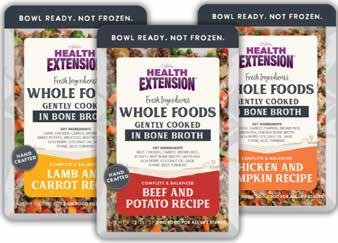

Holistic Health Extension introduces line of gently cooked dog food

Health Extension introduces its latest innovation in premium pet nutrition; gently Cooked dog food. These delectable recipes feature fresh whole food ingredients gently cooked in bone broth, ensuring a wholesome and convenient meal options for dogs. Unlike frozen altenatives, Gently Cooked is shelf stable, always ready to serve, making it the perfect choice for busy pet parents and dogs that crave a free homecooked meal.

Health extension’s

Gently Cooked recipes are thoughtfully crafted in small batches, incorporating a unique blend of superfoods to boost immunity, improve skin & coat, strengthen

expand its Noochies product line in the coming months to include nutritionally complete foods as well as supplements for dogs and cats, ensuring a wide range of options to cater to pets of all preferences and dietary needs.

To celebrate the launch, Noochies is offering free shipping on all orders and an additional 20 percent off with the promo code TAKEOFF20 from here for a limited time.

“We are excited to introduce Noochies treats to pet owners who seek the best for their beloved companions,” said Lekjjy Gafour, CEO of Cult. “Our commitment to innovation, sustainability and animal welfare has driven us to create a line of treats that not only deliver the taste our pets enjoy but also promote the well-being of the animals.

12 | October 2023 N C M Y CM MY CY CMY K

Bioflytech progresses with the construction of its second plant in Spain

Work on the plant Bioflytech is building in Palas de Rei, in the Spanish autonomous region of Galicia, is progressing well. The rendering and drying plants are being set up, and in the coming weeks the first of the six fattening halls will start operations, each of which will produce 2000 tonnes of fresh black soldier fly larvae per year, until reaching the maximum production capacity of this first phase of 12,000 tonnes per year, during 1Q2024. In the coming years, further major investments are planned in this plant in order to reach 100,000 tonnes per year of black soldier fly larvae production.

This new, second Bioflytech plant – the other is located in Fuente Álamo, in the Spanish region of Murcia – is equipped with a gas rendering installation designed by the company and unique in the market, a disruptive technology that will make it possible to manufacture tailor-made flours with specific percentages of protein and fats according to the customer’s demands, and which is set to revolutionise the insect protein flour production sector. The Palas de Rei plant will also have a second conventional rendering line, which is currently in the testing phase and is expected to start production this November.

Bioflytech was founded in 2012 as a biotechnology company linked to the University of Alicante. Six years later, the company Moira Capital

acquired the majority of its capital, and at the end of 2019 moved its operations to Fuente Álamo.

Bioflytech obtains mainly four products from the black soldier fly: dried larva, which is obtained after almost complete drying of the fresh larva and has highly digestible protein and all the necessary components for the diet of poultry, fish and other animals; high-protein meals; fats, which are obtained from the larvae and without using chemical agents or solvents; and compost, obtained as a result of the bio digestion of the plant material produced during the fattening process.

Bioflytech’s dried larvae is a product specially designed as a feed diet for laying hens and broiler chicken while the protein meals are intended for the petfood, aquaculture and poultry industries, and also to a lesser extent for animal feed for the fur industry. Fats are mainly used in animal feed,

but also in the pharmaceutical and cosmetics industry. Compost is used as a fertiliser.

One of the world’s leading players Bioflytech’s first and so far only plant in Fuente Alamo currently produces 4,000 tonnes of fresh larvae per year. One of the largest black soldier fly hatcheries in the world is located here, with a production of 180 kilos of black soldier fly eggs per month. Bioflytech’s strategic plan includes an investment of 2.8 million euros this year in various improvements in this plant, with the aim, among others, of increasing the monthly egg production to 350 kg. Now, with the start-up of the second Spanish plant – which will operate through its subsidiary Alternatives Fats and Proteins of Galicia –Bioflytech will consolidate its position as one of the world’s leading producers of insect-derived products for the animal feed industry.

14 | October 2023 - International Petfood N

Corbion introduces sustainable pet nutrition

Corbion, the global market leader in algae-based feed ingredients, announces the launch of its new AlgaPrime DHA P3, a high-performance, omega-3 ingredient enabling pet food manufacturers to enhance the nutritional profile of their products and boost DHA levels reducing dependency on marinebased resources and positively impacting their carbon footprint.

Produced via micro algae precise fermentation, AlgaPrime DHA P3 helps meet increasing consumer demand for more sustainable pet food ingredients, as nearly 70 percent of pet owners worldwide express concern about nutrition, climate change and a desire to make a positive impact on the environment through their everyday actions.

The ingredient supports manufacturers in their efforts to overcome the most common challenges of omega-3 DHA inclusion, as it provides the highest level of DHA on the market in biomass powder form (35 percent DHA), enabling flexibility for nutritionists and developers in working with higher DHA inclusions for added nutritional value, while advancing the sustainability of pet diets. In addition, it is stabilised with a natural antioxidant system. AlgaPrime DHA P3 is suitable for dry, wet and injectioncold applications, allowing efficient access to, and use of, long-chain omega-3s.

“The launch of AlgaPrime DHA P3 furthers Corbion’s mission to preserve what matters by offering sustainable ingredients for healthier people, pets and the planet,” said Tim Rotten, Vice President at Corbion Algae Ingredients. “We believe this breakthrough ingredient will play an important role in meeting the growing need for better nutrition and more sustainable solutions, while delivering value across the pet industry.”

AlgaPrime DHA P3 is sustainably produced in closed fermentation tanks where cane sugars are transformed into omega-3-rich algae powered by a renewable energy source. The unique production process and innovation opens new opportunities for DHA health benefits, sustainability and vegan claims while delivering stability and vegan claims while delivering stability and palatability.

Interzoo introduces new website

As part of a comprehensive relaunch, the Interzoo website has been given a new design and an optimised navigation structure to facilitate access to information on the world’s leading trade fair for the pet industry. The central benefits of the new website include:

Modern look and feel – a consistent use of up-to-date visuals, concise texts and a coherent linking of relevant content are essential features of the new Interzoo website. The new dynamic image reflects Interzoo’s role as a platform for innovations and industry trends.

Optimised user journey – a streamlined navigation menu helps exhibitors and visitors find the content they want quickly using modern teaser elements and anchor points.

Practical information about the trade fair – in addition to important registration information, the website also offers further services and useful information about travel, hotel bookings and accommodation during the exhibition. Find the right contact – whether FAQ or contact for exhibitors, visitors and press, the new website lists all relevant information and helps get in contact with the Interzoo team to help prepare your perfect trade fair experience at Interzoo.

“Together with the Interzoo App, our website is the most important digital communication channel with a high global reach. We are therefore happy to be able to support exhibitors, visitors and media representatives from all over the world in their preparations for Interzoo with the newly launched Interzoo website,” says Dr Rowena Arzt, head of Exhibitions at Interzoo organiser WZF. “The modern design with lots of trade fair impressions and the revised search tool allow quick access to the individually most important contents. We are pleased to be able to accompany our customers and partners digitally in the preparation of a successful Interzoo 2024.”

International Petfood - October 2023 | 15 N

β-glucans & MOS in Pet food

origin properties benefits

by Melina Bonato, Global R&D and Technical Manager & Céline Coutolleau, European Technical Supervisor, ICC, Brazil

The yeast ingredients have been widely used in pet food for decades, mainly as a source of protein and other nutrients (like complex B vitamins) and as a palatant enhancer. However, the yeast has typical components in its structure, which compose the cell wall: β-glucans and mannan oligosaccharides (MOS). The concentration and availability of these carbohydrates will vary depending on the type of yeast (Saccharomyces cerevisiae or others) and the fermentation process (brewers, bakers, molasses, distillers’ grains, etc.), as well as the following technologies that are applied to get different final products (inactive dried, autolyzed, hydrolyzed, etc.).

B- glucans

The β-glucans in the yeast cell wall are β-1,3 and 1,6-glucans linkage, different from those found in cereals (like oat, barely bran, and others) that are β-1,4 and 1,3-glucans. This physicochemical difference will impact their biological function because branched or linear β-1,4-glucans have limited activity (majority proportion in vegetable cells), while the β-1,3-glucans with an additional branching have the highest immunomodulatory effect (Petravić-Tominac et al., 2010). Thus, the β-glucans from Saccharomyces cerevisiae cell wall consist mainly of β-1,3-glucans linked in a central backbone with branches of β-1,6-glucans of various sizes (Petravić-Tominac et al., 2010) which in turn are linked with the mannan proteins,

serving as an anchor for the structure and integrity of the mannoprotein layer (Magnani & Castro-Gómez, 2008).

MOS

The manno glucans complex will maintain the primary stability of the MOS as it is and its insolubility in water. This is crucial for the biological function of it in the animal’s intestine. The MOS’s main known mode of action is to serve as a binding site for pathogenic bacteria, avoid their adhesion to the intestinal epithelium, and further colonisation and infection (Moran, 2004). Bacteria like Salmonella and E. coli utilise the type 1 fimbria, a mannose-specific lectin, to recognise glycoproteins in the enterocyte’s surface (Moran, 2004). Thus, this mechanism controls and reduces bacterial enteric load and infection.

MOS is widely called and classified as prebiotic in the literature; however, it could be possibly misunderstood since the definition of a prebiotic is “a non-digestible food ingredient that beneficially affects the host by selectively stimulating the growth and/or activity of one or a limited number of bacteria in the colon, and thus improves host health” (definition by Glenn & Roberfroid, 1995). Later on, the concept was updated by the International Scientific Associataion of Probiotics and Prebiotics (ISAPP) as: “a selectively fermented ingredient that results in specific changes in the composition and/or activity of the gastrointestinal microbiota, thus conferring benefit(s) upon host health.” According to ISAPP, the most studied and used prebiotics are inulin, fructooligosaccharides (FOS), galactooligosaccharides (GOS), and, more recently, human milk oligosaccharides (HMOs).

16 | October 2023 - International Petfood F

Benefits of Pet food

Studies with dogs from the literature have reported the benefits of MOS supplementation related to changes in the gut microbiota (significantly enhancing the beneficial bacteria and decreasing the pathogenic), digestive system (gut integrity, reduction of fecal odor, and improving the stool quality), modulating the immune system responses (phagocytic activity, interleukins, immunoglobulins), among others (Swanson et al., 2002; Grieshop et al., 2004; Middelbos et al., 2007; Pawar et al., 2017; Theodoro et al., 2019). However, many studies reports using a yeast cell wall product (a combination of β-glucans and MOS) or don’t completely clarify the composition of the MOS product used. This could lead to a misinterpretation of MOS vs. β-glucans mode of action and benefits.

The body does not synthesize β-glucans, so they must be recognized by the immune system, inducing immune responses (Petravić-Tominac et al., 2010), called immunomodulators. The process starts with the recognition by the phagocytic cells (macrophages, monocytes, dendritic cells, neutrophils, natural killers) with a toll-like receptor on their cell surface, which recognizes microbial patterns and induces an immediate innate immune response. The structure that allows recognition by the immune system is the pathogen-associated molecular patterns (PAMPs), and among the best-known PAMPs are β-glucans, which trigger responses to protect the host against pathogen invasion, characterizing innate immunity (Magnani & CastroGómez, 2008). After this activation and phagocytosis, the phagocyte presents a processed antigen fragment. It stimulates a chain response by releasing pro-inflammatory cytokines and activating the production, release, and mobilization of additional

phagocytic cells (produced in the bone marrow) (PetravićTominac et al., 2010), phagocytic activity, and other cellmediated immune responses.

This immunomodulatory effect means training the innate immune system and preparing it for a faster, better, and more intelligent response to challenges (Petravić-Tominac et al., 2010). The practical result is to reduce the inflammation process (costing less for the metabolism), control of infections and their consequences (oxidative stress, cell damage, etc.), and improve immunoglobulins and antibody production (over specific pathogens/antigens or vaccine titers).

Several purified and concentrated β-glucans products are available, and their immunomodulatory effect has been proven through the years, as well when β-glucans are complexed with MOS in the yeast cell wall. These benefits seem to be essential for puppies (due to the stage of the immune system and intestinal tract development, plus the vaccine intense period), senior animals (due to the immune system’s susceptibility in advanced ages), animals with intestinal problems or diseases that may cause depression in the immune response.

MOS and β-glucans are key components of yeast products. Their composition, concentration, and availability are closely related to the kind of yeast they are coming from. MOS and β-glucans benefit Pet food diets due to their interesting properties to balance the microbiota, preserve gut health, and modulate the immune response. Having a deeper understanding of those key properties helps valorise them better in Pet food applications and enables their tailored use to address specific challenges companion animals face, such as growth, reproduction, and recovery.

World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55 F International Petfood - October 2023 | 17

continuous Coating Technologies for premium quality petfood

by Alesia Stojku, PR Communications Assistant, PLP Systems, Italy

The increased interest in pet ownership, as well the increased demand for petfood, seems like a great news for petfood Industry. However, though pet owners are spending more on petfood and treats, they’re also demanding higher quality products.

The consistency and properties of the kibbles, as well as the consistency and properties of the liquid or powder coating, can all create unique obstacles in creating a uniformed coating. The right extrusion and liquid coating system can help to solve these challen=ges, with the correct considerations and applications. This is why PLP has developed the best solutions and equipment to ensure a homogeneous coating and a great palatability performance for your kibbles, while still preventing breakage of the croquettes during the coating and mixing processes.

An important area for PLP is the coating process that is used in different sectors including: post pellet coating for feed and aquafeed, petfood coating, seeds coating and fertiliser, as well as crisps, chips and snacks in the food sector. Specialising in machinery and systems for food, petfood, aquafeed, animal feed, chemical and concrete industries, PLP Systems is a company with over 40 years’ experience in dosing, mixing, spraying, coating

and handling of liquids and micro powder additives.

Developing a continuous coating system

Initially, testing for new coating applications were done using internal small-scale laboratory equipment, simulating what could possibly be a true production, but this procedure was limited in many aspects compared to real production conditions.

Key changes occurred once PLP developed a continuous coating test plant system in its workshop, which was able to reproduce the full capacity of the demands of the industry and minimise the difference in results between a lab test trial compared to a real production.

After having faced various challenges brought on by following a great variation of projects, we have managed to gain an extensive knowledge, understanding and competence in this field. This in-house continuous coating test plant is used for innovating PLP technology and Know-How in order to compete in the market with an advanced post pellet coating application.

The focus is not only on the coating machine but also on the development of new types of sprayers, dosing equipment and software managing systems. Customers that are looking for creative applications are able to test and develop new products for their Petfood.

Another service that the company provides for new customers,

18 | October 2023 - International Petfood F

is to let them fully test the PLP coating application before purchasing the system, in order to make them comfortable on deciding to choose PLP technology.

The test plant can be adapted for different products with a production capacity ranging from 300 kg/h up to 40 tonnes/h, managing different densities. It is equipped with an accurate gravimetric continuous dosing of the main product (pellets or mash) done by either a weighing belt or weighing screw.

The test plant can be integrated with three different PLP continuous coating technologies including: Drum Coaters, twin paddle Continuous Coater and Mass Spin Coater.

The Mass Spin Coater

The Mass Spin Coater(MSC) is a revolutionary system, patented by us, for the treatment and coating of additives on solid products.

For the addition of micro quantities with a maximum capacity of one percent, the Mass Spin Coater is the machine to handle this type of coating. It’s an on-line machine that can be easily fitted in any existing plant.

Through an integrated torsion transducer and a processor of Coriolis force data, the MSC is capable of identifying the mass delivery rate of solid products (pellets, flours, kibbles…). This permits a proportional control for adding doses of additives for the process such as oils, enzymes, antibiotics etc.

MT system

The MT system is a continuous double-shaft paddle mixer, which has received the most improvements during the last few years of R&D. There are different models that can cover all production ranges required with high inclusion rates of liquids or fats. The focus of the machine is the retention time, and this is achieved by independent speed regulations of

International Petfood - October 2023 | 19 F

Mass Spin Coater technology, PLP SYSTEMS

the shafts, internal damps and automatic hatch valve on the outlet that retains the product. Retention time in standard production can reach up to 200 seconds.

Drum Coater

The DC coating systems is a complete machine, consisting of a continuous weight dosage of the product, a mixing and coating system by rotating drum and a proportional dosing system of liquid or powder additives. In the petfood sector, this type of technology is used exclusively for the treatment of semi-moist products, biscuits, snacks, pillows, sticks or other very fragile products. Thanks to its ‘gentle’ movement, the damaging of the product is avoided.

Powder coating additives

Powders are often used to coat the products, if you look at the food sectors a wide range of powders (salts, pepper, garlic, paprika and many other spices) are added on the surface of the crisps and snacks. In petfood a lot of appetising powders are used to coat the kibbles.

PLP applies this science to the feed and aqua feed industry for the use of coating powder additives and medicines. The powders can be injected in a dry form, in a suspension or a solution of powder and liquid more or less concentrated, creating a slurry that is then sprayed on the pellets.

The company has developed different types of sprayers, motorised or statics, that are able to distribute and inject the liquid solution or the dry powder in a even way, avoiding the risk of blocking of the nozzles.

PLP is dedicated to the research and development of the use of other additives in petfood production, in order to improve the quality, the palatableness and the variety of it. Our offices are located in Lugagnano Val d’Arda (one hour from Milan) and from here we can offer first hand support to all our customers worldwide with the help of our many agents based throughout the main areas the continent.

Mt series coater, gravimetric feeding belt and Dosamix system for multiple oil inclusion and separate dosing of digest

Intern Drum Coater: “gentle” movement, PLP Systems

Intern Drum Coater: “gentle” movement, PLP Systems

20 | October 2023 - International Petfood F

Drum Coater, PLP Systems

––4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 Improving the Safety & Efficiency of Your Plant www.go4b.com A Worldwide Manufacturer www.go4b.com ELEVATOR COMPONENTS HAZARD MONITORS & SENSORS CONVEYOR CHAIN #23399 Global Ad Styles.indd 8 07/06/2023 10:07:25 International Petfood - October 2023 | 21 F

Guinea pigs - and their eating habits

by Niamh Cassidy, International petfood, UK

The diet of a guinea pig is not wildly complicated, but important to abide by! Less is more - there’s plenty of supplements, multivitamins and mineral wheels being sold to you that, with the right diet, are completely unnecessary, so stick to the standard nutritional advice and your guinea pigs will be happy as ever.

Diet

The best daily nutrition should consist of 85-90 percent hay and grass. In addition, approximately a tablespoon of grassbased pellets should be offered, with around a teacup amount of fresh greens.

Guinea pigs are true herbivores, who develop their food preferences early in life and stick to it. Any sudden changes made to their diet are not recommended, this includes food type, appearance, and presentation. They are fussy eaters and will refuse to eat if it’s too different.

As they are natural grazers, Hay is the staple of their diet. They need good-quality hay in abundance daily and can also eat fresh grass too (however lawn mower clipping should be avoided as they can be harmful to them). I’d recommend ‘Timothy Hay’ - a type of hay that is low in calcium and protein, whilst being high in fibre, which is particularly advantageous for small animal’s digestive systems. Timothy hay has a sweet grass aroma and is green in colour.

Pellets should be fed daily also, particularly grass based pellets, as they are a good source of Vitamin C. Make sure to monitor consumption, to avoid overfeeding, and be aware that

certain conditions (growing, nursing, or pregnancy) may require more pellets daily.

In conjunction with hay and pellets, vegetables (fresh leafy greens especially) are great to feed your guinea pigs, particularly those high in vitamin C such as bell peppers, tomatoes, and spring greens. Other fresh vegetables that are suitable for their diet include beetroot, carrot tops, cauliflower leaves and stalks, celery leaves, courgette, green beans, parsnips, lettuce (not iceberg), Bok choy, and swiss chard. Vegetables that should be fed in moderation only include Asparagus, broccoli, kale, spinach, cabbage, and parsley. They can also digest certain herbs such as basil, coriander, dill, mint oregano, rosemary, sage, and thyme. Any fruit fed should be limited, as high sugar content is dangerous for their intestinal tract.

Feeding behaviour

Guinea pigs don’t have specific feeding times, they eat often throughout the day and night, so make sure there is always food on offer. They’re also fussy eaters, so any changes to the diet should be introduced slowly and gradually. Choosing and maintaining the correct feeding bowl shouldn’t be dismissed also - Guinea pigs often lean on the bowl whilst eating and kick their bedding and droppings into the bowl, so try and get a heavy ceramic bowl, and regularly clean it out. Make sure to monitor the amount they eat and their dropping, as these are great indicators of health!

A unique source of nutrients!

Something a first-time pet owner may find alarming and peculiar is the particularly unique eating habit of guinea pigs. It is true that they eat their own droppings! In-fact, these droppings

22 | October 2023 - International Petfood F

are essential to their diet, providing a great source of nutrients.

There are two types of guinea pig droppings, the ‘caecotrophs’, aka soft, sticky pellets, and hard, dry pellets. Caecotrophs are the kind that they directly eat, immediately after passing them (so you shouldn’t see them very often). The hard dry pellets are the result of your guinea pig eating their caecotroph and pooping it out again - they do not eat these kinds.

Vitamin C & digestive danger

Vitamin C is a crucial requirement for their diet. It’s critical in preventing scurvy, aiding normal development and maintenance of the skin, joint, and mucosal surfaces, as well as healing. Without it, Guinea pigs are prone to diseases, infections and skin problems. A deficiency in Vitamin C would appear as a rough hair coat, lack of appetite, diarrhoea, reluctance to move, swollen feet and joints, haemorrhages, and ulcers on gums/skin.

A common health issue seen in guinea pigs is bladder stones, so reducing or eliminating foods high in oxalates, such as spinach, parsley, and strawberries, can provide benefit to ones that develop calcium oxalate stones.

Guinea pigs can also develop dental diseases without the proper diet; their teeth are always growing, however regularly eating hay helps wear them down sufficiently.

Toxic foods to avoid include citrus fruits, daffodils, foxgloves and poppies. If your guinea pigs run loose in your garden, be aware of these plants.

F International Petfood - October 2023 | 23

Ottevanger Milling Engineers

Ottevanger Milling Engineers is a leading global supplier of production equipment and processing lines for the grain processing and compound feed industry. Founded in 1909, Ottevanger Milling Engineers is today still an independent, privately owned, successful Dutch company, managed by of the fourth generation of the Ottevanger family.

Ottevanger does business world-wide as a dependable, high-quality component supplier, but also as a prime contractor or subcontractor on large-scale projects. They plan, design, manufacture and manage the construction of complete (turn-key) production facilities or individual lines for processes. Their expertise lies in; engineering, production and installation of machinery and complete installations in the dry-cereal and grain processing industry such as: feed mills, premix and concentration plants, aqua feed and pet food installations, cereal processing lines, biomass installations.

Company Feed Industry

Since the founding of our company, we have acquired more than 110 years of experience in a process of continuous development, improving and enhancing the performance of the equipment and processes by applying modern design standards and employing the latest production techniques. Our designers take full account of the norms and directives that apply to the intended installation, including CE, ATEX and GMP.

Cereal Processing

One of Ottevangers specialties is the design of complete process lines. They share our expertise by describing the basics of soy processing, premix & concentrates, grain storage & handling, compound feed, pet food and aqua feed. Every process line will be tailor made designed by the engineers. They do not promote or apply a ‘standard’ plant design and each project is assessed on its own merits. They take time consulting

with customers to ensure they fully understand customer requirements and more specifically requirements of the specific market the customer is serving.

Pet Food

Ottevangers acknowledge and understand how trends in the pet industry impact the design of pet food processing solutions. They took great care over many years developing technologies and equipment meeting and exceeding the growing demands of the global petfood industry.

Aquafeed

Aquatic feeds have very high requirements in terms of both nutritional and physical characteristics of feed. These nutritional and physical feed requirements are driven by the life stage of a specific species under consideration. Physical characteristics include issues such as pellet size and shape; pellet density allowing us to produce floating, slow sinking and sinking feeds; water stability and pellet durability. The challenge is to achieve all of these while having a negligible effect on the environment.

Premix and Concentrates

A very long history in the industry gave Ottevanger Milling Engineers the experience and expertise to supply tailor-made solutions for the complete spectrum of premix and concentrate applications. Engineering and Equipment solutions range from small mill-and-mix operations to large, dedicated feed mills.

Ottevanger equipment for premix and concentrate plants meet and exceed international standards in terms of design, hygiene, safety and efficiency. Innovative design results in exceptional mixing accuracy and end product quality. State-of-the-art engineering layout and process control design leads to negligible cross contamination.

24 | October 2023 - International Petfood Industry PROFILE

They may not say it, but you can see when your pet is feeling happy, healthy and loved.

With the highest quality ingredients to help boost their immune system, promote healthy coats, and build strong bones, Zinpro® is the best trace mineral nutrition for your loved one. It’s Nutrition You Can See™ .

See the difference Zinpro can make.

©2023 Zinpro Corp. All rights reserved.

Industry Training Online PetFood School

The online Petfood School began August 24 and is nearing completion! The course is designed to give an in-depth review of the process of making petfood’s, from simple and complex petfood, to treat production.

The live online webinars will consist of two and a half hours per week, for six weeks, and includes an additional in-person session at this year’s VICTAM LatAm in São Paulo, Brazil. Once the course is completed, attendees will receive a certificate, and the opportunity to watch the sessions on-demand

The programme is jointly organised by Progressus Agrischools and Perendale Publishers, and sponsored by Agentis Innovations, Tietjen, Andritz, Wenger, PLP Systems and International Milling Directory.

Week 4

Giuseppe R Bigliani is the first speaker to address the audience in week 4 of The Online Petfood School discussing ‘Dosing, Batching and mixing’ covering many topics such as:

• Flow patterns

• Flow issues

• Consistency between handling & storage

• Requirements to dosing elements

• Pre & post-grinding

• Dosing systems

• Scale hoppers

• Mixability

• Rotor speed & power

• Mixing accuracy

• contamination

The second speaker of the session was Joe Kearns who gave a presentation on both ‘Extrusion: Knives and Dies’ and ‘Drying Standards’ where he covered the topics of:

• Die types

• Drilled dies/wear plates

• Insufficient die restrictions

• Excessive die restrictions

• Back pressure valve

• Knife blades

• Knife sharpening

• Extradite expansion

• Co-extrusion die

• Troubleshooting dryers

• Dryer beds

• Conveyor maintenance

• Heat source maintenance

• Common dryer problems

• Consisted & random under-drying

The final presentation of the day was given by Keith Erdley on ‘Drying and cooling of pet foods’ where he discussed many topics such as:

• Dryer design history

• Primary drying components

• Spreaders

• Conveyor beds

• Gas burners

• Steam coils

• Electric coils

• Modern airflow design

• Factors of control

• Temperature

• Bed depth

• Product cooling

• Types of coolers

The session finished with a Q&A with attendees invited to ask their questions to the speakers and moderators.

Week 5

Coating, Final Cooling, Conveying, Quality control, Starting off the session was Joe Kearns, School Moderator and in-house trainer. He gave a presentation on ‘Coating and cooling of Petfoods’, which covered areas such as:

• Recall In the Bag Temperatures

• Conveyor Beds, Keep it in Dryer and Cooler

• Spreading, horizontal cooling, vertical coolers, Counterflow coolers

• Coating; atmospheric and vacuum, reel coating

• The Coating system, cell structure, fat absorption

The next presentation was given by Marco Prati, CEO of PLP Systems, in Italy. Marco Prati, CEO of PLP Systems, gave an interesting presentation on the development of this innovative Italian-based company and its unique coating technologies. Next Joe Kearns gave a presentation on ‘Quality control Pet foods in the line and on line’, which encapsulated:

• Quality control in the plant

• Effect of raw material protein quality

• Causes of white buildup on screws and die orifices

• Screws, dust free downspout

• Product temperature,

extruder moisture, pressure regulating valves

• Ingredient flow, stem flow, water flow

• Steam traps, bucket traps, thermostatic traps

• Pneumatic systems, in line analysis

He also presented on ‘Lab analysis’, which touched upon:

Product analysis and laboratory tests for pet foods

Moisture, NIR, Water Activity, PH, Particle size analysis

Bulk density, starch gelatinization, Fat absorption, pellet durability

Week 6

The presentations today were led by Joe Kearns, School moderator and In-house trainer. The session looked at plant computer control systems, and sanitation of Petfood plants. The presentations covered topics such as:

• Levels of Control systems (manual, individual loop, integrated, automated)

• Raw material area

• Loss-in-weight control of dry recipe

• Extrusion additions

• PID Control

• Raw material area, dry area, dry cleaning

• Loose metal parts, extrusion area, wet cleaning, extruder barrel, die area

• Conditioning cylinder area to mix dry with liquids

• Pneumatic systems

TRAINING

26 | October 2023 - International Petfood

Troubleshooting

Perendale Publishing and Credo Online Milling School just finished our 2023 Petfood Production School. One thing we do in these courses is have questions and answers at the end of each session. We try and cover all aspects of production from ingredient spec and storage through to the end of the process. The questions in these courses are quite interesting. Let’s look at a few.

Grinding

Lifetime of the parts and when to replace the hammers? Hard to say on the lifetime as different formulas grind differently. It should be noted one of the top longevity goals is to eliminate stones and other materials that can punch a hole in the screen. Metal detectors and destones before the process will get most of the debris. Another topic is screens wear and the hammers. Screen wear is the variation over time in the opening in the screen where hammers have four grinding surfaces, all four corners. Rotation as wear occurs, don’t let them go too far, allows them to be rotated and increase life by using all four grinding spots on the hammers. Keep in mind the entire system is balanced and thus all parts that rotate need to be weighed and insure they are practically equal so as to eliminate as much vibration as possible.

Extrusion

Extruder parts wear how and when to replace? Wear in an extruder occurs mostly at the discharge end of the extruder. Typically, this is stated as a percentage of wear when compared to the original tolerance. As an example, if the original clearance is 0.1 inches or 2.5 mm then a factor of 2 to 2.5 times the original tolerance is the point the parts need to be changed. So, when the gap on one side (need to divide the corresponding screw and head diameters by two) approaches 5 to 6 mm then back flow can increase causing unstable conditions. Screws and heads are usually made from different materials, hardness, thus the screws usually wear faster. The end of the extruder parts might be replaced three times to the inlet end of the barrel as the pressure and friction at the discharge is much higher. Keeping track of parts diameters individually can assist in determining the cycle of parts replacement as well as allow for the same part to be moved in the barrel if more than one of the same parts is used.

Drying

Exhaust air volumes and how to be sure the air is evenly heated? History of dryers centered on advancements to dry evenly. Drying being relationship between time, temperature and airflow resulted in mainly advancing the airflow of the dryer for the desired results. In both horizontal and vertical dryers the time factor has always been controllable, adjust the speeds of the horizontal beds or control the timers to drop the product to the next level. Temperature was also mostly very controllable but improved as steam coil and gas burner designs improved. What has changed greatly is how the air is moved in the dryer in relation to the product. It has been modified to be a more even approach from side to side and top to bottom in the individual dryer beds for horizontal dryers. Air velocity and mixing panels to mix the fresh air with the recycled air assist greatly in improving the air quality being evenly applied in both temperature, volume and velocity. Results are a more even overall kibble moisture and from kibble to kibble. Exhaust air volume and its relative humidity is a key in efficient water removal.

These are just a few and we will continue with more next month.

Previously on Troubleshooting...

1. Density

An examination of product density and its relationship with moisture levels, heating, cooling feeder screw rate and automation.

2. Non-uniform and rough appearance

A guide to understanding the science involved in improving the art of making products of all the same size.

3. Extrusion dies

This article takes a look at aspects of the process including high, medium and low shear as well the adjustments required when producing feed for small mammals.

4. Dryers

The dryer is without a doubt one of the machines in the system which greatly impacts the bottom line.

5. The extruder barrel - Part 1

Forming extruders are used for some select products – thus this part of the discussion centres on single and twin designs.

6. Cook in the extruder barrel – part 2

As discussed last month, the extruder barrel has a number of functions, but the main goal is to finalise the cook, yield the desired shape with the density target.

7. Coating

The coating process has a few areas of importance, with this edition of ‘Troubleshooting’ exploring the most important of these.

8. Expanded cat food

Dry expanded cat food production is similar to dog food production, but there are some differences, with this edition exploring a choice selection of these.

9. Extrusion during operation

This month we discuss steam input into the conditioner. During the water addition process, the steam is usually in the two-bar range.

TROUBLESHOOTING

International Petfood - October 2023 | 27

Innovations this month October 2023

This month’s Production Showcase section features equipment and ingredients that will help in the production of petfood, taking you right from the recipe book, right up until until your product is ready to leave your factory door.

If you would like your product or service to appear on this page in a future edition of International Petfood magazine, then please contact us at editorial@perendale.co.uk

The ETI Batch Coating System by Extru-Tech

Designed to be integral and stackable with the Extru-Tech Vertical Cooler to optimise installation, the ETI Batch Coating System offers benefits and capabilities never before available with traditional spinning disk or open drum coating systems. Plus, the Extru-Tech system offers the sanitary design and dosing accuracy demanded by today’s food safety and traceability requirements.

The ETI Batch Coating System was designed to handle up to 40,000 lbs/hour at batch sizes of 2500 pounds at 63 percent fill level.

A multi-functional time/ pressure spray design provides optimal liquid application uniformity across the entire batch. The automated control system determines the optimal spray time for each liquid and then sets the spray pressure for each of the pressure supply tanks. This allows the spray time to be extended to the maximum length of time, thereby providing the most even and accurate coating possible.

www.extru-techinc.com

PRODUCTION

Download your online version We invite you to use the code below for a free edition of our magazine either mailed to you or via our App Use coupon code: HNY23 Leiber YeaFi® –Brewers’ yeast bound to functional f ibres! | dietetic and prebiotic active ingredients | supports digestion | promotes skin and coat quality | technological advantages Available with different fibre carriers like spent grain, DDGS or apple pomace. Visit our website: leibergmbh.de Unique synergy! Leiber GmbH | Franz-Leiber-Straße 1 | 49565 Bramsche Germany | info@leibergmbh.de 140823_International Petfood_90 mm x 270 mm + 3 mm Beschnitt.indd 1 14.08.23 16:25 28 | October 2023 - International Petfood

FOCUS

Crusher CR from Tietjen

The crusher CR is a versatile machine for coarse crushing of bulk materials. It is suitable for crushing agglomerates or for pre-crushing coarse material pieces for further grinding.

By homogenising the raw material in the crusher, energy is saved in the further grinding in the hammer mill, as the desired grain spectrum is achieved more quickly. At the same time, the screens of the hammer mill are protected against screen breakage. Especially in pet food and fish feed production, particularly fine screens used, here the use of the crusher is particularly worthwhile.

The crusher is designed for continuous industrial operation. It convinces with its robust design with generously dimensioned inlet, long-life rotor and hardened impact plates. The beaters are also optimised for primary crushing and are made of Hardox. A variable grain size range can also be achieved in pre-shredding by using different screen sizes. www.tietjen-original.com

Pro Plan Sport Performance 30/20 by Purina

Help your active dog excel with fine-tuned nutrition that fuels champions. Purina Pro Plan Sport Performance 30/20 Beef & Bison dry formula offers great-tasting performance nutrition with real beef as an ingredient and real, high-quality bison. Plus, Pro Plan is the official performance dog food of Ducks Unlimited®, so you can feel confident in helping your dog achieve his full athletic potential with every serving.

• Purina Pro Plan is the official performance dog food of Ducks Unlimited®

• Concentrated nutrition optimizes oxygen metabolism (VO2 max) for increased

• Made with glucosamine and EPA, an Omega-3 fatty acid, for joint health and mobility

• Amino acids help support muscles, including the crucial time after exercise

• Antioxidants for a healthy immune system

• Formulated for all life stages, including puppies and reproducing females

• No artificial colours or flavours www.purina.com

Gently cooked dog food by Holistic Health Extension

Health Extension introduces its latest innovation in premium pet nutrition - Gently Cooked dog food. These delectable recipes feature fresh whole food ingredients gently cooked in bone broth, ensuring a wholesome and convenient meal options for dogs. Unlike frozen altenatives, Gently Cooked is shelf stable, always ready to serve, making it the perfect choice for busy pet parents and dogs that crave a free home-cooked meal. Health extension’s Gently Cooked recipes are thoughtfully crafted in small batches, incorporating a unique blend of superfoods to boost immunity, improve skin & coat, strengthen joints and support digestive health; such as goji berry, sage, thyme, kelp, turmeric and coconut oil. Each recipe is complete and balanced to meet the dietary needs of dogs of all ages, with real lamb, beef or chicken as the first ingredient. These nourishing meals are enriched with whole vegetables, including carrots, sweet potatoes and broccoli.

www.healthextension.com

SEE YOUR PRODUCTS IN THIS MAGAZINE

If you produce a product that you think we should feature in International Petfood magazine, please get in touch

To be considered for inclusion in the magazine please; Email: editorial@perendale.co.uk

Include 75 words about the product along with a high resolution image and a web link to more information about the product in your email

Centrifugal Sifter by Dinnissen